Preparation and Properties of Titanium Obtained by Spark Plasma Sintering of a Ti Powder–Fiber Mixture

Abstract

1. Introduction

2. Materials and Methods

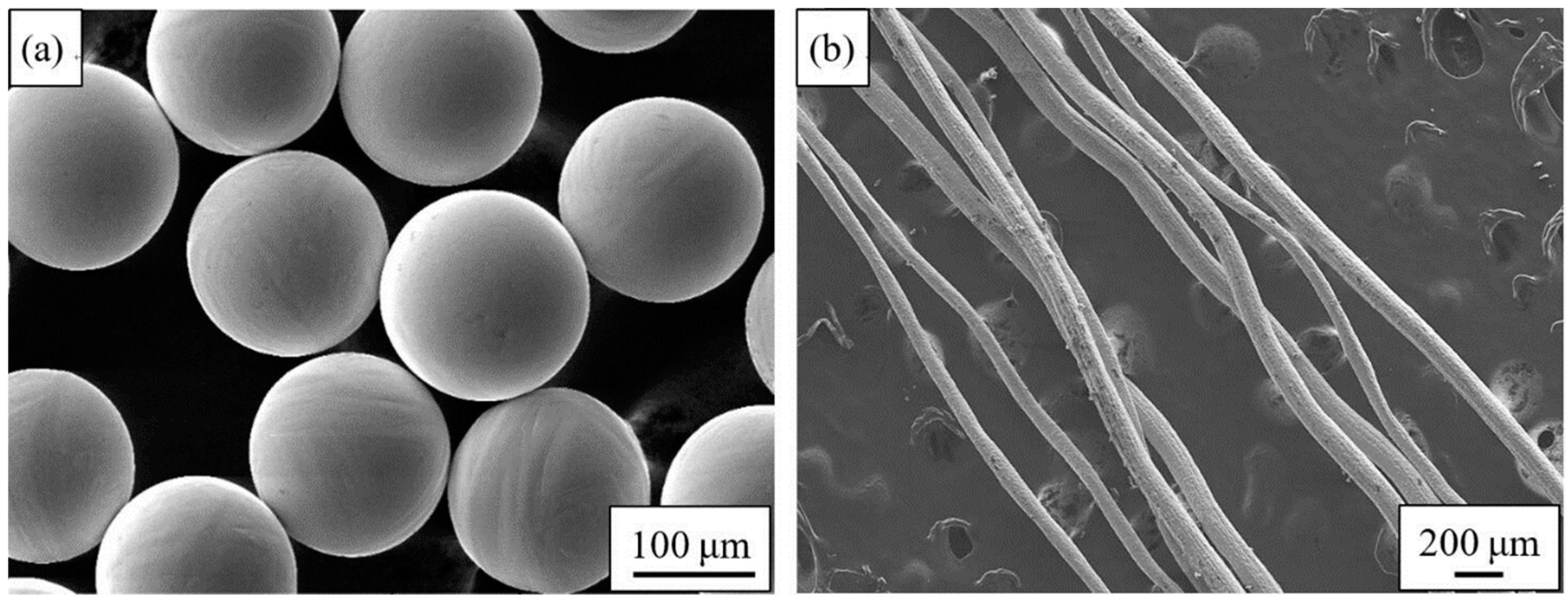

2.1. Material

2.2. Preparation of Porous Titanium

2.3. Characterization

3. Results and Discussion

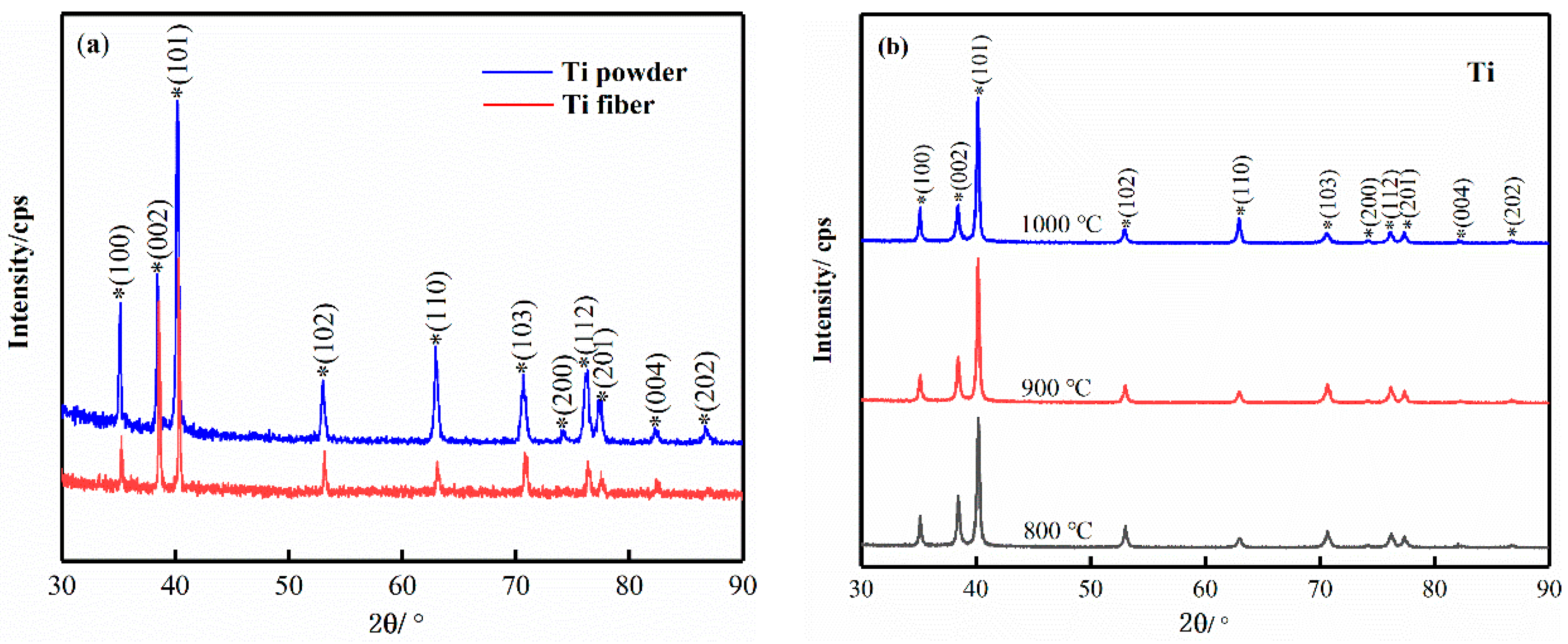

3.1. Phase Analysis

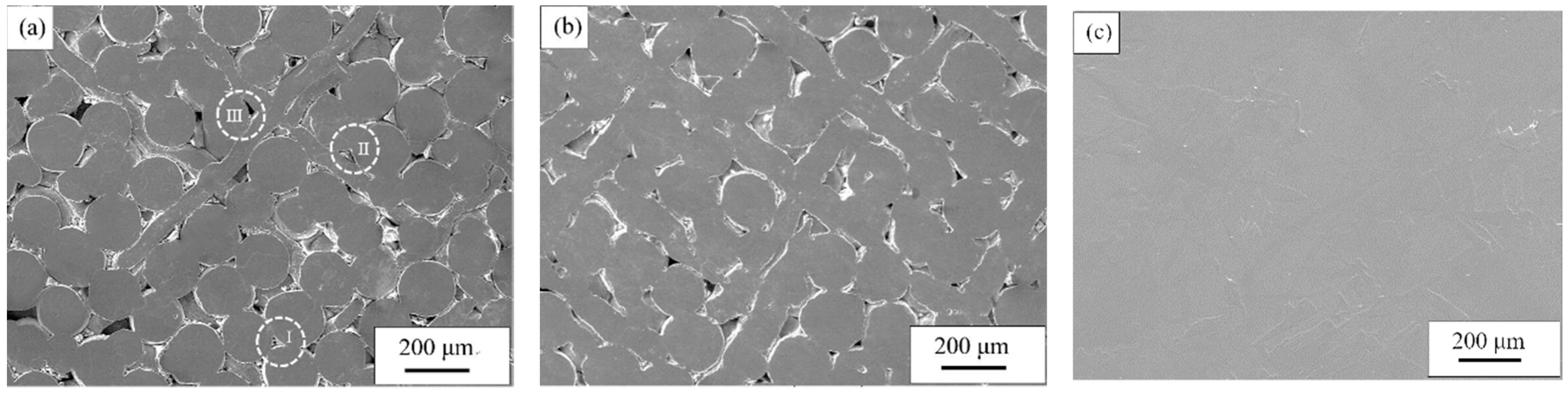

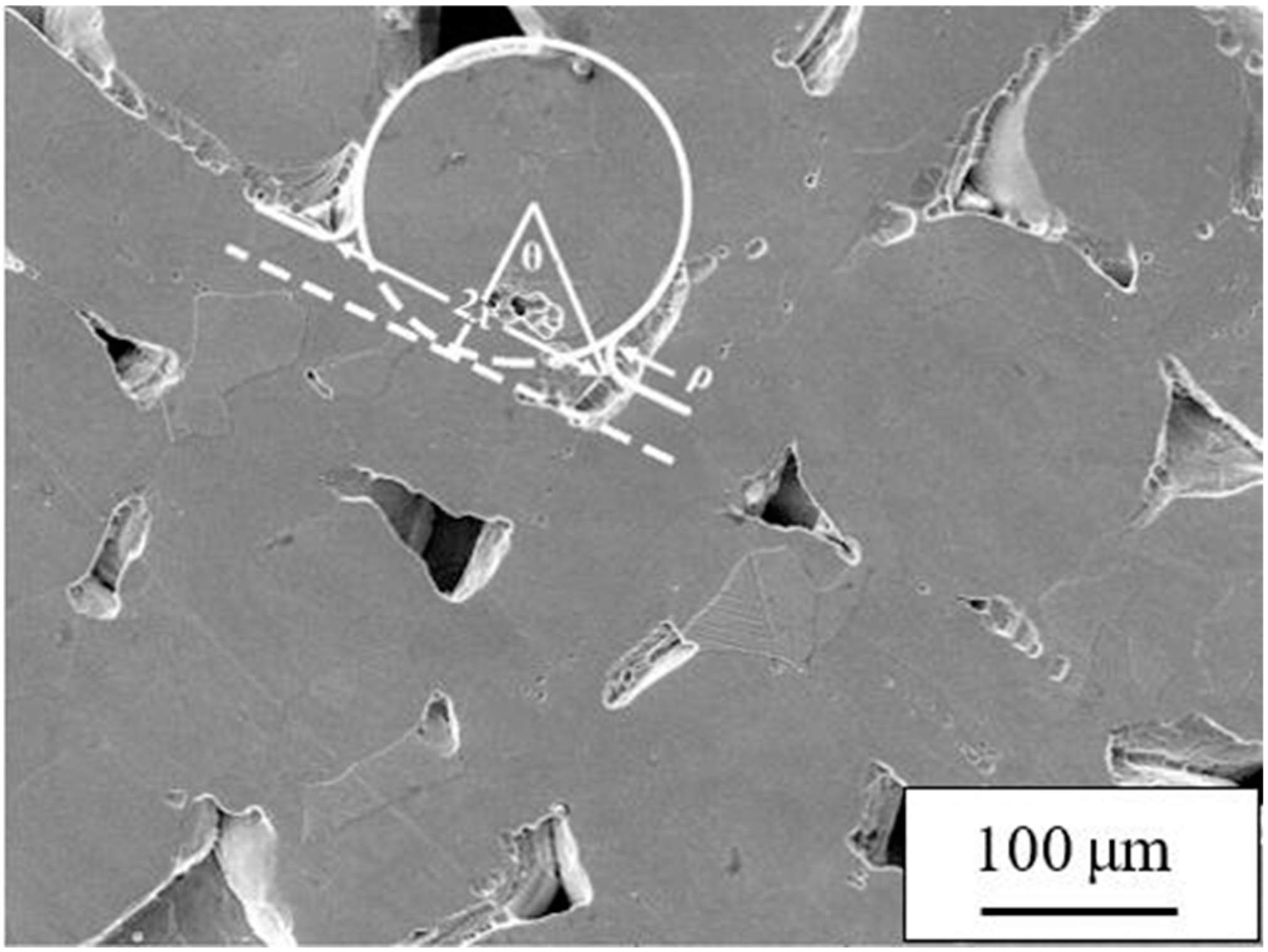

3.2. Microstructure and Pore Characteristic

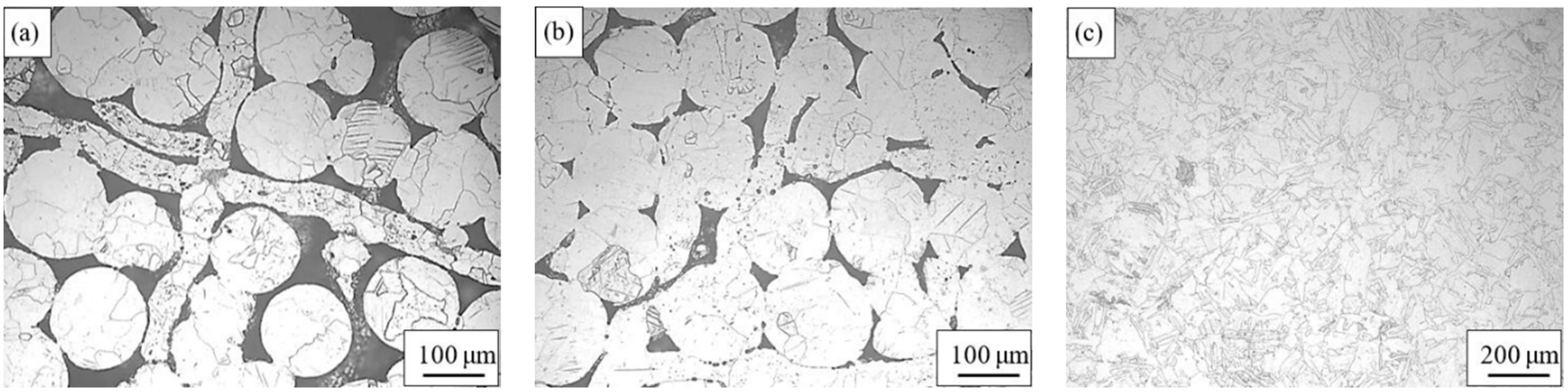

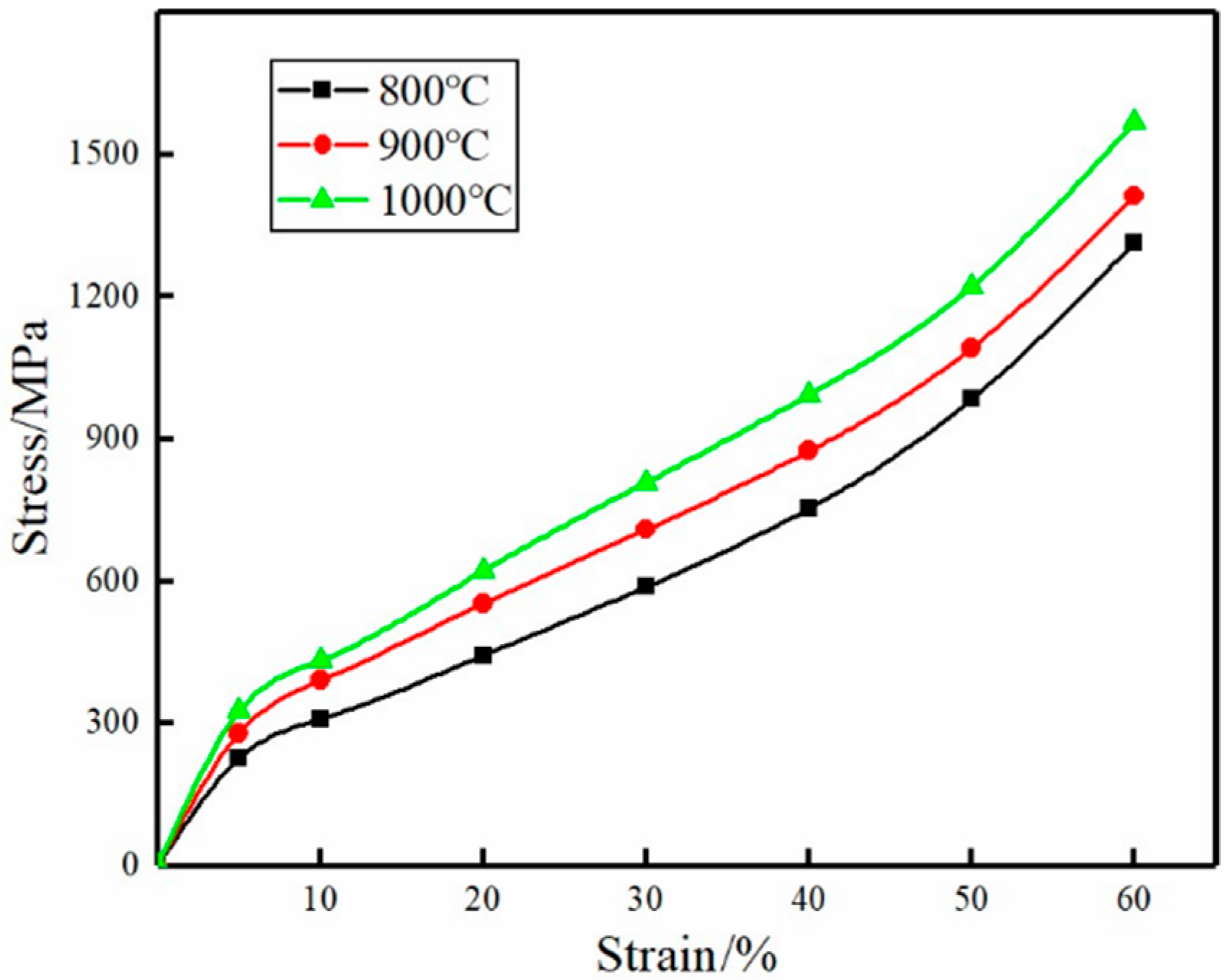

3.3. Mechanical Properties

4. Conclusions

- (1)

- After preparation of composite pore structure porous titanium with a Ti fiber–powder mixture by SPS technology, there were no new phases occurring in porous titanium with porosity of 1.24–24.6% after sintering, and the main phase of the porous titanium was α-hcp Ti;

- (2)

- Titanium fiber and titanium powder formed a composite pore structure through powder/powder, powder/fiber and fiber/fiber sintering. The formation and growth of the sintered neck were dominated by the grain boundary diffusion mechanism and surface diffusion mechanism. The surface grain of the fiber was more uniform and finer than that of the powder, and other diffusion mechanisms were supplemented. The grain size of the sample grew with the increase of sintering temperature, and the grain surface grain was more uniform and finer than that on the powder;

- (3)

- The stress–strain curve of porous titanium obtained by SPS of a Ti powder–fiber mixture consisted of three distinct parts during the compression process: an elastic deformation stage, yield platform stage and densification stage. There was no obvious yield point, and the porous titanium had excellent mechanical properties. The compressive strength of the sample was higher at higher sintering temperatures;

- (4)

- The best sintering process for porous titanium obtained by SPS of a Ti powder–fiber mixture is sintering temperature of 900 °C, and sintering pressure of 20 MPa.

Author Contributions

Funding

Conflicts of Interest

References

- Wally, Z.; van Grunsven, W.; Claeyssens, F.; Goodall, R.; Reilly, G. Porous Titanium for Dental Implant Applications. Metals 2015, 5, 1902–1920. [Google Scholar] [CrossRef]

- Shbeh, M.M.; Goodall, R. Open Celled Porous Titanium. Adv. Eng. Mater. 2017, 19, 1600664. [Google Scholar] [CrossRef]

- Kolli, R.; Devaraj, A. A Review of Metastable Beta Titanium Alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Li, F.; Jiang, X.; Shao, Z.; Zhu, D.; Luo, Z. Microstructure and Mechanical Properties of Nano-Carbon Reinforced Titanium Matrix/Hydroxyapatite Biocomposites Prepared by Spark Plasma Sintering. Nanomaterials 2018, 8, 729. [Google Scholar] [CrossRef] [PubMed]

- PaIka, K.; Pokrowiecki, R. Porous Titanium Implants: A Review. Adv. Eng. Mater. 2018, 20, 1700648. [Google Scholar] [CrossRef]

- Özbilen, S.; Liebert, D.; Beck, T.; Bram, M. Fatigue behavior of highly porous titanium produced by powder metallurgy with temporary space holders. Mater. Sci. Eng. C 2016, 60, 446–457. [Google Scholar] [CrossRef] [PubMed]

- Leśniewski, W.; Wawrylak, M.; Wieliczko, P.; Boroń, Ł.; Krzak, I. Porous Titanium Materials Produced Using the HIP Method. Key Eng. Mater. 2016, 687, 149–154. [Google Scholar] [CrossRef]

- Yamada, K.; Ito, M.; Akazawa, T.; Murata, M.; Yamamoto, T.; Iwasaki, N. A preclinical large animal study on a novel intervertebral fusion cage covered with high porosity titanium sheets with a triple pore structure used for spinal fusion. Eur. Spine J. 2015, 24, 2530–2537. [Google Scholar] [CrossRef]

- Ghosh, N.C.; Harimkar, S.P. 3–Consolidation and synthesis of MAX phases by Spark Plasma Sintering (SPS): A review. Adv. Sci. Technol. Mn+1axn Phases 2012, 47–80. [Google Scholar] [CrossRef]

- Fu, Z.; Wang, K.; Tan, T.; Xiong, Y.; He, D.; Wang, Y.; Munir, Z.A. Study on the Process Mechanism in Spark Plasma Sintering; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; pp. 1–21. [Google Scholar]

- Trzaska, Z.; Collard, C.; Durand, L.; Couret, A.; Chaix, J.-M.; Fantozzi, G.; Monchoux, J.-P. Spark plasma sintering microscopic mechanisms of metallic systems: Experiments and simulations. J. Am. Ceram. Soc. 2018. [Google Scholar] [CrossRef]

- Yang, X. Study on Preparation and Consolidation Mechanism of TiAl-Based Alloy Prepared by Spark Plasma Sintering. Ph.D. Thesis, Central South University, Changsha, China, 2012. [Google Scholar]

- Zhang, L.; Tan, J.; Meng, Z.D.; He, Z.Y.; Zhang, Y.Q.; Jiang, Y.H.; Zhou, R. Low elastic modulus Ti-Ag/Ti radial gradient porous composite with high strength and large plasticity prepared by spark plasma sintering. Mater. Sci. Eng. A 2017, 688, 330–337. [Google Scholar] [CrossRef]

- Guo, Y.; Tan, Y.; Liu, Y.; Liu, S.; Zhou, R.; Tang, H. Low modulus and bioactive Ti/α-TCP/Ti-mesh composite prepared by spark plasma sintering. Mater. Sci. Eng. C 2017, 80, 197–206. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Zhang, Q.; Song, W.; Wang, J.; Tang, H.; Jin, F. Tensile Behavior of Sintered Stainless Steel Fiber Felts: Effect of Sintering Joints and Fiber Ligaments. Metals 2018, 8, 768. [Google Scholar] [CrossRef]

- Zhu, B.; Duke, M.; Dumée, L.; Merenda, A.; des Ligneris, E.; Kong, L.; Hodgson, P.; Gray, S. Short Review on Porous Metal Membranes—Fabrication, Commercial Products, and Applications. Membranes 2018, 8, 83. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Xi, Z.; Tang, H.; Yang, X.; Zhang, Z. Compressive Behavior of Porous Titanium Fiber Materials. J. Iron Steel Res. Int. 2014, 21, 793–796. [Google Scholar] [CrossRef]

- Cheng, G.; Fu, B.; Hou, Q.; Zhou, X.; Wang, J. Diffusion behavior of helium in titanium and the effect of grain boundaries revealed by molecular dynamics simulation. Chin. Phys. B 2016, 25, 076602. [Google Scholar] [CrossRef]

- Zhou, X.S.; Liu, Q.; Zhang, L.; Peng, S.M.; Long, X.G.; Ding, W.; Cheng, G.; Wang, W.D.; Liang, J.H.; Fu, Y.Q. Effects of tritium content on lattice parameter, 3He retention, and structural evolution during aging of titanium tritide. Int. J. Hydrog. Energy 2014, 39, 20062–20071. [Google Scholar] [CrossRef]

- Blaschko, O.; Pleschiutschnig, J.; Glas, R.; Weinzierl, P. Helium damage in metal-tritium systems. Phys. Rev. B Condens. Matter 1991, 44, 9164. [Google Scholar] [CrossRef] [PubMed]

- Pang, H.; Luo, S.; Long, X.; An, Z.; Liu, N.; Duan, Y.; Wu, X.; Yang, B.; Wang, P.; Zheng, S. Effects of Substrate Temperature on Helium Content and Microstructure of Nanocrystalline Titanium Films. Chin. Phys. Lett. 2006, 23, 3238. [Google Scholar]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Zou, S.; Wan, Z.; Lu, L.; Tang, Y. Experimental Study on Tensile Properties of a Novel Porous Metal Fiber/Powder Sintered Composite Sheet. Materials 2016, 9, 712. [Google Scholar] [CrossRef] [PubMed]

- Jen, A.; Gupta, K. Advanced Technology for Evaluation of Pore Structure Characteristics of Filtration Media to Optimize Their Design and Performance; Unpublished document; Porous Materials Inc.: Ithaca, NY, USA, 2003. [Google Scholar]

- Skorokhod, V.V. Development of Sintering Theory at the Frantsevich Institute for Problems of Materials Science Under the National Academy of Sciences of Ukraine. Powder Metall. Metal Ceram. 2017, 56, 366–369. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Sintering Fundamentals: Historical Aspects. Mater. Sci. Forum 2016, 835, 1–49. [Google Scholar] [CrossRef]

- Manière, C.; Chan, S.; Lee, G.; Mckittrick, J.; Olevsky, E.A. Sintering dilatometry based grain growth assessment. Results Phys. 2018, 10, 91–93. [Google Scholar] [CrossRef]

- Olevsky, E.A. Theory of sintering: From discrete to continuum. Mater. Sci. Eng. 1998, 23, 41–100. [Google Scholar] [CrossRef]

- Kuczynski, G.C. Model Experiments and the Theory of Sintering; Springer: Dordrecht, The Netherlands, 1990; pp. 501–508. [Google Scholar]

- Kuczynski, G.C. Self-Diffusion in Sintering of Metallic Particles. JOM 1949, 1, 169–178. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Du, S.; Yang, Z.; He, T.; Li, Z. Study on the Tribological Performance of Copper-Based Powder Metallurgical Friction Materials with Cu-Coated or Uncoated Graphite Particles as Lubricants. Materials 2018, 11, 2016. [Google Scholar] [CrossRef]

- Liu, S.; Xi, Z.; Tang, H.; Yang, X.; Zhang, Z.; Liu, Q. Sintering Behavior of Porous Titanium Fiber Materials. J. Iron Steel Res. Int. 2014, 21, 849–854. [Google Scholar] [CrossRef]

- Andrews, E.W.; Gibson, L.J.; Ashby, M.F. The creep of cellular solids. Acta Mater. 1999, 47, 2853–2863. [Google Scholar] [CrossRef]

- Reig, L.; Tojal, C.; Busquets, D.; Amigó, V. Microstructure and Mechanical Behavior of Porous Ti–6Al–4V Processed by Spherical Powder Sintering. Materials 2013, 6, 4868–4878. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Liu, S.; Wang, Q.; Yang, X.; Zhang, G. Preparation and Properties of Titanium Obtained by Spark Plasma Sintering of a Ti Powder–Fiber Mixture. Materials 2018, 11, 2510. https://doi.org/10.3390/ma11122510

Shi M, Liu S, Wang Q, Yang X, Zhang G. Preparation and Properties of Titanium Obtained by Spark Plasma Sintering of a Ti Powder–Fiber Mixture. Materials. 2018; 11(12):2510. https://doi.org/10.3390/ma11122510

Chicago/Turabian StyleShi, Mingjun, Shifeng Liu, Qingge Wang, Xin Yang, and Guangxi Zhang. 2018. "Preparation and Properties of Titanium Obtained by Spark Plasma Sintering of a Ti Powder–Fiber Mixture" Materials 11, no. 12: 2510. https://doi.org/10.3390/ma11122510

APA StyleShi, M., Liu, S., Wang, Q., Yang, X., & Zhang, G. (2018). Preparation and Properties of Titanium Obtained by Spark Plasma Sintering of a Ti Powder–Fiber Mixture. Materials, 11(12), 2510. https://doi.org/10.3390/ma11122510