Analysing Performance Characteristics of Biomass Haulage in Ireland for Bioenergy Markets with GPS, GIS and Fuel Diagnostic Tools

Abstract

:1. Introduction

- To adopt fleet tracking systems in order to analyse characteristics of timber trucking in Ireland with respect to distance, time, fuel consumption and use of the different road classes.

- To estimate the least-cost route for the distribution of biomass in Ireland with the use of GIS.

2. Materials and Methods

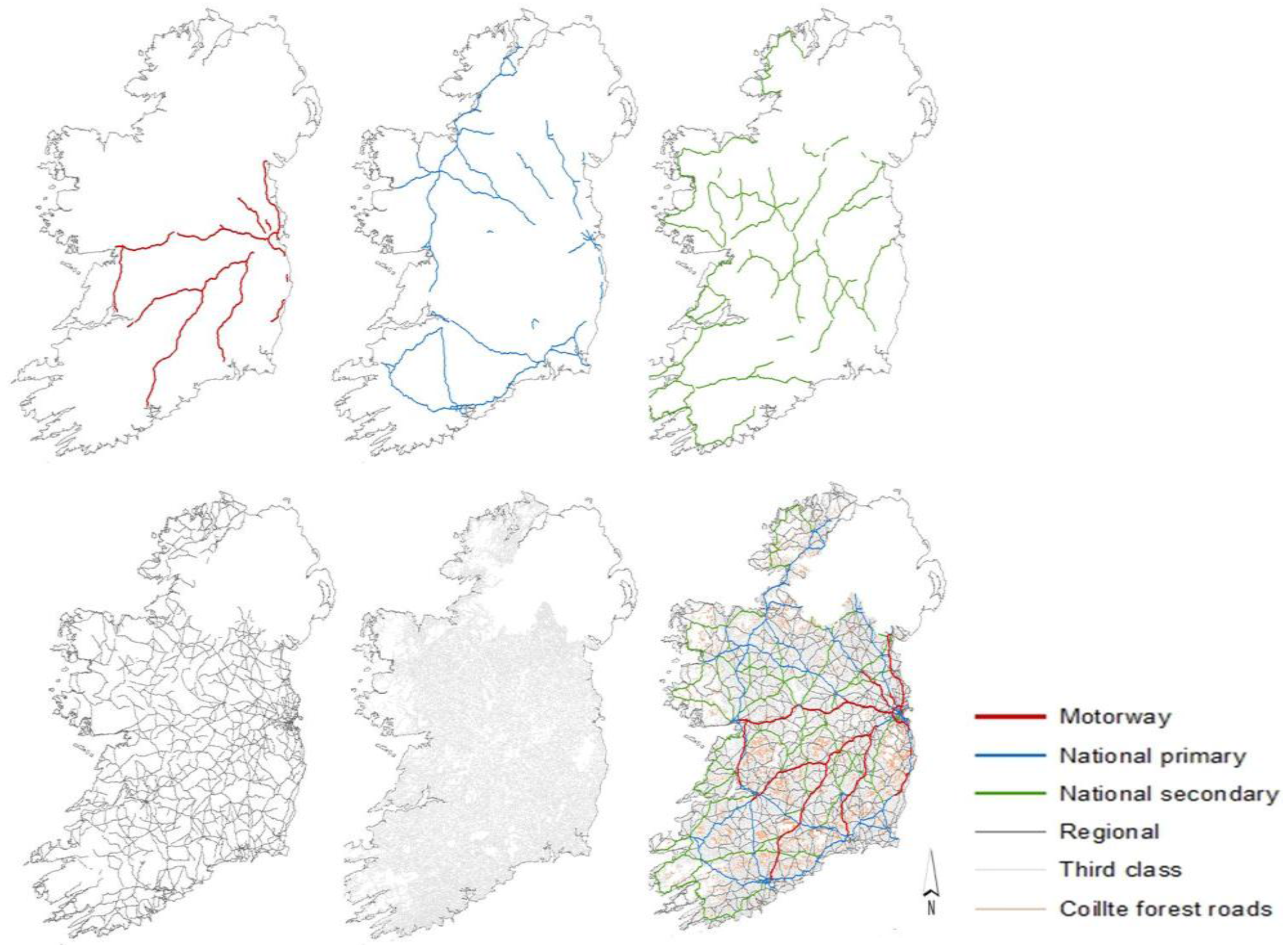

2.1. Ireland’s Road Network

2.2. Truck Used in the Study

2.3. Fleet Management Systems

2.4. Data Management and Analysis

| Work Phase | Description |

|---|---|

| Driving | Driving includes the total time driving from the depot to the forest, forest to the plant and plant to the depot during the total working shift. |

| Legal breaks | Legal breaks includes the truck stopping at resting areas for legal breaks. |

| Refuelling | Time filling the truck’s tank with fuel. |

| Loading | Loading time starts when the driver stops the truck to start using the truck’s loading crane, and finishes when the truck starts moving from the loading site |

| Unloading | Unloading time starts when the truck enters the weighbridge at the mill and ends when the truck leaves without a load. |

| Driving loaded | Driving from when the truck leaves the forest road area after loading to when the truck stops at the mill gates to deliver the load. |

| Driving unloaded | Driving from when the truck leaves the mill entrance after unloading to when the truck stops at the stat of the forest road to be loaded. |

2.5. Selection of Optimal Routes

- -

- Scenario 1 (S1): The route was chosen based on the least accumulative distance travelled on the road network.

- -

- Scenario 2 (S2): The route was designed based on the less required ravelled time.

- -

- Scenario 3 (S3): Shortest distance routes were chosen while prioritising travelling on higher-class roads.

- -

- Scenario 4 (S4): Shortest time routes were chosen while prioritising travelling on higher-class roads.

| Road Classification | Road Description | Cost Weighting (units/km) |

|---|---|---|

| M | Motorway | 1 |

| NP | National primary | 3 |

| NS | National secondary | 5 |

| R | Regional | 8 |

| L | Third class | 12 |

3. Results and Discussion

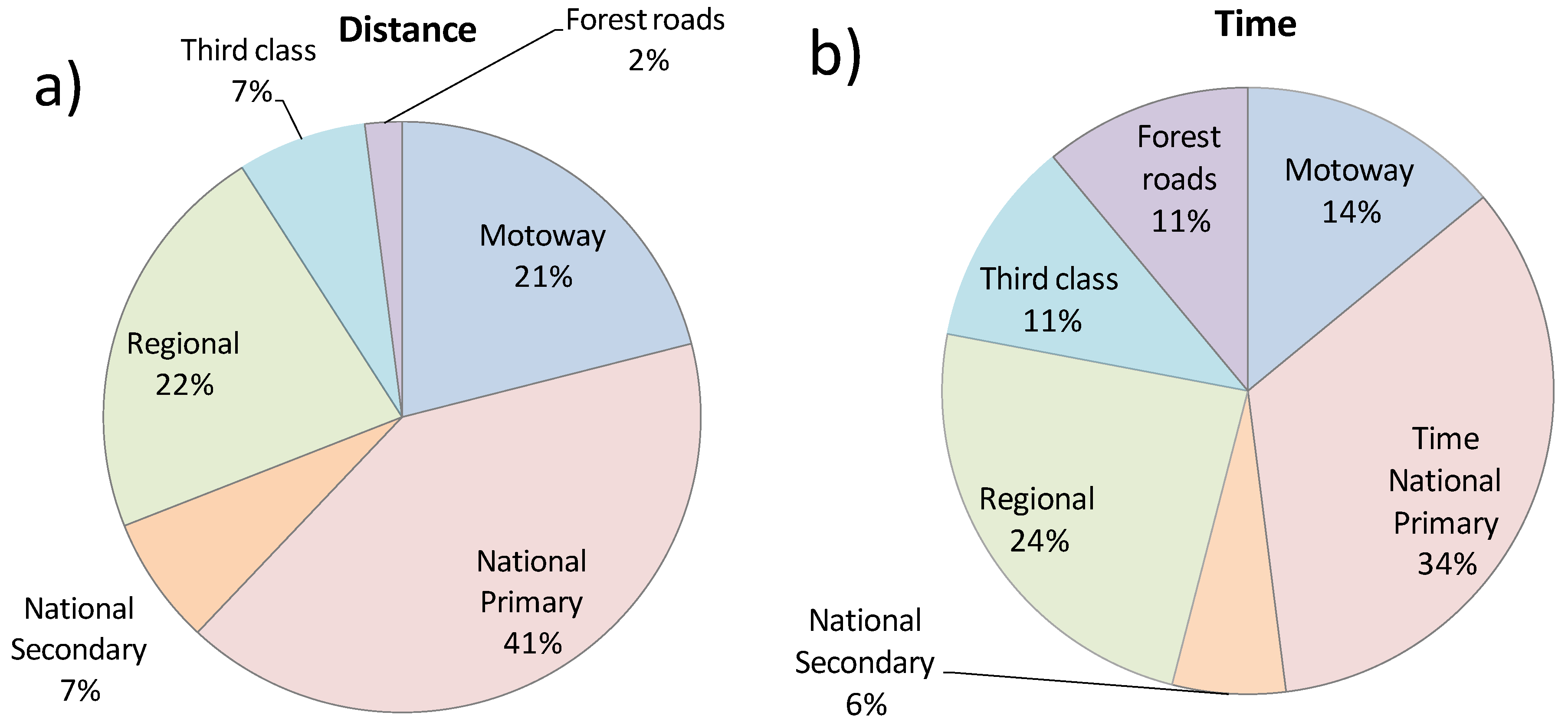

3.1. Time and Road Network Utilisation

| Work Operations | Time (min) | % Time Used | Std. Dev. | |

|---|---|---|---|---|

| Per shift | Driving | 543 | 69.17 | 90 |

| Legal breaks | 98 | 12.48 | 13 | |

| Refuelling | 15 | 1.91 | 08 | |

| Loading | 75 | 9.55 | 26 | |

| Unloading | 54 | 6.88 | 14 | |

| Per trip | Loading | 35 | 9.78 | 05 |

| Unloading | 27 | 7.54 | 07 | |

| Driving loaded | 152 | 42.46 | 17 | |

| Driving unloaded | 144 | 40.22 | 18 | |

3.2. Truck’s Speeds on the Road Network

| Road type | Legal limit (km/h) | Avg. Speed (km/h) | Speed Unloaded (km/h) | Speed Loaded (km/h) | ||

|---|---|---|---|---|---|---|

| Avg. | Std. Dev. | Avg. | Std. Dev. | |||

| Motorway | 120 | 83 | 86 | 6 | 81 | 3 |

| National primary | 100 | 73 | 74 | 4 | 72 | 2 |

| National secondary | 100 | 70 | 72 | 6 | 66 | 5 |

| Regional | 80 | 53 | 54 | 7 | 51 | 9 |

| Third class | 50 | 35 | 40 | 4 | 33 | 7 |

| Forest roads | - | - | 15 | 2 | 15 | 2 |

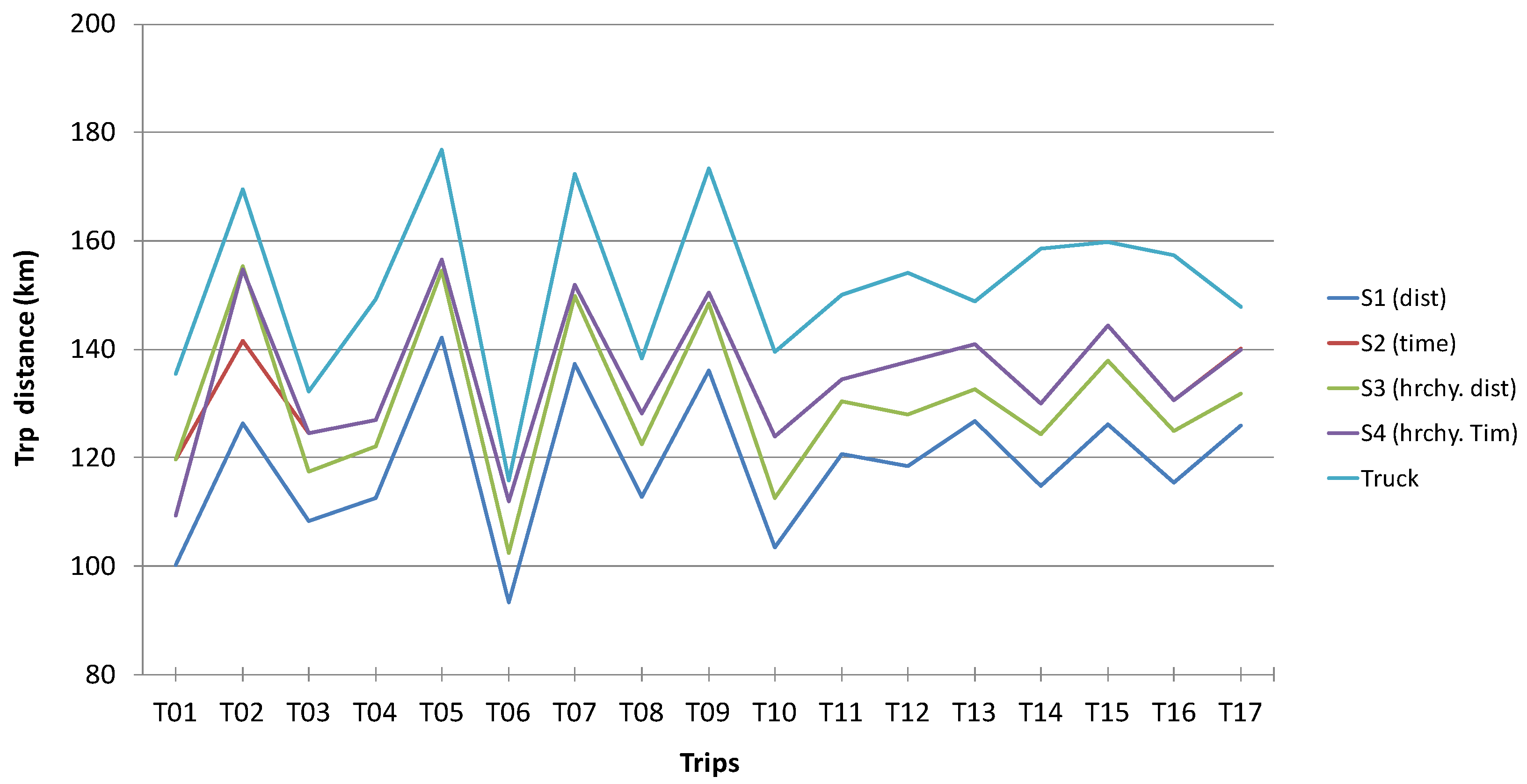

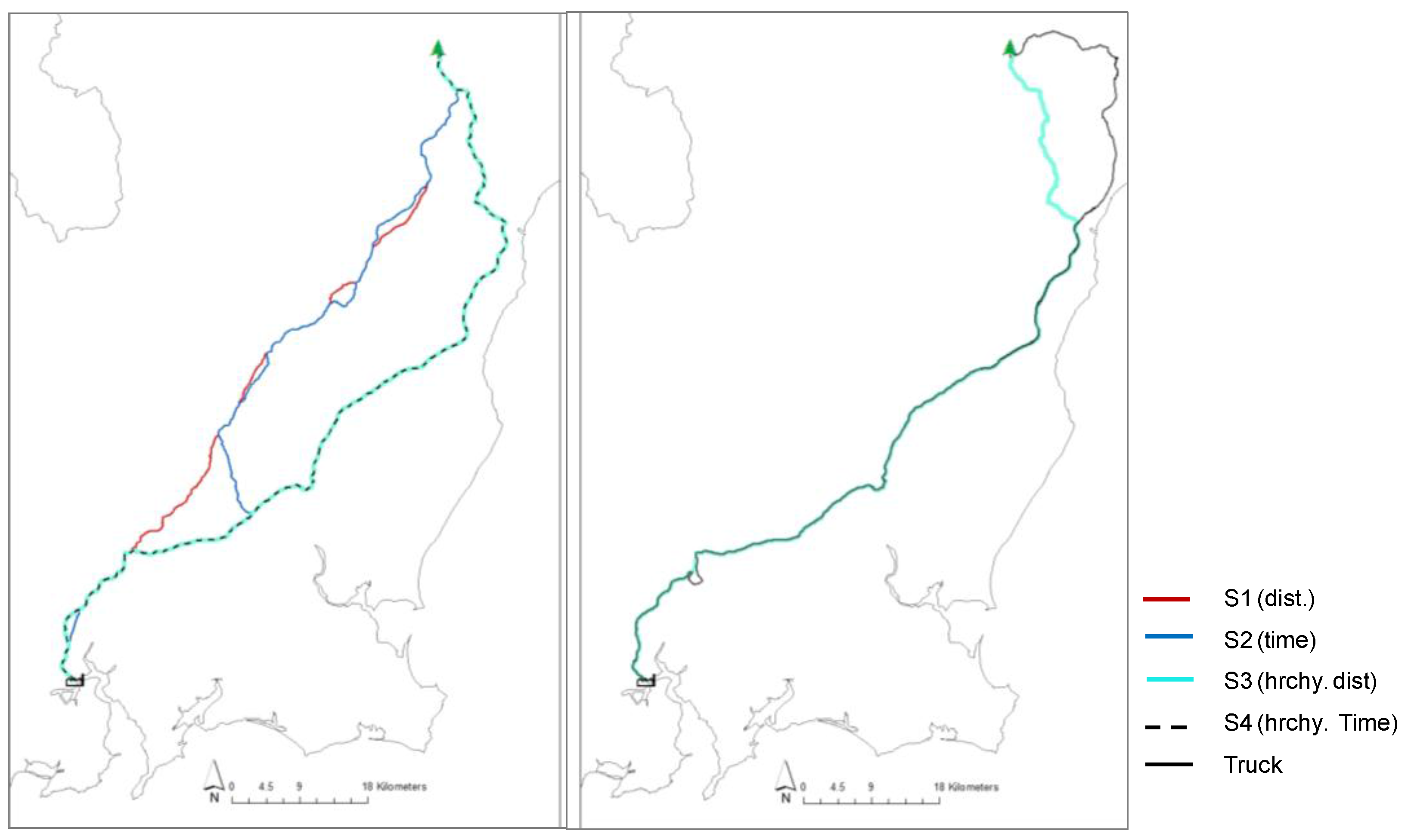

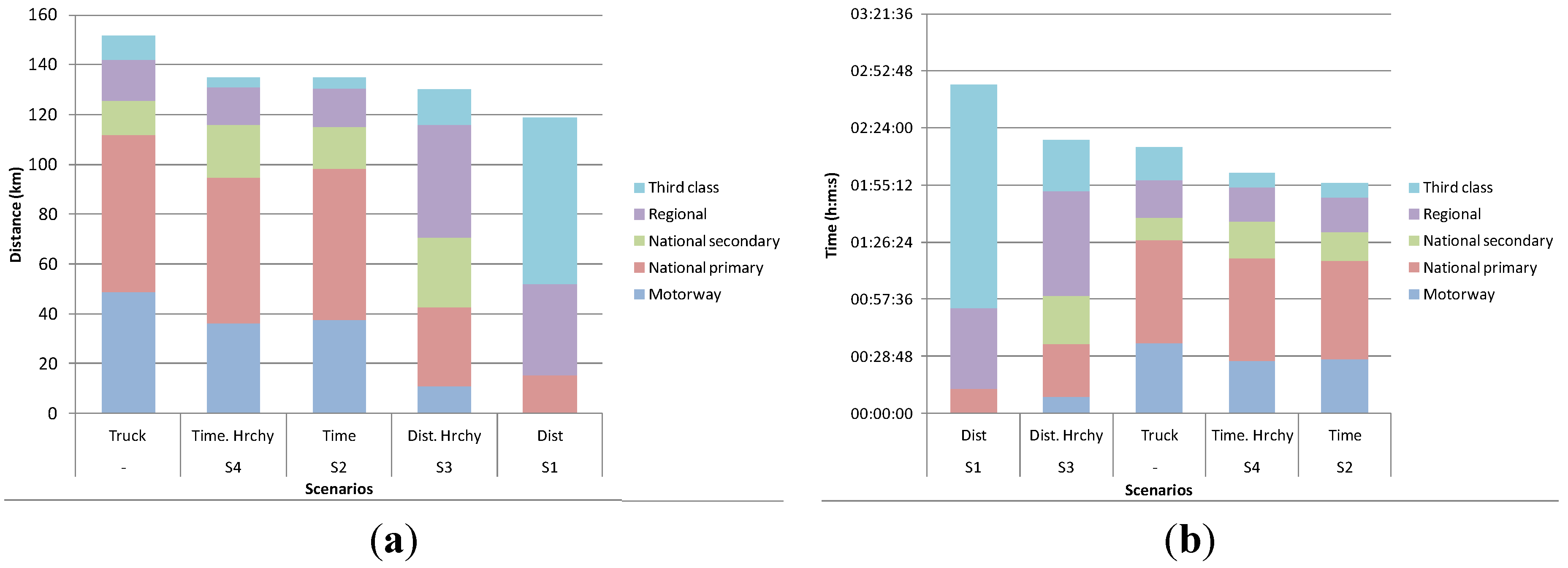

3.3. Determination of Best Routes for Biomass Haulage

| Road class | (S1) Distance | (S2) Time | (S3) Distance (hierarchy) | (S4) Time (hierarchy) | Truck | |

|---|---|---|---|---|---|---|

| Distance (km) | Motorway | 0 | 37.63 | 11.03 | 36.21 | 48.86 |

| National primary | 15.11 | 60.80 | 31.38 | 58.50 | 63.05 | |

| National secondary | 0.2 | 16.65 | 28.07 | 21.35 | 13.54 | |

| Regional | 36.44 | 15.56 | 45.33 | 14.97 | 16.57 | |

| Third class | 67.11 | 4.29 | 14.46 | 4.04 | 9.70 | |

| Total | 118.21 | 134.91 | 130.27 | 135.06 | 151.72 | |

| Time (h:m:s) | Motorway | 0 | 00:27:12 | 00:08:12 | 00:26:31 | 00:35:19 |

| National primary | 00:12:13 | 00:49:58 | 00:26:33 | 00:48:44 | 00:51:49 | |

| National secondary | 00:00:10 | 00:14:16 | 00:24:46 | 00:18:33 | 00:11:36 | |

| Regional | 00:40:35 | 00:17:37 | 00:52:50 | 00:17:10 | 00:18:45 | |

| Third class | 01:53:11 | 00:07:21 | 00:25:32 | 00:07:01 | 00:16:38 | |

| Total | 02:46:10 | 01:56:24 | 02:17:54 | 01:57:59 | 02:14:08 | |

| Description | Truck | Trailer | |

|---|---|---|---|

| Cost basis | Vehicle cost (€) | 86,000 | 33,000 |

| Depreciation years | 6 | 10 | |

| Average km annually | 120,000 | 40,000 | |

| Working days annually | 240 | 240 | |

| Average tyre life km | 100,000 | 50,000 | |

| Standing costs per annum | Wages (€) | 38,000 | 0 |

| Depreciation (€) | 14,333 | 3300 | |

| Road tax (€) | 2600 | 0 | |

| Insurance (€) | 5300 | 400 | |

| Interest (€) | 4300 | 1500 | |

| Overhead per vehicle (€) | 14,497 | 0 | |

| Standing cost per annum (€) | 79,337 | 5200 | |

| Standing cost per day (€) | 330.6 | 22 | |

| Running cost per km | Cost of 1 litre of fuel (net of vat) (€) | 0.97 | 0 |

| Litres per 100 km’s | 64 | 0 | |

| Km’s per litre | 1.56 | 0 | |

| Fuel cost per km (€) | 0.62 | 0 | |

| Tyres (€) | 0.06 | 0.06 | |

| Maintenance/Repairs (€) | 0.04 | 0.05 | |

| Running cost per km (€) | 0.72 | 0.11 | |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tahvanainen, T.; Anttila, P. Supply chain cost analysis of long-distance transportation of energy wood in Finland. Biomass Bioenergy 2011, 35, 3360–3375. [Google Scholar] [CrossRef]

- Murphy, G.; Hall, P. Reducing Trucks on the Road through Optimal Route Scheduling and Shared Log Transport Services. South. J. Appl. For. 2003, 27, 198–205. [Google Scholar]

- Knaggs, G.; O’Driscoll, E. Woodflow and Forest-Based Biomass Energy Use on the Island of Ireland 2013; Programme of Competitive Forestry Research for Development (COFORD): Dublin, Ireland, 2014. [Google Scholar]

- Murphy, F.; Devlin, G.; McDonnell, K. Forest biomass supply chains in Ireland: A life cycle assessment of GHG emissions and primary energy balances. Appl. Energy 2014, 116, 1–8. [Google Scholar] [CrossRef]

- Klvač, R.; Kolařík, J.; Volná, M.; Drápela, K. Fuel Consumption in Timber Haulage. Croat. J. For. Eng. 2013, 34, 229–240. [Google Scholar]

- Transport Research Laboratory. Overseas Road Note 40: A Guide to Axle Load Surveys and Traffic Counts for Determining Traffic Loading on Pavements; Department for International Development: Berkshire, UK, 2004. [Google Scholar]

- Road Haulage of Round Timber: Code of Practice; Irish Forest Industry Chain: Dublin, Ireland, 2003.

- Holzleitner, F.; Kanzian, C.; Stampfer, K. Analyzing time and fuel consumption in road transport of round wood with an onboard fleet manager. Eur. J. For. Res. 2010, 130, 293–301. [Google Scholar] [CrossRef]

- Sikanen, L.; Asikainen, A.; Lehikoinen, M. Transport control of forest fuels by fleet manager, mobile terminals and GPS. Biomass Bioenergy 2005, 28, 183–191. [Google Scholar] [CrossRef]

- Dahal, P.; Mehmood, S. A GIS Approach to Determining Efficient Timber Transportation Routes. Avaliable online: http://sofew.cfr.msstate.edu/papers/0604dahal.pdf (accessed on 21 April 2013).

- Devlin, G.; McDonnell, S.; Ward, S. Development of a Spatial Decision Support System (SDSS) for route costing calculation within the Irish timber haulage sector. Trans. ASABE Am. Soc. Agric. Biol. Eng. 2008, 51, 273–279. [Google Scholar]

- Morgenroth, J.; Visser, R. Uptake and barriers to the use of geospatial technologies in forest management. N. Z. J. For. Sci. 2013, 43. [Google Scholar] [CrossRef]

- Ranta, T.; Rinne, S. The profitability of transporting uncomminuted raw materials in Finland. Biomass Bioenergy 2006, 30, 231–237. [Google Scholar] [CrossRef]

- Devlin, G.; McDonnell, K.; Ward, S. Timber haulage routing in Ireland: An analysis using GIS and GPS. J. Transp. Geogr. 2008, 16, 63–72. [Google Scholar] [CrossRef]

- Martin, A.; Owende, P.; Holden, N.; Ward, S.; O’Mahony, M. Designation of timber extraction routes in a GIS using road maintenance cost data. For. Prod. J. 2001, 51, 32–38. [Google Scholar]

- UK Timber Transport Forum, Agreed Route Maps 2012. Available online: http://timbertransportforum.org.uk/maps/agreed-routes (accessed on 13 April 2013).

- Devlin, G. Developing a GIS based Agreed Routes Map for Sustainable Timber Transport in Ireland—MARTT. In Proceedings of the IrBEA National BioEnergy Conference, Dublin, Ireland, 4 February 2015.

- Flisberg, P.; Lidén, B.; Rönnqvist, M.; Selander, J. Route selection for best distances in road databases based on drivers’ and customers’ preferences. Can. J. For. Res. 2012, 42, 1126–1140. [Google Scholar] [CrossRef]

- GIS explained 2012. Available online: http://www.osi.ie/education/gis-explained/ (accessed on21 January 2013).

- Blue Tree Systems, R:COM Truck management 2011. Available online: http://www.bluetreesystems.com/region/eu/products/solutions/ (accessed on 3 July 2012).

- Fleet Management System. 2014. Available online: http://www.geneko.rs/en/products/tracking-products-and-solutions/fox-fleet-management-system-fms.html (accessed on 7 March 2015).

- Using ArcGIS 9: Using ArcMap; Environmental Systems Research Institute (ESRI): Redlands, CA, USA, 2005.

- Möller, B. Least-cost allocation strategies for wood fuel supply for distributed generation in Denmark—A geographical study. Int. J. Sustain. Energy 2004, 23, 187–197. [Google Scholar] [CrossRef]

- Alfonso, D.; Perpiñá, C.; Pérez-Navarro, A.; Peñalvo, E.; Vargas, C.; Cárdenas, R. Methodology for optimization of distributed biomass resources evaluation, management and final energy use. Biomass Bioenergy 2009, 33, 1070–1079. [Google Scholar] [CrossRef]

- Panichelli, L.; Gnansounou, E. GIS-based approach for defining bioenergy facilities location: A case study in Northern Spain based on marginal delivery costs and resources competition between facilities. Biomass Bioenergy 2008, 32, 289–300. [Google Scholar] [CrossRef]

- Nurminen, T.; Heinonen, J. Characteristics and Time Consumption of Timber Trucking in Finland. Silva Fenn. 2007, 41, 471–487. [Google Scholar] [CrossRef]

- Regulation (EC) No 561/2006 of the European Parliament and of the Council of 15 March 2006 on the Harmonisation of Certain Social Legislation and Amending Council Regulations (EEC) No 3821/85 and (EC) No 2135/98 and Repealing Council Regulation (EEC) No 3; European Comission: Brussels, Belgium, 2006.

- Road Traffic Act 2004; Irish Department of Transport: Dublin, Ireland, 2010.

- Devlin, G.; Klvac, R.; McDonnell, K. Fuel efficiency and CO2 emissions of biomass based haulage in Ireland—A case study. Energy 2013, 54, 55–62. [Google Scholar] [CrossRef]

- Devlin, G.; Talbot, B. Deriving cooperative biomass resource transport supply strategies in meeting co-firing energy regulations: A case for peat and wood fibre in Ireland. Appl. Energy 2014, 113, 1700–1709. [Google Scholar] [CrossRef]

- Weintraub, A.; Epstein, R.; Morales, M.; Seron, J.; Travieso, P. A truck scheduling system improves efficiency in the forest industry. Interfaces 1996, 26, 1–12. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sosa, A.; McDonnell, K.; Devlin, G. Analysing Performance Characteristics of Biomass Haulage in Ireland for Bioenergy Markets with GPS, GIS and Fuel Diagnostic Tools. Energies 2015, 8, 12004-12019. https://doi.org/10.3390/en81012004

Sosa A, McDonnell K, Devlin G. Analysing Performance Characteristics of Biomass Haulage in Ireland for Bioenergy Markets with GPS, GIS and Fuel Diagnostic Tools. Energies. 2015; 8(10):12004-12019. https://doi.org/10.3390/en81012004

Chicago/Turabian StyleSosa, Amanda, Kevin McDonnell, and Ger Devlin. 2015. "Analysing Performance Characteristics of Biomass Haulage in Ireland for Bioenergy Markets with GPS, GIS and Fuel Diagnostic Tools" Energies 8, no. 10: 12004-12019. https://doi.org/10.3390/en81012004

APA StyleSosa, A., McDonnell, K., & Devlin, G. (2015). Analysing Performance Characteristics of Biomass Haulage in Ireland for Bioenergy Markets with GPS, GIS and Fuel Diagnostic Tools. Energies, 8(10), 12004-12019. https://doi.org/10.3390/en81012004