An Environmental and Economic Assessment for Selecting the Optimal Ground Heat Exchanger by Considering the Entering Water Temperature

Abstract

:1. Introduction

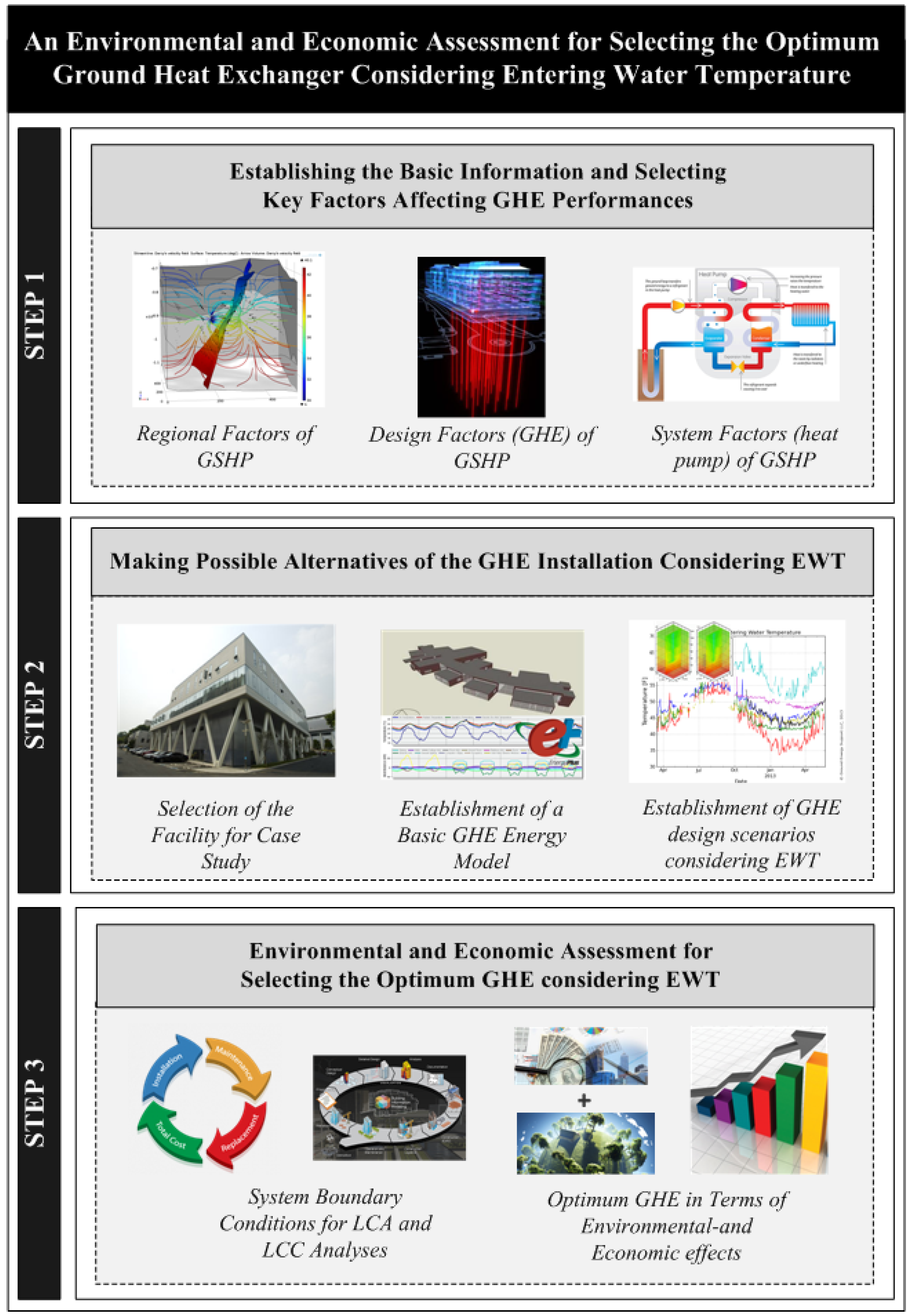

2. Establishing the Basic Information and Selecting Key Factors Affecting Ground Heat Exchanger (GHE) Performances

2.1. Regional Factors of a Ground Source Heat Pump (GSHP) System

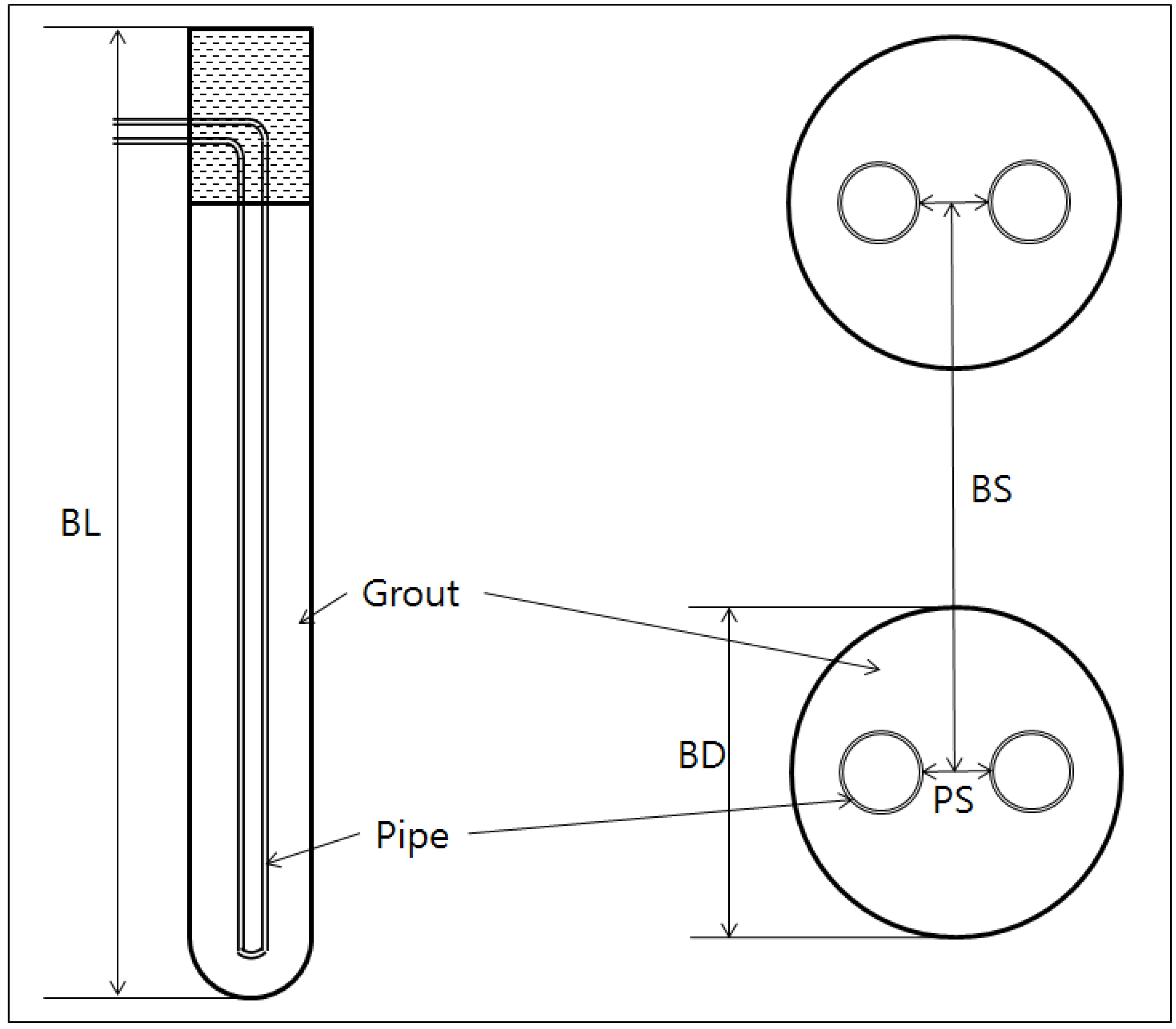

2.2. Design Factors of GHE for a GSHP System

- •

- Borehole length (BL): Borehole length usually affects largely the performances and cost of GHE, and, accordingly, multi-studies are being conducted on the design of optimal length. The optimal length is decided by all the factors affecting GHE such as underground environment, GHE components and G-function.

- •

- Number of boreholes and arrangement: The number and arrangement of boreholes is a factor that can affect the total length of the borehole and accounts for a significant portion of the cost. Besides, as the distribution of temperature transferred to underground varies according to a type of arrangement such as L-, U- and rectangle types, this factor affects the performances of boreholes.

- •

- Borehole spacing (BS): As heat capacity differs according to the type of ground, optimal spacing should be designed to prevent a reduction in GHE performances caused by intersection of the scopes of ground-source heats emitted and absorbed by each borehole.

- •

- Borehole diameter (BD): Borehole diameter is designed in consideration of the U-pipe through which fluid flows and the volume of grout that fills a borehole. As borehole thermal resistance is higher with an increase in the volume of grout, the performance decreases. If its volume is too small, the inner components protected by grout can be impaired. Thus, it is necessary to make proper thickness.

- •

- U-pipe spacing (PS), pipe size and pipe type: It is necessary to combine these factors to meet temperature load in consideration of the speed of fluid that flows inside a pipe and its related heat transfer capacity. These factors, which are related to the flowing fluid the pipe directly touches, require a strength and durability above a certain level.

- •

- Grout conductivity: Grout conductivity is an element that constitutes a borehole. The higher its thermal conductivity, the lower the overall borehole resistance.

- •

- Fluid type, flow rate: Fluid type and flow rate are variables of heat transfer that occur while fluid flows in a pipe. The usual mix with other material keeps fluid from freezing.

Table 1. Overview of key factor. Category Key Factor (Unit) References Regional Factor Ground temperature (°C), Soil type, Ground thermal conductivity (W/mK), Ground heat capacity (kJ/K·m3) [50,51,52,53] Ground Heat Exchanger Borehole length (BL) (m), Borehole spacing (BS) (m), Borehole diameter (BD) (mm), U-pipe spacing (PS) (mm), Number of boreholes: arrangement, Grout conductivity (W/mK), Borehole thermal resistance (K/(W/m)), Pipe type, Pipe size, Fluid type, Flow rate (L/s), Entering water temperature (°C) [54,55,56,57,58,59,60,61,62] Heat Pump Capacity (kW), Power input (kW), Heat of rejection (kW), Heat of extraction (kW), Coefficient of performance, Energy efficient rating, Entering water temperature (°C) [27,63,64,65] Figure 2. Components of Ground Source Heat Pump (GSHP) system. - •

- Borehole thermal resistance: Borehole thermal resistance, which is the thermal resistance of the overall borehole determined by a mix of the above factors, affects the design of a borehole.

- •

- Entering water temperature (EWT): EWT, which is an indicator that can evaluate the final performance by a mix of each key factor, is the GHE outlet temperature that meets the energy demand of the building [66]. To calculate the EWT, Equation (1) was used [67]. EWT is designed to provide water at a high temperature in the case of heating, and at a low temperature in the case of cooling, which can minimize the load of a heat pump. Hence, the design process of the GHE will be a core factor in the design of the overall GSHP system.

2.3. System Factors (Heat Pump) of GSHP System

3. Creating Possible Alternatives for the GHE Installation by Considering Entering Water Temperature (EWT)

3.1. Selection of a Facility for Case Study

- •

- According to the 2013 Annual End-Use Energy Statistics, the total energy and CO2 emissions from high energy consumption buildings that use 2000 toe per year reached 2,307,000 toe and 10,083,000 ton-CO2, respectively. The energy used by the schools among them reached 336,000 toe with CO2 emissions of 1,397,000 ton-CO2, which accounted for around 15% of the total amount used by buildings [1].

- •

- The GSHP system among an NRE system can be installed underground and designed around the systematic characteristics. Accordingly, the region with the lowest high building density should be selected.

- •

- A building that fully uses an air cooling and heating GSHP system was selected to calculate the environmental and economic effects of a GSHP system according to GHE scenarios.

| Category | University Facilities |

|---|---|

| Year established | 2012 |

| Location | Seoul |

| Building type | Educational facility |

| Electricity system | On-grid |

| Heating system | Individual heating |

| Progressive tax | No |

| Floor space of gym | 1197.54 m2 |

| Major energy service | Ground source heat pump (GSHP) |

| Installation of capacity | Cooling: 204 kW/Heating: 218 kW |

| Borehole | Length: 143 m/hole: 22 EA |

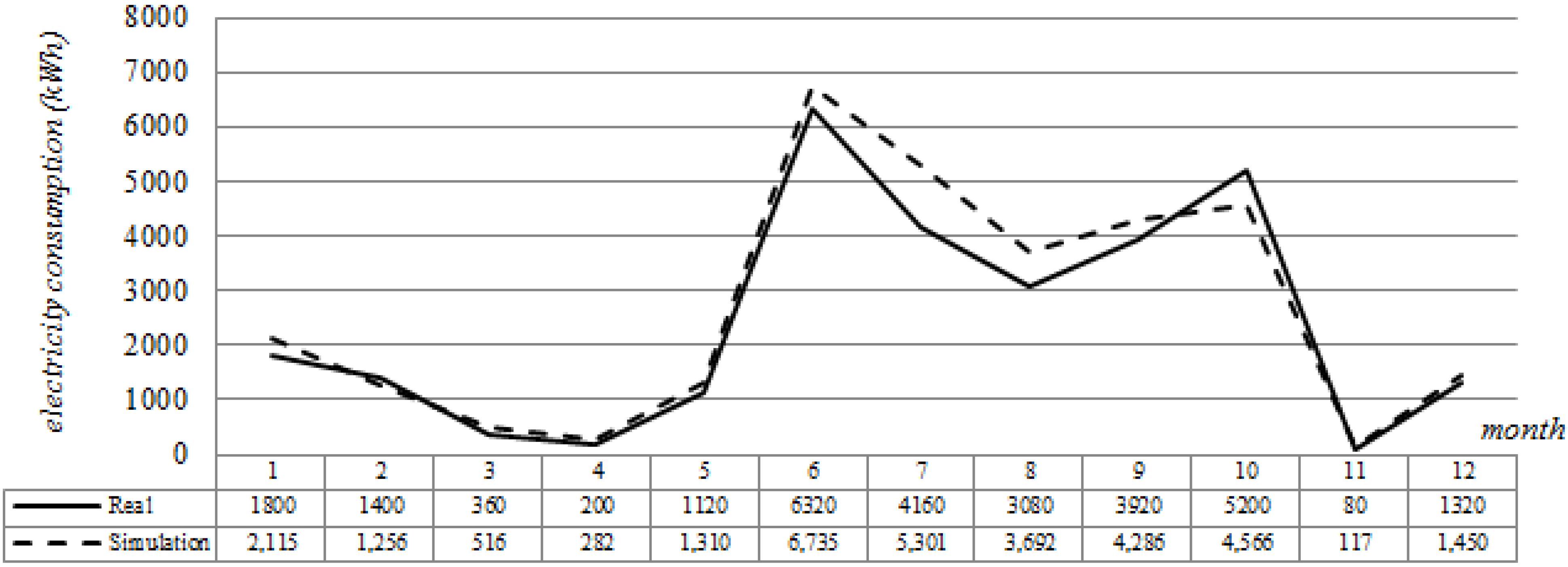

3.2. Establishment of a Basic GHE Energy Model

3.3. Establishment of GHE Design Scenarios Considering EWT

4. Environmental and Economic Assessment for Selecting the Optimal GHE by Considering EWT

4.1. System Boundary Conditions for Life-Cycle Assessment (LCA) and Life-Cycle Cost (LCC) Analyses

| Maximum Entering Water Temperature: 23 °C, Minimum Entering Water Temperature: 5 °C | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Boreholes: Arrangement (U) | Borehole Spacing | Grout Conductivity (W/mK) | U-Tube Type and Size | U-Tube Type and Size | U-Tube Type and Size | |||||||||

| PN10, DN25 | PN10, DN32 | PN10, DN40 | ||||||||||||

| Borehole Diameter | Borehole Diameter | Borehole Diameter | ||||||||||||

| 125 mm | 150 mm | 125 mm | 150 mm | 125 mm | 150 mm | |||||||||

| U-Pipe Spacing | U-Pipe Spacing | U-Pipe Spacing | ||||||||||||

| 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | |||

| 22 (EA): 8 × 8 | 4 m | 1 W/mK | 249.1 | 227.3 | 251.9 | 232.6 | 212.1 | 194.1 | 215.1 | 198.7 | 182.5 | 168.3 | 185.2 | 173.3 |

| 1.4 W/mK | 216.7 | 196.9 | 217.7 | 199.7 | 189.0 | 174.6 | 189.8 | 177.1 | 166.2 | 154.2 | 167.0 | 156.5 | ||

| 1.8 W/mK | 195.8 | 181.1 | 195.8 | 182.4 | 174.7 | 162.1 | 166.6 | 163.0 | 155.8 | 145.3 | 155.2 | 145.9 | ||

| 5 m | 1 W/mK | 247.6 | 225.4 | 250.5 | 231.1 | 210.4 | 192.5 | 213.4 | 197.2 | 180.3 | 166.0 | 183.1 | 170.8 | |

| 1.4 W/mK | 214.9 | 195.2 | 216.1 | 198.1 | 187.3 | 172.2 | 188.2 | 174.8 | 164.0 | 152.2 | 164.8 | 154.4 | ||

| 1.8 W/mK | 194.4 | 179.0 | 194.3 | 180.2 | 172.3 | 159.8 | 172.0 | 160.7 | 153.8 | 143.6 | 153.3 | 144.2 | ||

| 6 m | 1 W/mK | 246.6 | 224.0 | 249.5 | 229.9 | 209.1 | 191.4 | 207.8 | 195.8 | 179.2 | 165.1 | 181.9 | 169.7 | |

| 1.4 W/mK | 212.8 | 194.3 | 214.7 | 196.9 | 186.0 | 171.1 | 182.3 | 173.9 | 163.0 | 151.1 | 163.8 | 153.4 | ||

| 1.8 W/mK | 193.2 | 177.9 | 193.1 | 179.0 | 171.5 | 158.7 | 166.6 | 159.6 | 152.7 | 142.5 | 152.2 | 143.1 | ||

| Number of Scenario | Max./Min. Entering Water Temperature | Number of Boreholes: Arrangement (U) | Borehole Spacing | Grout Conductivity (W/mK) | U-Tube Type and Size | Borehole Diameter | U-Pipe Spacing | Borehole Length |

|---|---|---|---|---|---|---|---|---|

| Scenario #1 | 30/5 °C | 22 (EA): 8 × 8 | 6 m | 1.8 W/mK | PN10, DN25 | 150 mm | 20 mm | 90 m |

| Scenario #2 | 27/5 °C | 107 m | ||||||

| Scenario #3 | 25/5 °C | 123 m | ||||||

| Scenario #4 (exist GHE) | 23/5 °C | 143 m | ||||||

| Scenario #5 | 20/5 °C | 195 m |

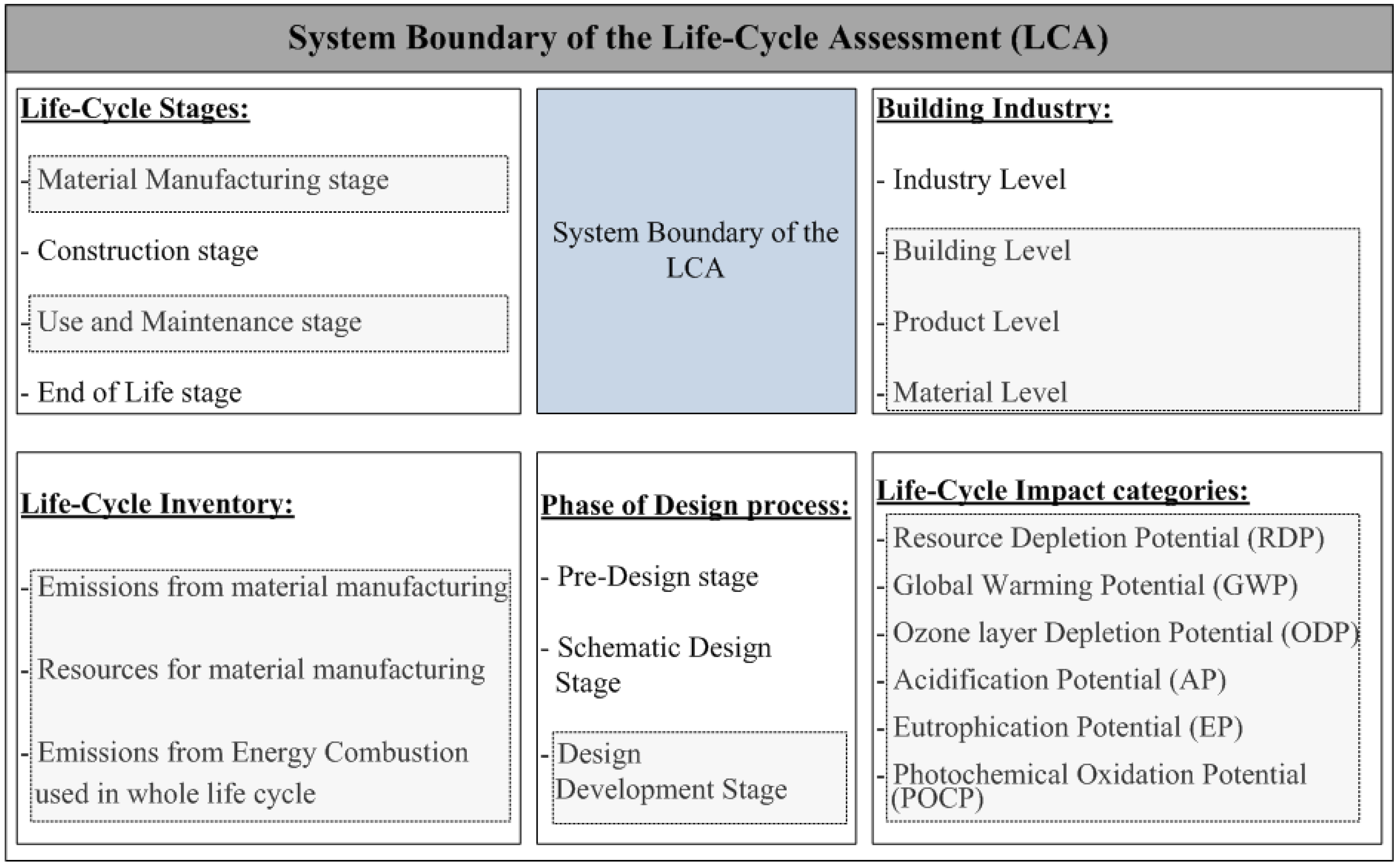

4.1.1. Establishment of System Boundary and Assumptions for LCA

- •

- Step 1. Goal and scope definition: Based on the information available in whole life cycle, environmental impact generated from the material manufacturing phase and use and maintenance stage are analyzed. The functional unit is defined as “the entire building supplied from design and use and maintenance for a whole service life”.

- •

- Step 2. LCI analysis: Using the LCI analysis results by life-cycle phase, the environmental-impact substances can be calculated. First, using input-output (I-O) LCA, energy source quantity utilized to produce the material for each life-cycle phase was calculated. Second, employing a process-based LCA, the national LCI database of South Korea established that the environmental-impact substances produced in the material and energy production process can be calculated (refer to Equation (5)) [71,72].where Ei is the emission of substance (i), QEk is the quantity of energy source (k), EPik is the emission factor of substance (i) emitted in producing one unit of energy source (k), and ECik is the emission factor of substance (i) emitted in consuming one unit of energy source (k).

- •

- Step 3. Life-cycle impact assessment: LCIA converts the environmental-impact substances from the LCI analysis into the environmental impacts. LCIA is made up four categories: (i) Classification; (ii) Characterization; (iii) Normalization; (iv) Weighting [70,71]. In this study, classification and characterization were used to calculate the characterized environmental impact. The process of classification and characterization was calculated by Equation (6) [71,72]. To calculate characterized impacts (CCIl), the characterization factor (CFl,i) of each substance is required. Based on the “environmental labeling type III” standard, the characterized environmental impacts on six environmental-impact categories (i.e., RDP, GWP, ODP, AP, EP, and POCP) were presented.where CCIl is the characterized impact of impact category (l), Ei is the emission of substance (i), and CFl,i is the characterization factor of substance (i) to impact category (l).

- •

- Step 4. Results and interpretations: Using the estimated environmental impact, environmental and economic values are calculated. Environmental cost signifies the cost generated using end-point LCA methodology [70,73,74]. In this study, the environmental-cost conversion factor proposed in EPS 2000 was used to convert the environmental impact to environmental cost [75] (refer to Table A5). By analyzing the relative degree of the impact on the global environment of the environmental-impact categories, all the environmental impacts can be converted into environmental cost.

4.1.2. Establishment of System Boundary and Assumptions for LCC

- •

- Analysis approach: For the analysis approach, net present value (NPV) was selected for the LCC analysis. NPV is the method used to convert the future value of a design alternative into the present value by considering the discount rate and the time value (refer to Equation (7)). If NPV > 0, the project is deemed feasible; if NPV = 0, the break-even point is deemed to have been reached [76].where NPV is the net present value, BESt is the benefit from the energy savings in year t, BETt is the benefit from the emissions trading in year t, CIt is the cost of the initial investment in year t, CRrt is the cost of the repair in maintenance phase in year t, CRtt is the cost of the replacement in maintenance phase in year t, r is the real discount rate, and n is the period of the life-cycle analysis.

- •

- Analysis period: Generally, the analysis period for the LCC analysis can be established based on the service life of a product, which is based on the building’s structural type [71]. In this study, a 40-year time frame was used for the analysis period of the LCC.

- •

- Interest rate (refer to Equation (8)): In this study, the real discount rate was calculated using the nominal interest rate and various inflation rates (refer to Table A6) [71]. It can be used for converting various benefits and costs into present values.where i is the real discount rate, in is the nominal interest rate, and f is the inflation rate (i.e., electricity price growth rate, gas price growth rate, carbon dioxide emission trading price growth rate).

- •

- Significant cost of ownership: From the life-cycle perspective, the initial investment cost and the use and maintenance cost need to be considered. The material consumption information was collected from the bill of quantities of the GHE and heat pump. The energy consumption information, on the other hand, was established through energy simulation, which was allocated to the energy cost among the use costs. Meanwhile, the repair rate, repair cycle, and replacement cycle of each material should be considered to calculate the cost in the maintenance phase. In this study, resources such as “Public Procurement Service”, “Ministry of National Defense” and “Implementing Regulations of the Housing Act in Korea (Appendix 5)”, which are provided by respectable institutions, were used [71].

4.2. Optimal GHE in Terms of Environmental and Economic Effects

- •

- First, life-cycle environmental cost: Saving effect of life-cycle environmental cost of Scenario #3 was determined at 2.2% compared with the existing GHE (Scenario #4). Although the initial investment environmental cost is higher than that of the existing GHE, the operation and maintenance environmental cost is lower than that of the existing GHE.

Table 5. Life-cycle environmental and economic cost of scenarios. Scenario Classification Environmental Impact Category Environmental Cost Economic Cost Total Cost RDP GWP ODP AP EP POCP (kg-Sb-eq) (kg-CO2-eq) (kg-CFC11-eq) (kg-SO2-eq) (kg-PO43-eq) (kg-C2H4-eq) Scenario #1 Initial cost 260 151,144 - 804 62 227 23,136 94,638 117,774 O and M cost 1275 724,427 - 1244 231 2 108,246 104,664 212,909 Total cost 1535 875,572 - 2047 293 229 131,381 199,302 330,683 Scenario #2 Initial cost 288 168,762 - 898 69 250 25,819 103,296 129,115 O and M cost 1150 653,432 - 1122 209 2 97,638 96,079 193,716 Total cost 1437 822,194 - 2020 277 252 123,457 199,375 322,831 Scenario #3 Initial cost 315 186,416 - 993 76 274 28,508 111,969 140,477 O and M cost 1096 622,723 - 1069 199 2 93,049 92,421 185,469 Total cost 1411 809,139 - 2062 275 276 121,557 204,390 325,947 Scenario #4 Initial cost 352 210,223 - 1121 85 305 32,133 123,610 155,743 O and M cost 1085 616,970 - 1059 197 2 92,189 91,824 184,014 Total cost 1437 827,193 - 2180 282 307 124,322 215,434 339,756 Scenario #5 Initial cost 439 265,811 - 1419 107 379 40,600 150,977 191,578 O and M cost 966 549,094 - 943 175 2 82,047 83,713 165,760 Total cost 1405 814,905 - 2362 282 381 122,647 234,690 357,337 Notes: Unit (US$); operation and maintenance phase (O and M); resource depletion potential (RDP); global warming potential (GWP); ozone layer depletion potential (ODP); acidification potential (AP); eutrophication potential (EP); and photochemical oxidation potential (POCP). - •

- Second, life-cycle economic cost: Saving effect of life-cycle economic cost of Scenario #1 was determined to be 7.5% as compared to the existing GHE (Scenario #4). Although the initial investment cost is higher than that of the existing GHE, the operation and maintenance cost is lower than that of the existing GHE.

- •

- Third, life-cycle environmental and economic cost: Saving effect of total cost of Scenario #2 was determined to be 5.0% compared with the existing GHE (Scenario #4). Although the initial investment cost is higher than that of the existing GHE, the operation and maintenance cost is lower than that of the existing GHE.

5. Conclusions

- •

- Life-cycle environmental cost: Saving effect of life-cycle environmental cost of Scenario #3 was determined to be 2.2% compared with existing GHE (Scenario #4).

- •

- Life-cycle economic cost: Saving effect of life-cycle economic cost of Scenario #1 was determined at 7.5% compared with existing GHE (Scenario #4).

- •

- Life-cycle environmental and economic cost: Saving effect of total cost of scenario #2 was determined at 5.0% compared with existing GHE (Scenario #4).

Acknowledgements

Author Contributions

Conflicts of Interest

Appendix

| Maximum Entering Water Temperature: 30 °C, Minimum Entering Water Temperature: 5 °C | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Boreholes: Arrangement (U) | Borehole Spacing | Grout Conductivity (W/mK) | U-Tube Type and Size | U-Tube Type and Size | U-Tube Type and Size | |||||||||

| PN10, DN25 | PN10, DN32 | PN10, DN40 | ||||||||||||

| Borehole Diameter | Borehole Diameter | Borehole Diameter | ||||||||||||

| 125 mm | 150 mm | 125 mm | 150 mm | 125 mm | 150 mm | |||||||||

| U-Pipe Spacing | U-Pipe Spacing | U-Pipe Spacing | ||||||||||||

| 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | |||

| 22 (EA): 8 × 8 | 4 m | 1 W/mK | 157.4 | 142.4 | 159.3 | 145.8 | 134.1 | 123.0 | 135.7 | 126.3 | 114.7 | 105.7 | 116.4 | 108.8 |

| 1.4 W/mK | 136.5 | 125.1 | 137.1 | 126.9 | 119.1 | 109.7 | 119.7 | 111.3 | 104.2 | 96.9 | 104.8 | 98.2 | ||

| 1.8 W/mK | 124.3 | 113.9 | 124.3 | 114.6 | 109.8 | 101.5 | 109.6 | 102.1 | 97.9 | 91.8 | 97.5 | 92.2 | ||

| 5 m | 1 W/mK | 156.1 | 141.4 | 157.9 | 144.7 | 133.2 | 121.9 | 134.8 | 125.1 | 113.5 | 104.3 | 115.3 | 107.5 | |

| 1.4 W/mK | 135.6 | 123.9 | 136.2 | 125.8 | 117.9 | 108.5 | 118.5 | 110.1 | 102.9 | 95.7 | 103.4 | 97.0 | ||

| 1.8 W/mK | 123.2 | 112.7 | 123.1 | 113.4 | 108.5 | 100.2 | 108.4 | 100.8 | 96.6 | 90.6 | 96.3 | 91.0 | ||

| 6 m | 1 W/mK | 155.4 | 140.7 | 157.3 | 144.0 | 132.4 | 120.8 | 134.0 | 124.2 | 112.7 | 103.8 | 114.4 | 106.9 | |

| 1.4 W/mK | 134.9 | 123.0 | 136.5 | 124.8 | 117.1 | 107.8 | 117.7 | 109.4 | 102.3 | 95.3 | 102.9 | 96.6 | ||

| 1.8 W/mK | 122.3 | 111.9 | 122.2 | 112.7 | 107.9 | 99.8 | 107.7 | 100.3 | 96.2 | 90.1 | 95.9 | 90.4 | ||

| Maximum Entering Water Temperature: 23 °C, Minimum Entering Water Temperature: 5 °C | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Boreholes: Arrangement (U) | Borehole Spacing | Grout Conductivity (W/mK) | U-Tube Type and Size | U-Tube Type and Size | U-Tube Type and Size | |||||||||

| PN10, DN25 | PN10, DN32 | PN10, DN40 | ||||||||||||

| Borehole Diameter | Borehole Diameter | Borehole Diameter | ||||||||||||

| 125 mm | 150 mm | 125 mm | 150 mm | 125 mm | 150 mm | |||||||||

| U-Pipe Spacing | U-Pipe Spacing | U-Pipe Spacing | ||||||||||||

| 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | |||

| 22 (EA): 8 × 8 | 4 m | 1 W/mK | 186.5 | 169.1 | 188.5 | 173.1 | 158.4 | 144.6 | 160.7 | 148.5 | 135.7 | 122.4 | 133.7 | 125.8 |

| 1.4 W/mK | 161.8 | 147.0 | 162.7 | 149.3 | 140.3 | 130.4 | 141.0 | 132.2 | 124.1 | 112.9 | 121.5 | 114.4 | ||

| 1.8 W/mK | 146.1 | 134.9 | 146.0 | 135.7 | 130.5 | 120.8 | 130.3 | 121.5 | 114.0 | 107.0 | 113.5 | 107.4 | ||

| 5 m | 1 W/mK | 185.0 | 167.5 | 187.2 | 171.5 | 156.8 | 143.3 | 159.0 | 147.1 | 132.0 | 122.1 | 133.6 | 125.6 | |

| 1.4 W/mK | 160.0 | 145.7 | 161.0 | 147.9 | 139.1 | 129.1 | 139.8 | 131.0 | 120.5 | 112.3 | 121.1 | 113.9 | ||

| 1.8 W/mK | 144.8 | 133.8 | 144.8 | 134.5 | 129.2 | 119.4 | 129.0 | 120.0 | 113.4 | 106.3 | 113.0 | 106.7 | ||

| 6 m | 1 W/mK | 184.1 | 166.9 | 186.3 | 170.8 | 156.0 | 142.5 | 158.2 | 146.3 | 131.9 | 121.9 | 133.6 | 125.3 | |

| 1.4 W/mK | 159.3 | 144.9 | 160.0 | 147.1 | 138.3 | 128.0 | 139.0 | 129.9 | 120.1 | 111.9 | 120.8 | 113.5 | ||

| 1.8 W/mK | 144.1 | 132.9 | 144.0 | 133.7 | 128.0 | 118.3 | 127.9 | 118.9 | 113.0 | 105.9 | 112.6 | 107.0 | ||

| Maximum Entering Water Temperature: 23 °C, Minimum Entering Water Temperature: 5 °C | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Boreholes: Arrangement (U) | Borehole Spacing | Grout Conductivity (W/mK) | U-Tube Type and Size | U-Tube Type and Size | U-Tube Type and Size | |||||||||

| PN10, DN25 | PN10, DN32 | PN10, DN40 | ||||||||||||

| Borehole Diameter | Borehole Diameter | Borehole Diameter | ||||||||||||

| 125 mm | 150 mm | 125 mm | 150 mm | 125 mm | 150 mm | |||||||||

| U-Pipe Spacing | U-Pipe Spacing | U-Pipe Spacing | ||||||||||||

| 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | |||

| 22 (EA): 8 × 8 | 4 m | 1 W/mK | 212.6 | 192.9 | 215.4 | 197.0 | 181.5 | 166.3 | 184.1 | 170.4 | 155.1 | 142.6 | 157.5 | 146.8 |

| 1.4 W/mK | 185.2 | 168.8 | 186.1 | 171.3 | 161.3 | 148.1 | 162.1 | 150.3 | 140.8 | 132.2 | 141.5 | 133.8 | ||

| 1.8 W/mK | 168.0 | 154.0 | 168.0 | 155.0 | 148.1 | 137.7 | 147.9 | 138.3 | 133.4 | 125.1 | 132.9 | 125.6 | ||

| 5 m | 1 W/mK | 211.2 | 191.5 | 213.8 | 195.7 | 179.8 | 164.4 | 182.2 | 168.6 | 153.4 | 141.2 | 155.7 | 145.3 | |

| 1.4 W/mK | 183.5 | 166.9 | 184.4 | 169.5 | 159.3 | 146.4 | 160.2 | 148.6 | 139.5 | 130.8 | 140.1 | 132.6 | ||

| 1.8 W/mK | 166.1 | 152.3 | 166.1 | 153.3 | 146.5 | 136.5 | 146.3 | 137.1 | 132.1 | 123.5 | 131.6 | 124.0 | ||

| 6 m | 1 W/mK | 210.1 | 190.6 | 212.8 | 197.8 | 178.8 | 163.6 | 181.1 | 167.7 | 182.9 | 140.3 | 154.8 | 144.4 | |

| 1.4 W/mK | 182.4 | 166.3 | 183.4 | 168.5 | 158.4 | 145.5 | 159.3 | 147.7 | 138.5 | 129.6 | 139.2 | 131.5 | ||

| 1.8 W/mK | 165.3 | 151.4 | 165.2 | 152.4 | 145.6 | 135.5 | 145.4 | 136.1 | 130.9 | 122.1 | 130.4 | 122.6 | ||

| Maximum Entering Water Temperature: 23 °C, Minimum Entering Water Temperature: 5 °C | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Boreholes: Arrangement (U) | Borehole Spacing | Grout Conductivity (W/mK) | U-Tube Type and Size | U-Tube Type and Size | U-Tube Type and Size | |||||||||

| PN10, DN25 | PN10, DN32 | PN10, DN40 | ||||||||||||

| Borehole Diameter | Borehole Diameter | Borehole Diameter | ||||||||||||

| 125 mm | 150 mm | 125 mm | 150 mm | 125 mm | 150 mm | |||||||||

| U-Pipe Spacing | U-Pipe Spacing | U-Pipe Spacing | ||||||||||||

| 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | 3 mm | 20 mm | |||

| 22 (EA): 8 × 8 | 4 m | 1 W/mK | 338.8 | 306.9 | 342.7 | 314.1 | 287.2 | 263.6 | 291.4 | 270.1 | 247.3 | 230.1 | 250.9 | 236.0 |

| 1.4 W/mK | 293.8 | 267.9 | 295.4 | 271.3 | 255.8 | 237.6 | 257.2 | 240.7 | 226.7 | 209.7 | 228.5 | 213.0 | ||

| 1.8 W/mK | 266.5 | 245.9 | 266.4 | 247.2 | 237.7 | 220.9 | 237.5 | 222.1 | 211.9 | 198.8 | 211.1 | 199.1 | ||

| 5 m | 1 W/mK | 337.1 | 305.4 | 341.1 | 312.4 | 285.5 | 261.8 | 289.6 | 268.7 | 245.5 | 227.2 | 249.0 | 233.9 | |

| 1.4 W/mK | 291.6 | 266.1 | 293.3 | 269.9 | 254.0 | 235.5 | 255.4 | 238.8 | 224.2 | 206.9 | 225.4 | 210.6 | ||

| 1.8 W/mK | 264.6 | 243.8 | 264.5 | 245.3 | 235.7 | 218.3 | 235.4 | 219.5 | 209.6 | 195.9 | 208.8 | 196.6 | ||

| 6 m | 1 W/mK | 335.9 | 304.2 | 340.0 | 311.2 | 284.3 | 260.5 | 288.4 | 267.7 | 274.3 | 225.5 | 247.6 | 232.3 | |

| 1.4 W/mK | 290.3 | 264.9 | 292.0 | 268.9 | 252.8 | 234.0 | 254.1 | 237.0 | 222.2 | 205.1 | 223.7 | 208.7 | ||

| 1.8 W/mK | 263.4 | 242.3 | 263.2 | 243.8 | 234.2 | 216.4 | 233.9 | 217.6 | 207.3 | 194.1 | 206.5 | 194.9 | ||

| Environmental Impact | Environmental Cost Conversion Factor |

|---|---|

| resource depletion potential (RDP) | 2.439 US$/kg-Sb-eq |

| global warming potential (GWP) | 0.167 US$/kg-CO2-eq |

| ozone layer depletion potential (ODP) | 145.172 US$/kg-CFC11-eq |

| acidification potential (AP) | 0.032 US$/kg-SO2-eq |

| eutrophication potential (EP) | 0.029 US$/kg-PO43-eq |

| photochemical oxidation potential (POCP) | 2.675 US$/kg-C2H4-eq |

| Classification | Detailed Classification | Detailed Description |

|---|---|---|

| Analysis Approach | Present Worth Method (NPV40) | |

| Analysis Period | 40 years | |

| Realistic Discount Rate | Interest | 3.30% |

| Electricity | 0.66% | |

| Gas | 0.11% | |

| KCERs | 2.66% | |

| Significant Cost of Ownership | Initial construction cost | Initial investment cost |

| Operation and maintenance cost | Replacement/repair cost | |

| Energy consumption cost | ||

| Operation and maintenance benefit | Gas savings, electricity savings | |

| Benefit from KCERs | ||

References

- Korea Energy Management Corporation (KEMCO). 2013 Annual End-Use Energy Statistics. Available online: http://www.kemco.or.kr/ (accessed on 28 June 2015).

- Maria, B. Energy concept design of zero energy buildings. Adv. Mater. Res. 2013, 649, 7–10. [Google Scholar]

- Koo, C.; Hong, T.; Park, H.S.; Yun, G. Framework for the analysis of the potential of the rooftop photovoltaic system to achieve the net-zero energy solar buildings. Prog. Photovolt. Res. Appl. 2014, 22, 462–478. [Google Scholar] [CrossRef]

- Saman, W.Y. Towards zero energy homes down under. Renew. Energy 2013, 49, 211–215. [Google Scholar] [CrossRef]

- Li, D.H.; Yang, L.; Lam, J.C. Zero energy buildings and sustainable development implications—A review. Energy 2013, 54, 1–10. [Google Scholar] [CrossRef]

- Hong, T.; Koo, C.; Kwak, T. Framework for the implementation of a new renewable energy system in an educational facility. Appl. Energy 2013, 103, 539–551. [Google Scholar] [CrossRef]

- Hong, T.; Koo, C.; Kwak, T.; Park, H.S. An economic and environmental assessment for selecting the optimal new renewable energy system for educational facility. Renew. Sustain. Energy. Rev. 2014, 29, 286–300. [Google Scholar] [CrossRef]

- Hong, T.; Koo, C.; Park, J.; Park, H.S. A GIS (geographic information system)-based optimization model for estimating the electricity generation of the rooftop PV (photovoltaic) system. Energy 2014, 65, 190–199. [Google Scholar] [CrossRef]

- Hearps, P.; McConnell, D. Renewable Energy Technology Cost Review; Melbourne Energy Institute: Carlton, Victoria, Australia, 2011. [Google Scholar]

- International Energy Agency. Medium-Term Renewable Energy Market Report 2012; OECD Publishing: Paris, France, 2012. [Google Scholar]

- Renewables 2012: Global Status Report; Renewable Energy Policy Network for the 21st Century: Paris, France, 2012.

- World Energy Outlook 2012; International Energy Agency: Paris, France, 2012.

- World Energy Outlook 2013; International Energy Agency: Paris, France, 2013.

- World Energy Outlook 2014; International Energy Agency: Paris, France, 2014.

- Hwang, Y.; Lee, J.K.; Jeong, Y.M.; Koo, K.M.; Lee, D.H.; Kim, I.K.; Kim, S.H. Cooling performance of a vertical ground-coupled heat pump system installed in a school building. Renew. Energy 2009, 34, 578–582. [Google Scholar] [CrossRef]

- Gao, Q.; Li, M.; Yu, M.; Spitler, J.D.; Yan, Y.Y. Review of development from GSHP to UTES in China and other countries. Renew. Sustain. Energy Rev. 2009, 13, 1383–1394. [Google Scholar] [CrossRef]

- Dalla Rosa, A.; Christensen, J.E. Low-energy district heating in energy-efficient building areas. Energy 2011, 36, 6890–6899. [Google Scholar] [CrossRef]

- Aikins, K.A.; Choi, J.M. Current status of the performance of GSHP (ground source heat pump) units in the Republic of Korea. Energy 2012, 47, 77–82. [Google Scholar] [CrossRef]

- Kharseh, M.; Nordell, B. Sustainable heating and cooling systems for agriculture. Int. J. Energy Res. 2011, 35, 415–422. [Google Scholar] [CrossRef]

- Li, S.F.; Shang, Y.; Chen, D. The numerical study on the environmentally sustainable system-ground-source heat pump system. Adv. Mater. Res. 2011, 320, 530–535. [Google Scholar] [CrossRef]

- Hepbasli, A. A key review on exergetic analysis and assessment of renewable energy resources for a sustainable future. Renew. Sustain. Energy Rev. 2008, 12, 593–661. [Google Scholar] [CrossRef]

- Hyysalo, S.; Juntunen, J.K.; Freeman, S. User innovation in sustainable home energy technologies. Energy Policy 2013, 55, 490–500. [Google Scholar] [CrossRef]

- Kaygusuz, K.; Kaygusuz, A. Geothermal energy in Turkey: The sustainable future. Renew. Sustain. Energy Rev. 2004, 8, 545–563. [Google Scholar] [CrossRef]

- Healy, P.F.; Ugursal, V.I. Performance and economic feasibility of ground source heat pumps in cold climate. Int. J. Energy Res. 1997, 21, 857–870. [Google Scholar] [CrossRef]

- Omer, A.M. Clean energies for sustainable development for built environment. J. Civ. Eng. Constr. Technol. 2012, 3, 1–16. [Google Scholar] [CrossRef]

- Ozudogru, T.Y.; Ghasemi-Fare, O.; Olgun, C.G.; Basu, P. Numerical modeling of vertical geothermal heat exchangers using finite difference and finite element techniques. Geotech. Geol. Eng. 2015, 33, 291–306. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, G.; Zhou, J.; Wu, J.; Shen, W. A techno-economic comparison of a direct expansion ground-source and a secondary loop ground-coupled heat pump system for cooling in a residential building. Appl. Therm. Eng. 2012, 35, 29–39. [Google Scholar] [CrossRef]

- Sanner, B.; Karytsas, C.; Mendrinos, D.; Rybach, L. Current status of ground source heat pumps and underground thermal energy storage in Europe. Geothermics 2003, 32, 579–588. [Google Scholar] [CrossRef]

- Ozgener, O.; Hepbasli, A. Modeling and performance evaluation of ground source (geothermal) heat pump systems. Energy Build. 2007, 39, 66–75. [Google Scholar] [CrossRef]

- Hepbasli, A. Exergetic modeling and assessment of solar assisted domestic hot water tank integrated ground-source heat pump systems for residences. Energy Build. 2007, 39, 1211–1217. [Google Scholar] [CrossRef]

- Badescu, V. Economic aspects of using ground thermal energy for passive house heating. Renew. Energy 2007, 32, 895–903. [Google Scholar] [CrossRef]

- Bichiou, Y.; Krarti, M. Optimization of envelope and HVAC systems selection for residential buildings. Energy Build. 2011, 43, 3373–3382. [Google Scholar] [CrossRef]

- Ghasemi-Fare, O.; Basu, P. A practical heat transfer model for geothermal piles. Energy Build. 2013, 66, 470–479. [Google Scholar] [CrossRef]

- Dieckmann, J. Heat pumps for cold climates. ASHRAE J. 2009, 51, 69–72. [Google Scholar]

- Ni, L.; Song, W.; Zeng, F.; Yao, Y. Energy Saving and Economic Analyses of Design Heating Load Ratio of Ground Source Heat Pump with Gas Boiler as Auxiliary Heat Source. In Proceedings of the International Conference on Electric Technology and Civil Engineering, Jiujiang, China, 22–24 April 2011.

- Genchi, Y.; Kikegawa, Y.; Inaba, A. CO2 payback-time assessment of a regional-scale heating and cooling system using a ground source heat-pump in a high energy-consumption area in Tokyo. Appl. Energy 2002, 71, 147–160. [Google Scholar] [CrossRef]

- Blum, P.; Campillo, G.; Münch, W.; Kölbel, T. CO2 savings of ground source heat pump systems—A regional analysis. Renew. Energy 2010, 35, 122–127. [Google Scholar] [CrossRef]

- Saner, D.; Juraske, R.; Kübert, M.; Blum, P.; Hellweg, S.; Bayer, P. Is it only CO2 that matters? A life cycle perspective on shallow geothermal systems. Renew. Sustain. Energy Rev. 2010, 14, 1798–1813. [Google Scholar] [CrossRef]

- Dong, H.; Geng, Y.; Xi, F.; Fujita, T. Carbon footprint evaluation at industrial park level: A hybrid life cycle assessment approach. Energy Policy 2013, 57, 298–307. [Google Scholar] [CrossRef]

- Hamada, Y.; Nakamura, M.; Ochifuji, K.; Nagano, K.; Yokoyama, S. Field performance of a Japanese low energy home relying on renewable energy. Energy Build. 2001, 33, 805–814. [Google Scholar] [CrossRef]

- Greening, B.; Azapagic, A. Domestic heat pumps: Life cycle environmental impacts and potential implications for the UK. Energy 2012, 39, 205–217. [Google Scholar] [CrossRef]

- Katsura, T.; Nagano, K.; Takeda, S. Method of calculation of the ground temperature for multiple ground heat exchangers. Appl. Therm. Eng. 2008, 28, 1995–2004. [Google Scholar] [CrossRef]

- Troldborg, M.; Heslop, S.; Hough, R.L. Assessing the sustainability of renewable energy technologies using multi-criteria analysis: Suitability of approach for national-scale assessments and associated uncertainties. Renew. Sustain. Energy Rev. 2014, 39, 1173–1184. [Google Scholar] [CrossRef]

- Geng, Y.; Sarkis, J.; Wang, X.; Zhao, H.; Zhong, Y. Regional application of ground source heat pump in China: A case of Shenyang. Renew. Sustain. Energy Rev. 2013, 18, 95–102. [Google Scholar] [CrossRef]

- Zhu, Y.; Tao, Y.; Rayegan, R. A comparison of deterministic and probabilistic life cycle cost analyses of ground source heat pump (GSHP) applications in hot and humid climate. Energy Build. 2012, 55, 312–321. [Google Scholar] [CrossRef]

- Sekine, K.; Ooka, R.; Yokoi, M.; Shiba, Y.; Hwang, S. Development of a ground-source heat pump system with ground heat exchanger utilizing the cast-in-place concrete pile foundations of buildings. ASHRAE Trans. 2007, 113, 1–9. [Google Scholar]

- Nagano, K.; Katsura, T.; Takeda, S. Development of a design and performance prediction tool for the ground source heat pump system. Appl. Therm. Eng. 2006, 26, 1578–1592. [Google Scholar] [CrossRef]

- Hamdy, M.; Hasan, A.; Siren, K. A multi-stage optimization method for cost-optimal and nearly-zero-energy building solutions in line with the EPBD-recast 2010. Energy Build. 2013, 56, 189–203. [Google Scholar] [CrossRef]

- Self, S.J.; Reddy, B.V.; Rosen, M.A. Geothermal heat pump systems: Status review and comparison with other heating options. Appl. Energy 2013, 101, 341–348. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, X.; Liu, J.; Li, K.S.; Yang, J. Thermal performance and ground temperature of vertical pile-foundation heat exchangers: A case study. Appl. Therm. Eng. 2008, 28, 2295–2304. [Google Scholar] [CrossRef]

- Hepbasli, A.; Akdemir, O.; Hancioglu, E. Experimental study of a closed loop vertical ground source heat pump system. Energy Convers. Manag. 2003, 44, 527–548. [Google Scholar] [CrossRef]

- Zhang, Q.; Murphy, W.E. Measurement of thermal conductivity for three borehole fill materials used for GSHP. ASHRAE Trans. 2000, 106, 434. [Google Scholar]

- Kharseh, M.; Altorkmany, L.; Nordell, B. Global warming’s impact on the performance of GSHP. Renew. Energy 2011, 36, 1485–1491. [Google Scholar] [CrossRef]

- Lamarche, L.; Kajl, S.; Beauchamp, B. A review of methods to evaluate borehole thermal resistances in geothermal heat-pump systems. Geothermics 2010, 39, 187–200. [Google Scholar] [CrossRef]

- Butler, D.K.; Curro, J.R., Jr. Crosshole seismic testing—Procedures and pitfalls. Geophysics 1981, 46, 23–29. [Google Scholar] [CrossRef]

- Fan, R.; Gao, Y.; Hua, L.; Deng, X.; Shi, J. Thermal performance and operation strategy optimization for a practical hybrid ground-source heat-pump system. Energy Build. 2014, 78, 238–247. [Google Scholar] [CrossRef]

- Zeng, H.; Diao, N.; Fang, Z. Efficiency of vertical geothermal heat exchangers in the ground source heat pump system. J. Therm. Sci. 2003, 12, 77–81. [Google Scholar] [CrossRef]

- Liu, X.L.; Wang, D.L.; Fan, Z.H. Modeling on heat transfer of a vertical bore in geothermal heat exchangers. Build. Energy Environ. 2001, 2, 1–3. [Google Scholar]

- Beier, R.A.; Smith, M.D.; Spitler, J.D. Reference data sets for vertical borehole ground heat exchanger models and thermal response test analysis. Geothermics 2011, 40, 79–85. [Google Scholar] [CrossRef]

- Inalli, M.; Esen, H. Experimental thermal performance evaluation of a horizontal ground-source heat pump system. Appl. Therm. Eng. 2004, 24, 2219–2232. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, J.X. Development of a graph method for preliminary design of borehole ground-coupled heat exchanger in North Louisiana. Energy Build. 2015, 92, 389–397. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, S.; Hong, D.; Kim, Y. Performance evaluation and modeling of a hybrid cooling system combining a screw water chiller with a ground source heat pump in a building. Energy 2010, 35, 2006–2012. [Google Scholar] [CrossRef]

- Madani, H.; Claesson, J. Retrofitting a variable capacity heat pump to a ventilation heat recovery system: Modeling and performance analysis. In Proceedings of the International Conference on Applied Energy, Singapore, 21–23 April 2010; pp. 649–658.

- Hepbasli, A.; Akdemir, O. Energy and exergy analysis of a ground source (geothermal) heat pump system. Energy Convers. Manag. 2004, 45, 737–753. [Google Scholar] [CrossRef]

- Sivasakthivel, T.; Murugesan, K.; Sahoo, P.K. Potential reduction in CO2 emission and saving in electricity by ground source heat pump system for space heating applications-a study on northern part of India. Procedia Eng. 2012, 38, 970–979. [Google Scholar] [CrossRef]

- Yavuzturk, C.; Spitler, J.D. A short time step response factor model for vertical ground loop heat exchangers. ASHARE Trans. 1999, 105, 475–485. [Google Scholar]

- Yavuzturk, C. Modeling of Vertical Ground Loop Heat Exchangers for Ground Source Heat Pump Systems. Ph.D. Thesis, Oklahoma State University, Stillwater, OK, USA, December 1999. [Google Scholar]

- Spitler, J.D. GLHEPRO—A Design Tool for Commercial Building Ground Loop Heat Exchangers. In Proceedings of the Fourth International Heat Pumps in Cold Climates Conference, Quebec, QC, Canada, 17–18 August 2000.

- Crawley, D.B.; Lawrie, L.K.; Pedersen, C.O.; Liesen, R.J.; Fisher, D.E.; Strand, R.K.; Taylor, R.D.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; et al. EnergyPlus: A New Generation Building Energy Simulation Program. In Proceedings of the Renewable and Advanced Energy Systems for the 21st Century, Maui, HI, USA, 11–15 April 1999.

- The American Institute of Architects (AIA). A Guide to Life Cycle Assessment of Buildings; AIA: New York, NY, USA, 2010. [Google Scholar]

- Kim, C.J.; Kim, J.; Hong, T.; Koo, C.; Jeong, K.; Park, H.S. A program-level management system for the life cycle environmental and economic assessment of complex building projects. Environ. Impact Assess. 2015, 54, 9–21. [Google Scholar] [CrossRef]

- Jeong, K.; Ji, C.; Koo, C.; Hong, T.; Park, H.S. A model for predicting the environmental impacts of educational facilities in the project planning phase. J. Clean. Prod. 2014. [Google Scholar] [CrossRef]

- Kosareo, L.; Ries, R. Comparative environmental life cycle assessment of green roofs. Build. Environ. 2007, 42, 2606–2613. [Google Scholar] [CrossRef]

- Kumaran, D.S.; Ong, S.K.; Tan, R.B.; Nee, A.Y.C. Environmental life cycle cost analysis of products. Environ. Manag. Health 2001, 12, 260–276. [Google Scholar] [CrossRef]

- Steen, B. A Systematic Approach to Environmental Priority Strategies in Product Development (EPS): Version 2000-General System Characteristics; Chalmers University of Technology: Göteborg, Sweden, 1999. [Google Scholar]

- Koo, C.; Park, S.; Hong, T.; Park, H.S. An estimation model for the heating and cooling demand of a residential building with a different envelope design using the finite element method. Appl. Energy 2014, 115, 205–215. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Hong, T.; Chae, M.; Koo, C.; Jeong, J. An Environmental and Economic Assessment for Selecting the Optimal Ground Heat Exchanger by Considering the Entering Water Temperature. Energies 2015, 8, 7752-7776. https://doi.org/10.3390/en8087752

Kim J, Hong T, Chae M, Koo C, Jeong J. An Environmental and Economic Assessment for Selecting the Optimal Ground Heat Exchanger by Considering the Entering Water Temperature. Energies. 2015; 8(8):7752-7776. https://doi.org/10.3390/en8087752

Chicago/Turabian StyleKim, Jimin, Taehoon Hong, Myeongsoo Chae, Choongwan Koo, and Jaemin Jeong. 2015. "An Environmental and Economic Assessment for Selecting the Optimal Ground Heat Exchanger by Considering the Entering Water Temperature" Energies 8, no. 8: 7752-7776. https://doi.org/10.3390/en8087752

APA StyleKim, J., Hong, T., Chae, M., Koo, C., & Jeong, J. (2015). An Environmental and Economic Assessment for Selecting the Optimal Ground Heat Exchanger by Considering the Entering Water Temperature. Energies, 8(8), 7752-7776. https://doi.org/10.3390/en8087752