Optimal Operation of Network-Connected Combined Heat and Powers for Customer Profit Maximization

Abstract

:1. Introduction

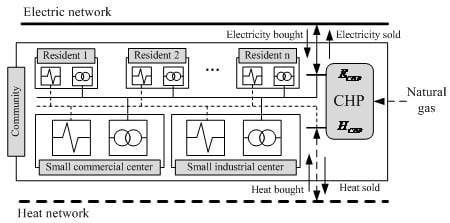

2. Modelling of Network-Connected Combined Heat and Power

2.1. Schematic Diagram of Network-Connected Combined Heat and Power System

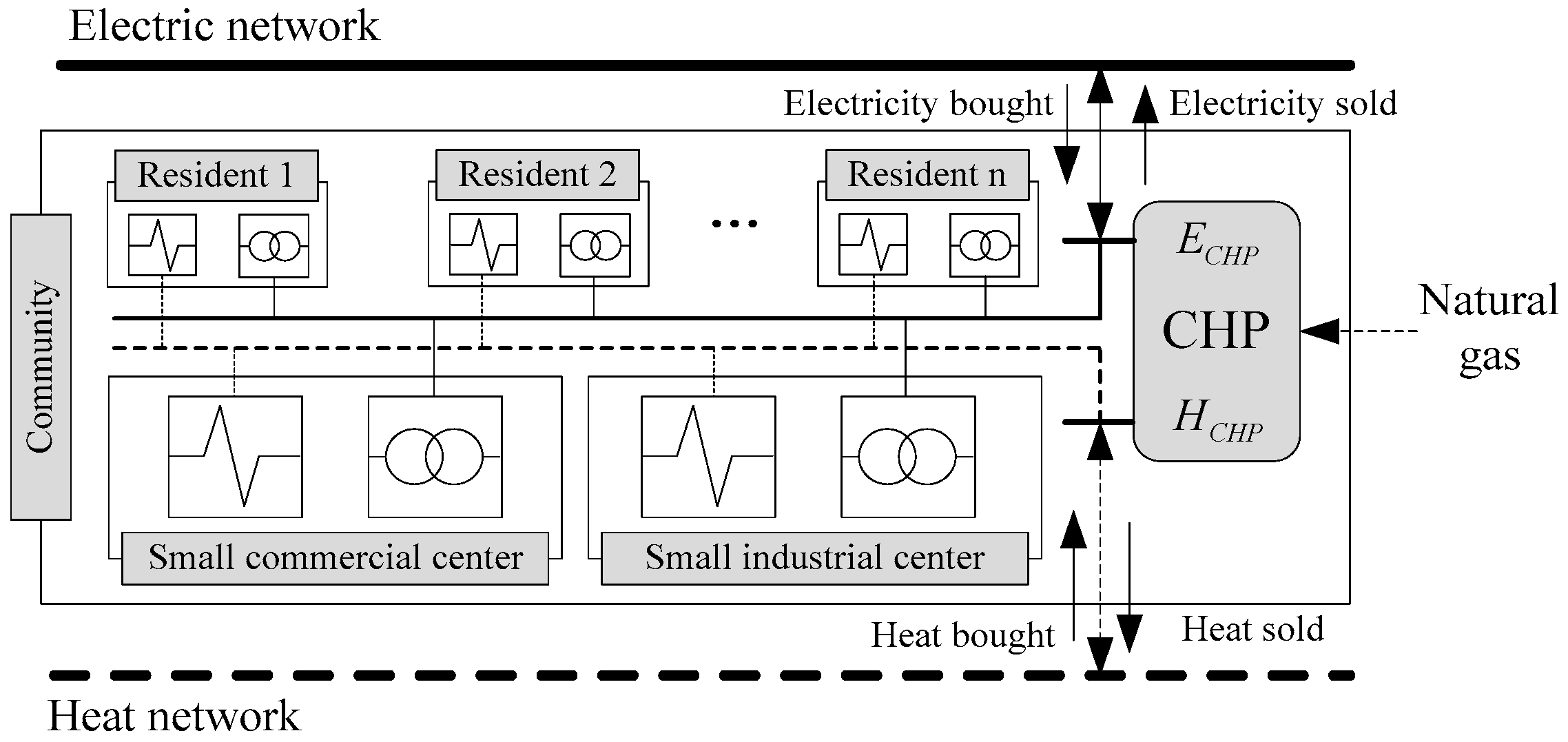

2.2. Technical Model of Combined Heat and Power

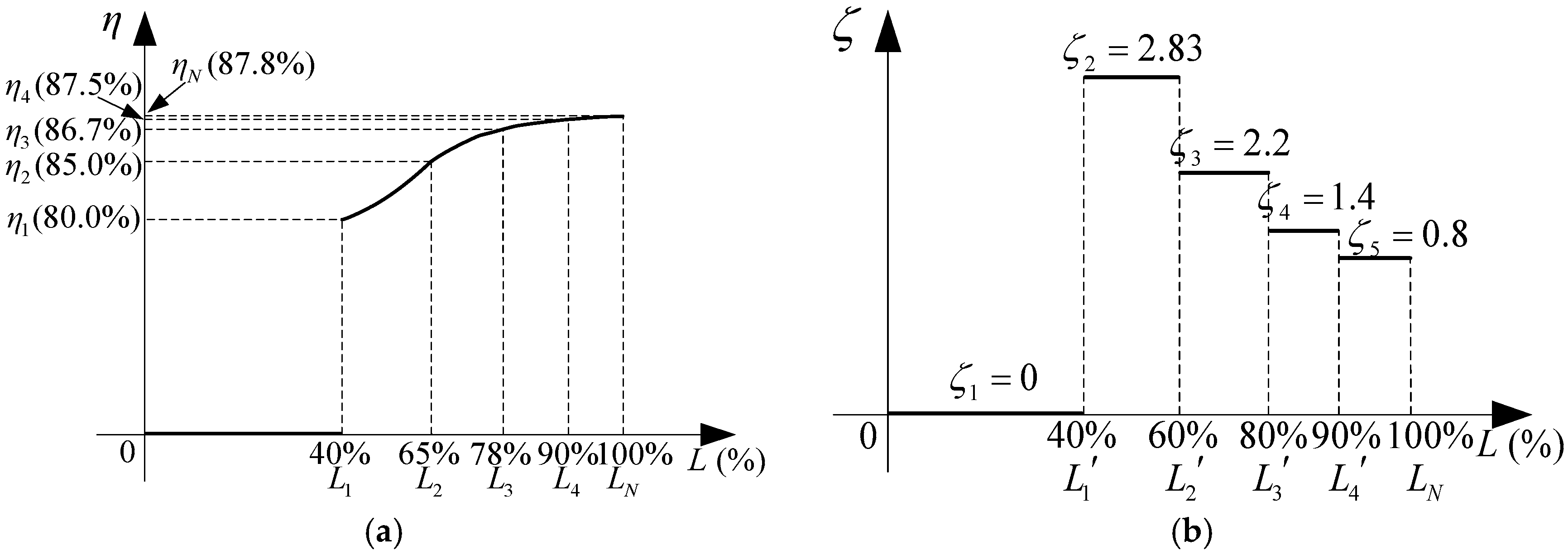

2.3. Profit Model for Combined Heat and Power

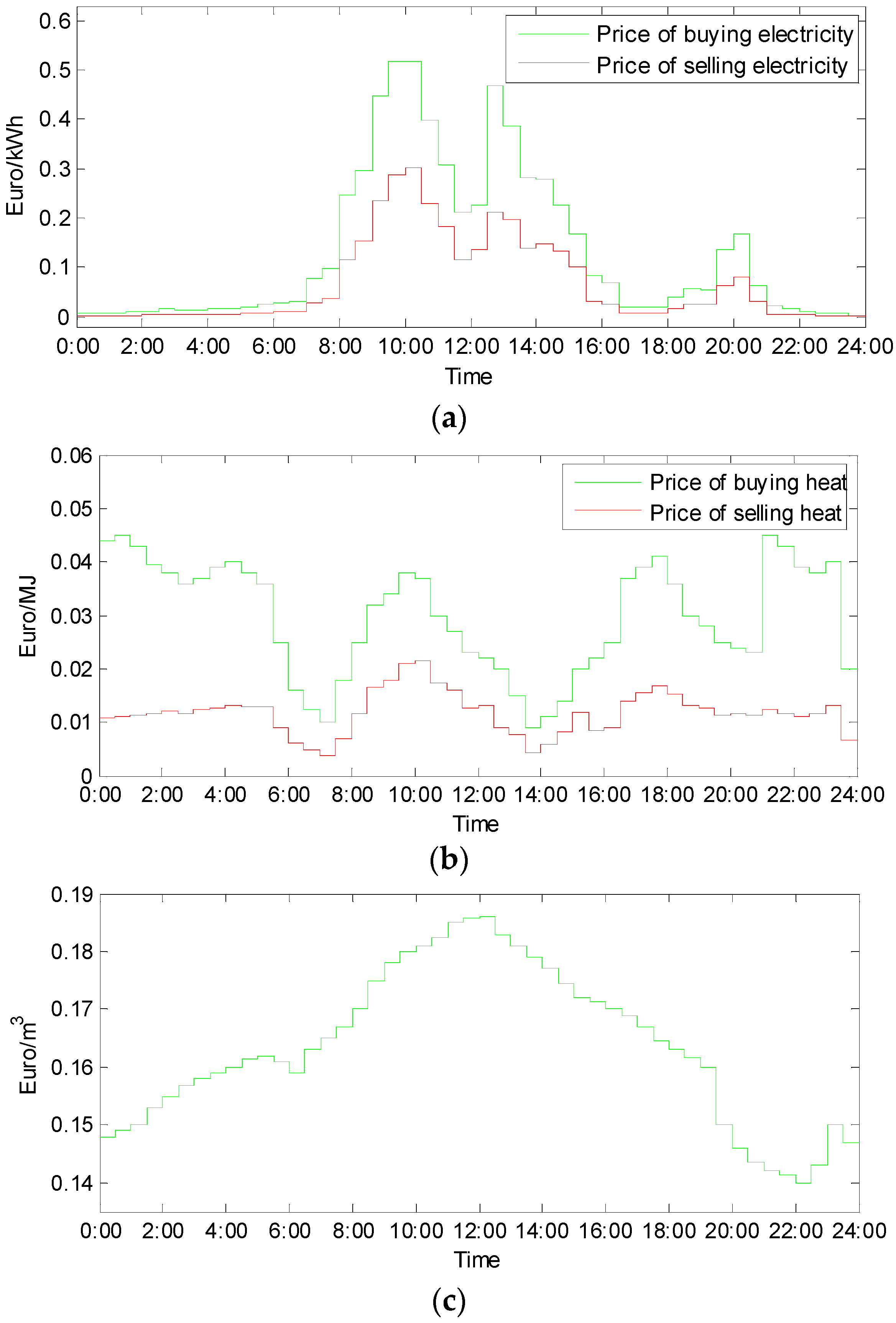

3. Optimization Model of Combined Heat and Power

3.1. Profit Model for Different Operation Modes

3.1.1. C1: PE,CHP > PE,L, PH,CHP > PH,L

3.1.2. C2: PE,CHP > PE,L, PH,CHP < PH,L

3.1.3. C3: PE,CHP < PE,L, PH,CHP > PH,L

3.1.4. C4: PE,CHP < PE,L, PH,CHP < PH,L

3.2. Optimization Model

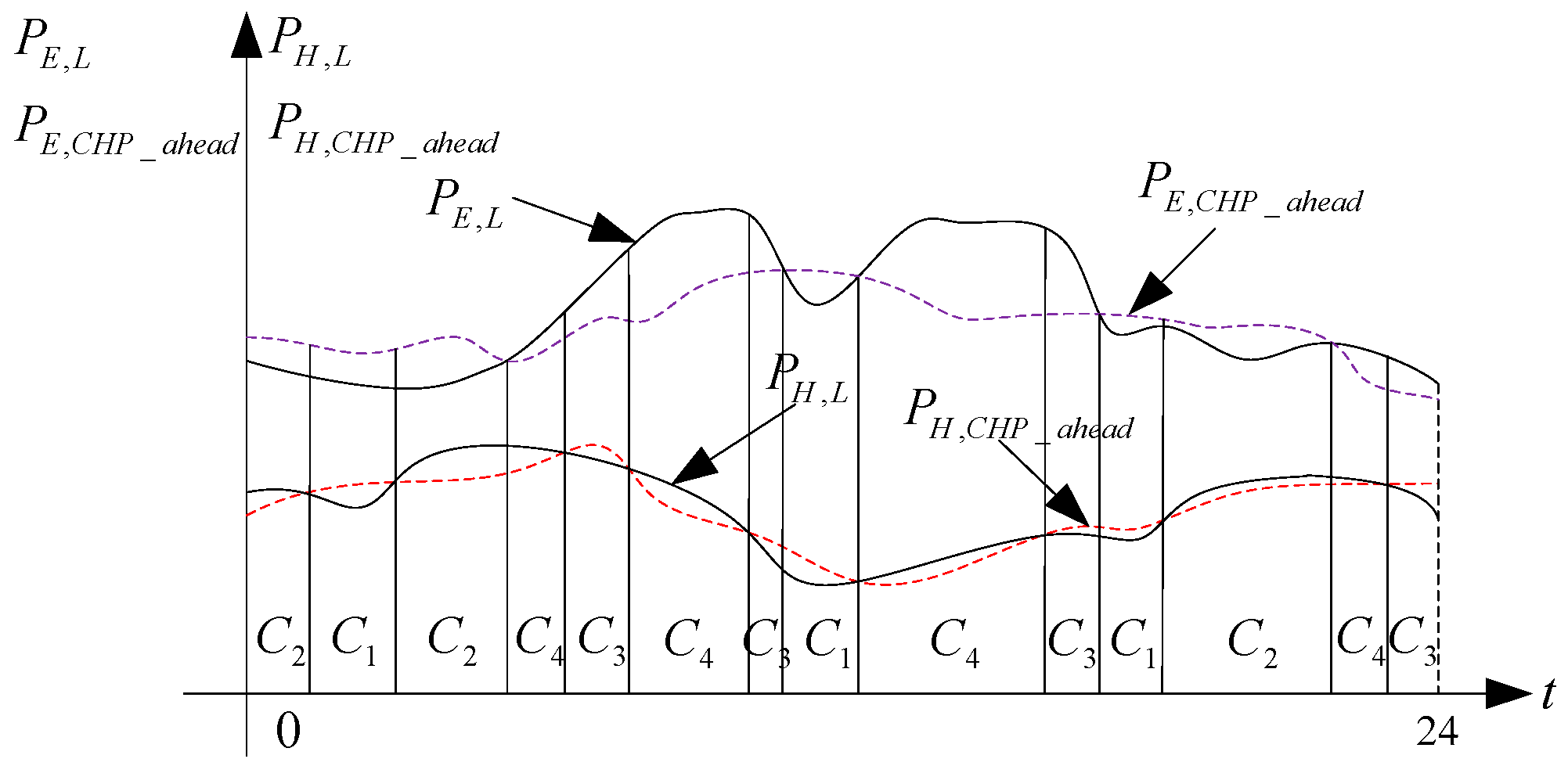

3.2.1. Operation Mode Identification

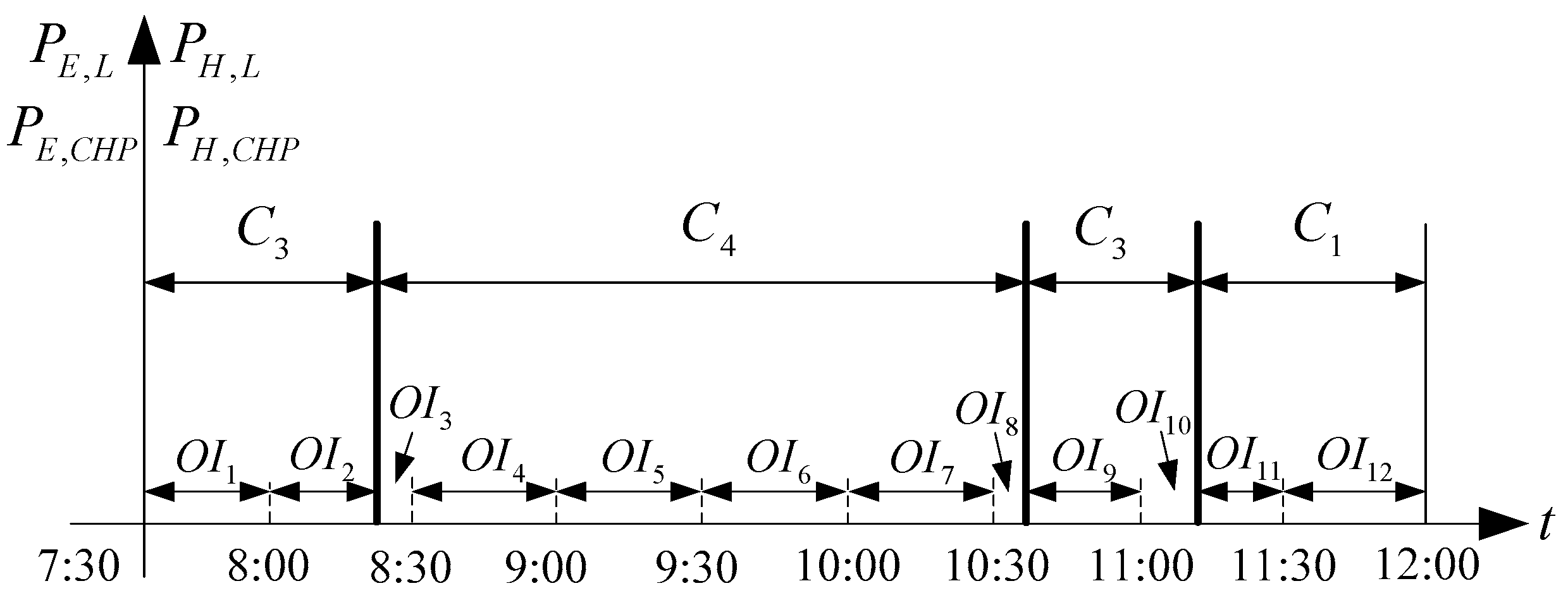

3.2.2. Optimization Interval Identification

- (1)

- In Mode C1

- (2)

- In Mode C2

- (3)

- In Mode C3

- (4)

- In Mode C4

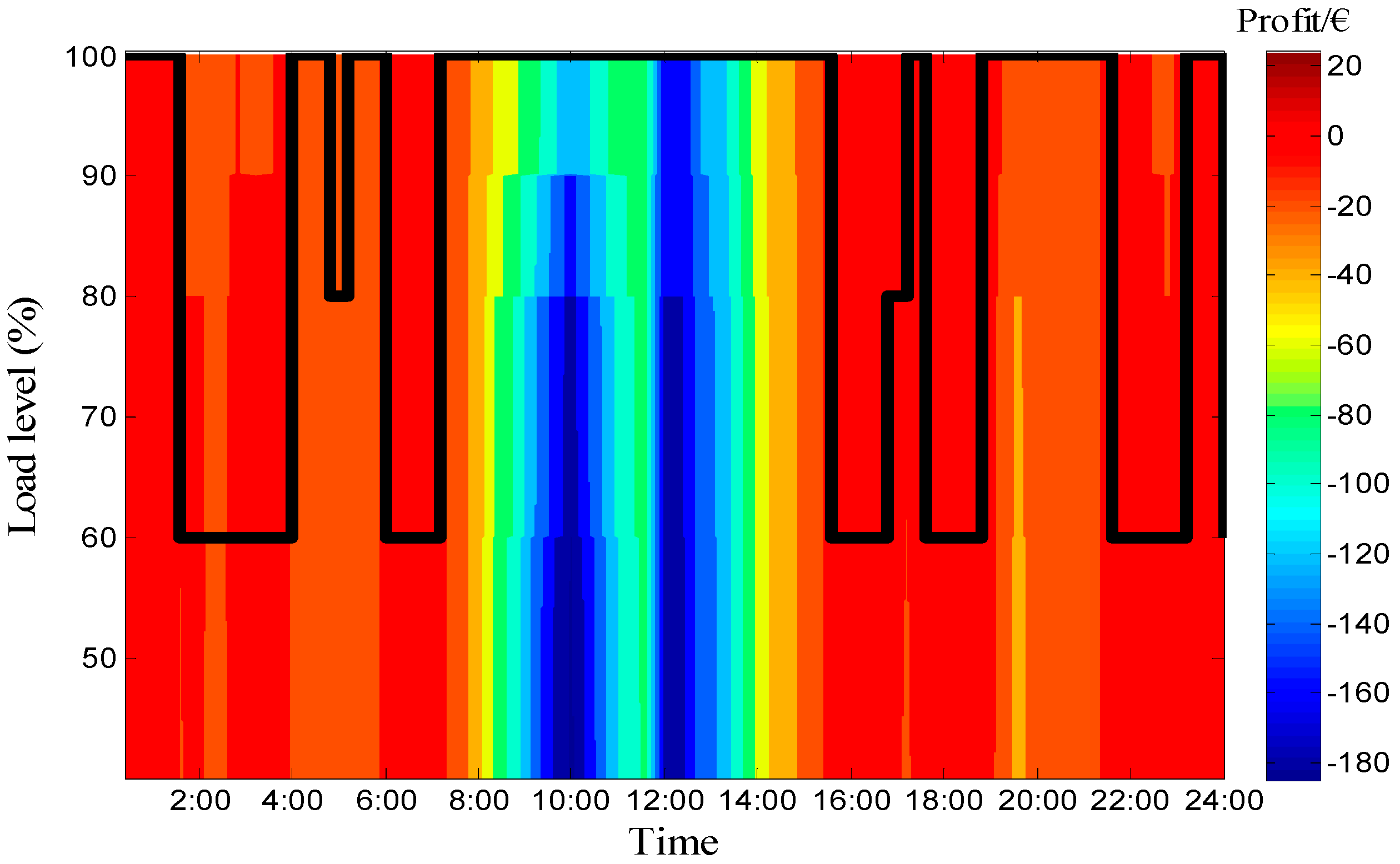

4. Demonstration Examples

5. Conclusions

- •

- There mainly exist four operation modes for network-connected CHP, determined by the relationship between the energy demand and supply. Based on the OI determined by operation modes and real-time prices, the operation of CHP can be optimized in a discrete way.

- •

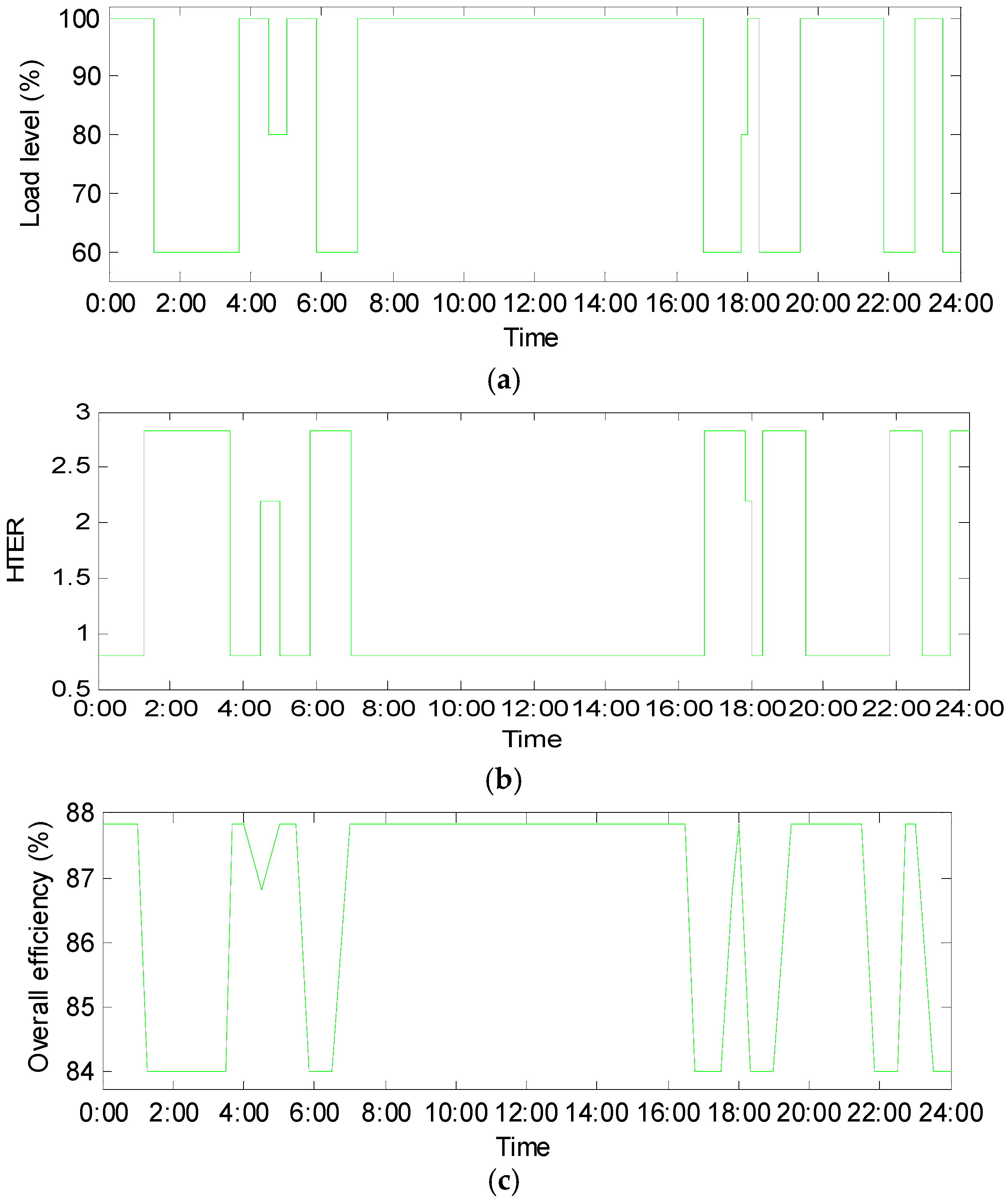

- The profit is determined by electric prices because it is usually high or much higher than that of heat. Thus, in the daytime, the CHP is operated at a high loading level to gain a low value of HTER to produce more electricity. At night, the CHP is operated at a low loading level to gain a higher value of HTER for more heat production.

- •

- A high loading level or high output does not always mean high profits. The loading level affects the HTER and overall efficiency of CHP tremendously. Under different load conditions and energy price scenarios, the CHP should use different optimal operation strategies.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| ECHP | kJ | The electric energy produced by the CHP |

| HCHP | kJ | The heat energy produced by the CHP |

| QU | kJ | The sum of heat and electricity produced by a CHP |

| GIN | kJ | The energy of input natural gas |

| η | % | The CHP efficiency converting gas energy to heat and electricity |

| ζ | % | Heat to electricity ratio (HTER) |

| VG | m3 | The volume of natural gas consumed by the CHP |

| q | kJ/m3 | The energy contained in a cubic meter of natural gas |

| CG | € | The fuel cost of CHP |

| PROCHP | € | The profit of the community |

| ILH | € | The equivalent heat income earned through consuming heat from CHP instead of heat network |

| ILE | € | The equivalent electric income earned through consuming electricity from CHP instead of electric network |

| INH | € | The income earned by selling surplus heat to the heat network |

| INE | € | The income earned by selling surplus electricity to the grid |

| € | The heat purchasing cost during peak loading hours | |

| € | The electricity purchasing cost during peak loading hours | |

| pLE | €/kJ | The real-time prices of buying electricity |

| pLH | €/kJ | The real-time prices of buying heat |

| pG | €/kJ | The real-time price of natural gas |

| pNE | €/kJ | The real-time prices of selling electricity to the grid |

| pNH | €/kJ | The real-time prices of selling heat to corresponding networks |

| EL,CHP | kJ | The consumed electricity energy supplied by CHP |

| HL,CHP | kJ | The consumed heat energy supplied by CHP |

| EN,CHP | kJ | The electricity energy sold to the corresponding networks |

| HN,CHP | kJ | The heat energy sold to the corresponding networks |

| kJ | The bought electricity from corresponding networks | |

| kJ | The bought heat from corresponding networks | |

| EL | kJ | The electric demand of the community |

| HL | kJ | The heat demand of the community |

| PE,CHP | kW | The output electricity power of the CHP |

| PH,CHP | kW | The output heat power of the CHP |

| PE,CHP_ahead | kW | The output electricity power of the CHP the day ahead |

| PH,CHP_ahead | kW | The output heat power of the CHP the day ahead |

| PE,L | kW | The electric power demand of the community |

| PH,L | kW | The heat power demand of the community |

| € | The profit of the community in Mode C1 | |

| € | The profit of the community in Mode C2 | |

| € | The profit of the community in Mode C3 | |

| € | The profit of the community in Mode C4 | |

| HCHP,min | kJ | The minimum heat energy produced by the CHP |

| HCHP,max | kJ | The maximum heat energy produced by the CHP |

| ECHP,min | kJ | The minimum electric energy produced by the CHP |

| ECHP,max | kJ | The maximum electric energy produced by the CHP |

| PH,CHP,min | kW | The minimum output heat power from the CHP |

| PH,CHP,max | kW | The maximum output heat power from the CHP |

| PE,CHP,min | kW | The minimum output electricity power from the CHP |

| PE,CHP,max | kW | The maximum output electricity power from the CHP |

| VG,min | m3 | The minimum volume of natural gas consumed by the CHP |

| VG,max | m3 | The maximum volume of natural gas consumed by the CHP |

Appendix

| Typical Overall Efficiency | Loading Level | HTER | Loading Level | ||

|---|---|---|---|---|---|

| η1 | 80% | 40% | ζ1 | 0 | 0%–40% |

| η2 | 85% | 65% | ζ2 | 2.83 | 40%–60% |

| η3 | 86.7% | 78% | ζ3 | 2.2 | 60%–80% |

| η4 | 87.5% | 90% | ζ4 | 1.4 | 80%–90% |

| ηN | 87.8% | 100% | ζ5 | 0.8 | 90%-100% |

| Nominal capacity SN (MW) | 1 | |

| Ramp capacity (kW/min) | 15 | |

| Electricity output PE,CHP (MW) | 0.7 (max) | 0.4 (min) |

| Heat output PH,CHP (MW) | Pramp 0.6 (max) | 0.3 (min) |

References

- Shin, J.; Shin, S.; Kim, Y.; Ahn, H.; Lee, S.; Jung, G.; Jeon, S.J.; Cho, D.H. Design and implementation of shaped magnetic-resonance-based wireless power transfer system for roadway-powered moving electric vehicles. IEEE Trans. Ind. Electron. 2014, 61, 1179–1192. [Google Scholar] [CrossRef]

- Gimelli, A.; Muccillo, M. Optimization criteria for cogeneration systems: Multi-objective approach and application in a hospital facility. Appl. Energy 2013, 104, 910–923. [Google Scholar] [CrossRef]

- Tibi, N.A.; Arman, H. A linear programming model to optimize the decision-making to managing cogeneration system. Clean Technol. Environ. Policy 2007, 9, 235–240. [Google Scholar] [CrossRef]

- Basu, A.K.; Bhattacharya, A.; Chowdhury, S.; Chowdhury, S.P. Planned scheduling for economic power sharing in a CHP-based micro-grid. IEEE Trans. Power Syst. 2012, 27, 30–38. [Google Scholar] [CrossRef]

- Wang, J.-J.; Jing, Y.-Y.; Zhang, C.-F. Optimization of capacity and operation for CCHP system by genetic algorithm. Appl. Energy 2010, 87, 1325–1335. [Google Scholar] [CrossRef]

- Muccillo, M.; Gimelli, A. Experimental development, 1D CFD simulation and energetic analysis of a 15 kw micro-CHP unit based on reciprocating internal combustion engine. Appl. Therm. Eng. 2014, 71, 760–770. [Google Scholar] [CrossRef]

- Blok, K.; Turkenburg, W.C. CO2 emission reduction by means of industrial CHP in The Netherlands. Energy Convers. Manag. 1994, 35, 317–340. [Google Scholar] [CrossRef]

- Smith, A.D.; Mago, P.J.; Fumo, N. Benefits of thermal energy storage option combined with CHP system for different commercial building types. Sustain. Energy Technol. Assess. 2013, 1, 3–12. [Google Scholar] [CrossRef]

- Anderson, J.O.; Toffolo, A. Improving energy efficiency of sawmill industrial sites by integration with pellet and CHP plants. Appl. Energy 2013, 111, 791–800. [Google Scholar] [CrossRef]

- Mohammadi-Ivatloo, B.; Moradi-Dalvand, M.; Rabiee, A. Combined heat and power economic dispatch problem solution using particle swarm optimization with time varying acceleration coefficients. Electr. Power Syst. Res. 2013, 95, 9–18. [Google Scholar] [CrossRef]

- Keirstead, J.; Samsatli, N.; Shah, N.; Weber, C. The impact of CHP (combined heat and power) planning restrictions on the efficiency of urban energy systems. Energy 2012, 41, 93–103. [Google Scholar] [CrossRef]

- Zogg, R.; Roth, K.; Brodrick, J. Using CHP systems in commercial buildings. ASHRAE J. 2005, 47, 33–34. [Google Scholar]

- Sun, Z.; Li, L.; Bego, A.; Dababneh, F. Customer-side electricity load management for sustainable manufacturing systems utilizing combined heat and power generation system. Int. J. Prod. Econ. 2015, 165, 112–119. [Google Scholar] [CrossRef]

- Bischi, A.; Taccari, L.; Martelli, E.; Amaldi, E.; Manzolini, G.; Silva, P.; Campanari, S.; Macchi, E. A detailed MILP optimization model for combined cooling, heat and power system operation planning. Energy 2014, 74, 12–26. [Google Scholar] [CrossRef]

- Muccillo, M.; Gimelli, A.; Sannino, R. Multi-objective optimization and sensitivity analysis of a cogeneration system for a hospital facility. Energy Procedia 2015, 81, 585–596. [Google Scholar] [CrossRef]

- Fragaki, A.; Andersen, A.N. Conditions for aggregation of CHP plants in the UK electricity market and exploration of plant size. Appl. Energy 2011, 88, 3930–3940. [Google Scholar] [CrossRef]

- Mago, P.J.; Chamra, L.M. Analysis and optimization of CCHP systems based on energy, economical, and environmental considerations. Energy Build. 2009, 41, 1099–1106. [Google Scholar] [CrossRef]

- Mohamed, A.; Cao, S.-L.; Hasan, A.; Sirén, K. Selection of micro-cogeneration for net zero energy buildings (NZEB) using weighted energy matching index. Energy Build. 2014, 80, 490–503. [Google Scholar] [CrossRef]

- Houwing, M.; Negenborn, R.R.; De Schutter, B. Demand response with micro-CHP systems. IEEE Proc. 2011, 99, 200–213. [Google Scholar] [CrossRef]

- Wang, J.-J.; Zhai, Z.-Q.; Jing, Y.-Y.; Zhang, C.-F. Optimization design of BCHP system to maximize to save energy and reduce environmental impact. Energy 2010, 35, 3388–3398. [Google Scholar] [CrossRef]

- Kavvadias, K.C.; Maroulis, Z.B. Multi-objective optimization of a trigeneration plant. Energy Policy 2010, 38, 945–954. [Google Scholar] [CrossRef]

- Frangopoulos, C.A. A method to determine the power to heat ratio, the cogenerated electricity and the primary energy savings of cogeneration systems after the European Directive. Energy 2012, 45, 52–61. [Google Scholar] [CrossRef]

- Niemi, R.; Mikkola, J.; Lund, P.D. Urban energy systems with smart multi-carrier energy networks and renewable energy generation. Renew. Energy 2012, 48, 524–536. [Google Scholar] [CrossRef]

- Cao, S.-L.; Mohamed, A.; Hasan, A.; Sirén, K. Energy matching analysis of on-site micro-cogeneration for a single-family house with thermal and electrical tracking strategies. Energy Build. 2014, 68, 351–363. [Google Scholar] [CrossRef]

- Aghaei, J.; Alizadeh, M.I. Multi-objective self-scheduling of CHP (combined heat and power)-based microgrids considering demand response programs and ESSs (energy storage systems). Energy 2013, 55, 1044–1054. [Google Scholar] [CrossRef]

- Wang, H.-C.; Jiao, W.-L.; Lahdelma, R.; Zou, P.-H. Techno-economic analysis of a coal-fired CHP based combined heating system with gas-fired boilers for peak load compensation. Energy Policy 2011, 39, 7950–7962. [Google Scholar] [CrossRef]

- Gu, C.-H.; Xie, D.; Sun, G.-B.; Wang, X.-T.; Ai, Q. Optimal operation of combined heat and power system based on forecasted energy prices in real-time markets. Energies 2015, 8, 14330–14345. [Google Scholar] [CrossRef]

- Dong, L.-L.; Liu, H.; Riffat, S. Development of small-scale and micro-scale biomass-fuelled CHP systems—A literature review. Appl. Therm. Eng. 2009, 29, 2119–2126. [Google Scholar] [CrossRef]

- SAV systems. Load Tracker CHP-LPG Fuelled Small Scale Modulating CHP Systems in Non-Mains Gas Areas. Available online: http://www.sav-systems.com/ (accessed on 10 September 2015).

- Schulz, C.; Kurrat, M. Considerations for Dispersed Cogeneration of Heat and Power in Low Voltage Networks. In Proceedings of the Symposium Power Systems with Dispersed Generation, Athens, Greece, 14 April 2004.

- Schulz, C.; Röder, G.; Kurrat, M. Virtual Power Plants with Combined Heat and Power Micro-Units. In Proceedings of the 2005 International Conference on Future Power Systems, Amsterdam, The Netherlands, 16–18 November 2005.

- Motevasel, M.; Seifi, A.R.; Niknam, T. Multi-objective energy management of CHP (combined heat and power)-based micro-grid. Energy 2013, 51, 123–136. [Google Scholar] [CrossRef]

| Time | Modes | Time | Modes | Time | Modes | Time | Modes |

|---|---|---|---|---|---|---|---|

| 0:00–0:30 | C3 | 6:00–6:30 | C2 | 13:00–13:30 | C3 | 19:00–19:30 | C2 |

| 0:30–1:00 | C3 | 6:30–7:00 | C2 | 13:30–14:00 | C3 | 19:30–19:50 | C2 |

| 1:00–1:15 | C3 | 7:00–7:10 | C2 | 14:00–14:30 | C3 | 19:50–20:00 | C4 |

| 1:15–1:30 | C2 | 7:10–7:30 | C4 | 14:30–15:00 | C3 | 20:00–20:30 | C4 |

| 1:30–2:00 | C2 | 7:30–8:00 | C4 | 15:00–15:30 | C3 | 20:30–20:45 | C4 |

| 2:00–2:30 | C2 | 8:00–8:30 | C4 | 15:30–16:00 | C3 | 20:45–21:00 | C3 |

| 2:30–3:00 | C2 | 8:30–9:00 | C4 | 16:00–16:30 | C3 | 21:00–21:30 | C3 |

| 3:00–3:30 | C2 | 9:00–9:30 | C4 | 16:30–16:45 | C3 | 21:30–21:50 | C3 |

| 3:30–3:40 | C2 | 9:30–10:00 | C4 | 16:45–17:00 | C2 | 21:50–22:00 | C1 |

| 3:40–4:00 | C3 | 10:00–10:30 | C4 | 17:00–17:30 | C2 | 22:00–22:15 | C1 |

| 4:00–4:30 | C3 | 10:30–11:00 | C4 | 17:30–17:50 | C2 | 22:15–22:30 | C2 |

| 4:30–5:00 | C3 | 11:00–11:30 | C4 | 17:50–18:00 | C4 | 22:30–22:45 | C2 |

| 5:00–5:30 | C3 | 11:30–12:00 | C3 | 18:00–18:20 | C4 | 22:45–23:00 | C3 |

| 5:30–5:50 | C3 | 12:00–12:30 | C3 | 18:20–18:30 | C2 | 23:00–23:30 | C3 |

| 5:50–6:00 | C2 | 12:30–13:00 | C3 | 18:30–19:00 | C2 | 23:30–24:00 | C1 |

| Time | Profit (Euro) | Time | Profit (Euro) | Time | Profit (Euro) | Time | Profit (Euro) |

|---|---|---|---|---|---|---|---|

| 0:00–0:30 | 2.04 | 6:00–6:30 | 4 | 13:00–13:30 | −149.2 | 19:00–19:30 | 7.55 |

| 0:30–1:00 | 2.19 | 6:30–7:00 | 4.48 | 13:30–14:00 | −119.9 | 19:30–19:50 | 12.07 |

| 1:00–1:15 | 0.83 | 7:00–7:10 | 4.3 | 14:00–14:30 | −110.2 | 19:50–20:00 | 0.78 |

| 1:15–1:30 | 0.01 | 7:10–7:30 | −11.2 | 14:30–15:00 | −80.78 | 20:00–20:30 | −9.95 |

| 1:30–2:00 | 0.4 | 7:30–8:00 | −28 | 15:00–15:30 | −50.6 | 20:30–20:45 | −0.92 |

| 2:00–2:30 | −0.77 | 8:00–8:30 | −43.46 | 15:30–16:00 | −27.61 | 20:45–21:00 | −7.14 |

| 2:30–3:00 | 0.86 | 8:30–9:00 | −58.01 | 16:00–16:30 | −21.15 | 21:00–21:30 | −14.13 |

| 3:00–3:30 | 0.56 | 9:00–9:30 | −73.26 | 16:30–16:45 | −1.71 | 21:30–21:50 | −0.85 |

| 3:30–3:40 | 0.29 | 9:30–10:00 | −95.82 | 16:45–17:00 | 1.91 | 21:50–22:00 | 1.75 |

| 3:40–4:00 | 0.15 | 10:00–10:30 | −119.3 | 17:00–17:30 | 2.63 | 22:00–22:15 | 2.01 |

| 4:00–4:30 | −0.56 | 10:30–11:00 | −99.92 | 17:30–17:50 | 1.63 | 22:15–22:30 | 0.54 |

| 4:30–5:00 | −0.67 | 11:00–11:30 | −79.91 | 17:50–18:00 | 1.69 | 22:30–22:45 | 0.12 |

| 5:00–5:30 | −1.51 | 11:30–12:00 | −76.96 | 18:00–18:20 | 0.59 | 22:45–23:00 | 0.52 |

| 5:30–5:50 | −2.51 | 12:00–12:30 | −72.01 | 18:20–18:30 | 2.06 | 23:00–23:30 | 1.61 |

| 5:50–6:00 | 1.22 | 12:30–13:00 | −153.8 | 18:30–19:00 | 8.91 | 23:30–24:00 | 0.65 |

| Time | Profit (Euro) | Time | Profit (Euro) | Time | Profit (Euro) | Time | Profit (Euro) |

|---|---|---|---|---|---|---|---|

| 0:00–0:30 | 1.97 | 6:00–6:30 | 3.98 | 13:00–13:30 | −157.00 | 19:00–19:30 | 7.54 |

| 0:30–1:00 | 2.10 | 6:30–7:00 | 4.48 | 13:30–14:00 | −123.67 | 19:30–19:50 | 12.02 |

| 1:00–1:15 | 0.81 | 7:00–7:10 | 4.28 | 14:00–14:30 | −113.83 | 19:50–20:00 | −1.42 |

| 1:15–1:30 | −0.03 | 7:10–7:30 | −11.82 | 14:30–15:00 | −83.68 | 20:00–20:30 | −18.40 |

| 1:30–2:00 | 0.34 | 7:30–8:00 | −29.11 | 15:00–15:30 | −52.71 | 20:30–20:45 | −2.15 |

| 2:00–2:30 | −0.81 | 8:00–8:30 | −55.05 | 15:30–16:00 | −28.64 | 20:45–21:00 | −7.52 |

| 2:30–3:00 | 0.81 | 8:30–9:00 | −71.85 | 16:00–16:30 | −21.99 | 21:00–21:30 | −14.33 |

| 3:00–3:30 | 0.50 | 9:00–9:30 | −97.61 | 16:30–16:45 | −1.78 | 21:30–21:50 | −0.96 |

| 3:30–3:40 | 0.27 | 9:30–10:00 | −124.17 | 16:45–17:00 | 1.88 | 21:50–22:00 | 1.75 |

| 3:40–4:00 | 0.08 | 10:00–10:30 | −147.73 | 17:00–17:30 | 2.57 | 22:00–22:15 | 2.01 |

| 4:00–4:30 | −0.68 | 10:30–11:00 | −121.56 | 17:30–17:50 | 1.59 | 22:15–22:30 | 0.51 |

| 4:30–5:00 | −0.69 | 11:00–11:30 | −96.42 | 17:50–18:00 | 1.65 | 22:30–22:45 | 0.10 |

| 5:00–5:30 | −1.66 | 11:30–12:00 | −79.65 | 18:00–18:20 | 0.45 | 22:45–23:00 | 0.51 |

| 5:30–5:50 | −2.68 | 12:00–12:30 | −74.90 | 18:20–18:30 | 2.04 | 23:00–23:30 | 1.61 |

| 5:50–6:00 | 1.20 | 12:30–13:00 | −159.90 | 18:30–19:00 | 8.90 | 23:30–24:00 | 0.66 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, D.; Lu, Y.; Sun, J.; Gu, C.; Yu, J. Optimal Operation of Network-Connected Combined Heat and Powers for Customer Profit Maximization. Energies 2016, 9, 442. https://doi.org/10.3390/en9060442

Xie D, Lu Y, Sun J, Gu C, Yu J. Optimal Operation of Network-Connected Combined Heat and Powers for Customer Profit Maximization. Energies. 2016; 9(6):442. https://doi.org/10.3390/en9060442

Chicago/Turabian StyleXie, Da, Yupu Lu, Junbo Sun, Chenghong Gu, and Jilai Yu. 2016. "Optimal Operation of Network-Connected Combined Heat and Powers for Customer Profit Maximization" Energies 9, no. 6: 442. https://doi.org/10.3390/en9060442

APA StyleXie, D., Lu, Y., Sun, J., Gu, C., & Yu, J. (2016). Optimal Operation of Network-Connected Combined Heat and Powers for Customer Profit Maximization. Energies, 9(6), 442. https://doi.org/10.3390/en9060442