Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study

Abstract

1. Introduction

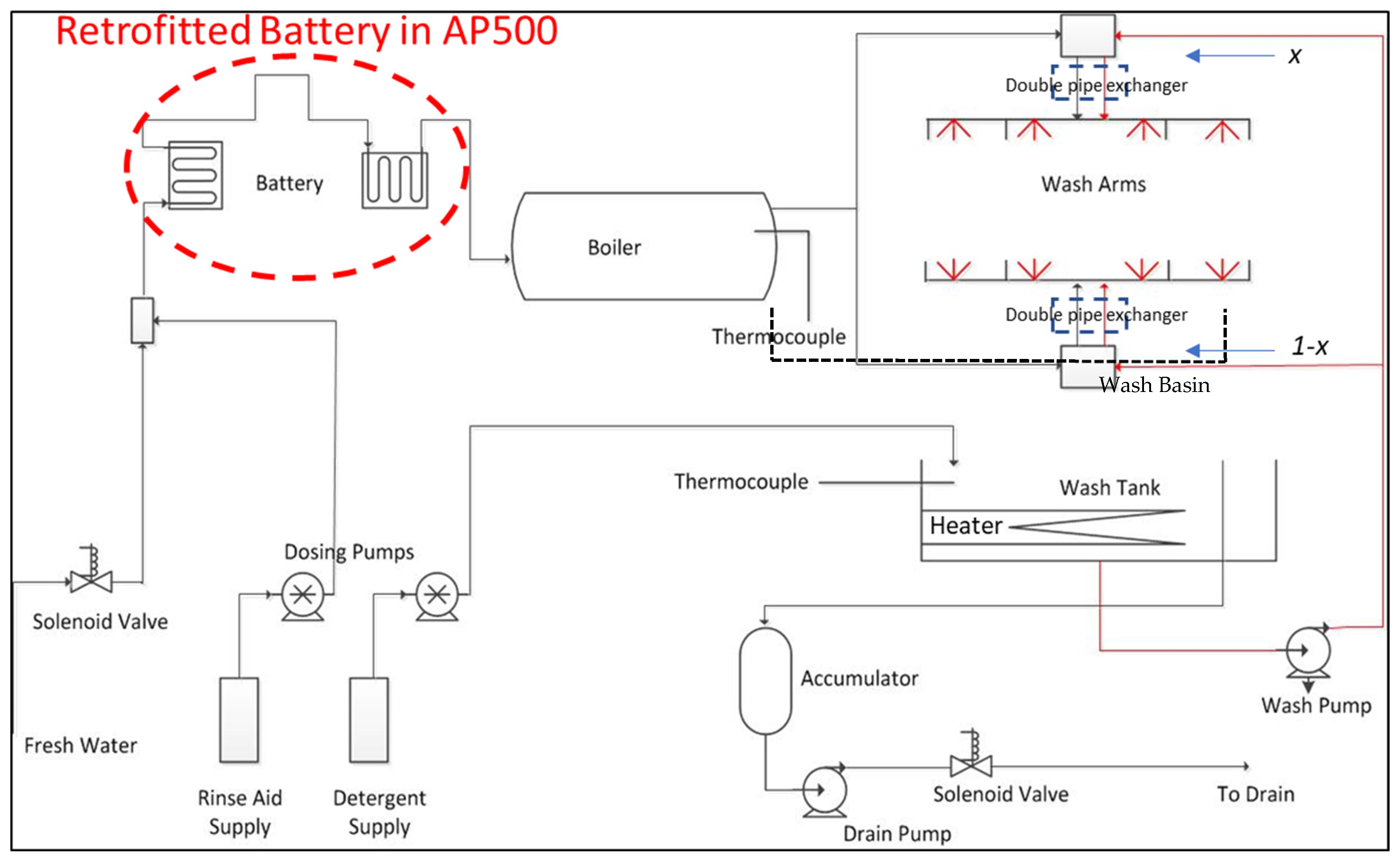

2. Methodology and Technique

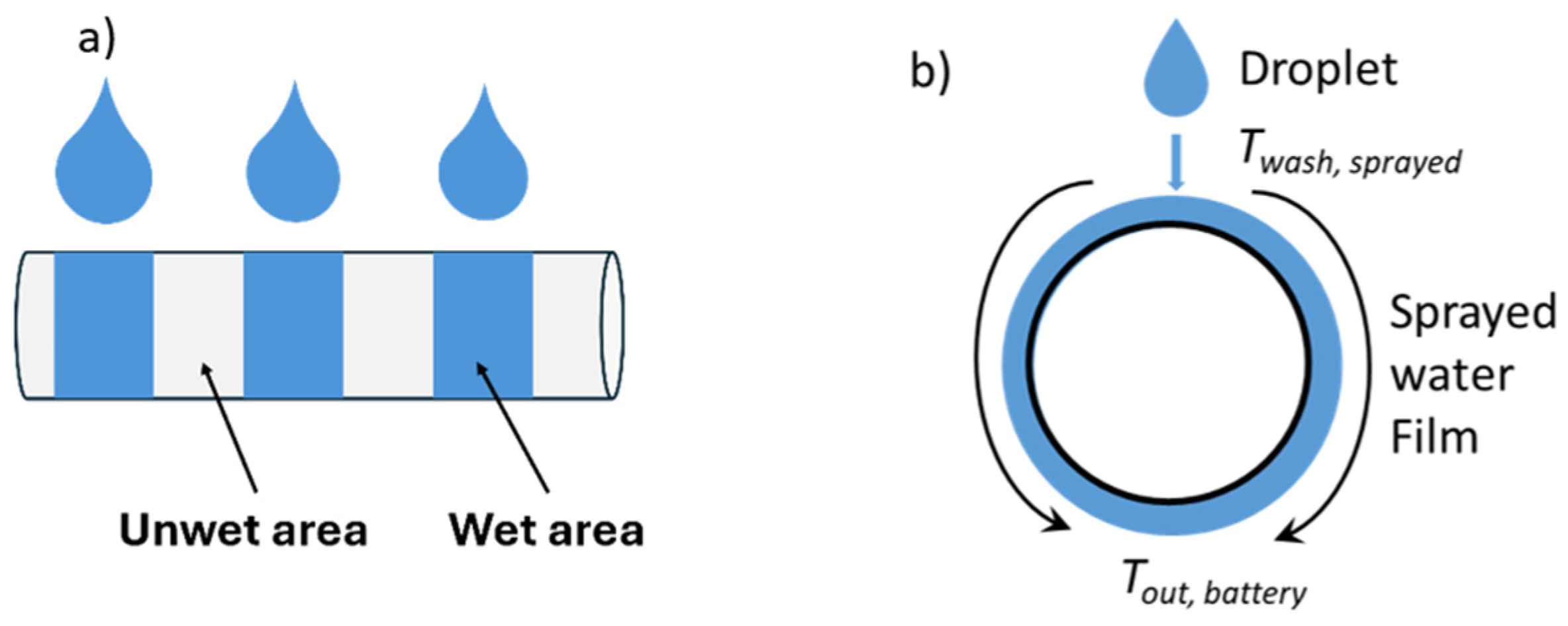

2.1. Theoretical Study

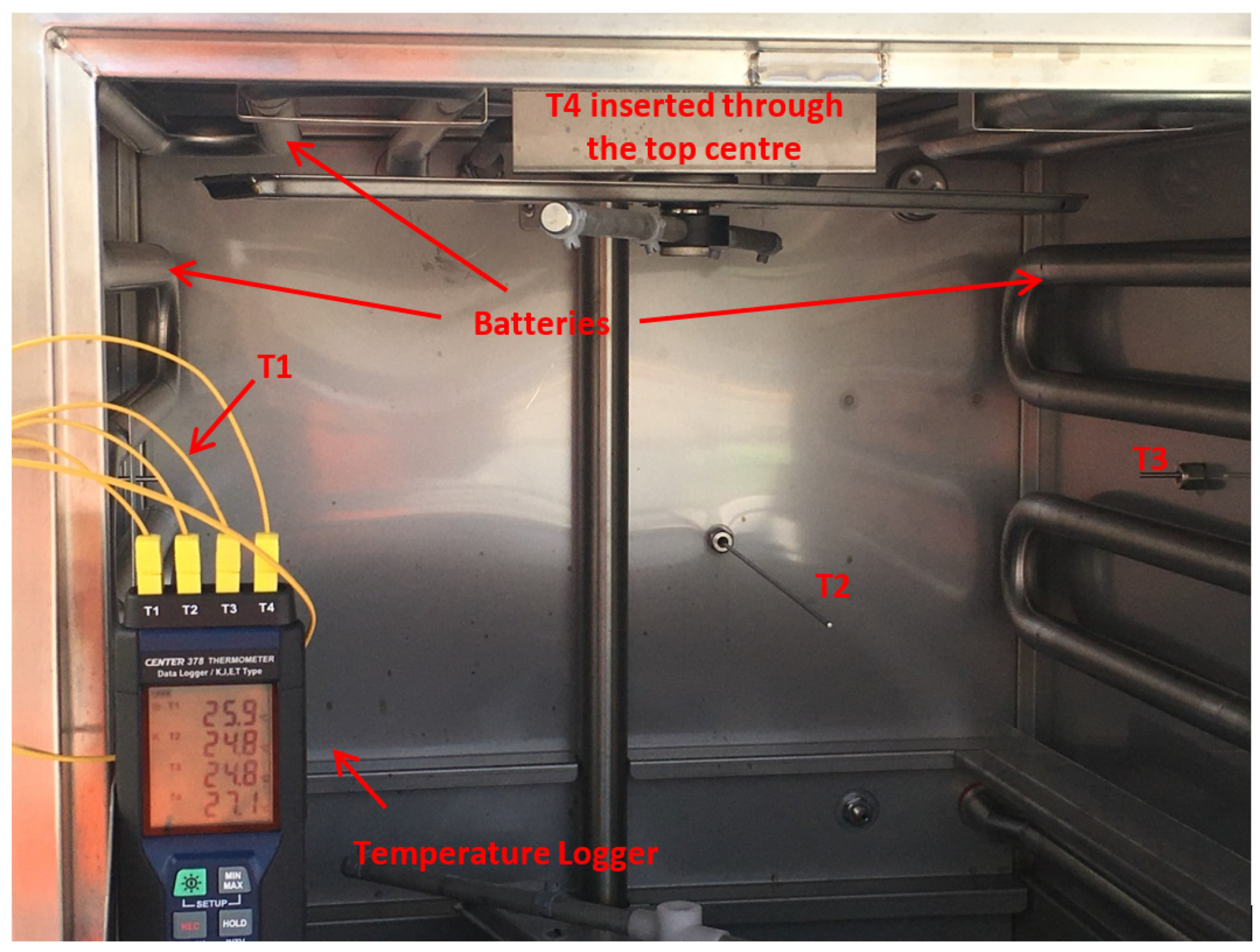

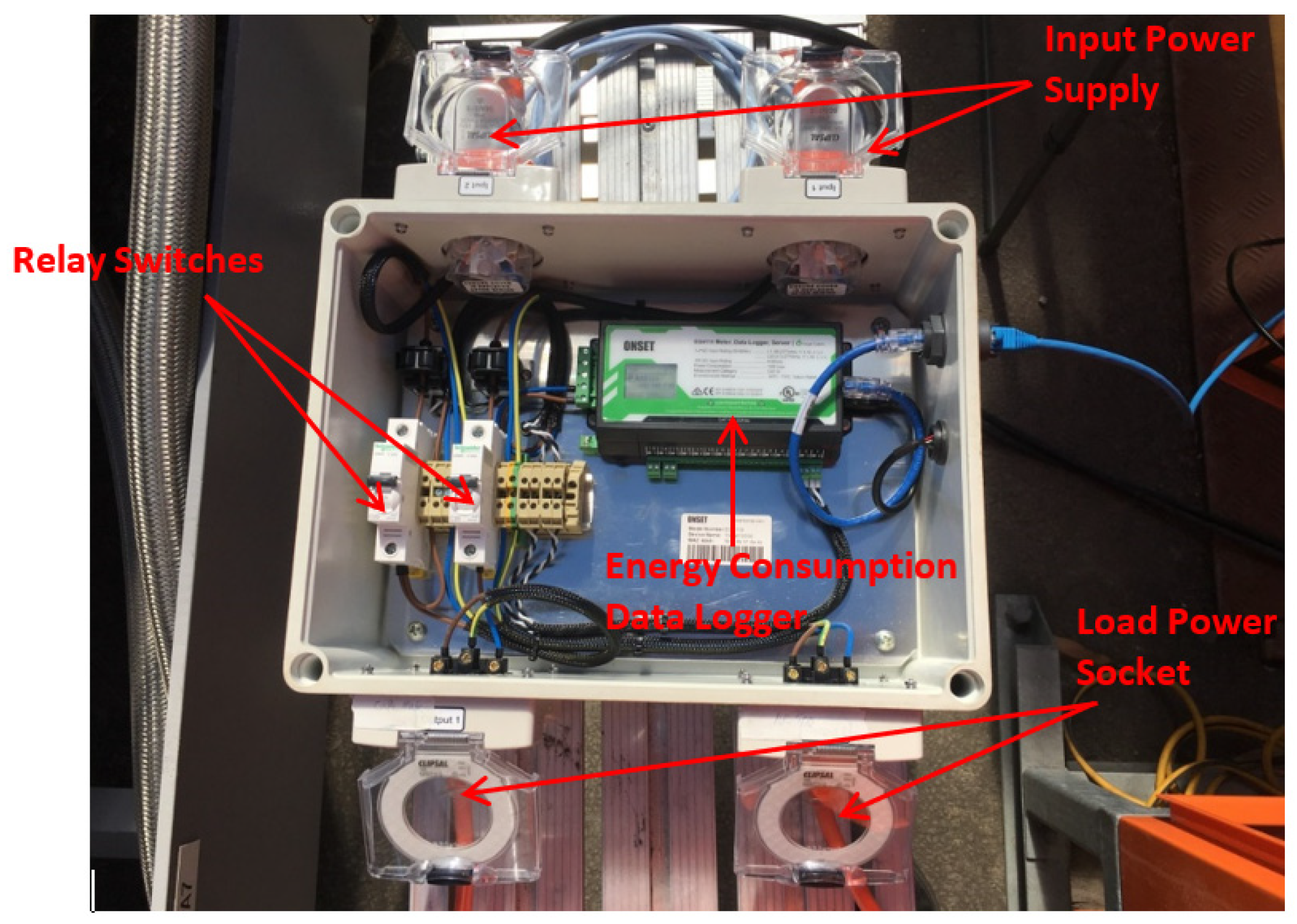

2.2. Experimental Study

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Cd | discharge coefficient of the orifice (0.8) |

| cp | heat capacity of water (Kj/kg °C) |

| dH | hydrodynamic diameter of the tube (m) |

| di | inside tube diameter (m) |

| do | outside battery diameter (m) |

| Ef | fraction of sprayed water that reaches the battery surface (25%) |

| f | friction factor |

| hD | convective heat transfer coefficient for droplets (W/m2°C) |

| hL | total head loss (m) |

| k | loss coefficient for the 90° turns (0.3) |

| Kw | thermal conductivity of sprayed water (W/m°C) |

| L | length of the battery (m) |

| Lw | tube length that water flows through to reach the wash arms (m) |

| ṁs | flow rate of sprayed water (kg/s) |

| n | number of orifices on each arm (8) |

| SR | saving ratio |

| Tin,freshwater | temperature of cold inlet water (°C) |

| Tout,battery | water temperature inside the battery as well as the sprayed water temperature leaving the battery surface (°C) |

| Tout,boiler | temperature of water leaving the boiler (°C) |

| ∆Tw/ retro. | temperature difference with retrofit (30 °C) |

| ∆Tw/o retro. | temperature difference without retrofit (60 °C) |

| twash | duration of the wash cycle (60 s) |

| Twash, sprayed | temperature of the sprayed water (62 ± 2 °C) |

| u | velocity of the fluid in the tube (m/s) |

| uo | velocity of the jet (m/s) |

| WR | wetting ratio (~20–30%) |

| x | fraction related to head loss in the top arm |

| 1 − x | fraction related to head loss in the bottom arm |

| β | ratio of orifice diameter to the tube diameter |

| ϵ | average pipe roughness (m) |

| μ | viscosity of sprayed water (Pa.s) |

| ν | kinematic viscosity of sprayed water (m2/s) |

| ρ | water density (kg/m3) |

| σ | surface tension of sprayed water (N/m) |

References

- Persson, T. Dishwasher and washing machine heated by a hot water circulation loop. Appl. Therm. Eng. 2007, 27, 120–128. [Google Scholar] [CrossRef]

- Caskey, S.L.; Groll, E.A. Modelica household dishwater model with external heat loop. In Proceedings of the 5th International High Performance Buildings Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018; Volume 3692, p. 2. [Google Scholar]

- Zhang, Z.; Zhang, J.; Yuan, H.; Chen, G.; Mei, N. Performance improvement of the electric water heater by a waste heat recovery method with the thermoelectric effect. Appl. Therm. Eng. 2023, 222, 119914. [Google Scholar] [CrossRef]

- Piotrowska, B.; Stys, D. Variant analysis of financial and energy efficiency of the heat recovery system and domestic hot water preparation for a single-family building: The case of Poland. J. Build. Eng. 2023, 65, 105769. [Google Scholar] [CrossRef]

- Kordana-Obuch, S.; Starzec, M. Horizontal shower heat exchanger as an effective domestic hot water heating alternative. Energies 2022, 15, 4829. [Google Scholar] [CrossRef]

- Selimi, S.; Eljetlawi, I. The experimental study of thermal energy recovery from shower greywater. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 23. [Google Scholar]

- Salameh, W.; Faraj, J.; Harika, E.; Murr, R.; Khaled, M. On the optimization of electrical water heaters: Modelling simulations and experimentation. Energies 2021, 14, 3912. [Google Scholar] [CrossRef]

- Caskey, S.L.; Groll, E.A. Modelica analysis of thermally connected residential appliances. In Proceedings of the 5th International High Performance Buildings Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018; Volume 3693, p. 1. [Google Scholar]

- Anim-Mensah, A.R.; Waechter, B.J. Warewasher with drain water tempering system with energy recovery using plate heat exchangers. U.S. Patent No. 9,986,886, 5 June 2018. [Google Scholar]

- White, F. Fluid Mechanics; McGraw-Hill Companies, Inc.: New York, NY, USA, 2011. [Google Scholar]

- Hu, X.; Jacobi, A.M. Departure-Site Spacing for Liquid Droplets and Jets Falling in Thin-Film Heat Exchangers; The University of Illinois at Urbana-Champaign: Champaign, IL, USA, 1997. [Google Scholar]

- Hu, X.; Jacobi, A.M. The intertube falling film: Part 2—Mode effects on sensible heat transfer to a falling liquid film. J. Heat transfer 1996, 118, 626–633. [Google Scholar] [CrossRef]

- Snajdarek, L.; Kracik, P.; Lisy, M.; Pospisil, J. The falling liquid film heat transfer outside horizontal tubes relation. Adv. Fluid Mech. Heat Mass Transf. 2012, 3, 3. [Google Scholar]

- Jafar, F.A. Flow Fields and Heat Transfer of Liquid Falling Film on Horizontal Cylinders. Ph.D. Thesis, Victoria University, Melbourne, Australia, 2011. [Google Scholar]

- Jeong, S.; Garimella, S. Falling-film and droplet mode heat and mass transfer in a horizontal tube LiBr/water absorber. Int. J. Heat Mass Transf. 2002, 45, 1445–1458. [Google Scholar] [CrossRef]

| Scenarios | Start-up (min) | CYCLE-I | CYCLE-II | CYCLE-III | CYCLE-IV | CYCLE-V | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Waiting time (min) | Loading (min) | Rinse/Wash (min) | Waiting time (min) | Loading (min) | Rinse/Wash (min) | Waiting time (min) | Loading (min) | Rinse/Wash (min) | Waiting time (min) | Loading (min) | Rinse/Wash (min) | Waiting time (min) | Loading (min) | Rinse/Wash (min) | ||

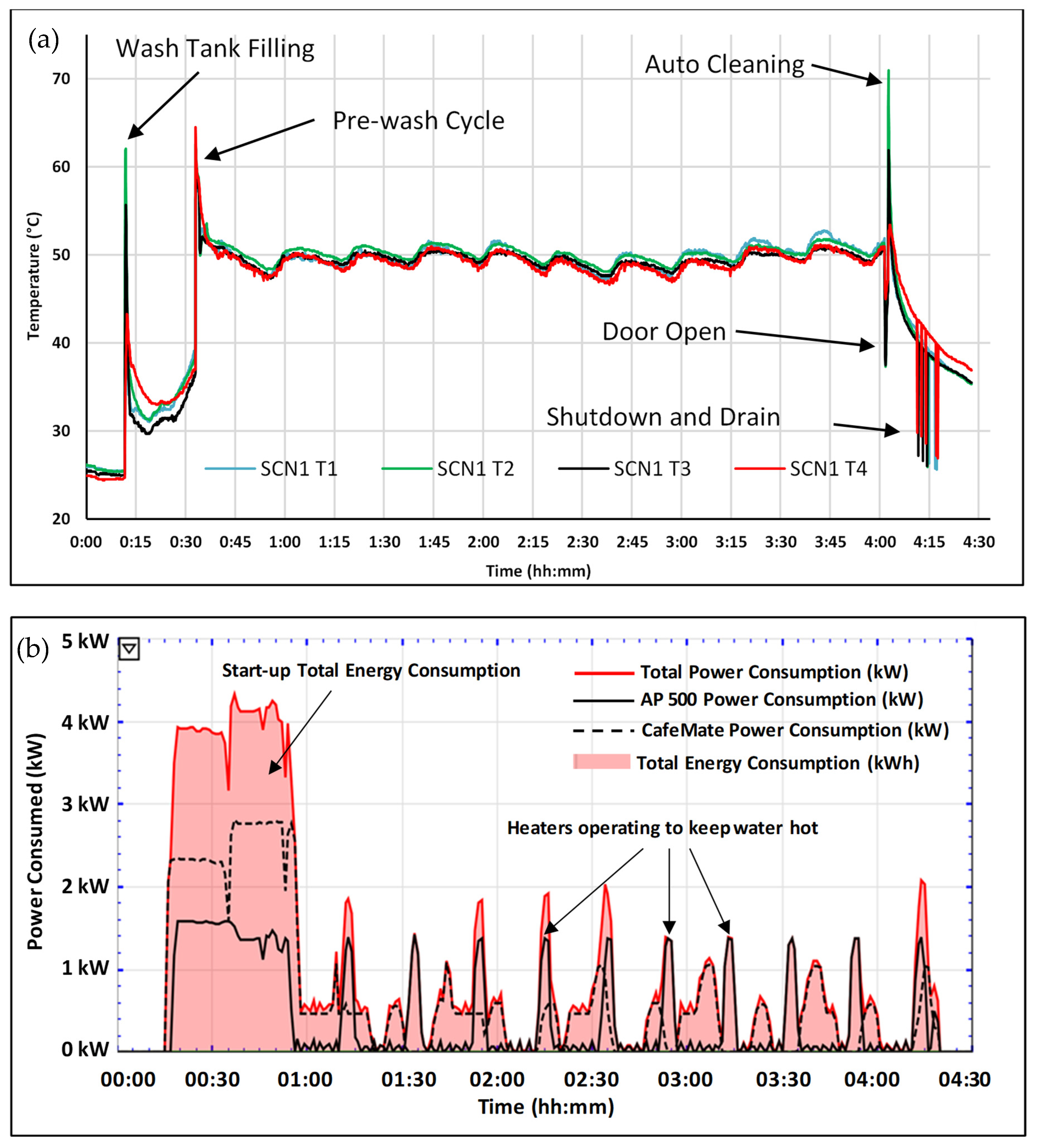

| Scenario 1 | 60 | 180 | 0 | Default | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA |

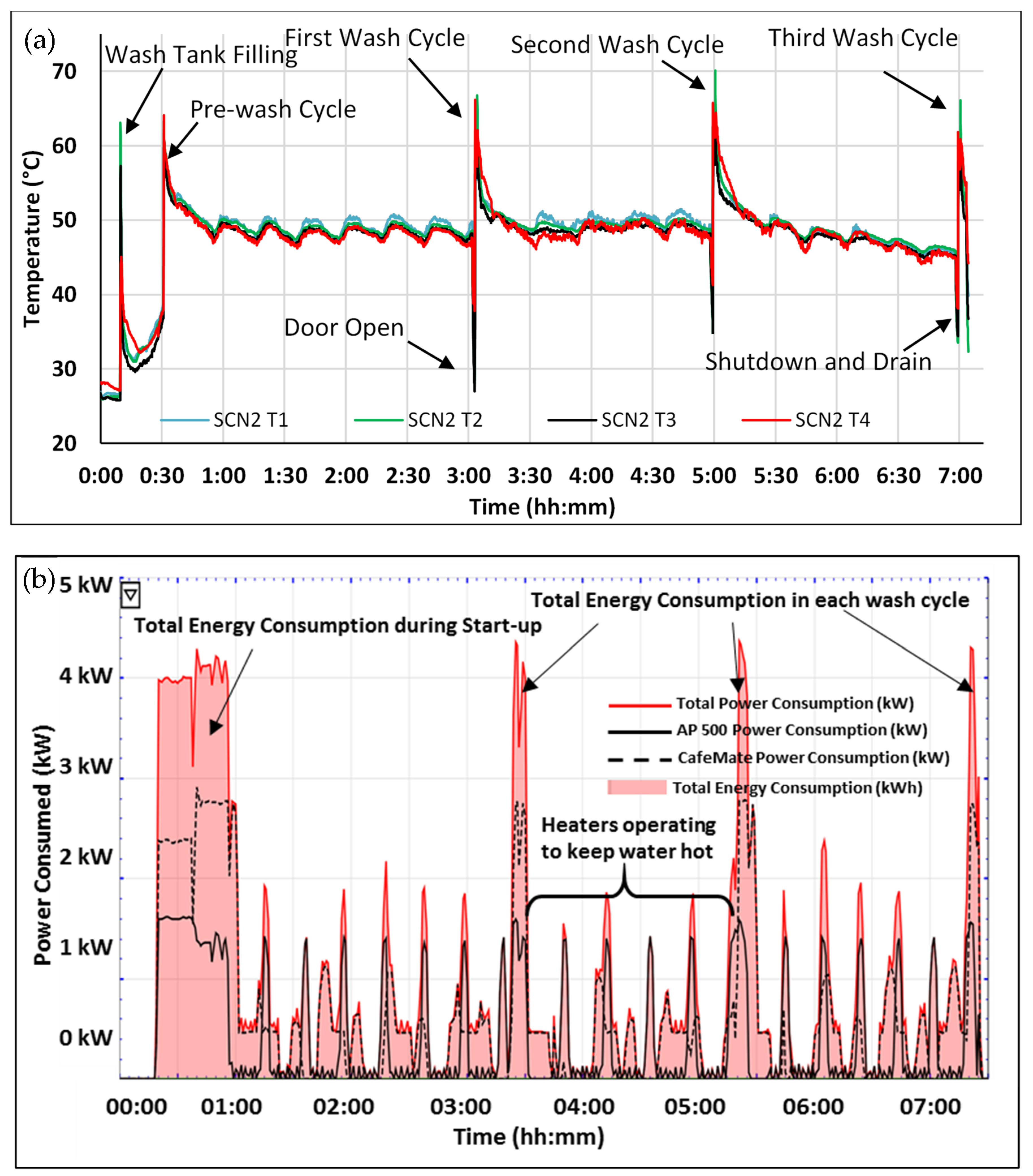

| Scenario 2 | 60 | 120 | 1 | Default | 120 | 1 | Default | 120 | 1 | Default | NA | NA | NA | NA | NA | NA |

| Scenario 3 | 60 | 60 | 1 | Default | 60 | 1 | Default | 60 | 1 | Default | 60 | 1 | Default | NA | NA | NA |

| Scenario 4 | 60 | 30 | 1 | Default | 30 | 1 | Default | 30 | 1 | Default | 30 | 1 | Default | NA | NA | NA |

| Scenario 5 | 60 | 15 | 1 | Default | 15 | 1 | Default | 15 | 1 | Default | 15 | 1 | Default | 15 | 1 | Default |

| Scenario 6 | 60 | 5 | 1 | Default | 5 | 1 | Default | 5 | 1 | Default | 5 | 1 | Default | 5 | 1 | Default |

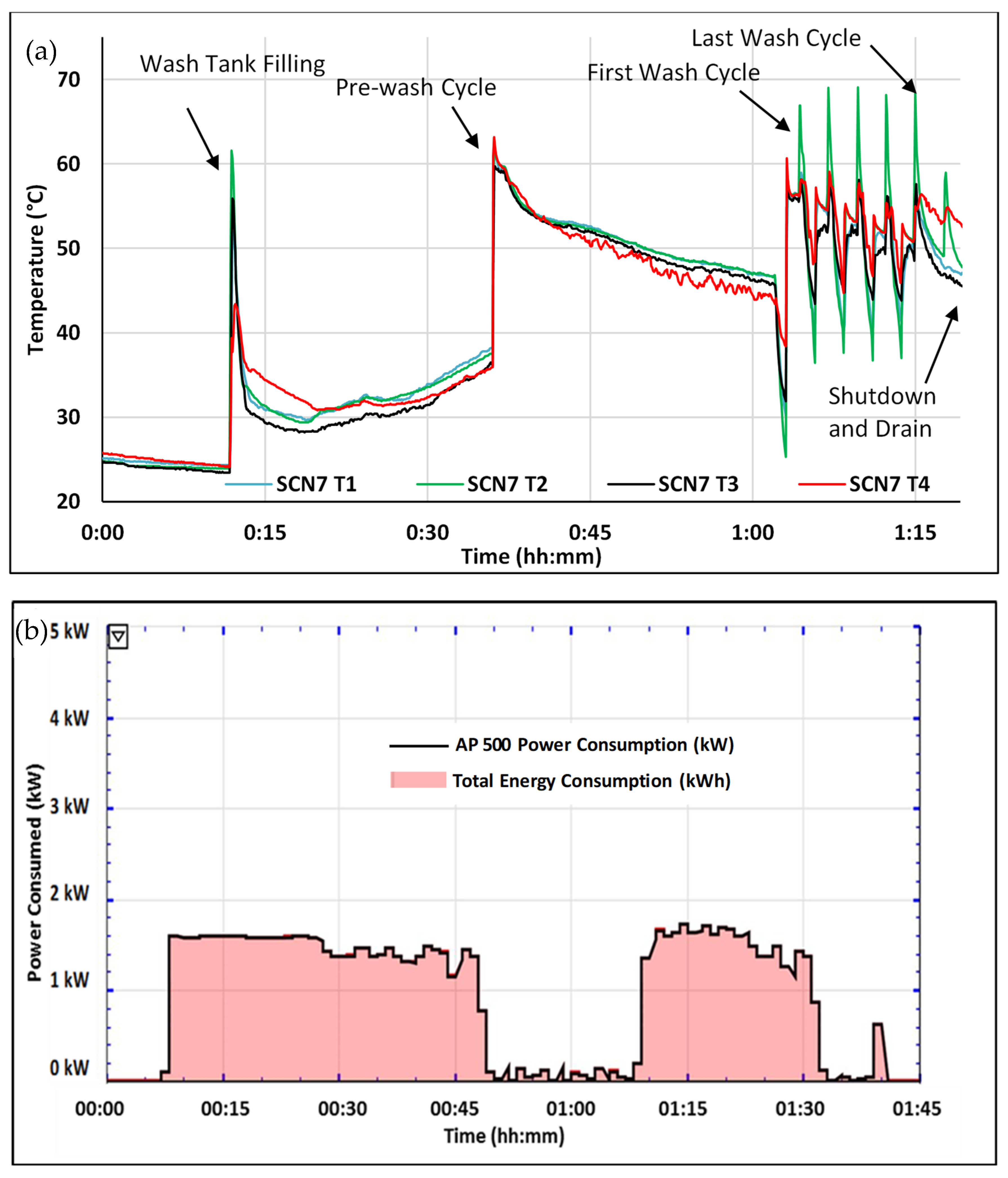

| Scenario 7 | 60 | 0 | 1 | Default | 0 | 1 | Default | 0 | 1 | Default | 0 | 1 | Default | 0 | 1 | Default |

| WR | Tout, battery °C (Equation (11)) | Tout, battery °C (Equation (12)) |

|---|---|---|

| 20 | 56.05 | 58.8 |

| 25 | 58.2 | 60.2 |

| 30 | 59.6 | 61 |

| Parameter | Value/Equation | Description |

|---|---|---|

| x | 0.49 | fraction of sprayed water flowing in the top arm |

| hL (m) | 6.1 | total head loss |

| ṁs (kg/s) | 1 | mass flow rate of sprayed wash water |

| L (m) | 33.8Ef | relationship between L and Ef (Equation (3)) |

| Scenarios | Total Energy Savings | Average Energy Savings per Wash Cycle | Cost Savings per Cycle ($) |

|---|---|---|---|

| 1 | 37% | 0 | 0 |

| 2 | 38% | 53% | 0.14 |

| 3 | 41% | 46% | 0.12 |

| 4 | 44% | 41% | 0.10 |

| 5 | 49% | 49% | 0.17 |

| 6 | 48% | 46% | 0.15 |

| 7 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanganeh, J.; Seyfaee, A.; Gates, G.; Moghtaderi, B. Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study. Energies 2025, 18, 2338. https://doi.org/10.3390/en18092338

Zanganeh J, Seyfaee A, Gates G, Moghtaderi B. Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study. Energies. 2025; 18(9):2338. https://doi.org/10.3390/en18092338

Chicago/Turabian StyleZanganeh, Jafar, Adrian Seyfaee, Greg Gates, and Behdad Moghtaderi. 2025. "Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study" Energies 18, no. 9: 2338. https://doi.org/10.3390/en18092338

APA StyleZanganeh, J., Seyfaee, A., Gates, G., & Moghtaderi, B. (2025). Thermal Management and Energy Recovery in Commercial Dishwashers: A Theoretical and Experimental Study. Energies, 18(9), 2338. https://doi.org/10.3390/en18092338