Damage Characteristics of PELE Projectile with Gradient Density Inner Core Material

Abstract

:1. Introduction

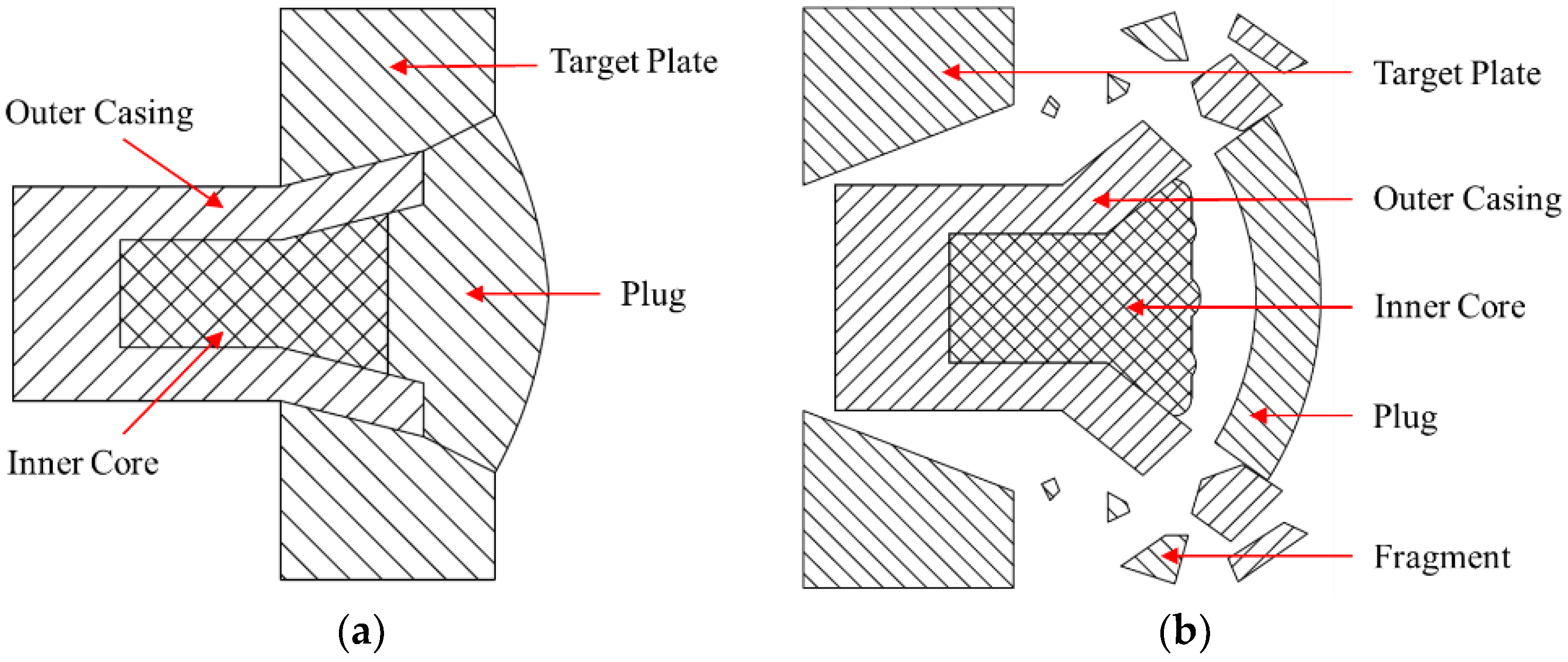

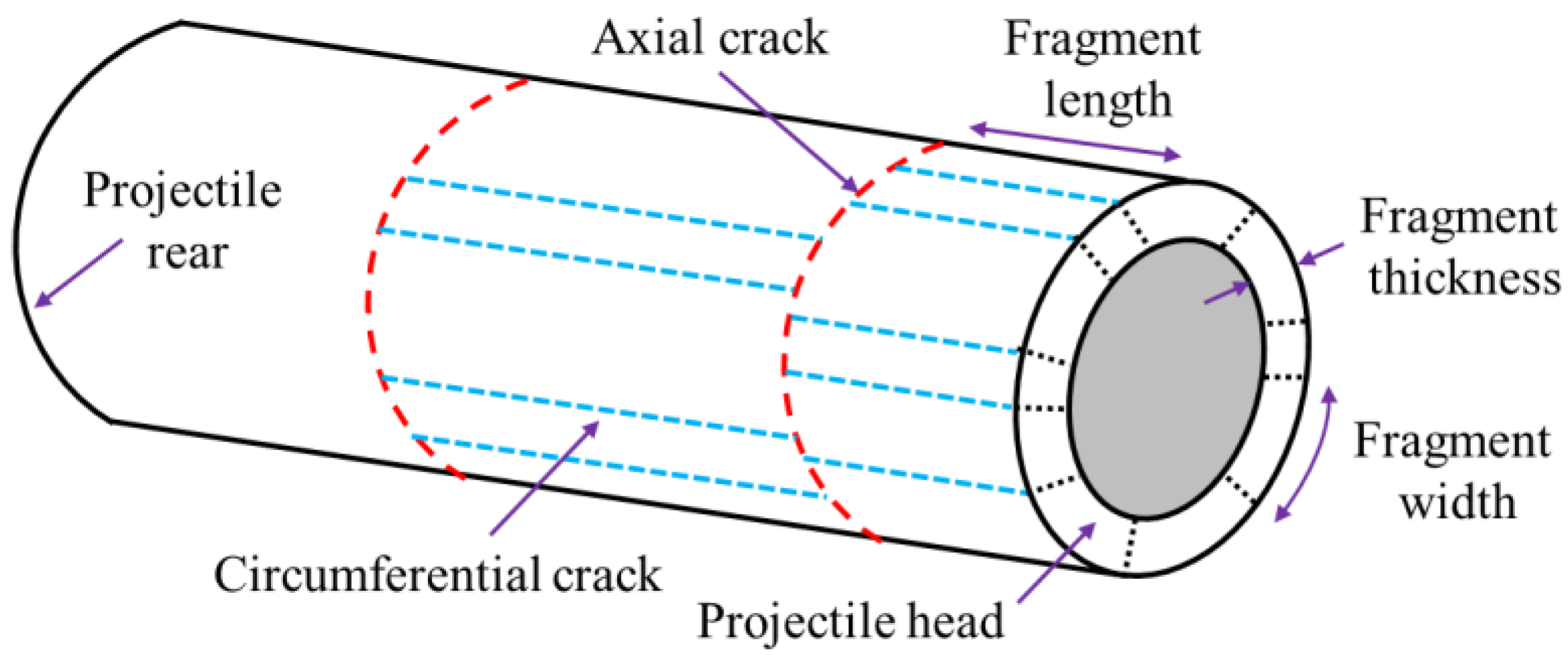

2. Analysis of the Fracture Process of PELE Projectile

3. Numerical Simulation

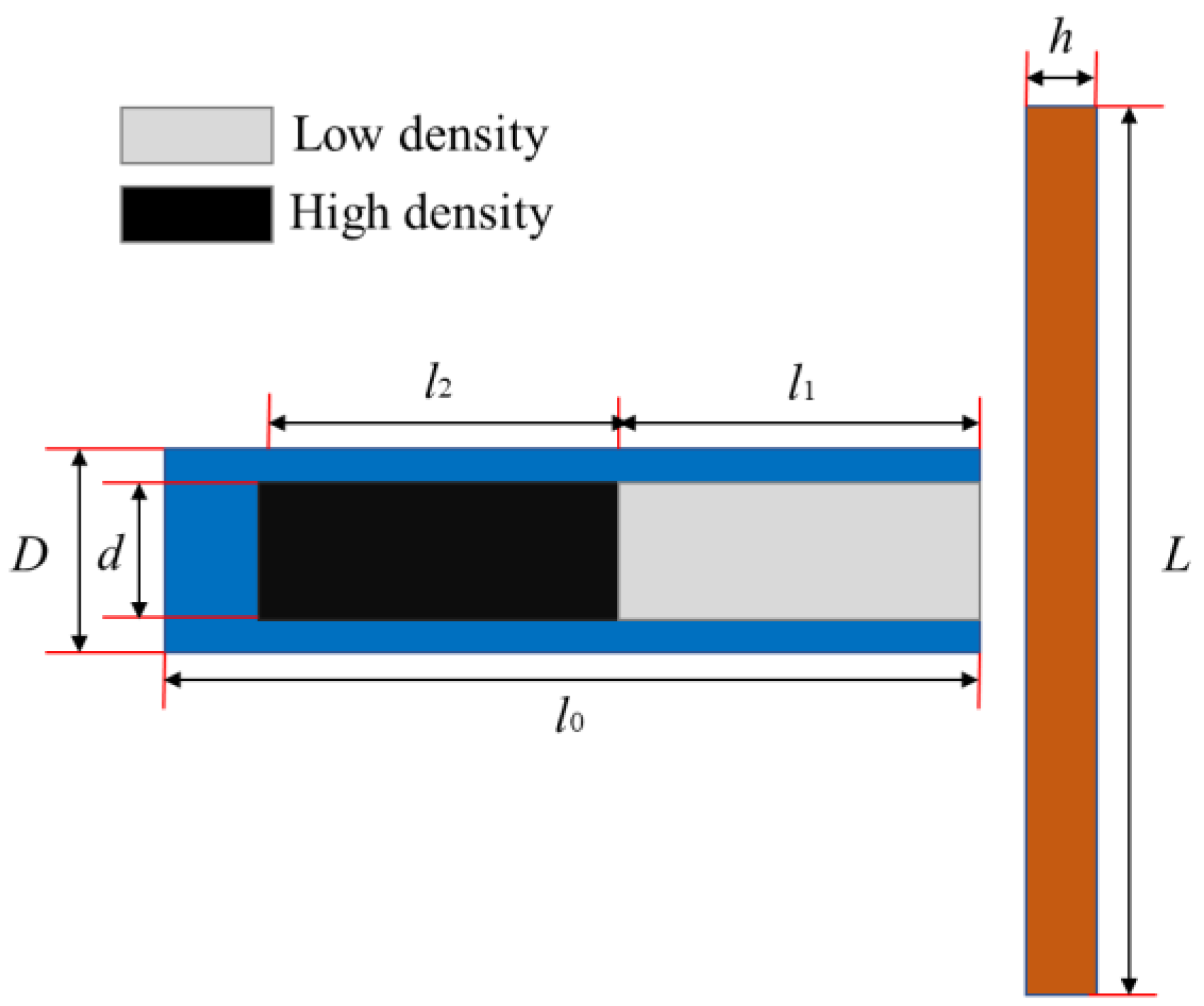

3.1. Finite Element Model

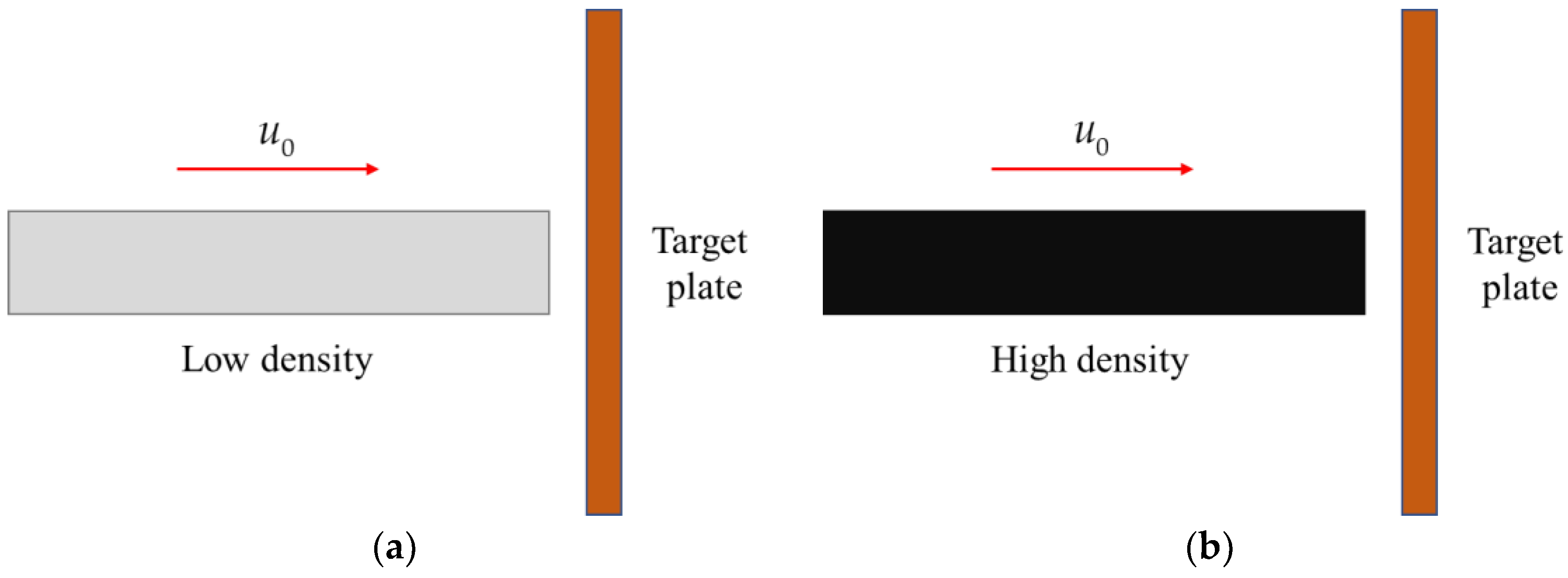

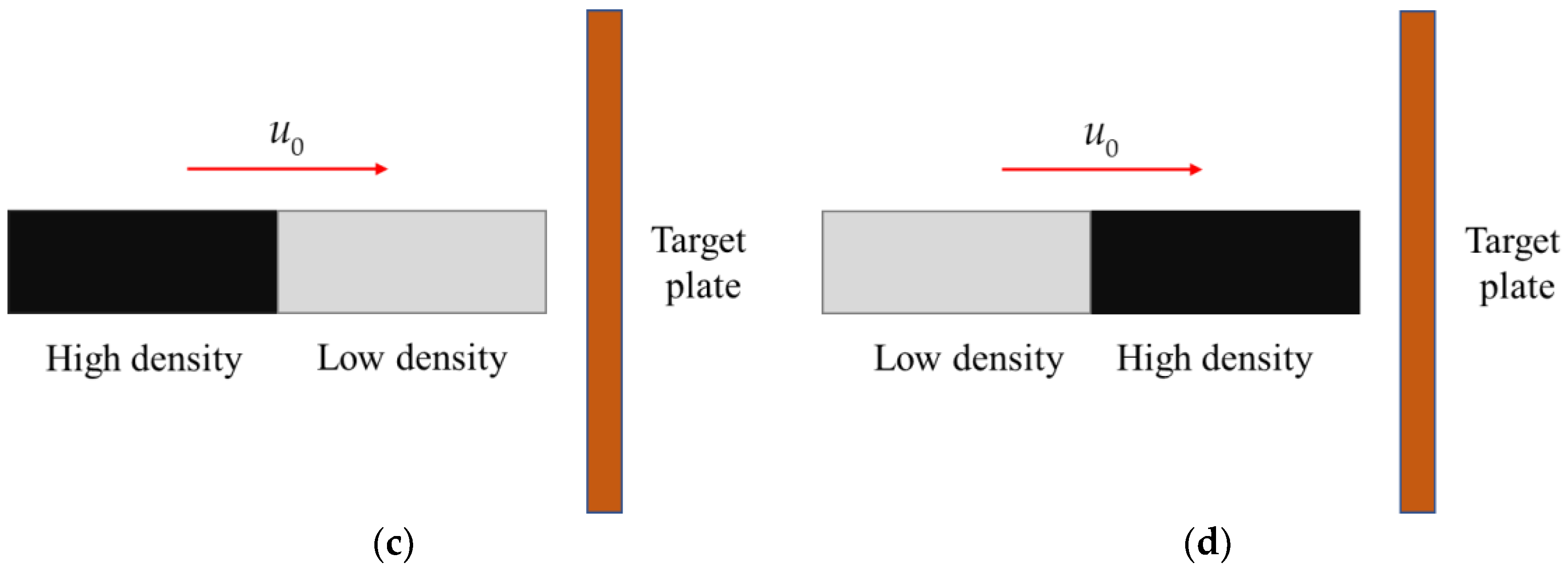

3.2. Simulation Condition

3.3. Material Model and Parameters

4. Analysis and Discussion of the Simulation Results

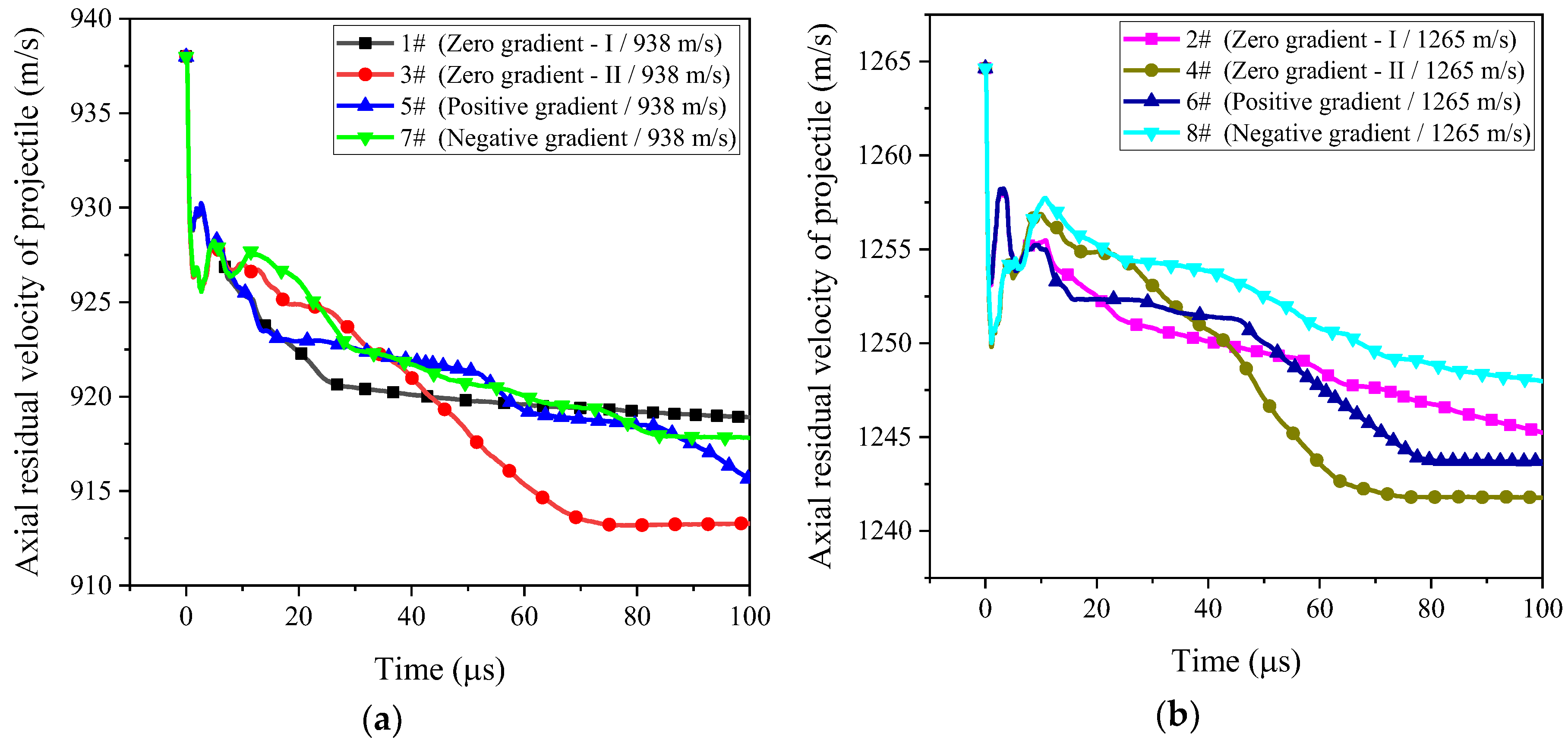

4.1. Influence of Inner Core Combination Type on the Penetration Ability of PELE Projectile

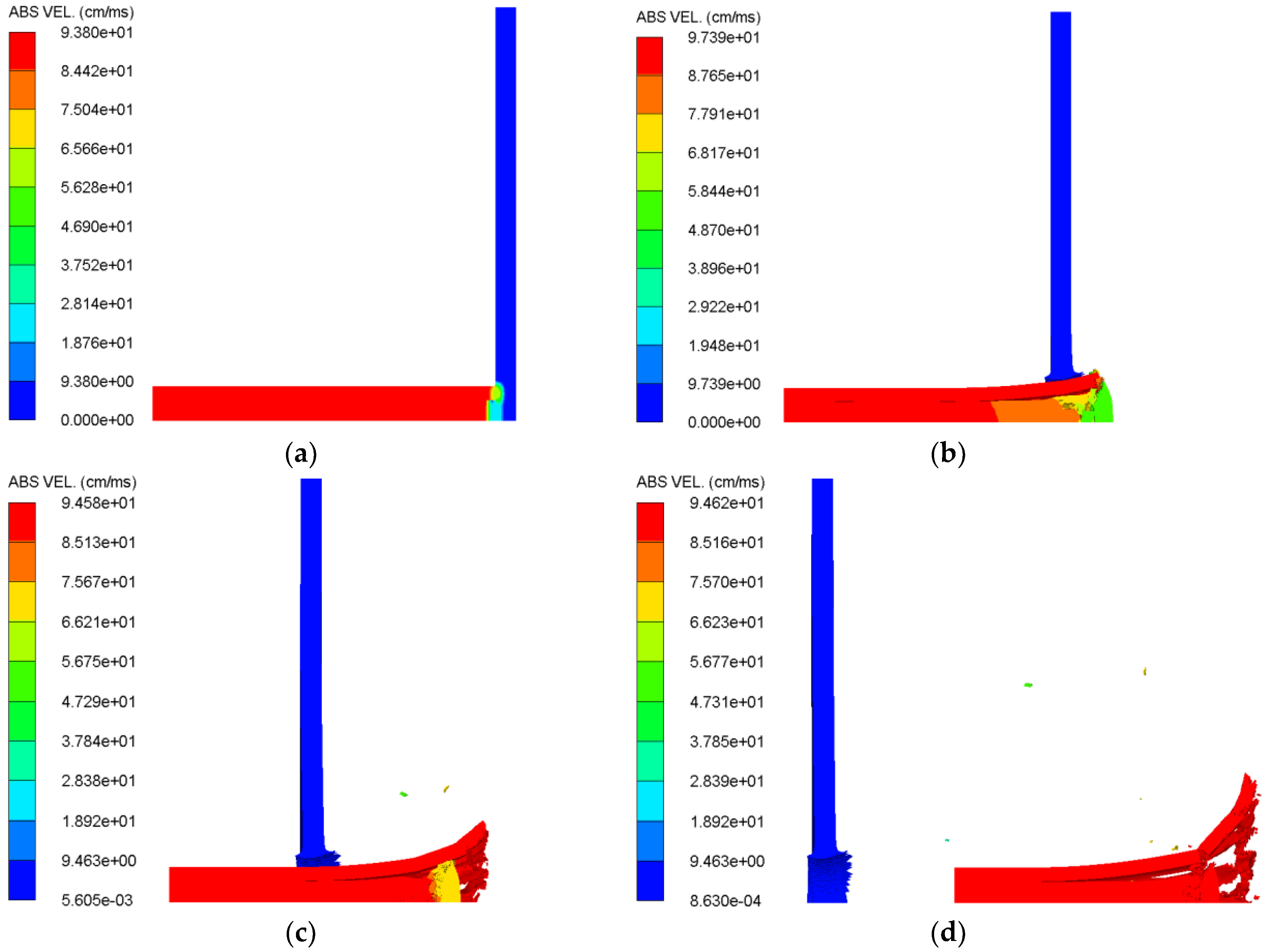

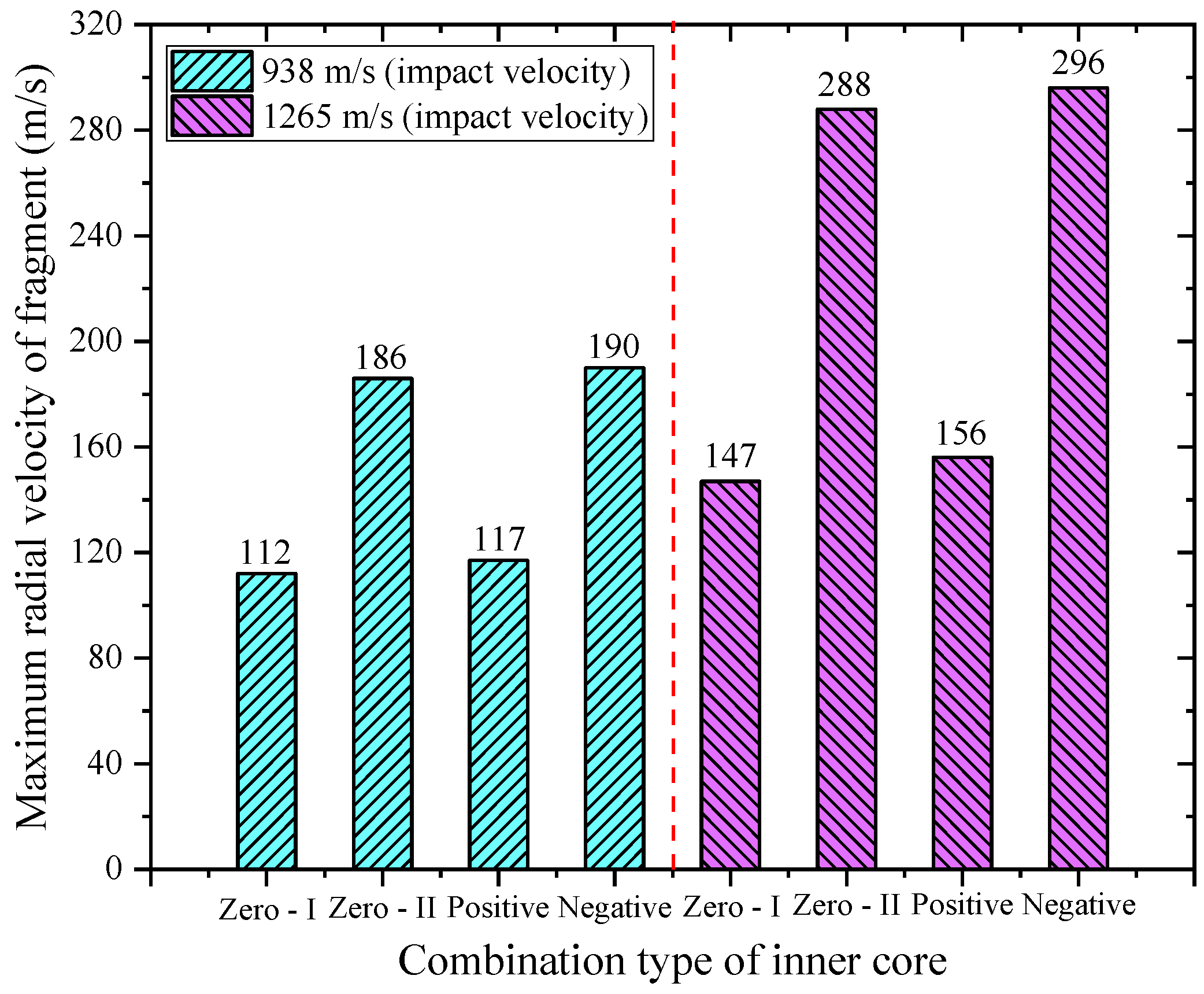

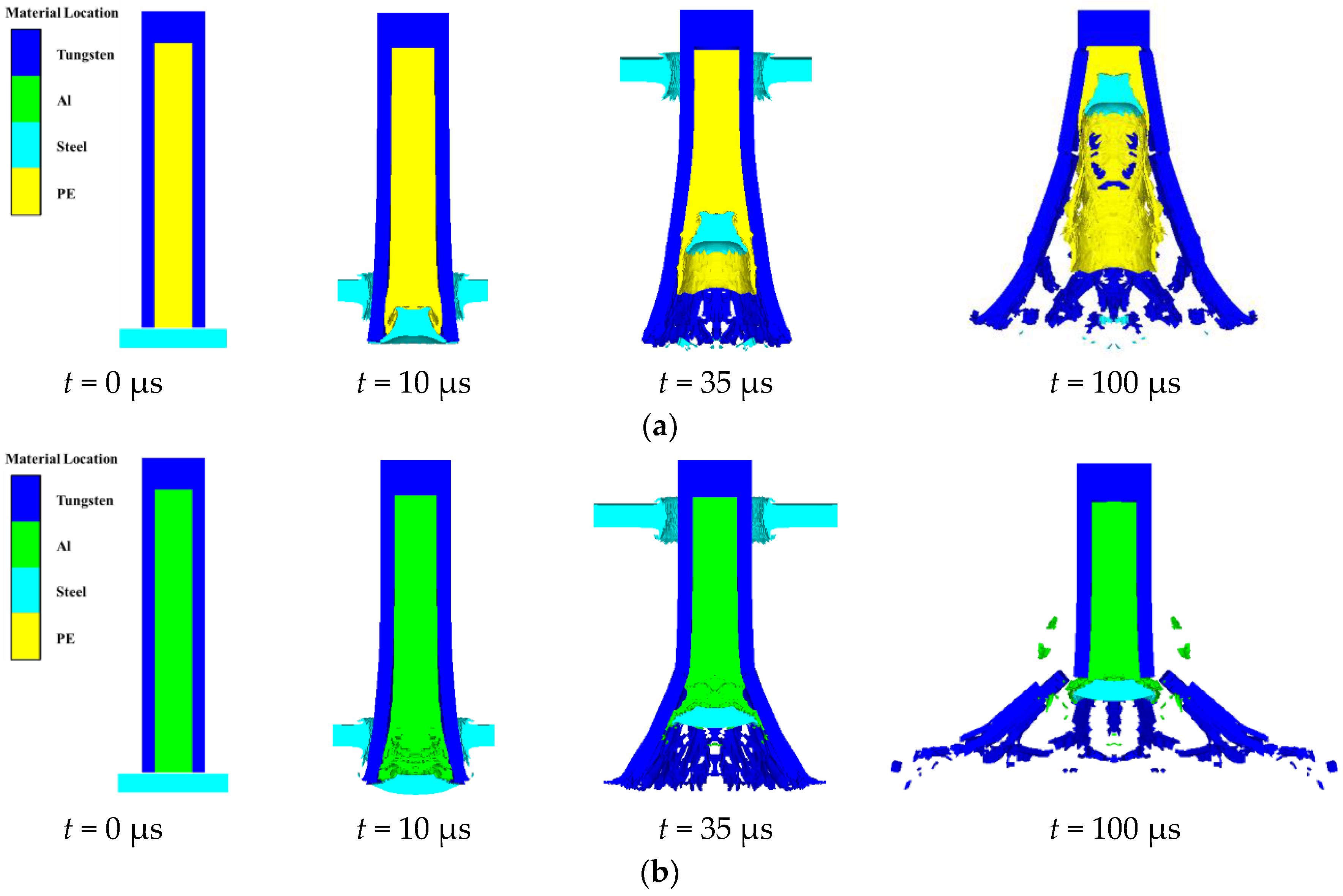

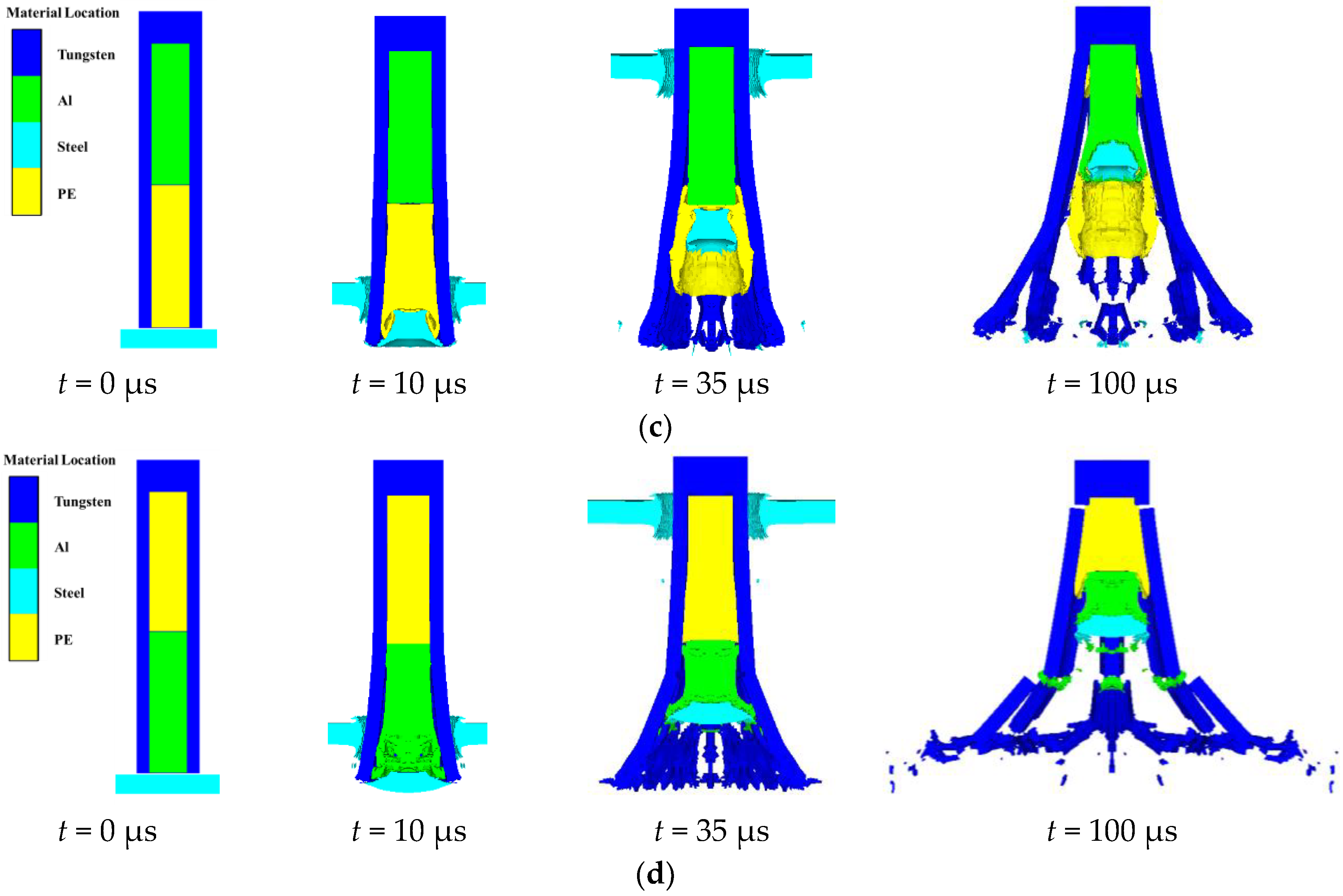

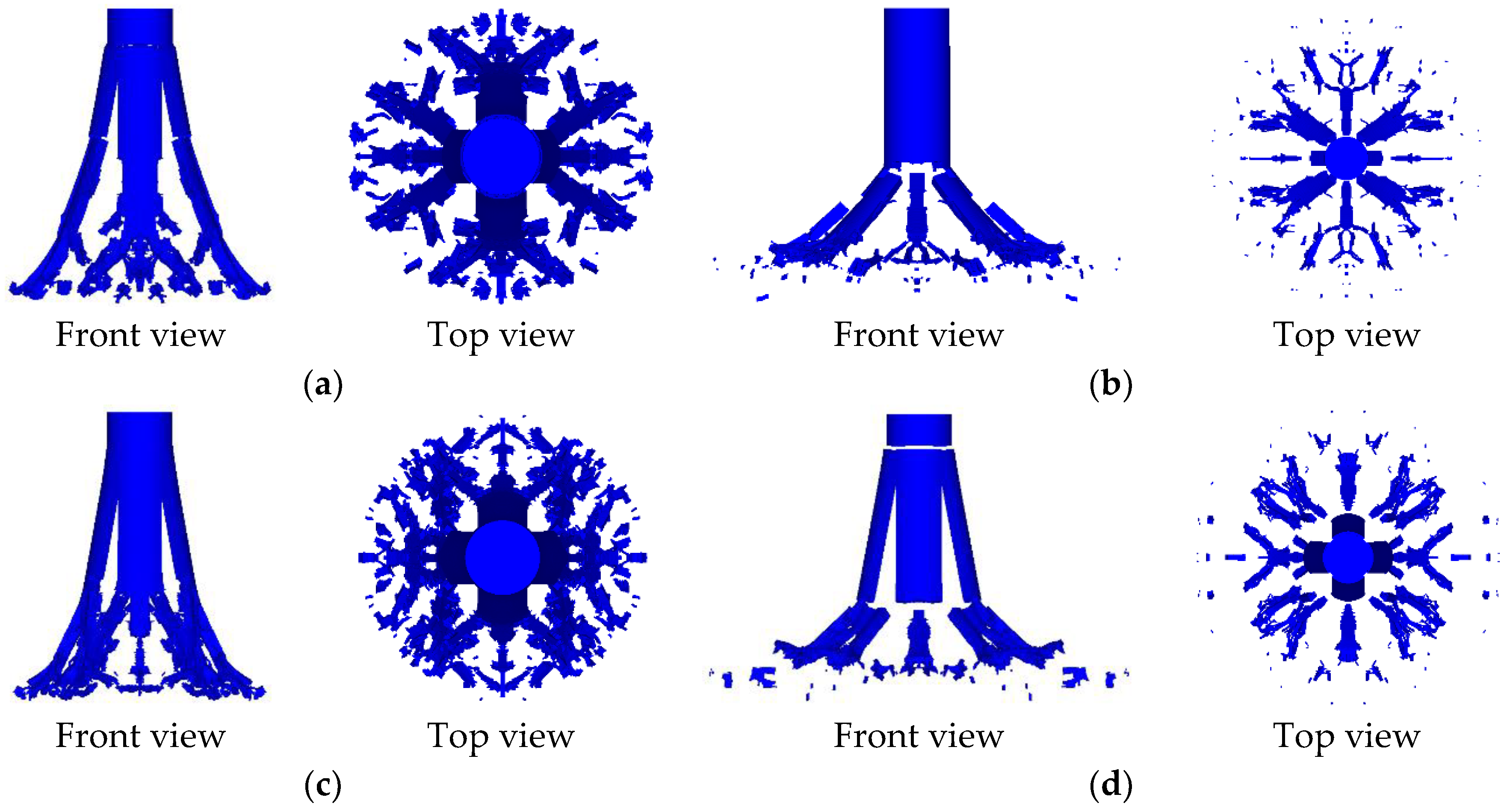

4.2. Influence of Inner Core Combination Type on the Fragmentation Effect of PELE Projectile

4.3. Penetration Ability and Fragmentation Effect of Different Inner Core Combinations PELE Projectile under the Same Initial Kinetic Energy

5. Conclusions

- (1)

- The axial residual velocity of projectile can reflect the damage capability of the projectile to the subsequent target, so it is desirable that the velocity loss of the projectile during the target penetration is as small as possible. As shown in Table 3, when the impact velocity is 938 m/s, the velocity loss corresponding to the negative gradient inner core combination is 2.1%; when the impact velocity is 1265 m/s, the velocity loss corresponding to the negative gradient inner core combination is 1.3%; they are all the minimum values under their respective impact conditions. In other words, the axial residual velocity corresponding to the negative gradient inner core combination is the largest, which means that it is superior to the other three types of projectiles in penetration ability.

- (2)

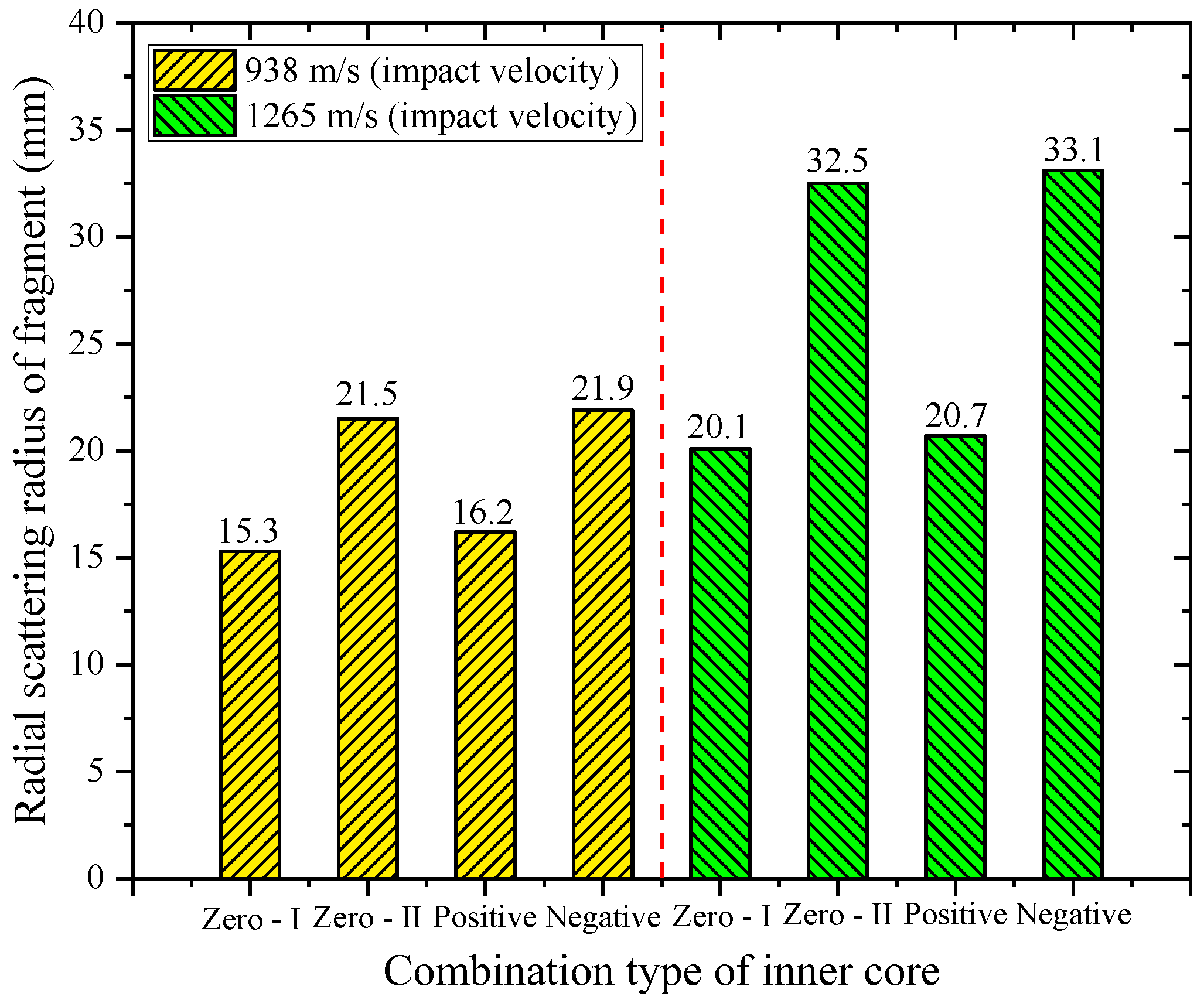

- The maximum radial velocity of fragments and the maximum radial scattering radius of fragments directly reflect the damage area of fragments, so it is hoped that the two parameters are as large as possible. As shown in Table 4, when the impact velocity is 938 m/s, the two parameters corresponding to the negative gradient inner core combination are 190 m/s, 21.9 mm; when the impact velocity is 1265 m/s, the two parameters corresponding to the negative gradient inner core combination are 296 m/s, 33.1 mm. Obviously, the two parameters corresponding to the negative gradient inner core combination are higher than the other three types of projectiles under different impact conditions. With the increase of impact velocity, the two parameters corresponding to the four types of projectiles are significantly enhanced, which means that the coverage area of fragments is increased, and the lateral effect is improved. However, at the same impact velocity, these two parameters mainly depend on the front inner core material, that is, if the front inner core is the same material, the values of the two parameters are not much different.

- (3)

- The fragmentation effect of PELE projectile should be concerned not only with the maximum radial velocity of fragments and the maximum radial scattering radius of fragments but, also, with the effective mass of fragments. In this paper, the residual length of projectile is used to characterize the effective mass of fragments, that is, the shorter the residual length of projectile means that the more casings will be converted into fragments. As shown in Table 4, when the impact velocity is 938 m/s, the parameter corresponding to the negative gradient inner core combination is 13.5 mm; when the impact velocity is 1265 m/s, the parameter corresponding to the negative gradient inner core combination is 5.8 mm. The residual length of projectile corresponding to negative gradient inner core combination is the shortest of the four types, that is to say, the fragment conversion rate corresponding to negative gradient inner core combination type is the highest.

- (4)

- The different types of inner core materials will lead to the different shape of the target plug, which will, in turn, lead to the different interaction process between the plug and the inner core. In addition, it is also found that the radial velocity and radial scattering radius of fragments can be improved by properly increasing the strength of the front inner core material, and the residual length of projectile can be reduced, or the fragment conversion rate can be enhanced by properly reducing the strength of the rear inner core material.

Author Contributions

Funding

Conflicts of Interest

References

- Kesberg, G.; Schirm, V.; Kerk, S. PELE: The future ammunition concept. In Proceedings of the 21st International Symposium on Ballistics (ISB’21), Adelaide, Australia, 19–23 April 2004. [Google Scholar]

- Paulus, G.; Chanteret, P.Y.; Wollmann, E. PELE: A new penetrator concept for generating lateral effects. In Proceedings of the 21st International Symposium on Ballistics (ISB’21), Adelaide, Australia, 19–23 April 2004. [Google Scholar]

- Rheinmetall Waffe Munition. 105/120/125 mm PELE Firing Results. Available online: https://ndiastorage.blob.core.usgovcloudapi.net/ndia/2005/garm/wednesday/borngen.pdf (accessed on 30 October 2018).

- Gloude, D. Capabilities of Penetrator with Enhanced Lateral Efficiency. Available online: https://ndiastorage.blob.core.usgovcloudapi.net/ndia/2007/gun_missile/GMTueAM1/GloudePresentation.pdf (accessed on 30 October 2018).

- Paulus, G.; Schirm, V. Impact behavior of PELE projectiles perforating thin target plates. Int. J. Impact Eng. 2006, 33, 566–579. [Google Scholar] [CrossRef]

- Zhu, J.; Zhao, G.; Du, Z.; Wang, X. Mechanism of PELE projectiles perpendicularly impacting on thin target plates. Explos. Shock Waves 2009, 29, 281–288. [Google Scholar]

- Du, Z.; Song, L.; Zhong, K.; Wang, F. Influence of the ratio of inner to outer diameter on penetrator with enhanced lateral efficiency. J. Comput. Theor. Nanosci. 2011, 4, 1525–1528. [Google Scholar] [CrossRef]

- Grady, D. Fragmentation of Rings and Shells: The Legacy of NF Mott; Springer: Heidelberg, Germany, 2006. [Google Scholar]

- Hirsch, E. The Mott fragmentation model and the Vpl break-up parameter. Propellants Explos. Pyrotech. 1989, 14, 31–38. [Google Scholar] [CrossRef]

- Verreault, J. Analytical and numerical description of the PELE fragmentation upon impact with thin target plates. Int. J. Impact Eng. 2015, 76, 196–206. [Google Scholar] [CrossRef]

- Verreault, J.; Hinsberg, N.; Abadjieva, E. PELE fragmentation dynamics. In Proceedings of the 27th International Symposium on Ballistics (ISB’27), Freiburg, Germany, 22–26 April 2013. [Google Scholar]

- Verreault, J. Modeling of the PELE fragmentation dynamics. J. Phys. Conf. Ser. 2013, 500, 152015. [Google Scholar] [CrossRef]

- Fan, Z.; Ran, X.; Tang, W.; Ke, Y.; Li, Z. The model to calculate the radial velocities of fragments after PELE perforating a thin plate. Int. J. Impact Eng. 2016, 95, 12–16. [Google Scholar] [CrossRef]

- Zhu, J.; Zhao, G.; Du, Z. Influence of the filling material on the PELE effect. J. Ballist. 2007, 19, 62–65. [Google Scholar]

- Zhu, J.; Zhao, G.; Du, Z.; Li, D. Experimental study of the influence factors on small caliber PELE impacting thin target. Chin. J. Exp. Mech. 2007, 22, 505–510. [Google Scholar]

- Ye, X.; Du, Z.; Hu, C.; Song, C.; Sheng, X. Simulation Studies on the Influence of Impact Velocity on the PELE Penetrated and Broken Reinforced Concrete. Adv. Mater. Res. 2013, 690, 3108–3111. [Google Scholar] [CrossRef]

- Tu, S.; Wang, J.; An, Z.; Chang, Y. Influence of thickness of armor on the burst-effect of steel shell PELE. In Proceedings of the 9th International Conference on Electronic Measurement & Instruments, Beijing, China, 16–19 August 2009. [Google Scholar]

- Tu, S.; Wang, J.; An, Z.; Xia, C. Influence of the material characteristic of shell and core on the penetration aftereffect of PELE. J. North Univ. China Nat. Sci. Ed. 2009, 30, 213–216. [Google Scholar]

- Jiang, J.; Zhang, M.; Men, J.; Wang, S. Experimental study on multi-layered target penetration of PELE with different cores. Trans. Beijing Inst. Technol. 2013, 33, 1009–1012. [Google Scholar]

- Yin, J.; Wang, Z.; Wei, J. Influence of filling material density on terminal effect of PELE projectile. J. North Univ. China Nat. Sci. Ed. 2011, 32, 671–675. [Google Scholar]

- Wang, H.; Yin, Y.; Jin, X.; Lu, P.; Zheng, Y. Numerical simulation of penetration behavior of PELE filled core materials with density gradient. Trans. Beijing Inst. Technol. 2010, 30, 101–104. [Google Scholar]

- Ding, L.; Zhou, J.; Tang, W.; Ran, X.; Cheng, Y. Research on the crushing process of PELE casing material based on the crack-softening algorithm and stochastic failure algorithm. Materials 2018, 11, 1561. [Google Scholar] [CrossRef] [PubMed]

- Rosenberg, Z.; Dekel, E. On the deep penetration and plate perforation by rigid projectiles. Int. J. Solids Struct. 2009, 46, 4169–4180. [Google Scholar] [CrossRef]

- Rosenberg, Z.; Dekel, E. On the deep penetration of deforming long rods. Int. J. Solids Struct. 2010, 47, 238–250. [Google Scholar] [CrossRef]

- Century Dynamics Inc. Interactive Non-Linear Dynamic Analysis Software AUTODYN User Manual; Century Dynamics Inc.: Oakland, CA, USA, 2003. [Google Scholar]

| Condition Number | Target Material | Target Thickness | Inner Core Combination Type | Impact Velocity | Front Core Material | Rear Core Material |

|---|---|---|---|---|---|---|

| #1 | Steel | 3 mm | ① Zero gradient—I (l1 = 45 mm, l2 = 0 mm) | 938 m/s | PE | -- |

| #2 | 1265m/s | |||||

| #3 | ② Zero gradient—II (l1 = 0 mm, l2 = 45 mm) | 938 m/s | -- | Al | ||

| #4 | 1265m/s | |||||

| #5 | ③ Positive gradient (l1 = l2 = 22.5 mm) | 938 m/s | PE | Al | ||

| #6 | 1265m/s | |||||

| #7 | ④ Negative gradient (l1 = l2 = 22.5 mm) | 938 m/s | Al | PE | ||

| #8 | 1265 m/s |

| Variable | Material | |||

|---|---|---|---|---|

| Tungsten | Al-6061 | PE | Steel-4340 | |

| EOS | Shock | Shock | Shock | Shock |

| Strength Model | von Mises | von Mises | von Mises | von Mises |

| Failure Model | Principal Stress/Strain | Principal Stress | -- | Plastic Strain |

| Erosion | Geometric Strain | Geometric Strain | Geometric Strain | Failure |

| ρ0 (g/cm3) | 18 | 2.65 | 0.92 | 7.823 |

| c0 (km/s) | 4.03 | 5.24 | 2.9 | 4.57 |

| s | 1.237 | 1.4 | 1.48 | 1.49 |

| Grüneisen Coefficient | -- | 1.97 | 1.6 | -- |

| Cp (J/kg·K) | -- | 885 | 2300 | -- |

| Shear Modulus G (GPa) | 139.02 | 27.5 | 0.13 | 77 |

| Yield Stress Y (GPa) | 1.5 | 0.3 | 0.02 | 0.8 |

| Principle Tensile Stress σT (GPa) | 2.8 | 0.5 | -- | -- |

| Principle Tensile Strain εT | 0.035 | -- | -- | -- |

| Fracture Energy Gf (J/m2) | 45 | -- | -- | -- |

| Stochastic Variance γ | 36.5 | -- | -- | -- |

| Geometric Strain | 0.6 | 0.8 | 1.8 | Failure |

| Condition Number | Impact Velocity (m/s) | Inner Core Combination Type | Axial Residual Velocity of Projectile (m/s) | Velocity Loss of Projectile (%) |

|---|---|---|---|---|

| #1 | 938 | Zero gradient—I | 919 | 2.0 |

| #3 | Zero gradient—II | 913 | 2.7 | |

| #5 | Positive gradient | 916 | 2.3 | |

| #7 | Negative gradient | 918 | 2.1 | |

| #2 | 1265 | Zero gradient—I | 1245 | 1.6 |

| #4 | Zero gradient—II | 1242 | 1.8 | |

| #6 | Positive gradient | 1244 | 1.7 | |

| #8 | Negative gradient | 1248 | 1.3 |

| Condition Number | Impact Velocity (m/s) | Inner Core Combination Type | Radial Velocity of Fragment (m/s) | Radial Scattering Radius of Fragment (mm) | Residual Length of Outer Casing (mm) |

|---|---|---|---|---|---|

| #1 | 938 | Zero gradient—I | 112 | 15.3 | 14.8 |

| #3 | Zero gradient—II | 186 | 21.5 | 32.2 | |

| #5 | Positive gradient | 117 | 16.2 | 21.6 | |

| #7 | Negative gradient | 190 | 21.9 | 13.5 | |

| #2 | 1265 | Zero gradient—I | 147 | 20.1 | 6.0 |

| #4 | Zero gradient—II | 288 | 32.5 | 26.7 | |

| #6 | Positive gradient | 156 | 20.7 | 8.3 | |

| #8 | Negative gradient | 296 | 33.1 | 5.8 |

| Inner Core Material | Impact Velocity | Axial Residual Velocity of Projectile (m/s) | Radial Velocity of Fragment (m/s) | |||||

|---|---|---|---|---|---|---|---|---|

| Reference [5] | This Paper | Reference [5] | This Paper | Error (%) | Reference [5] | This Paper | Error (%) | |

| PE | 936 | 938 | 889 | 919 | 3.37 | 94 | 112 | 16.0 |

| 1262 | 1265 | 1206 | 1245 | 3.23 | 145 | 147 | 1.38 | |

| Al | 925 | 938 | 895 | 913 | 2.01 | 184 | 186 | 1.09 |

| 1261 | 1265 | 1231 | 1241 | 0.81 | 243 | 288 | 18.5 | |

| Condition Number | Target Material | Target Thickness | Impact Velocity | Inner Core Combination Type | Front Core Material | Rear Core Material |

|---|---|---|---|---|---|---|

| #2 | Steel | 3 mm | 1265 m/s | Zero gradient—I | PE | -- |

| #9 | 1237 m/s | Zero gradient—II | -- | Al | ||

| #10 | 1251 m/s | Positive gradient | PE | Al | ||

| #11 | 1251 m/s | Negative gradient | Al | PE |

| Condition Number | Impact Velocity (m/s) | Inner Core Combination Type | Velocity Loss of Projectile (%) | Radial Scattering Radius of Fragment (mm) | Residual Length of Outer Casing (mm) |

|---|---|---|---|---|---|

| #2 | 1265 | Zero gradient—I | 15.8 | 20.1 | 6.0 |

| #9 | 1237 | Zero gradient—II | 13.1 | 31.1 | 24.4 |

| #10 | 1251 | Positive gradient | 16.8 | 19.4 | 10.6 |

| #11 | 1251 | Negative gradient | 12.3 | 32.3 | 4.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, L.; Zhou, J.; Tang, W.; Ran, X.; Cheng, Y. Damage Characteristics of PELE Projectile with Gradient Density Inner Core Material. Materials 2018, 11, 2389. https://doi.org/10.3390/ma11122389

Ding L, Zhou J, Tang W, Ran X, Cheng Y. Damage Characteristics of PELE Projectile with Gradient Density Inner Core Material. Materials. 2018; 11(12):2389. https://doi.org/10.3390/ma11122389

Chicago/Turabian StyleDing, Liangliang, Jingyuan Zhou, Wenhui Tang, Xianwen Ran, and Ye Cheng. 2018. "Damage Characteristics of PELE Projectile with Gradient Density Inner Core Material" Materials 11, no. 12: 2389. https://doi.org/10.3390/ma11122389

APA StyleDing, L., Zhou, J., Tang, W., Ran, X., & Cheng, Y. (2018). Damage Characteristics of PELE Projectile with Gradient Density Inner Core Material. Materials, 11(12), 2389. https://doi.org/10.3390/ma11122389