1. Introduction

As increasingly concerning on the deterioration in air quality and decrease in petroleum resources, a great interest is shown in the development of safe, clean, and high-efficient transportation. It has been well recognized that the electric vehicle (EV), hybrid electric vehicle (HEV), and fuel cell electric vehicle (FCEV) are the most promising solution to the problem of land transportation in the future [

1]. Since showing improvement in fuel consumption with minimum extra cost, HEVs are considered to offer the best promise in the short to mid-term [

2]. In HEVs, the internal combustion engine (ICE) provides driving power together with one or more reversible energy storage systems (ESSes), such as a bank of batteries and ultra-capacitors, which are generally used as an energy buffering unit to recycle braking energy and change engine operating points as well as provide an extra degree of freedom for energy management strategies (EMSes). Undeniably, the introduction of ESSes makes driving modes more flexible but EMSes more complicated. Therefore, it is especially important to design an excellent EMS for HEV development and application [

3,

4].

As early as 1997, Jalil used a set of predefined rules based on the battery state of charge (SOC) and power demand to assign the power to the engine, battery, or a combination of both, for a series HEV to ensure the high efficiency of the engine and battery operation [

5]. Such rule-based strategies developed from heuristic ideas are widely used in HEVs [

6,

7,

8] because they can be implemented in real-time, but making rules commonly depends on engineering experience, known mathematical models, large numbers of experimental results,

etc., having limited benefits for fuel economy. In order to improve the fuel economy of rule-based methods, Schouten and Duan directly adopted fuzzy rules instead of deterministic ones to improve the operation efficiency of vehicle system in 2002 and 2003 [

9,

10]. Zhao added a fuzzy algorithm to modify the rules in 2013 [

11]. However, the fuel-saving potential of HEVs cannot be fully exploited because the membership functions and rules of a fuzzy controller are designed based on human expertise and heuristics. To further reduce fuel consumption, fuzzy controllers were modified by offline optimizing membership functions and rules through a particle swarm optimization algorithm [

12], a genetic algorithm [

13], or a machine learning algorithm [

14]. Alternatively, a learning vector quantization neural network [

15] or a fuzzy neural network [

16] is used in a fuzzy EMS to identify the driving cycle style periodically.

By contrast with above heuristic-based strategies, EMSes based on optimal control theory, such as dynamic programming (DP) and Pontryagin’s minimum principle (PMP) have been investigated quite intensively in recent years. For a prior known driving cycle, DP discretizes continuous states and control values into finite grids and decomposes the overall dynamic optimization problem into a sequence of sub-problems. The cost function of each sub-problem is the fuel consumption from current step to last step. By calculating backwards along the horizon based on Bellman’s Principle of Optimality, DP generated an optimal EMS of HEVs, but with a large computational load that exponentially increases as the state variables increase in number [

17,

18,

19,

20]. Theoretically, if the whole driving cycle is known in advance and the performance index is defined as an integral of fuel consumption rate, the EMS obtained from DP will minimize the total fuel consumption. However, such an optimal solution is only suitable for the known driving cycle rather than other ones. The requirement for future driving demands to be known in advance leads to a real-time problem, so DP always acts as a benchmark to assess other EMSs [

21,

22]. To apply the optimal results of DP in real-time, many attempts have been made, such as extracting rules from optimal results [

23,

24], modeling the power demand as a random Markov chain [

25,

26] or predicting future driving conditions [

27,

28,

29].

As another popular theory-based method, PMP formulates the optimal control problem of HEVs as a two-point boundary value problem of nonlinear differential equations. In this method, the whole driving cycle still needs to be known in advance but the computation load is much less than DP [

30]. A study on the comparison between PMP and DP demonstrated that the optimal results generated by PMP are very close to DP [

31], so PMP can also be a benchmark. Furthermore, Kim, Cha, and Peng had proved in 2011 that under the assumption that the battery SOC varies within a small range, the Lagrange multiplier

, which is also called as a co-state, is a constant [

32]. On the other hand,

can be interpreted as an equivalent factor to equate the electrical usage of a battery to virtual fuel consumption. When

is a constant, the dynamic optimization problem is converted into a static one, and the equivalent consumption minimization strategy (ECMS) is developed [

33,

34]. However,

is still very sensitive to driving cycles. Much work has been reported to solve the above problem, such as developing a function to estimate equivalent factors through observing a number of optimal results calculated from DP and PMP [

35], designing a driving cycle recognizer using a neural adaptive network [

36], or adding an online algorithm to ECMS framework to periodically refresh equivalent factors combined with the past and predicted vehicle speed and GPS data [

37]. However, if these modified theory-based methods are applied to real vehicles, they are sub-optimal, complex, and time-consuming.

In summary, the rule-based strategies are suitable for real-time applications but with limited fuel economy while the optimal theory-based strategies have the real-time problem caused by two main reasons. One is that the future driving cycle (or vehicle speed commands) should be known prior to deciding the control parameters (for example, the co-state of PMP). Another is that their calculation is relatively large. In this paper, we apply linear quadratic optimal control theory to solve the power management problem of HEVs for the first time, overcoming the shortcomings of existing theory-based strategies with little loss in fuel economy. The proposed power management strategy is termed as the quadratic performance index strategy (QPIS), whose engine power and motor power are related to current vehicle velocity and battery residual energy as well as their desired values, and independent of future driving conditions. The fuel economy of QPIS is significantly improved from two aspects: one is to average and smooth the engine and motor power to indirectly reduce fuel consumption through a designed quadratic performance index; another is to avoid the inefficient engine operation by switching control modes based on requested driving power. The simulation results over various driving cycles show that with the same weight coefficients of quadratic performance index, the QPIS has excellent control performance on vehicle drivability, SOC sustainability, especially the fuel consumptions of QPIS are very close to that of PMP.

The remainder of this paper is organized as follows.

Section 2 introduces a nonlinear vehicle model as the controlled plant and linearizes this nonlinear model for deriving QPIS. The main innovation of this paper is presented in

Section 3, including constructing a quadratic performance index combing with rules and deriving the control law. In

Section 4, comparative simulations in Advanced Vehicle Simulator (ADVISOR) over different driving cycles, road slopes, and vehicle total masses are performed and the results confirm the good performance of QPIS. Finally, conclusions are summarized in

Section 5.

2. Vehicle Model

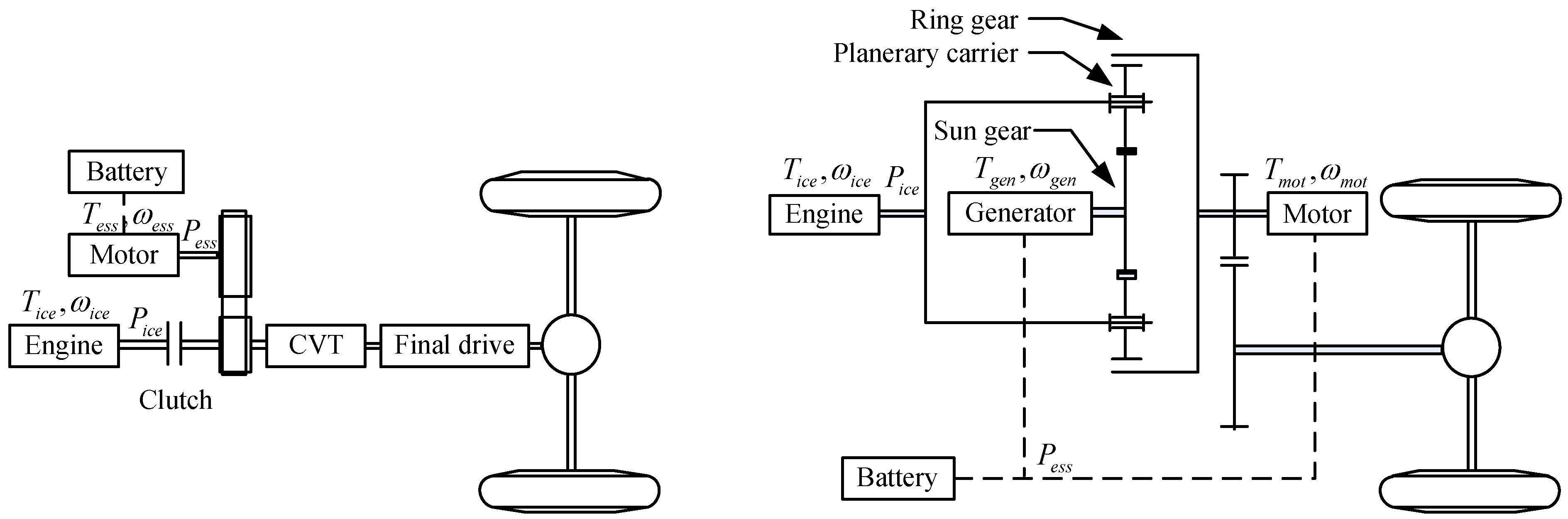

In general, the electromechanical coupling systems of HEVs are classified into three categories: torque coupling, speed coupling, and power coupling systems. The QPIS proposed in this paper is suitable for power-coupling HEVs, whose configurations are depicted in

Figure 1, satisfying the assumptions as follows.

Figure 1.

Schematic diagrams of HEVs. (a) HEV equipt with a CVT; (b) HEV equipt with a planetary gear mechanism.

Figure 1.

Schematic diagrams of HEVs. (a) HEV equipt with a CVT; (b) HEV equipt with a planetary gear mechanism.

(a) A continuously-variable transmission (CVT) adopted in

Figure 1a or a planetary gear mechanism adopted in

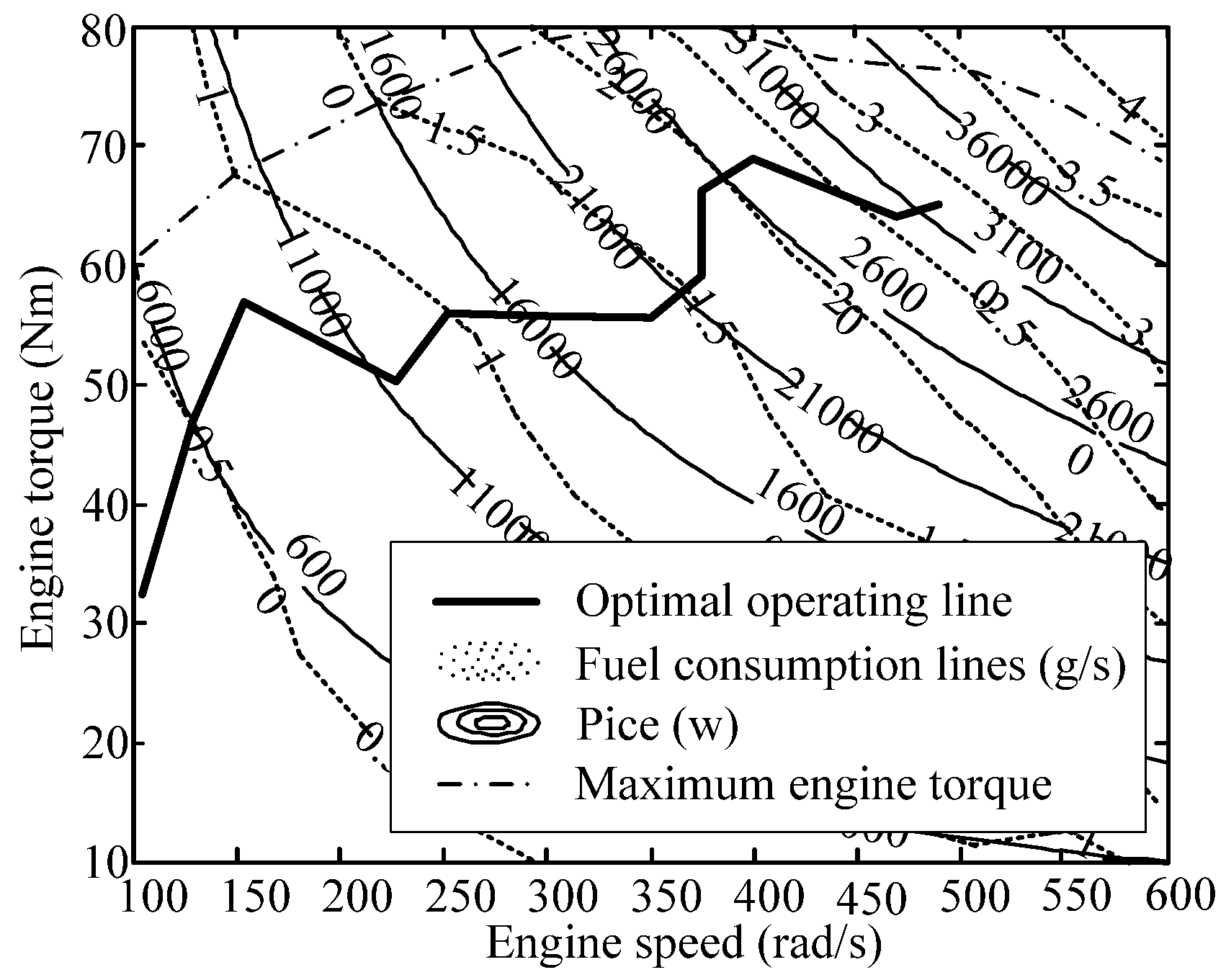

Figure 1b (such as the Toyota Prius and Ford Escape Hybrid) makes it possible for the engine to always operate on an optimal operating line as the bold solid one plotted in

Figure 2. Every engine operating point of optimal operating line is confined to a specific output torque and speed and has the minimum fuel consumption [

32]. In other words, for a given engine power

, we can determine an optimal engine operating point

based on this optimal operating line. Thus control variables of energy management for HEVs are reduced from the torque and speed to only the power.

(b) Through reasonably choosing battery capacity, the battery SOC mainly varies in a narrow region, for example, 0.6–0.8, so the charge-discharge characteristics of battery are almost invariable. In other words, the open-circuit voltage and equivalent internal resistance of battery can be regarded as constants [

32].

Figure 2.

Optimal operating line of the engine.

Figure 2.

Optimal operating line of the engine.

(c) The motor driving system has sufficient capability of short-time overload (overtorque or overpower), adequate field-weaking range, and wide high-efficiency area. The motor efficiency is not sensitive to engine operating points.

(d) Because the dynamic response time of engine or motor is much shorter than that of vehicle accelerating or decelerating and battery charging or discharging, the dynamic process of engine and motor can be neglected and only static efficiency models need to be considered [

22].

In this study, a pedal position is interpreted as a velocity demand

. The proposed algorithm can calculate the engine power

and motor power

based on current velocity, desired velocity

, current SOC, and desired SOC. For the vehicle in

Figure 1a, the optimal operation point

can be determined by

, then we can jointly regulate the engine throttle and transmission ratio of CVT to make the engine run on the optimal operating line and satisfy

. Meanwhile, the motor speed

is determined by the CVT ratio and

can be satisfied by regulating the motor torque

. For the vehicle in

Figure 1b, the ring gear is connected to the final drive, so current vehicle velocity dictates the speed of the motor and ring gear. By jointly regulating the generator speed and engine throttle, the engine can run on the optimal operating line and satisfy

. At the same time, we can regulate the motor torque to ensure the sum of the motor and generator power is equal to

. In the following, we take the hybrid system in

Figure 1a as an example to derive the QPIS. The main parameters of the vehicle originated from ADVISOR are listed in

Table 1.

Table 1.

Vehicle parameters.

Table 1.

Vehicle parameters.

| Vehicle unit | Parameter |

|---|

| Engine FC_SI41emis | Displacement: 1.0 L |

| Maximum power: 41 kW @ 5700 rpm |

| Maximum torque: 81 Nm @ 3477 rpm |

| Battery ESS_NIMH | Capacity: 6 Ah |

| Voltage: 308 V |

| Motor MC_PRIUS_JPN | Maximum power: 31 kW |

| Transmission efficiency | 0.71–0.93 |

| Rotating mass coefficient | 1.1 |

| Frontal area | 2.0 m2 |

| Aerodynamic drag coefficient | 0.335 |

| Rolling resistance coefficient | 0.009 |

| Vehicle total mass | 1287 kg |

2.1. Nonlinear HEV Model for Simulations

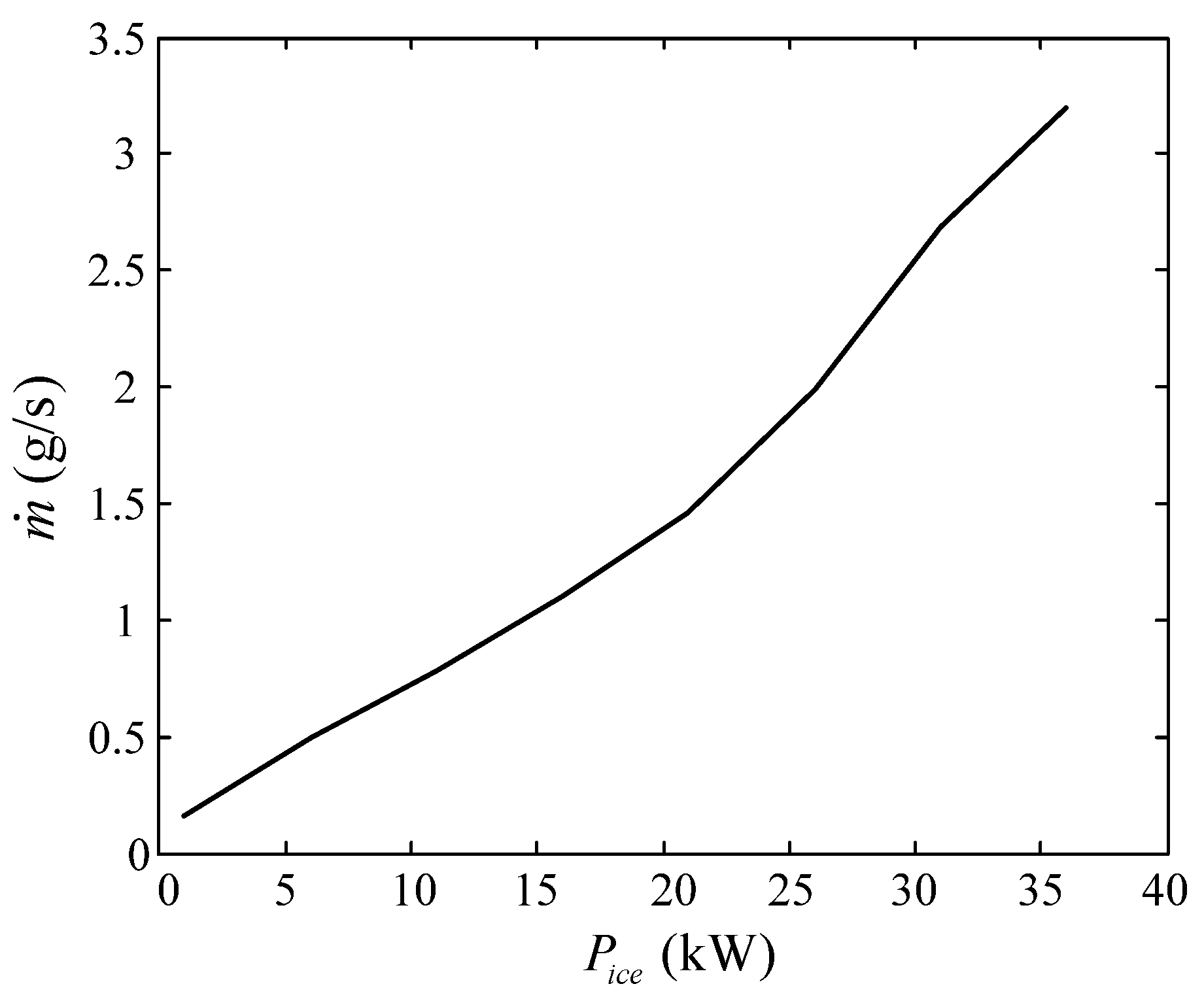

The MAP of Engine FC_SI41emis and its optimal operating line are shown in

Figure 2. The corresponding optimal fuel consumption line is plotted in

Figure 3, which shows the relation between

and the fuel consumption rate

. The fuel consumption of control algorithms in simulations is the integral of

over the whole driving cycle.

Figure 3.

Optimal fuel consumption line.

Figure 3.

Optimal fuel consumption line.

If the vehicle is running at the velocity

, the driving force

can be calculated by:

where

is the rotating mass coefficient;

is the vehicle total mass, including the passengers and cargo;

is the gravitational acceleration constant;

is the rolling resistance coefficient;

is the road slope;

is the air density;

is the aerodynamic drag coefficient;

is the vehicle frontal area, and

is the transmission efficiency, which is the function of vehicle velocity, load torque and CVT ratio,

and

is the requested power, which satisfies:

where

is the engine power and

is the motor power.

Multiplying Equation (1) by

, we will get the vehicle dynamic model:

The energy storage system is a 6Ah Ni-MH battery. The battery power

satisfies:

where

is the total energy of battery;

is the residual energy of battery;

and

are the open-circuit voltage and equivalent internal resistance, respectively [

32].

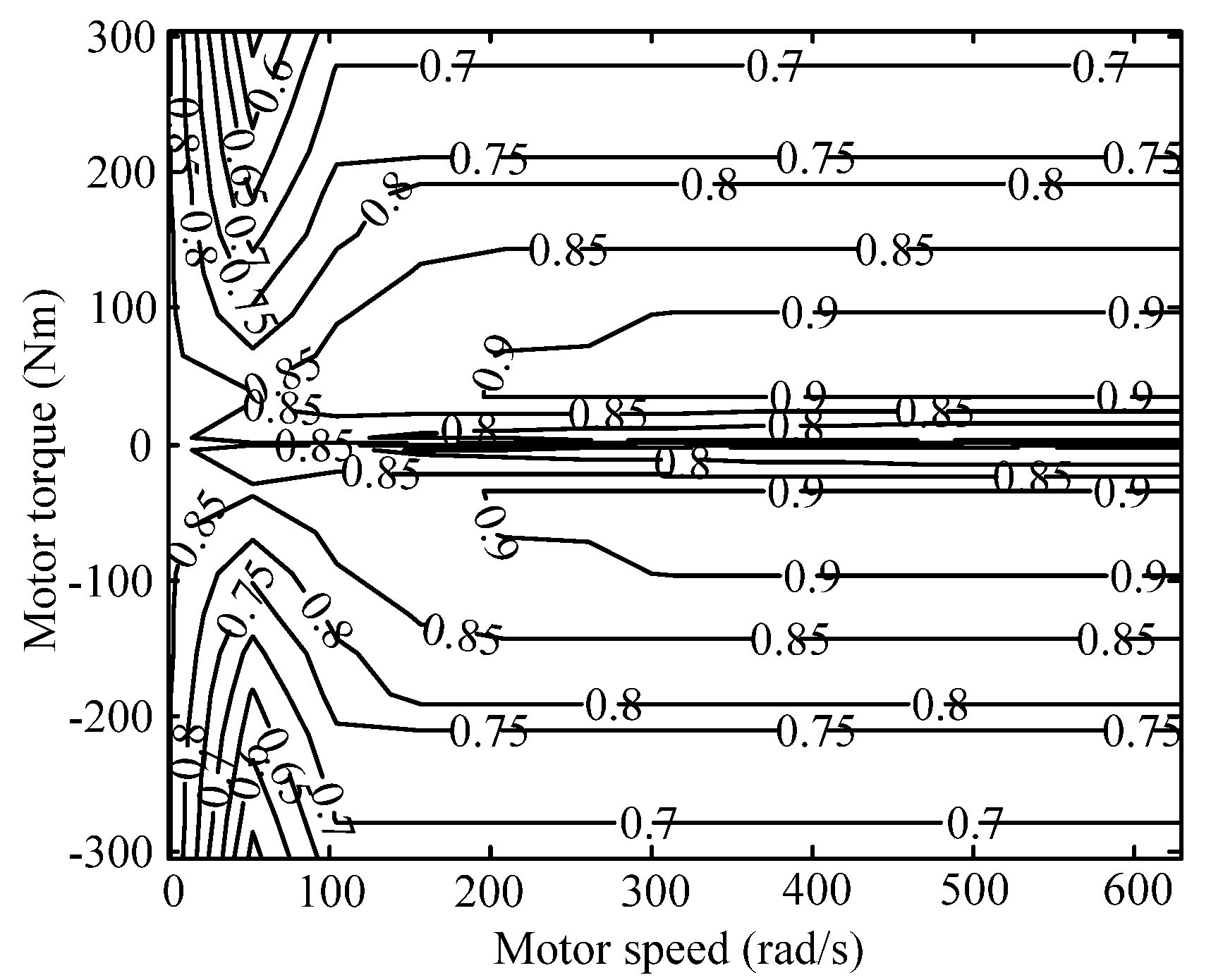

As assumptions stated above, a permanent magnet motor is selected, whose efficiency map is shown in

Figure 4. The motor power

can be expressed as:

where

is the motor efficiency, which is the function of motor torque and motor speed,

(

indicates that the battery is discharging and

indicates that the battery is charging).

Figure 4.

Efficiency map of the motor.

Figure 4.

Efficiency map of the motor.

2.2. Linear HEV Model for QPIS

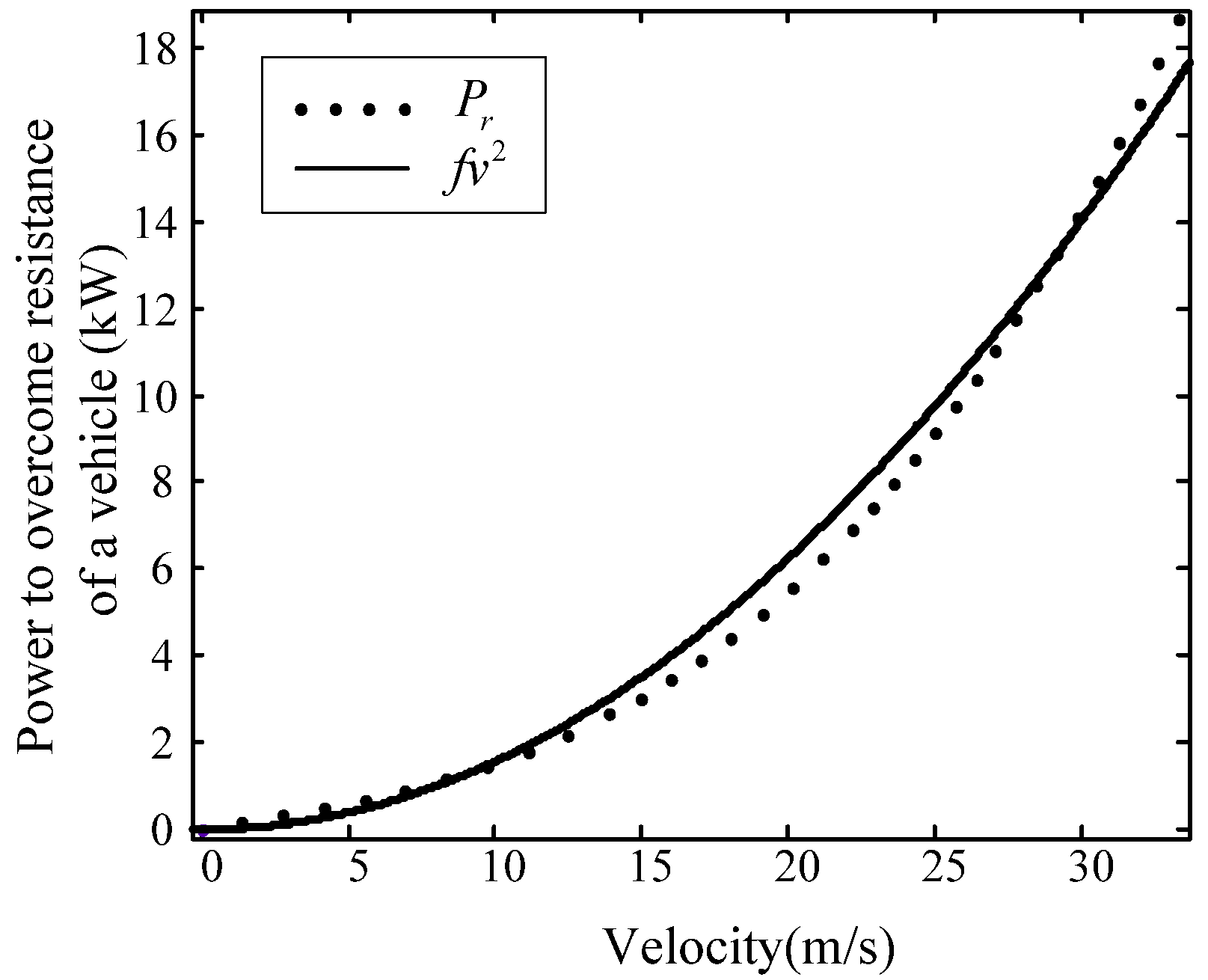

To utilize linear quadratic optimal control theory to derive control functions of QPIS, we should establish a linear model of HEV. The dot line shown in

Figure 5 depicts the relationship between

and the power to overcome resistance

, when

. The correlation between

and

should be fitted as a parabola,

(the solid line, which is available in the involved power range), to obtain the linear model, so we can replace

with

(

). In addition,

should be replaced by average efficiency,

. Then the vehicle dynamic model can be expressed as Equation (6) with

as the state variable:

Figure 5.

Relationship between and .

Figure 5.

Relationship between and .

For the battery, when the SOC changes within the interval [0.6,0.8] and

varies in the interval [−15 kW,0], the battery charging efficiency calculated by

ranges in

. When the SOC changes within the interval [0.6,0.8] and

varies in the interval [0,15 kW], the battery discharging efficiency calculated by

ranges in [1,0.7664]. Then the average efficiency of battery can be computed,

i.e.,

. For the motor, the efficiency map is symmetric about the horizontal axis as shown in

Figure 4, based on which the average efficiency of motor is

.

Thus, the linear relation between the state variable

and

is:

In the above linearization process, the linear vehicle dynamic model (6) is obtained when . However, in fact, vehicles usually run on slopes, which degrades the vehicle drivability and SOC sustainability. To overcome the influences caused by road slopes, two integral actions, and , are added to the HEV model as two extended state variables. As known from linear quadratic optimal control theory, the control law is the feedback of system states, so the control variables of QPIS contain not only the feedback of current states ( and ) but also the integrals of the deviations of actual states from commands ( and ). Such integral actions can eliminate the influences of various driving conditions on the control performance of QPIS, especially overcome the influences of road slopes effectively.

Selecting

as state variables and

as control variables, and combining Equations (6) and (7), we can establish the linear HEV system as:

where

,

, and

are the coefficient matrixes of the system;

are the commands;

is the desired vehicle velocity decided by the pedal position, and

is the desired battery SOC (a constant that the SOC changes around to efficiently use and protect the battery). It should be noted that the aim of linearizing the original nonlinear vehicle model is just to utilize linear quadratic optimal control theory to obtain the QPIS. The HEV model to be controlled by the strategies involved in the simulations is the same nonlinear one introduced in

Section 2.1.

3. Power Management Strategy Based on Quadratic Performance Index

To compare with the proposed strategy in this paper, PMP is briefly introduced at first. In fact, applying PMP to solve the minimum fuel consumption problem of HEVs is to search for the motor power

to minimize the fuel consumption under a specific driving cycle. Since the driving cycle is known previously, the requested power

can be calculated based on vehicle parameters when the vehicle is running along the vehicle velocity line of driving cycle. In this way, for the given

, which satisfies the Equation (2), the above minimum fuel consumption control problem is to calculate

to minimize the integral performance index as:

where

is the fuel consumption rate of the engine when its output power is

. The relationship between

and

is plotted in

Figure 3 based on the assumption (a) in

Section 2. Meanwhile,

satisfies Equations (4) and (5), the terminal constraint condition:

and the maximum and minimum constraints of

and

.

According to PMP, the necessary condition that the solution of above optimal control problem should satisfy is to minimize the Hamiltonian:

for each sampling instant [

32]. In Equation (11),

is called co-state and satisfies the co-state equation

Since

and

are not the functions of SOC, (

i.e., the assumption (b) in

Section 2),

is a constant [

32]. Known from the Introduction,

can be interpreted as an equivalent factor to equate the electrical usage of a battery to the virtual fuel consumption. Therefore, an empirical value of equivalent factor can be chosen as the initial co-state. For example, 30 kWh of battery energy corresponds to 10 L gasoline; then we can calculate the empirical value that equals −6.935 × 10

−5 as the initial co-state. For a specific driving cycle and a set co-state,

can be calculated by minimizing Equation (11) in its feasible range for each sampling instant

. If

of the battery controlled by

satisfies

,

is the result that we desire in this paper. If

(or

), a new co-state, whose absolute value is smaller (or greater) than the absolute value of empirical co-state, is chosen to repeat the above calculation process. Obviously, to achieve optimal fuel economy,

are different for different driving cycles. Moreover,

and

in Equation (11) are both nonlinear; thus, it is a relatively large calculation to minimize the Equation (11) in the feasible range of

for each sampling instant

. In the following, an EMS is obtained based on the quadratic performance index to overcome the disadvantages of PMP with little loss in fuel economy.

3.1. Power-Split Strategy Based on Quadratic Performance Index

For the system (8), we try to find a linear state feedback control

to ensure the system stability. If

is set to be constant, after the dynamic regulation process is completed, the vehicle velocity is

, the battery residual energy is

, the engine power is

, the motor power is

, and the corresponding outputs of the integral regulator,

and

, are constant and satisfies

. We define these steady states and control inputs as

and

, the deviation of actual states from steady ones as

, and the deviation of actual control inputs from steady ones as

. Since

,

, and

, the performance index about

and

:

should be finite, and the solution to minimize the above quadratic performance index can be obtained based on the regulator theory of optimal control theory. The control law has the form of state feedback as:

where

is the solution of differential Riccati equation; and

is the state feedback matrix. Known from the quadratic optimal control theory, if

is large enough,

convergences to its terminal value only when

approaches

, and in the most time of

,

is constant and satisfies the algebraic Riccati equation:

In this way,

and

, where

, the control variable to minimize

is a form of state feedback:

Additionally, the system stability can be ensured because is a stable matrix based on linear quadratic optimal control theory.

For the system (8), the changes of

in value caused by the energy flow direction (indicated by

and

) lead to the variation of

. For the simplification of this algorithm,

is rewritten as the product of two matrices:

Setting

,

and

is the engine and motor power excluding the loss power of transmission, motor, and battery, the system (8) can be rewritten as:

where

is constant so that the variation of

caused by

can be avoided.

Accordingly, the performance index is rewritten as:

where

and

are the matrixes of weight coefficients. We can quicken the regulating process of state and control variables by increasing the corresponding weight coefficient of the deviation term in

. The calibration of weight coefficients needs to ensure vehicle drivability, prevent large fluctuations of SOC, cut peaks and fill valleys of engine power, and smooth the engine power to indirectly reduce fuel consumption.

For the optimal control problem of the system (18) and performance index (19), the solution has the form of Equation (16):

where

is the matrix of state feedback and

satisfies:

Then, the engine power and motor power can be calculated by:

where

changes with

and

, based on

and

, respectively,

i.e.,

and

.

3.2. Two Control Modes

To further improve the fuel economy, two rules are designed to switch control modes (electric mode and hybrid mode) based on

for avoiding inefficient engine operation. The selection of a switch point between the two control modes is combined with engine characteristics, vehicle parameters, and the principle of benefiting fuel economy. In this paper, the switch point is

, which is decided by comparing the energy conversion efficiency of a vehicle propelled separately by an engine and a motor. That is, when

, the efficiency of vehicle propelled solely by an engine is equal to the product of the efficiency of a vehicle propelled solely by a motor and the efficiency of the battery charged by an engine [

38]. The two control modes are realized by choosing different weight coefficients of the quadratic performance index as follows:

(1) If : the battery should provide the total driving power to avoid inefficient engine operation or recover the braking energy that will be stored in the battery. Thus, we should set to make approach to zero, and , to temporarily not consider the constraint of SOC unless SOC reaches the maximum or minimum value.

(2) If : the engine and battery should provide requested power together. The battery shares the driving energy to restrain fluctuations of . Now the constraint of SOC should be necessarily involved in the performance index for battery energy sustainability.

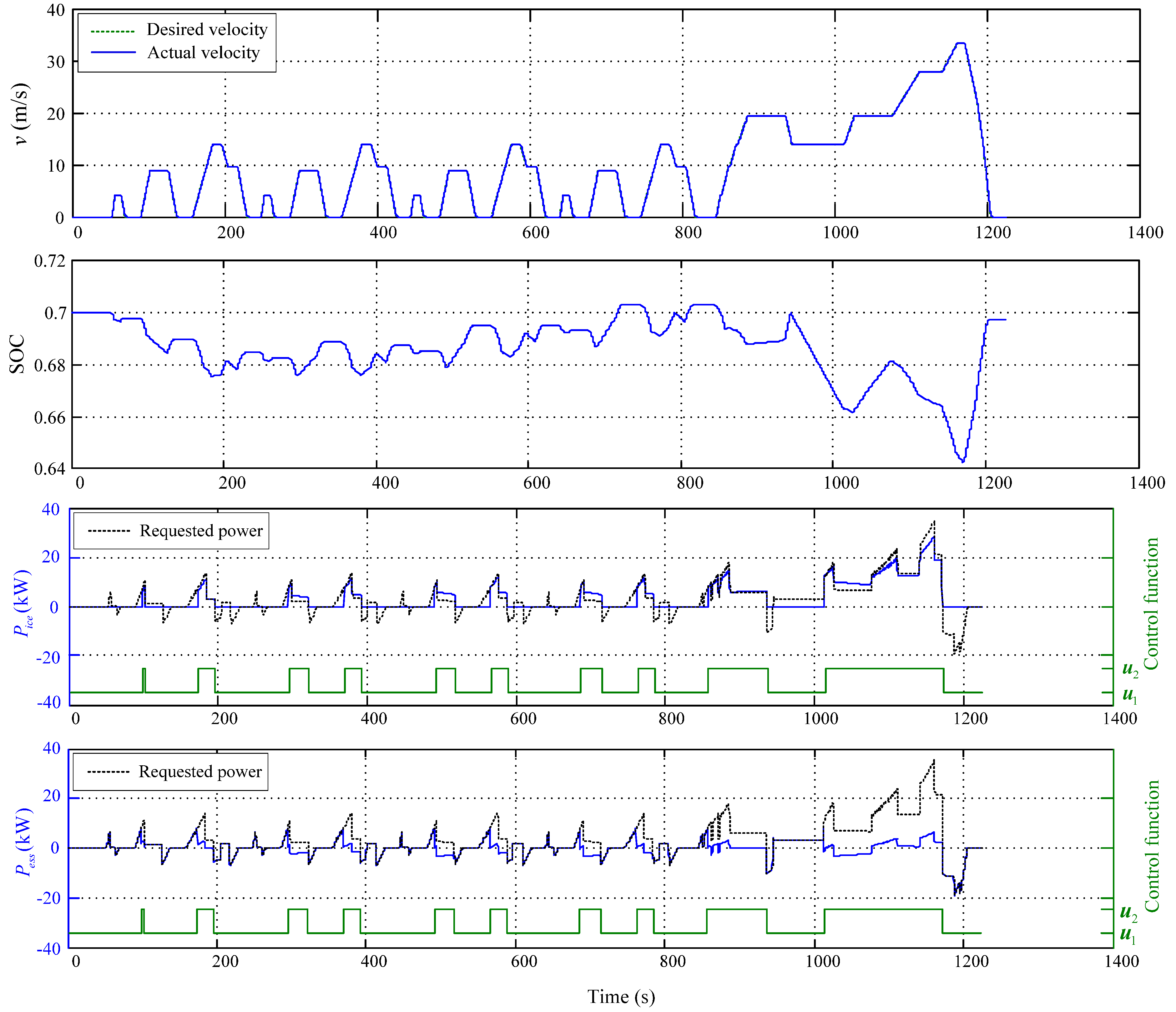

In general, the weight coefficients of two control modes can be calibrated by a test, where the desired SOC is 0.7 and the desired vehicle velocity line is shown in

Figure 6. In the calibration, to tune the weight coefficients of

is similar to design a proportional integral (PI) controller:

and

correspond to proportional gains,

and

correspond to integral gains. In other words, increasing

and

results in faster response and smaller tracking errors of

, but paying the price of larger fluctuations of SOC and more power provided by the engine and motor that may exceed their feasible bounds. Similarly, increasing

and

quickens the response of SOC and maintains SOC nearer to 0.7 with a little influence on trajectories of

,

and

, but weakens the buffering effect of the battery. Additionally, the fluctuations ranges of

(or

) can be restricted within the feasible bounds by appropriately increasing

(or

) with a slight increment of tracking errors of

. According to the above changing laws about the control effect over weight coefficients, we can tune the weight coefficients of two control modes by compromising between the tracking errors of states and fluctuation ranges of control variables until obtaining a relatively better result of vehicle velocity error, final SOC, and fuel economy. In this paper, the calibrated weight coefficients and corresponding

and

are given in

Table 2. The test results with above weight coefficients are shown in

Figure 6.

Table 2.

Weight coefficients and state feedback matrixes of two rules.

Table 2.

Weight coefficients and state feedback matrixes of two rules.

| Operational condition | Weight coefficients | K′ | L′ |

|---|

| | | |

| | | |

Actually, the more the detailed operational conditions are divided, the better the control effect of QPIS is obtained, but much more complex algorithms are needed, which will weaken the adaptability of QPIS. Eventually, the concrete form of QPIS is:

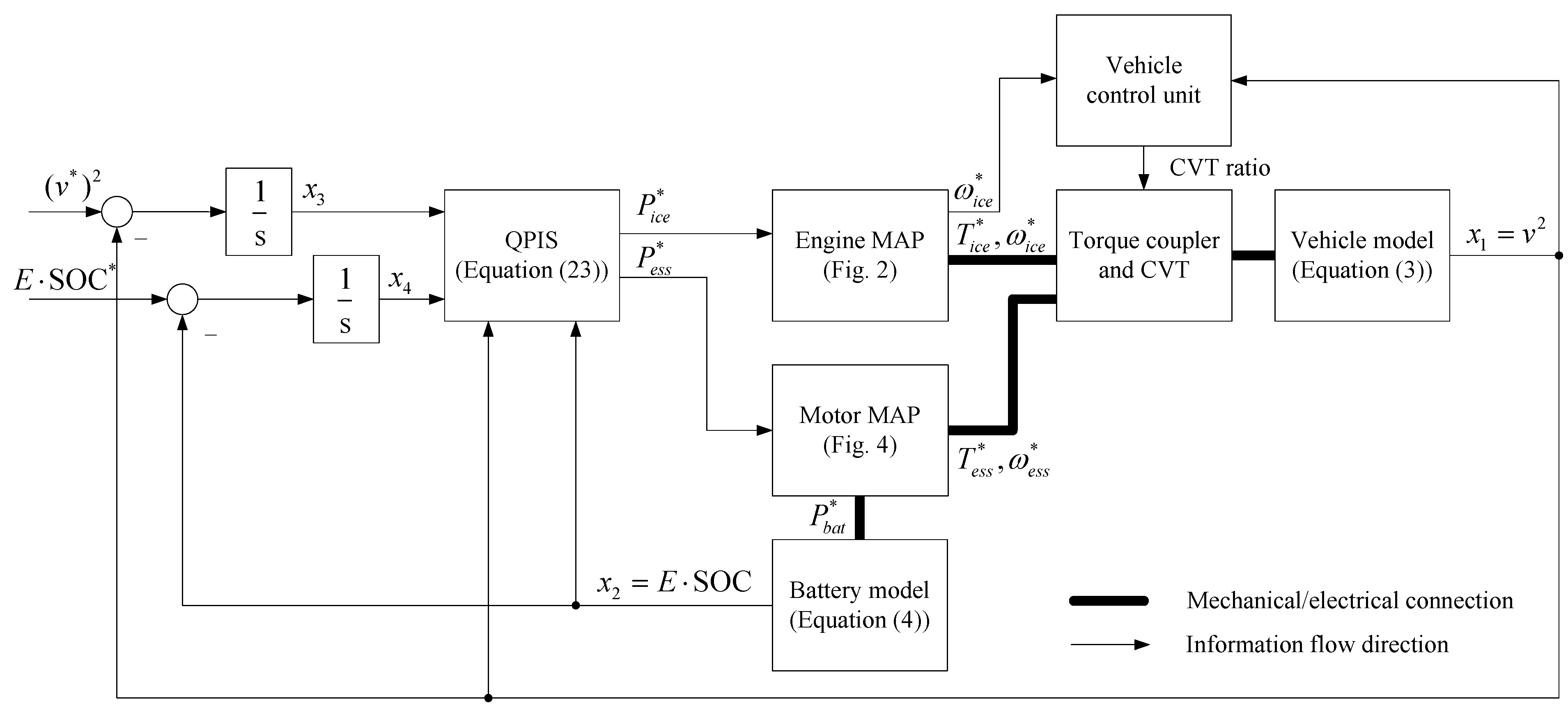

The control system of QPIS is shown in

Figure 7. It can be observed that the control variables of QPIS are simple linear functions of current system states

without future driving conditions. This interesting feature makes QPIS simply structured and particularly suitable for real-time optimization control. Furthermore,

, and

are switched based on

, which is the sum of

and

calculated by QPIS. To avoid frequent switches of control functions at switch points, we necessarily add a hysteresis loop when

, of which the switch on and off points are

and

, respectively, and the engine power and motor power of

and

are limited in their respective feasible ranges.

Figure 6.

Test results of calibrated weight coefficients.

Figure 6.

Test results of calibrated weight coefficients.

Figure 7.

Control system diagram of QPIS.

Figure 7.

Control system diagram of QPIS.