Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study

Abstract

:1. Introduction

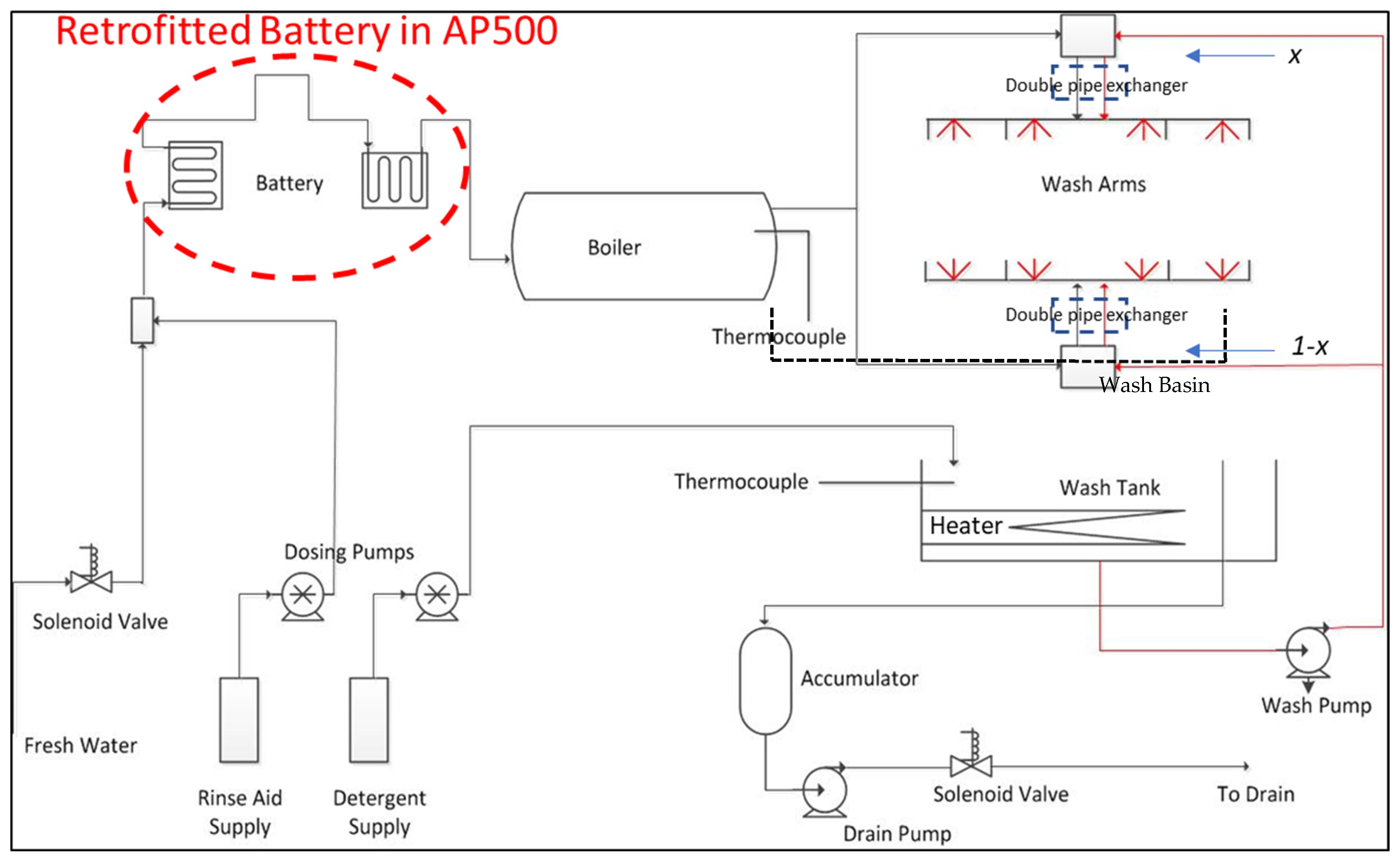

2. Methodology and Technique

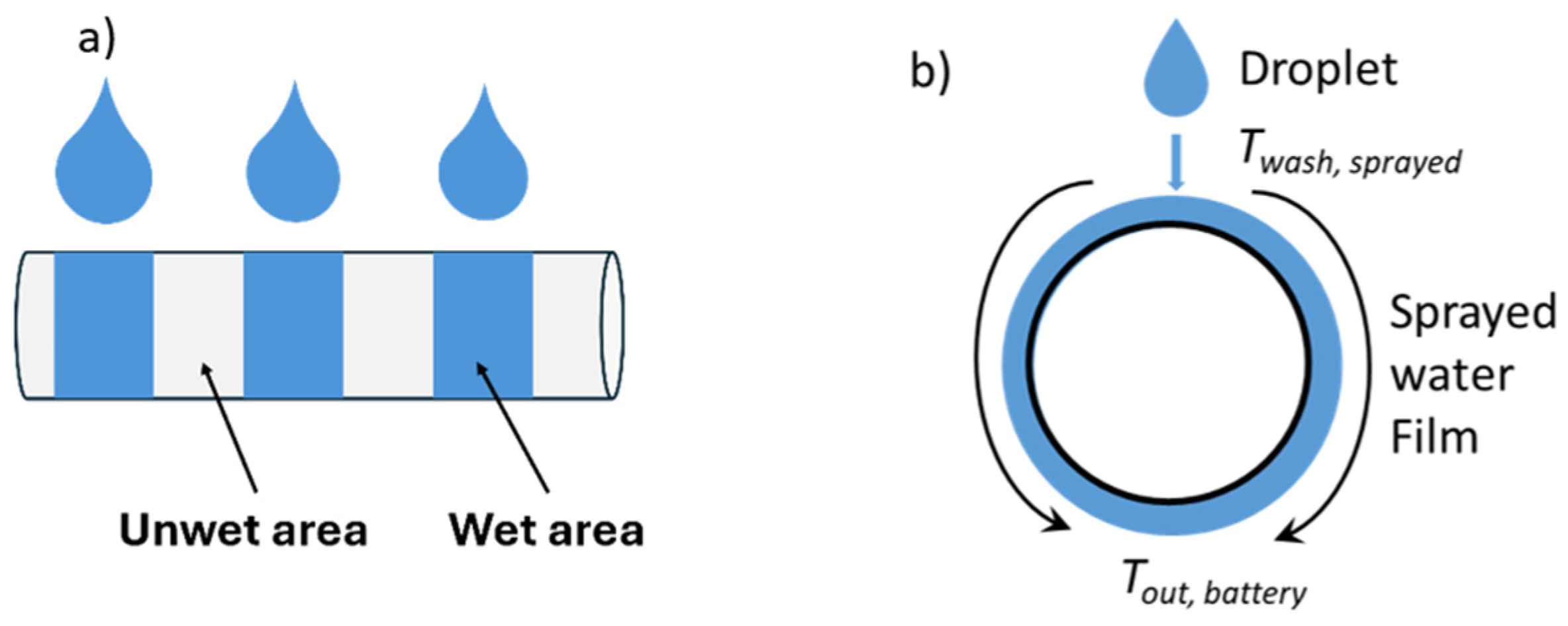

2.1. Theoretical Study

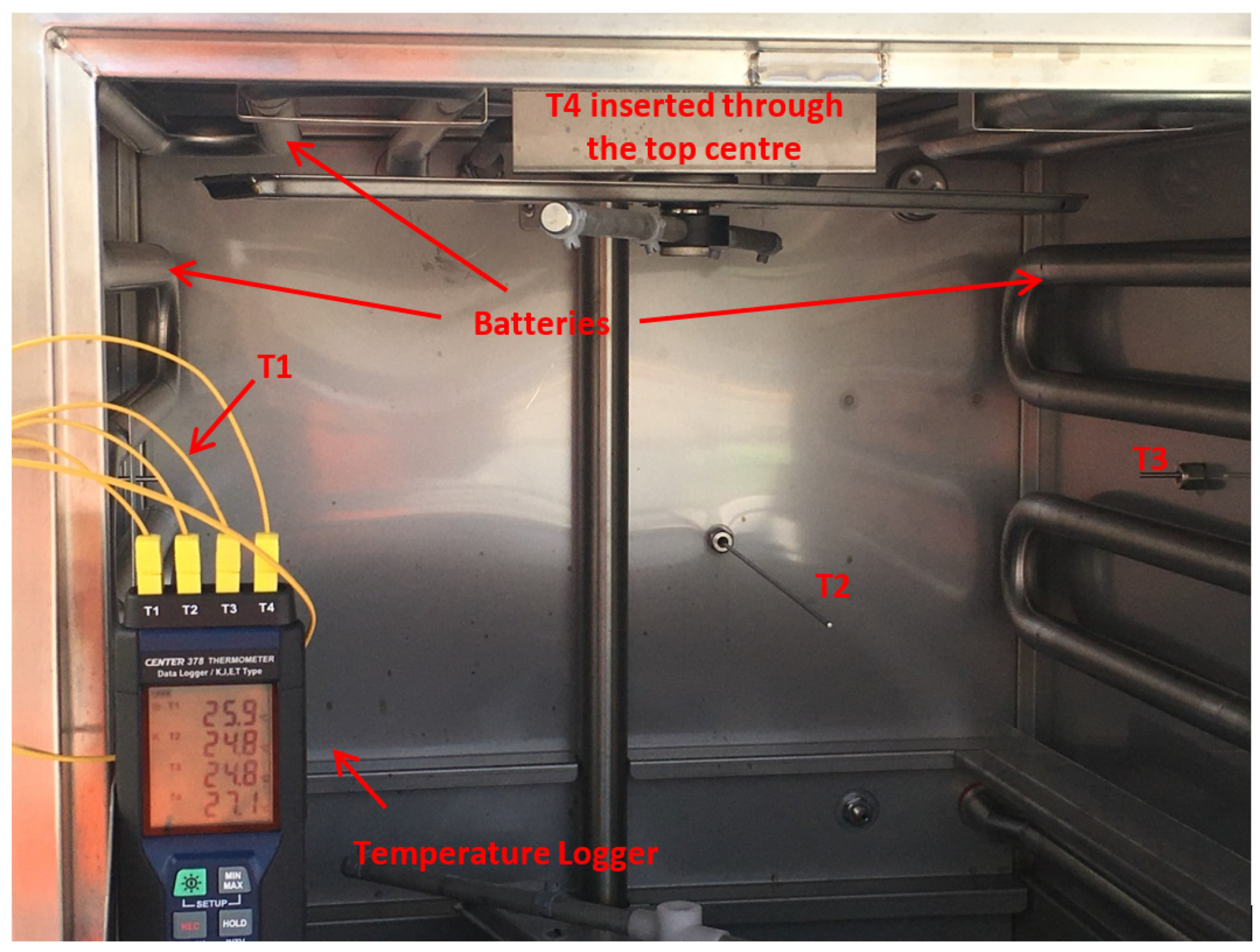

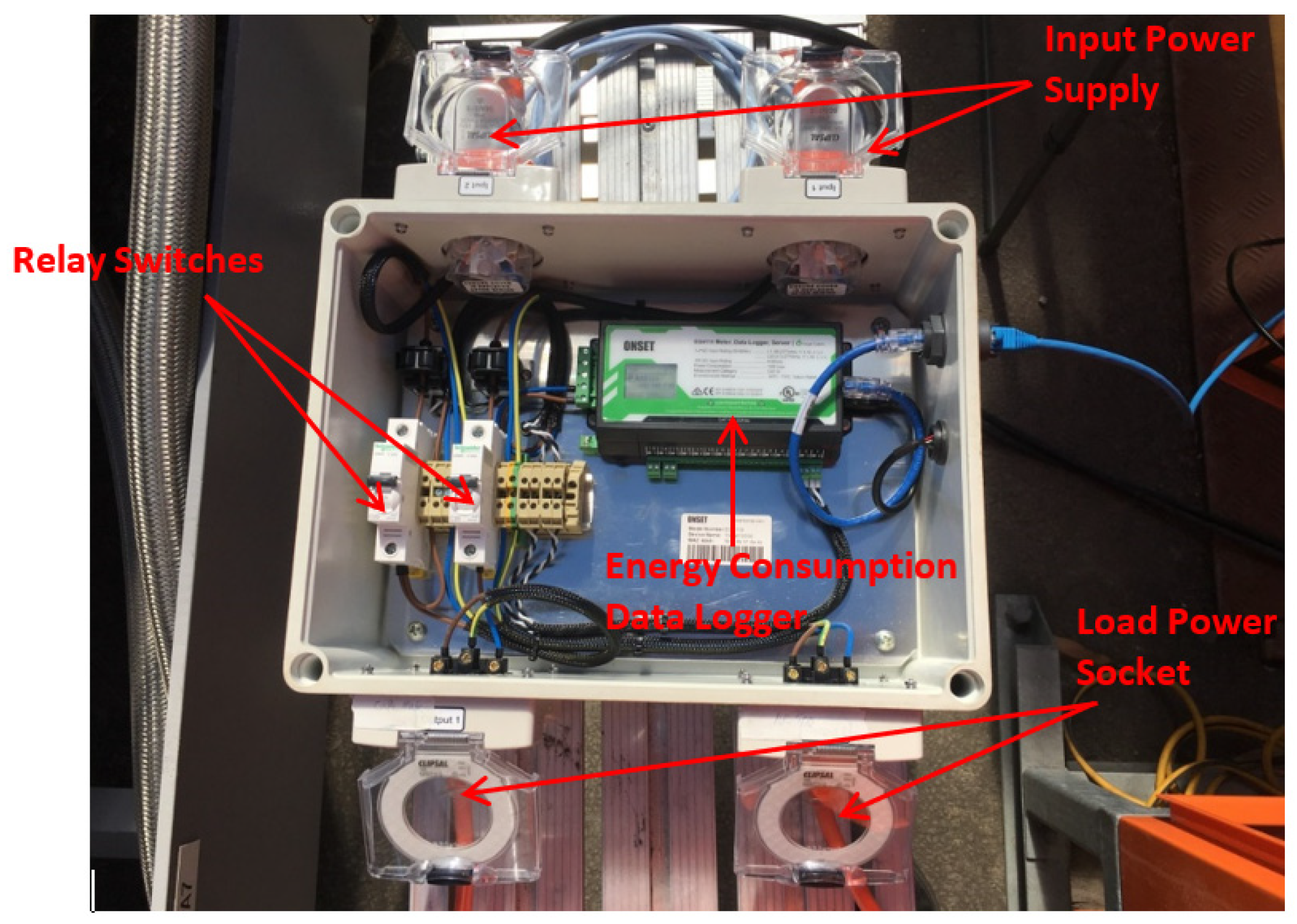

2.2. Experimental Study

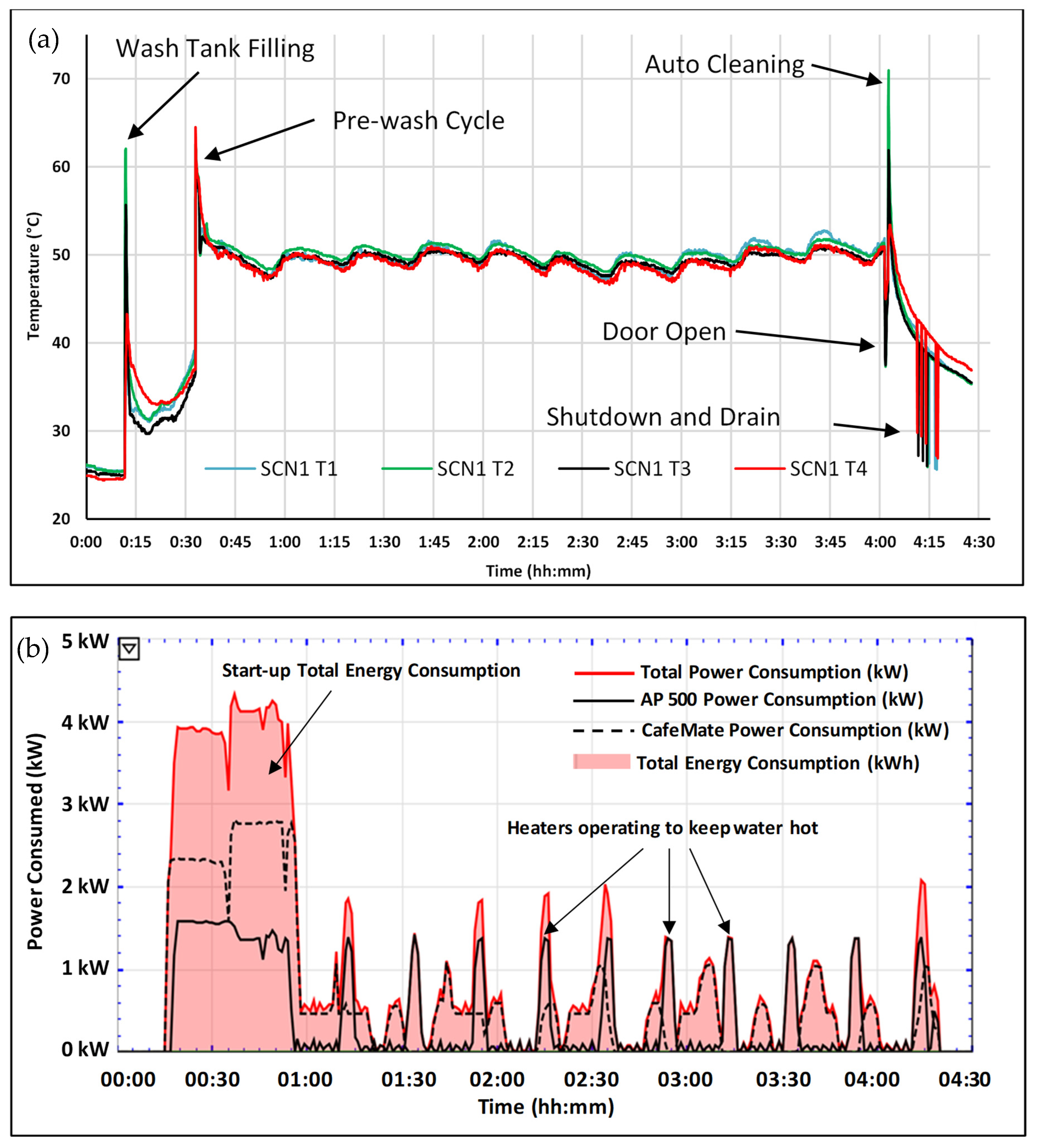

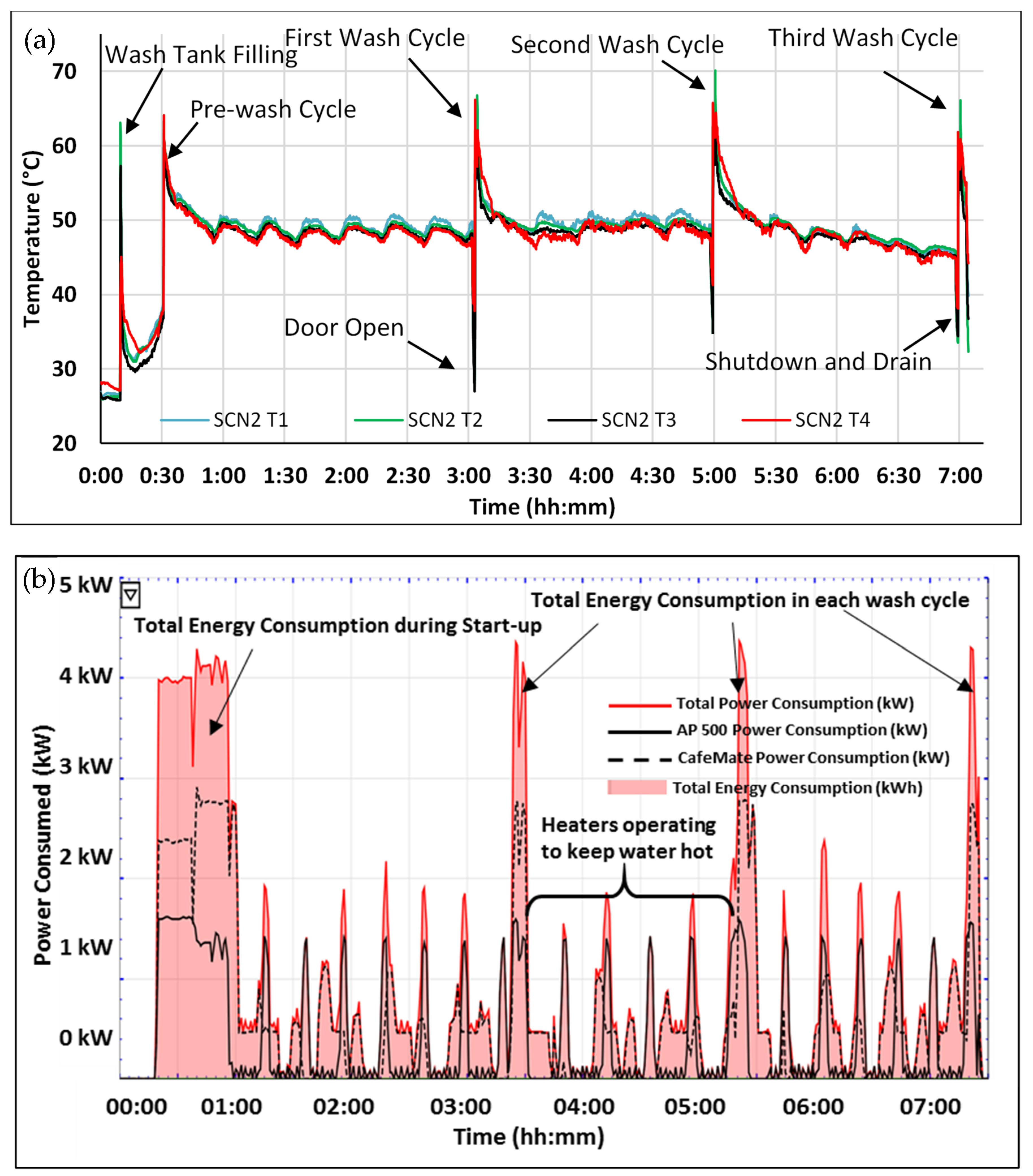

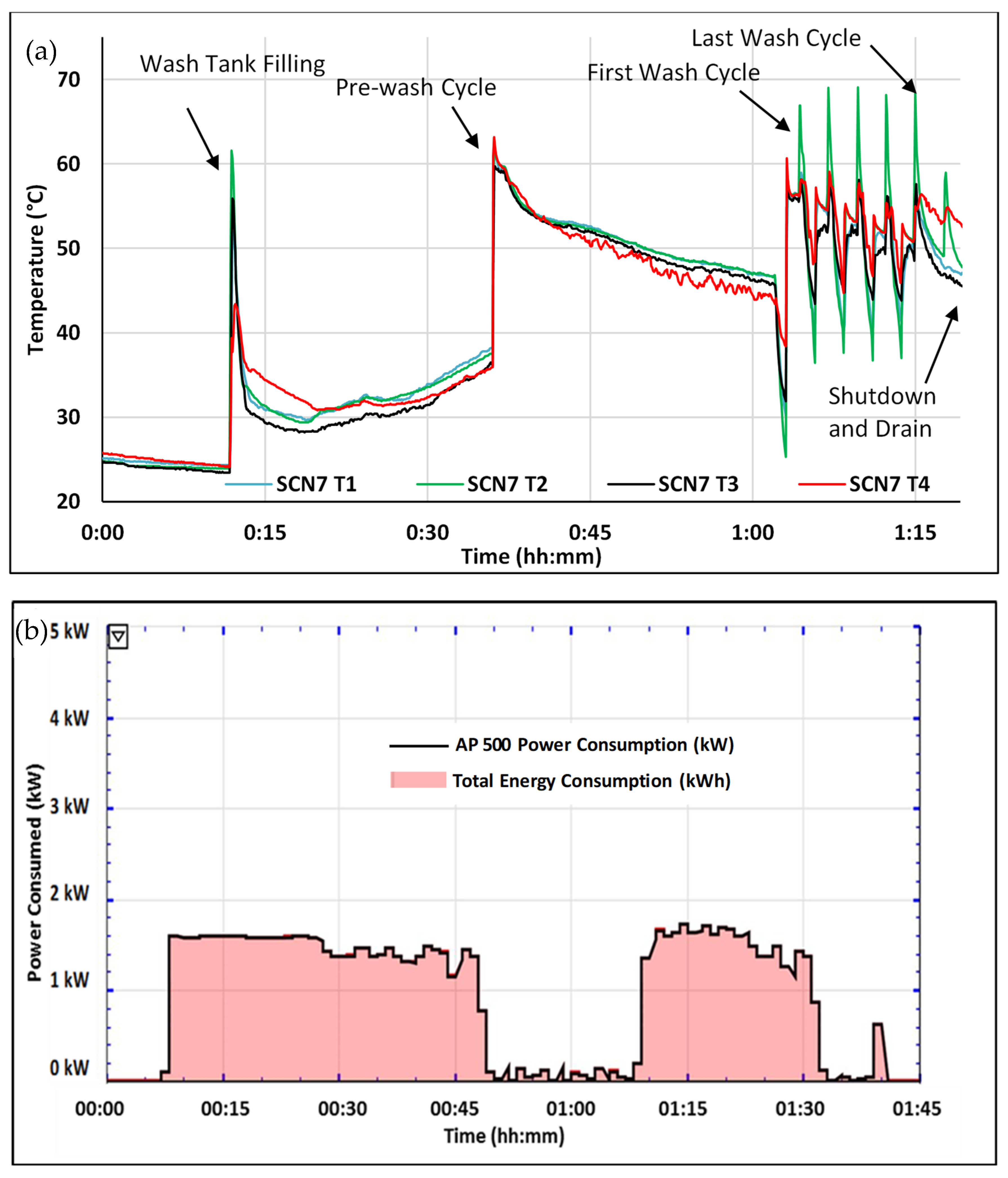

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Cd | discharge coefficient of the orifice (0.8) |

| cp | heat capacity of water (Kj/kg °C) |

| dH | hydrodynamic diameter of the tube (m) |

| di | inside tube diameter (m) |

| do | outside battery diameter (m) |

| Ef | fraction of sprayed water that reaches the battery surface (25%) |

| f | friction factor |

| hD | convective heat transfer coefficient for droplets (W/m2°C) |

| hL | total head loss (m) |

| k | loss coefficient for the 90° turns (0.3) |

| Kw | thermal conductivity of sprayed water (W/m°C) |

| L | length of the battery (m) |

| Lw | tube length that water flows through to reach the wash arms (m) |

| ṁs | flow rate of sprayed water (kg/s) |

| n | number of orifices on each arm (8) |

| SR | saving ratio |

| Tin,freshwater | temperature of cold inlet water (°C) |

| Tout,battery | water temperature inside the battery as well as the sprayed water temperature leaving the battery surface (°C) |

| Tout,boiler | temperature of water leaving the boiler (°C) |

| ∆Tw/ retro. | temperature difference with retrofit (30 °C) |

| ∆Tw/o retro. | temperature difference without retrofit (60 °C) |

| twash | duration of the wash cycle (60 s) |

| Twash, sprayed | temperature of the sprayed water (62 ± 2 °C) |

| u | velocity of the fluid in the tube (m/s) |

| uo | velocity of the jet (m/s) |

| WR | wetting ratio (~20–30%) |

| x | fraction related to head loss in the top arm |

| 1 − x | fraction related to head loss in the bottom arm |

| β | ratio of orifice diameter to the tube diameter |

| ϵ | average pipe roughness (m) |

| μ | viscosity of sprayed water (Pa.s) |

| ν | kinematic viscosity of sprayed water (m2/s) |

| ρ | water density (kg/m3) |

| σ | surface tension of sprayed water (N/m) |

References

- Persson, T. Dishwasher and washing machine heated by a hot water circulation loop. Appl. Therm. Eng. 2007, 27, 120–128. [Google Scholar] [CrossRef]

- Caskey, S.L.; Groll, E.A. Modelica household dishwater model with external heat loop. In Proceedings of the 5th International High Performance Buildings Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018; Volume 3692, p. 2. [Google Scholar]

- Zhang, Z.; Zhang, J.; Yuan, H.; Chen, G.; Mei, N. Performance improvement of the electric water heater by a waste heat recovery method with the thermoelectric effect. Appl. Therm. Eng. 2023, 222, 119914. [Google Scholar] [CrossRef]

- Piotrowska, B.; Stys, D. Variant analysis of financial and energy efficiency of the heat recovery system and domestic hot water preparation for a single-family building: The case of Poland. J. Build. Eng. 2023, 65, 105769. [Google Scholar] [CrossRef]

- Kordana-Obuch, S.; Starzec, M. Horizontal shower heat exchanger as an effective domestic hot water heating alternative. Energies 2022, 15, 4829. [Google Scholar] [CrossRef]

- Selimi, S.; Eljetlawi, I. The experimental study of thermal energy recovery from shower greywater. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 23. [Google Scholar]

- Salameh, W.; Faraj, J.; Harika, E.; Murr, R.; Khaled, M. On the optimization of electrical water heaters: Modelling simulations and experimentation. Energies 2021, 14, 3912. [Google Scholar] [CrossRef]

- Caskey, S.L.; Groll, E.A. Modelica analysis of thermally connected residential appliances. In Proceedings of the 5th International High Performance Buildings Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018; Volume 3693, p. 1. [Google Scholar]

- Anim-Mensah, A.R.; Waechter, B.J. Warewasher with drain water tempering system with energy recovery using plate heat exchangers. U.S. Patent No. 9,986,886, 5 June 2018. [Google Scholar]

- White, F. Fluid Mechanics; McGraw-Hill Companies, Inc.: New York, NY, USA, 2011. [Google Scholar]

- Hu, X.; Jacobi, A.M. Departure-Site Spacing for Liquid Droplets and Jets Falling in Thin-Film Heat Exchangers; The University of Illinois at Urbana-Champaign: Champaign, IL, USA, 1997. [Google Scholar]

- Hu, X.; Jacobi, A.M. The intertube falling film: Part 2—Mode effects on sensible heat transfer to a falling liquid film. J. Heat transfer 1996, 118, 626–633. [Google Scholar] [CrossRef]

- Snajdarek, L.; Kracik, P.; Lisy, M.; Pospisil, J. The falling liquid film heat transfer outside horizontal tubes relation. Adv. Fluid Mech. Heat Mass Transf. 2012, 3, 3. [Google Scholar]

- Jafar, F.A. Flow Fields and Heat Transfer of Liquid Falling Film on Horizontal Cylinders. Ph.D. Thesis, Victoria University, Melbourne, Australia, 2011. [Google Scholar]

- Jeong, S.; Garimella, S. Falling-film and droplet mode heat and mass transfer in a horizontal tube LiBr/water absorber. Int. J. Heat Mass Transf. 2002, 45, 1445–1458. [Google Scholar] [CrossRef]

| Scenarios | Start-up (min) | CYCLE-I | CYCLE-II | CYCLE-III | CYCLE-IV | CYCLE-V | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Waiting time (min) | Loading (min) | Rinse/Wash (min) | Waiting time (min) | Loading (min) | Rinse/Wash (min) | Waiting time (min) | Loading (min) | Rinse/Wash (min) | Waiting time (min) | Loading (min) | Rinse/Wash (min) | Waiting time (min) | Loading (min) | Rinse/Wash (min) | ||

| Scenario 1 | 60 | 180 | 0 | Default | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| Scenario 2 | 60 | 120 | 1 | Default | 120 | 1 | Default | 120 | 1 | Default | NA | NA | NA | NA | NA | NA |

| Scenario 3 | 60 | 60 | 1 | Default | 60 | 1 | Default | 60 | 1 | Default | 60 | 1 | Default | NA | NA | NA |

| Scenario 4 | 60 | 30 | 1 | Default | 30 | 1 | Default | 30 | 1 | Default | 30 | 1 | Default | NA | NA | NA |

| Scenario 5 | 60 | 15 | 1 | Default | 15 | 1 | Default | 15 | 1 | Default | 15 | 1 | Default | 15 | 1 | Default |

| Scenario 6 | 60 | 5 | 1 | Default | 5 | 1 | Default | 5 | 1 | Default | 5 | 1 | Default | 5 | 1 | Default |

| Scenario 7 | 60 | 0 | 1 | Default | 0 | 1 | Default | 0 | 1 | Default | 0 | 1 | Default | 0 | 1 | Default |

| WR | Tout, battery °C (Equation (11)) | Tout, battery °C (Equation (12)) |

|---|---|---|

| 20 | 56.05 | 58.8 |

| 25 | 58.2 | 60.2 |

| 30 | 59.6 | 61 |

| Parameter | Value/Equation | Description |

|---|---|---|

| x | 0.49 | fraction of sprayed water flowing in the top arm |

| hL (m) | 6.1 | total head loss |

| ṁs (kg/s) | 1 | mass flow rate of sprayed wash water |

| L (m) | 33.8Ef | relationship between L and Ef (Equation (3)) |

| Scenarios | Total Energy Savings | Average Energy Savings per Wash Cycle | Cost Savings per Cycle ($) |

|---|---|---|---|

| 1 | 37% | 0 | 0 |

| 2 | 38% | 53% | 0.14 |

| 3 | 41% | 46% | 0.12 |

| 4 | 44% | 41% | 0.10 |

| 5 | 49% | 49% | 0.17 |

| 6 | 48% | 46% | 0.15 |

| 7 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanganeh, J.; Seyfaee, A.; Gates, G.; Moghtaderi, B. Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study. Energies 2025, 18, 2338. https://doi.org/10.3390/en18092338

Zanganeh J, Seyfaee A, Gates G, Moghtaderi B. Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study. Energies. 2025; 18(9):2338. https://doi.org/10.3390/en18092338

Chicago/Turabian StyleZanganeh, Jafar, Adrian Seyfaee, Greg Gates, and Behdad Moghtaderi. 2025. "Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study" Energies 18, no. 9: 2338. https://doi.org/10.3390/en18092338

APA StyleZanganeh, J., Seyfaee, A., Gates, G., & Moghtaderi, B. (2025). Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study. Energies, 18(9), 2338. https://doi.org/10.3390/en18092338