Enhanced Microwave Absorption and Surface Wave Attenuation Properties of Co0.5Ni0.5Fe2O4 Fibers/Reduced Graphene Oxide Composites

Abstract

:1. Introduction

2. Experimental Section

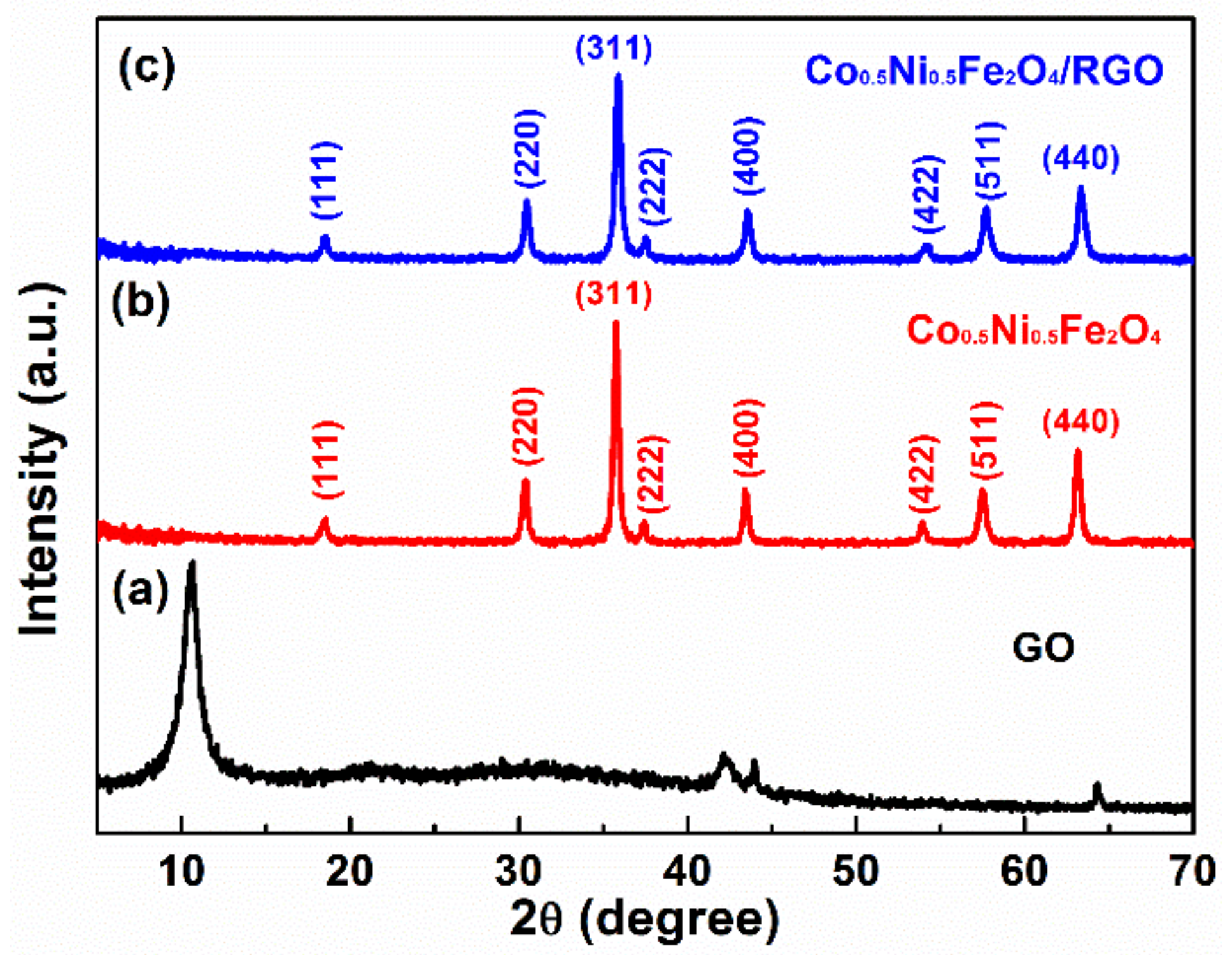

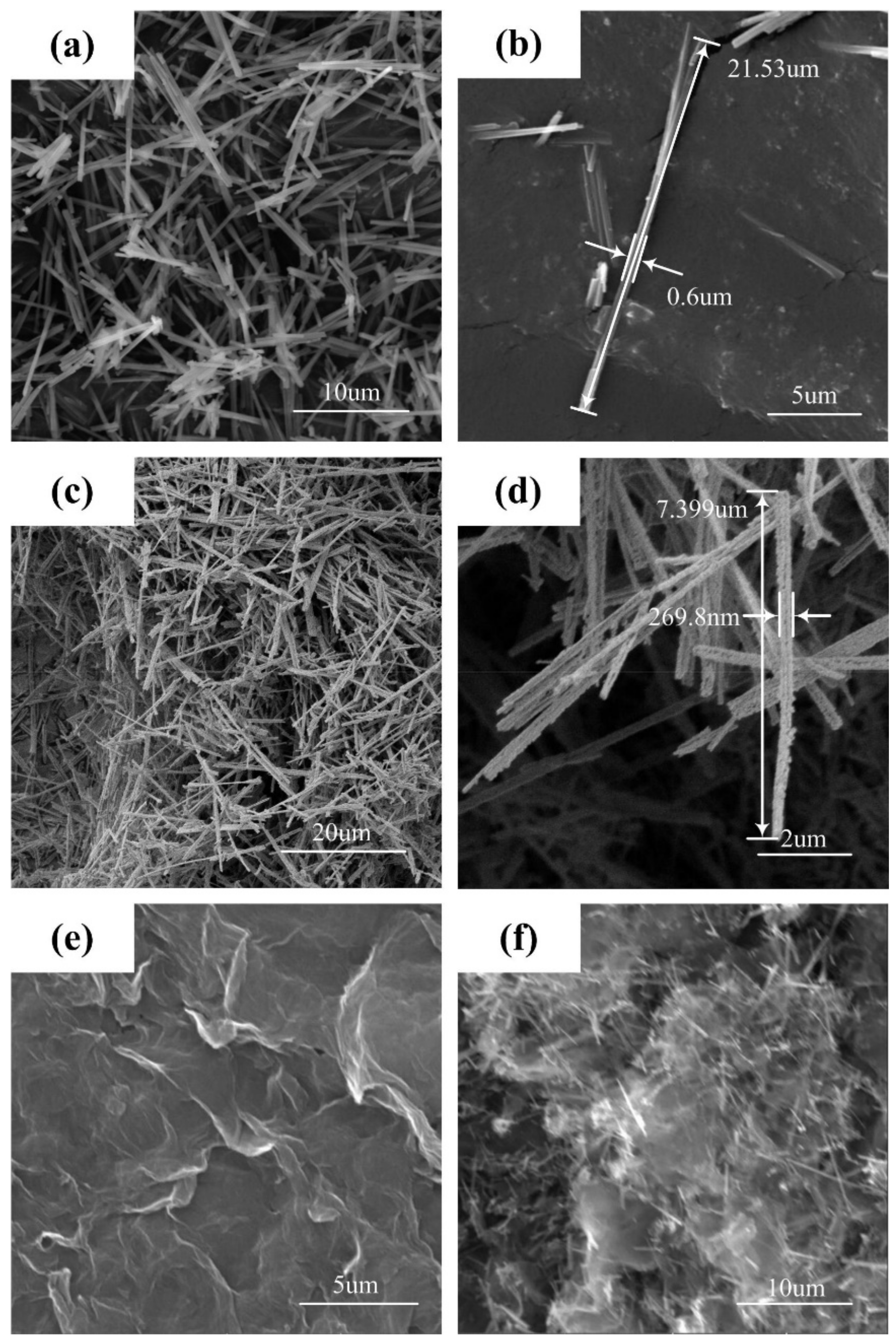

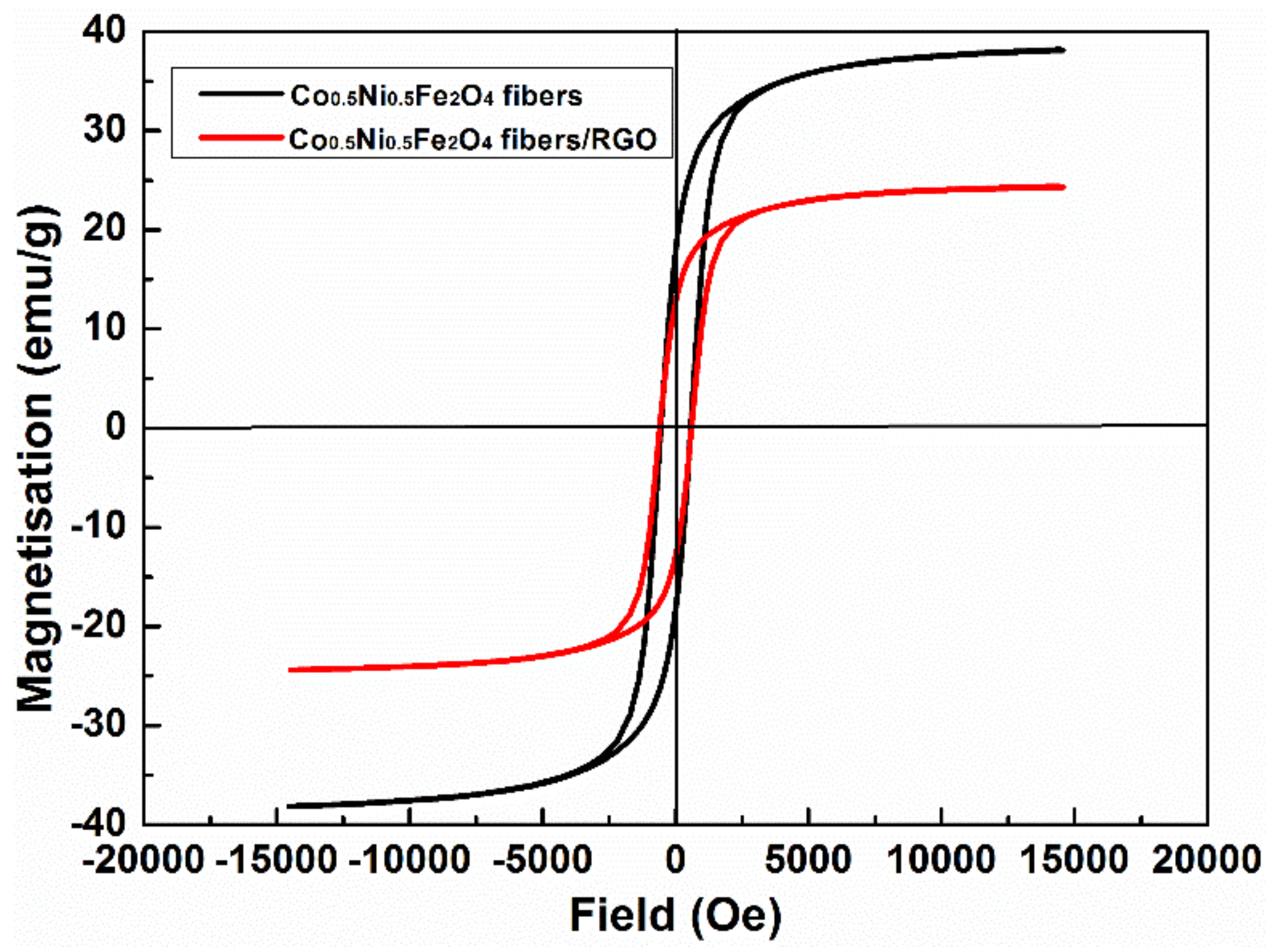

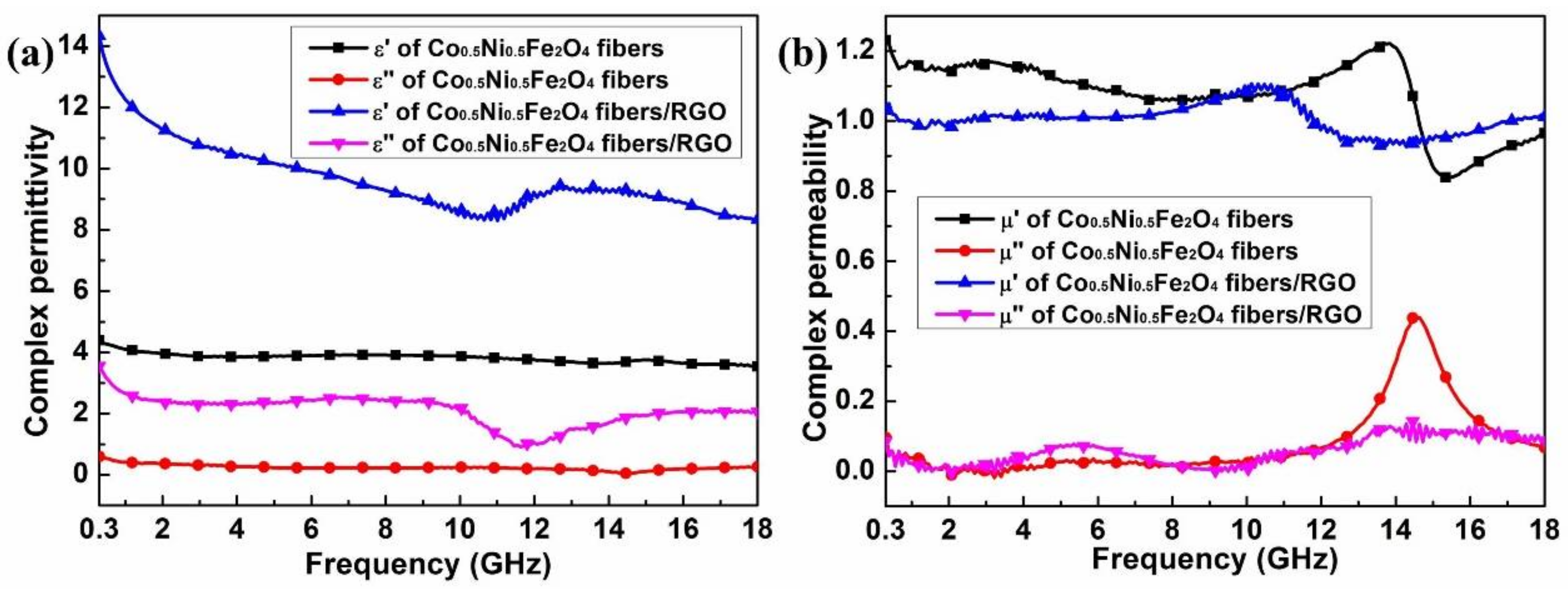

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lim, W.G.; Yu, J.W. Scattering by a dielectric-loaded conducting wedge with concaved edge: TE case. Prog. Electromagn. Res. 2009, 89, 85–100. [Google Scholar] [CrossRef]

- Terracher, F.; Berginc, G. Scattering by doubly periodic gaps and cracks. J. Electromagn. Waves Appl. 2000, 14, 1143–1158. [Google Scholar] [CrossRef]

- Ivrissimtzis, L.P.; Marhefka, R.J. Edge-wave diffraction for flat-plate structures. IEE Proc. Microw. Antennas Propag. 1994, 141, 30–36. [Google Scholar] [CrossRef]

- Hu, X.J.; Ge, D.B. Study on conformal FDTD for electromagnetic scattering by targets with thin coating. Prog. Electromagn. Res. 2008, 79, 305–319. [Google Scholar] [CrossRef]

- Oraizi, H.; Abdolali, A. Ultra wide band RCS optimization of multilayerd cylindrical structures for arbitrarily polarized incident plane waves. Prog. Electromagn. Res. 2008, 78, 129–157. [Google Scholar] [CrossRef]

- Yan, W.Z.; Du, Y.; Wu, H.; Liu, D.; Wu, B.I. EM scattering from a long dielectric circular cylinder. Prog. Electromagn. Res. 2008, 85, 39–67. [Google Scholar] [CrossRef]

- Ding, D.Z.; Chen, R.S. Electromagnetic scattering by conducting bor coated with chiral media above a lossy half-space. Prog. Electromagn. Res. 2010, 104, 385–401. [Google Scholar] [CrossRef]

- Chen, H.Y.; Lu, L.J.; Guo, D.J.; Lu, H.P.; Zhou, P.H.; Xie, J.L.; Deng, L.J. Relationships between Surface Wave Attenuation and the Reflection Properties of Thin Surface Wave Absorbing Layer. In Proceedings of the PIERS 2014, Guangzhou, China, 25–28 August 2014; pp. 1146–1150. [Google Scholar]

- Caruso, F.; Spasova, M.; Susha, A.; Giersig, M.; Caruso, R.A. Magnetic nanocomposite particles and hollow spheres constructed by a sequential layering approach. Chem. Mater. 2001, 13, 109–116. [Google Scholar] [CrossRef]

- Hyeon, T.; Lee, S.S.; Park, J.; Chung, Y.; Na, H.B. Synthesis of highly crystalline and monodisperse maghemite nanocrystallites without a size-selection process. J. Am. Chem. Soc. 2001, 123, 12798–12801. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.; Xie, Y.; Chen, S.; Li, Z. Fabrication of Self-Supported Patterns of Aligned β-FeOOH Nanowires by a Low-Temperature Solution Reaction. Chem. A Eur. J. 2003, 9, 4991–4996. [Google Scholar] [CrossRef] [PubMed]

- Woo, K.; Lee, H.J.; Ahn, J.P.; Park, Y.S. Sol–gel mediated synthesis of Fe2O3 nanorods. Adv. Mater. 2003, 15, 1761–1764. [Google Scholar] [CrossRef]

- Teng, X.; Yang, H. Effects of surfactants and synthetic conditions on the sizes and self-assembly of monodisperse iron oxide nanoparticles. J. Mater. Chem. 2004, 14, 774–779. [Google Scholar] [CrossRef]

- Yu, A.C.C.; Mizuno, M.; Sasaki, Y.; Kondo, H.; Hiraga, K. Structural characteristics and magnetic properties of chemically synthesized CoPt nanoparticles. Appl. Phys. Lett. 2002, 81, 3768–3770. [Google Scholar] [CrossRef]

- Fan, X.; Guan, J.; Wang, W.; Tong, G. Morphology evolution, magnetic and microwave absorption properties of nano/submicrometre iron particles obtained at different reduced temperatures. J. Phys. D Appl. Phys. 2009, 42, 075006. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, X.; Wei, J.; Zhao, S.; Wang, L.; Feng, B. Morphology-controlled synthesis and novel microwave absorption properties of hollow urchinlike α-MnO2 nanostructures. J. Phys. Chem. C 2010, 115, 1398–1402. [Google Scholar] [CrossRef]

- Gao, B.; Qiao, L.; Wang, J.; Liu, Q.; Li, F.; Feng, J.; Xue, D. Microwave absorption properties of the Ni nanowires composite. J. Phys. D Appl. Phys. 2008, 41, 235005. [Google Scholar] [CrossRef]

- Xie, B.Q.; Qian, Y.; Zhang, S.; Fu, S.; Yu, W. A Hydrothermal Reduction Route to Single-Crystalline Hexagonal Cobalt Nanowires. Eur. J. Inorg. Chem. 2006, 2006, 2454–2459. [Google Scholar] [CrossRef]

- Tong, G.; Hu, Q.; Wu, W.; Li, W.; Qian, H.; Liang, Y. Submicrometer-sized NiO octahedra: Facile one-pot solid synthesis, formation mechanism, and chemical conversion into Ni octahedra with excellent microwave-absorbing properties. J. Mater. Chem. 2012, 22, 17494–17504. [Google Scholar] [CrossRef]

- Wang, W.; Wang, C.G.; Guo, Y. Fabrication and microwave characteristics of Fe3O4/C composites. Adv. Mater. Res. Trans Tech Publ. 2012, 430, 146–149. [Google Scholar] [CrossRef]

- Hu, C.; Mou, Z.; Lu, G.; Chen, N.; Dong, Z.; Hu, M.; Qu, L. 3D graphene–Fe3O4 nanocomposites with high-performance microwave absorption. Phys. Chem. Chem. Phys. 2013, 15, 13038–13043. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.L.; Bi, H.; Yang, R.B. Enhanced microwave absorption property of bowl-like Fe3O4 hollow spheres/reduced graphene oxide composites. J. Appl. Phys. 2012, 111, 07A522. [Google Scholar] [CrossRef]

- Singh, V.K.; Shukla, A.; Patra, M.K.; Saini, L.; Jani, R.K.; Vadera, S.R.; Kumar, N. Microwave absorbing properties of a thermally reduced graphene oxide/nitrile butadiene rubber composite. Carbon 2012, 50, 2202–2208. [Google Scholar] [CrossRef]

- Gadelrab, K.R.; Chiesa, M.; Bonilla, F.A. Implications of the idea of effective tip shape on nanoindentation unloading curves: AFM measurements and FE simulation. J. Mater. Res. 2012, 27, 126–131. [Google Scholar] [CrossRef]

- Chen, C.Y.; Pu, N.W.; Liu, Y.M.; Huang, S.Y.; Wu, C.H.; Ger, M.D.; Chou, Y.C. Remarkable microwave absorption performance of graphene at a very low loading ratio. Compos. Part B Eng. 2017, 114, 395–403. [Google Scholar] [CrossRef]

- Cao, W.Q.; Wang, X.X.; Yuan, J.; Wang, W.Z.; Cao, M.S. Temperature dependent microwave absorption of ultrathin graphene composites. J. Mater. Chem. C 2015, 3, 10017–10022. [Google Scholar] [CrossRef]

- He, J.Z.; Wang, X.X.; Zhang, Y.L.; Cao, M.S. Small magnetic nanoparticles decorating reduced graphene oxides to tune the electromagnetic attenuation capacity. J. Mater. Chem. C 2016, 4, 7130–7140. [Google Scholar] [CrossRef]

- Chen, C.Y.; Pu, N.W.; Liu, Y.M.; Chen, L.H.; Wu, C.H.; Cheng, T.Y.; Grubb, P.M. Microwave absorption properties of holey graphene/silicone rubber composites. Compos. Part B Eng. 2018, 135, 119–128. [Google Scholar] [CrossRef]

- Wang, C.; Han, X.; Xu, P.; Zhang, X.; Du, Y.; Hu, S.; Wang, X. The electromagnetic property of chemically reduced graphene oxide and its application as microwave absorbing material. Appl. Phys. Lett. 2011, 98, 072906. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Mao, Z.; Wang, W.; Liu, Y.; Zhang, L.; Xu, H.; Zhong, Y. Infrared stealth property based on semiconductor (M)-to-metallic (R) phase transition characteristics of W-doped VO2 thin films coated on cotton fabrics. Thin Solid Films 2014, 558, 208–214. [Google Scholar] [CrossRef]

- Bi, A.; Zhu, J. Hydrothermal synthesis of W and Mo co-doped VO2 (B) nanobelts. J. Exp. Nanosci. 2013, 8, 46–53. [Google Scholar] [CrossRef]

- Bai, X.; Zhai, Y.; Zhang, Y. Green approach to prepare graphene-based composites with high microwave absorption capacity. J. Phys. Chem. C 2011, 115, 11673–11677. [Google Scholar] [CrossRef]

- Quan, L.; Qin, F.X.; Estevez, D.; Wang, H.; Peng, H.X. Magnetic graphene for microwave absorbing application: Towards the lightest graphene-based absorber. Carbon 2017, 125, 630–639. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Cheng, R.M.; Wen, Z.; Zhao, L. Synthesis and Characterization of Single-Crystalline MnFe2O4 Ferrite Nanocrystals and Their Possible Application in Water Treatment. Eur. J. Inorg. Chem. 2011, 2011, 2942–2947. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, Y.; Fu, M.; Jiao, Q.; Li, H. Microemulsion-mediated solvothermal synthesis of hollow Co–Ni ferrite nanoparticle tubes and their magnetic properties. Micro Nano Lett. 2013, 8, 68–69. [Google Scholar] [CrossRef]

- Zhang, Z.; Rondinone, A.J.; Ma, J.X.; Shen, J.; Dai, S. Morphologically templated growth of aligned spinel CoFe2O4 nanorods. Adv. Mater. 2005, 17, 1415–1419. [Google Scholar] [CrossRef]

- Zhang, X.F.; Guan, P.F.; Dong, X.L. Multidielectric polarizations in the core/shell Co/graphite nanoparticles. Appl. Phys. Lett. 2010, 96, 223111. [Google Scholar] [CrossRef]

- Kim, S.S.; Kim, S.T.; Yoon, Y.C.; Lee, K.S. Magnetic, dielectric, and microwave absorbing properties of iron particles dispersed in rubber matrix in gigahertz frequencies. J. Appl. Phys. 2005, 97, 10F905. [Google Scholar] [CrossRef]

- Che, R.; Peng, L.M.; Duan, X.F.; Chen, Q.; Liang, X.L. Microwave absorption enhancement and complex permittivity and permeability of Fe encapsulated within carbon nanotubes. Adv. Mater. 2004, 16, 401–405. [Google Scholar] [CrossRef]

- Wang, W.; Zang, C.; Jiao, Q. Synthesis, structure and electromagnetic properties of Mn–Zn ferrite by sol–gel combustion technique. J. Magn. Magn. Mater. 2014, 349, 116–120. [Google Scholar] [CrossRef]

- Ren, X.; Xu, G. Electromagnetic and microwave absorbing properties of NiCoZn-ferrites doped with La3+. J. Magn. Magn. Mater. 2014, 354, 44–48. [Google Scholar] [CrossRef]

- Wang, C.; Han, X.; Zhang, X.; Hu, S.; Zhang, T.; Wang, J.; Xu, P. Controlled synthesis and morphology-dependent electromagnetic properties of hierarchical cobalt assemblies. J. Phys. Chem. C 2010, 114, 14826–14830. [Google Scholar] [CrossRef]

- Li, H.; Huang, Y.; Sun, G.; Yan, X.; Yang, Y.; Wang, J.; Zhang, Y. Directed growth and microwave absorption property of crossed ZnO netlike micro-/nanostructures. J. Phys. Chem. C 2010, 114, 10088–10091. [Google Scholar] [CrossRef]

- Luo, H.; Gong, R.; Wang, X.; Song, K.; Zhu, C.; Wang, L. Synthesis and excellent microwave absorption properties of reduced graphene oxide/FeNi3/Fe3O4 composite. New J. Chem. 2016, 40, 6238–6243. [Google Scholar] [CrossRef]

- Sun, G.; Dong, B.; Cao, M.; Wei, B.; Hu, C. Hierarchical dendrite-like magnetic materials of Fe3O4, γ-Fe2O3, and Fe with high performance of microwave absorption. Chem. Mater. 2011, 23, 1587–1593. [Google Scholar] [CrossRef]

- Ufimtsev, P.Y.; Ling, R.T.; Scholler, J.D. Transformation of surface waves in homogeneous absorbing layers. IEEE Trans. Antennas Propag. 2000, 48, 214–222. [Google Scholar] [CrossRef]

- Ling, R.T.; Scholler, J.D.; Ufimtsev, P.Y. The propagation and excitation of surface waves in an absorbing layer. Prog. Electromagn. Res. 1998, 19, 49–91. [Google Scholar] [CrossRef]

- Li, Y.; Li, D.; Wang, X.; Nie, Y.; Gong, R. Influence of the electromagnetic parameters on the surface wave attenuation in thin absorbing layers. AIP Adv. 2018, 8, 056616. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Li, D.; Yang, J.; Luo, H.; Chen, F.; Wang, X.; Gong, R. Enhanced Microwave Absorption and Surface Wave Attenuation Properties of Co0.5Ni0.5Fe2O4 Fibers/Reduced Graphene Oxide Composites. Materials 2018, 11, 508. https://doi.org/10.3390/ma11040508

Li Y, Li D, Yang J, Luo H, Chen F, Wang X, Gong R. Enhanced Microwave Absorption and Surface Wave Attenuation Properties of Co0.5Ni0.5Fe2O4 Fibers/Reduced Graphene Oxide Composites. Materials. 2018; 11(4):508. https://doi.org/10.3390/ma11040508

Chicago/Turabian StyleLi, Yinrui, Dongmeng Li, Jing Yang, Hui Luo, Fu Chen, Xian Wang, and Rongzhou Gong. 2018. "Enhanced Microwave Absorption and Surface Wave Attenuation Properties of Co0.5Ni0.5Fe2O4 Fibers/Reduced Graphene Oxide Composites" Materials 11, no. 4: 508. https://doi.org/10.3390/ma11040508

APA StyleLi, Y., Li, D., Yang, J., Luo, H., Chen, F., Wang, X., & Gong, R. (2018). Enhanced Microwave Absorption and Surface Wave Attenuation Properties of Co0.5Ni0.5Fe2O4 Fibers/Reduced Graphene Oxide Composites. Materials, 11(4), 508. https://doi.org/10.3390/ma11040508