Sensitive Five-Fold Local Symmetry to Kinetic Energy of Depositing Atoms in Cu-Zr Thin Film Growth

Abstract

1. Introduction

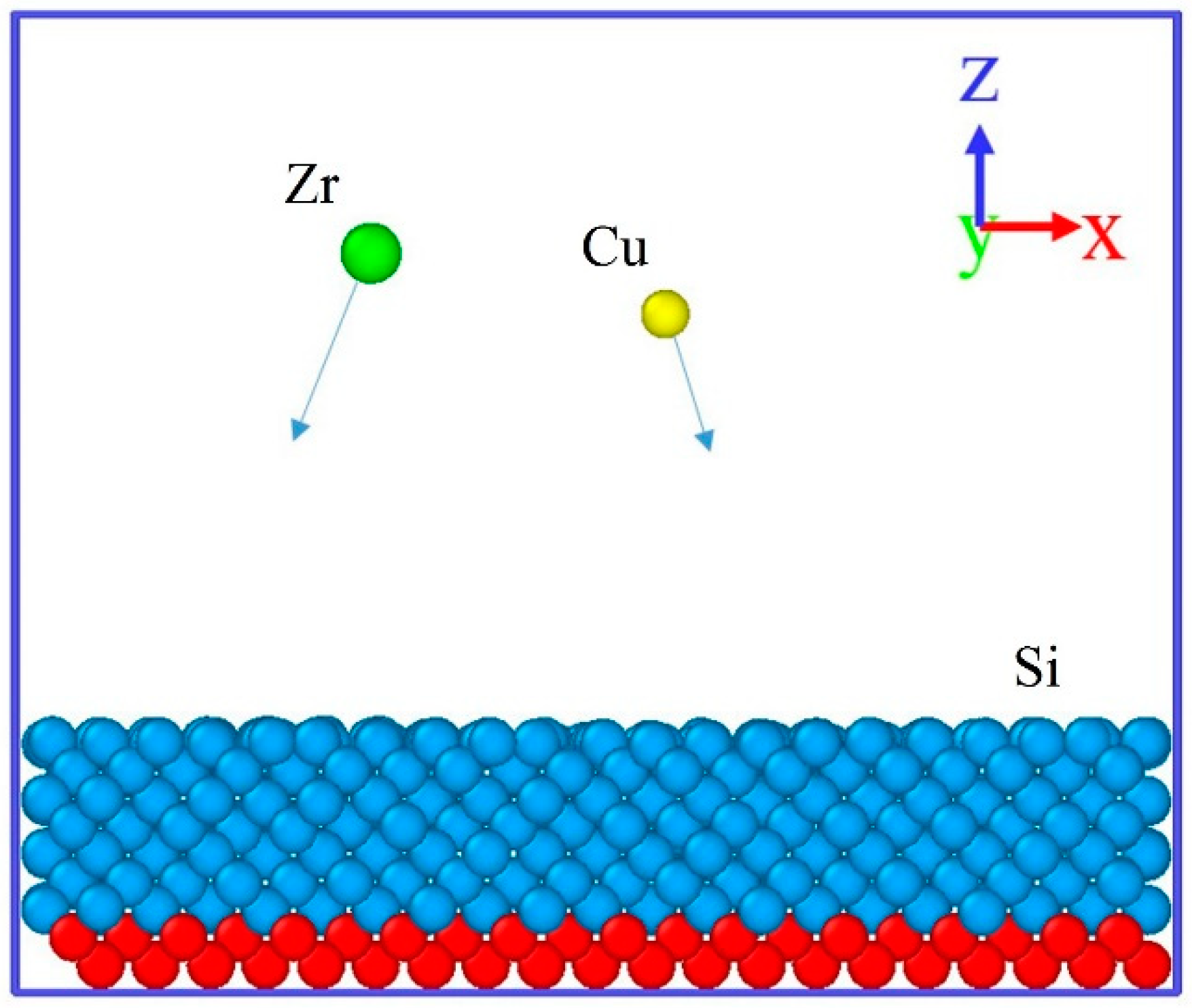

2. Models and Methods

2.1. Modeling

2.2. Simulation Process

3. Results and Discussion

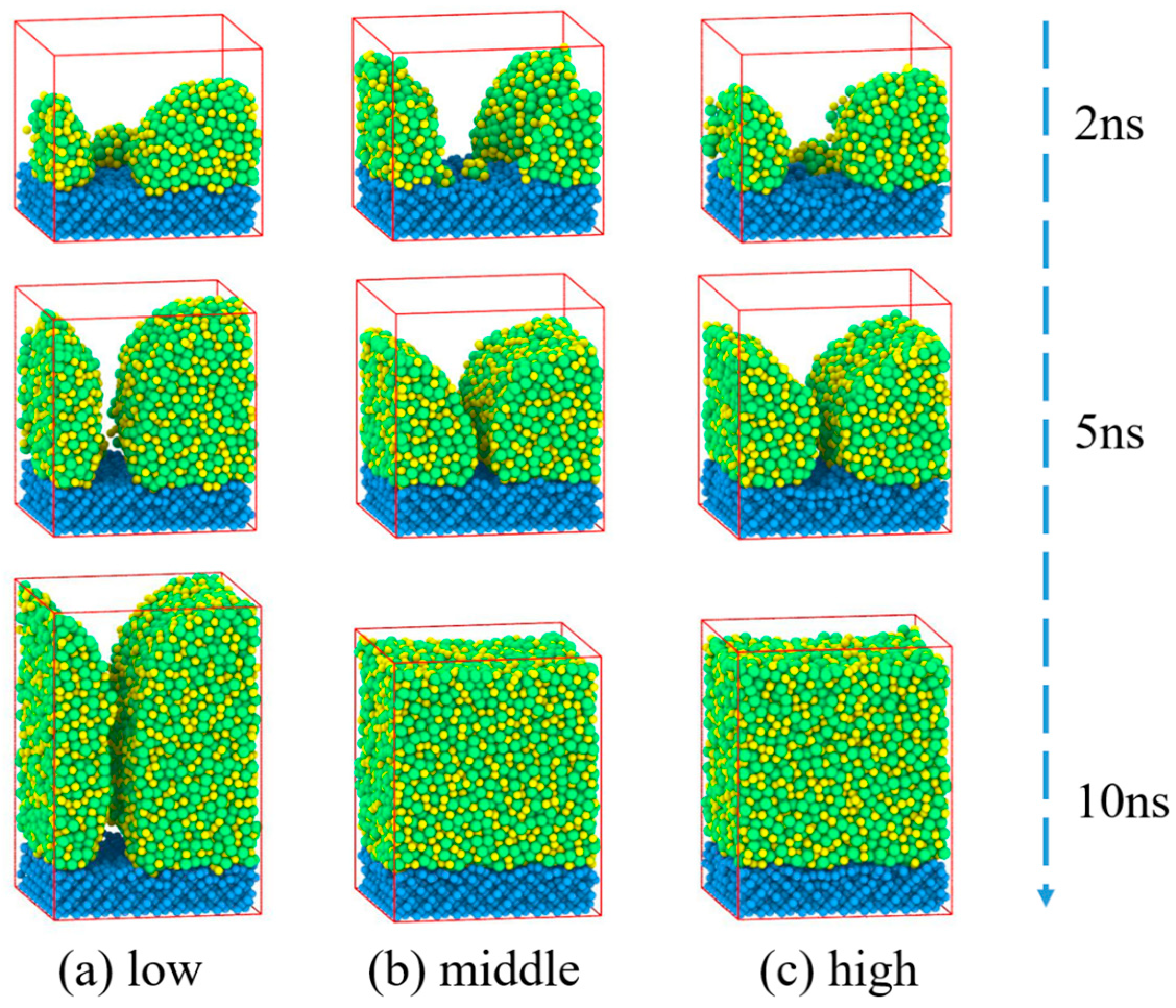

3.1. Zr50Cu50

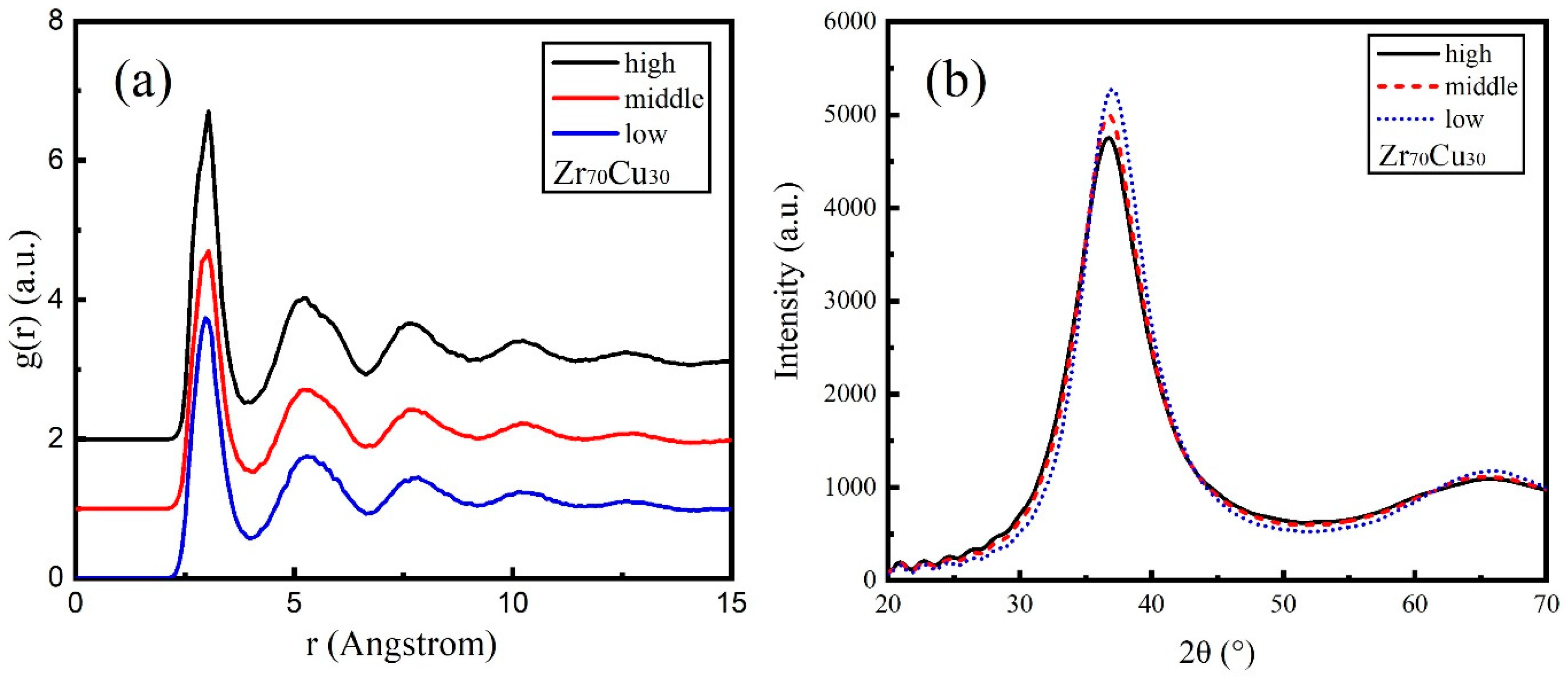

3.2. Zr70Cu30

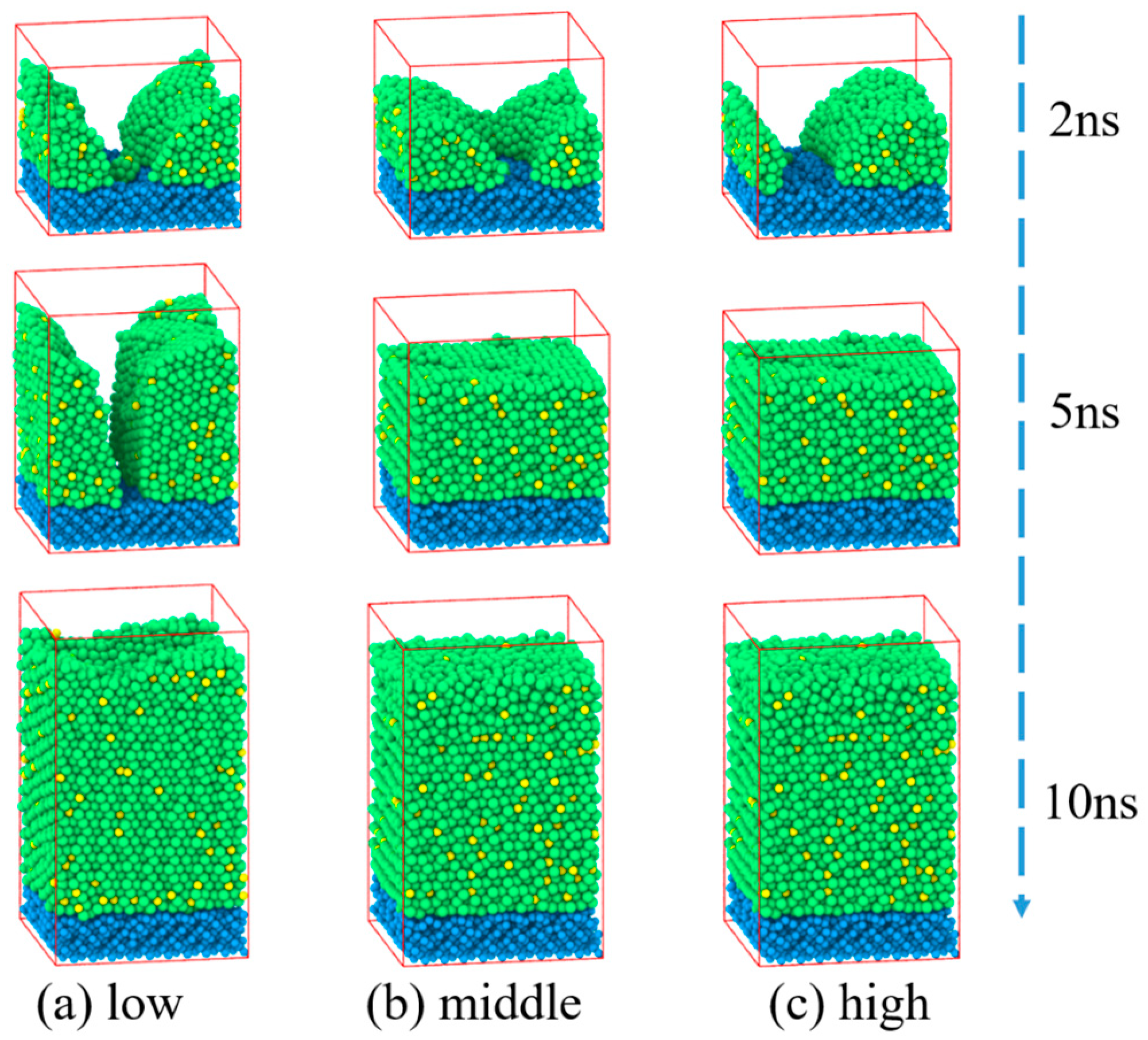

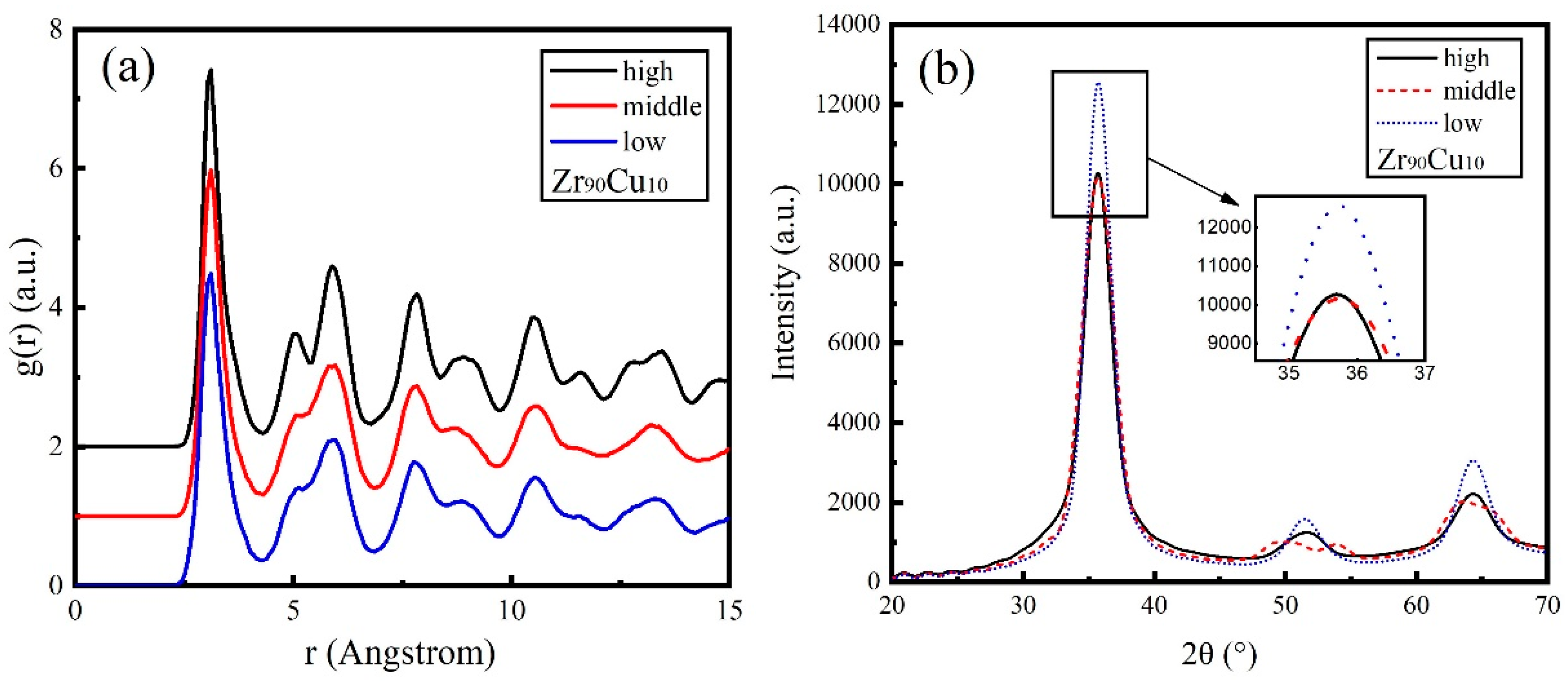

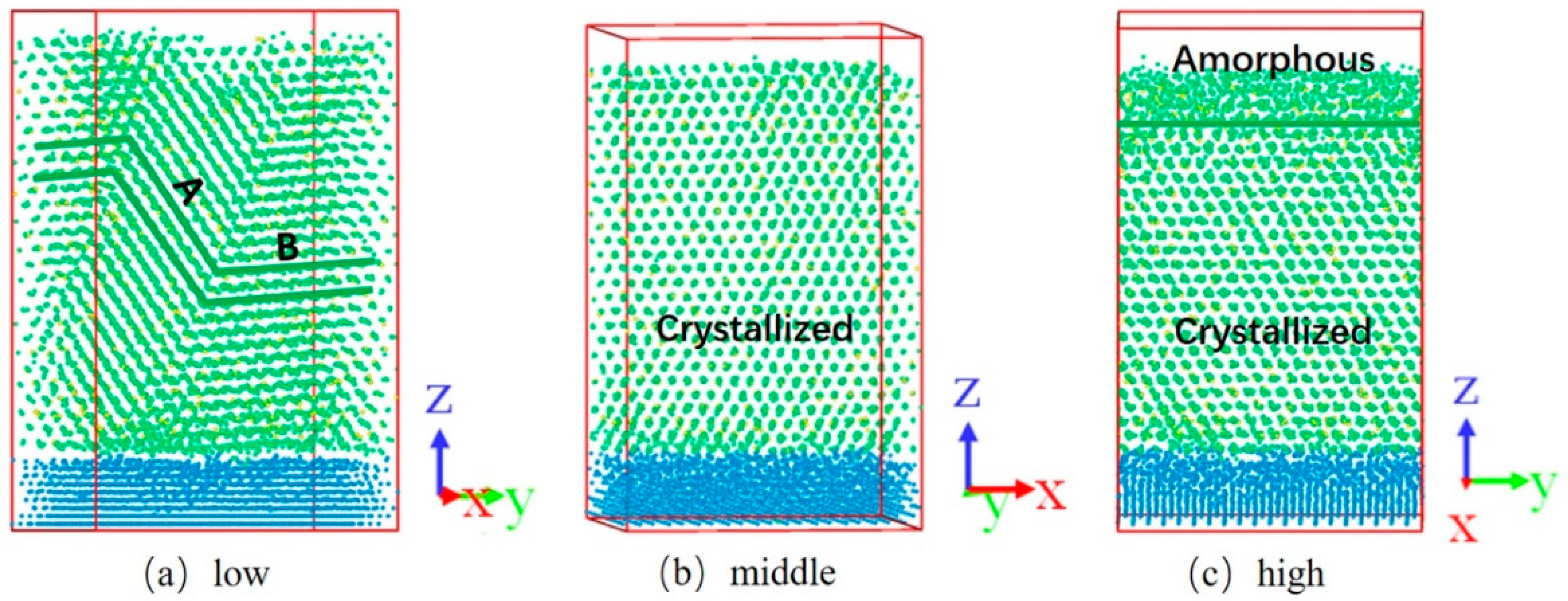

3.3. Zr90Cu10

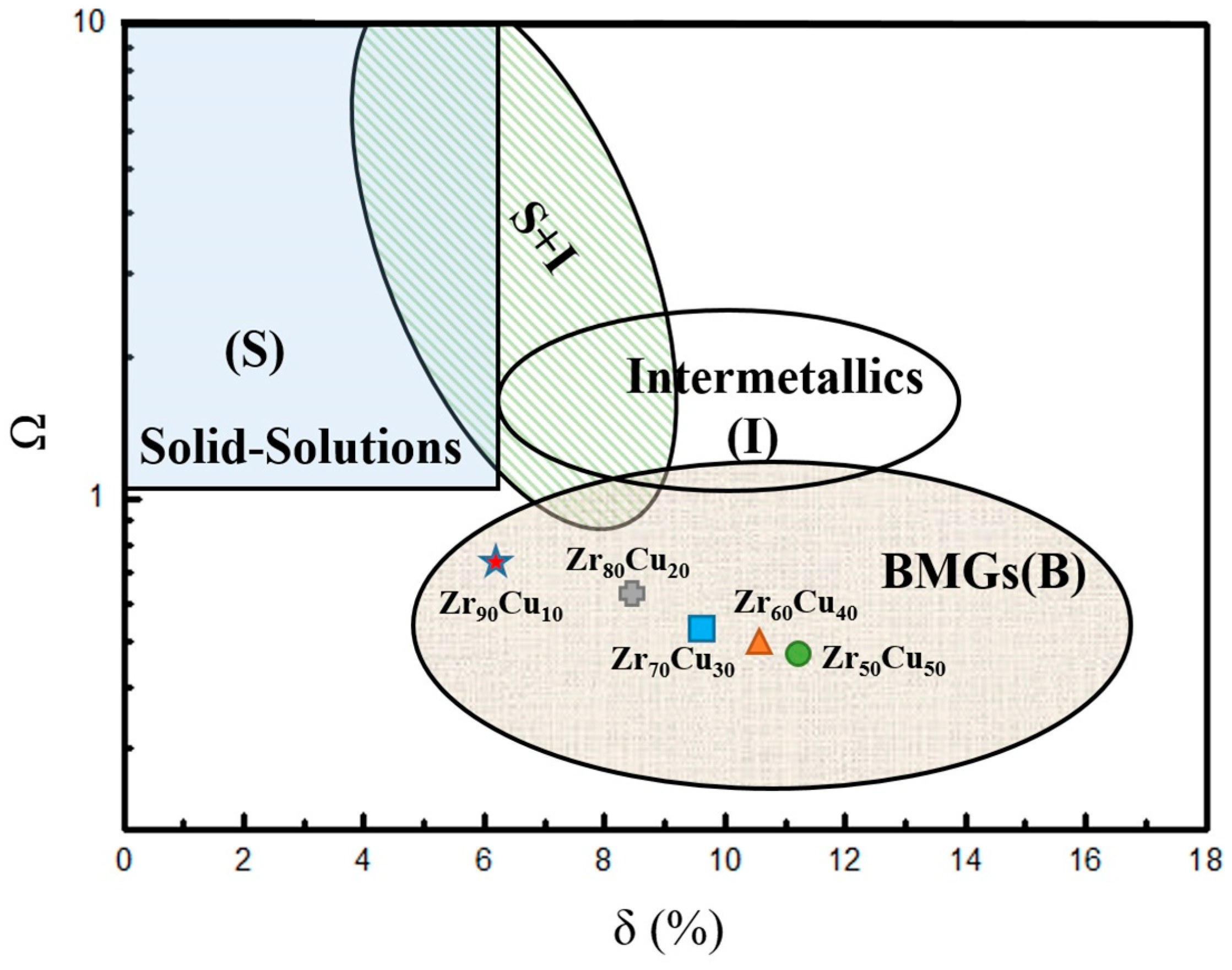

3.4. Glass Forming Ability

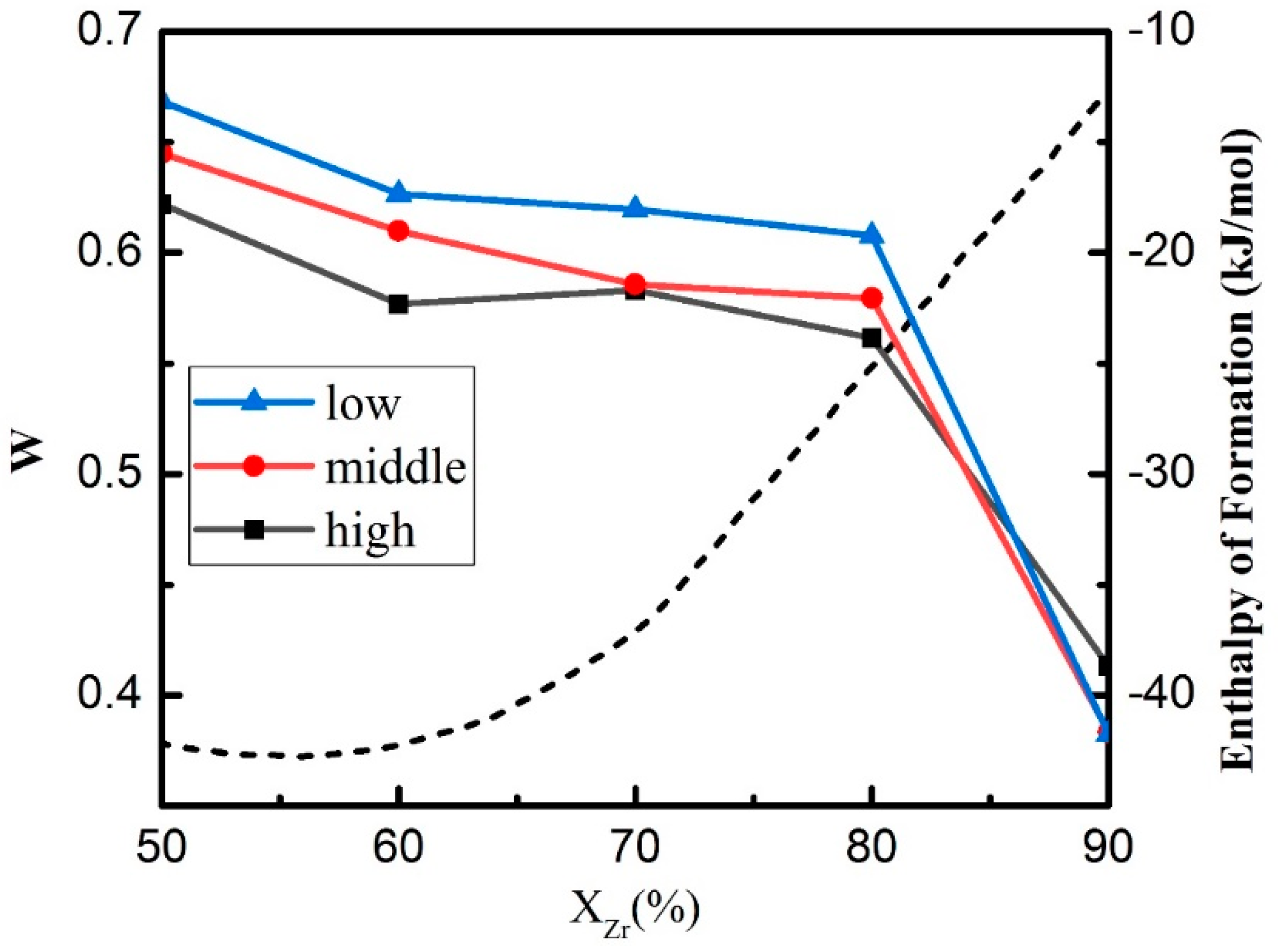

3.5. Five-Fold Local Symmetry Analysis.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Wang, W.H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 2012, 57, 487–656. [Google Scholar] [CrossRef]

- Si, J.; Mei, J.; Wang, R.; Chen, X.; Hui, X. Fe-B-Si-Zr bulk metallic glasses with ultrahigh compressive strength and excellent soft magnetic properties. Mater. Lett. 2016, 181, 282–284. [Google Scholar] [CrossRef]

- Niu, B.; Sun, M.H.; Wang, D.; Wang, L.N. Thermoplasticity of Cu45Zr42.55Y3.45Al9 metallic glass. Mater. Heat. Treat 2010, 8, 6–9. [Google Scholar]

- Liao, G.; Long, Z.; Zhao, M.; Zhong, M.; Liu, W.; Chai, W. Serrated flow behavior in a Pd-based bulk metallic glass under nanoindentation. J. Non-Cryst. Solids 2017, 460, 47–53. [Google Scholar] [CrossRef]

- Mattern, N. Structure Formation in Metallic Glasses. Available online: http://www.ww.tu-freiberg.de/mk/bht/Abstracts/mattern.pdf (accessed on 13 December 2018).

- Masumoto, T. Recent progress of amorphous metallic materials. Mater. Sci. Eng. A 1994, 179–180, 8–16. [Google Scholar] [CrossRef]

- Laws, K.J.; Miracle, D.B.; Ferry, M. A predictive structural model for bulk metallic glasses. Nat. Commun. 2015, 6, 8123. [Google Scholar] [CrossRef]

- Cheng, Y.Q.; Ma, E. Atomic-level structure and structure–property relationship in metallic glasses. Prog. Mater. Sci. 2011, 56, 379–473. [Google Scholar] [CrossRef]

- Zeman, P.; Zítek, M.; Zuzjaková, Š.; Čerstvý, R. Amorphous Zr-Cu thin-film alloys with metallic glass behavior. J. Alloys Compd. 2017, 696, 1298–1306. [Google Scholar] [CrossRef]

- Musil, J.; Daniel, R. Structure and mechanical properties of magnetron sputtered Zr–Ti–Cu–N films. Surf. Coat. Technol. 2003, 166, 243–253. [Google Scholar] [CrossRef]

- Eckert, J.; Das, J.; Kim, K.B.; Baier, F.; Tang, M.B.; Wang, W.H.; Zhang, Z.F. High strength ductile Cu-base metallic glass. Intermetallics 2006, 14, 876–881. [Google Scholar] [CrossRef]

- Xu, D.; Lohwongwatana, B.; Duan, G.; Johnson, W.; Garland, C. Bulk metallic glass formation in binary Cu-rich alloy series—Cu100−xZrx (x= 34, 36, 38.2, 40 at %) and mechanical properties of bulk Cu64Zr36 glass. Acta Mater. 2004, 52, 2621–2624. [Google Scholar] [CrossRef]

- Karpe, N.; Bøttiger, J.; Krog, J.P.; Nordström, A.; Rapp, Ö. Influence of deposition conditions and ion irradiation on thin films of amorphous Cu-Zr superconductors. Thin Solid Films 1996, 275, 82–86. [Google Scholar] [CrossRef]

- Dudonis, J.; Bručas, R.; Miniotas, A. Synthesis of amorphous Zr-Cu alloys by magnetron co-sputtering. Thin Solid Films 1996, 275, 164–167. [Google Scholar] [CrossRef]

- Apreutesei, M.; Djemia, P.; Belliard, L.; Abadias, G.; Esnouf, C.; Billard, A.; Steyer, P. Structural-elastic relationships of Zr-TL (TL = Cu, Co, Ni) thin films metallic glasses. J. Alloys Compd. 2017, 707, 126–131. [Google Scholar] [CrossRef]

- Aji, D.P.B.; Hirata, A.; Zhu, F.; Pan, L.; Reddy, K.M.; Song, S.; Liu, Y.; Fujita, T.; Kohara, S.; Chen, M. Ultrastrong and Ultrastable Metallic Glass. Available online: https://arxiv.org/ftp/arxiv/papers/1306/1306.1575.pdf (accessed on 13 December 2018).

- Xu, B.; Falk, M.L.; Li, J.F.; Kong, L.T. Predicting Shear Transformation Events in Metallic Glasses. Phys. Rev. Lett. 2018, 120, 125503. [Google Scholar] [CrossRef]

- Peng, Q.; Meng, F.; Yang, Y.; Lu, C.; Deng, H.; Wang, L.; De, S.; Gao, F. Shockwave generates <100> dislocation loops in bcc iron. Nat. Commun. 2018, 9, 4880. [Google Scholar] [CrossRef] [PubMed]

- Utz, M.; Peng, Q.; Nandagopal, M. Athermal simulation of plastic deformation in amorphous solids at constant pressure. J. Polym. Sci. B Polym. Phys. 2004, 42, 2057–2065. [Google Scholar]

- Sha, Z.D.; Zhang, Y.W.; Feng, Y.P.; Li, Y. Molecular dynamics studies of short to medium range order in Cu64Zr36 metallic glass. J. Alloys Compd. 2011, 509, 8319–8322. [Google Scholar] [CrossRef]

- Wu, T.W.; Feng, S.D.; Qi, L.; Gao, W.; Ma, M.Z.; Zhang, X.Y.; Li, G.; Jing, Q.; Liu, R.P. The compressive behaviour after crystallisation in Zr 85 Cu 15 metallic glasses studied by molecular dynamics simulations. J. Non-Cryst. Solids 2017, 468, 41–45. [Google Scholar] [CrossRef]

- Yang, G.J.; Xu, B.; Kong, L.T.; Li, J.F.; Zhao, S. Size effects in Cu 50 Zr 50 metallic glass films revealed by molecular dynamics simulations. J. Alloys Compd. 2016, 688, 88–95. [Google Scholar] [CrossRef]

- Xie, L.; Brault, P.; Bauchire, J.-M.; Thomann, A.-L.; Bedra, L. Molecular dynamics simulations of clusters and thin film growth in the context of plasma sputtering deposition. J. Phys. D Appl. Phys. 2014, 47, 224004. [Google Scholar] [CrossRef]

- Sha, Z.; Feng, Y.; Li, Y. Statistical composition-structure-property correlation and glass-forming ability based on the full icosahedra in Cu–Zr metallic glasses. Appl. Phys. Lett. 2010, 96, 061903. [Google Scholar] [CrossRef]

- Hajlaoui, K.; Alsaleh, N.; Alrasheedi, N.H.; Yavari, A.R. Coalescence and subsequent twinning of nanocrystals during deformation of CuZr-based metallic glasses: The grain size effect. J. Non-Cryst. Solids 2017, 464, 39–43. [Google Scholar] [CrossRef]

- Almyras, G.A.; Lekka, C.E.; Mattern, N.; Evangelakis, G.A. On the microstructure of the Cu65Zr35 and Cu35Zr65 metallic glasses. Scr. Mater. 2010, 62, 33–36. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Chattopadhyay, P.P.; Ganguly, S. A predictable glass forming ability expression by statistical learning and evolutionary intelligence. Intermetallics 2017, 90, 9–15. [Google Scholar] [CrossRef]

- Turchanin, A.A.; Tomilin, I.A.; Turchanin, M.A.; Belokonenko, I.V.; Agraval, P.G. Enthalpies of formation of liquid and amorphous Cu–Zr alloys. J. Non-Cryst. Solids 1999, 250–252, 582–585. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Hu, Y.C.; Li, F.X.; Li, M.Z.; Bai, H.Y.; Wang, W.H. Five-fold symmetry as indicator of dynamic arrest in metallic glass-forming liquids. Nat. Commun. 2015, 6, 8310. [Google Scholar] [CrossRef] [PubMed]

- Lü, Y.J.; Bi, Q.L.; Huang, H.S.; Pang, H.H. Role of fivefold symmetry in the dynamical slowing down of metallic glass-forming liquids. Phys. Rev. B 2017, 96, 064301. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Berendsen, H.J.C.; Postma, J.P.M.; van Gunsteren, W.F.; DiNola, A.; Haak, J.R. Molecular dynamics with coupling to an external bath. J. Chem. Phys. 1984, 81, 3684–3690. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 1984, 29, 6443–6453. [Google Scholar] [CrossRef]

- Graves, D.B.; Brault, P. Molecular dynamics for low temperature plasma–surface interaction studies. J. Phys. D Appl. Phys. 2009, 42, 194011. [Google Scholar] [CrossRef]

- Zhen, S.; Davies, G.J. Calculation of the Lennard-Jones n–m potential energy parameters for metals. Phys. Status Solid 1983, 78, 595–605. [Google Scholar] [CrossRef]

- Xie, L.; Brault, P.; Thomann, A.-L.; Bedra, L. Molecular dynamic simulation of binary ZrxCu100−x metallic glass thin film growth. Appl. Surf. Sci. 2013, 274, 164–170. [Google Scholar] [CrossRef]

- Finney, J.L. Modelling the structures of amorphous metals and alloys. Nature 1977, 266, 309–314. [Google Scholar] [CrossRef]

- Wu, Z.W.; Li, M.Z.; Wang, W.H.; Liu, K.X. Hidden topological order and its correlation with glass-forming ability in metallic glasses. Nat. Commun. 2015, 6, 6035. [Google Scholar] [CrossRef]

- Liu, X.J.; Xu, Y.; Lu, Z.P.; Hui, X.; Chen, G.L.; Zheng, G.P.; Liu, C.T. Atomic packing symmetry in the metallic liquid and glass states. Acta Mater. 2011, 59, 6480–6488. [Google Scholar] [CrossRef]

- Zhang, W.; Liaw, P.K.; Zhang, Y. Science and technology in high-entropy alloys. Sci. China Mater. 2018, 61, 2–22. [Google Scholar] [CrossRef]

- Li, M.Z.; Peng, H.L.; Hu, Y.C.; Li, F.X.; Zhang, H.P.; Wang, W.H. Five-fold local symmetry in metallic liquids and glasses. Chin. Phys. B 2017, 26, 016104. [Google Scholar] [CrossRef]

- Spaepen, F. Condensed-matter science: Five-fold symmetry in liquids. Nature 2000, 408, 781–782. [Google Scholar] [CrossRef] [PubMed]

| Sample of Mean Kinetic Energy | Zr (eV) | Cu (eV) |

|---|---|---|

| (a) Low energy group | 0.13 | 0.34 |

| (b) Middle energy group | 7.65 | 6.67 |

| (c) High energy group | 12.6 | 9.61 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, L.; An, H.; Peng, Q.; Qin, Q.; Zhang, Y. Sensitive Five-Fold Local Symmetry to Kinetic Energy of Depositing Atoms in Cu-Zr Thin Film Growth. Materials 2018, 11, 2548. https://doi.org/10.3390/ma11122548

Xie L, An H, Peng Q, Qin Q, Zhang Y. Sensitive Five-Fold Local Symmetry to Kinetic Energy of Depositing Atoms in Cu-Zr Thin Film Growth. Materials. 2018; 11(12):2548. https://doi.org/10.3390/ma11122548

Chicago/Turabian StyleXie, Lu, Haojie An, Qing Peng, Qin Qin, and Yong Zhang. 2018. "Sensitive Five-Fold Local Symmetry to Kinetic Energy of Depositing Atoms in Cu-Zr Thin Film Growth" Materials 11, no. 12: 2548. https://doi.org/10.3390/ma11122548

APA StyleXie, L., An, H., Peng, Q., Qin, Q., & Zhang, Y. (2018). Sensitive Five-Fold Local Symmetry to Kinetic Energy of Depositing Atoms in Cu-Zr Thin Film Growth. Materials, 11(12), 2548. https://doi.org/10.3390/ma11122548