The simulations and experiments were performed at the Energy Area Laboratory in the Department of Agricultural Engineering of the Federal University of Vicosa, Vicosa (MG, Brazil) at 20°45′14′′ S latitude, 42°52′53′′ W longitude and 648.74 m altitude.

2.1. Material

The prototype built for this study was composed of six Kyocera Solartec KS5 PV modules (Kyocera Solar of Brazil, Rio de Janeiro, RJ, Brazil), produced with multi-crystalline cells. The power rating of each PV module was 5 W

p, with 580.8 cm

2 module area (35.2 cm length and 16.5 cm width) and floor plan area used for each prototype of 1.04 m

2 [

17].

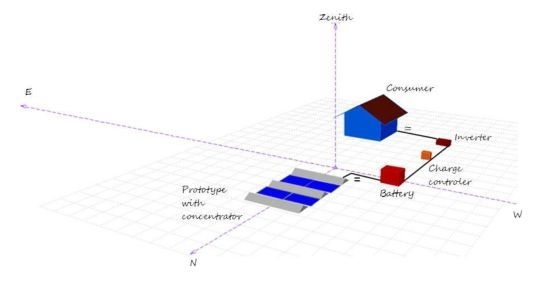

The concentrator model selected,

Figure 1, was used because: (i) it was considered the most energetically efficient; (ii) it is a fixed system with possibility of seasonal alignments for greater performance; and (iii) is appropriate for low radiation concentration.

Figure 1.

V-trough radiation concentrator illustrating the project parameters.

Figure 1.

V-trough radiation concentrator illustrating the project parameters.

In

Figure 1, α is the acceptance angle, ψ is the channel angle,

A is the collector-opening width,

B is the PV module/absorber base width,

H is the length of the side of concentrator, δ is the opening angle of the V-troughs and ξ is the prototype inclination [

18,

19,

20].

Table 1 lists the physical characteristics of the prototypes.

The PV system was built using specular anodized aluminum mirrors (Lucchi, Sao Paulo, Brazil) with 0.3 mm thickness, 86% total reflection TR 2, 12% diffuse reflection and low iridescence [

21].

Pyranometers were used for measurement of global solar radiation on horizontal and inclined planes, CMP3 model (Campbell Scientific, Logan, UT, USA), with frequency bands of light spectrum between 310 to 2800 nm, [

22].

Table 1.

Physical characteristics of the V-trough type prototype with and module or prototype without radiation concentrators.

Table 1.

Physical characteristics of the V-trough type prototype with and module or prototype without radiation concentrators.

| Parameter | Prototype with Concentrator (PWC) | Prototype without Concentrator (PWoutC) |

|---|

| Dimension of cell area in the module, length × width (m) | 0.165 × 0.352 | 0.165 × 0.352 |

| Number of modules | 6 | 1 |

| Dimension of a module (m) | 0.205 × 0.352 × 0.022 | 0.205 × 0.352 × 0.022 |

| System area (m2) | 0.34848 | 0.05808 |

| System weight (modules, and concentrator) (kg) | ~8 | ~1.2 |

| Mirror area of system concentrator (m2) | ~1.5 | – |

A potentiometer (0 to 100 Ω) was used as load for generation determination of current signal and voltage. A prototype with radiation concentrator (PWC) was used for the load variation in field test, while a system without radiation concentrator (PWoutC) was used as the standard.

The thermal image of the studied PV systems was recorded using an infrared i-series high resolution, thermo-graphic camera (Flir Systems, Portland, OR, USA) with 0.1 °C thermal sensibility at 25 °C [

23]. The temperature of the concentrators, on the front and back parts of the modules was also measured with a portable digital thermometer, model Kiltherm 500 (Cotergavi, Santa Cecilia, Sao Paulo, Brazil) [

24].

2.3. System Assembly and Methodology

The prototype was developed in two stages: concentrators were dimensioned according to size of the selected PV module, followed by determination of channel inclination angle. The mirrors were then cut and folded to the proposed form for a radiation concentration ratio of nearly two, and for system cooling which allows atmospheric air convection.

The prototype design considered values for PV module width (B), reflector inclination height (H) and cells area, so that the set volume was the smallest possible.

Solar energy concentration and the sizes of the concentrator for the selected model are described by Equations (1) and (2), in accordance with [

18]:

where

C, solar radiation concentration, decimal;

n, series of reflections from reflector before reaching radiation PV module, decimal; ψ, channel angle, (°); α, acceptance angle, (°);

H, length of the side of concentrator, m; and

B, PV module or absorber width, m.

Figure 3 illustrates the incidence of solar radiation on concentrators and other optical and geometrical characteristics to be considered in PV systems with radiation concentration.

Figure 3.

Relationships among θc (angle beyond which the solar radiation does not reach the PV module), α (acceptance angle), ψ (angle channel), δ (light cone angle) and the tangents Tα and Tc.

Figure 3.

Relationships among θc (angle beyond which the solar radiation does not reach the PV module), α (acceptance angle), ψ (angle channel), δ (light cone angle) and the tangents Tα and Tc.

The PV module, according to studies developed by [

14,

15,

19,

25], must be positioned between two concentrators, thus receiving a higher intensity of reflected radiation from each. The number of radiation reflections varies according to the radiation angle of incidence, where θ

c is the rejection angle, α is the acceptance angle, δ is the opening semi-angle and the tangents

Tα and

Tc are drawn for the circle passing through the extremities of the PV module.

Figure 3 characterizes the PV system with radiation concentrators [

13,

15,

25].

The sizing of the radiation concentrator was done by performing the following:

- (i)

Determine the solar radiation acceptance angle incident on the PV module; α;

- (ii)

Evaluate direct and reflected solar radiation, incident on the PV modules; and

- (iii)

Determine the angle from which reflectors stop reflecting, i.e., angle from which the PV module no longer receives solar radiation, θc.

For determination of angles α and θ

c, the following procedure is assessed:

- (i)

Tangents Tα and Tc are drawn for the circle passing through the extremities of the PV module;

- (ii)

Opening semi angle is determined, defined as that perpendicular to the PV module by the reference circle circumference; and

- (iii)

The angles α and θ

c are obtained from

Tα and

Tc, as indicated in

Figure 3.

The relationship between α, acceptance angle, radiation incident on the PV module and θ

c, rejection angle, angle from which the PV module no longer receives solar radiation, is given by Equation (3), according to [

15]:

where θ

c is the ejection angle, angle from which the PV module no longer receives solar radiation, (°); α is the acceptance angle, radiation incident on the PV module, (°); and δ is the opening semi-angle, (°).

The relationship between the angular acceptance α and θ

c, as cited by [

15], necessary to avoid radiation losses requires that α + δ < π/2 and ϕ < π/4, with values |θ

in| < α. It was noticed that as the angular acceptance decreases, the value of the angle at which the reflectors stop reflecting, θ

c, increases, indicating that the PV module will not receive any more radiation on its surface.

It is important to observe the following characteristics of the radiation concentrator [

15,

25]: factor of radiation concentration, acceptance angle (for lower values, higher concentrations), sensibility to concentrator alignment errors (which may lead to non-uniform radiation of PV module), concentrator area and mean reflection number.

The 1.077 m × 2.258 m aluminum structure was built so that the PV modules with concentrators were arranged in such a way that the channel angle was maintained.

The concentrator design has the following characteristics:

- i)

Solar radiation concentration ratio on surface of the PV module/absorber of approximately two, i.e., the concentration factor, C, was around two;

- ii)

Use of specular aluminum with high reflection coefficient rate, exceeding 86%;

- iii)

Assembly of the PV module and concentrator set forming channels or ducts that allow air circulation, in order to permit passive cooling of the PV module and concentrator set; and

- iv)

Need for seasonal positioning adjustments, to avoid shading.

According to [

18] radiation and reflection uniformity losses should be observed, which vary according to the channel design. For channel angles lower than 20°, solar radiation incidence on the absorbing surface is not uniform and requires a larger area for the concentrator; however, greater energy conversion efficiency is obtained in comparison with channel angles higher than 40°.

Selection of the concentrator geometrical characteristics was performed based on determination of the maximum yield of solar radiation conversion into electric energy by the PV module and concentrator set. The characteristics of the concentrators compared were: PV module width (B), length of the side of concentrator (H) and trough angle that are given by Equations (1) and (2).

The studied trough angles were 10°, 20°, 30° and 40°. The concentrators built with these angles were denominated PWC I, PWC II, PWC III and PWC IV, respectively. For each built concentrator model characteristic curves were determined, i.e., voltage versus current curve for each radiation concentrator and solar PV module set.

Reflection originating from a mirror or reflecting surface, used as optical mechanism to concentrate solar energy, depends on the incident light wave length, material used for reflection, surface conditions and incidence angle. The characteristic quality parameters are reflectance, roughness, undulation, form and alignment. External agents that may cause changes to the expected results of these systems are temperature, solar radiation and wind [

13,

14,

26].

According to [

19,

25,

26], two conditions should be met: the concentrator must be ideally specular so that the PV module is uniformly radiated, maximizing PV module efficiency and no ray should suffers more than one reflection so not to lose energy intensity from solar radiation. The relationship between incident radiation,

Rinc, and the normal radiation intensity on the concentrator surface,

Rnor, is given by Equation (4), [

15]:

where:

Rinc, incident radiation, W·m

−2;

Rnor, normal radiation intensity on the concentrator surface, W·m

−2; and γ, reflectivity of side wall reflectors in the V-troughs, decimal.

2.4. Performed Tests

In the present study, preliminary tests were carried out with clear sky conditions, cloudless. The ambient temperature, solar radiation and wind speed conditions met the requirements determined for standard test conditions,

i.e., solar radiation around 1000 W·m

−2, ambient temperature around 25 °C and wind speed around 1.5 m·s

−1 [

27].

The prototype with concentrator, PWC, was exposed to radiation with data acquisition every one minute for voltage, PV module temperature, solar radiation on horizontal and inclined plans, rainfall, wind direction and speed and relative humidity. The sampling period presented in this study was five randomly chosen days from the collected data that met the standard test conditions.

Determination of the moments for the preliminary tests considered the period when the optical air mass was 1.5 AM. This procedure was performed in order to reduce the influence of spectral distribution of solar radiation incident on the absorbing surface on the results [

28]. The SunPlot 3D Program was used to determine the preliminary test moments. This program is part of the package Solar Design Studio 5.0

®, Maui software

® (Maui Solar Energy Software, Gaithersburg, MD, USA). The input data to determine the solar hour, azimuth and prototype inclination regarding the horizontal plane for realization of tests were the test dates, latitude and longitude of the location.

Characteristic current/voltage (

I ×

V) and power/voltage (

P ×

V) curves were determined with the collected data, using a potentiometer, voltmeter, ammeter and global radiation sensors (pyranometer) [

27]. The relationship between solar radiation conversion efficiency into electric energy and the PV module temperature was determined by Equation (5) (where * means nominal conditions) [

9]:

where: η

el, efficiency of solar into electric energy, %; η

ref, efficiency of solar into electric energy at reference temperature, %; β, temperature coefficient, °C

−1;

TModule, PV module temperature, °C; and

Tref reference temperature, 25 °C.

Equation (6) was used to estimate the form or fill factor (

FF) value, indicative of PV module quality, where proximity of the value to one indicates better module performance,

i.e., the PV module presents higher conversion efficiency [

9]:

where:

FF, form factor, decimal;

Voc, open circuit voltage, V;

Isc, short circuit current, A;

VM, maximum power voltage, V; and

IM, maximum power current, A.

And Equation (7):

where: η

module, module efficiency, %;

A, module area, m

2;

Isc, short circuit current, A; and

R, global solar radiation, W·m

−2.

The Equations (8) and (9) were used to estimate the variation of the short circuit current,

Isc, the open circuit voltage,

Voc with the solar radiation and the temperature (where * means nominal conditions) [

9,

29]:

where:

R, global solar radiation, W·m

−2; α, temperature coefficient, %·°C

−1, and

TModule, module temperature, °C.

and Equation (10):

where:

Ns, number of associated cells in series in the module;

m, ideality factor, dimensionless;

K, boltzman constant, J·K

−1;

T, module temperature, °C; and

e, electron charge, C.

The influence of temperature on efficiency of the prototypes was statistically evaluated using the t-test at 5% probability.

Equation (11) were used to evaluate the short circuit current and diode saturation as a function of the current density and area, respectively, in both cases: with and without radiation concentration for the prototypes:

where:

Isc, short-circuit current, A;

Ac, total cell area, m

2; and

Jsc, density of short-circuit current, A·m

−2.