Production of Synthetic Natural Gas from Refuse-Derived Fuel Gasification for Use in a Polygeneration District Heating and Cooling System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Thermodynamic Model

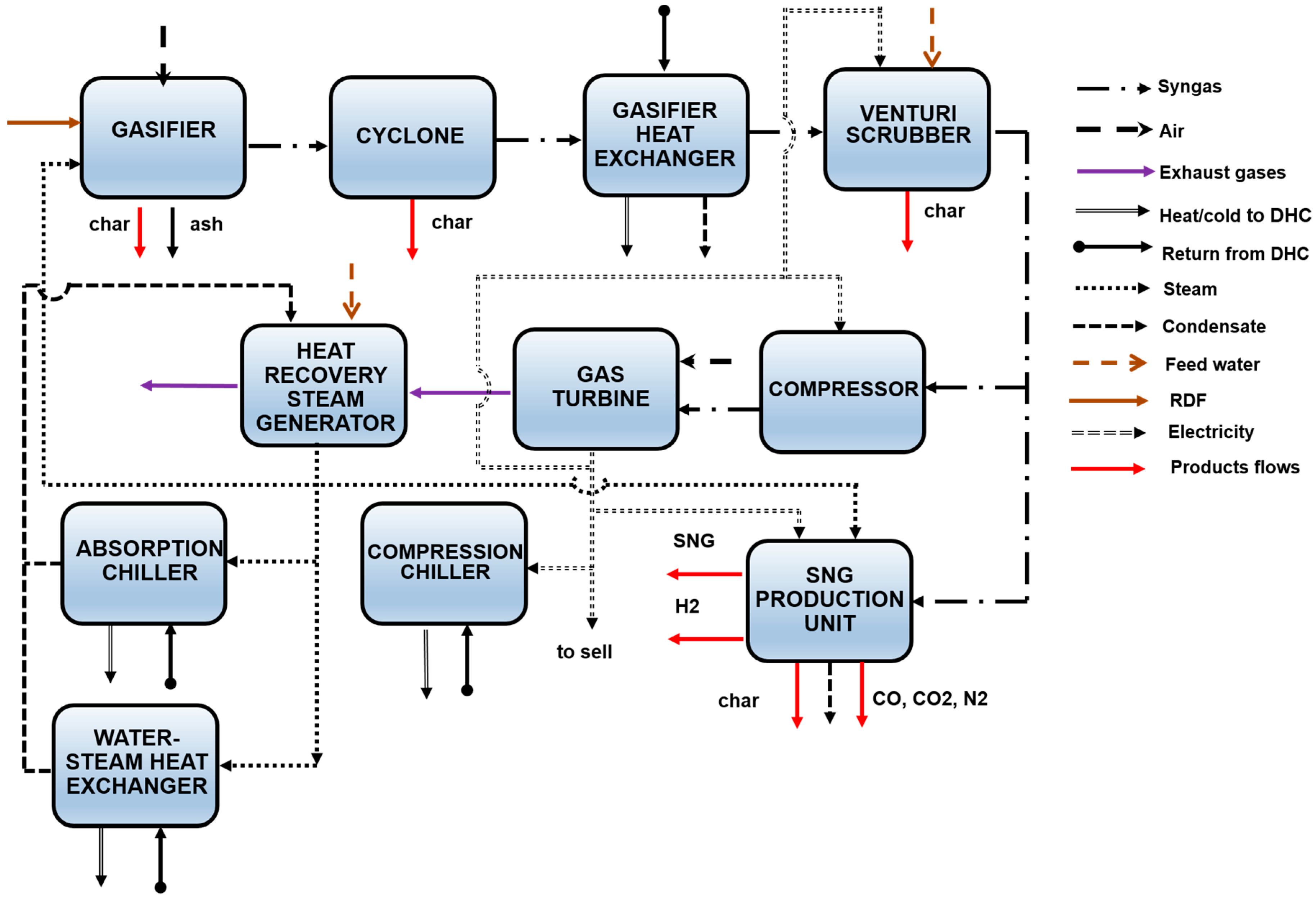

- Ideal gas behavior;

- GT operates always at full load;

- The gasifier and the SNG production units have priority in steam supply—excess steam (if available) is delivered to the absorption chiller and to the WSt HEX;

- The main internal electricity consumers are compressors, Venturi scrubbers and the compression chiller;

- The heat load for the DHC customers is supplied from two sources: (i) From the waste heat from the gasifier HEX and the SNG production units; and (ii) from the WSt HEX;

- The cold load for the DHC customers is supplied from the absorption and compression chillers, with the priority given to the former;

- The exhaust gas energy potential is exploited in the HRSG to meet the steam demand;

- The condensate return comes only from the WSt HEX and the absorption chiller—condensate losses are compensated by the feed water influx.

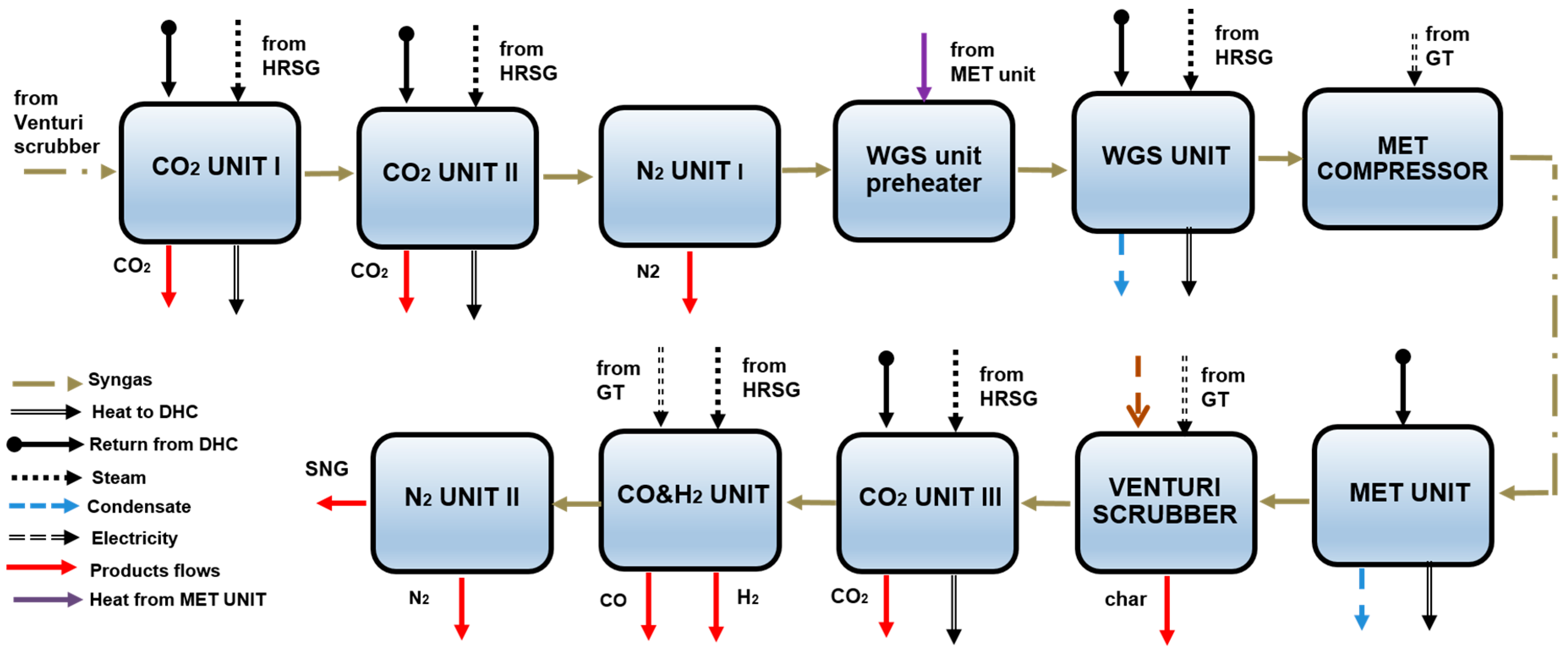

- Gasification was assumed to occur through two main reactions: the water–gas shift (WGS) reaction:and the methanation (hydrogasification) reaction:Reactions (2) and (3) are prevalent between 1073 K and 1173 K [34]. More detailed information on the reaction mechanisms may be found in [22]; the appropriate equilibrium constants were taken from references [35,36,37]. The model was validated with experimental data from reference [38], while the results of the validation may be found in reference [30].Figure 2 shows a schematic of the proposed SNG production unit. This unit can be divided into three components according to their functionality, namely:

- A first component that is responsible for the syngas conditioning, where the syngas is purified from CO2 and N2 prior to the water–gas shift unit (WGS unit). It includes three units: CO2 units I and II for CO2 removal, and a N2 unit I for N2 removal. The CO2 removal process requires two units to ensure molar ratios smaller than 0.5 mol. % to favor the direct WGS reaction in the WGS unit;

- A second component, where the pretreated syngas is transformed into SNG through methanation. In the preheater of the WGS unit, the syngas in heated up by the heat flow from the methanation unit (MET unit) to guarantee thermodynamic equilibrium in the WGS unit. Subsequently, in the WGS reactor, the H2 and CO contents are modified, while the methanation compressor adjusts the syngas pressure to 3000 kPa to ensure the occurrence of the direct methanation reaction. Finally, in the methanation unit (MET unit), the syngas is transformed into SNG;

- A third component, where the SNG is upgraded and the impurities are removed (H2, CO2, CO, char and N2). In order to be transported through the NG distribution networks and the SNG composition, and, in particular, the impurities content has to be adjusted to the NG average contaminant level [15]. To this end, the average NG composition for the Magreb pipeline (Algeria—Portugal) [39] was taken as a reference for allowable H2, CO and CO2 contents. The H2 and CO contents were set up in accordance with the European Association for the Streamlining of Energy Exchange-gas (EASEE-gas) to prevent flashback in the GT. The maximum CO2 content was set equal to 2.5 mol. % [15]. The SNG upgrading component also includes a Venturi unit, where the char is removed from the gas flow; a CO2 unit III, where the SNG is cleaned from CO2; a CO&H2 unit, where H2 and CO are removed from the gas; and, finally, a N2 unit II, where the SNG is cleaned of N2.

2.2. Economic Model

3. Results and Discussion

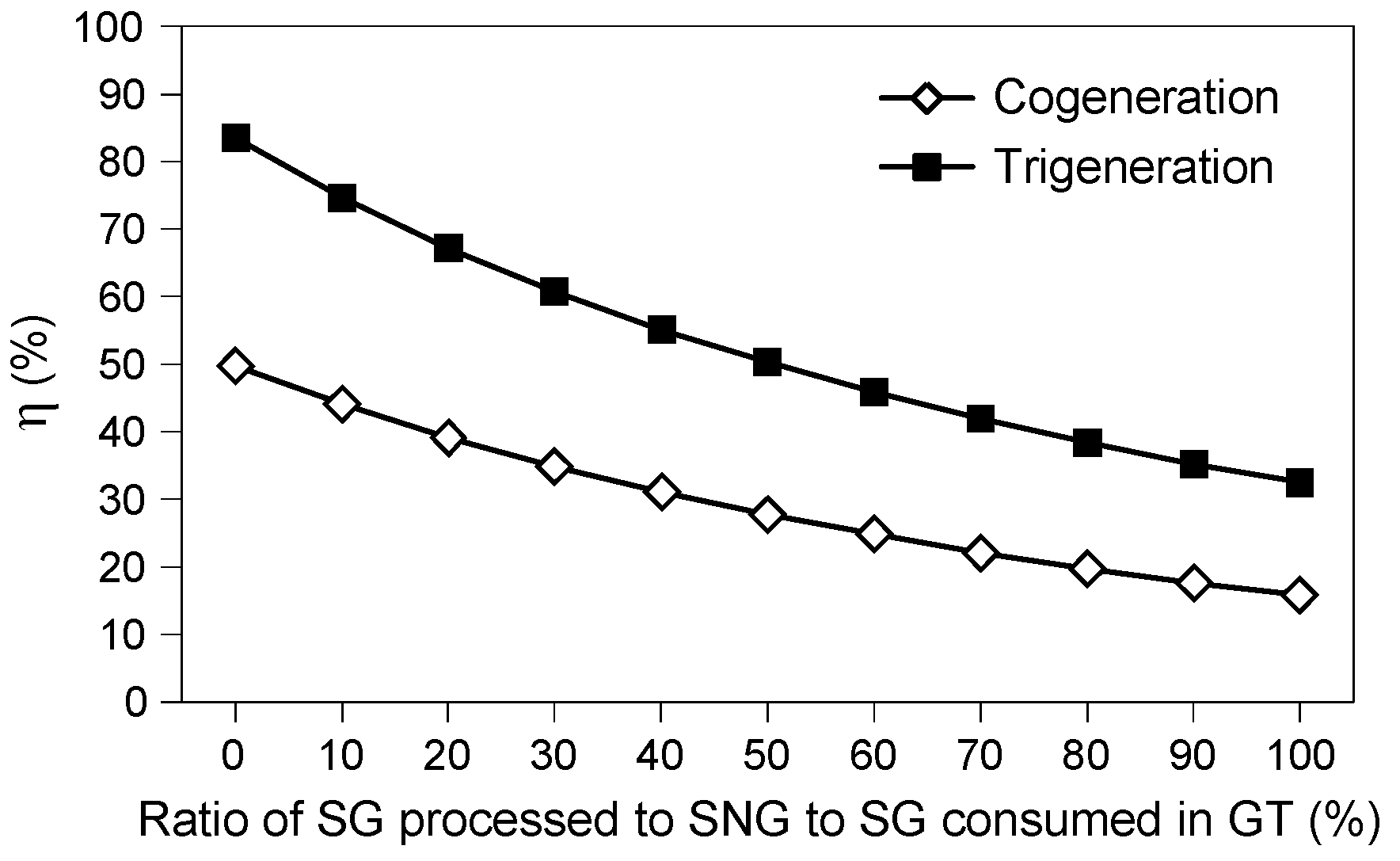

3.1. Thermodynamic Analysis

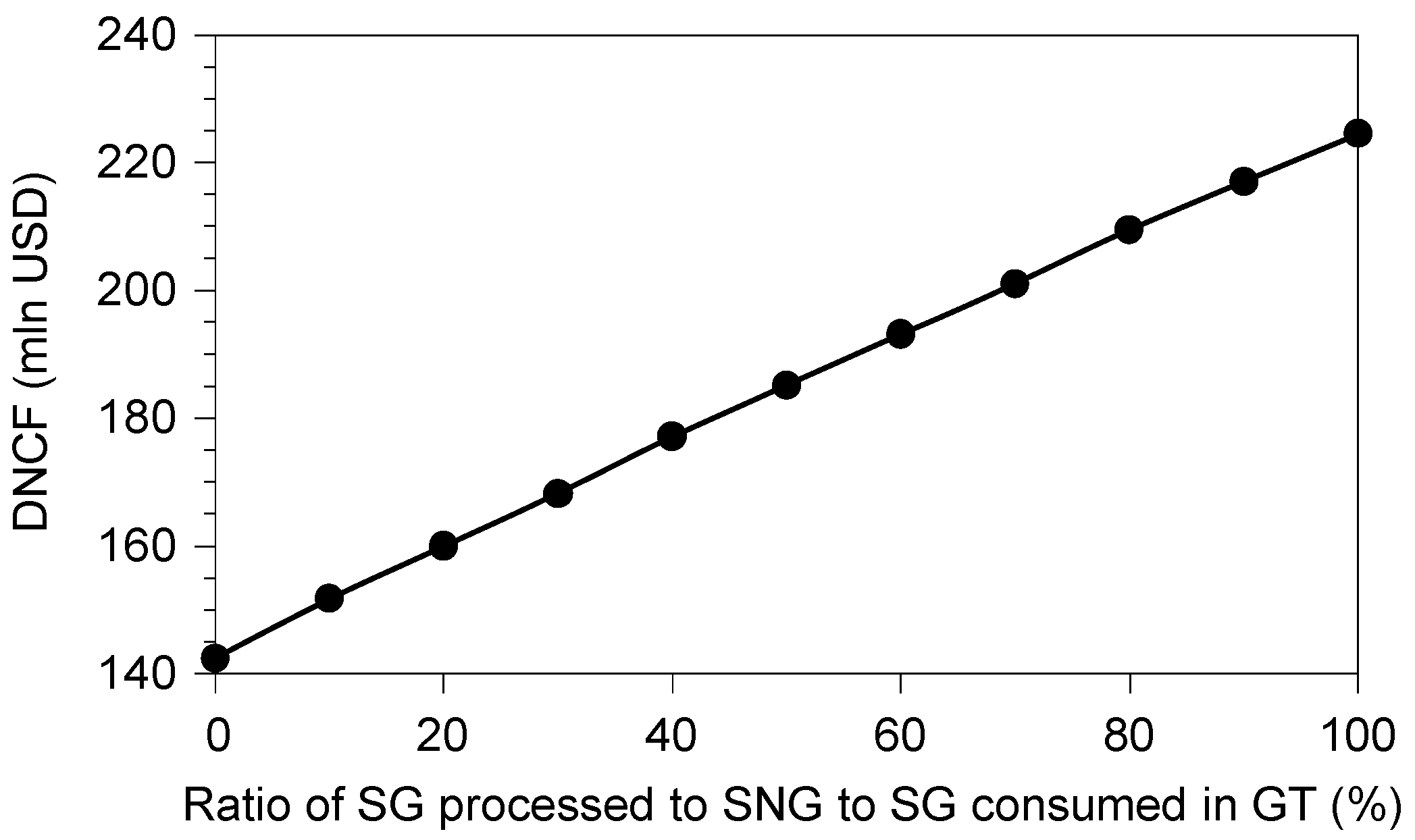

3.2. Economic Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Energy Agency. Key World Energy Statistics. 2014. Available online: https://www.iea.org (accessed on 6 September 2016).

- Serra, L.M.; Lozano, M.-A.; Ramos, J.; Ensinas, A.V.; Nebra, S.A. Polygeneration and efficient use of natural resources. Energy 2009, 34, 575–586. [Google Scholar] [CrossRef]

- Ilic, D.D.; Dotzauer, E.; Trygg, L. District heating and ethanol production through polygeneration in Stockholm. Appl. Energy 2012, 91, 214–221. [Google Scholar] [CrossRef]

- Rudra, S.; Rosendahl, L.; Blarke, M.B. Process analysis of a biomass-based quad-generation plant for combined power, heat, cooling, and synthetic natural gas production. Energy Convers. Manag. 2015, 106, 1276–1285. [Google Scholar] [CrossRef]

- Gustavsson, C.; Hulteberg, C. Co-production of gasification based biofuels in existing combined heat and power plants—Analysis of production capacity and integration potential. Energy 2016, 111, 830–840. [Google Scholar] [CrossRef]

- Starfelt, F.; Daianova, L.; Yan, J.; Thorin, E.; Dotzauer, E. The impact of lignocellulosic ethanol yields in polygeneration with district heating—A case study. Appl. Energy 2012, 92, 791–799. [Google Scholar] [CrossRef]

- Gerssen-Gondelach, S.J.; Saygin, D.; Wicke, B.; Patel, M.K.; Faaij, A.P.C. Competing uses of biomass: Assessment and comparison of the performance of bio-based heat, power, fuels and materials. Renew. Sustain. Energy Rev. 2014, 40, 964–998. [Google Scholar] [CrossRef]

- Ilic, D.D.; Dotzauer, E.; Trygg, L.; Broman, G. Integration of biofuel production into district heating. Part I: An evaluation of biofuel production costs using four types of biofuel production plants as case studies. J. Clean. Prod. 2014, 69, 176–187. [Google Scholar] [CrossRef]

- Gustavsson, L.; Truong, N.L. Coproduction of district heat and electricity or biomotor fuels. Energy 2011, 36, 6263–6277. [Google Scholar] [CrossRef]

- Daianova, L.; Dotzauer, E.; Thorin, E.; Yan, J. Evaluation of a regional bioenergy system with local production of biofuel for transportation, integrated with a CHP plant. Appl. Energy 2012, 92, 739–749. [Google Scholar] [CrossRef]

- Ahrenfeldt, J.; Thomsen, T.P.; Henriksen, U.; Clausen, L.R. Biomass gasification cogeneration. A review of state of the art technology and near future perspectives. Appl. Therm. Eng. 2013, 50, 1407–1417. [Google Scholar] [CrossRef]

- Difs, K.; Wetterlund, E.; Trygg, L.; Söderström, M. Biomass gasification opportunities in a district heating system. Biomass Bioenergy 2010, 34, 637–651. [Google Scholar] [CrossRef]

- Heyne, S.; Thunman, H.; Harvey, S. Extending existing combined heat and power plants for synthetic natural gas production. Int. J. Energy Res. 2012, 36, 670–681. [Google Scholar] [CrossRef]

- Kohl, T.; Laukkanen, T.; Tuomaala, M.; Niskanen, T.; Siitonen, S.; Järvinen, M.P.; Ahtila, P. Comparison of energy efficiency assessment methods: Case bio-SNG process. Energy 2014, 74, 88–98. [Google Scholar] [CrossRef]

- European Association for the Streamlining of Energy Exchange-gas (EASEE-gas). CBP 2005–001/02. Common Business Practice. Harmonisation of Natural Gas Quality; EASEE-gas: Paris, France, 2005. [Google Scholar]

- Hermann, H.; Reinhard, R.; Klaus, B.; Reinhard, K.; Christian, A. Biomass CHP Plant Güssing: A Success Story. Available online: http://members.aon.at/biomasse/strassbourg.pdf (accessed on 14 December 2016).

- EU Waste Legislation. Available online: http://ec.europa.eu/environment/waste/legislation/a.htm (accessed on 12 November 2016).

- Molino, A.; Nanna, F.; Ding, Y.; Bikson, B.; Braccio, G. Biomethane production by anaerobic digestion of organic waste. Fuel 2013, 103, 1003–1009. [Google Scholar] [CrossRef]

- Molino, A.; Nanna, F.; Migliori, M.; Iovane, P.; Ding, Y.; Bikson, B. Experimental and simulation results for biomethane production using peek hollow fiber membrane. Fuel 2013, 112, 489–493. [Google Scholar] [CrossRef]

- Molino, A.; Braccio, G. Synthetic natural gas SNG production from biomass gasification—Thermodynamics and processing aspects. Fuel 2015, 139, 425–429. [Google Scholar] [CrossRef]

- Molino, A.; Migliori, M.; Ding, Y.; Bikson, B.; Giordano, G.; Braccio, G. Biogas upgrading via membrane process: Modelling of pilot plant scale and the end uses for the grid injection. Fuel 2013, 107, 585–592. [Google Scholar] [CrossRef]

- Fahlen, E.; Ahlgren, E.O. Assessment of integration of different biomass gasification alternatives in a district-heating system. Energy 2009, 34, 2184–2195. [Google Scholar] [CrossRef]

- Steubing, B.; Zah, R.; Ludwig, C. Life cycle assessment of SNG from wood for heating, electricity, and transportation. Biomass Bioenergy 2011, 35, 2950–2960. [Google Scholar] [CrossRef]

- De Souza-Santos, M.L. Solid Fuels Combustion and Gasification. Modeling, Simulation, and Equipment Operations, 2nd ed.; Chemical Rubber Company (CRC) Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory, 2nd ed.; Academic Press: Burlington, VT, USA, 2013. [Google Scholar]

- Klinghoffer, N.B.; Castaldi, M.J. Waste to Energy Conversion Technology; Woodhead: Cambridge, UK, 2013. [Google Scholar]

- Bidart, C.; Fröhling, M.; Schultmann, F. Municipal solid waste and production of substitute natural gas and electricity as energy alternatives. Appl. Therm. Eng. 2013, 51, 1107–1115. [Google Scholar] [CrossRef]

- Vitasari, C.R.; Jurascik, M.; Ptasinski, K.J. Exergy analysis of biomass-to-synthetic natural gas (SNG) process via indirect gasification of various biomass feedstock. Energy 2011, 36, 3825–3837. [Google Scholar] [CrossRef]

- Castanheira, J. The Lisbon DHC: A model for Southern Europe. In Proceedings of the 34th Congress of Euroheat & Power, Venice, Italy, 25–26 May 2009.

- Kabalina, N.; Costa, M.; Martin, V. Development of a polygeneration district heating and cooling system based on gasification of RDF. In Proceedings of the 14th International Symposium on District Heating and Cooling, Stockholm, Sweden, 7–9 September 2014; pp. 114–119.

- Kabalina, N.; Costa, M.; Yang, W.; Martin, A.; Santarelli, M. Exergy analysis of a polygeneration-enabled district heating and cooling system based on gasification of refuse derived fuel. J. Clean. Prod. 2017, 141, 760–773. [Google Scholar] [CrossRef]

- Desrosiers, R. Thermodynamics of gas-char reactions. In A Survey of Biomass Gasification; Reed, T.B., Ed.; Solar Energy Research Institute: Golden, CO, USA, 1979. [Google Scholar]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Thermodynamics of gas-char reactions: First and second law analysis. Chem. Eng. Sci. 2003, 58, 1003–1011. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J. From coal to biomass gasification: Comparison of thermodynamic efficiency. Energy 2007, 32, 1248–1259. [Google Scholar] [CrossRef]

- Zainal, Z.A.; Ali, R.; Lean, C.H.; Seetharamu, K.N. Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers. Manag. 2001, 42, 1499–1515. [Google Scholar] [CrossRef]

- Pedroso, D.T.; Aiello, R.C.; Conti, L.; Mascia, S. Biomass gasification on a new really tar free downdraft gasifier. Rev. Ciênc. Exatas 2005, 59–62. [Google Scholar]

- Barman, N.S.; Ghosh, S.; De, S. Gasification of biomass in a fixed bed downdraft gasifier: A realistic model including tar. Bioresour. Technol. 2012, 107, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Galvagno, S.; Casciaro, G.; Casu, S.; Martino, M.; Mingazzini, C.; Russo, A.; Portofino, S. Steam gasification of tyre waste, poplar, and refuse-derived fuel: A comparative analysis. Waste Manag. 2009, 29, 678–689. [Google Scholar] [CrossRef] [PubMed]

- Gas Properties. Specification M-00000-SPC-MI-0002. 2008. Available online: http://www.mercado.ren.pt/PT/Gas/InfoMercado/Documentacao/BibOutros/GasProperties.pdf (accessed on 24 August 2016).

- Rubin, E.S.; Rao, A.B. A Technical Economic and Environmental Assessment of Amine-Based CO2 Capture Technology for Power Plant Greenhouse Gas Control; Annual Technical Progress Report; U.S. Department of Energy, National Energy Technology Laboratory: Morgantown, WV, USA, 2002.

- Yang, Y.; Zhai, R. MEA-Based CO2 Capture Technology and Its Application in Power Plants, Paths to Sustainable Energy; Artie, N., Ed.; InTech: Rijeka, Croatia, 2010. [Google Scholar]

- Kohl, A.; Nielsen, R. Gas Purification; Gulf Publishing Company: Houston, TX, USA, 1997. [Google Scholar]

- Francois, J.; Abdelouahed, L.; Mauviel, G.; Pattison, F.; Mirgaux, O.; Rogaume, C.; Rogaume, Y.; Feidt, M.; Dufour, A. Detailed process modeling of a wood gasification combined heat and power plant. Biomass Bioenergy 2013, 51, 68–82. [Google Scholar] [CrossRef]

- Outotec® Cascade Scrubber. Specification. Available online: http://www.outotec.com (accessed on 24 August 2016).

- Gallagher, J.E.; Euker, C.A. Catalytic coal gasification for SNG manufacture. Int. J. Energy Res. 1980, 4, 137–147. [Google Scholar] [CrossRef]

- Gassner, M.; Marechal, F. Thermo-economic process model for thermochemical production of synthetic natural gas (SNG) from lignocellulosic biomass. Biomass Bioenergy 2009, 33, 1587–1604. [Google Scholar] [CrossRef]

- Duret, A.; Friedli, C.; Marechal, F. Process design of synthetic natural gas (SNG) production using wood gasification. J. Clean. Prod. 2005, 13, 1434–1446. [Google Scholar] [CrossRef]

- Li, S.; Ji, X.; Zhang, X.; Gao, L.; Jin, H. Coal to SNG: Technical progress, modeling and system optimization through exergy analysis. Appl. Energy 2014, 136, 98–109. [Google Scholar] [CrossRef]

- Bader, A.; Bauersfeld, S.; Brunhuber, C.; Pardemann, R.; Meyer, B. Modelling of a chemical reactor for simulation of a methanisation plant. In Proceedings of the 8th Modelica Conference, Dresden, Germany, 20–22 March 2011.

- Lide, D.R. (Ed.) Handbook of Chemistry and Physics, 89th ed.; Taylor and Francis: Boca Raton, FL, USA, 2009.

- Crundwell, F.K. Finance for Engineers. Evaluation and Funding of Capital Projects; Springer: London, UK, 2008. [Google Scholar]

- Frangopoulos, C. Introduction into environomics: Design, analysis and improvement of energy systems. In Proceedings of the American Society of Mechanical Engineers (ASME) Advanced Energy Systems Division, Atlanta, GA, USA, 1–6 December 1991; Volume 25, pp. 49–54.

- Pelster, S. Environomic Modeling and Optimization of Advanced Combined Cycle Cogeneration Power plants including CO2 Separation Units. Ph.D. Thesis, L’Ecole Polytechnigue Federale de Lausanne, Lausanne, Switzerland, 1998. [Google Scholar]

- Spelling, J.D. Hybrid Solar Gas-Turbine Power Plants. A Thermoeconomical Analysis. Ph.D. Thesis, Kunliga Technicka hoglosklan, Stockholm, Sweden, 2013. [Google Scholar]

- Phillips, S.; Aden, A.; Jechura, J.; Dayton, D.; Eggeman, T. Thermochemical Ethanol via Indirect Gasification and Mixed Alcohol Synthesis of Lignocellulosic Biomass; Technical Report NREL/TP-510–41168; National Renewable Energy Laboratory: Golden, CO, USA, 2007.

- Chemical Engineering. Available online: http://www.chemengonline.com/pci-home (accessed on 24 August 2016).

- Peters, M.S.; Timmerhaus, K.D. Plant Design and Economics for Chemical Engineers, 4th ed.; McGraw-Hill: Boston, MA, USA, 1991. [Google Scholar]

- Thiel, S.; Thomé-Kozmiencky, K.J. Co-combustion of solid recovered fuels in coal-fired power plants. Waste Manag. Res. 2012, 30, 392–403. [Google Scholar] [CrossRef] [PubMed]

| Equipment | Technology | Parameter | Value | Ref. |

|---|---|---|---|---|

| CO2 unit I, II and III | Absorption on monoethanolamine | Removal efficiency | 0.9 | [40] |

| Energy demand | 3.8 GJ/ton | [41] | ||

| Heat of CO2 absorption | 85 kJ/mole CO2 | [42] | ||

| N2 unit I and II | Absorption on organic metal complexes | Removal efficiency | 0.99 | - |

| Venturi scrubber | Wet scrubbing | Removal efficiency | 1.0 | [43] |

| Energy demand | 7 kWh/m3 | - | ||

| Water demand | 5–40 m3/h | [44] | ||

| CO&H2 unit | Cryogenic distillation | CO removal efficiency | 0.97 | [45] |

| H2 removal efficiency | 0.97 | |||

| Energy demand | 18751 kJ/kg |

| Parameter | Value |

|---|---|

| Tgas (K) | 1173 |

| ER | 0.03 |

| S/C | 2.2 |

| SNG production rate (%) | 10 |

| RDF price (Euro/ton [58]) | 10 |

| Discount rate (%) | 7 |

| Component | Syngas | SNG at the Exit of the Unit | |

|---|---|---|---|

| At the Exit of the Gasifier | At the Input of the SNG Unit | ||

| CO (mol. %) | 10.7 | 16.6 | <0.001 |

| CO2 (mol. %) | 8.9 | 14.0 | 1.5 |

| CH4 (mol. %) | 0.9 | 1.3 | 96.6 |

| H2 (mol. %) | 31.1 | 48.4 | 1.9 |

| H2O (mol. %) | 35.8 | 0.00 | 0.0 |

| N2 (mol. %) | 12.6 | 19.7 | 0.01 |

| Molar mass (kg/kmol) | 17.7 | 17.5 | 16.1 |

| LHV (kJ/kg) | 6351 | 9997 | 47,979 |

| SNG mass yield (%) | - | - | 13.8 |

| Parameter | SNG Production Rate (%) | ||

|---|---|---|---|

| 10 | 69 | 104 | |

| Annual Demand, (kton) | |||

| RDF | 37.5 | 57.6 | 69.6 |

| Annual Supply, (kton) | |||

| SNG | 0.8 | 5.4 | 8.2 |

| Hydrogen | 0.06 | 0.4 | 0.6 |

| Char | 0.6 | 1.2 | 1.6 |

| Daily Heat Supply (average), (MWh) | |||

| Surplus heat | 129.9 | 164.3 | 164.6 |

| WSt HEX | 34.7 | 0.4 | 0 |

| Daily Cold Supply (average), (MWh) | |||

| Adsorption chiller | 175.9 | 112.2 | 1.9 |

| Compression chiller | 1.9 | 65.6 | 175.9 |

| Daily Electricity Load (average), (MWh) | |||

| Export to the grid | 90.6 | 35.0 | 1.3 |

| Import from the grid | 0 | 0.003 | 13.1 |

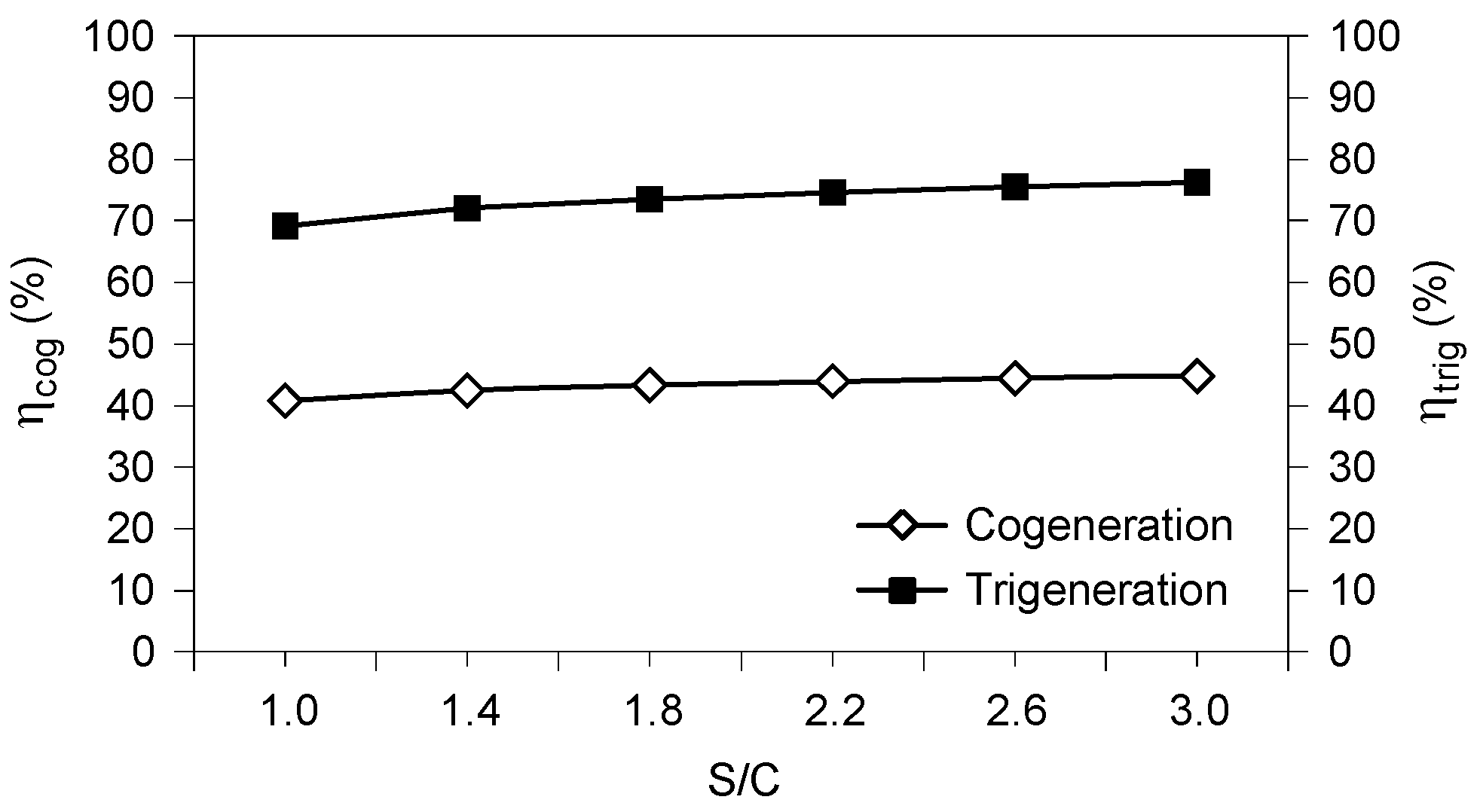

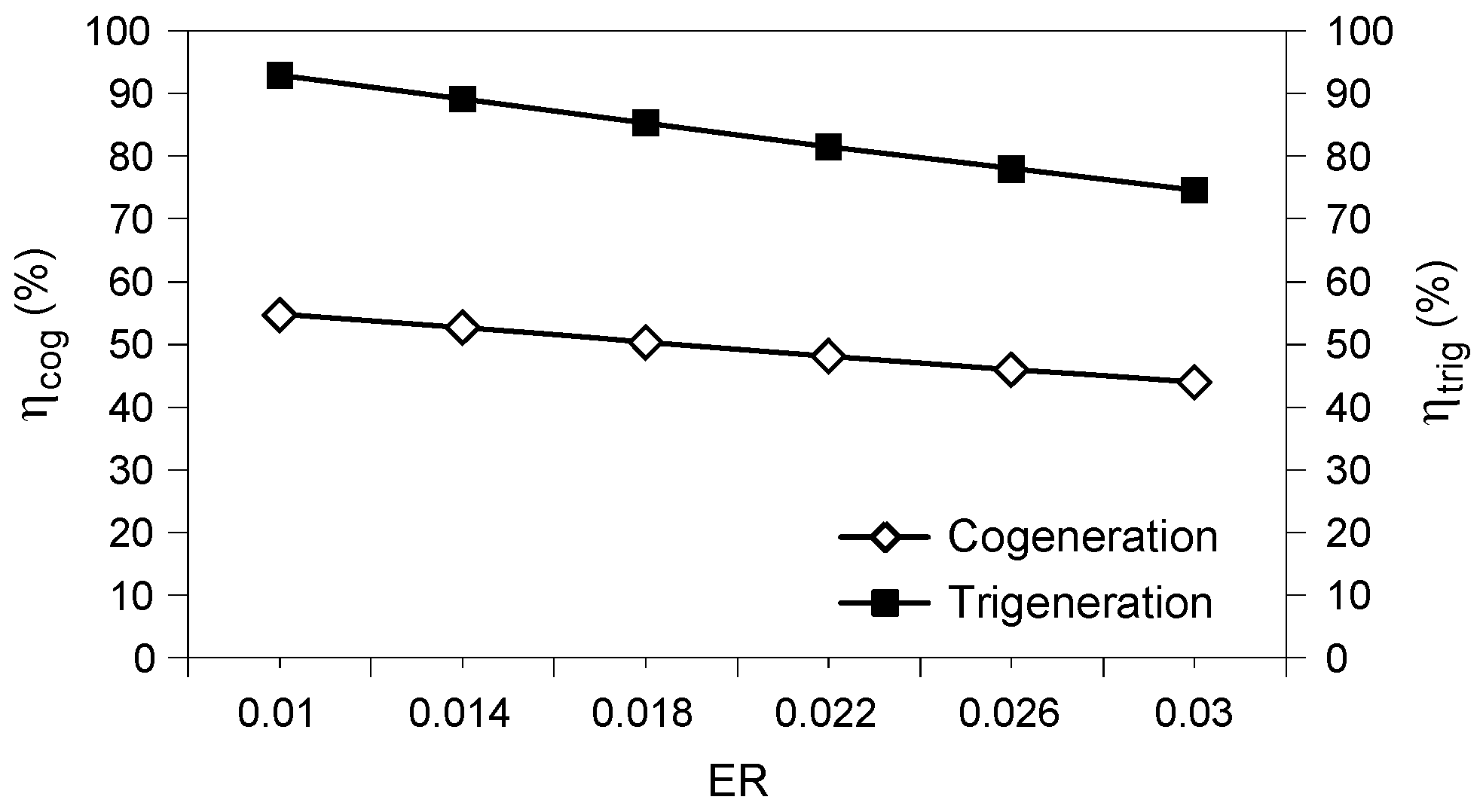

| Daily System Efficiency (average), (%) | |||

| Cogeneration | 44.0 | 22.4 | 15.3 |

| Trigeneration | 74.6 | 42.3 | 31.5 |

| Parameter | SNG Production Rate (%) | ||

|---|---|---|---|

| 10 | 69 | 104 | |

| CapEx (million USD) | 26.4 | 32.7 | 36.1 |

| OpEx (million USD) | 3.9 | 4.5 | 5.0 |

| Revenues (million USD) | 21.9 | 27.9 | 31.4 |

| incl. SNG | 0.9 | 6.3 | 9.5 |

| incl. H2 | 0.3 | 1.7 | 2.6 |

| incl. char | 0.01 | 0.01 | 0.01 |

| Total DNCF (million USD) | 151.7 | 200.2 | 227.5 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabalina, N.; Costa, M.; Yang, W.; Martin, A. Production of Synthetic Natural Gas from Refuse-Derived Fuel Gasification for Use in a Polygeneration District Heating and Cooling System. Energies 2016, 9, 1080. https://doi.org/10.3390/en9121080

Kabalina N, Costa M, Yang W, Martin A. Production of Synthetic Natural Gas from Refuse-Derived Fuel Gasification for Use in a Polygeneration District Heating and Cooling System. Energies. 2016; 9(12):1080. https://doi.org/10.3390/en9121080

Chicago/Turabian StyleKabalina, Natalia, Mário Costa, Weihong Yang, and Andrew Martin. 2016. "Production of Synthetic Natural Gas from Refuse-Derived Fuel Gasification for Use in a Polygeneration District Heating and Cooling System" Energies 9, no. 12: 1080. https://doi.org/10.3390/en9121080

APA StyleKabalina, N., Costa, M., Yang, W., & Martin, A. (2016). Production of Synthetic Natural Gas from Refuse-Derived Fuel Gasification for Use in a Polygeneration District Heating and Cooling System. Energies, 9(12), 1080. https://doi.org/10.3390/en9121080