Bio-Wastes as an Alternative Household Cooking Energy Source in Ethiopia

Abstract

:1. Introduction

Background of the Country

2. Methodology

2.1. Description of the System Analyses

2.2. Determining the Study Assumptions

2.2.1. Energy Demand for Cooking

2.2.2. Thermal Output of the Conversion Systems

| Stoves | Technology | Feedstock | LHV (GJ/t) | Efficiency (%) b | Thermal output (GJ/t) |

|---|---|---|---|---|---|

| TSF | traditional | residues or dung | 15 | 10 | 1.5 |

| ISB | briquetting | residues | 19 | 20 | 3.8 |

| Biogas | AD | residues | 8.8 a | 55 | 4.8 |

| Biogas | AD | dung | 6.2 a | 55 | 3.4 |

2.2.3. Availability of Bio-Wastes

| Crops | Land area (Mha) | Crop yield (t/ha) | RPR | Residues (t/ha) | Available residues (t/ha) | Available residues (mt) |

|---|---|---|---|---|---|---|

| Teff | 2.8 | 1.8 | 2.3 | 4.1 | 1.2 | 3.3 |

| Barley | 1.0 | 1.8 | 1.3 | 2.3 | 0.7 | 0.7 |

| Wheat | 1.6 | 2.1 | 1.3 | 2.7 | 0.8 | 2.3 |

| Sorghum | 1.9 | 2.1 | 1.5 | 3.2 | 0.9 | 1.7 |

| Maize | 2.0 | 3.0 | 1.4 | 4.2 | 1.3 | 2.6 |

| Finger millet | 0.4 | 1.8 | 1.3 | 2.3 | 0.7 | 0.3 |

| Other crops * | 2.4 | 1.5 | 1.3 | 2.0 | 0.6 | 1.4 |

| Total/ave. | 12.0 | 2.0 | 1.5 | 3.0 | 0.9 | 11.0 |

| Bio-wastes | Annual yield | Unit | Availability factor | Annual available yield | Unit |

|---|---|---|---|---|---|

| Residues | 3.0 | t/ha | 0.3 | 0.9 | t/ha |

| Dung | 0.7 | t/cow | 0.4 | 0.3 | t/cow |

2.2.4. Driving the System Relationship

3. Results

3.1. Resources Required to Meet the Households’ Demands

| Conversion technologies | Households biomass resources required to meet the demand | |||

|---|---|---|---|---|

| Residues (t) | Land (ha) | Dung (t) | Cows | |

| TSF | 4.0 | 4.4 | 4.0 | 15 |

| ISB | 1.6 | 1.8 | - | - |

| Biogas | 1.2 | 1.3 | 1.6 | 6 |

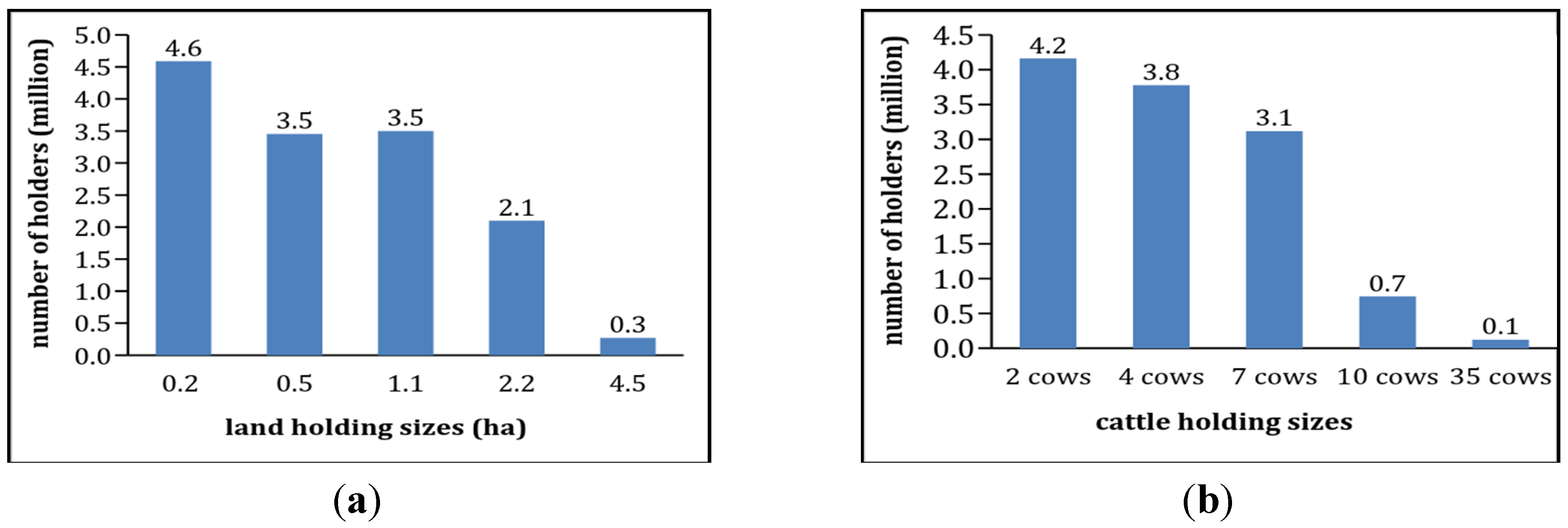

3.2. Availability of Resources to Meet the Households’ Demand

| Tenure size | Land (10 6 ha) | Households (10 6) | Holders (%) | Average holding (ha/hh) | Residues (ton/hh) | Potential energy (GJ/hh) | Useful energy per hh (GJ) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| gross | available | gross | available | briquette | biogas | |||||

| 0.1–0.5 | 0.7 | 4.6 | 33 | 0.2 | 0.5 | 0.1 | 9 | 3 | 0.6 | 0.7 |

| 0.51–1.0 | 1.9 | 3.5 | 25 | 0.5 | 2 | 0 | 29 | 9 | 2 | 2 |

| 1.01–2.0 | 3.9 | 3.5 | 25 | 1.1 | 3 | 1 | 59 | 18 | 4 | 5 |

| 2.01–5.0 | 4.5 | 2.1 | 15 | 2.2 | 6 | 2 | 117 | 35 | 7 | 9 |

| 5.01–8.0 | 1.0 | 0.2 | 2 | 4.2 | 13 | 4 | 227 | 68 | 14 | 18 |

| 8.01–11 | 0.2 | 0.03 | 0.2 | 8.5 | 25 | 8 | 458 | 137 | 29 | 37 |

| total/ave | 12.2 | 13.9 | 100 | 0.9 | 3 | 1 | 48 | 14 | 3 | 4 |

| Cattle holding size | Cattle (106) | Holders (106) | Holders (%) | Cattle per hh | Dry dung per household (tons) | Potential energy (GJ/hh) | Useful energy | ||

|---|---|---|---|---|---|---|---|---|---|

| gross | available | gross | available | biogas (GJ/hh) | |||||

| 1–2 | 6 | 4 | 35 | 2 | 1 | 0.4 | 19 | 8 | 1 |

| 3–4 | 13 | 4 | 32 | 4 | 2 | 1 | 44 | 18 | 3 |

| 5–9 | 22 | 3 | 26 | 7 | 5 | 2 | 88 | 35 | 7 |

| 10–19 | 7 | 1 | 6 | 10 | 7 | 3 | 120 | 48 | 9 |

| 20–49 | 4 | 0.1 | 1 | 35 | 24 | 10 | 435 | 174 | 33 |

| Total/av | 53 | 12 | 100 | 4 | 3 | 1.2 | 56 | 22 | 4 |

4. Discussion

4.1. Opportunities and Challenges of Using Bio-Wastes as Cooking Energy Sources

4.2. Comparing the Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- CSA. Ethiopian Welfare Monitoring Survey Report of 2011; Central Statistical Agency (CSA) of Ethiopia: Addis Ababa, Ethiopia, 2012.

- IEA. Energy for All: Financial Access for the Poor in World Energy Outlook 2011; International Energy Agency (IEA): Paris, France, 2011. [Google Scholar]

- UNDP. The Energy Access Situation in Developing Countries: A Review Focussing on Least Developed Countries and Sub-Saharan Africa; United Nations Development Programme and World Health Organization (UNDP): New York, NY, USA, 2009. [Google Scholar]

- Arnold, J.; Köhlin, G.; Persson, R. Woodfuels, livelihoods, and policy interventions: Changing perspectives. World Dev. 2006, 34, 596–611. [Google Scholar] [CrossRef]

- Kebede, B.; Bekele, A.; Kedir, E. Can the urban poor afford modern energy? The case of Ethiopia. Energy Policy 2002, 30, 1029–1045. [Google Scholar] [CrossRef]

- Cooke, P.; Kohlin, G.; Hyde, W.F. Fuelwood, forests and community management—Evidence from household studies. Environ. Dev. Econ. 2008, 13, 103–135. [Google Scholar] [CrossRef]

- Gebreegziabher, Z.; Mekonnen, A.; Kassie, M.; Köhlin, G. Household Tree Planting in Tigrai, Northern Ethiopia: Tree Species, Purposes, and Determinants; Working Papers in Economics No 432; University of Gothenburg: Gothenburg, Sweden, 2010. [Google Scholar]

- Jetter, J.J.; Kariher, P. Solid-fuel household cook stoves: Characterization of performance and emissions. Biomass Bioenergy 2009, 33, 294–305. [Google Scholar] [CrossRef]

- MacCarty, N.; Still, D.; Ogle, D. Fuel use and emissions performance of fifty cooking stoves in the laboratory and related benchmarks of performance. Energy Sustain. Dev. 2010, 14, 161–171. [Google Scholar] [CrossRef]

- Subedi, M.; Matthews, R.B.; Pogson, M.; Abegaz, A.; Balana, B.B.; Oyesiku-Blakemore, J.; Smith, J. Can biogas digesters help to reduce deforestation in Africa? Biomass Bioenergy 2014, 70, 87–98. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Abdul Salam, P. Low greenhouse gas biomass options for cooking in the developing countries. Biomass Bioenergy 2002, 22, 305–317. [Google Scholar] [CrossRef]

- Werther, J.; Saenger, M.; Hartge, E.; Ogada, T.; Siagi, Z. Combustion of agricultural residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Dasappa, S. Potential of biomass energy for electricity generation in Sub-Saharan Africa. Energy Sustain. Dev. 2011, 15, 203–213. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Global potential bioethanol production from wasted crops and crop residues. Biomass Bioenergy 2004, 26, 361–375. [Google Scholar] [CrossRef]

- Smeets, E.M.W.; Faaij, A.P.C.; Lewandowski, I.M.; Turkenburg, W.C. A bottom-up assessment and review of global bio-energy potentials to 2050. Prog. Energy Combust. Sci. 2007, 33, 56–106. [Google Scholar] [CrossRef]

- Duku, M.H.; Gu, S.; Hagan, E.B. A comprehensive review of biomass resources and biofuels potential in Ghana. Renew. Sustain. Energy Rev. 2011, 15, 404–415. [Google Scholar] [CrossRef]

- Jingura, R.M.; Matengaifa, R. The potential for energy production from crop residues in Zimbabwe. Biomass Bioenergy 2008, 32, 1287–1292. [Google Scholar] [CrossRef]

- Nzila, C.; Dewulf, J.; Spanjers, H.; Kiriamiti, H.; van Langenhove, H. Biowaste energy potential in Kenya. Renew. Energy 2010, 35, 2698–2704. [Google Scholar] [CrossRef]

- Ravindranath, N.H.; Somashekar, H.I.; Nagaraja, M.S.; Sudha, P.; Sangeetha, G.; Bhattacharya, S.C.; Abdul Salam, P. Assessment of sustainable non-plantation biomass resources potential for energy in India. Biomass Bioenergy 2005, 29, 178–190. [Google Scholar] [CrossRef]

- Orskov, E.R.; Anchang, K.Y.; Subedi, M.; Smith, J. Overview of holistic application of biogas for small scale farmers in Sub-Saharan Africa. Biomass Bioenergy 2014, 70, 4–16. [Google Scholar] [CrossRef]

- Eshete, G.; Sonder, K.; ter Heegde, F. Report on the Feasibility Study of a National Programme for Domestic Biogas in Ethiopia; SNV Netherlands Development Organization: Addis Ababa, Ethiopia, 2006. [Google Scholar]

- Kariko-Buhwezi, B. Challenges to the sustainability of small scale biogas technologies in Uganda. In Proceedings of the Second International Conference on Advances in Engineering and Technology, Entebbe, Uganda, 31 January–1 February 2011.

- FAO. FAOSTAT. 2014. Available online: http://faostat.fao.org/ (accessed on 13 May 2014).

- Hurni, H. Agroecological Belts of Ethiopia. Explanatory Notes on Three Maps at a Scale of 1:1,000,000; University of Bern: Bern, Switzerland, 1998. [Google Scholar]

- CSA. National Land Utilizations, Crop Production and Livestock Survey Report; National Statistical Agency of Ethiopia (CSA), 2012. Available online: http://www.csa.gov.et/ (accessed on 11 May 2014).

- UN. World Urban and Rural Population; Population Estimates and Projection Section, United Nations Population Division: New York, NY, USA, 2014. [Google Scholar]

- Demirbas, K.; Sahin-Demirbas, K.A. Compacting of Biomass for Energy Densification. Energy Sources Part A Recovery Util. Environ. Eff. 2009, 31, 1063–1068. [Google Scholar] [CrossRef]

- Tucho, G.T.; Weesie, P.D.; Nonhebel, S. Assessment of renewable energy resources potential for large scale and standalone applications in Ethiopia. Renew. Sustain. Energy Rev. 2014, 40, 422–431. [Google Scholar] [CrossRef]

- Barnes, D.F.; Floor, W.M. Rura enery in developing countries: A Challenge for Economic Development. Annu. Rev. Energy Environ. 1996, 21, 497–530. [Google Scholar] [CrossRef]

- Kowsari, R.; Zerriffi, H. Three dimensional energy profile: A conceptual framework for assessing household energy use. Energy Policy 2011, 39, 7505–7517. [Google Scholar] [CrossRef]

- Ameha, A. Sustainable Supply of Wood Resources from Adaba-Dodola Forest Priority Area. Paper Presented on the Alumni Seminar; Addis Ababa University: Addis Ababa, Ethiopia, 2002. [Google Scholar]

- Bewket, W. Household level tree planting and its implications for environmental management in the northwestern highlands of Ethiopia: A case study in the Chemoga watershed, Blue Nile basin. Land Degrad. Dev. 2003, 14, 377–388. [Google Scholar] [CrossRef]

- O’Sullivan, K.; Barnes, D.F. Energy Policies and Multitopic Household Surveys: Guidelines for Questionnaire Design in Living Standards Measurement Studies; World Bank Publications: Washington, DC, USA, 2007. [Google Scholar]

- Rosillo-Calle, F. The Biomass Assessment Handbook: Bioenergy for a Sustainable Environment; Earthscan: London, UK, 2007. [Google Scholar]

- Jekayinfa, S.; Scholz, V. Potential availability of energetically usable crop residues in Nigeria. Energy Sources Part A 2009, 31, 687–697. [Google Scholar] [CrossRef]

- Zeng, X.; Ma, Y.; Ma, L. Utilization of straw in biomass energy in China. Renew. Sustain. Energy Rev. 2007, 11, 976–987. [Google Scholar] [CrossRef]

- Purohit, P.; Tripathi, A.K.; Kandpal, T.C. Energetics of coal substitution by briquettes of agricultural residues. Energy 2006, 31, 1321–1331. [Google Scholar] [CrossRef]

- Demirbas, A. Sustainable charcoal production and charcoal briquetting. Energy Sources Part A 2009, 31, 1694–1699. [Google Scholar] [CrossRef]

- Zinoviev, S.; Müller-Langer, F.; Das, P.; Bertero, N.; Fornasiero, P.; Kaltschmitt, M.; Centi, G.; Miertus, S. Next-generation biofuels: Survey of emerging technologies and sustainability issues. ChemSusChem 2010, 3, 1106–1133. [Google Scholar] [CrossRef] [PubMed]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Batzias, F.A.; Sidiras, D.K.; Spyrou, E.K. Evaluating livestock manures for biogas production: A GIS based method. Renew. Energy 2005, 30, 1161–1176. [Google Scholar] [CrossRef]

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Jingura, R.M.; Matengaifa, R. Optimization of biogas production by anaerobic digestion for sustainable energy development in Zimbabwe. Renew. Sustain. Energy Rev. 2009, 13, 1116–1120. [Google Scholar] [CrossRef]

- Omer, A.; Fadalla, Y. Biogas energy technology in Sudan. Renew. Energy 2003, 28, 499–507. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Lehtomäki, A. Biogas Production from Energy Crops and Crop Residues; University of Jyväskylä: Jyväskylä, Finland, 2006. [Google Scholar]

- Rajendran, K.; Aslanzadeh, S.; Taherzadeh, M.J. Household biogas digesters—A review. Energies 2012, 5, 2911–2942. [Google Scholar] [CrossRef]

- Karaj, S.; Rehl, T.; Leis, H.; Müller, J. Analysis of biomass residues potential for electrical energy generation in Albania. Renew. Sustain. Energy Rev. 2010, 14, 493–499. [Google Scholar] [CrossRef]

- Scarlat, N.; Martinov, M.; Dallemand, J.-F. Assessment of the availability of agricultural crop residues in the European Union: Potential and limitations for bioenergy use. Waste Manag. 2010, 30, 1889–1897. [Google Scholar] [CrossRef] [PubMed]

- Lal, R. Soil carbon sequestration impacts on global climate change and food security. Science 2004, 304, 1623–1627. [Google Scholar] [CrossRef] [PubMed]

- Haileslassie, A.; Priess, J.; Veldkamp, E.; Teketay, D.; Lesschen, J.P. Assessment of soil nutrient depletion and its spatial variability on smallholders’ mixed farming systems in Ethiopia using partial versus full nutrient balances. Agric. Ecosyst. Environ. 2005, 108, 1–16. [Google Scholar] [CrossRef]

- Haileslassie, A.; Priess, J.A.; Veldkamp, E.; Lesschen, J.P. Smallholders’ soil fertility management in the Central Highlands of Ethiopia: Implications for nutrient stocks, balances and sustainability of agroecosystems. Nutr. Cycl. Agroecosyst. 2006, 75, 135–146. [Google Scholar] [CrossRef]

- Duguma, L.A.; Minang, P.A.; Freeman, O.E.; Hager, H. System wide impacts of fuel usage patterns in the Ethiopian highlands: Potentials for breaking the negative reinforcing feedback cycles. Energy Sustain. Dev. 2014, 20, 77–85. [Google Scholar] [CrossRef]

- Valbuena, D.; Erenstein, O.; Tui, S.; Abdoulaye, T.; Claessens, L.; Duncan, A.J.; Gerard, B.; Rufino, M.C.; Teufel, N.; van Rooyen, A.; et al. Conservation agriculture in mixed crop-livestock systems: Scoping crop residue trade-offs in sub-Saharan Africa and South Asia. Field Crops Res. 2012, 132, 175–184. [Google Scholar] [CrossRef]

- Mengistu, M.G.; Simane, B.; Eshete, G.; Workneh, T.S. A review on biogas technology and its contributions to sustainable rural livelihood in Ethiopia. Renew. Sustain. Energy Rev. 2015, 48, 306–316. [Google Scholar] [CrossRef]

- Gwavuya, S.G.; Abele, S.; Barfuss, I.; Zeller, M.; Müller, J. Household energy economics in rural Ethiopia: A cost-benefit analysis of biogas energy. Renew. Energy 2012, 48, 202–209. [Google Scholar] [CrossRef]

- Fischer, G.; Schrattenholzer, L. Global bioenergy potentials through 2050. Biomass Bioenergy 2001, 20, 151–159. [Google Scholar] [CrossRef]

- Berndes, G.; Hoogwijk, M.; van den Broek, R. The contribution of biomass in the future global energy supply: A review of 17 studies. Biomass Bioenergy 2003, 25, 1–28. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tucho, G.T.; Nonhebel, S. Bio-Wastes as an Alternative Household Cooking Energy Source in Ethiopia. Energies 2015, 8, 9565-9583. https://doi.org/10.3390/en8099565

Tucho GT, Nonhebel S. Bio-Wastes as an Alternative Household Cooking Energy Source in Ethiopia. Energies. 2015; 8(9):9565-9583. https://doi.org/10.3390/en8099565

Chicago/Turabian StyleTucho, Gudina Terefe, and Sanderine Nonhebel. 2015. "Bio-Wastes as an Alternative Household Cooking Energy Source in Ethiopia" Energies 8, no. 9: 9565-9583. https://doi.org/10.3390/en8099565

APA StyleTucho, G. T., & Nonhebel, S. (2015). Bio-Wastes as an Alternative Household Cooking Energy Source in Ethiopia. Energies, 8(9), 9565-9583. https://doi.org/10.3390/en8099565