Understanding the Contribution of Mining and Transportation to the Total Life Cycle Impacts of Coal Exported from the United States

Abstract

:1. Introduction

2. Results

2.1. Life Cycle GHG Results

2.2. TRACI 2.1 Impact Assessment Results

3. Discussion

3.1. Implications of the Results

3.2. Direction for Further Studies

4. Materials and Methods

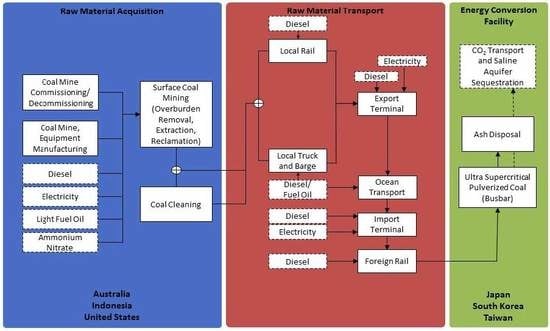

4.1. Study Boundaries

4.2. Analysis Tools and Methods

4.3. Life Cycle Modeling Data—Coal Extraction

4.4. Life Cycle Modeling Data—Coal Transport

4.5. Life Cycle Modeling Data—Power Plant Operations

Supplementary Materials

Author Contributions

Conflicts of Interest

References

- U.S. Energy Information Administration (EIA). Monthly Energy Review; U.S. Energy Information Administration: Washington, DC, USA, 2016. [Google Scholar]

- EIA. Short-Term Energy Outlook; U.S. Energy Information Administration: Washington, DC, USA, 2016. [Google Scholar]

- Porzio, M.U.S. Coal Production and Prices Decline in 2015. Available online: http://www.forbes.com/sites/mattporzio/2016/01/19/u-s-coal-production-and-prices-decline-in-2015/#5a31ac226ba9 (accessed on 12 April 2016).

- EIA. Annual Coal Report 2013; U.S. Energy Information Administration: Washington, DC, USA, 2015. [Google Scholar]

- EIA. Coal: Data; U.S. Energy Information Administration: Washington, DC, USA, 2015. [Google Scholar]

- EIA. Quarterly Coal Report; U.S. Energy Information Administration: Washington, DC, USA, 2015. [Google Scholar]

- Cornot-Gandolphe, S. US Coal Exports: The Long Road to Asian Markets; Oxford Institute for Energy Studies: Oxford, UK, 2015. [Google Scholar]

- Campbell, K. Coal Scorecard: Your Guide to Coal in the Northwest. Available online: http://www.opb.org/news/article/coal-score-card/ (accessed on 24 June 2015).

- Bohnengel, B.; Patiño-Echeverri, D.; Bergerson, J. Environmental implications of united states coal exports: A comparative life cycle assessment of future power system scenarios. Environ. Sci. Technol. 2014, 48, 9908–9916. [Google Scholar] [CrossRef] [PubMed]

- World Coal Association. Coal Facts 2014. Available online: https://web.archive.org/web/20160202160918/https://www.worldcoal.org/sites/default/files/coal_facts_2014%2812_09_2014%29.pdf (accessed on 2 February 2016).

- IEA. Coal Medium-Term Market Report 2014: Market Analysis and Forecasts to 2019; International Energy Agency: Paris, France, 2014. [Google Scholar]

- NETL. Low rank coal to electricity: Combustion cases. In Cost and Performance Baseline for Fossil Energy Plants; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2011; Volume 3. [Google Scholar]

- NETL. Life Cycle Analysis: Supercritical Pulverized Coal (SCPC) Power Plant; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2010. [Google Scholar]

- NETL. Life Cycle Analysis: Integrated Gasification Combined Cycle (IGCC) Power Plant, Revision 2, June 2013. Available online: http://www.netl.doe.gov/File%20Library/Research/Energy%20Analysis/Life%20Cycle%20Analysis/IGCC-LCA-Report.zip (accessed on 11 July 2016).

- IPCC. Climate Change 2013 the Physical Science Basis; Intergovernmental Panel on Climate Change; Cambridge University Press: New York, NY, USA, 2013. [Google Scholar]

- Bare, J. Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts (TRACI): Traci Version 2.1—User’s Manual; U.S. EPA National Risk Management Laboratory: Cincinnati, OH, USA, 2012. [Google Scholar]

- Mewing, M. International Coal Specifications and Operations; Cooney, G., Ed.; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2015. [Google Scholar]

- U.S. Environmental Protection Agency (EPA). Control of Emissions from New and in-Use Nonroad Compression-Ignition Engines: Emission Standards and Related Requirements, 40 C.F.R. §1039.101; U.S. Environmental Protection Agency: Washington, DC, USA, 2005. [Google Scholar]

- EPA. Diesel Fuel. Available online: https://web.archive.org/web/20150922140217/http://www3.epa.gov/otaq/fuels/dieselfuels/index.htm (accessed on 22 September 2015).

- Australian Government Department of the Environment. Working towards a National Clean Air Agreement: Discussion Paper; Department of the Environment, Commonwealth of Australia: Canberra, Australia, 2015. [Google Scholar]

- Australian Government Department of the Environment. Diesel Fuel Quality Standard. Available online: https://web.archive.org/web/20151217204223/https://www.environment.gov.au/topics/environment-protection/fuel-quality/standards/diesel (accessed on 17 December 2015).

- NSW EPA. Cleaner Non-Road Diesel Plant and Equipment. Available online: https://web.archive.org/web/20151217202839/http://www.epa.nsw.gov.au/air/nonroaddiesel.htm (accessed on 17 December 2015).

- United Nations Environment Programme (UNEP). Status of Fuel Quality and Vehicle Emission Standards in Asia-Pacific. Available online: https://web.archive.org/web/20151211203916/http://www.unep.org/transport/new/pcfv/pdf/Maps_Matrices/AP/matrix/AP_Matrix_Jan2015.pdf (accessed on 7 July 2016).

- NETL. Unit Process Library. Available online: http://www.netl.doe.gov/research/energy-analysis/life-cycle-analysis/unit-process-library (accessed on 7 July 2016).

- Fogarty, D. Indonesia Tries to Clamp down on Coal Sector’s Worst Excesses. Available online: http://news.mongabay.com/2014/10/indonesia-tries-to-clamp-down-on-coal-sectors-worst-excesses/ (accessed on 4 December 2015).

- Gateway Pacific Terminal. Gateway Pacific Terminal. Available online: http://gatewaypacificterminal.com/the-project/ (accessed on 8 January 2015).

- NETL. Power Plant Flexible Model (PPFM); National Energy Technology Laboratory: Pittsburgh, PA, USA, 2013. [Google Scholar]

- BNSF Railway. Guide to Coal Mines—Mines Served by Bnsf Railway; Coal Business Unit BNSF Railway: Fort Worth, TX, USA, 2013. [Google Scholar]

- Union Pacific. Coal Specifications Table. Available online: http://www.up.com/customers/coal/mines/specs_table/index.htm (accessed on 1 July 2015).

- Research Gate. 1.3 Properties of Coal. Availble online: http://www.researchgate.net/publictopics.PublicPostFileLoader.html?id=55101748d5a3f291118b45de&key=099d2483-4e58-44f1-9f50-bd4206c0658f (accessed on 1 July 2015).

- NETL. Quality Guidelines for Energy Systems Studies: Detailed Coal Specifications; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2012. [Google Scholar]

- World Coal Association. Coal Conversion Statistics. Available online: http://www.worldcoal.org/resources/coal-statistics/coal-conversion-statistics/ (accessed on 1 July 2015).

- EPA. Handbook for Developing Watershed Plans to Restore and Protect Our Waters—Glossary; U.S. Environmental Protection Agency: Washington, DC, USA, 2008. [Google Scholar]

- EPA. Particulate Matter: Basic Information. Available online: http://www.epa.gov/airquality/particlepollution/basic.html (accessed on 17 June 2013).

- Humbert, S. Geographically Differentiated Life-Cycle Impact Assessment of Human Health; University of California: Berkeley, CA, USA, 2009. [Google Scholar]

- EPA. Coal Mine Methane Country Profiles. Available online: https://www.globalmethane.org/documents/toolsres_coal_overviewfull.pdf (accessed on 11 July 2016).

- NETL. Gate-to-Grave Life Cycle Analysis Model of Saline Aquifer Sequestration of Carbon Dioxide; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2013. [Google Scholar]

- NETL. Comprehensive Analysis of Coal and Biomass Conversion to Jet Fuel: Oxygen Blown, Transport Reactor Integrated Gasifier (TRIG) and Fischer-Tropsch (F-T) Catalyst Configurations; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2014. [Google Scholar]

- U.S. Department of Energy (DOE). Energy and Environmental Profile of the U.S. Mining Industry; U.S. Department of Energy: Washington, DC, USA, 2002. [Google Scholar]

- National Mining Association. Reclamation: Did You Know? Available online: http://www.nma.org/index.php/land/reclamation (accessed on 11 July 2016).

- USGS. Estimates of Electricity Requirements for the Recovery of Mineral Commodities, with Examples Applied to Sub-Saharan Africa; U.S. Geological Survey: Reston, VA, USA, 2011; Open-File Report 2011–1253. [Google Scholar]

- Mitra, R.; Saydam, S. Surface Coal Mining Methods in Australia; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Miller, K. Epa Tier IV Requirements and Equipment Engine Size; Skone, T.J., Pickenpaugh, G., Cooney, G., Eds.; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2015. [Google Scholar]

- EPA. Stationary point and area sources. In Compilation of Air Pollutant Emission Factors; U.S. Environmental Protection Agency: Durham, NC, USA, 1995; Volume I. [Google Scholar]

- DieselNet. Nonroad Diesel Engines. Available online: https://www.dieselnet.com/standards/us/nonroad.php (accessed on 18 September 2015).

- EIA. Electricity supply, disposition, prices, and emissions, reference case. In Annual Energy Outlook 2015; U.S. Energy Information Administration: Washington, DC, USA, 2015. [Google Scholar]

- Maunder, D.; Sersland, D. Utility Provider for the Spring Creek Mine in Montana; Mutchek, M., Ed.; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2015. [Google Scholar]

- Australian Bureau of Resources and Energy Economics (BREE). Australian Energy Projections to 2049–50; Australian Bureau of Resources and Energy Economics: Canberra, Australia, 2014. [Google Scholar]

- NETL. Development of Baseline Data and Analysis of Life Cycle Greenhouse Gas Emissions of Petroleum-Based Fuels; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2008. [Google Scholar]

- NETL. Grid Mix Explorer; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2015. [Google Scholar]

- NETL. Life Cycle Analysis of Natural Gas Extraction and Power Generation; U.S. Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, 2014. [Google Scholar]

- EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2013; U.S. Environmental Protection Agency: Washington, DC, USA, 2015. [Google Scholar]

- U.S. Department of Interior Bureau of Land Management (BLM). Environmental Assessment for Spring Creek Coal Lease Modification MTM-069782 and Amendment to Land Use Lease MTM-74913 ea# mt-doi-blm-mt-020-2010-29; U.S. Department of Interior Bureau of Land Management: Miles City, MT, USA, 2010. [Google Scholar]

- Australian Government Department of the Environment. The australian government submission to the united nations framework convention on climate change australian national greenhouse accounts. In National Inventory Report 2012; Commonwealth of Australia: Canberra, Australia, 2014; Volume 1. [Google Scholar]

- EPA. Summary Report: Global Anthropogenic Non-Co2 Greenhouse Gas Emissions: 1990–2030; U.S. Environmental Protection Agency: Washington, DC, USA, 2012. [Google Scholar]

- BNSF Railway. Bnsf Rail Miles Inquiry. Available online: http://www.bnsf.com/bnsf.was6/RailMiles/RMCentralController (accessed on 1 July 2015).

- Australian Government Department of Industry. Australian Energy Resource Assessment, 2nd ed.; Economics, Bureau of Resources and Energy Economics: Canberra, Australia, 2014. [Google Scholar]

- DieselNet. Locomotives. Available online: http://www.dieselnet.com/standards/us/loco.php (accessed on 24 September 2015).

- Lucarelli, B. The History and Future of Indonesia’s Coal Industry: Impact of Politics Regulatory Framework on Industry Structure and Performance; Freeman Spogli Institute for International Studies: Stanford, CA, USA, 2010. [Google Scholar]

- ENVIRON International Corporation. Gateway Pacific Terminal Air Quality Technical Report Revised Site Layout; ENVIRON International Corporation: Lynnwood, WA, USA, 2014. [Google Scholar]

- SeaRates, L.P. Distance and Time Online Calculator. Available online: http://www.searates.com/reference/portdistance/ (accessed on 1 July 2015).

- NETL. Carbon sequestration Atlas of the United States and Canada Fourth Edition, 4th ed.; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2012. [Google Scholar]

| Coal Property | U.S. PRB | Australia | Indonesia | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Decker | Spring Creek | Black Thunder South | Black Thunder | Antelope | North Antelope/Rochelle Complex | HunterValley | Ensham | Adaro | Mulia | |

| Moisture | 24.5% | 26.8% | 26.0% | 27.0% | 26.5% | 27.6% | 9.0% | 11.5% | 25.0% | 35.0% |

| Carbon | 52.7% | 55.1% | 52.4% | 52.3% | 52.1% | 52.1% | 63.9% | 63.1% | 52.2% | 42.7% |

| Hydrogen 1 | 4.2% | 4.0% | 4.0% | 3.9% | 4.0% | 4.0% | 4.3% | 4.0% | 4.8% | 4.0% |

| Nitrogen 2 | 0.7% | 0.7% | 0.7% | 0.7% | 0.7% | 0.7% | 1.3% | 1.3% | 0.7% | 0.7% |

| Chlorine 2 | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.3% | 0.3% | 0.0% | 0.0% |

| Sulfur | 0.5% | 0.3% | 0.2% | 0.3% | 0.2% | 0.2% | 0.6% | 0.7% | 0.2% | 0.2% |

| Ash | 5.1% | 4.3% | 4.6% | 5.2% | 5.3% | 4.5% | 13.5% | 12.0% | 2.0% | 3.9% |

| Oxygen 3 | 12.3% | 8.8% | 12.1% | 10.6% | 11.2% | 10.9% | 7.2% | 7.2% | 15.2% | 13.5% |

| HHV (Megajoule/kg) | 21.8 | 22.8 | 21.7 | 21.6 | 21.6 | 21.6 | 26.5 | 26.2 | 21.6 | 17.6 |

| HHV (Btu/lb) 4 | 9373 | 9820 | 9320 | 9300 | 9270 | 9270 | 11,406 | 11,271 | 9283 | 7575 |

| LHV (MJ/kg) | 20.7 | 21.7 | 20.6 | 20.5 | 20.5 | 20.5 | 25.4 | 25.1 | 20.5 | 16.5 |

| LHV (Btu/lb) | 8903 | 9350 | 8850 | 8830 | 8800 | 8800 | 10,936 | 10,801 | 8813 | 7105 |

| Data Source 5 | [17] | [28,29] | [28,29] | [28,29] | [28,29] | [28,29] | [17] | [17] | [17] | [17] |

| Parameter 1 | Parameter 2 | Export Location | ||

|---|---|---|---|---|

| PRB | Australia | Indonesia | ||

| Coal Mine Methane (scf/ton) | Low Value | 0.8 | 34.3 | 27.9 |

| Expected Value | 8.0 | 42.9 | ||

| High Value | 38.7 | 54.4 | ||

| Diesel Scalar | Low Value | 1 | 1 | 2 |

| Expected Value | 3 | |||

| High Value | 4 | |||

| Mine Electricity Switch | N/A | 1 | 1 | 0 |

| Strip Ratio | Low Value | 2 | 8 | 3 |

| Expected Value | 3 | 9 | 5.5 | |

| High Value | 4 | 10 | 8 | |

| Coal Cleaning Switch | N/A | 0 | 1 | 0 |

| Sulfur Concentration of Diesel Fuel (ppm) | N/A | 15 | 10 | 3500 |

| Rail Distance (km) | Low Value | 1900 | 150 | N/A |

| Expected Value | 2000 | 225 | ||

| High Value | 2100 | 300 | ||

| Truck Distance (km) | Low Value | N/A | N/A | 44 |

| Expected Value | 79 | |||

| High Value | 114 | |||

| River Barge Distance (km) | Low Value | N/A | N/A | 100 |

| Expected Value | 250 | |||

| High Value | 450 | |||

| Ocean Distance (km) L/H are ±10% | To Japan | 7892 | 8075 | 4683 |

| To South Korea | 8451 | 8558 | 4380 | |

| To Taiwan | 9904 | 7888 | 2997 | |

| Coal Type | Low Value | Spring Creek | Hunter Valley 1 | Adaro, Mulia Modeled Separately |

| Expected Value | Decker | |||

| High Value | North Antelope | |||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mutchek, M.; Cooney, G.; Pickenpaugh, G.; Marriott, J.; Skone, T. Understanding the Contribution of Mining and Transportation to the Total Life Cycle Impacts of Coal Exported from the United States. Energies 2016, 9, 559. https://doi.org/10.3390/en9070559

Mutchek M, Cooney G, Pickenpaugh G, Marriott J, Skone T. Understanding the Contribution of Mining and Transportation to the Total Life Cycle Impacts of Coal Exported from the United States. Energies. 2016; 9(7):559. https://doi.org/10.3390/en9070559

Chicago/Turabian StyleMutchek, Michele, Gregory Cooney, Gavin Pickenpaugh, Joe Marriott, and Timothy Skone. 2016. "Understanding the Contribution of Mining and Transportation to the Total Life Cycle Impacts of Coal Exported from the United States" Energies 9, no. 7: 559. https://doi.org/10.3390/en9070559

APA StyleMutchek, M., Cooney, G., Pickenpaugh, G., Marriott, J., & Skone, T. (2016). Understanding the Contribution of Mining and Transportation to the Total Life Cycle Impacts of Coal Exported from the United States. Energies, 9(7), 559. https://doi.org/10.3390/en9070559