3.2. Formulation of a Theoretical Model

The increase in

resultant from the addition of winglets must be weighed against the consequent increase in

. Although an individual turbine will benefit from increased

, higher wake deficits resultant from increased

may reduce the power production of downwind turbines. While this compromise may be exceedingly complex in a real wind farm, a simple case may help illustrate the tradeoff. Here, we consider one wind turbine directly upwind of another, and use the simplified wake model proposed by Jensen [

21] to estimate total power output of the system. Note that the Jensen model is only a crude estimate, and other, more accurate, wake models may be used in its place (see Bastankhah and Porté-Agel [

22] for a discussion on the subject of wake modeling). The Jensen wake model assumes a top-hat distribution for the wake deficit, and uses the principle of mass conservation in the linearly expanding wake. The velocity downstream of a turbine is given in Equation (3), where

is the undisturbed upstream velocity,

is the velocity downstream of the first turbine,

κ is the wake expansion coefficient, and

x is separation distance between the two turbines. Typical values of

= 0.8 and

κ = 0.05 suggested by Barthelmie

et al. [

23] for an offshore wind farm will be used.

The upwind turbine faces a velocity of

and the downwind turbine faces a velocity of

. Then, supposing the addition of winglets to the rotor increased the power coefficient by a given percentage, an acceptable increase in thrust coefficient can be estimated by considering the combined power output of the two turbines. The upwind turbine will be expected to produce a power output of

, and the downwind one will produce

. By setting

equal to unity, the total power output of the system is given in Equation (4).

Taking the effects of the winglets into account by increasing

and

, the maximum allowable increase in

that will keep the combined power output unchanged can be calculated for a given increase in

. Note that while the initial value of the

changes the results, the initial value of the

does not.

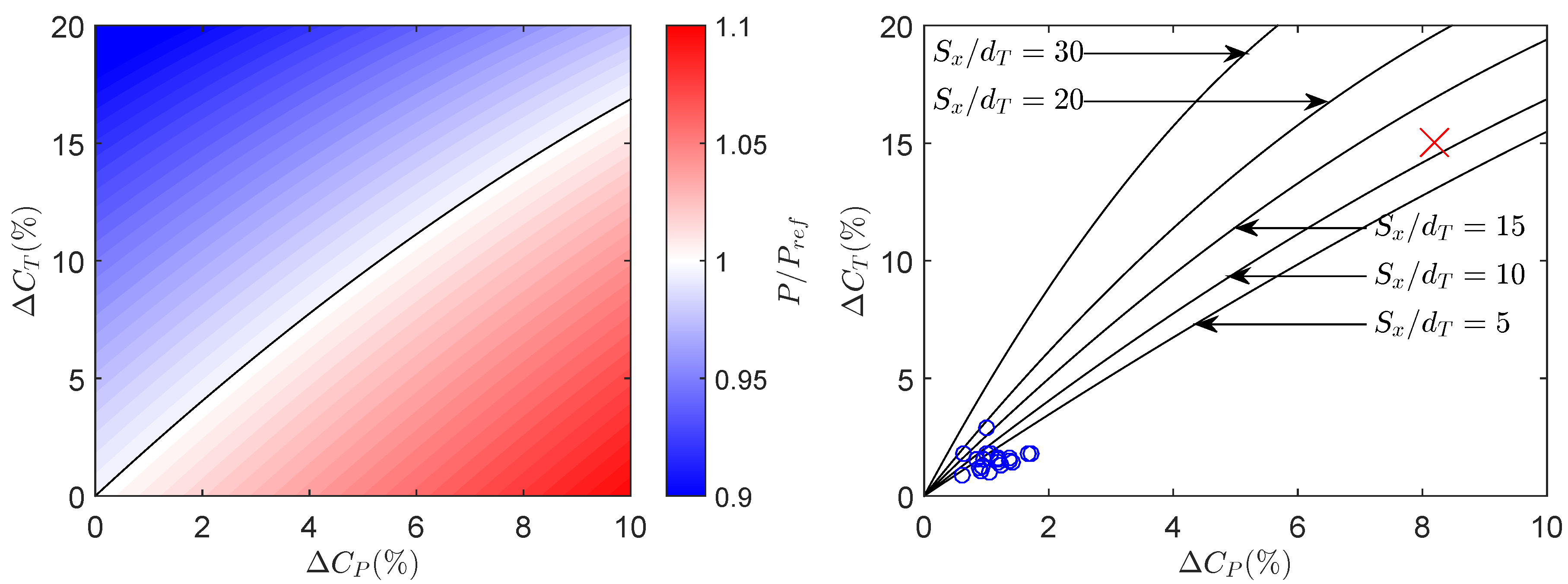

Figure 5 shows the results of this analysis, where

is the increase in

from adding winglets,

is the increase in

,

P is the combined power of the two wingletted turbines, and

is the power output of the two turbines with reference values of

and

. The left figure uses an inter-turbine spacing of 10 rotor diameters and shows the combined power output, where red areas have a higher output than the base case, and blue areas have a lower output, and the black line shows the border between the two. The right figure shows the break-even curve for several inter-turbine spacings.

Figure 5.

Illustration of maximum allowable increase in for a given increase in . Left: combined power output for given increase in and , normalized by the reference power, where inter-turbine spacing is 10 rotor diameters. Right: break-even lines for several inter-turbine spacings. Red crosses come from this experiment. Blue circles are from Johansen and Sørensen.

Figure 5.

Illustration of maximum allowable increase in for a given increase in . Left: combined power output for given increase in and , normalized by the reference power, where inter-turbine spacing is 10 rotor diameters. Right: break-even lines for several inter-turbine spacings. Red crosses come from this experiment. Blue circles are from Johansen and Sørensen.

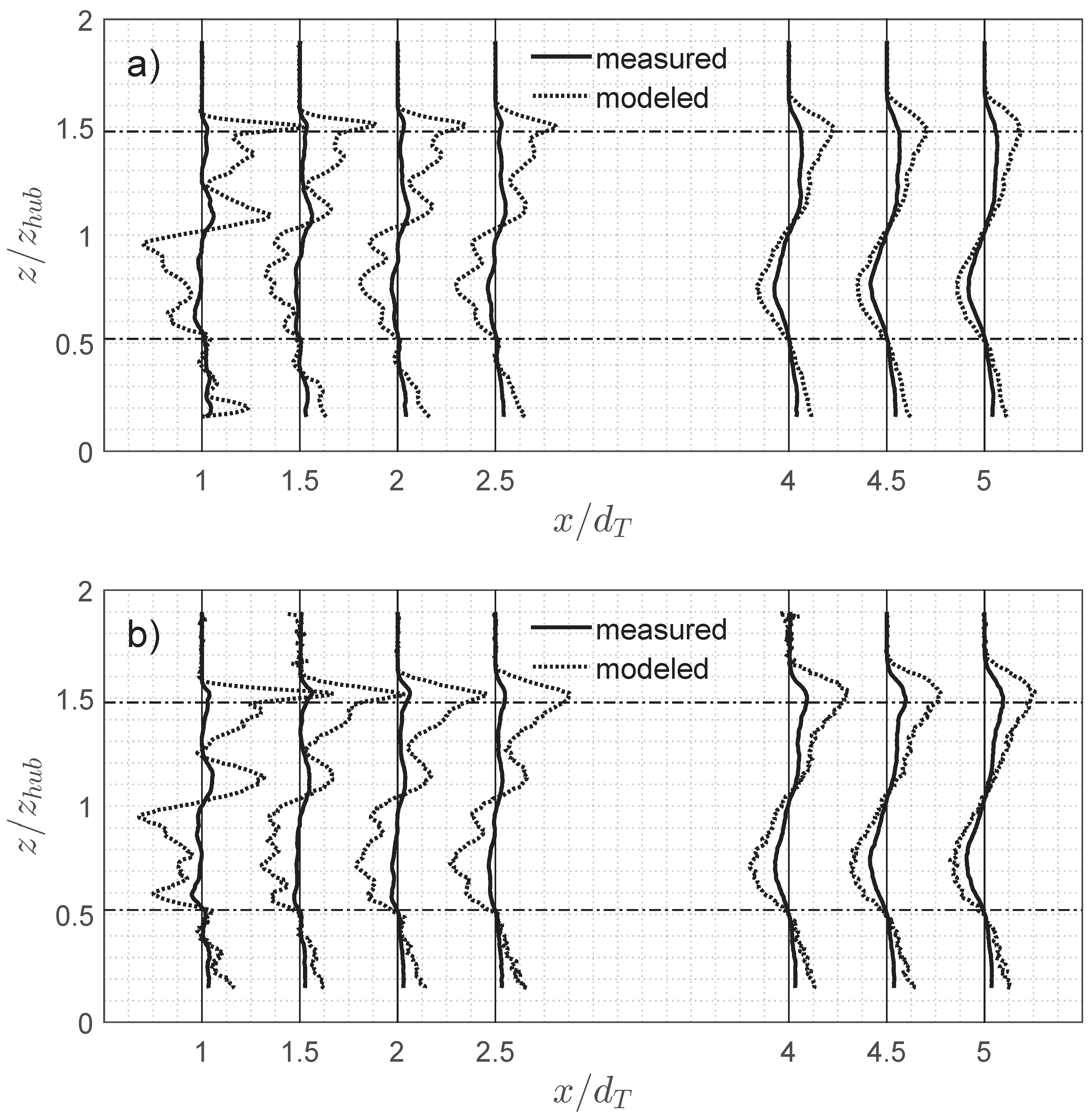

3.3. Wake Characteristics

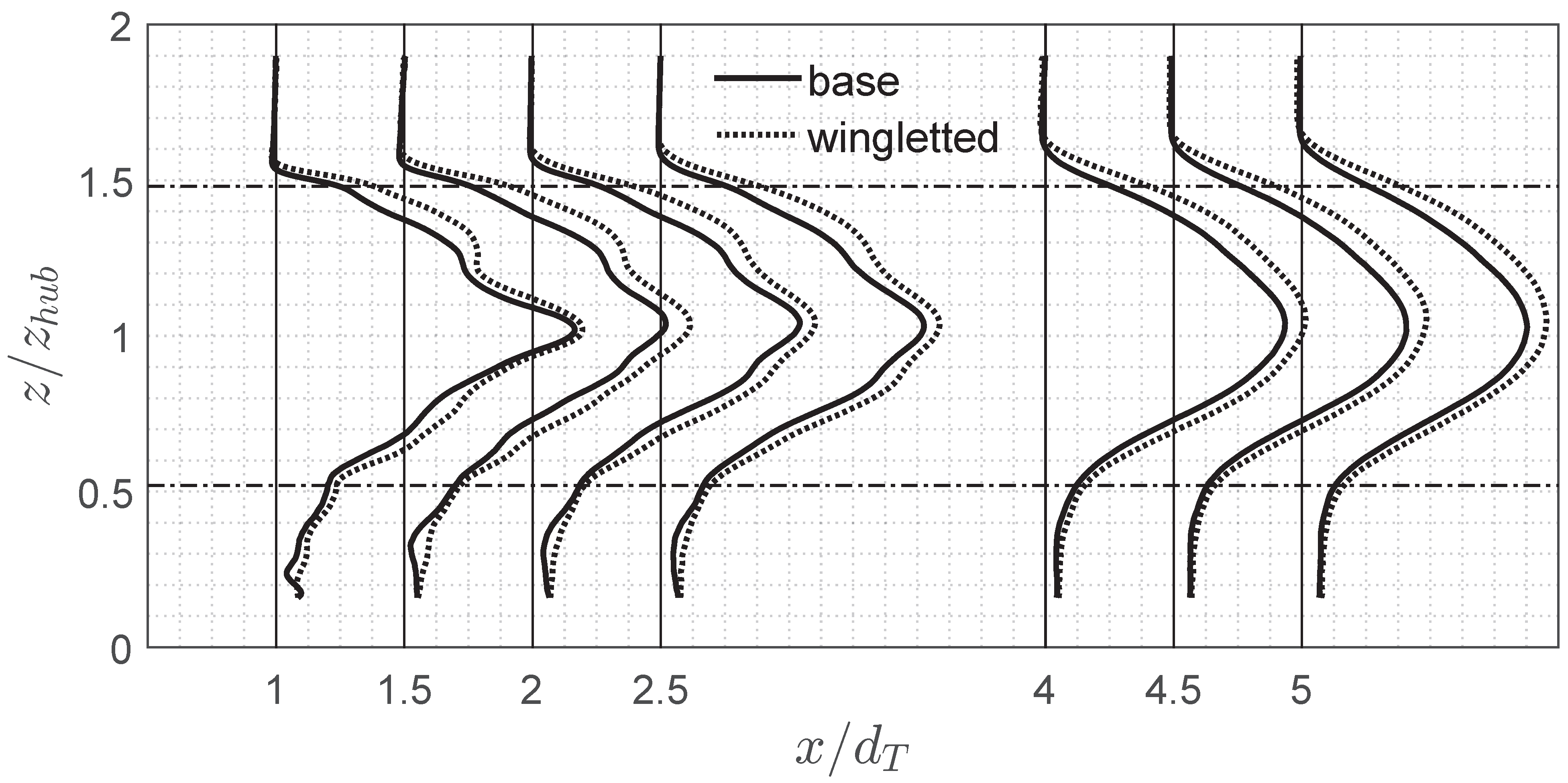

Due to the ∼15% increase in

caused by the winglets, there is a non-negligible difference in the velocity defect profile in the near wake region, as illustrated in

Figure 6. The difference is the greatest in the outer portions of the turbine wake, where the downwash-diminishing effect of the winglets is the highest. In the outer portions of the rotor, the difference in velocity defect is up to 10% of the mean incoming velocity. This is consistent with the results of Johansen and Sørensen [

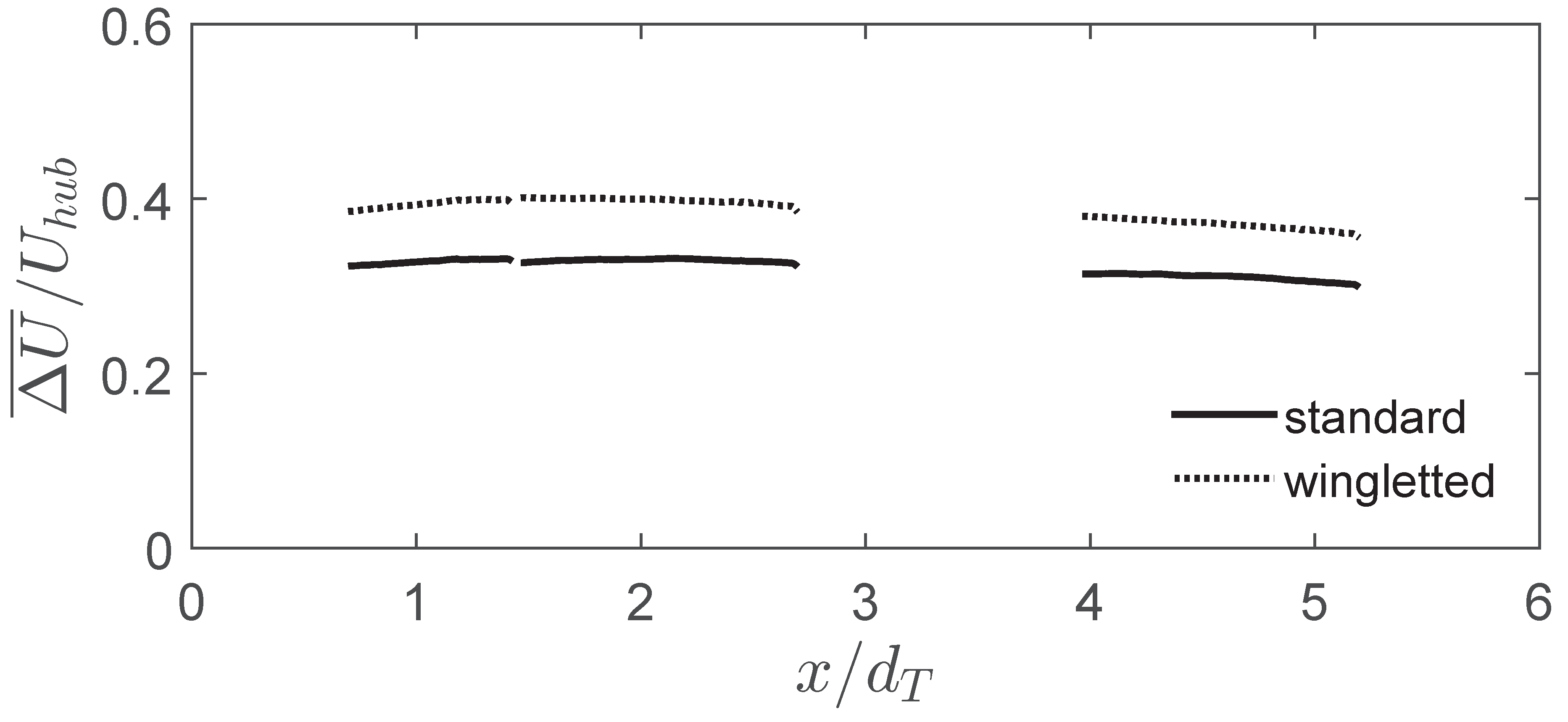

4], where the force distribution was increased in the outer 14% of the rotor. While the difference in velocity defect becomes less localized downstream by turbulent mixing, the total wake deficit that might be experienced by a downstream turbine stays consistently higher in the wingletted case. The average wake deficit,

, was calculated with a solid of revolution concept in the same way as the thrust coefficient was, where the top and bottom measured wake profiles were assumed as the radial distribution over their respective half of the rotor area. Results for the standard and wingletted cases are given in

Figure 7. The total wake deficit is higher by ∼6% of the hub height velocity in the wingletted case. The difference in average wake deficit does not change significantly with downstream distance.

Figure 6.

Comparison of the mean wake deficit profiles, , at the central plane of the standard and wingletted turbine models at several downstream locations. Horizontal dash-dot lines indicate the location of the bottom and top tips of the turbine. Vertical solid lines indicate local zeros, and grid squares have a width of 0.1 × .

Figure 6.

Comparison of the mean wake deficit profiles, , at the central plane of the standard and wingletted turbine models at several downstream locations. Horizontal dash-dot lines indicate the location of the bottom and top tips of the turbine. Vertical solid lines indicate local zeros, and grid squares have a width of 0.1 × .

Figure 7.

Non-dimensional average wake deficit for the two turbine cases as a function of downstream distance.

Figure 7.

Non-dimensional average wake deficit for the two turbine cases as a function of downstream distance.

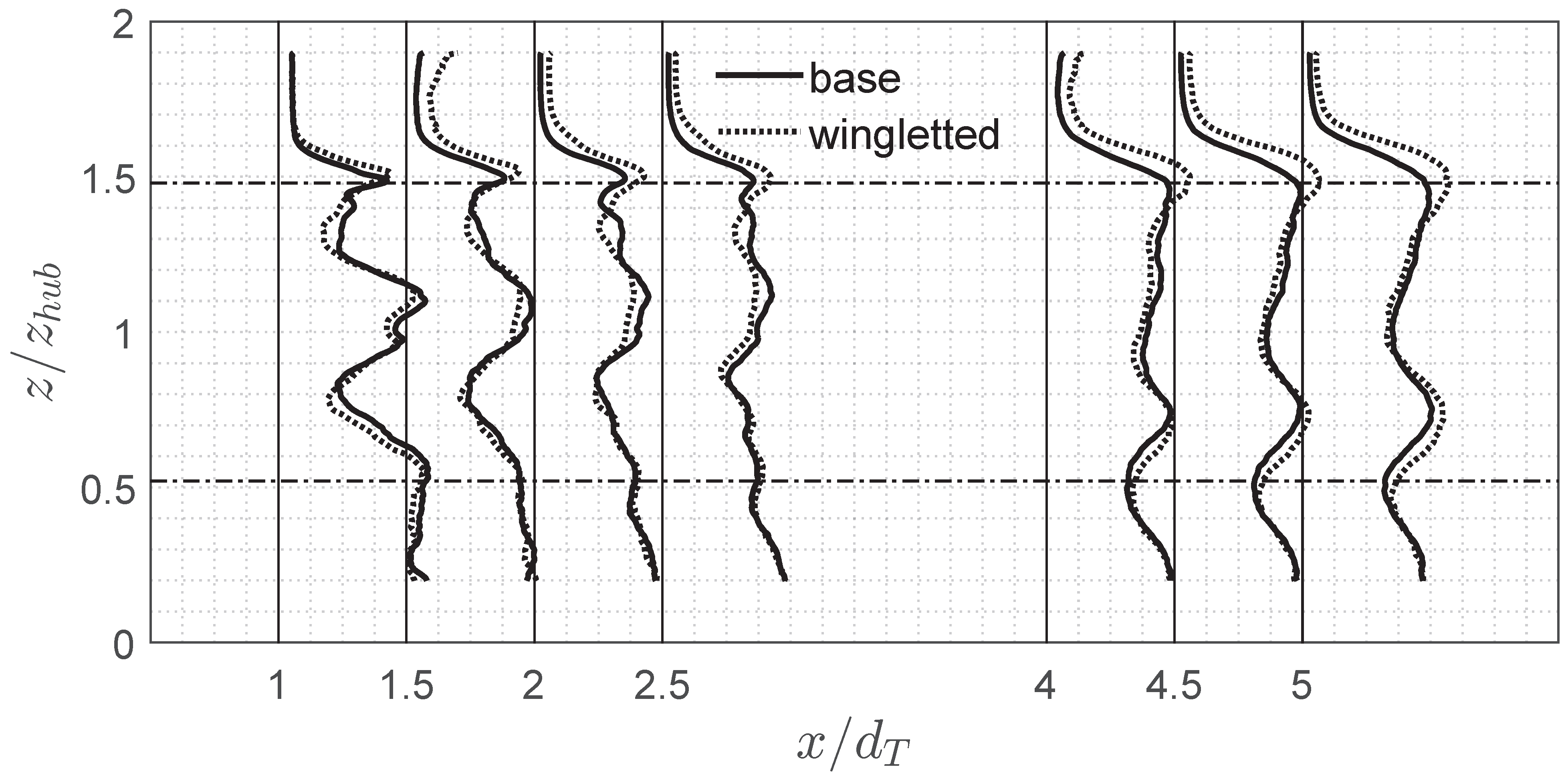

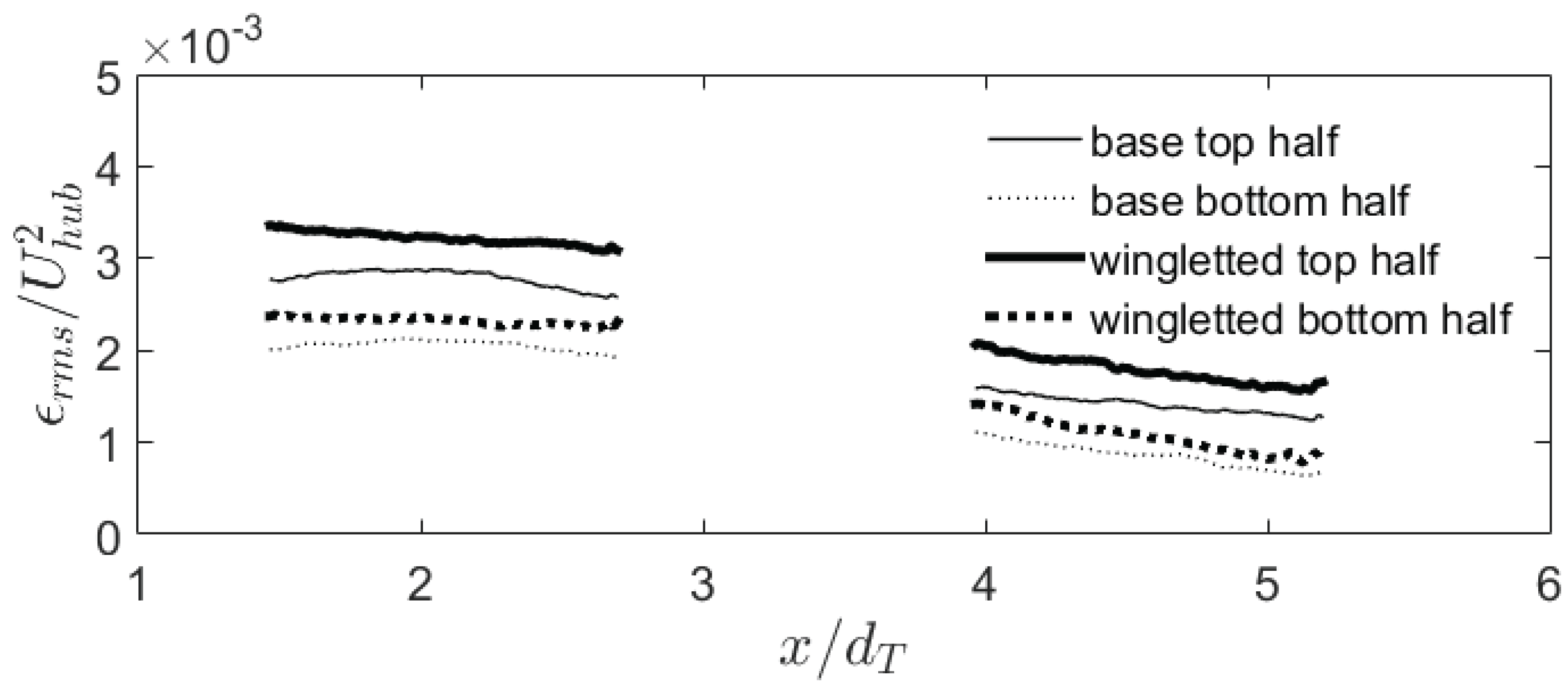

In addition to larger velocity deficits, the wingletted turbine also exhibits slightly higher turbulence intensity in the third FOV (4

5.3), which is illustrated in

Figure 8. This is a result of the higher mean shear in the outer portion of the rotor of the wingletted turbine wake due to the increased thrust force, as the generation of turbulent kinetic energy

G =

.

Figure 8.

Comparison of the standard deviation of velocity profiles at the central plane of the standard and wingletted turbine models at several downstream locations. Horizontal dash-dot lines indicate the location of the bottom and top tips of the turbine. Vertical solid lines indicate local zeros, and grid squares have a width of 0.025 × .

Figure 8.

Comparison of the standard deviation of velocity profiles at the central plane of the standard and wingletted turbine models at several downstream locations. Horizontal dash-dot lines indicate the location of the bottom and top tips of the turbine. Vertical solid lines indicate local zeros, and grid squares have a width of 0.025 × .

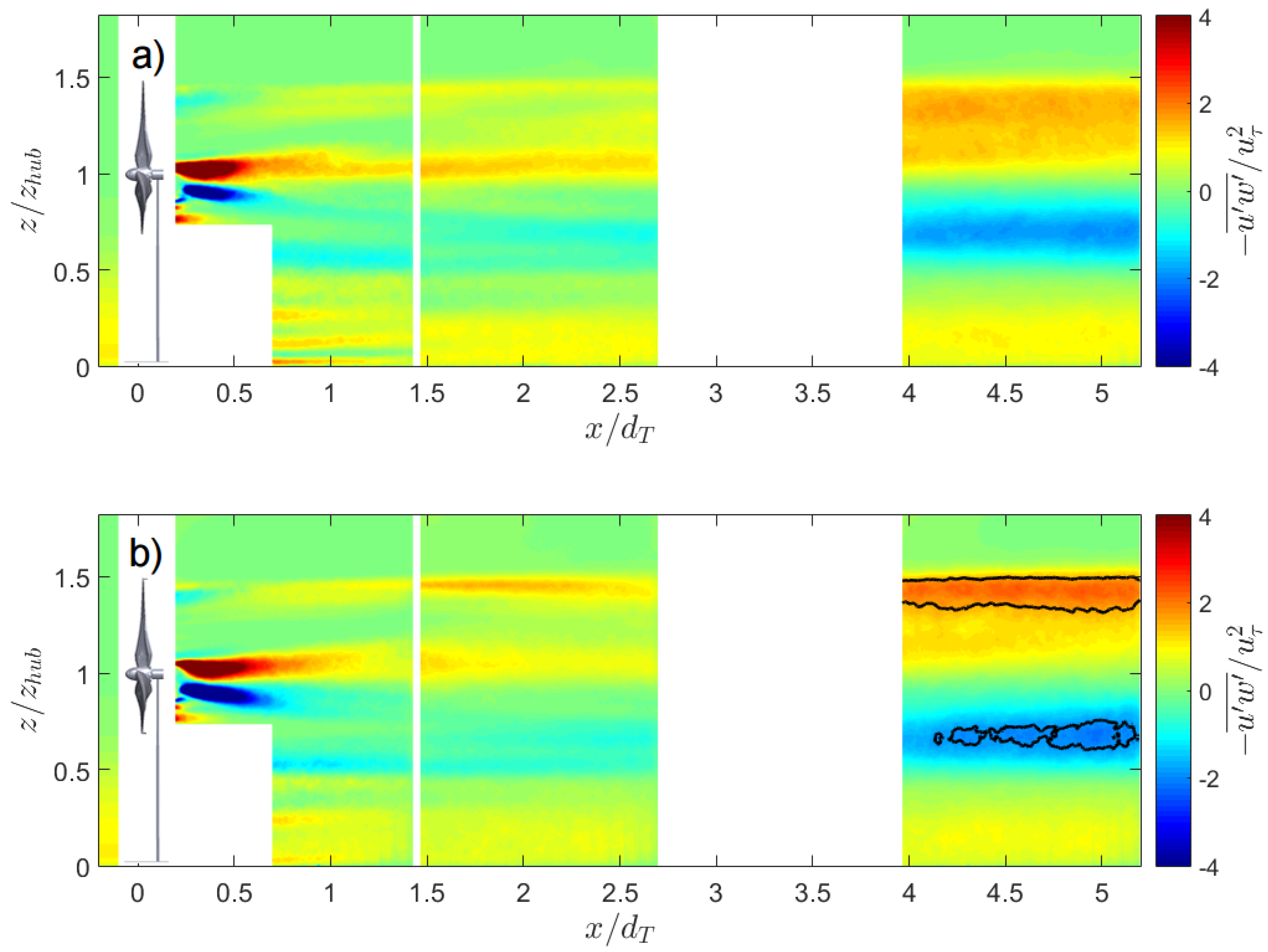

The Reynolds stresses are significantly altered by the addition of winglets to the turbine. In the third FOV at

, the streamwise-vertical component of the Reynolds stress is 10% higher for the wingletted turbine in the outer top part of the wake, shown in

Figure 9. The black lines in

Figure 9b highlight the region of greater Reynolds stress, and are contours of the maximum levels from the base case. To quantify the extent to which the flow has reached an equilibrium state, we apply Prandtl’s mixing length theory for jets and wakes. In the mixing length theory, the Reynolds stress can be modeled as in Equation (5),

where

is the wake width,

is the maximum velocity defect, and

b is a constant, reported as

b by Davidson [

24] for a round jet when Δ is defined such that the wake deficit

away from the centerline is 10% the centerline value. The wake width is estimated from the PIV measurements, and the centerline wake deficit is taken locally as

, where

is the velocity of the incoming boundary layer at height

z. By comparing the measured and estimated distributions of

, as shown in

Figure 10, a measure of the degree of self-similarity can be determined, since the measured Reynolds stress is expected to match the mixing length theory in a fully developed turbulent flow. The mismatch between them in a non-equilibrium flow is indicative of the further potential for the flow to attain a self-similar shape via turbulence production by mean shear. A root mean square (r.m.s.) error,

, of the mixing length model’s prediction is used as a quantitative means to compare the self-similarity between the two cases, because a fully self-similar flow will be most effectively spreading the momentum deficit due to the higher levels of turbulent shear stress. These r.m.s. values for both turbines, and for both the top and bottom parts of the wake, are illustrated in

Figure 11. When calculating r.m.s. values for the top or bottom, points reaching from the hub to 1.4R were considered, so as to account for wake expansion (results from the first FOV are excluded due to the strong effect of the generator’s wake). Results indicate that the base turbine is closer to equilibrium than the wingletted one at all downstream locations, and that the lower, more turbulent portion of the wake is also closer to equilibrium. This is likely a result of the higher levels of shear in the wingletted wake that need to be diffused by the turbulence. It should be noted that the analysis above is rather simplified—the model of the Reynolds stress should be, in general, a function of the initial disturbance and radial position (see Johansson

et al. [

25] for an in-depth discussion of axisymmetric turbulent wakes). The results are not particularly sensitive to the value of

b; changing the value by 50% in either direction changes the magnitudes of the r.m.s. errors, but not their rankings.

Figure 9.

Reynolds stress distribution in the turbine wake: (a) standard rotor; (b) wingletted. Incoming Reynolds stress is shown upstream of the turbine. Areas in the third panel enclosed in black contours have values higher than the maxima in (a).

Figure 9.

Reynolds stress distribution in the turbine wake: (a) standard rotor; (b) wingletted. Incoming Reynolds stress is shown upstream of the turbine. Areas in the third panel enclosed in black contours have values higher than the maxima in (a).

Figure 10.

Comparison between measured kinematic Reynolds stress and the shear-based mixing length model. (a) Base turbine; (b) wingletted turbine. Horizontal dash-dot lines indicate the location of the bottom and top tips of the turbine. Vertical solid lines indicate local zeros, and grid squares have a width of 2 × .

Figure 10.

Comparison between measured kinematic Reynolds stress and the shear-based mixing length model. (a) Base turbine; (b) wingletted turbine. Horizontal dash-dot lines indicate the location of the bottom and top tips of the turbine. Vertical solid lines indicate local zeros, and grid squares have a width of 2 × .

Figure 11.

Normalized root mean square error () of mixing length estimate with downstream distance.

Figure 11.

Normalized root mean square error () of mixing length estimate with downstream distance.

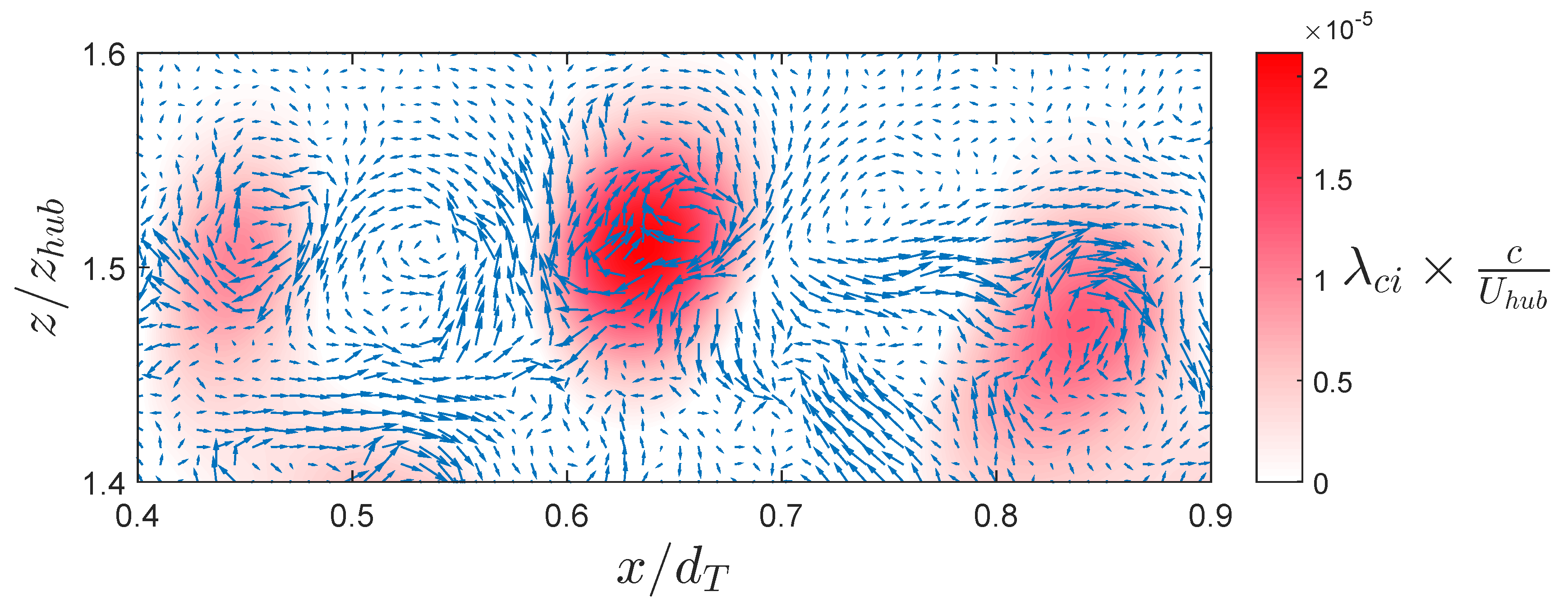

Further, the tip-vortex features were investigated by determining vortex strength as a function of downstream distance. The PIV velocity fields were conditioned using an

LES decomposition with a filter width approximately the size of the tip vortex to eliminate small-scale structures, while the

criterion of the filtered velocity field was used to identify tip vortices. For further information on the

LES conditioning of velocity fields and identification of vortices, see Adrian

et al. [

26]. The quantity

is the imaginary part of the complex conjugate eigenvalues of the velocity gradient tensor [

27]. By calculating

of the filtered velocity field, individual vortices are identified. A continuous (8-connected) region of non-zero

was taken as a single tip vortex, with its core coincident with the maximum value of

. An example

field overlaid with instantaneous velocity vectors is shown in

Figure 12. When a vortex core was identified, the instantaneous field was counted into an average that also had a core at that specific downstream location, giving phase-averaged results. Some tolerance was given for the

z-location of the vortex core, but ∼90% were within one core radius of the average

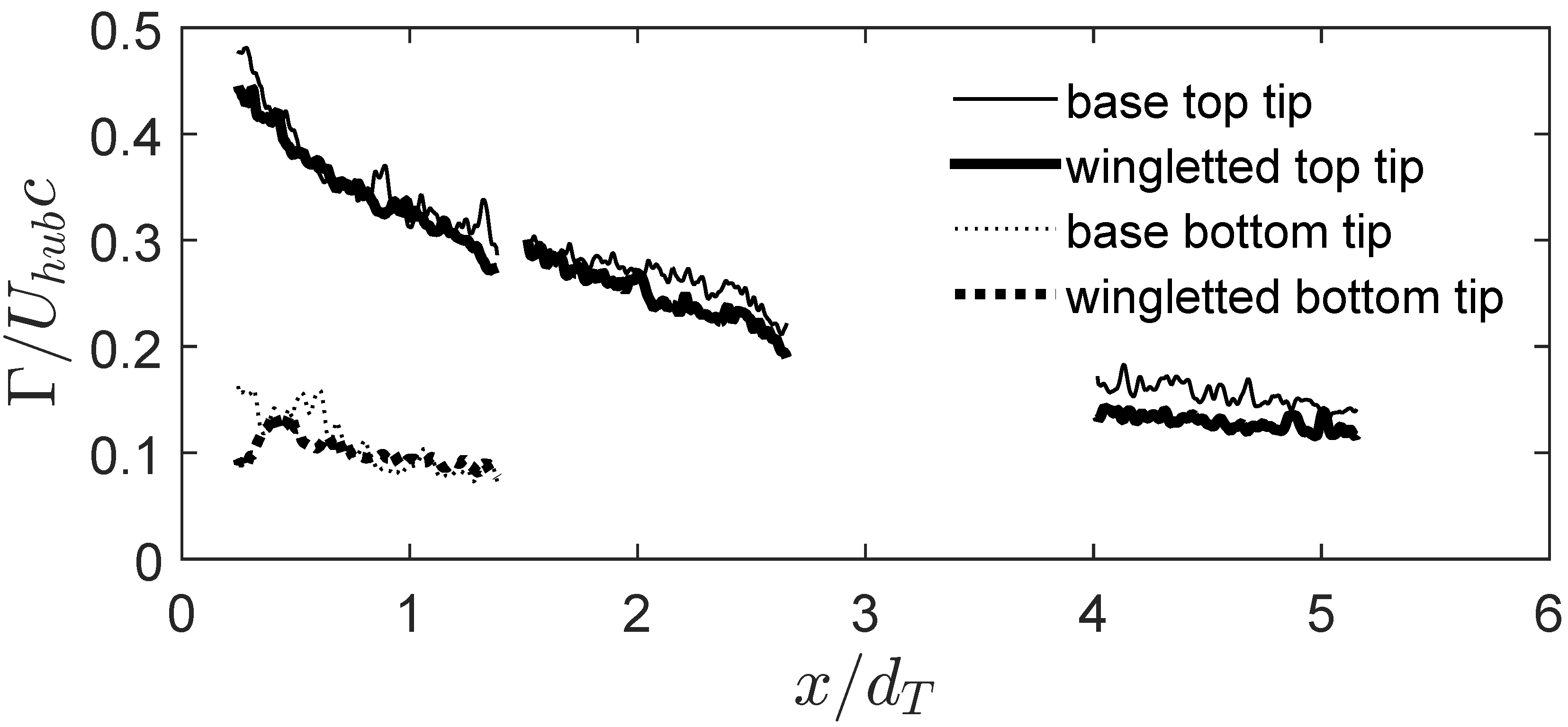

z-location. Between 50 and 125 fields were used for each streamwise location. This averaging allowed for the quantification of tip-vortex strength and the exclusion of turbulent vortices from the averaging farther downstream. The average non-dimensional vortex strength, where Γ is the vortex circulation and

c is the average chord length, with downstream distance is shown in

Figure 13 for the two turbine cases at the bottom and top tips. Circulation was measured with a closed path integral of the velocity field as defined in Equation (6) along a square circuit 7.25 mm on a side to coincide with the radial position of maximum tangential velocity. This is considered the characteristic circulation of a viscous vortex [

28].

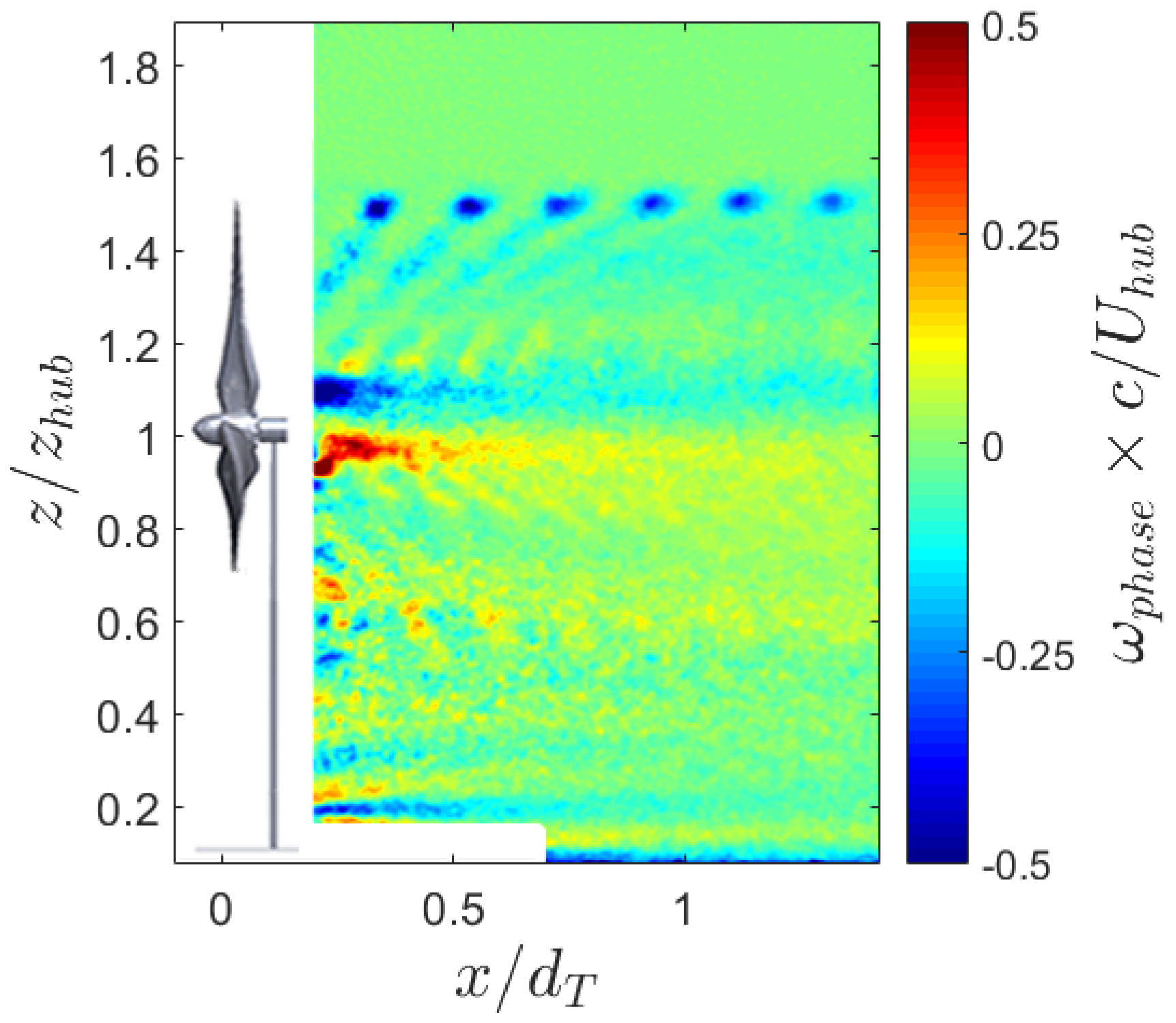

Example phase-average contours are given in

Figure 14, clearly showing the tip-vortex structures and the footprint of the vortex sheet along the blades very near the turbine. The difference in tip-vortex strength measured in the upper half of the wake in the base and wingletted turbine cases becomes more pronounced farther downwind, where the base turbine has slightly stronger tip vortices, potentially as a result of the lower turbulence intensity. While the tip vortex may be predicted to be smaller from a wingletted airfoil, it is possible that the similar values observed in this study come from the fact that the area of integration for the circulation is larger on a side than the length of the winglet, thereby including some vorticity from the base of the wing as well as the body of the winglet. Also included in

Figure 13 is the strength of vortices from the bottom tip. The lower values are likely a result of the vortex structure passing over the tower.

Figure 12.

Instantaneous velocity field fluctuations overlaid on (red area) to illustrate the identification of tip vortices.

Figure 12.

Instantaneous velocity field fluctuations overlaid on (red area) to illustrate the identification of tip vortices.

Figure 13.

Average tip-vortex strength Γ as a function of the distance from the turbine for the standard and wingletted turbines.

Figure 13.

Average tip-vortex strength Γ as a function of the distance from the turbine for the standard and wingletted turbines.

Figure 14.

Example phase-average vorticity contour ( where is phase-average velocity) for the base turbine, normalized with blade chord length c and hub velocity .

Figure 14.

Example phase-average vorticity contour ( where is phase-average velocity) for the base turbine, normalized with blade chord length c and hub velocity .