Restoration of Worn Movable Bridge Props with Use of Bronze Claddings

Abstract

:1. Introduction

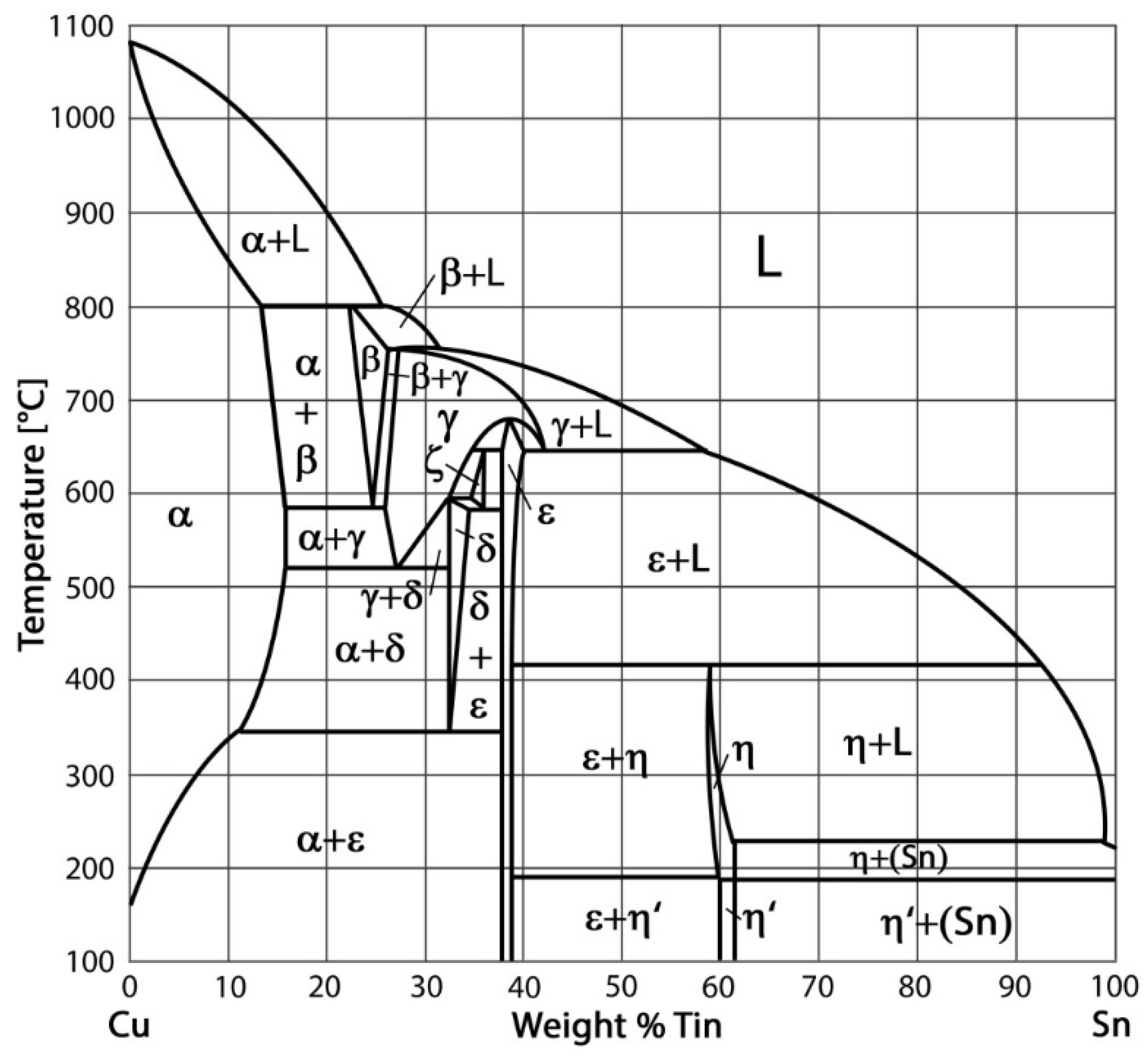

2. Metallurgical Aspects of Bronze Cladding

2.1. Cladding Methods Suitable for Bronze–Steel Applications

2.2. Creating and Finishing Cladding Layers

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

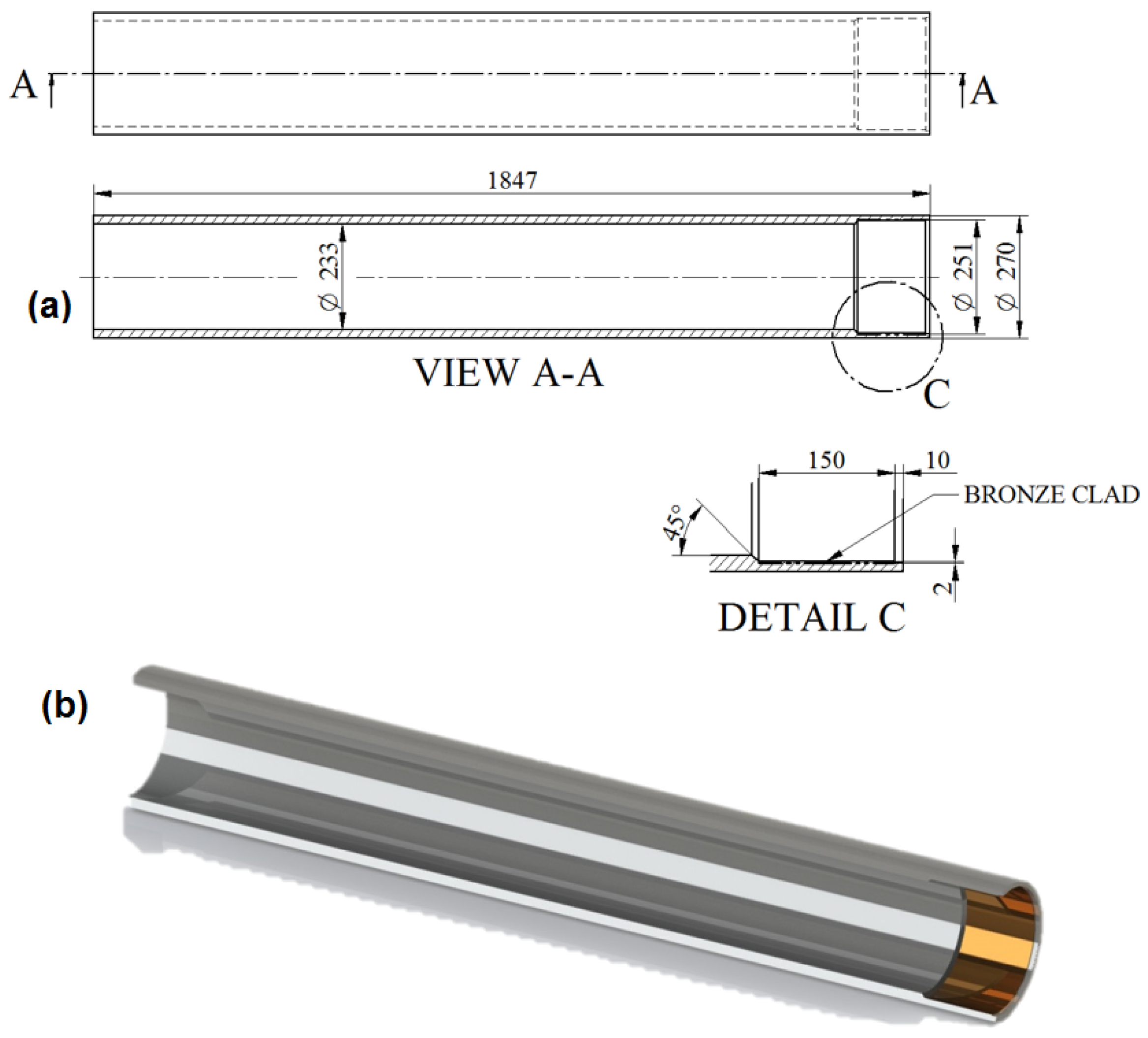

3. Materials and Methods

3.1. Materials

3.2. Cladding Parameters

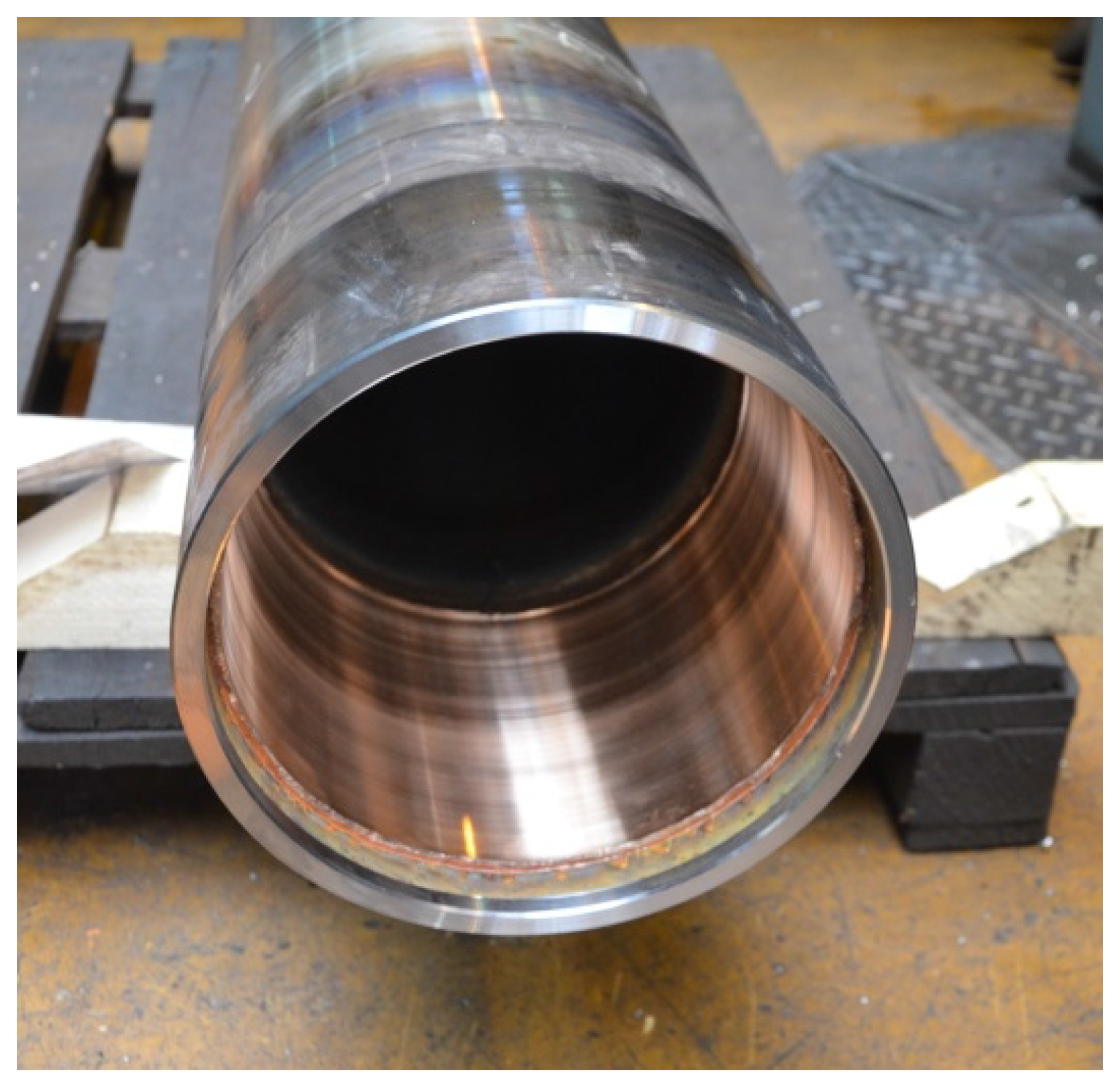

3.3. Cladding Procedure

4. Results

5. Conclusions

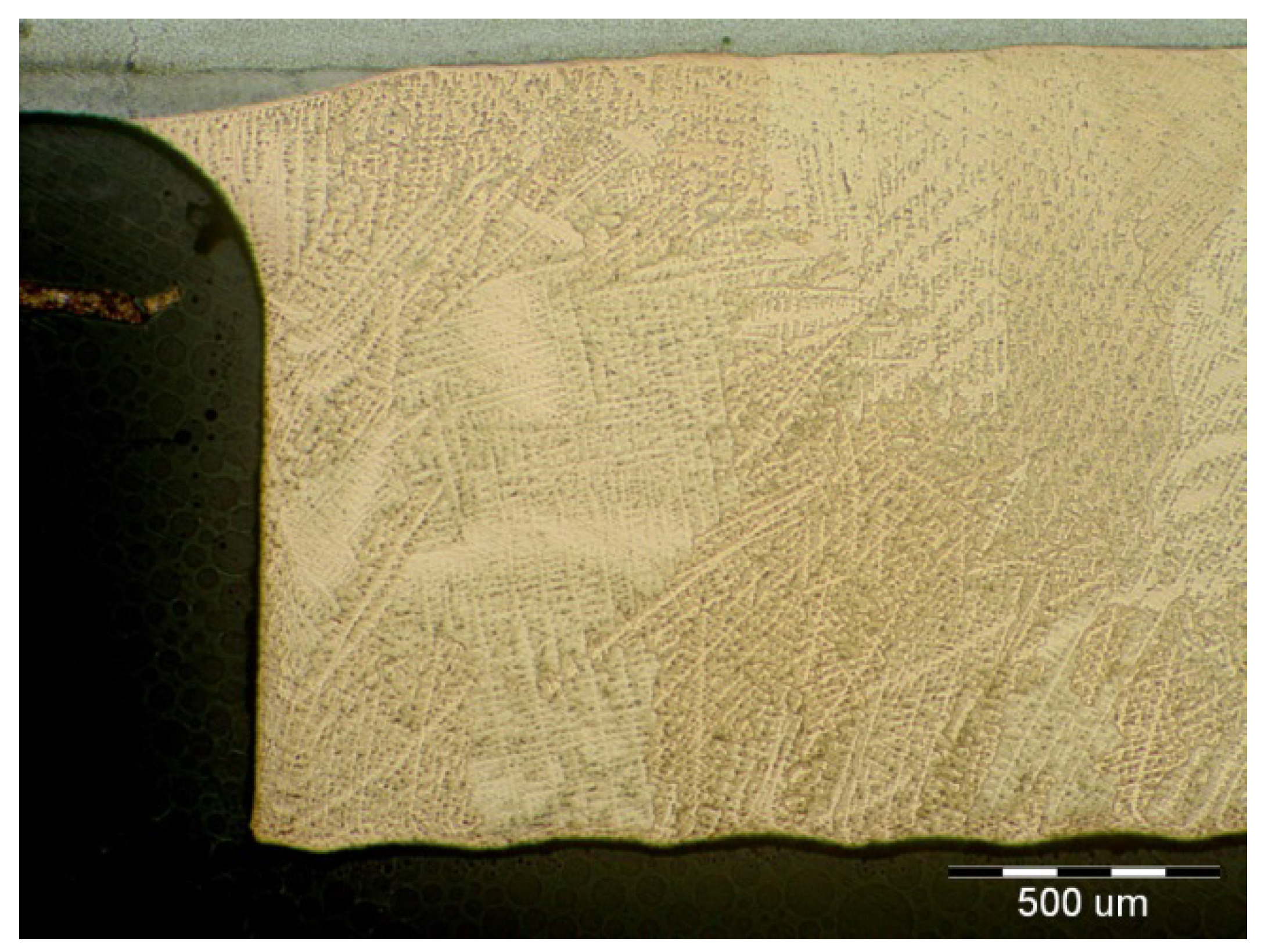

- Claddings are suitable for protecting the internal functional surfaces of supports that must exhibit good tribological properties, such as a low friction index and high resistance against adhesive wear and corrosion. The functional layers are tightly interconnected with the underlying base material (steel) through so-called diffusion welds. The connections formed between the two materials reduce the production costs of telescopic props. If the cylinder is monolithic and made of bronze (specific weight of CuSn is 8800 kg/m3) and/or structural steel and uses a set of ball bearings, it will result in a structure with a high thickness and increased weight.

- Making a bimetal cladding of CuSn6P and steel requires complete optimization of the cladding process. The most important parameter of the cladding process is the heat input, which can be minimized by using the GMAW and GTAW methods and a pulsed welding arc. The cold metal transfer method is also a promising one.

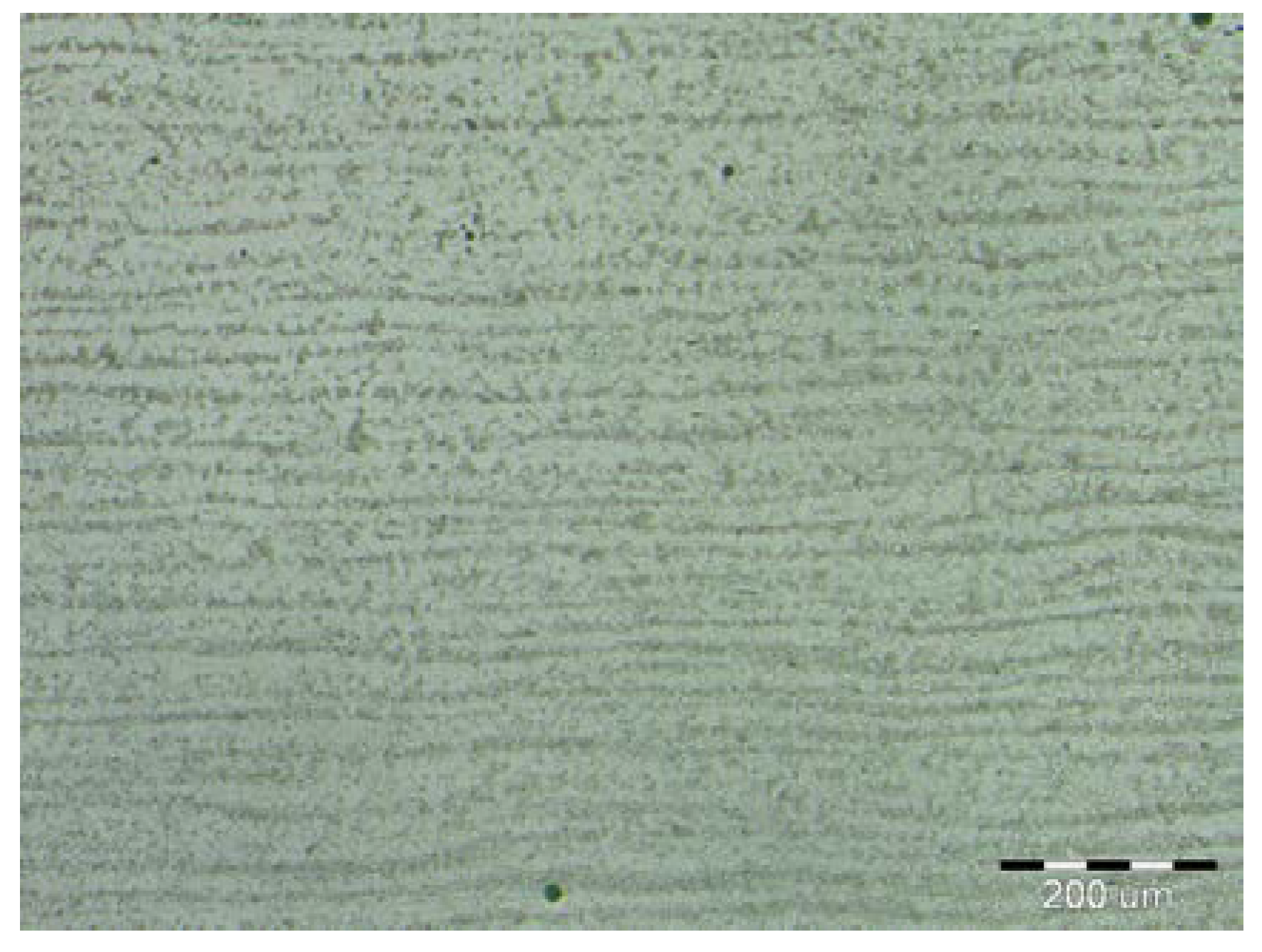

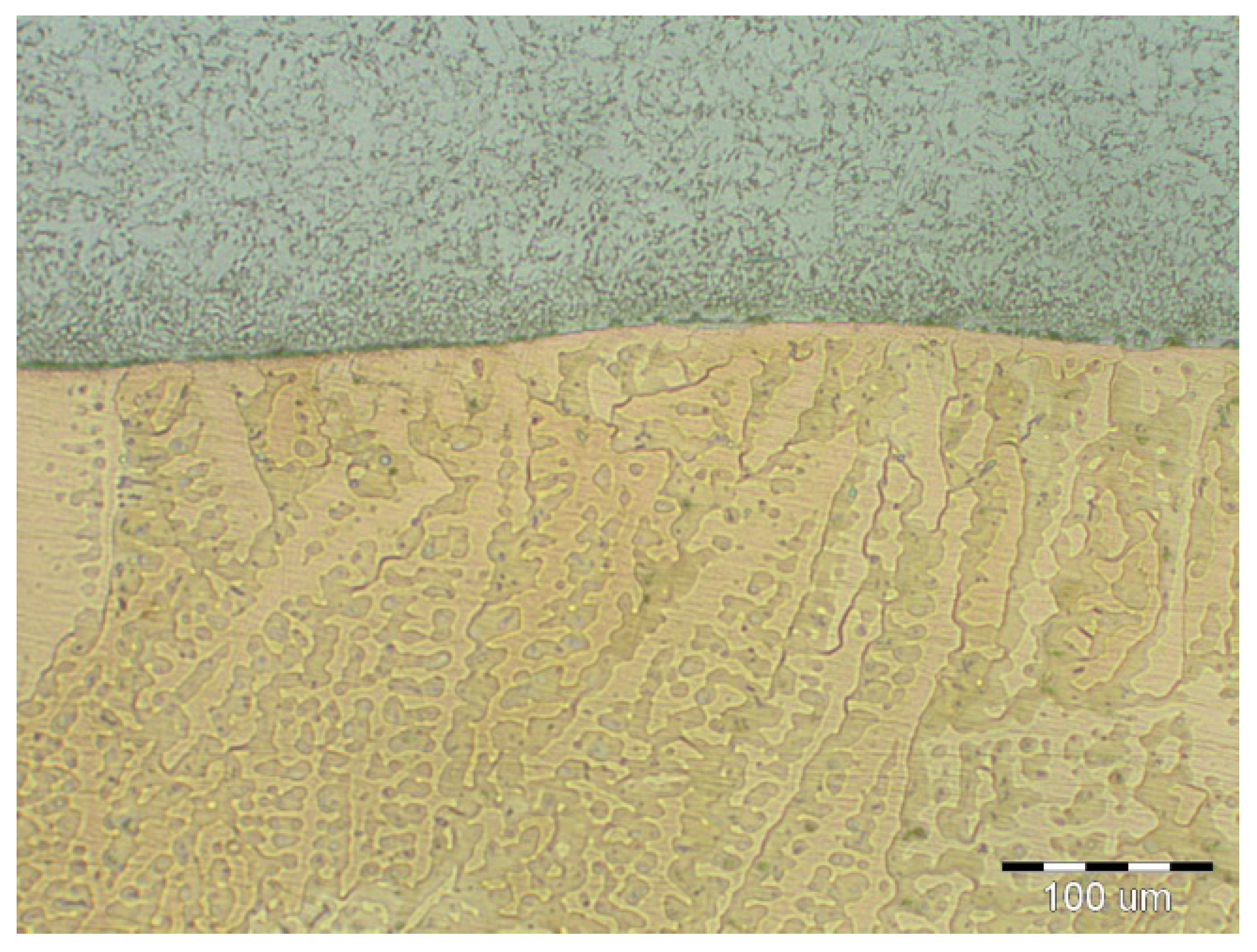

- The formation of microcracks in the transition region between the base and cladding materials is a risk associated with arc cladding. The microcracks can be intergranular with a transversal direction or have a longitudinal orientation with respect to the cladding direction. However, transversal granular cracks are rarely observed in bimetal claddings formed by arc welding.

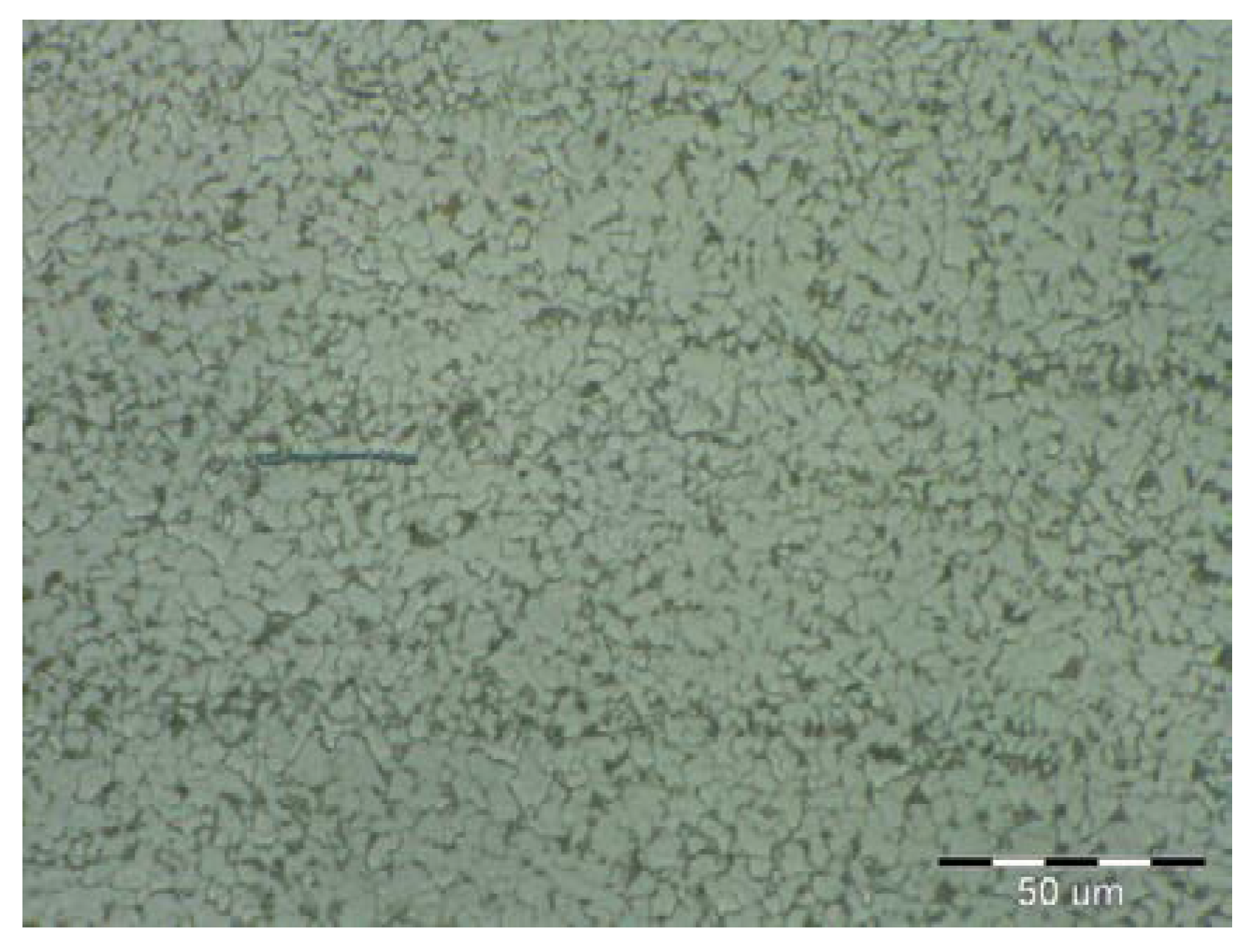

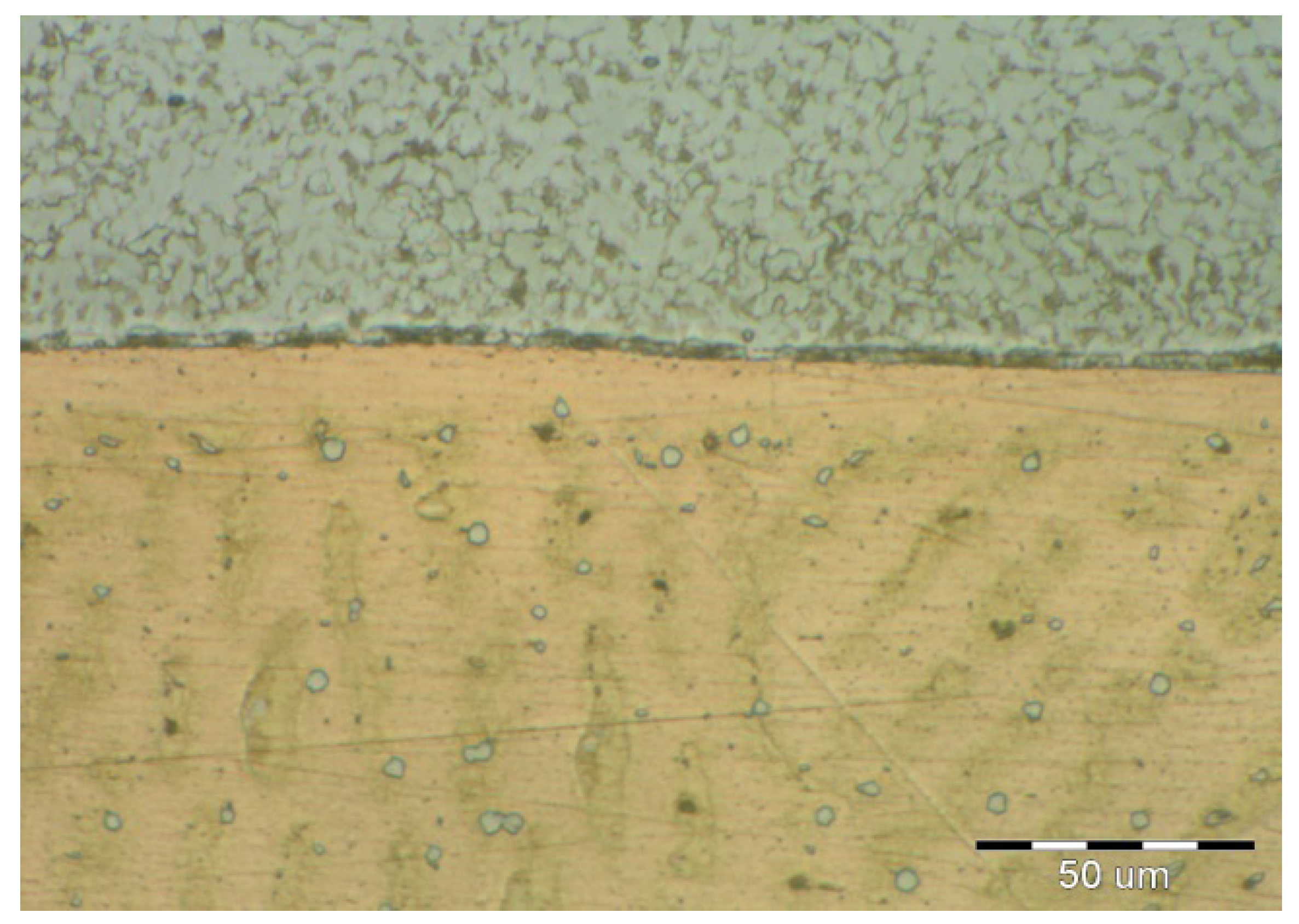

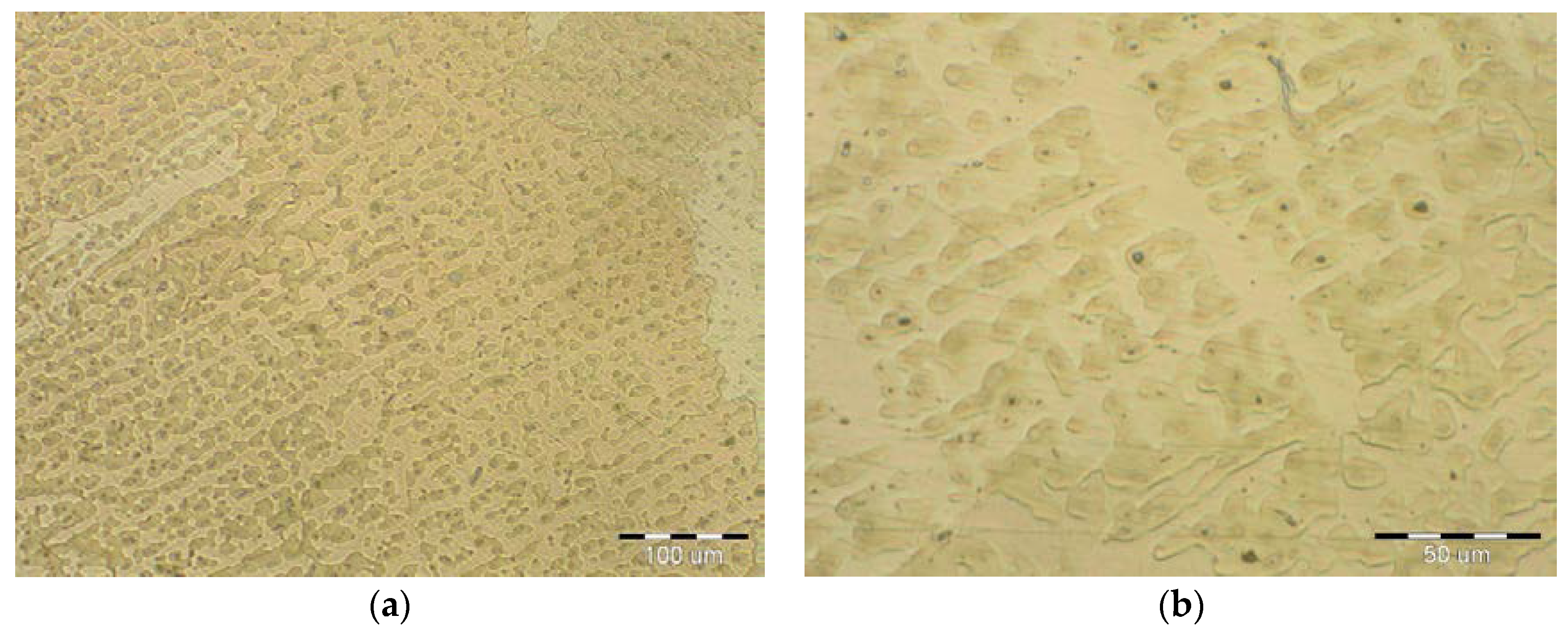

- GTAW has been confirmed to be a suitable method for the production of bronze CuSn6P claddings on the steel base material with regard to microcrack formation. No microcracks were detected on the interface between the base material and overlay within all tested samples, as shown in Figure 8, Figure 9, Figure 10 and Figure 11.

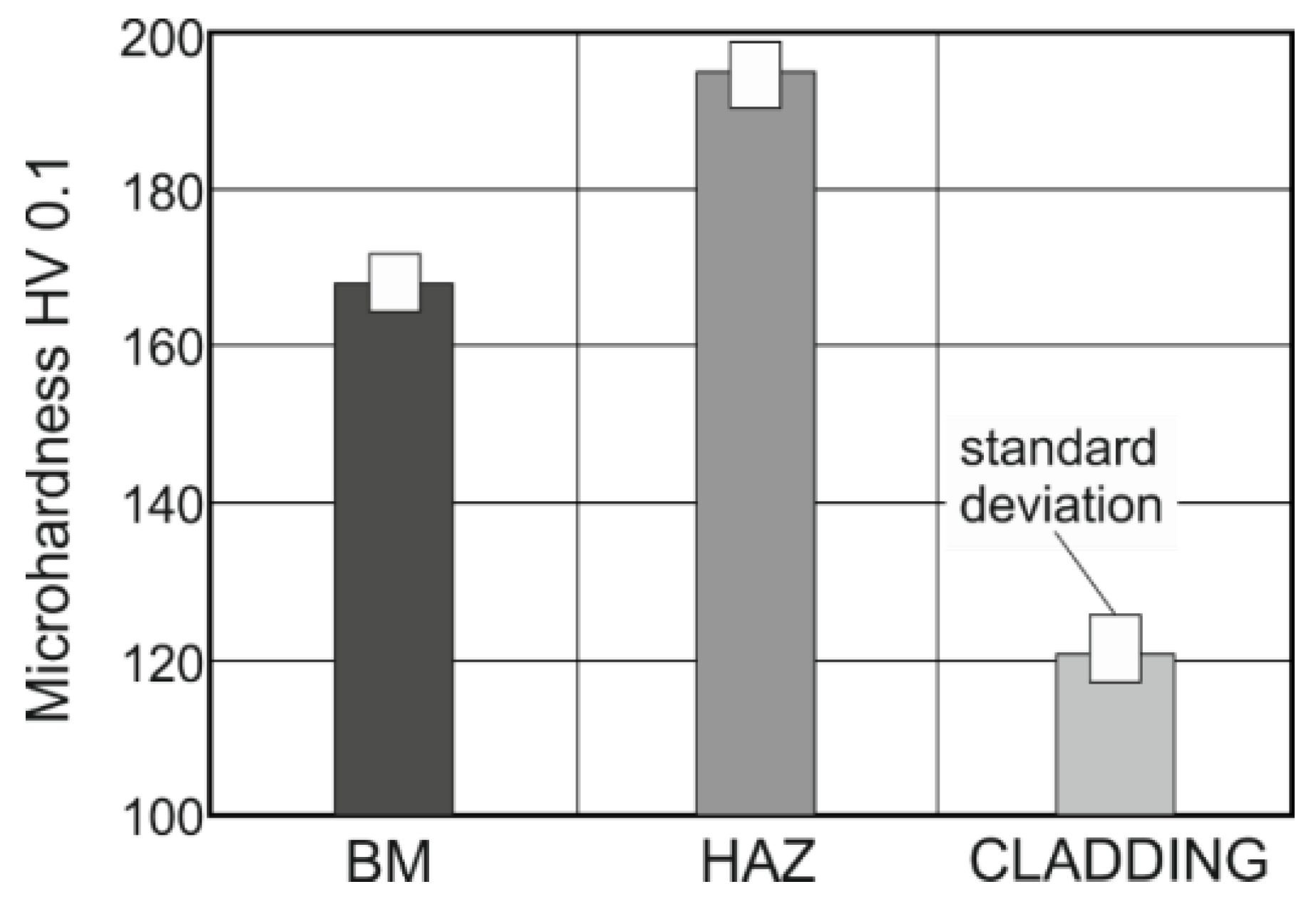

- The hardness of cladding is about 30% lower than the hardness of the base material (169 HV) while the highest hardness (194 HV) was measured in HAZ.

- The employed shielding gas, Ar 99.999% at rate of 16 L/min, proved to be an eligible protective welding atmosphere because no undesirable oxides were identified in the weld metal.

- Both the β-phase and the γ-phase were observed in the microstructure of the cladding cover layer after the first-pass.

- The quality of the claddings and diffusion at the junction are affected by the inert gas used. The gas purity, volume, and flow pattern depend on the nozzle geometry. The use of improper parameters can result in the local formation of CuO2 particles in the cladding–base material transition zone. These particles adversely affect the strength of the weld joints.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gagg, C.; Lewis, P. Wear as a product failure mechanism—Overview and case studies. Eng. Fail. Anal. 2017, 14, 1618–1640. [Google Scholar] [CrossRef]

- Kestursatya, M.; Kim, J.K.; Rohatgi, P.K. Wear performance of copper–graphite composite and a leaded copper alloy. Mater. Sci. Eng. A 2003, 339, 150–158. [Google Scholar] [CrossRef]

- Kimura, T.; Shimizu, K.; Terada, K. Sliding wear characteristic evaluation of copper alloy for bearing. Wear 2007, 263, 586–591. [Google Scholar] [CrossRef]

- Ozsarac, U.; Findik, F.; Durman, M. The wear behaviour investigation of sliding bearings with a designed testing machine. Mater. Des. 2007, 28, 345–350. [Google Scholar] [CrossRef]

- Sudhakar, K.V.; Paredes, J.C. Failure mechanisms in motor bearings. Eng. Fail. Anal. 2005, 12, 35–42. [Google Scholar] [CrossRef]

- Ünlü, B.S.; Atik, E. Evaluation of effect of alloy elements in copper based CuSn10 and CuZn30 bearings on tribological and mechanical properties. J. Alloys Compd. 2010, 489, 262–268. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, G.; Li, W.Y.; Dembinski, L.; Gao, Y.; Liao, H.; Coddet, C. Microstructure, microhardness and dry friction behavior of cold-sprayed tin bronze coatings. Appl. Surf. Sci. 2007, 254, 1482–1488. [Google Scholar] [CrossRef]

- Gao, F.; Liu, R.; Wu, X.J. Tribaloy alloy reinforced tin–bronze composite coating for journal bearing applications. Thin Solid Films 2011, 519, 4809–4817. [Google Scholar] [CrossRef]

- Muzakkir, S.M.; Hirani, H.; Thakre, G.D.; Tyagi, M.R. Tribological failure analysis of journal bearings used in sugar mills. Eng. Fail. Anal. 2011, 18, 2093–2103. [Google Scholar] [CrossRef]

- Demianova, K.; Behulova, M.; Ondruska, J.; Sahul, M.; Turna, M. Numerical simulation of induction heating at brazing copper to brass. In Proceedings of the International Conference on Innovative Technologies IN-TECH; CTU Publishing House: Prague, Czech Republic, 2010; pp. 414–417. [Google Scholar]

- Hodulova, E.; Lechovic, B.; Szewczykova, B.; Kovarikova, I. Study of interfaces lead-free solder joints (in Slovak). In Proceedings of the International Conference Welding 2008; Slovak Welding Society: Tatranská Lomnica, Slovakia, 2008; pp. 296–300. [Google Scholar]

- Skorupa, A.; Krawczyk, S.; Góral, T. Influence of pressure on tribological properties of multilayer surfacing welds of bronze CuSn6 padded onto steel substrate by means of the MIG method. Weld. Int. 2015, 29, 610–613. [Google Scholar] [CrossRef]

- Ying, L.X.; Wang, X.H.; Zhang, C.J.; Liu, G.N.; Wang, G.X. Effect of PTFE Content on Microstructure and Tribological Properties of Cu-Sn Coating. Adv. Mater. Res. 2017, 1142, 173–177. [Google Scholar] [CrossRef]

- Sharma, S.C.; Satish, B.M.; Girish, B.M.; Somashekar, D.R. Wear characteristics of phosphor—bronze/silicon carbide particulate composites. J. Mater. Process. Technol. 2001, 118, 65–68. [Google Scholar] [CrossRef]

- Hansen, M.; Anderko, K.; Salzberg, H.W. Constitution of Binary Alloys. J. Electrochem. Soc. 1958, 105, 260C–261C. [Google Scholar] [CrossRef]

- Hansen, M.; Anderko, K. Cu–Sn Copper–Tin; Genium Publishing Corporation: Amsterdam, NY, USA, 1985. [Google Scholar]

- Arias-Gonzalez, F.; del Val, J.; Comesana, R.; Penide, J.; Lusquinos, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Pou, J. Production of phosphor bronze coating by laser cladding. Procedia Manuf. 2017, 13, 177–182. [Google Scholar] [CrossRef]

- Kim, H.I.; Park, H.S.; Koo, J.M.; Seok, C.S.; Yang, S.H.; Kim, M.Y. Evaluation of welding characteristics for manual overlay and laser cladding materials in gas turbine blades. J. Mech. Sci. Technol. 2012, 26, 2015–2018. [Google Scholar] [CrossRef]

- Huang, Y.; Yuan, S. Modeling the geometric formation and powder deposition mass in laser induction hybrid cladding. J. Mech. Sci. Technol. 2012, 26, 2347–2351. [Google Scholar] [CrossRef]

- Ondrejcek, P. Steel Welding in Shielding Gas with Consumable; Eterna Press: Bratislava, Slovakia, 2003. [Google Scholar]

- Orszagh, V.; Orszagh, P. TIG Welding of Steels and Nonferrous Materials; Polygrafia SAV: Bratislava, Slovakia, 1998. [Google Scholar]

- Klocke, F.; Lung, D.; Gerschwiler, K.; Vogtel, P.; Cordes, S.; Niehaus, F. Recommended Machining Parameters for Copper and Cop-Per Alloys; German Copper Institute: Dusseldorf, Germany, 2010; Available online: https://www.copper.org/applications/marine/cuni/pdf/DKI-Machining.pdf (accessed on 30 January 2018).

- Nobel, C.; Klocke, F.; Lung, D.; Wolf, S. Machinability Enhancement of Lead-free Brass Alloys. Procedia CIRP 2014, 14, 95–100. [Google Scholar] [CrossRef]

- Taha, M.A.; El-Mahallawy, N.A.; Hammouda, R.M.; Moussa, T.M.; Gheith, M.H. Machinability characteristics of lead free-silicon brass alloys as correlated with microstructure and mechanical properties. Ain Shams Eng. J. 2012, 3, 383–392. [Google Scholar] [CrossRef]

- Sornakumar, T.; Kumar, A.S. Machinability of bronze—Alumina composite with tungsten carbide cutting tool insert. J. Mater. Process. Technol. 2008, 202, 402–405. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | Cu |

|---|---|---|---|---|

| 0.10% | 0.84% | 0.61% | 1.11% | 0.45% |

| N | Ni | P | S | Fe |

| 0.02% | 0.4% | 0.06% | 0.02% | Res. |

| Tensile Strength Rm (MPa) | Yield Strength Re (MPa) | Expansion A5 (%) | Impact Energy (J) (0 °C) | Hardness HV |

|---|---|---|---|---|

| 490–630 | ≥345 | ≥22 | ≥27 | 155 |

| Sn (%) | P (%) | Cu (%) | Tensile Strength Rm (MPa) | Expansion A5 (%) | Impact Energy (J) (20 °C) | Hardness HB |

|---|---|---|---|---|---|---|

| 6.3 | 0.22 | Res. | ≥260 | ≥30 | ≥32 | 80–60 |

| Welding Current (A) | Open Arc Voltage (V) | Travel Speed (cm/min) | Polarity | Travel Angle (°) | Wire Feed Speed (m/min) |

|---|---|---|---|---|---|

| 145 | 22 | 42 | DC | 15 | 0.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viňáš, J.; Vrabeľ, M.; Greš, M.; Brezina, J.; Sabadka, D.; Fedorko, G.; Molnár, V. Restoration of Worn Movable Bridge Props with Use of Bronze Claddings. Materials 2018, 11, 459. https://doi.org/10.3390/ma11040459

Viňáš J, Vrabeľ M, Greš M, Brezina J, Sabadka D, Fedorko G, Molnár V. Restoration of Worn Movable Bridge Props with Use of Bronze Claddings. Materials. 2018; 11(4):459. https://doi.org/10.3390/ma11040459

Chicago/Turabian StyleViňáš, Ján, Marek Vrabeľ, Miroslav Greš, Jakub Brezina, Dušan Sabadka, Gabriel Fedorko, and Vieroslav Molnár. 2018. "Restoration of Worn Movable Bridge Props with Use of Bronze Claddings" Materials 11, no. 4: 459. https://doi.org/10.3390/ma11040459

APA StyleViňáš, J., Vrabeľ, M., Greš, M., Brezina, J., Sabadka, D., Fedorko, G., & Molnár, V. (2018). Restoration of Worn Movable Bridge Props with Use of Bronze Claddings. Materials, 11(4), 459. https://doi.org/10.3390/ma11040459