Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems

Abstract

:1. Introduction

1.1. Background

1.2. Methods and Scope

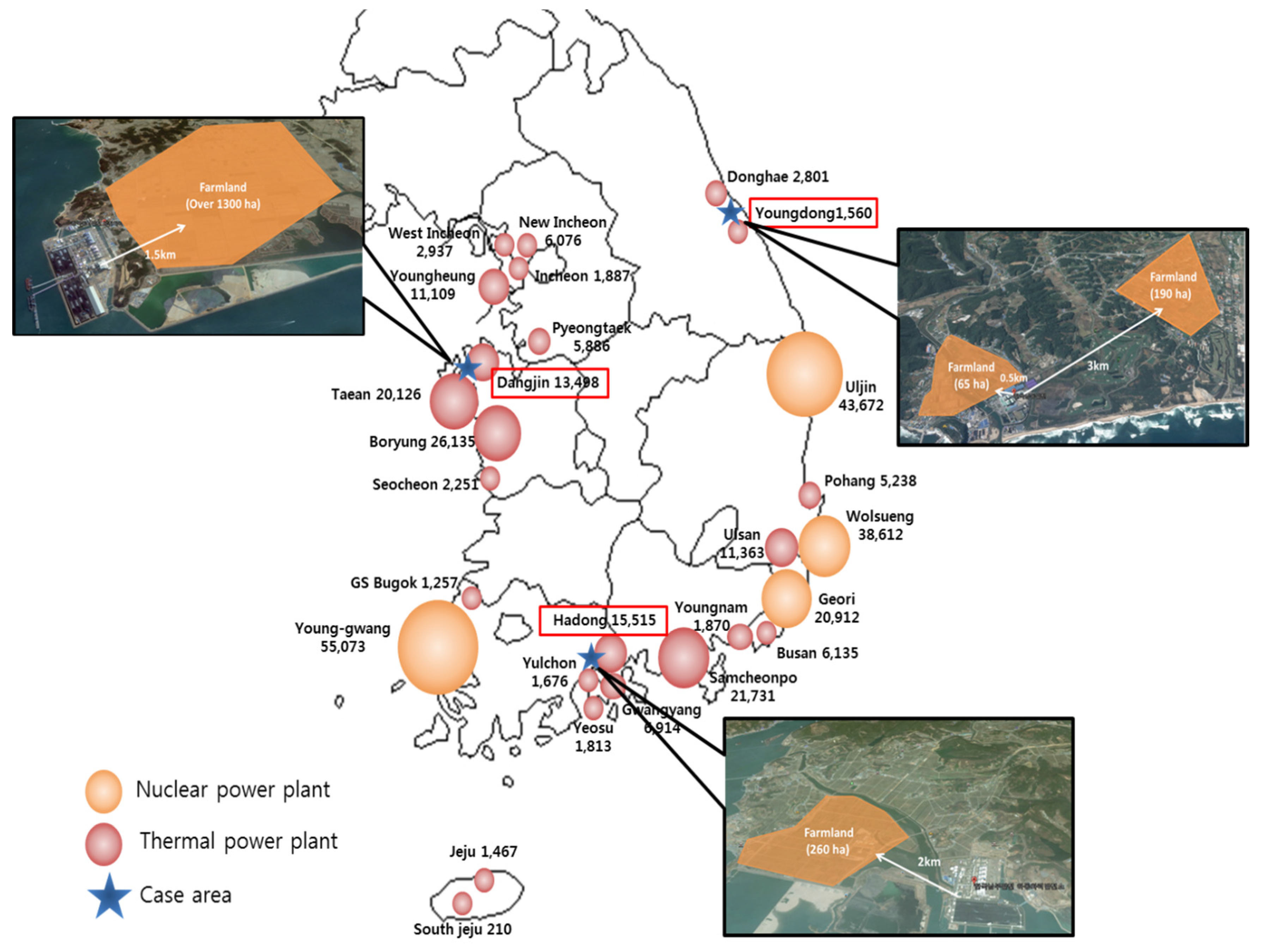

2. Energy Reserves of Power Plant Waste Heat

2.1. Overview of Power Plant Waste Heat

2.2. Calculation of Power Plant Waste Heat Energy Reserves

3. Evaluation Methods

3.1. Case Study Area

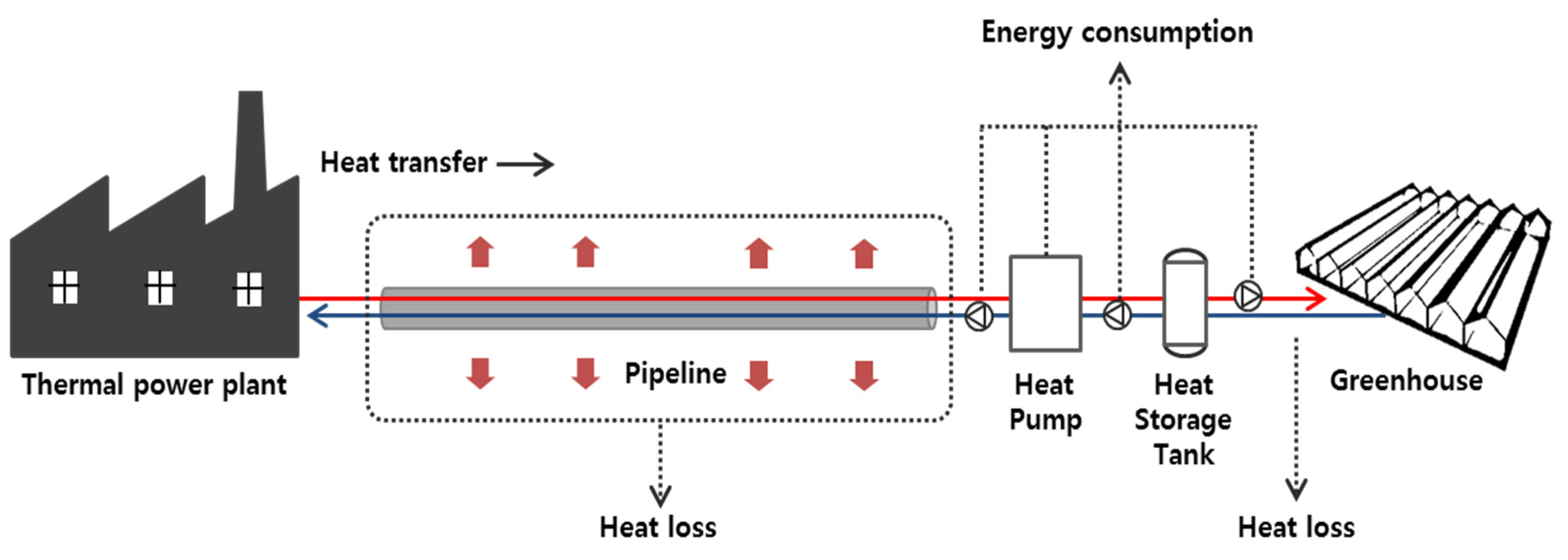

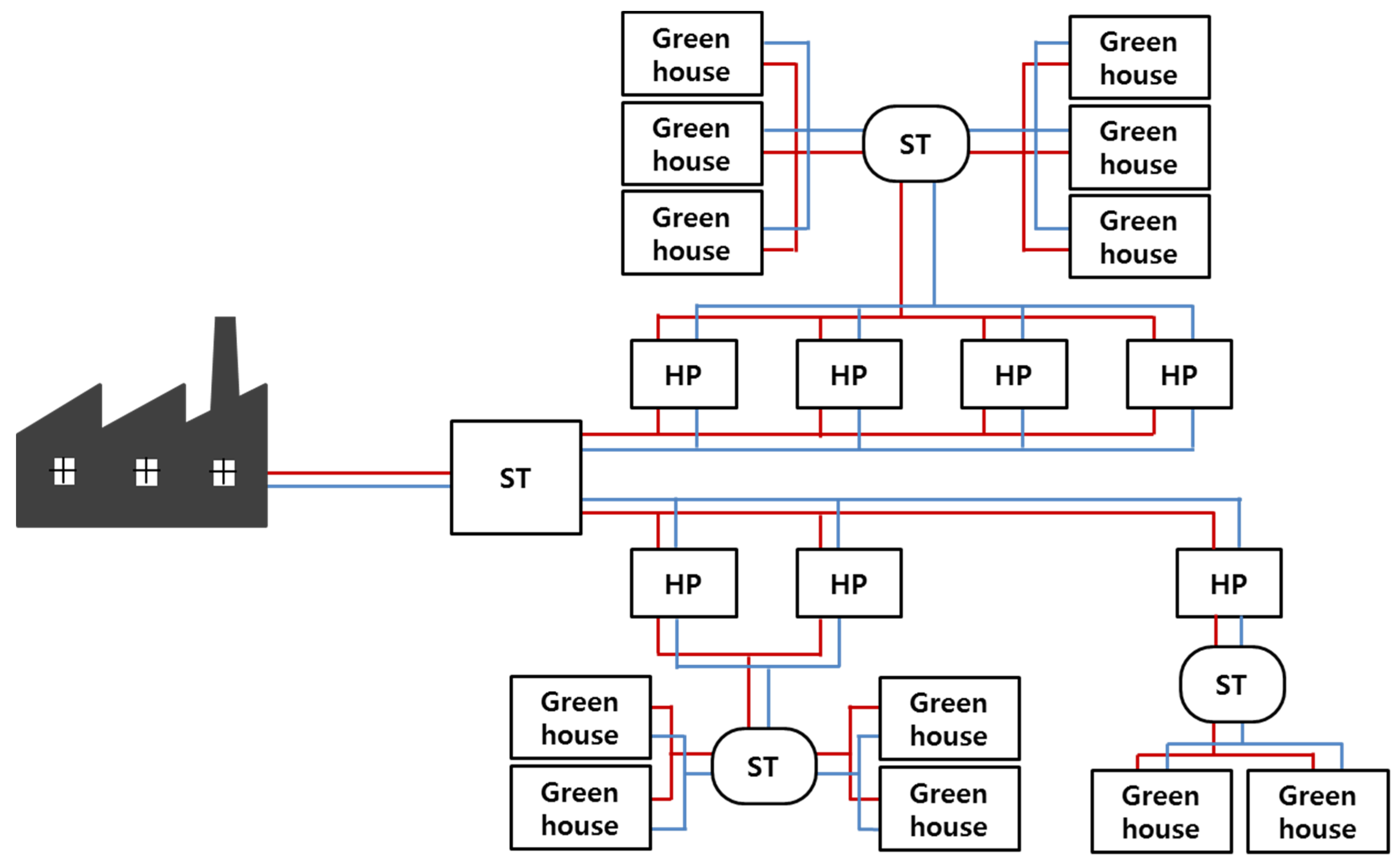

3.2. Description of Total Framework

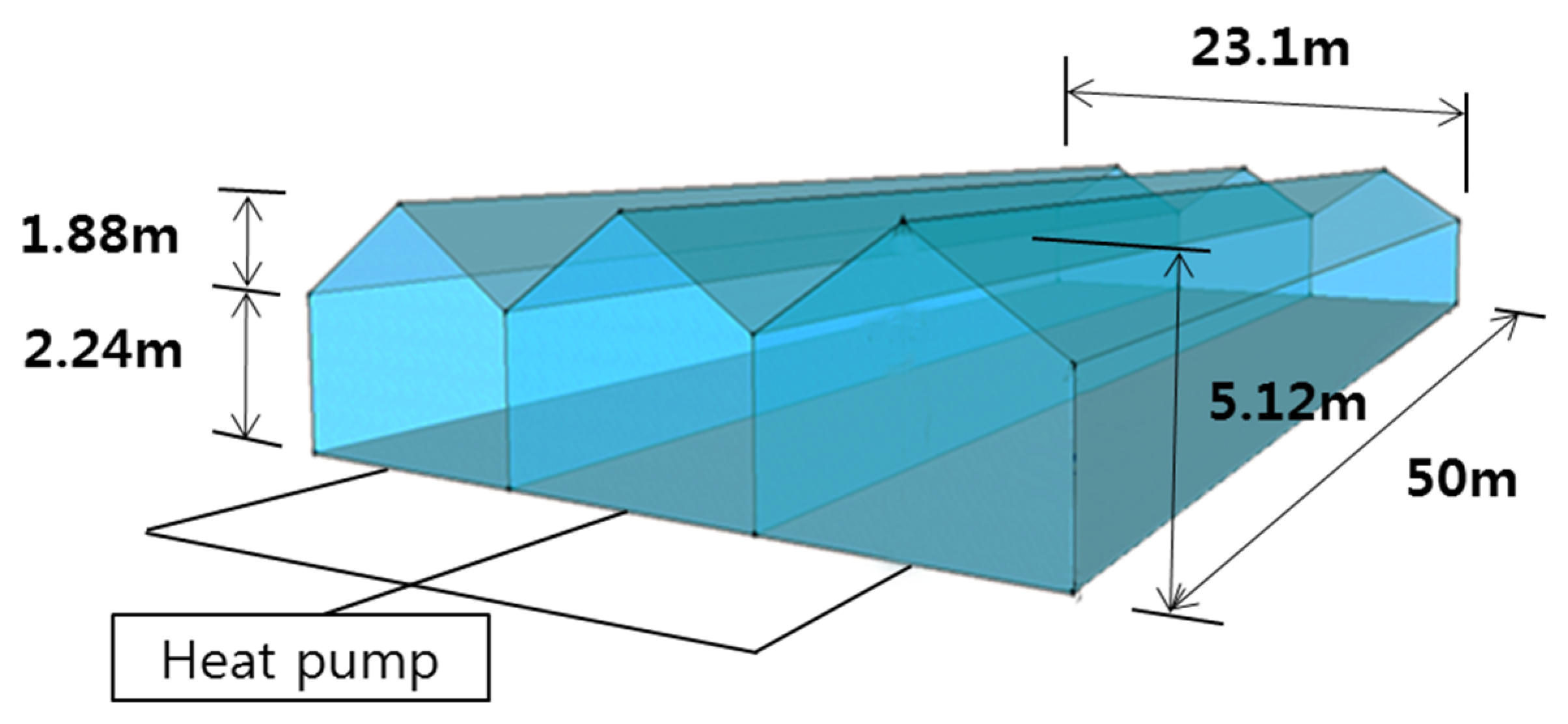

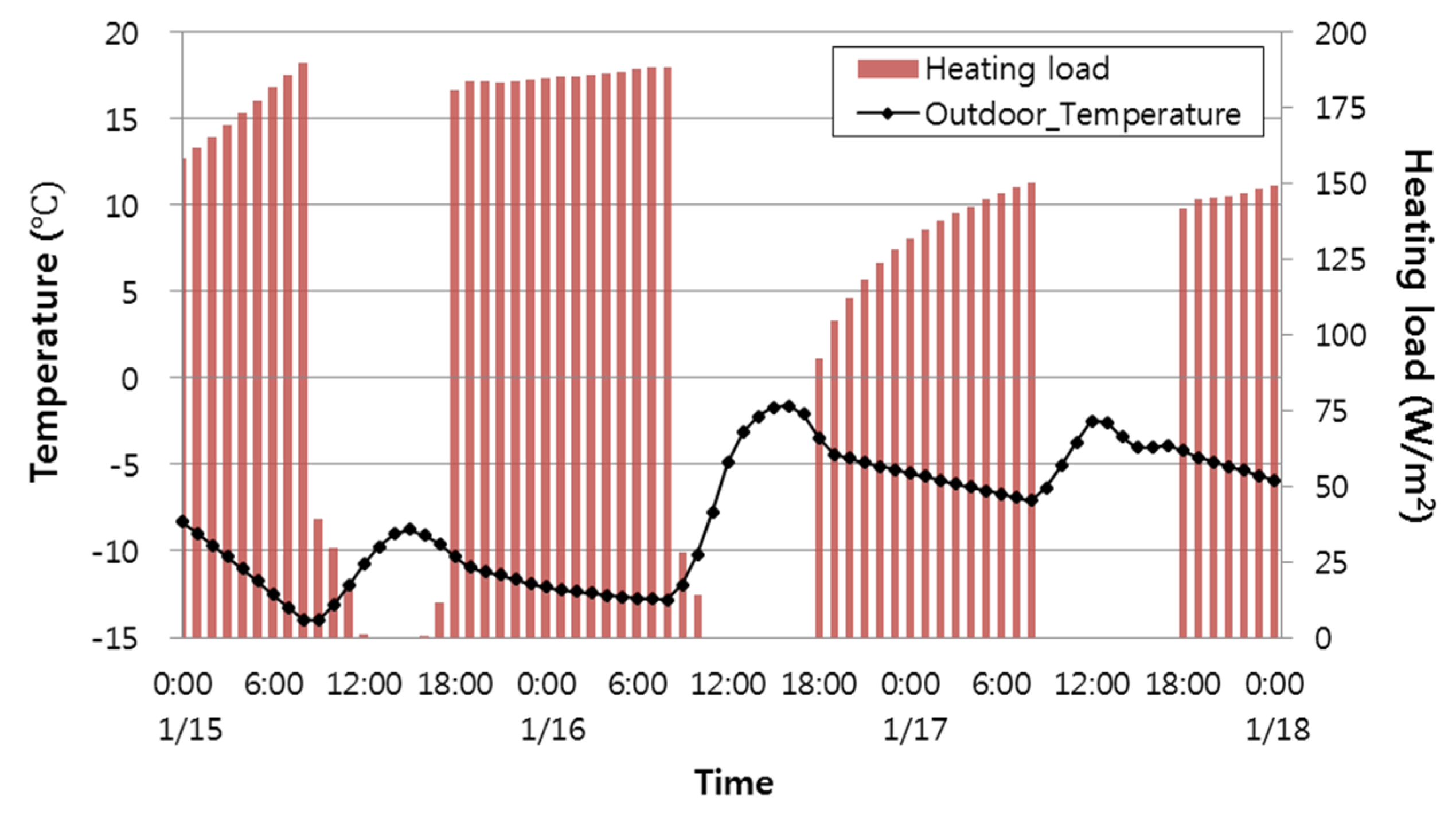

3.3. Description of Load Analysis Model

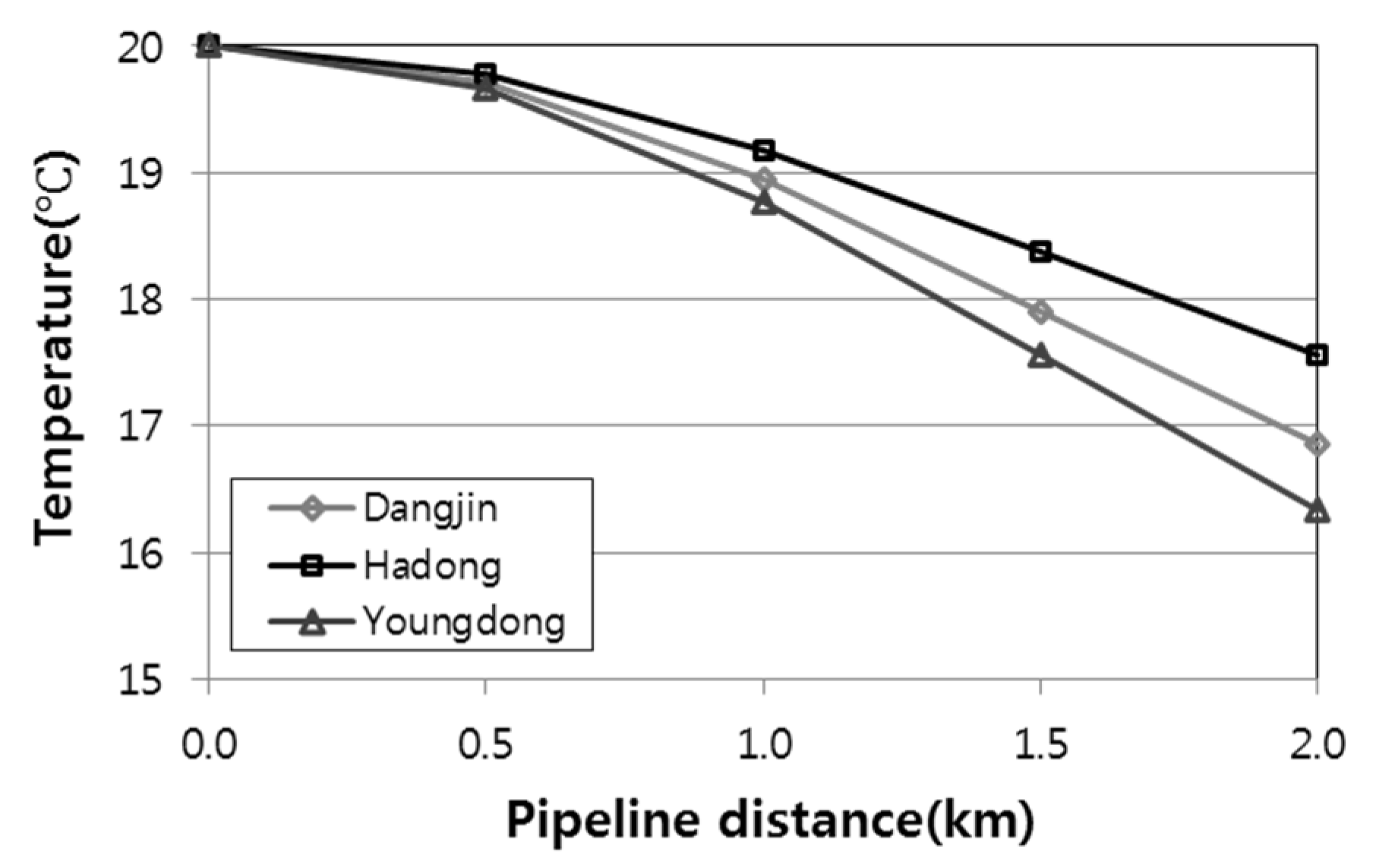

3.4. Evaluation Method of Heat Loss through Pipeline

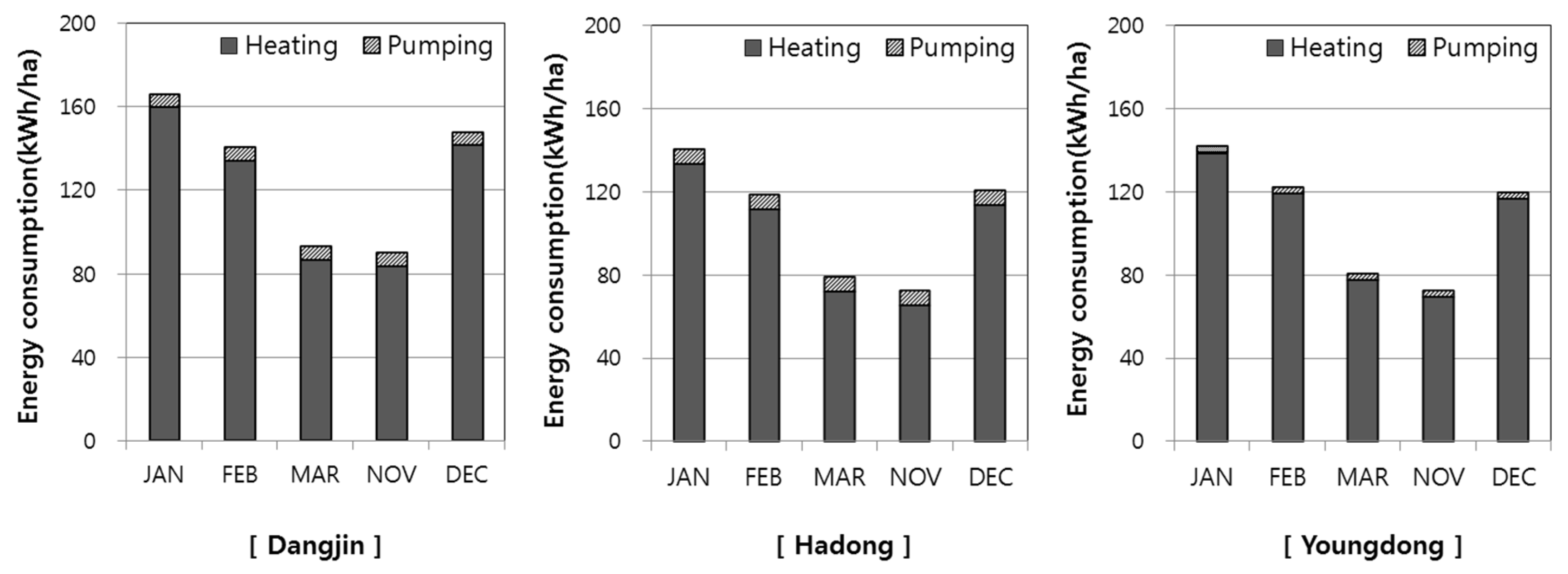

3.5. Calculation Method of Energy Consumption

4. Analysis Results

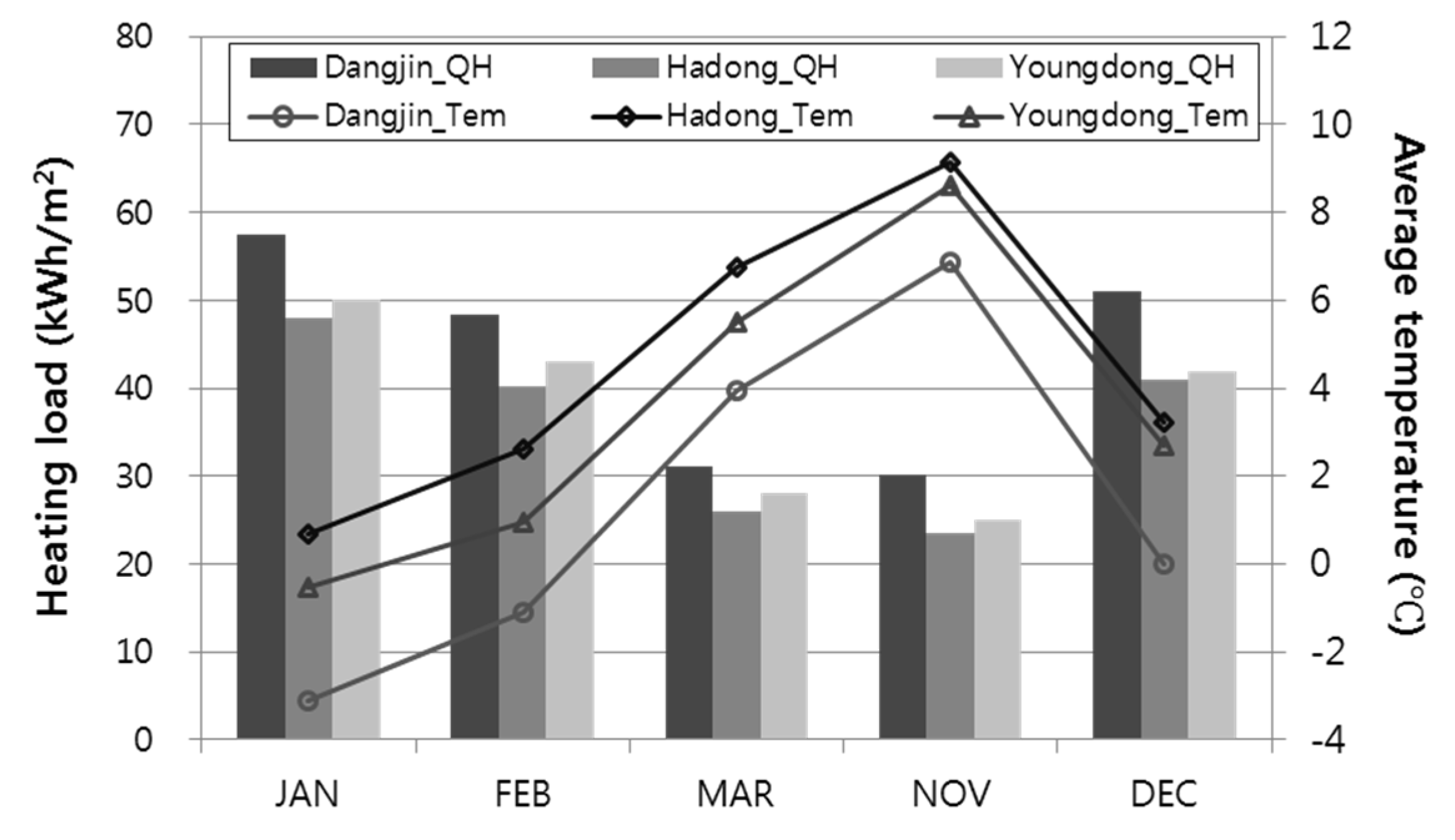

4.1. Heating Load Analysis

4.2. Outlet Fluid Temperature Analysis

4.3. Energy Consumption Analysis

4.4. Horticulture Scale Analysis

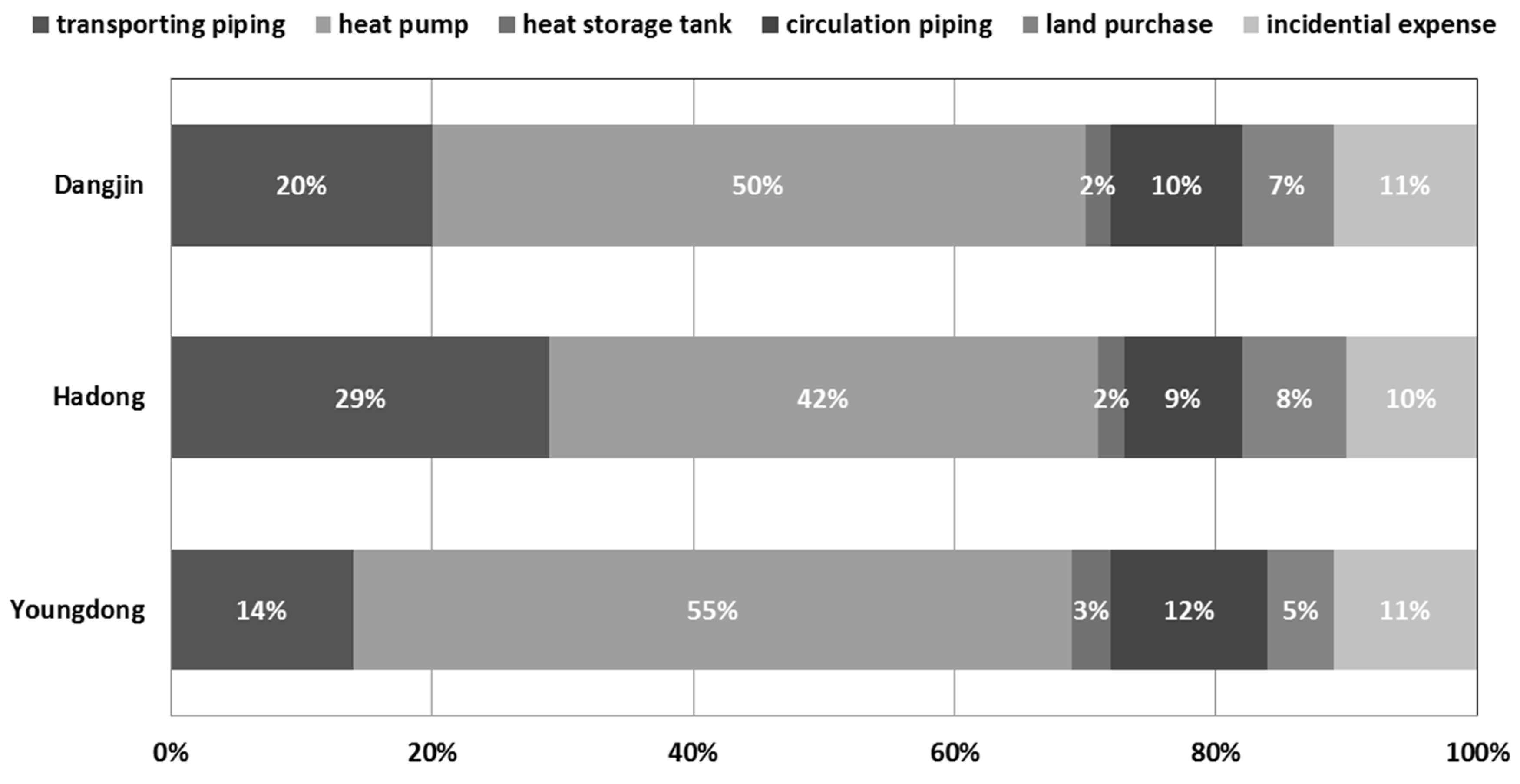

5. Life Cycle Cost Analysis

5.1. Outline of Economic Analysis

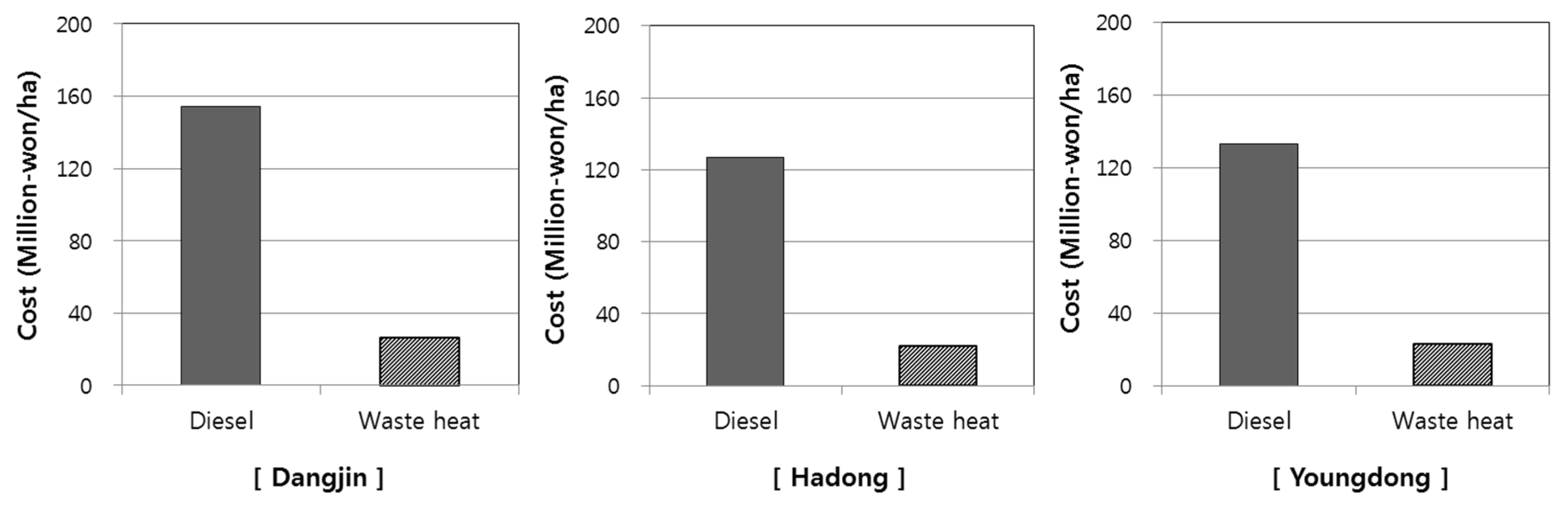

5.2. Operation Cost

5.3. Payback Period Analysis

6. Conclusions

- It was confirmed that the discharged thermal effluent capacity differed between power plants located on each coast of Korea. According to the survey, power plants were located mainly on the West and South coast and the energy reserves of the nuclear power plants were higher than those of thermal power plants. Moreover, the energy reserves were a key variable to examine the applicability of waste heat as energy source compared with the heating energy consumption.

- According to the heating load analysis, the largest load was indicated in Dangjin, where the weather conditions are the coldest, followed by Youngdong and Hadong. From this result, there is a correlation between each regional weather condition and heating load. On the other hand, an increased heating load means increased heating energy consumption.

- Comparing the energy reserves and heating energy consumption, it was confirmed that there was sufficient amount of reserves to supply energy to the assumed areas in this paper. In Dangjin, by utilizing about 20% of energy reserves of the Dangjin thermal power plant, it was assumed that an area of 500 ha could be used. In Hadong, the assumed area is 260 ha, utilizing about 7.4% of the energy reserves of the Hadong thermal power plant. In Youngdong, an assumed area of 65 ha can be constructed when utilizing about 19% of the energy reserves of the Youngdong thermal power plant.

- Based on the energy analysis for each case, a comparative analysis with a conventional energy supply system was carried out. The initial investment can be recovered from the approximately 83% reduction the annual operating costs. It was confirmed that the investment could be recovered after about two years in Dangjin, three years in Hadong, and two years in Youngdong.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, Y.J. Trend of clean energy industry and the prospect of its expandability to agricultural sector. J. Korea Rural Econ. Inst. (KREI) 2011, R635, 1–284. [Google Scholar]

- Kim, Y.J.; Park, H.T.; Han, H.S.; Moon, D.H. Management analysis of cooling-heating system and thermal type in the major horticultural crops. J. Korea Rural Econ. Inst. (KREI) 2014, D373, 1–82. [Google Scholar]

- Yu, M.G.; Nam, Y.J.; Lee, G.H. Design method of heat storage type ground source heat pump system considering energy load pattern of greenhouse. J. Korea Inst. Ecol. Archit. Environ. (KIEAE) 2015, 15, 57–63. [Google Scholar] [CrossRef]

- Park, M.L.; Ryoo, Y.S.; Kim, J.W.; Lee, Y.U.; Bae, S.D.; Chae, K.B. A study on analysis of reserves and available capacity of unutilized energy in rural community. J. Korean Sol. Energy Soc. (KSES) 2014, 34, 19–25. [Google Scholar] [CrossRef]

- Park, J.T.; Chang, K.C. An investigation on quantity of unused energy using temperature difference energy as heat source and its availability. J. Korea Soc. Energy Eng. (KOSEE) 2002, 11, 106–113. [Google Scholar]

- Hyun, I.T.; Lee, J.H.; Yoon, Y.B.; Lee, K.H.; Nam, Y.J. The potential and utilization of unused energy source for large-scale horticulture facility applications under Korean climatic conditions. Energies 2014, 7, 4781–4801. [Google Scholar] [CrossRef]

- Chau, J.; Sowlati, T.; Sokhansanj, S.; Preto, F.; Melin, S.; Bi, X. Economic sensitivity of wood biomass utilization for greenhouse heating application. Appl. Energy 2009, 86, 616–621. [Google Scholar] [CrossRef]

- Benli, H. Energetic performance analysis of a ground-source heat pump system with latent heat storage for a greenhouse heating. Energy Convers. Manag. 2011, 52, 581–589. [Google Scholar] [CrossRef]

- Benli, H.; Durmus, A. Evaluation of ground source heat pump combined latent heat storage system performance in greenhouse heating. Energy Build. 2009, 41, 220–228. [Google Scholar] [CrossRef]

- Esen, M.; Yuksel, T. Experimental evaluation of using various renewable energy sources for heating a greenhouse. Energy Build. 2013, 65, 340–351. [Google Scholar] [CrossRef]

- Cho, J.H.; Kim, D.Y.; Lee, J.S. Directions for developing green aquaculture using thermal effluent from power plant. J. Korea Marit. Inst. 2010, 5, 1–141. [Google Scholar]

- Heo, T.H. On the application of the heat pump system to facility horticulture, using hot waste water from power plants. Ph.D. Dissertation, Jeju National University, Jeju, Korea, 2012. [Google Scholar]

- Dalla Rosa, A.; Boulter, R.; Church, K.; Svendsen, S. District heating (DH) network design and operation toward a system-wide methodology for optimizing renewable energy solutions (SMORES) in Canada: A case study. Energy 2012, 45, 960–974. [Google Scholar] [CrossRef]

- Dalla Rosa, A.; Li, H.; Svendsen, S. Method for optimal design of pipes for low-energy district heating, with focus on heat losses. Energy 2011, 36, 2407–2418. [Google Scholar] [CrossRef]

- Tol, H.I.; Svendsen, S. A comparative study on substation types and network layouts in connection with low-energy district heating systems. Energy Convers. Manag. 2012, 64, 551–561. [Google Scholar] [CrossRef]

- Li, X.-L.; Duanmu, L.; Shu, H.-W. Optimal design of district heating and cooling pipe network of seawater-source heat pump. Energy Build. 2010, 42, 100–104. [Google Scholar] [CrossRef]

- Yildirim, N.; Toksoy, M.; Gokcen, G. Piping network design of geothermal district heating systems: Case study for a university campus. Energy 2010, 35, 3256–3262. [Google Scholar] [CrossRef]

- Ivner, J.; Viklund, S.B. Effect of the use of industrial excess heat in district heating on greenhouse gas emissions: A systems perspective. Resources. Conserv. Recycl. 2015, 100, 81–87. [Google Scholar] [CrossRef]

- Michon, X. Agricultural use of waste heat from condensing circuits of French nuclear power stations [warm water, greenhouses and plastic tunnels, waste water, Saint-Laurent des Eaux, Dampierre-en-Burly, Buguey, Chinon, Le Blayais]. J. Int. Inf. Syst. Agric. Sci. Technol. (AGRIS) 1986, 71, 6. [Google Scholar]

- Lee, J.H.; Yoon, Y.B.; Hyun, I.T.; Lee, K.H. The Korean effect of pip network materials and distance on unused energy source system performance for large-scale horticulture facilities. J. Korea Inst. Ecol. Archit. Environ. (KIEAE) 2014, 14, 119–125. [Google Scholar]

- Lee, J.H.; Hyun, I.T.; Yoon, Y.B.; Lee, K.H.; Nam, Y.J. Energetic and economic assessment of pipe network effects on unused energy source system performance in large-scale horticulture facilities. Energies 2015, 8, 3328–3350. [Google Scholar] [CrossRef]

- Ryou, Y.S.; Kang, Y.K.; Jang, J.K.; Kim, J.G.; Kang, G.C. Heat exchanger design of a heat pump system using the heated effluent of thermal power generation plant as a heat source for greenhouse heating. J. Korean Soc. Bio Environ. Control 2012, 21, 372–378. [Google Scholar] [CrossRef]

- Electric Power Statistics Information System (EPSIS). Available online: https://epsis.kpx.or.kr (accessed on 16 August 2015).

- Yu, M.G.; Cho, J.H.; Nam, Y.J. Feasibility study of the energy supply system for horticulture facility using dynamic energy simulation. J. Korea Inst. Ecol. Archit. Environ. (KIEAE) 2015, 15, 105–111. [Google Scholar] [CrossRef]

- Takuya, T.; Tsuyoshi, F.; Liang, D.; Minoru, F.; Makoto, O. Feasibility assessment of the use of power plant-sourced waste heat for plant factory heating considering spatial configuration. J. Clean. Prod. 2014, 81, 60–69. [Google Scholar]

- Korean Rural Development Administration. New Agricultural Energy-Saving Technology for the Improvement of Farm Management Balance; Korean Rural Development Administration (RDA): Jeonju, Korea, 2010. [Google Scholar]

- Korean Institute of Energy Research (KIER). Available online: http://kredc.kier.re.kr/kier (accessed on 17 August 2015).

- Park, J.C. Design direction and standard model of korean-type glasshouse. J. Korean Soc. Bio Environ. Control 1993, 6, 16–30. [Google Scholar]

- DAESUNGHEATPUMP. Available online: http://www.dsheatpump.co.kr (accessed on 17 August 2015).

- Korean Rural Development Administration (RDA). Available online: http://www.rda.go.kr (accessed on 17 August 2015).

- Korea National Oil Corporation (KNOC). Available online: http://www.opinet.co.kr (accessed on 17 August 2015).

- Korean Electric Power Corporation (KEPCO). Available online: http://cyber.kepco.co.kr (accessed on 15 July 2014).

| Plant | Thermal Effluent | Plant | Thermal Effluent | ||

|---|---|---|---|---|---|

| Capacity (106 ton/Year) | Δt (°C) | Capacity (106 ton/Year) | Δt (°C) | ||

| West Incheon | 4.6 | 6.4 | Youngnam | 2.3 | 8~8.3 |

| Incheon | 2.2 | 7~10.2 | Wolseung | 47.2 | 8.2 |

| New Incheon | 8.7 | 7 | Posco, Pohang | 7.0 | 7~8 |

| Posco Incheon | 1.9 | 10~13.5 | Uljin | 60.8 | 7.2 |

| Youngheung | 17.4 | 6.4 | Donghae | 3.9 | 7.2 |

| Pyeongtaek | 5.9 | 10 | Youngdong | 1.7 | 9.2 |

| gs Bugok | 1.8 | 7 | Yeosu | 2.3 | 6.4~9.4 |

| Dangjin | 20.5 | 6.4~6.8 | Honam | 6.3 | 8.8 |

| Taean | 26.2 | 7.7 | Gwangyang | 12.6 | 5~6 |

| Boryung | 39.1 | 6.4~7 | Yulchon | 2.4 | 7 |

| Seocheon | 2.4 | 9.4 | Posco, Gwangyang | 8.6 | 7~8 |

| Younggwang | 74.6 | 7.4 | Hadong | 24.3 | 6.4 |

| Pusan | 7.5 | 8.2 | Samcheonpo | 27.4 | 6.4~9.5 |

| Geori | 44.6 | 4.7 | Jeju | 2.1 | 7 |

| Ulsan | 13.4 | 7~10 | South Jeju | 0.3 | 7 |

| Plant | Reserves (Tcal/Year) | Heating Available Capacity (Tcal/Year) | Plant | Reserves (Tcal/Year) | Heating Available Capacity (Tcal/Year) |

|---|---|---|---|---|---|

| West Incheon | 2937 | 1020 | Youngnam | 1870 | 649 |

| Incheon | 1887 | 655 | Wolseung | 38,612 | 13,407 |

| New Incheon | 6076 | 2110 | Posco,Pohang | 5238 | 1819 |

| Posco Incheon | 2227 | 773 | Uljin | 43,672 | 15,164 |

| Youngheung | 11,109 | 3857 | Donghae | 2801 | 973 |

| Pyeongtaek | 5886 | 2044 | Youngdong | 1560 | 542 |

| gs Bugok | 1257 | 436 | Yeosu | 1813 | 629 |

| Dangjin | 13,498 | 4687 | Honam | 5531 | 1920 |

| Taean | 20,126 | 6988 | Gwangyang | 6914 | 2401 |

| Boryung | 26,135 | 9075 | Yulchon | 1676 | 582 |

| Seocheon | 2251 | 781 | Posco, Gwangyang | 6435 | 2234 |

| Younggwang | 55,073 | 19,122 | Hadong | 15,515 | 5387 |

| Pusan | 6135 | 2130 | Samcheonpo | 21,731 | 7546 |

| Geori | 20,912 | 7261 | Jeju | 1467 | 509 |

| Ulsan | 11,363 | 3945 | South Jeju | 210 | 73 |

| Fixed Value | |

|---|---|

| Simulation period | January, February, March, November, December |

| Heating schedule | 17:00~08:00 |

| Agricultural crops | Paprika |

| Set heating temperature | 18 °C |

| Outer wall | Glass (5.29 W/m2·K) |

| Ventilation | 1.57 times/h |

| Location | January | February | March | November | December | Peak (W/m2) |

|---|---|---|---|---|---|---|

| Dangjin | 58 | 48 | 31 | 30 | 51 | 190 |

| Hadong | 48 | 40 | 26 | 24 | 41 | 166 |

| Youngdong | 50 | 43 | 28 | 25 | 42 | 177 |

| Location | Heating Energy Consumption | Pumping Energy Consumption |

|---|---|---|

| Dangjin | 605,556 | 32,589 |

| Hadong | 497,222 | 35,566 |

| Youngdong | 522,222 | 15,232 |

| Location | Average Thermal Supply (Gcal/h) | Peak Heating Load (Mcal/hah) | Horticulture Scale (ha) |

|---|---|---|---|

| Dangjin | 2083 | 1629 | 1279 |

| Hadong | 2388 | 1419 | 1683 |

| Youngdong | 240 | 1513 | 159 |

| Fuel | System | Investment Cost (Won/ha) |

|---|---|---|

| Diesel | Boiler | 3,600,000 |

| Thermal effluent | Heat pump | 1,000,000,000 |

| Fuel | Price | Unit |

|---|---|---|

| Tax free diesel | 605 | Won/L |

| Agricultural electricity | 39.2 | Won/kWh |

| Location | Diesel Consumption (L) | Diesel Price (Won) |

|---|---|---|

| Dangjin | 253,194 | 154,195,122 |

| Hadong | 207,898 | 126,609,756 |

| Youngdong | 218,351 | 132,975,610 |

| Location | Electricity Consumption (kWh) | Electricity Price (Won) |

|---|---|---|

| Dangjin | 638,144 | 26,530,290 |

| Hadong | 532,788 | 21,931,009 |

| Youngdong | 537,455 | 23,072,293 |

| Dangjin | Hadong | Youngdong | |

|---|---|---|---|

| Initial cost | 100,000,473 | 52,000,631 | 13,000,158 |

| Operation cost | 13,265,145 | 5,702,062 | 1,499,699 |

| Annual cost reduction | 63,832,416 | 27,216,474 | 7,143,716 |

| Payback period | 2 | 3 | 2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, M.G.; Nam, Y. Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems. Energies 2016, 9, 112. https://doi.org/10.3390/en9020112

Yu MG, Nam Y. Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems. Energies. 2016; 9(2):112. https://doi.org/10.3390/en9020112

Chicago/Turabian StyleYu, Min Gyung, and Yujin Nam. 2016. "Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems" Energies 9, no. 2: 112. https://doi.org/10.3390/en9020112

APA StyleYu, M. G., & Nam, Y. (2016). Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems. Energies, 9(2), 112. https://doi.org/10.3390/en9020112