Influence of Pyrolysis Temperature on Rice Husk Char Characteristics and Its Tar Adsorption Capability

Abstract

:1. Introduction

2. Methodology

2.1. Rice Husk Material

| Ultimate analysis (wt% dry basis) | ||||

|---|---|---|---|---|

| C | H | N | Cl | |

| 37.9 | 3.9 | 0.4 | 0.1 | |

| Proximate analysis (wt% dry basis) | ||||

| Volatile matter content | Fixed carbon | Ash | ||

| 69.7 | 9.8 | 20.6 | ||

2.2. Experimental Setup

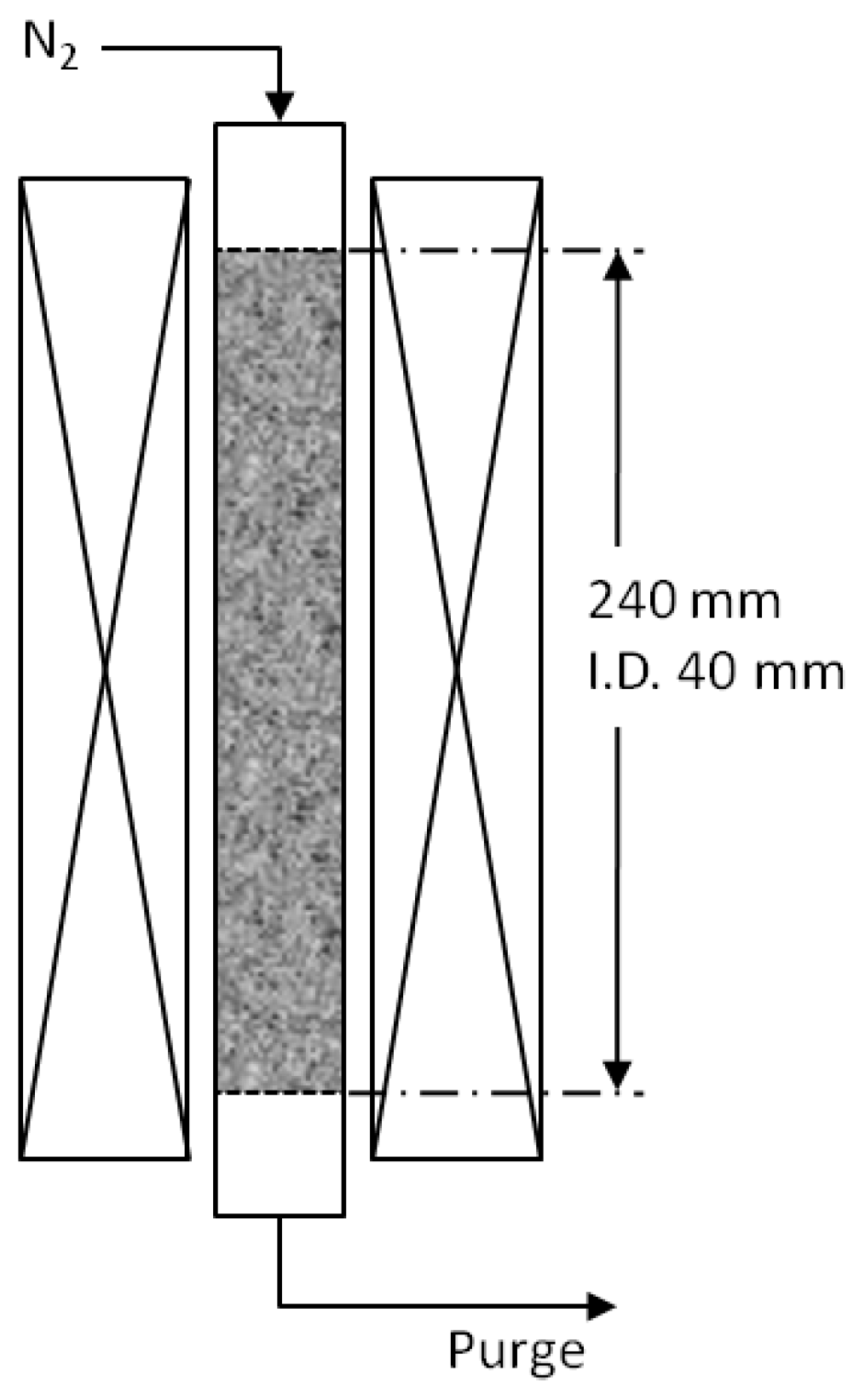

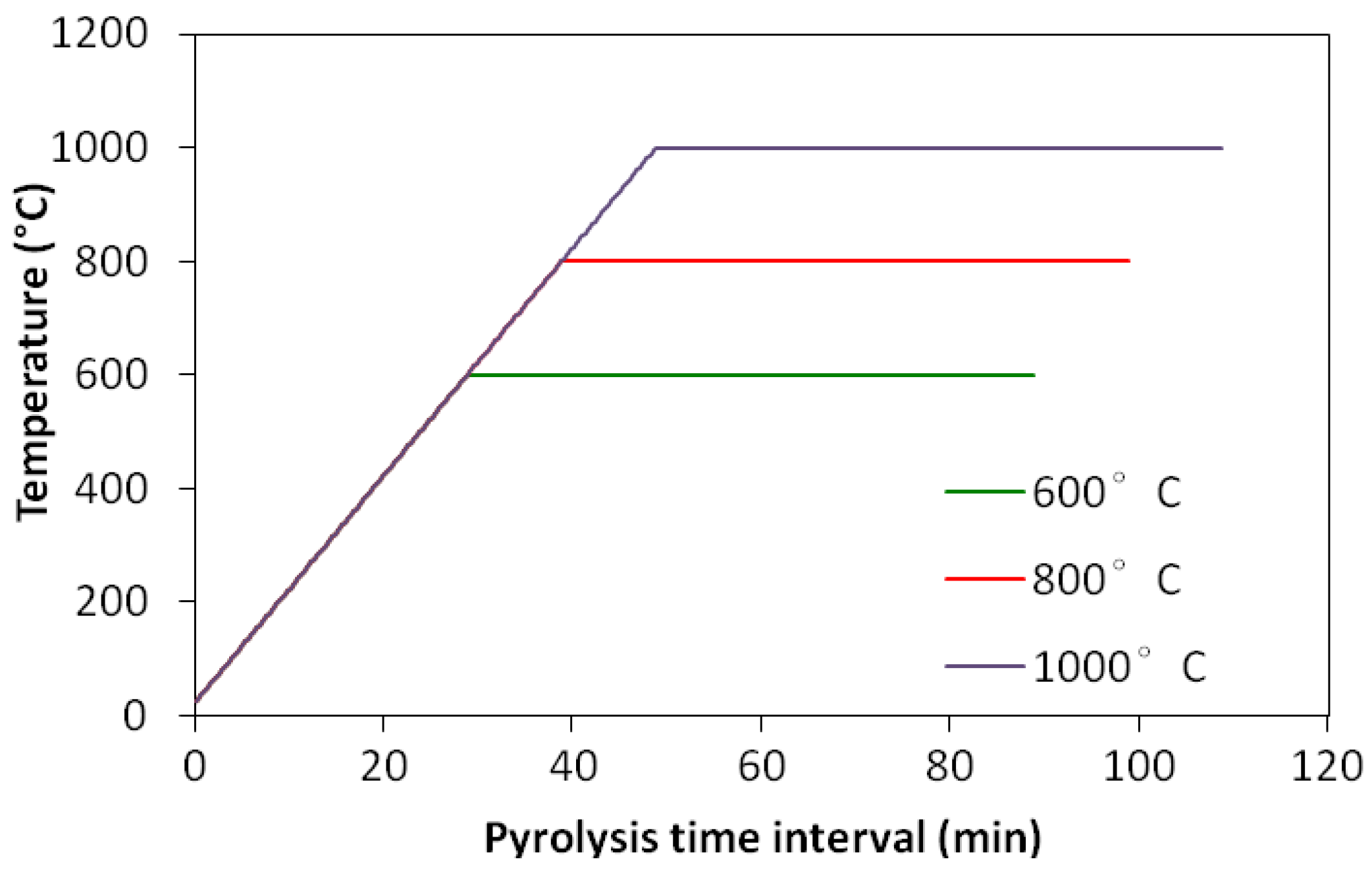

2.2.1. Rice Husk Char Preparation

| Parameter | Experimental conditions |

|---|---|

| Material | Rice husk |

| Material size | Original size (8–11 mm) |

| Pyrolysis temperature | 600, 800 and 1000 °C |

| Heating rate | 20 °C/min |

| Holding time | 1 h (after reaching the target temperature) |

| Carrier gas | Nitrogen |

| Carrier gas flow rate | 1.5 L/min |

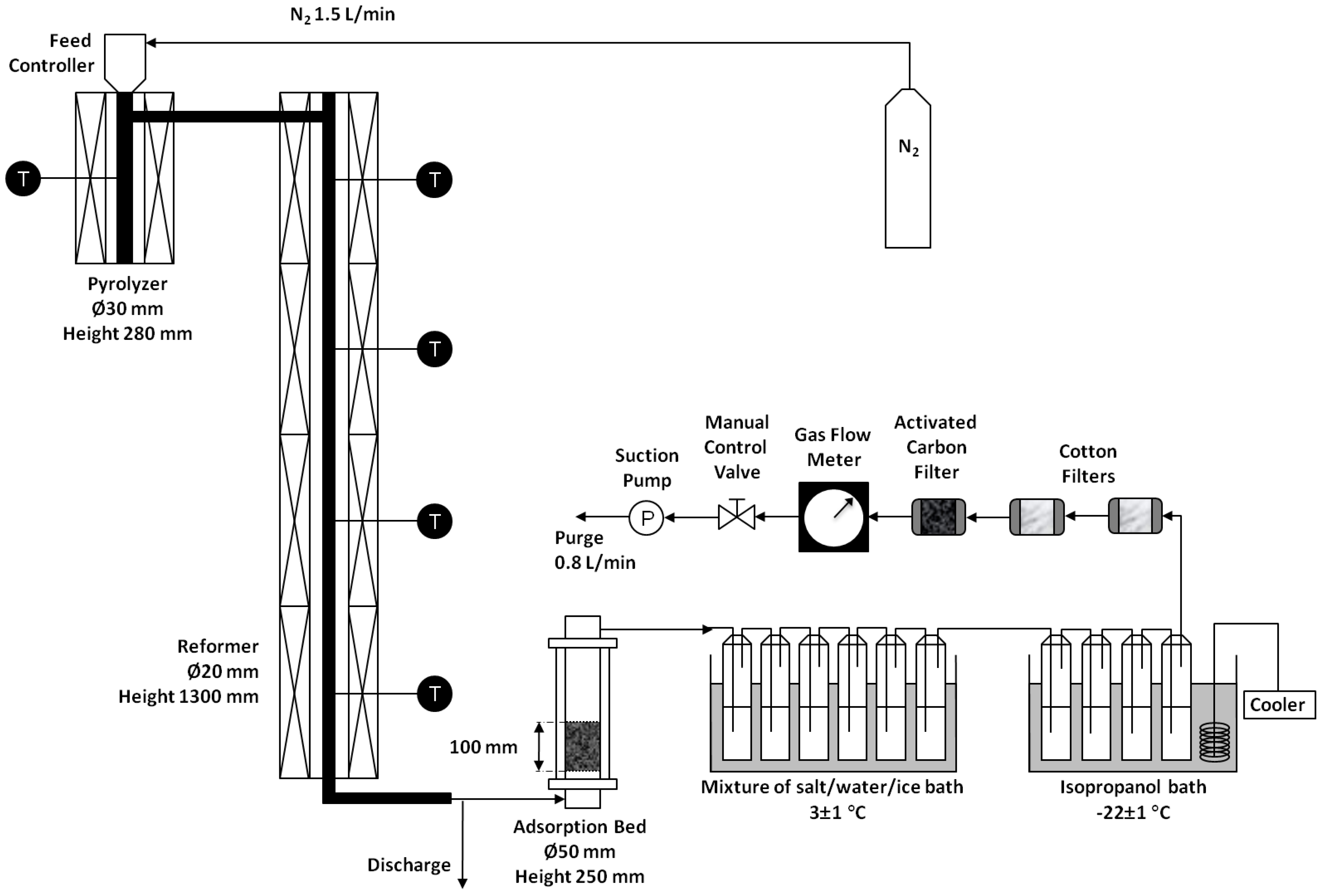

2.2.2. Tar Removal Investigation

| Parameter | Experimental conditions |

|---|---|

| Feed material | Rice husk |

| Feedstock size | 0.125–0.50 mm |

| Feed rate | 0.6 g/min |

| Pyrolyzer temperature | 800 °C |

| Reformer temperature | 800 °C |

| Carrier gas | N2 |

| Carrier gas flow rate | 1.5 L/min |

| Tar adsorbent | Rice husk char pyrolyzed at 600, 800 and 1000 °C |

| Char bed height | 100 mm |

2.3. Characterization of Char

2.3.1. Thermal Gravimetric Analysis (TGA)

| Parameter | Stage 1 | Stage 2 |

|---|---|---|

| Heating rate | 20 °C/min | 50 °C/min |

| Target temperature | 105 °C | 900 °C |

| Keeping time at target temperature | 5 min | 30 min |

| Carrier gas | Nitrogen | Nitrogen and Air |

| Carrier gas flow rate | 150 mL/min | 150 mL/min |

2.3.2. Surface Characterization

3. Results and Discussion

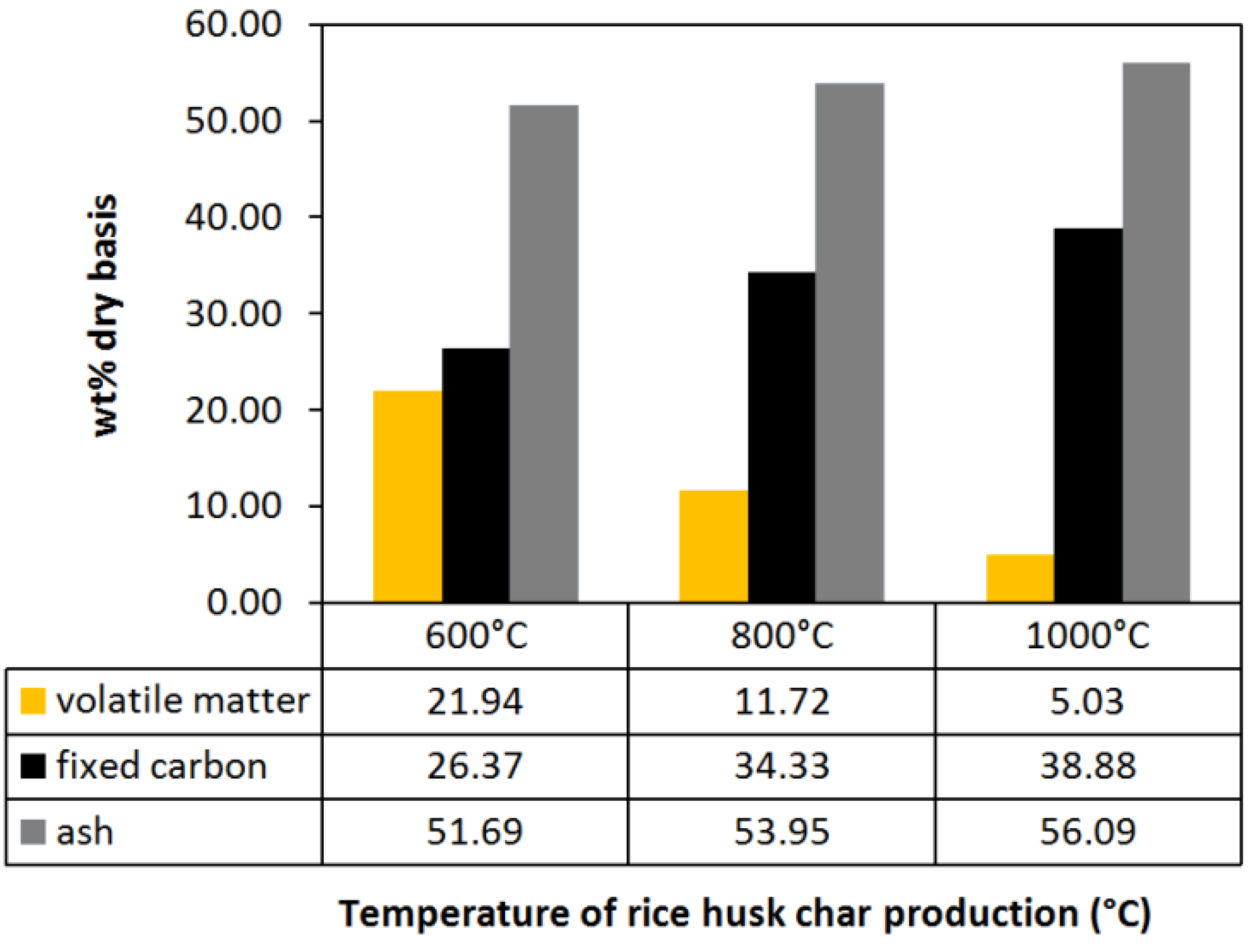

3.1. Thermal Effects on Characterizations of Rice Husk Char

3.2. Thermal Effect on Specific Surface Area of Rice Husk Char

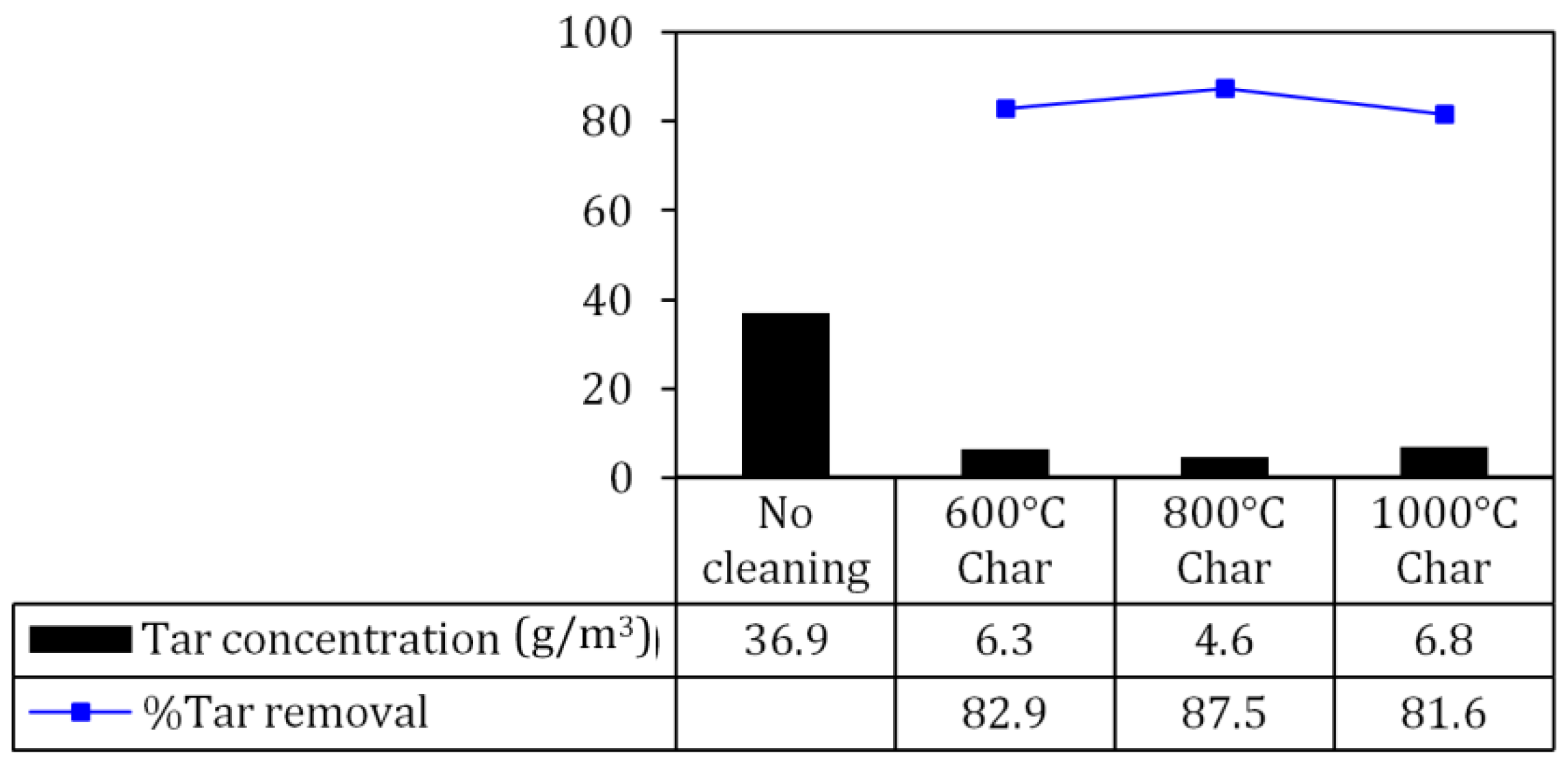

3.3. Tar Removal Ability Investigation

3.4. Analysis of Rice Husk Char after Tar Adsorption

| Proximate analysis (wt% dry basis) | 600 °C Char | 800 °C Char | 1000 °C Char | |||

|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |

| Volatile matter | 21.9 | 36.1 | 11.7 | 30.0 | 5.0 | 18.7 |

| Fixed carbon | 26.4 | 12.3 | 34.3 | 17.0 | 38.9 | 27.7 |

| Ash | 51.7 | 51.6 | 53.9 | 53 | 56.1 | 53.6 |

4. Conclusions

References

- Maiti, S.; Dey, S.; Purakayastha, S.; Ghosh, B. Physical and thermochemical characterization of rice husk char as a potential biomass energy source. Bioresour. Technol. 2006, 97, 2065–2070. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.S.; Manan, Z.A.; Alwi, S.R.W.; Hashim, H. A review on utilization of biomass from rice industry as a source of renewable energy. Renew. Sustain. Energy Rev. 2012, 16, 3084–3094. [Google Scholar] [CrossRef]

- Gonzalez, J.F.; Roman, S.; Encinar, J.M.; Martinez, G. Pyrolysis of various biomass residues and char utilization for the production of activated carbons. J. Anal. Appl. Pyrolysis 2009, 85, 134–141. [Google Scholar] [CrossRef]

- Raveendran, K.; Ganesh, A. Adsorption characteristics and pore-development of biomass-pyrolysis char. Fuel 1998, 77, 769–781. [Google Scholar] [CrossRef]

- Fu, P.; Yi, W.; Bai, X.; Li, Z.; Hu, S.; Xiang, J. Effect of temperature on gas composition and char structural features of pyrolyzed agricultural residues. Bioresour. Technol. 2011, 102, 8211–8219. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Xiang, J.; Sun, L.; Xu, M.; Qiu, J.; Fu, P. Characterization of char from rapid pyrolysis of rice husk. Fuel Process. Technol. 2008, 89, 1096–1105. [Google Scholar] [CrossRef]

- Liu, W.J.; Zeng, F.X.; Jiang, H.; Zhang, X.S. Preparation of high adsorption capacity bio-chars from waste biomass. Bioresour. Technol. 2011, 102, 8247–8252. [Google Scholar] [CrossRef]

- Paethanom, A.; Nakahara, S.; Kobayashi, M.; Prawisudha, P.; Yoshikawa, K. Performance of tar removal by absorption and adsorption for biomass gasification. Fuel Process. Technol. 2012, 104, 144–154. [Google Scholar] [CrossRef]

- Phuphuakrat, T.; Namioka, T.; Yoshikawa, K. Tar removal from biomass pyrolysis gas in two-step function of decomposition and adsorption. Appl. Energy 2010, 87, 2203–2211. [Google Scholar] [CrossRef]

- El-Rub, Z.A.; Bramer, E.A.; Brem, G. Experimental comparison of biomass chars with other catalysts for tar reduction. Fuel 2008, 87, 2243–2252. [Google Scholar] [CrossRef]

- Wang, D.; Yuan, W.; Ji, W. Char and char-supported nickel catalysts for secondary syngas cleanup and conditioning. Appl. Energy 2011, 88, 1656–1663. [Google Scholar] [CrossRef]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Tar reduction in pyrolysis vapours from biomass over a hot char bed. Bioresour. Technol. 2009, 100, 6045–6051. [Google Scholar] [CrossRef] [PubMed]

- Brownsort, P.A. Biomass Pyrolysis Processes: Review of Scope, Control and Variability; UKBRC Working Paper 5; UK Biochar Research Centre: Edinburgh, UK, 2009. [Google Scholar]

- Sukiran, M.A.; Kheang, L.S.; Bakar, N.A.; May, C.Y. Production and characterization of bio-char from the pyrolysis of empty fruit bunches. Am. J. Appl. Sci. 2011, 8, 984–988. [Google Scholar] [CrossRef]

- Arenas, E.; Chejne, F. The effect of the activating agent and temperature on the porosity development of physically activated coal chars. Carbon 2004, 42, 2451–2455. [Google Scholar] [CrossRef]

- Fu, P.; Hu, S.; Xiang, J.; Sun, L.; Yang, T.; Zhang, A.; Wang, Y.; Chen, G. Effect of pyrolysis temperature on characteristics of porosity in biomass chars. In Proceedings of International Conference on Energy and Environmental Technology, Guangxi, China, 16–18 October 2009.

- Guerrero, M.; Pilar Ruiz, M.; Millera, A.; Alzueta, M.U.; Bilbao, R. Characterization of biomass chars formed under different devolatilization conditions: Differences between rice husk and eucalyptus. Energy Fuels 2008, 22, 1275–1284. [Google Scholar] [CrossRef]

- Chan, M.L.; Jones, J.M.; Pourkashanian, M.; Williams, A. The oxidative reactivity of coal chars in relation to their structure. Fuel 1999, 78, 1539–1552. [Google Scholar] [CrossRef]

- Sharma, R.K.; Wooten, J.B.; Baliga, V.L.; Hajaligol, M.R. Characterization of chars from biomass-derived materials: Pectin chars. Fuel 2001, 80, 1825–1836. [Google Scholar] [CrossRef]

- Hurt, R.; Sun, J.K.; Lunden, M. A kinetic model of carbon burnout in pulverized coal combustion. Combust. Flame 1998, 113, 181–197. [Google Scholar] [CrossRef]

- Russell, N.V.; Gibbins, J.R.; Williamson, J. Structural ordering in high temperature coal chars and the effect on reactivity. Fuel 1999, 78, 803–807. [Google Scholar] [CrossRef]

- Pastor-Villegas, J.; Duran-Valle, C.J. Pore structure of chars and activated carbons prepared using carbon dioxide at different temperatures from extracted rockrose. J. Anal. Appl. Pyrolysis 2001, 57, 1–13. [Google Scholar] [CrossRef]

- Lu, L.; Kong, C.; Sahajwalla, V.; Harris, D. Char structure ordering during pyrolysis and combustion and its influence on char reactivity. Fuel 2002, 81, 1215–1225. [Google Scholar] [CrossRef]

- Biagini, E.; Pintus, S.; Tognotti, L. Characterization of high heating-rate chars from alternative fuels using an electrodynamic balance. Proc. Combust. Inst. 2005, 30, 2205–2212. [Google Scholar] [CrossRef]

- Huang, Y.; Jin, B.; Zhong, Z.; Zhong, W.; Xiao, R. Characteristic and mercury adsorption of activated carbon produced by CO2 of chicken waste. J. Environ. Sci. 2008, 20, 291–296. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Paethanom, A.; Yoshikawa, K. Influence of Pyrolysis Temperature on Rice Husk Char Characteristics and Its Tar Adsorption Capability. Energies 2012, 5, 4941-4951. https://doi.org/10.3390/en5124941

Paethanom A, Yoshikawa K. Influence of Pyrolysis Temperature on Rice Husk Char Characteristics and Its Tar Adsorption Capability. Energies. 2012; 5(12):4941-4951. https://doi.org/10.3390/en5124941

Chicago/Turabian StylePaethanom, Anchan, and Kunio Yoshikawa. 2012. "Influence of Pyrolysis Temperature on Rice Husk Char Characteristics and Its Tar Adsorption Capability" Energies 5, no. 12: 4941-4951. https://doi.org/10.3390/en5124941

APA StylePaethanom, A., & Yoshikawa, K. (2012). Influence of Pyrolysis Temperature on Rice Husk Char Characteristics and Its Tar Adsorption Capability. Energies, 5(12), 4941-4951. https://doi.org/10.3390/en5124941