1. Introduction

Metro systems aim to provide frequent, safe and comfortable journeys to a large number of passengers in a short period of time, which make them become an important part of public transportation to relieve traffic congestion. In addition, metro systems can transport more passengers with less energy consumption and, thus, are regarded as a green transportation mode when compared to buses and private car services. However, due to the large-scale operations of metro systems (especially in big cities) and high-frequency services, a great amount of energy is consumed for the daily operation. For example, in Beijing metro systems, there are 18 operating lines, and the passengers can on average reach 10 million per day, which could increase to 11.5 million for peak periods. The corresponding annual energy consumption is over 500 MWh. Hence, improving the energy efficiency of metro systems will be of great interest for the operation company to reduce the energy consumption, as well as the operational cost. Furthermore, according to the investigation in the Railenergy project [

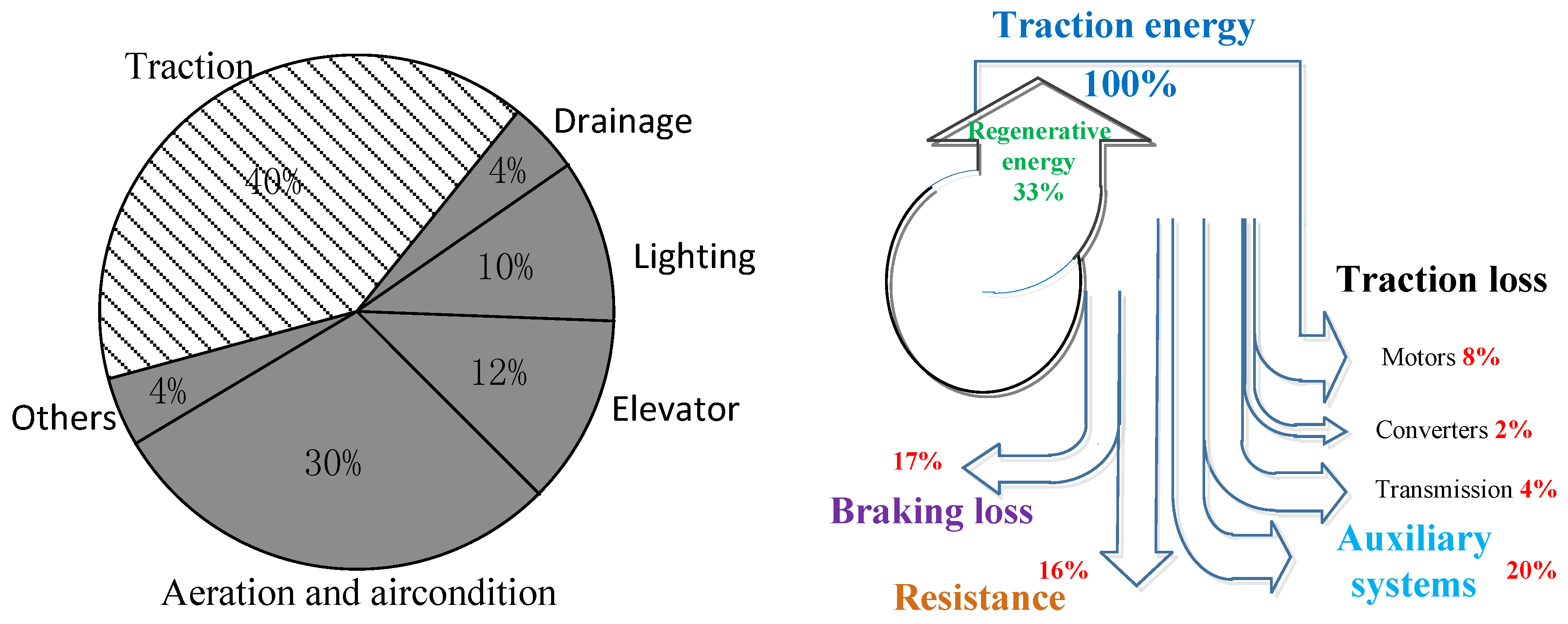

1], the energy consumption in metro systems is mainly consumed in traction, aeration, air condition, elevator, lighting and drainage (see

Figure 1), among which the traction energy plays the most important role. This implies that reducing the traction energy has a great potential in improving the energy efficiency of metro systems, which will be studied in this paper consequently.

Figure 1.

Energy consumption in metro systems.

Figure 1.

Energy consumption in metro systems.

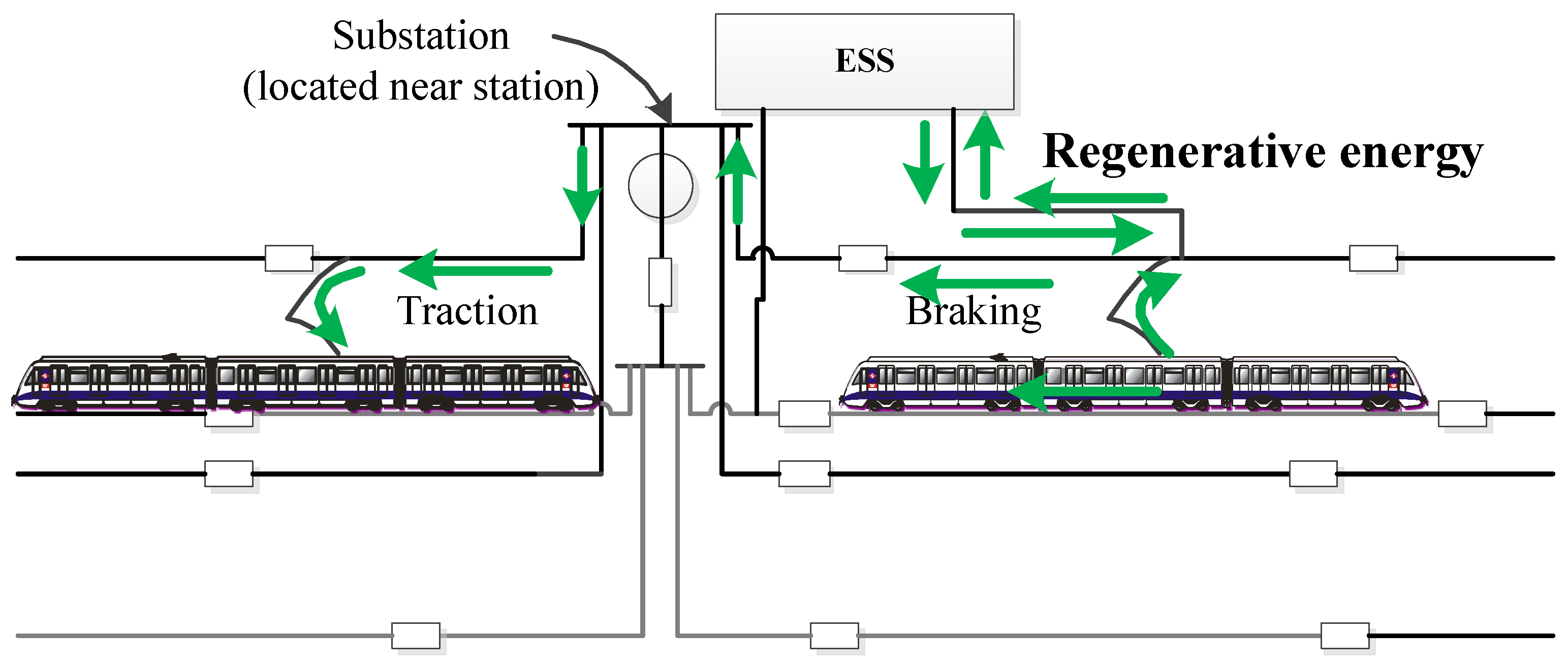

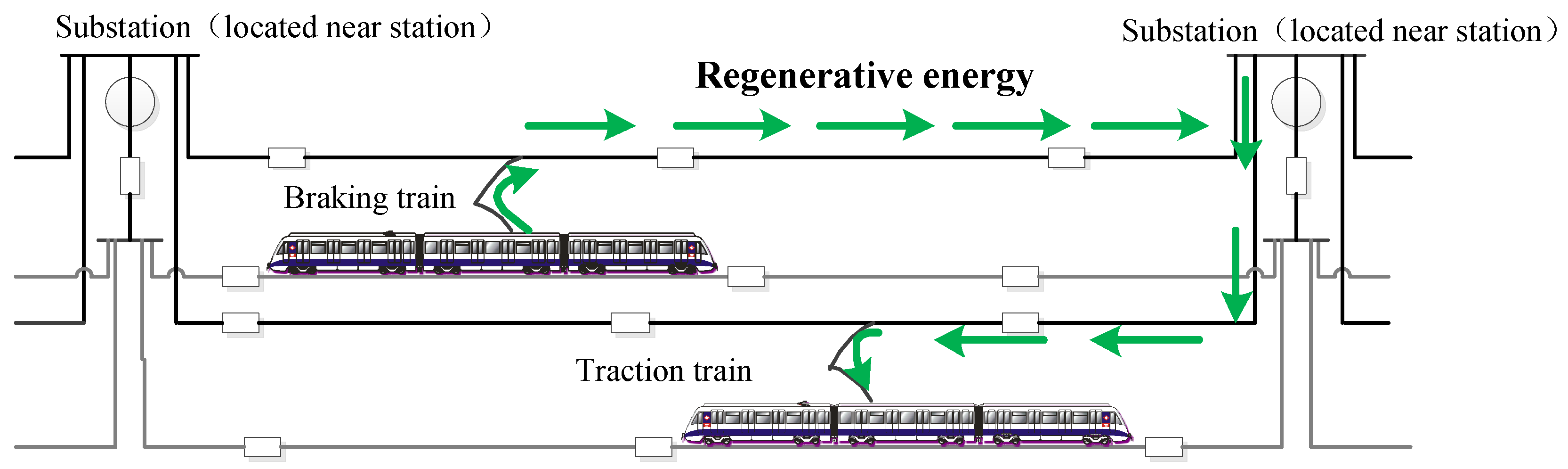

As shown in

Figure 1, the traction energy absorbed from the power supply system is mainly consumed at the auxiliary system, overcoming the resistance, traction loss and the braking loss. For most metro systems, the train’s kinetic energy can be converted back to electric energy when trains apply regenerative braking. This part of regenerative braking energy can be reused by itself, stored in on-board energy storage systems or be transmitted backwards to the overhead catenary or the third rail and utilized by other trains,

i.e., the regenerative energy could be reused in the systems. Hence, the research on reducing the train traction energy consists of two aspects: cutting down the losses and increasing the reused regenerative energy.

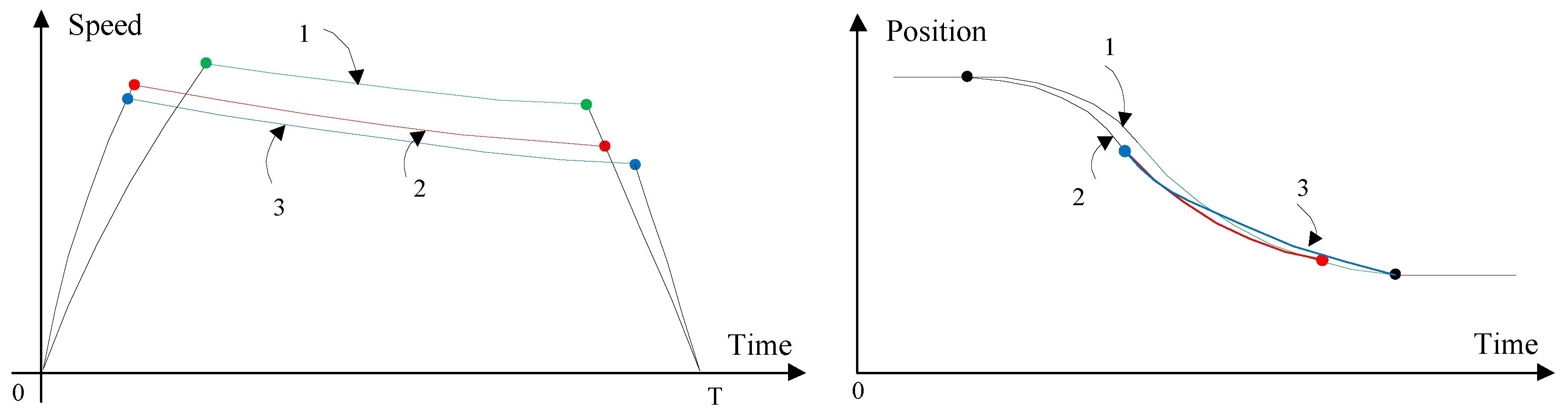

From the view of system engineering, the energy-efficient strategies can also be classified into operational strategies and energy-efficient system design. Operational strategies aim to optimize the utilization of the traction energy with the given infrastructure and vehicle conditions, e.g., energy-efficient driving strategy and timetable optimization. For a given interval, many driving strategies are feasible with the fixed trip time, among which the energy-efficient driving strategy consumes the minimum energy. Many literature works studied the optimal train control strategies to minimize the mechanical traction energy [

2,

3]. The constraints in the optimal train control model include the trip time, trip distance, maximum traction force, the maximum braking force and speed limit. Additionally, the optimization problem can be solved by analytic methods [

4,

5], numerical methods [

6,

7] and searching algorithms [

8,

9]. Differing from the works mentioned above, this paper gives a detailed analysis on how the factors in the optimal train control model influence the trains’ energy consumption and presents some possible energy-efficient strategies for metro systems. Recently, theoretical studies have been directed towards the problem of designing an energy-efficient timetable to save energy [

6,

10]. Albrecht [

10] proposed a dynamic programming approach to find the energy-efficient trip times based on the solution to the optimal train control problem. Su [

6] used an iterative algorithm to obtain the driving strategy for the entire route, which integrated the driving strategy optimization and the distribution of the trip time. Scheepmaker [

11] incorporated energy-efficient train operation into the railway timetable by distributing the time supplements into segments, and the robustness of the generated timetable was analyzed. Similar studies can be found in [

12,

13]. Su [

14] proposed a cooperative train control model to efficiently use the regenerative energy by adjusting the departure time of the accelerating train. Gong [

15] proposed an energy-efficient operation methodology for metro lines, including timetable optimization and the driving strategy optimization. The proposed approach in [

15] can adjust the dwell time of trains for better utilization of the regenerative energy.

Energy-efficient system design integrates the efficient strategies into the design process, such that the operational energy consumption could be reduced. To some extent, the energy-efficient system design is of greater significance. Some researchers have studied smart infrastructure and vehicle design methods to improve the efficiency of the metro systems, including the mass reduction, the energy-efficient slopes, the installation of energy storage and the improvement of aerodynamics. Carruthers [

16] analyzed the influence of the material selection on the train mass and proposed that 7% of the savings in energy can be achieved with a 10% reduction in the train mass. Similar studies were done by Rochard [

17]. Walter [

18] gave an overview of the various possibilities of increased energy efficiency in electric railway systems, and highly reliable energy storage was focused on to save energy and operation cost in the paper. Wang [

19] and Xia [

20] studied the optimization on the location and size of the energy storage systems in metro lines, acting as a compromise between satisfying better energy savings, voltage profile and lower installation cost.

The contribution of this paper is to create a connection between the operational strategies and the system design strategies. The relative energy-efficient strategies are analyzed, and the influence of the system design on the operational energy consumption can be quantitatively evaluated with the optimal train control solution. The simulation results can give the decision makers an overview of the energy-efficient performances with different strategies, which may help them to balance with the investment according to their practical experience and make the final decision from a short- or a long-term view.

The rest of this paper is organized as follows. In

Section 2, the optimal train control model and the corresponding solution are presented. In

Section 3, some energy-efficient strategies with the optimal train control model and the energy-efficient performances are evaluated with the practical data of the Beijing Yizhuang metro line. A short discussion and future work are included in

Section 4.

2. Optimal Train Control Model

The optimal train control problem applies the optimal control theory to optimize the driving strategy between successive stations, such that the mechanical traction energy is minimized [

3,

21].

E,

T and

v are the energy consumption, trip time and train speed, respectively.

F denotes the available maximum traction force, and

is the relative traction force,

i.e., the ratio between the applied traction force and the maximum traction force. The mass-point model of the train is widely used to describe the train movement as the following equations:

where

B and

denote the available maximum braking force and the relative braking force.

g is the gradient and curve resistance.

r is the running resistance, which includes the friction and air resistance. Generally, trains will not apply the traction and braking forces at the same time. Hence,

The boundary conditions and the constraint on the speed limit are:

In addition, the trip distance constraint should be satisfied,

Additionally, the constraints on the relative traction and braking force are shown as follows.

The optimal train control model is concluded as Equations (

1) to (

6). By using the the Pontryagin maximum principle, the optimal driving strategies are proven to consist of maximum acceleration, cruising with partial power, cruising with partial braking, coasting and maximum braking [

3,

5]. The previous works [

6,

7] have proposed a numerical algorithm to calculate the energy-efficient driving strategy, which includes the control sequences and the corresponding switching points. The proposed algorithm will firstly present an iterative algorithm to calculate the driving strategy for one section. Then, the solution is extended to solve the driving strategy of multiple sections by distributing the energy units to sections.

2.1. Calculation of the Driving Strategy for One Section

It is noted that the minimum energy consumption is uniquely determined by the trip time and

vice versa. Hence, the energy-efficient driving strategy can be calculated with either the known trip time or the known energy consumption. For a section (section in the algorithm is defined as a small part of the trip with a constant gradient and speed limit), the driving strategies of each section will be maximum acceleration (MA), cruising (CR), coasting (CO) and maximum braking (MB) [

22]. With the given energy consumption, we can firstly generate the speed sequences for the MA phase. The CR speed sequences will be calculated with the remaining energy when the train speed has reached the speed limit. The speed sequences of the rest of the journey will be covered by the CO and MB phases. The details for obtaining the speed sequences of a given section are described in Algorithm 1.

| Algorithm 1: calculation of the energy-efficient driving strategy for a given section. |

- Step 1:

Initialize the initial speed and the energy consumption Ej for section j; - Step 2:

Divide the section into nj pieces, such that the distance of each piece is Δx; - Step 3:

Generate the speed sequences for the MA phase; , while Ej > 0, < V, do - Step 4:

If the speed has reached the speed limit, then partial braking or partial power is applied to keep cruising, and the speed sequences are calculated as - Step 5:

Generate the speed sequences for CO phase as, ; - Step 6:

If the MB phase exists, we calculate the braking speed sequences {} as, , , and then, let ; - Step 7:

Return the optimal speed sequences and the trip time of this section .

|

is a small distance unit, which is assumed to be 1 m in the algorithm.

2.2. Calculation of the Driving Strategy for Multiple Sections

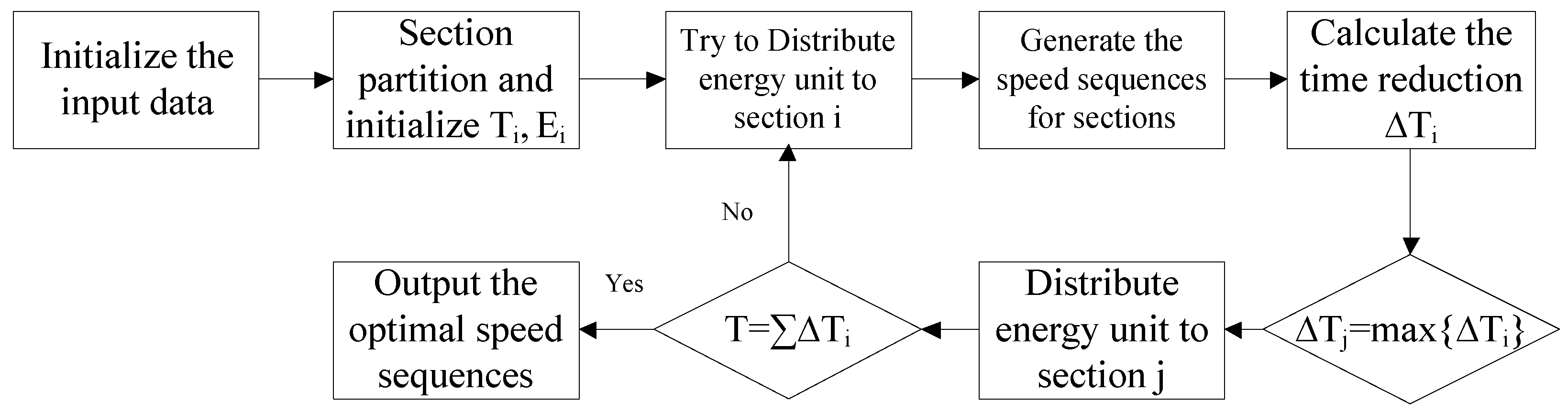

For dealing with variable gradients and speed limits, the trip is divided into several sections, such that each section has the constant gradient and speed limit. The speed sequence of each section can be generated by Algorithm 1. Then, based on a primary solution, the energy unit (a small amount of energy, which is assumed to be 0.05 kW·h in this algorithm) will be attempted to distribute to each section for achieving the corresponding time reductions. After a comparison among these time reductions, the energy unit will be finally assigned to the section that can achieve the maximum time reduction. This distribution process will be repeated to shorten the primary trip time until the practical trip time is delivered, after which the driving strategy and the speed profile will be obtained. The flow chart of the algorithm is described in

Figure 2 [

6,

7,

23].

Figure 2.

The flow chart for calculating the energy-efficient driving strategy of multiple sections.

Figure 2.

The flow chart for calculating the energy-efficient driving strategy of multiple sections.

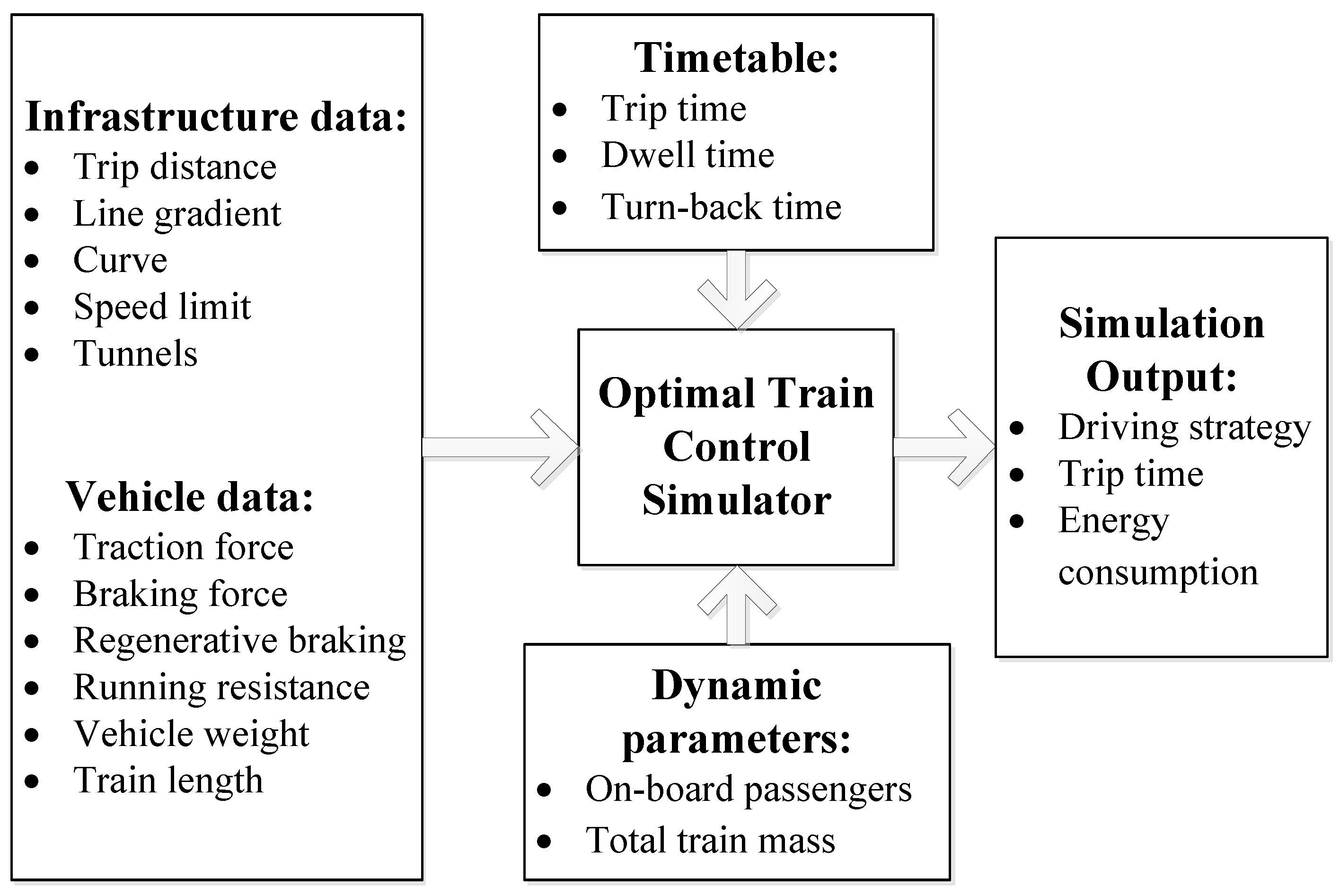

The algorithm is used to design an Optimal Train Control Simulator (OTCS). The trip distance, trip time, gradient, resistance, traction and braking characteristics and train mass are the inputs. The energy-efficient train control strategies and the corresponding energy consumptions are the outputs (see

Figure 3). When the train stops at stations are taken as a speed limit of 0 km/h, the OTCS can also be used to calculate the energy-efficient driving strategy for multiple interstations, as well as the trip time at each interstation.

Figure 3.

The flow chart of the OTCS.

Figure 3.

The flow chart of the OTCS.

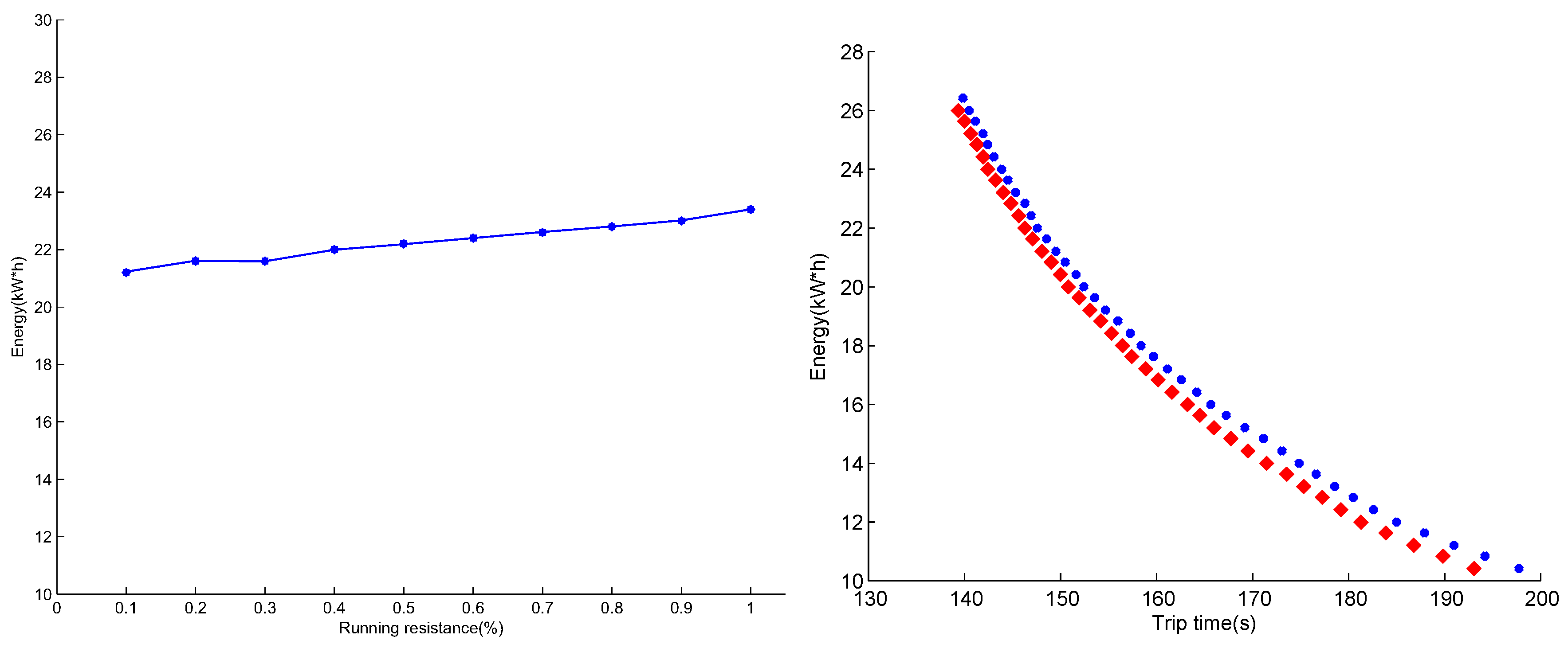

4. Conclusions and Future Research

The main contribution of this paper is to analyze how the factors in the optimal train control model influence the traction energy consumption based on the OTCS. A connection between the energy-efficient operational strategies and energy-efficient system design strategies has been built. Some energy-efficient design strategies, such as mass reduction, energy-efficient timetable, improving the air aerodynamics and friction, the good design of gradients, increasing the maximum traction and braking force and introducing regenerative braking, are concluded. These energy-efficient strategies are evaluated with the data of the Beijing Yizhuang metro line, as shown in

Table 11. The simulation results illustrate that the energy reductions range from 1.5%–15% if appropriate improvement on one factor is made, which may be over 20% by integrating all of the energy-efficient strategies. Note that mass reduction, energy-efficient slopes and the improvement of vehicle traction and braking characteristics aim to achieve a fast acceleration process with the constraint of riding comfort. Except for saving energy, the installation of the ESSs on board may also increase the traction energy consumption by increasing the train mass. Hence, the integrated performance of all of the strategies is not simply the sum of all single strategies. The proposed research could give important implications to the operators, sponsors and engineers that the energy-efficient strategies should penetrate from the system design and operations procedures.

Table 11.

Evaluation of different energy-efficient strategies.

Table 11.

Evaluation of different energy-efficient strategies.

| Factors | Strategies | Energy-Saving% |

|---|

| Trip time | Timetable optimization | 3.5 |

| Train mass | 10% reduction | 7 |

| Gradient | Optimized slopes distance | 2 |

| Maximum traction force | Increase by 10% | 3 |

| Maximum braking force | Increase by 5% | 1.5 |

| Regenerative braking | Installation ESSs | 15 |

| Regenerative braking | Timetable optimization | 11 |

| Running resistance | 15% reduction | 3 |

The application of the proposed energy-efficient strategies will be further studied in our future work. For example, the reduction of the train mass and the increasing of the maximum traction and braking forces may need new reformed vehicles. It is better to consider the design of the energy-efficient gradient in the system design period. When installing the ESSs, the costs and benefits should also be analyzed. This research will help the operators, sponsors and engineers to make the final decision.