Failure Criteria of Gas-Infiltrated Sandy Shale Based on the Effective Stress Principle

Abstract

:1. Introduction

2. Laboratory Experiments on Triaxial Compression

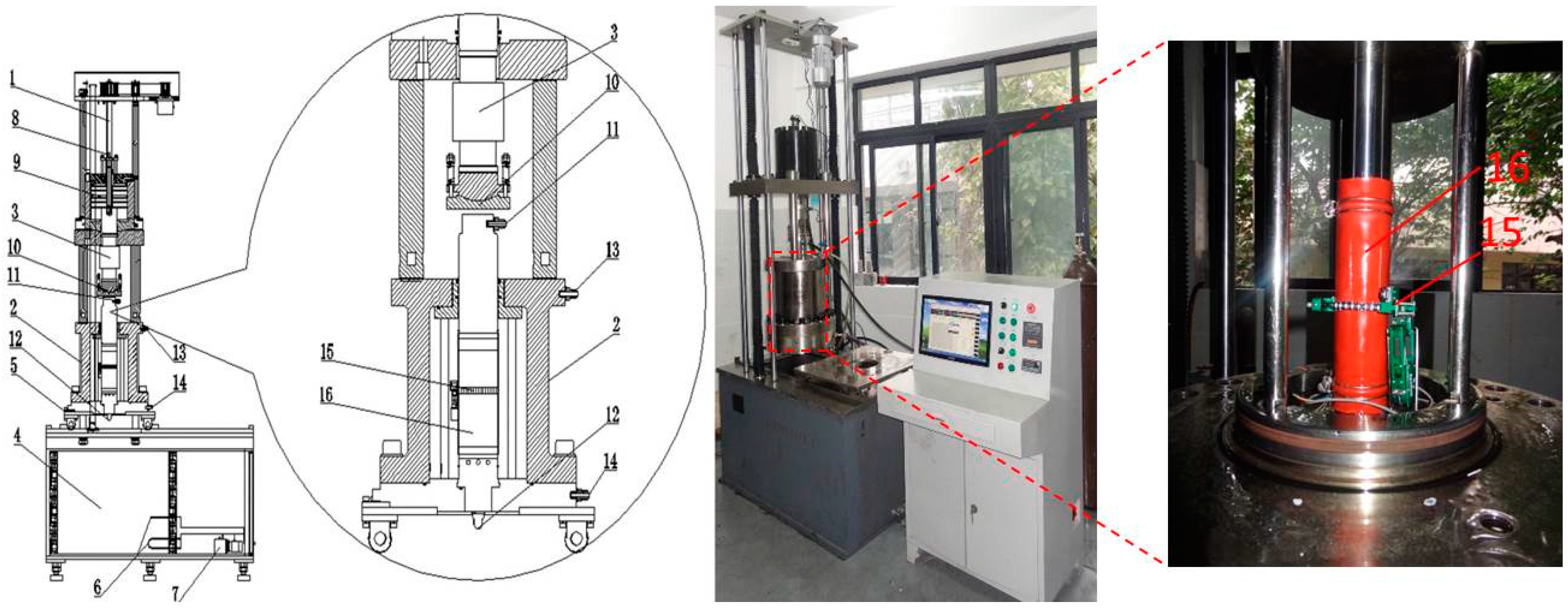

2.1. Experimental Apparatus

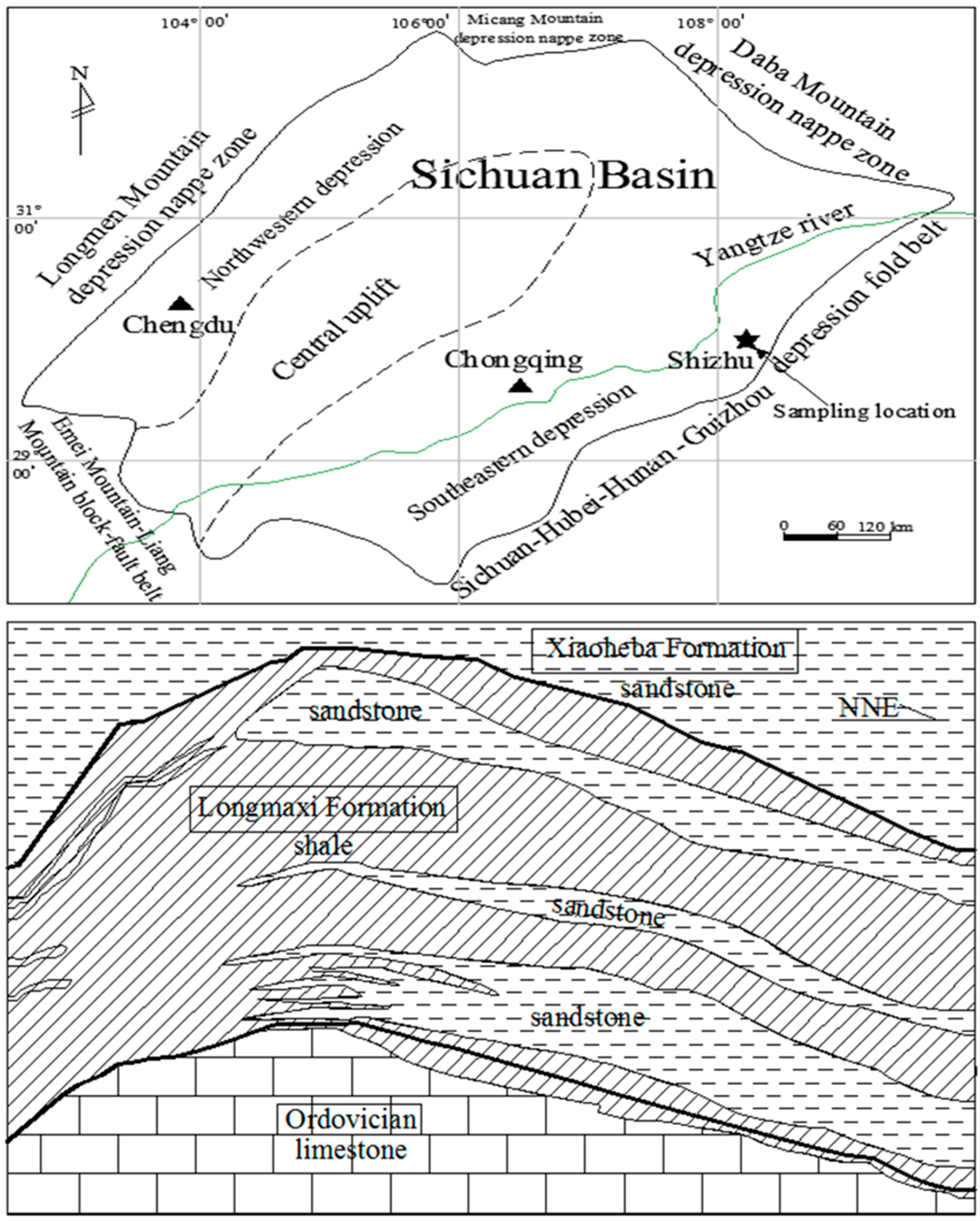

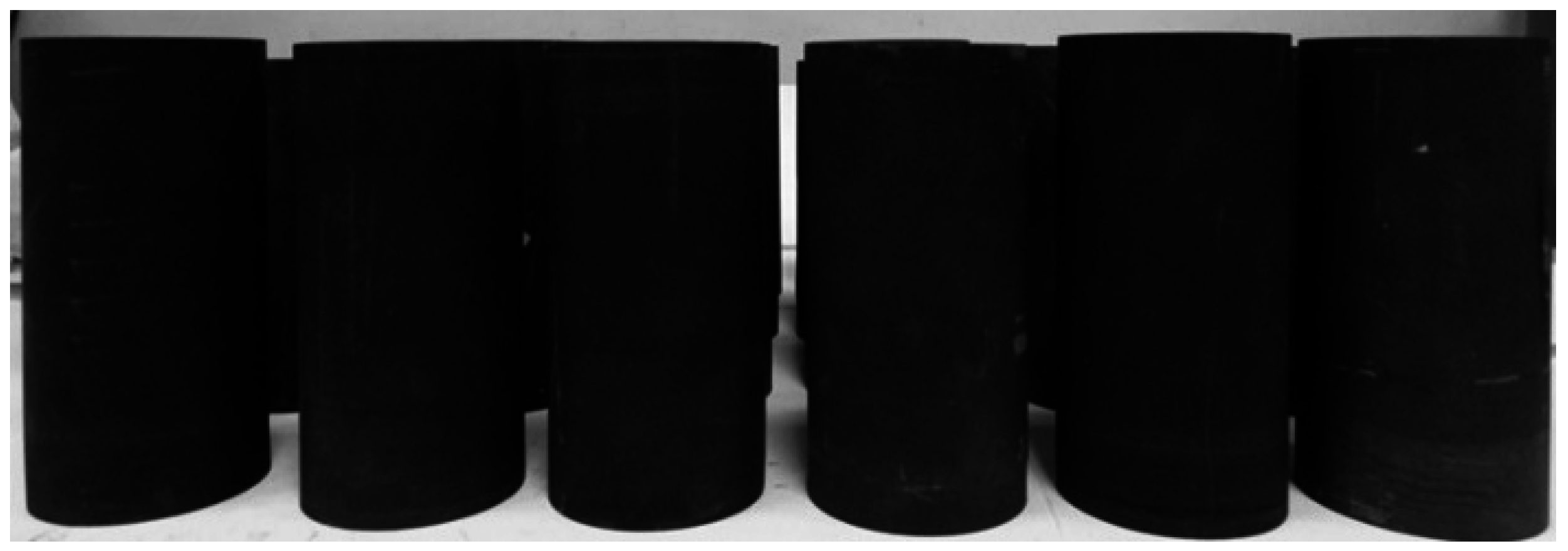

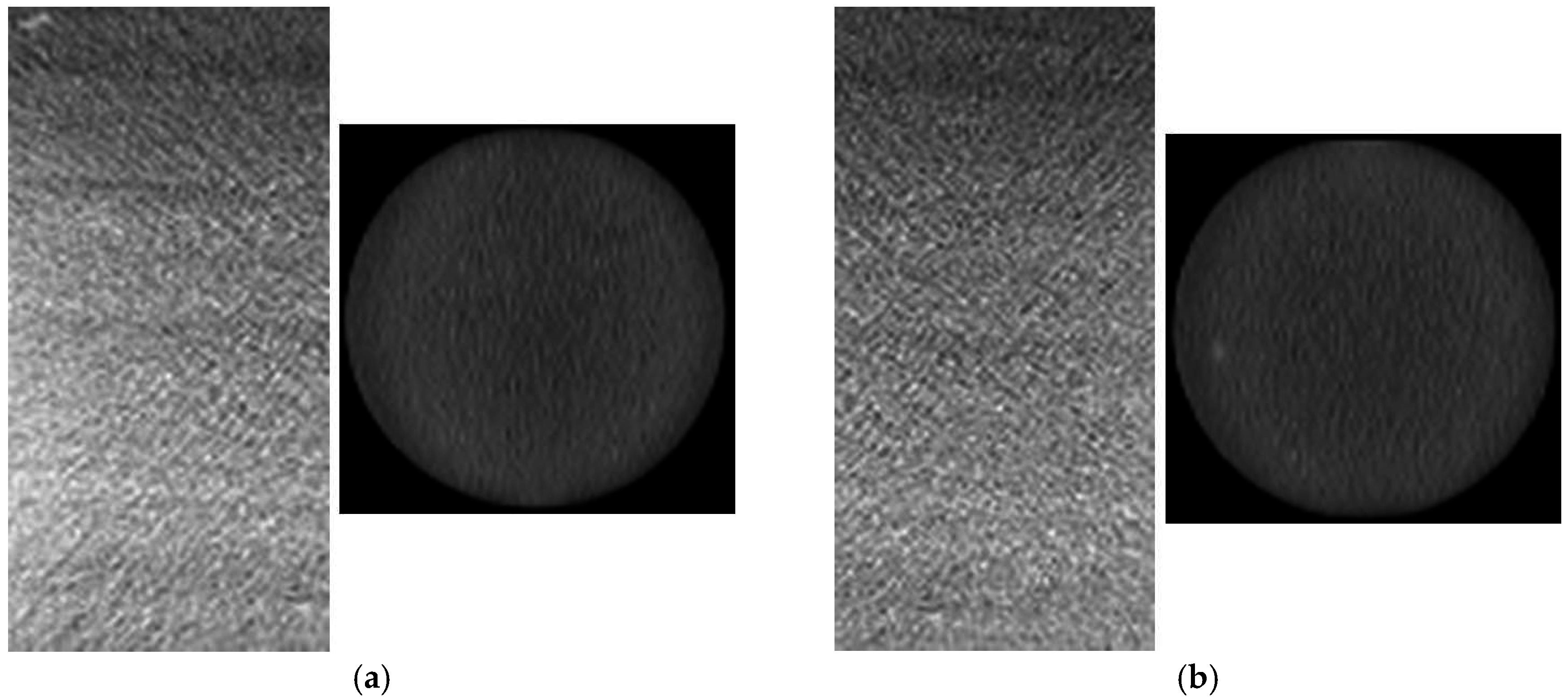

2.2. Sandy Shale Specimens and Sample Preparation

2.3. Testing Scheme

2.3.1. Scheme 1

2.3.2. Scheme 2

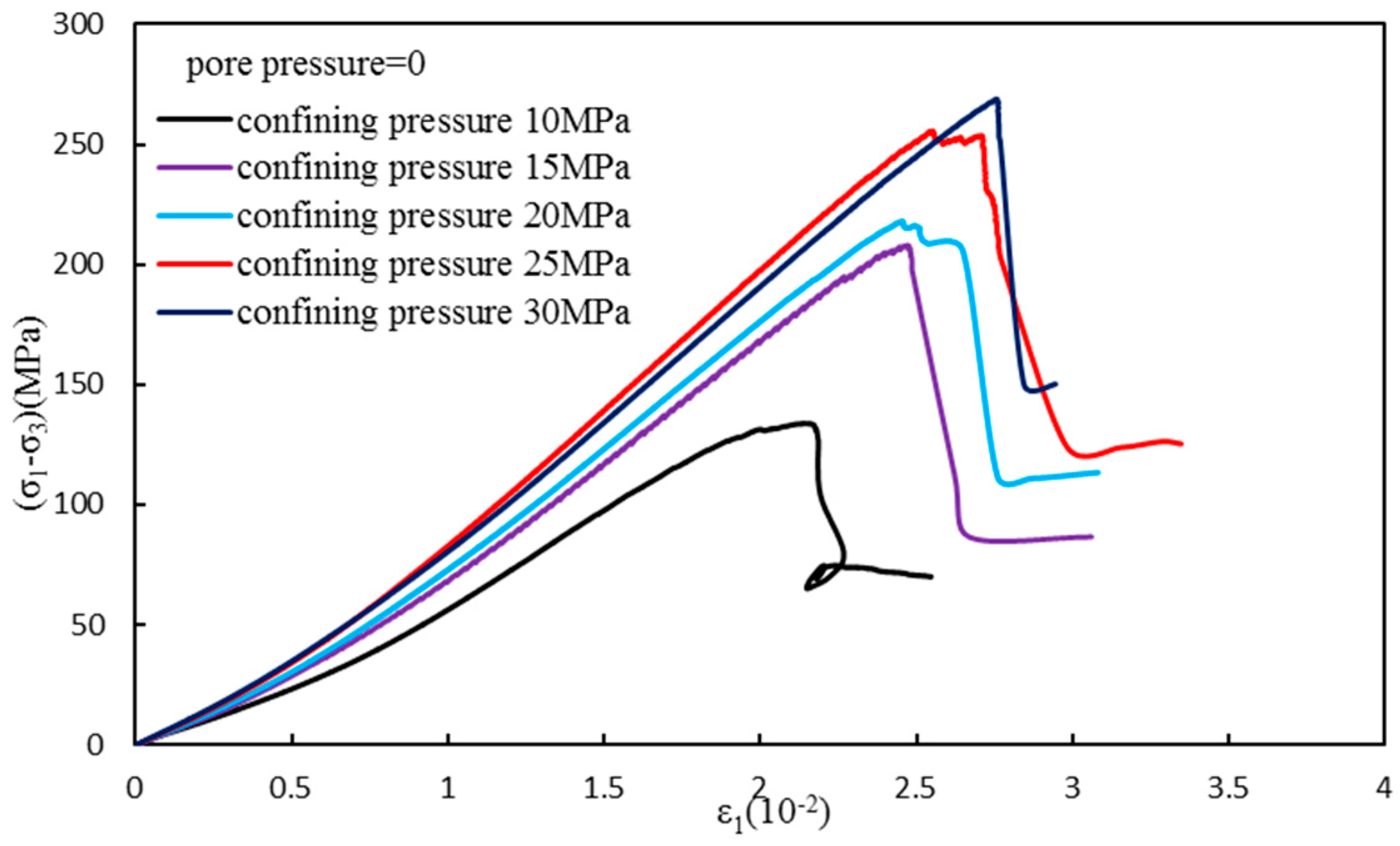

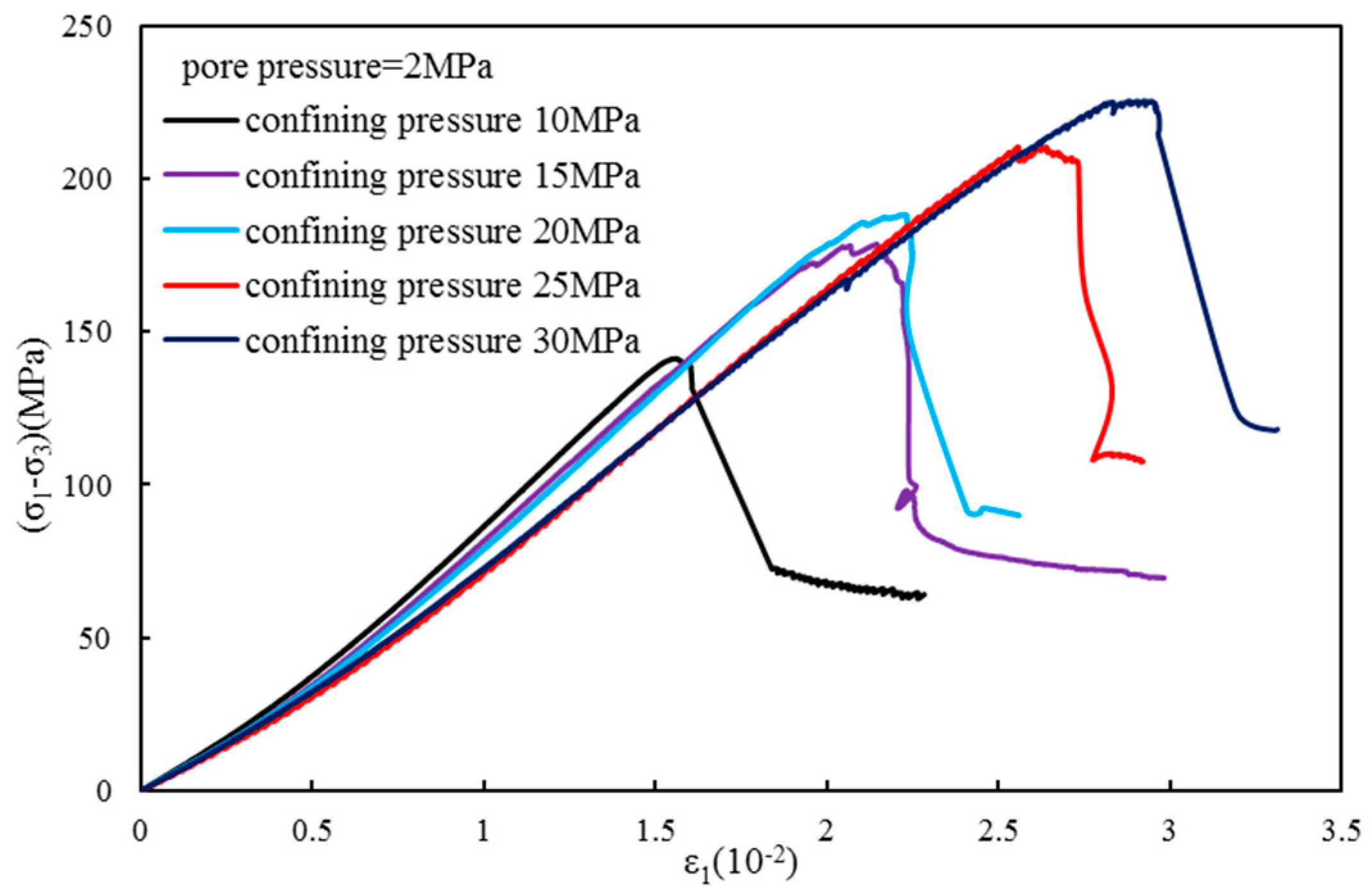

2.4. Testing Results

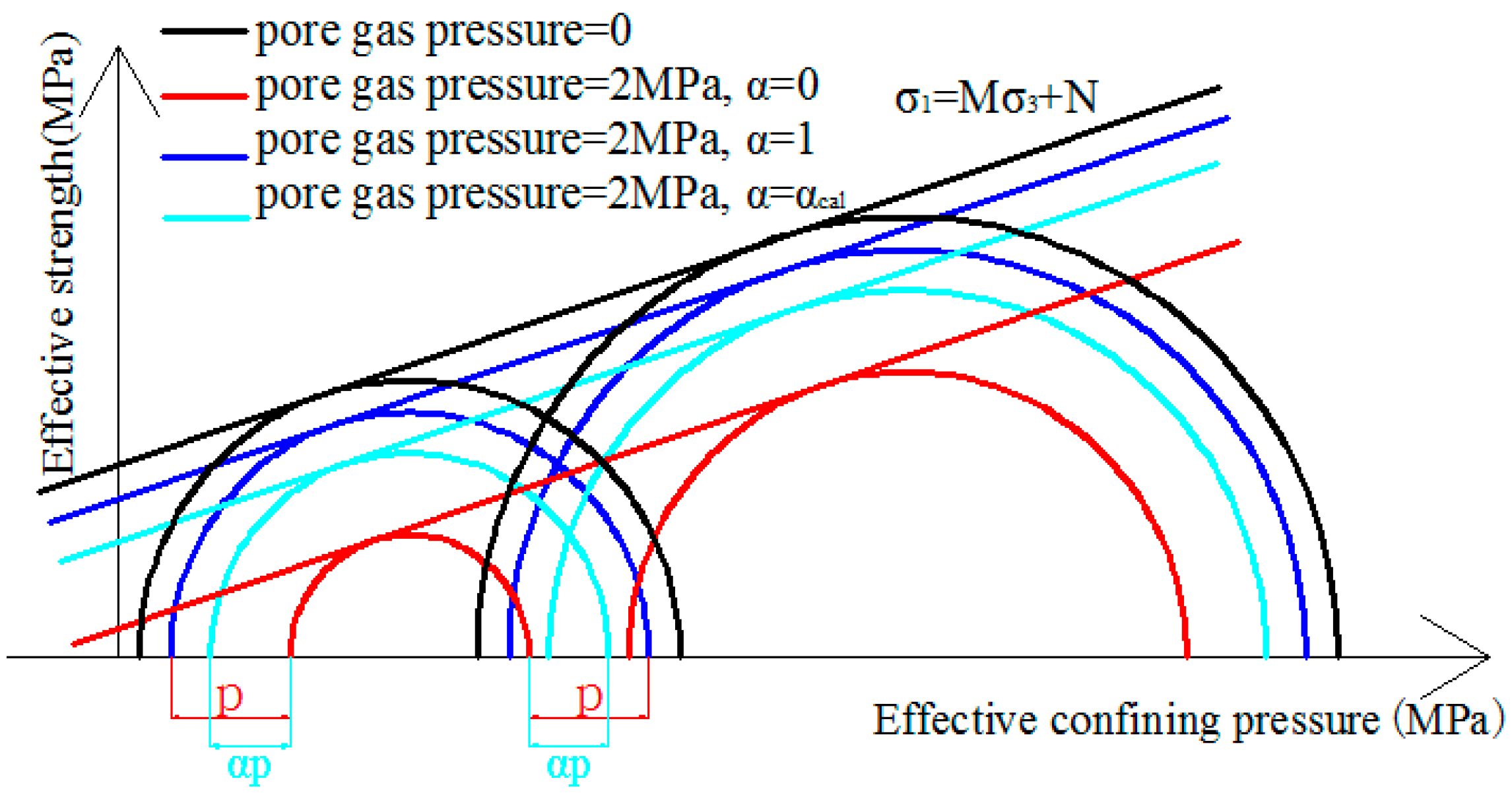

3. Modified Failure Criteria Based on Effective Stress

3.1. Effective Stress of Gas-infiltrated Sandy Shale

3.2. Mohr-Coulomb Failure Criterion

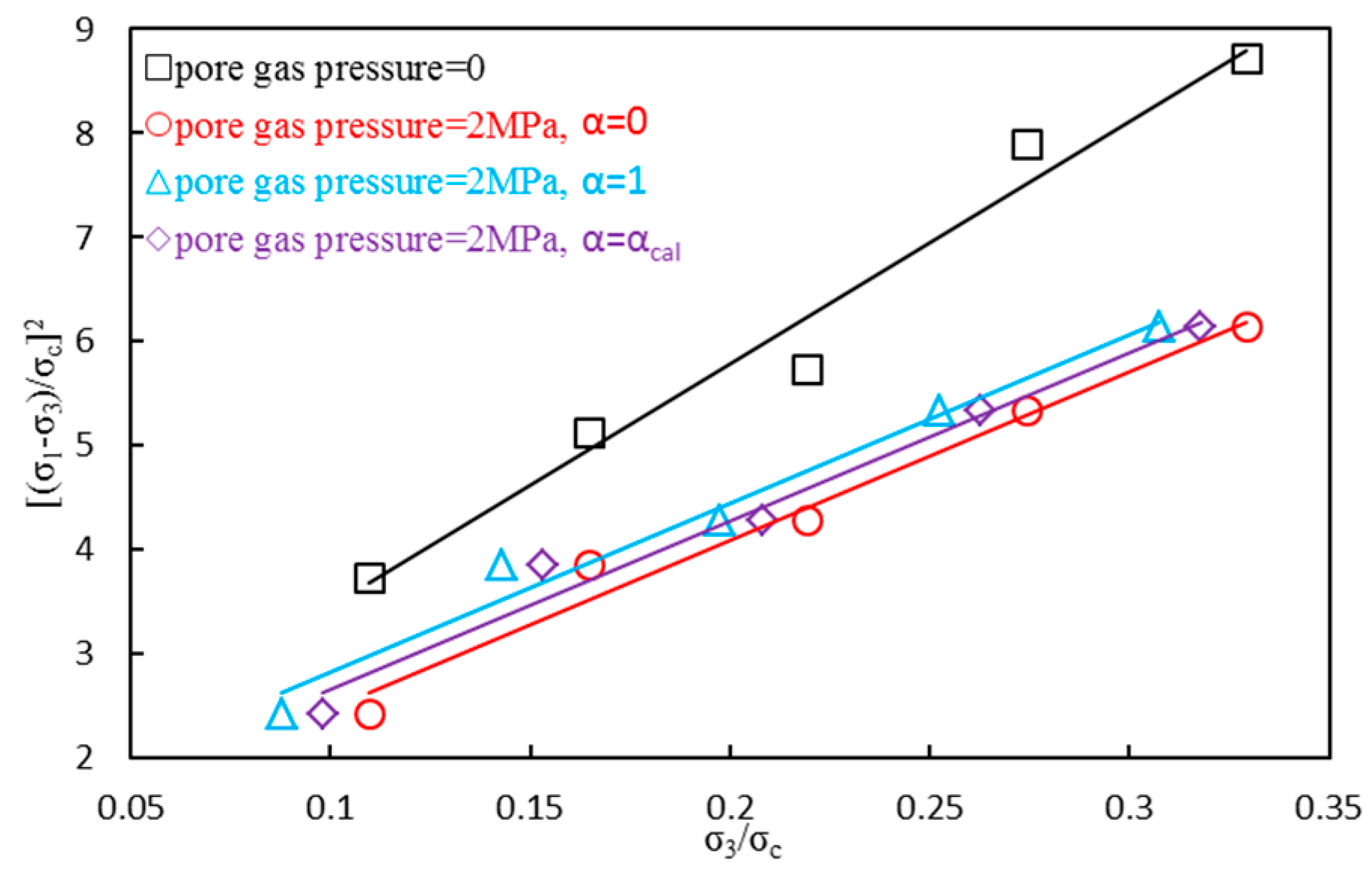

3.3. Hoek-Brown Failure Criterion

3.4. Drucker-Prager Failure Criterion

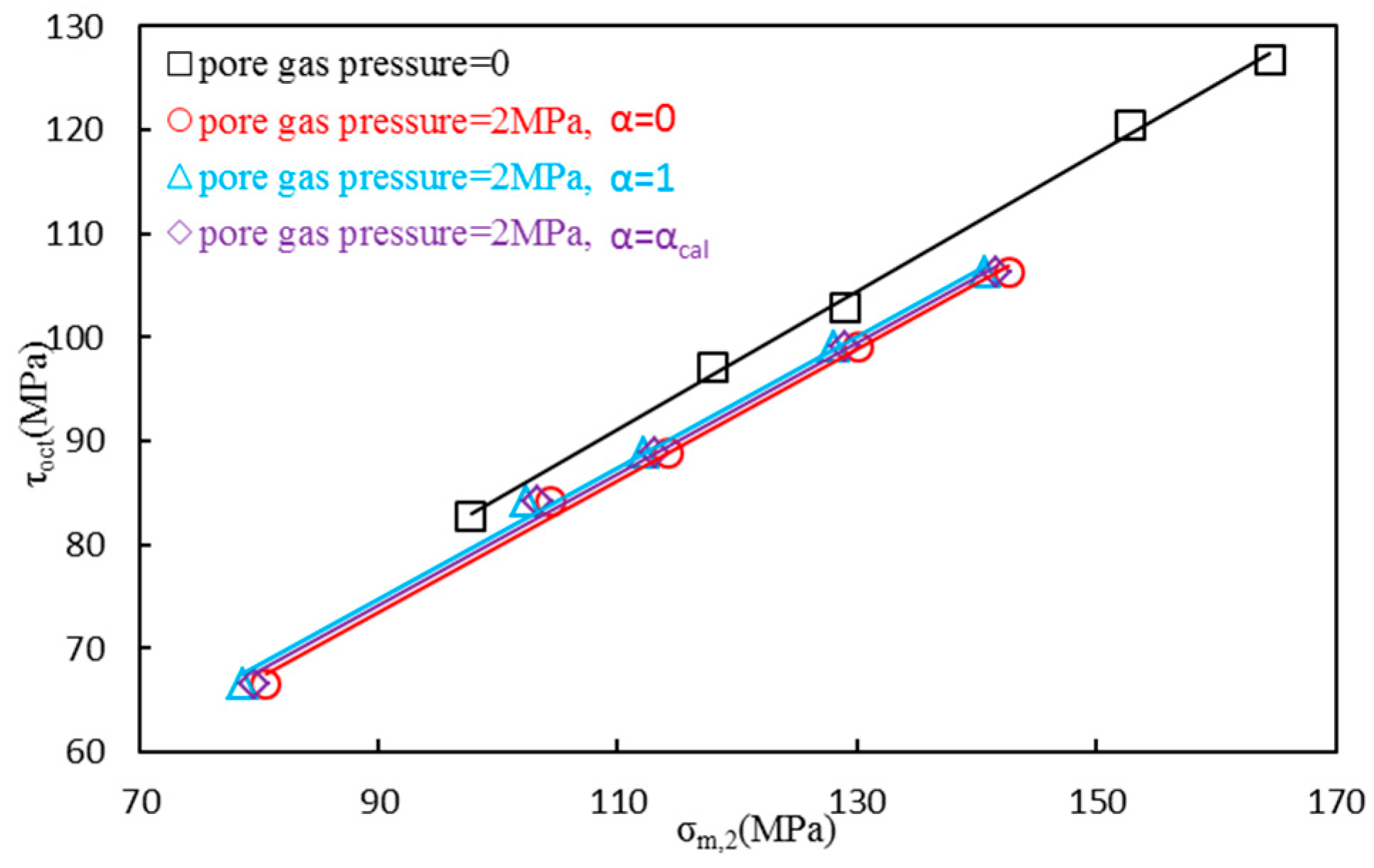

3.5. Linear Mogi Failure Criterion

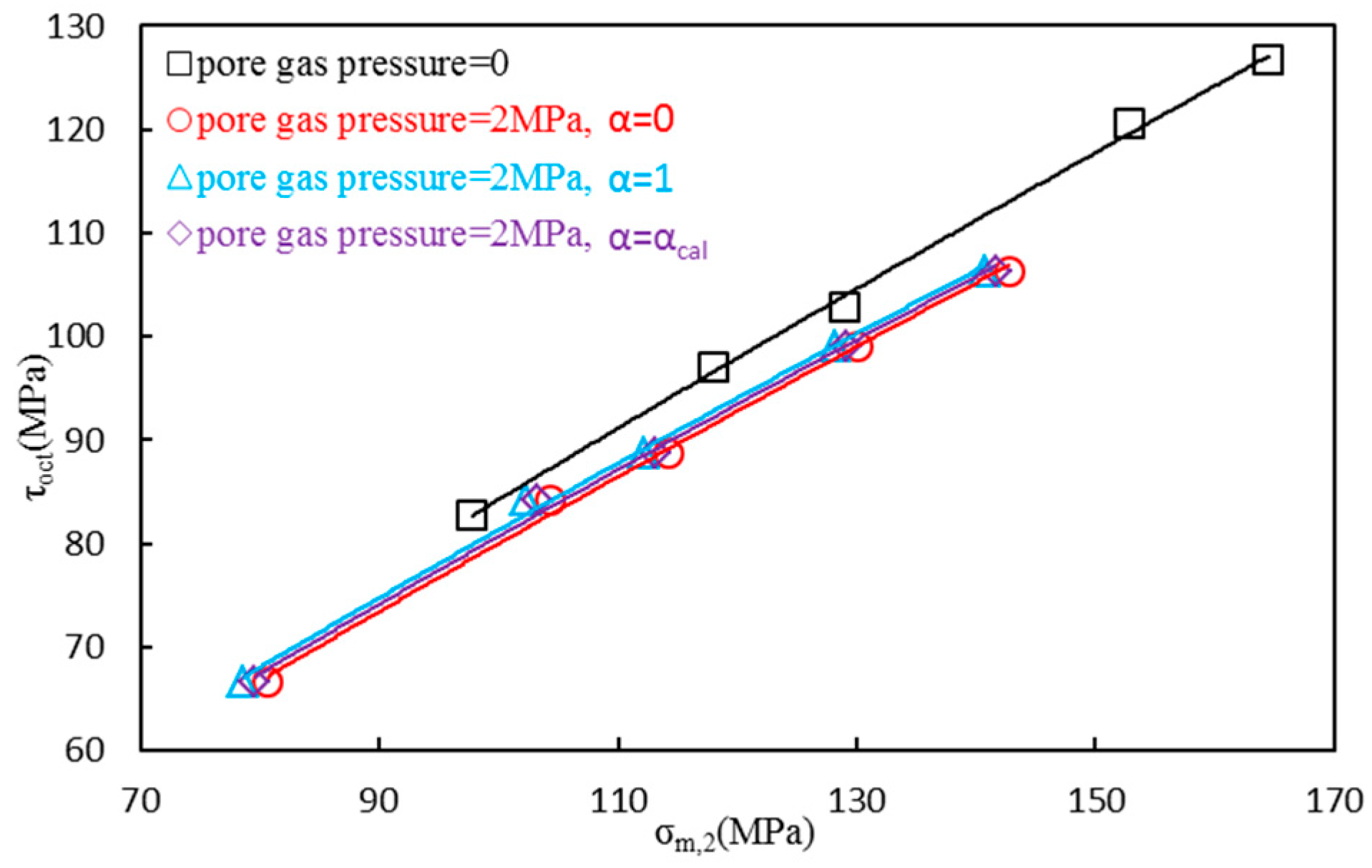

3.6. Non-Linear Mogi Failure Criterion

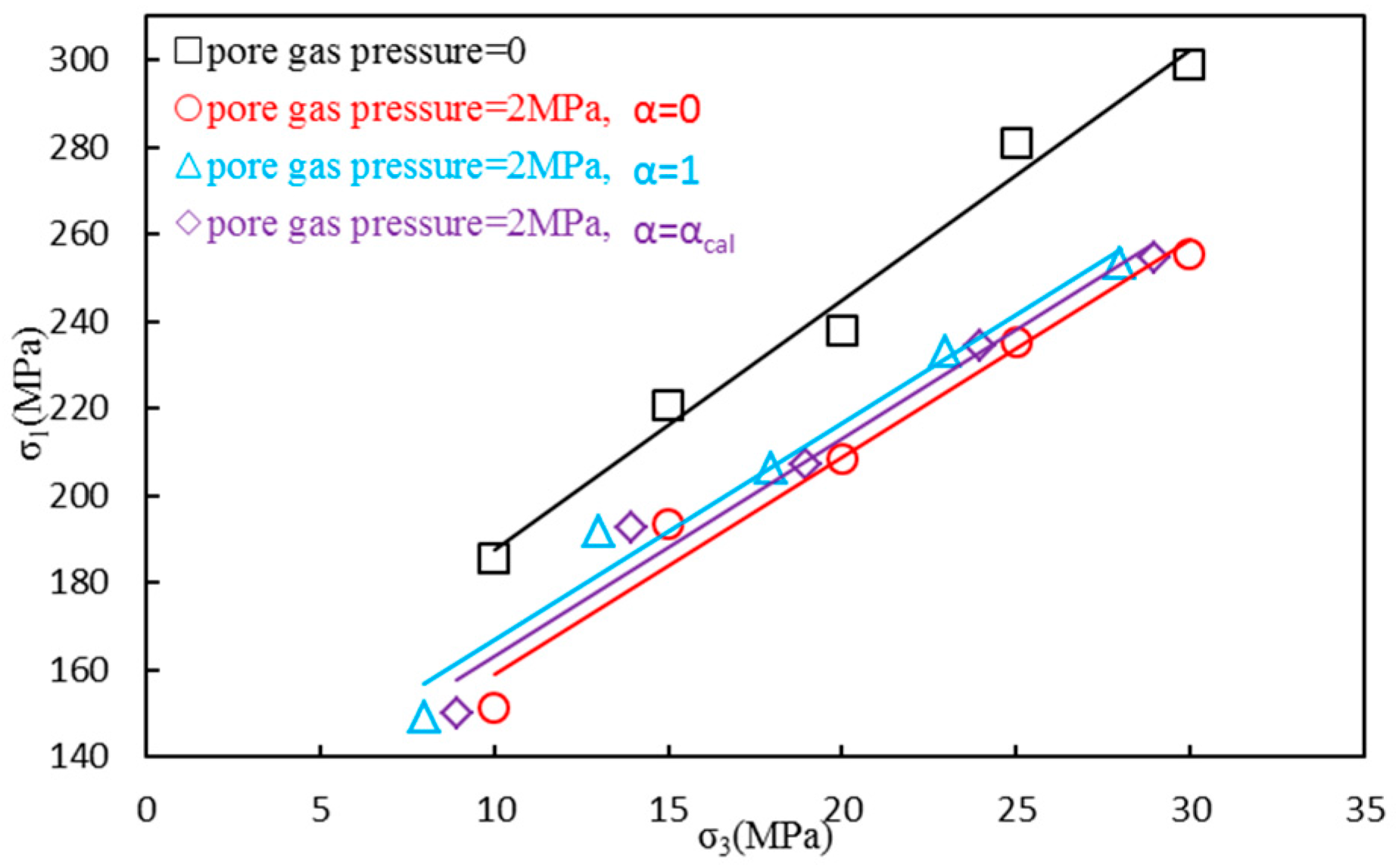

4. Experimental Failure Data Fitting

5. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Boyer, C.; Kieschnick, J.; Suarez-Rivera, R.; Lewis, R.E.; Waters, G. Producing gas from its source. Oilfield Rev. 2006, 18, 36–49. [Google Scholar]

- Lal, M. Shale stability: Drilling fluid interaction and shale strength. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 20–22 April 1999.

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Tutuncu, A.N.; Mese, A.I. Relationship between permeability, acoustic, mechanical and strength anisotropies in unconventional reservoirs and seal shales. In Proceedings of the 45th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 26–29 June 2011.

- Sone, H.; Zoback, M.D. Strength, creep and frictional properties of gas shale reservoir rocks. In Proceedings of the 44th US Rock Mechanics Symposium and 5th U.S.-Canada Rock Mechanics Symposium, Salt Lake City, UT, USA, 27–30 June 2010.

- AL-Bazali, T. The impact of water content and ionic diffusion on the uniaxial compressive strength of shale. Egypt. J. Pet. 2013, 22, 249–260. [Google Scholar] [CrossRef]

- Gale, J.F.W.; Reed, R.M.; Holder, J. Natural fractures in the Barnett Shale and their importance for hydraulic fracture treatments. AAPG Bull. 2007, 91, 603–622. [Google Scholar] [CrossRef]

- Ulusay, R.; Hudson, J.A. Suggested methods for rock failure criteria: General introduction. Rock Mech. Rock Eng. 2012, 45, 971. [Google Scholar] [CrossRef]

- Benz, T.; Schwab, R. A quantitative comparison of six rock failure criteria. Int. J. Rock Mech. Min. Sci. 2008, 42, 1176–1186. [Google Scholar] [CrossRef]

- Zhao, J. Applicability of Mohr-Coulomb and Hoek-Brown strength criteria to the dynamic strength of brittle rock. Int. J. Rock Mech. Min. Sci. 2000, 37, 1115–1121. [Google Scholar] [CrossRef]

- Ghazvinian, A.H.; Fathi, A.; Moradian, Z.A. Failure behavior of marlstone under triaxial compression. Int. J. Rock Mech. Min. Sci. 2008, 45, 807–814. [Google Scholar] [CrossRef]

- Jespersen, C.; MacLaughlin, M.; Hudyma, N. Strength, Deformation modulus and failure modes of cubic analog specimens representing macroporous rock. Int. J. Rock Mech. Min. Sci. 2010, 47, 1349–1356. [Google Scholar] [CrossRef]

- Rafiai, H. New empirical polyaxial criterion for rock strength. Int. J. Rock Mech. Min. Sci. 2011, 48, 922–931. [Google Scholar] [CrossRef]

- Peng, J.; Rong, G.; Cai, M.; Wang, X.J.; Zhou, C.B. An empirical failure criterion for intact rocks. Rock Mech. Rock Eng. 2014, 47, 347–356. [Google Scholar] [CrossRef]

- Singh, M.; Raj, A.; Singh, B. Modified Mohr-Coulomb criterion for non-linear triaxial and polyaxial strength of intact rocks. Int. J. Rock Mech. Min. Sci. 2011, 48, 546–555. [Google Scholar] [CrossRef]

- Singh, M.; Singh, B. A strength criterion based on critical state mechanics for intact rocks. Rock Mech. Rock Eng. 2005, 38, 243–248. [Google Scholar] [CrossRef]

- Singh, M.; Singh, B. Modified Mohr-Coulomb criterion for non-linear triaxial and polyaxial strength of jointed rocks. Int. J. Rock Mech. Min. Sci. 2012, 51, 43–52. [Google Scholar] [CrossRef]

- Priest, S. Three-dimensional failure criteria based on the Hoek-Brown criterion. Rock Mech. Rock Eng. 2012, 45, 989–993. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, H. Three-dimensional Hoek-Brown strength criterion for rocks. J. Geotech. Geoenviron. Eng. ASCE 2007, 133, 1128–1135. [Google Scholar] [CrossRef]

- Pan, X.D.; Hudson, J.A. A simplified three-dimensional Hoek-Brown yield criterion. In Rock Mechanics and Power Plants; Romana, M., Ed.; Balkema: Rotterdam, The Netherlands, 1988; pp. 95–103. [Google Scholar]

- Priest, S.D. Comparisons between selected three-dimensional yield criteria applied to rock. Rock Mech. Rock Eng. 2009, 43, 379–389. [Google Scholar] [CrossRef]

- Priest, S.D. Determination of shear strength and three-dimensional yield strength for the Hoek-Brown criterion. Rock Mech. Rock Eng. 2005, 38, 299–327. [Google Scholar] [CrossRef]

- You, M.Q. True-triaxial strength criteria for rock. Int. J. Rock Mech. Min. Sci. 2009, 46, 115–127. [Google Scholar] [CrossRef]

- Haimson, B.; Chang, C. A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of Westerly granite. Int. J. Rock Mech. Min. Sci. 2000, 37, 285–296. [Google Scholar] [CrossRef]

- Chang, C.; Haimson, B. True triaxial strength and deformability of the German Continental Deep Drilling Program (KTB) deep hole amphibolite. J. Geophys. Res. 2000, 105, 18999–19013. [Google Scholar] [CrossRef]

- Arora, S.; Mishra, B. Investigation of the failure mode of shale rocks in biaxial and triaxial compression tests. Int. J. Rock Mech. Min. Sci. 2015, 79, 109–123. [Google Scholar] [CrossRef]

- Chen, Q.; Nezhad, M.M.; Fisher, Q.; Zhu, H.H. Multi-scale approach for modeling the transversely isotropic elastic properties of shale considering multi-inclusions and interfacial transition zone. Int. J. Rock Mech. Min. Sci. 2016, 84, 95–104. [Google Scholar] [CrossRef]

- Nezhad, M.M.; Zhu, H.H.; Woody, J.; Chen, Q. A simplified multiscale damage model for the transversely isotropic shale rocks under tensile loading. Int. J. Damage Mech. 2016, 25, 705–726. [Google Scholar] [CrossRef]

- Murphy, M.M. Shale failure mechanics and intervention measures in underground coal mines: Results from 50 years of ground control safety research. Rock Mech. Rock Eng. 2016, 49, 661–671. [Google Scholar] [CrossRef] [PubMed]

- Morgan, S.P.; Einstein, H.H. The effect of bedding plane orientation on crack propagation and coalescence in shale. In Proceedings of the 48th US Rock Mechanics/Geomechanics Symposium, Minneapolis, MN, USA, 1–4 June 2014.

- Saroglou, H.; Tsiambaos, G. A modified Hoek-Brown failure criterion for anisotropic intact rock. Int. J. Rock Mech. Min. Sci. 2008, 45, 223–234. [Google Scholar] [CrossRef]

- Singh, M.; Samadhiya, N.K.; Kumar, A.; Kumar, V.; Singh, B. A nonlinear criterion for triaxial strength of inherently anisotropic rocks. Rock Mech. Rock Eng. 2015, 48, 1387–1405. [Google Scholar] [CrossRef]

- Yin, G.Z.; Jiang, C.B.; Wang, J.G.; Xu, J. Combined effect of stress, pore pressure and temperature on methane permeability in anthracite coal: An experimental study. Transp. Porous Media 2013, 100, 1–16. [Google Scholar] [CrossRef]

- Yin, G.Z.; Li, M.H.; Wang, J.G.; Xu, J.; Li, W.P. Mechanical behavior and permeability evolution of gas infiltrated coals during protective layer mining. Int. J. Rock Mech. Min. Sci. 2015, 80, 292–301. [Google Scholar] [CrossRef]

- Liu, J.H.; Zhu, X.Y.; Wang, S.L.; Wei, J.S. Geologic-tectonic evolutional characteristics and prospecting potential for ISL-amenable sandstone type uranium deposits in Sichuan basin. Uranium Geol. 2005, 21, 321–330. [Google Scholar]

- Yang, F.; Ning, Z.F.; Zhang, R.; Zhao, H.W.; Krooss, B.M. Investigations on the methane sorption capacity of marine shales from Sichuan Basin, China. Int. J. Coal Geol. 2015, 146, 104–117. [Google Scholar] [CrossRef]

- Liu, S.G.; Ma, W.X.; Luba, J.; Huang, W.M.; Zeng, X.L.; Zhang, C.J. Characteristics of the shale gas reservoir rocks in the Lower Silurian Longmaxi Formation, East Sichuan basin, China. Acta Petrol. Sin. 2011, 27, 2239–2252. [Google Scholar] [CrossRef]

- Haimson, B.; Bobet, A. Introduction to suggested methods for failure criteria. Rock Mech. Rock Eng. 2012, 45, 973–974. [Google Scholar] [CrossRef]

- Ghabezloo, S.; Sulem, J.; Guédon, S.; Martineau, F. Effective stress law for the permeability of a limestone. Int. J. Rock Mech. Min. Sci. 2009, 46, 297–306. [Google Scholar] [CrossRef]

- Terzaghi, K. Erdbaumechanik auf Bodenphysikalischer Grundlage; Deuticke: Leipzig, Germany, 1925. [Google Scholar]

- Biot, M.A. General theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Wang, J.G.; Liu, J.S.; Kabir, A. Combined effects of directional compaction, non-Darcy flow and anisotropic swelling on coal seam gas extraction. Int. J. Coal Geol. 2013, 109–110, 1–14. [Google Scholar] [CrossRef]

- Geertsma, J. The effect of fluid pressure decline on volumetric changes of porous rocks. Trans. AIME 1957, 210, 331–340. [Google Scholar]

- Zhang, K.; Zhou, H.; Hu, D.W.; Zhao, Y.; Feng, X.T. Theoretical model of effective stress coefficient for rock/soil-like porous materials. Acta Mech. Solida Sin. 2009, 22, 251–260. [Google Scholar] [CrossRef]

- Walsh, J.B. Effect of pore pressure and confining pressure on fracture permeability. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 429–435. [Google Scholar] [CrossRef]

- Kranzz, R.L.; Frankel, A.D.; Engelder, T.; Scholz, C.H. The permeability of whole and jointed barre granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1979, 16, 225–234. [Google Scholar] [CrossRef]

- George, J.D.S.; Barakat, M.A. The change in effective stress associated with shrinkage from gas desorption in coal. Int. J. Coal Geol. 2001, 45, 105–113. [Google Scholar] [CrossRef]

- Nur, A.; Byerlee, J.D. An exact effective stress law for elastic deformation of rock with fluids. J. Geophys. Res. 1971, 76, 6414–6419. [Google Scholar] [CrossRef]

- Hu, D.W.; Zhou, H.; Zhang, F.; Shao, J.F. Evolution of poroelastic properties and permeability in damaged sandstone. Int. J. Rock Mech. Min. Sci. 2010, 47, 962–973. [Google Scholar] [CrossRef]

- Dassanayake, A.B.N.; Fujii, Y.; Fukuda, D.; Kodama, J.I. A new approach to evaluate effective stress coefficient for strength in Kimachi sandstone. J. Petrol. Sci. Eng. 2015, 131, 70–79. [Google Scholar] [CrossRef]

- Labuz, J.F.; Zang, A. Mohr-Coulomb failure criterion. Rock Mech. Rock Eng. 2012, 45, 975–979. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. Underground Excavations in Rock; The Institution of Mining and Metallurgy: London, UK, 1980. [Google Scholar]

- Hoek, E.; Brown, E.T. The Hoek–Brown failure criterion—A 1988 update. In Proceedings of the 15th Canadian Rock Mechanics Symposium, Montreal, QC, Canada, 19–21 June 1996; Curran, J., Ed.; University of Toronto: Toronto, ON, Canada, 1988; pp. 31–38. [Google Scholar]

- Hoek, E. Strength of jointed rock masses, twenty-third Rankine lecture. Geotechnique 1983, 33, 187–223. [Google Scholar] [CrossRef]

- Hoek, E.; Kaiser, P.K.; Bawden, W.F. Support of Underground Excavations in Hard Rock; A.A. Balkema: Rotterdam, The Netherlands, 1995. [Google Scholar]

- Drucker, D.C.; Prager, W. Soil mechanics and plastic analysis or limit design. Q. Appl. Math. 1952, 10, 157–165. [Google Scholar]

- Mogi, K. Fracture and flow of rocks under high triaxial compression. J. Geophys. Res. 1971, 76, 1255–1269. [Google Scholar] [CrossRef]

- Al-Ajmi, A.M.; Zimmerman, R.W. Relation between the Mogi and the Coulomb failure criteria. Int. J. Rock Mech. Min. Sci. 2005, 42, 431–439. [Google Scholar] [CrossRef]

| Samples No. | σ3/MPa | Pore Gas Pressure/MPa | σ1–σ3/MPa |

|---|---|---|---|

| 1 | 10 | 0 | 135.03 |

| 2 | 15 | 0 | 205.96 |

| 3 | 20 | 0 | 218.02 |

| 4 | 25 | 0 | 255.71 |

| 5 | 30 | 0 | 268.94 |

| 6 | 10 | 2 | 122.29 |

| 7 | 15 | 2 | 178.68 |

| 8 | 20 | 2 | 188.34 |

| 9 | 25 | 2 | 210.22 |

| 10 | 30 | 2 | 225.42 |

| Parameters | Condition | MC | HB | DP | Linear Mogi | Non-Linear Mogi |

|---|---|---|---|---|---|---|

| RMSE/MPa | p = 0 | 19.69 | 18.47 | 19.40 | 19.37 | 18.57 |

| p = 2, α = 0 | 16.96 | 16.74 | 16.87 | 16.88 | 16.17 | |

| p = 2, α = 1 | 12.89 | 11.18 | 12.70 | 13.25 | 11.18 | |

| p = 2, α = αcal | 12.76 | 11.81 | 12.48 | 11.93 | 11.29 | |

| c/MPa | p = 0 | 27.20 | - | 36.29 | 26.71 | - |

| p = 2, α = 0 | 26.16 | - | 34.42 | 25.41 | - | |

| p = 2, α = 1 | 24.37 | - | 31.98 | 23.59 | - | |

| p = 2, α = αcal | 25.33 | - | 33.31 | 24.58 | - | |

| φ/° | p = 0 | 44.65 | - | 34.06 | 44.99 | - |

| p = 2, α = 0 | 41.79 | - | 31.47 | 42.27 | - | |

| p = 2, α = 1 | 41.79 | - | 31.47 | 42.27 | - | |

| p = 2, α = αcal | 41.77 | - | 31.43 | 42.24 | - |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Zhang, D.; Li, M. Failure Criteria of Gas-Infiltrated Sandy Shale Based on the Effective Stress Principle. Energies 2016, 9, 972. https://doi.org/10.3390/en9110972

Li W, Zhang D, Li M. Failure Criteria of Gas-Infiltrated Sandy Shale Based on the Effective Stress Principle. Energies. 2016; 9(11):972. https://doi.org/10.3390/en9110972

Chicago/Turabian StyleLi, Wenpu, Dongming Zhang, and Minghui Li. 2016. "Failure Criteria of Gas-Infiltrated Sandy Shale Based on the Effective Stress Principle" Energies 9, no. 11: 972. https://doi.org/10.3390/en9110972

APA StyleLi, W., Zhang, D., & Li, M. (2016). Failure Criteria of Gas-Infiltrated Sandy Shale Based on the Effective Stress Principle. Energies, 9(11), 972. https://doi.org/10.3390/en9110972