Abstract

Increasing the efficiency and capacity of nuclear power units is a promising direction for the development of power generation systems. Unlike thermal power plants, nuclear power plants operate at relatively low temperatures of the steam working fluid. Due to this, the thermodynamic efficiency of such schemes remains relatively low today. The temperature of steam and the efficiency of nuclear power units can be increased by integrating external superheating of the working fluid into the schemes of steam turbine plants. This paper presents the results of a thermodynamic analysis of thermal schemes of NPPs integrated with hydrocarbon-fueled plants. Schemes with a remote combustion chamber, a boiler unit and a gas turbine plant are considered. It has been established that superheating fresh steam after the steam generator is an effective superheating solution due to the utilization of heat from the exhaust gases of the GTU using an afterburner. Furthermore, there is a partial replacement of high- and low-pressure heaters in the regeneration system, with gas heaters for condensate and steam superheating after the steam generator for water-cooled and liquid-metal reactor types. An increase in the net efficiency of the hybrid NPP is observed by 8.49 and 5.11%, respectively, while the net electric power increases by 93.3 and 76.7%.

1. Introduction

Enhancing the efficiency of steam power units in thermal and nuclear power plants has consistently been a critical concern throughout the history of large-scale energy production [1,2]. The primary and most effective method for improving efficiency is to elevate the initial parameters of the thermodynamic cycle [3]. In addition, methods that use non-traditional working bodies [4,5,6] to generate electricity at small- [7,8] and large-capacity nuclear power plants, as well as the use of cogeneration [9,10], are being actively considered [11,12,13,14]. Currently, the initial parameters of installations utilizing organic fuel are at a higher level compared to those of nuclear power plants, resulting in the thermal efficiency of contemporary thermal power plants surpassing that of nuclear power plants. The main reason why the increase in initial steam parameters is not used at most operating nuclear power plants (NPPs) is due to the design and technological limitations of existing reactor installations. In particular, in water-cooled reactors (WCR) and boiling water-cooled reactors (BWR), steam generators are designed to produce saturated steam. This is due to the fact that increasing the steam temperature above the critical point of water (374.15 °C) in the primary circuit can lead to the transition of the coolant to a supercritical state, which reduces the efficiency of neutron moderation and, therefore, affects the safety and stability of the reactor. However, new generation designs, such as BREST and WCR, with supercritical parameters [15,16], consider the possibility of using steam superheating to increase the efficiency of NPPs. These designs provide design solutions that ensure safe operation of equipment at higher steam parameters.

At the same time, if organic fuel is available in the area where the nuclear power plant is located, the efficiency of nuclear power units can be increased by using external fire superheating of steam.

The concept of steam superheating at NPPs using organic fuel is not new. For example, the Indian Point 1 power unit (New York, NY, USA) with a PWR reactor operated with an integrated organic fuel superheater, a device in which the heat of fuel combustion is absorbed by fresh steam through a radiation-convective heat exchange. The steam at the outlet of the steam generator was superheated from 271 °C to 540 °C at a pressure of 2.5 MPa. The power unit was decommissioned in 1974, after 12 years of operation. In [17], it is noted that despite the relatively short period of operation, due in part to economic factors, the use of a combined cycle ensured increased energy efficiency and a reduction in the cost of electricity supply and could become a promising direction in the future. Another example of a nuclear power plant project using organic fuel is the Lingen Nuclear Power Plant (Lingen, Germany) with a 540 MW BWR reactor. An additional 214 MW of thermal energy was supplied to the cycle in a separate organic fuel superheater. The plant operated from 1968 to 1977, after which it was decommissioned. The Garigliano Nuclear Power Plant (Italy), a plant with an external steam superheater, which had been in operation since 1964, was closed in 1978 because, after a maintenance stop, a decision was made to completely decommission it due to the short remaining estimated service life and high prices for organic fuel [18].

In addition to superheating steam with natural gas, there are many studies in which steam is superheated with hydrogen fuel in a remote combustion chamber. Such solutions are still theoretical due to the explosive nature of H2, but research in this area and in the area of safe hydrogen-use systems shows promise for increasing the capacity and efficiency of nuclear power plants [19,20,21,22].

Today, when the world is seeing a trend towards the decarbonization of the energy sector, with a simultaneous increase in energy consumption, the direction of developing and creating new power units that have both a low level of emissions into the atmosphere and a wide range of load changes is becoming relevant. These factors, together with developments in the field of power engineering, can make the direction of hybrid nuclear–hydrocarbon power units relevant again. The return of interest in this direction is evidenced, among other things, by publications from recent years.

Due to the superheating of fresh steam, the power of the steam turbine increases significantly and the final humidity of the steam decreases. An increase in the average integral temperature of the heat supply has a positive effect on the thermal efficiency and, consequently, on the net efficiency. An increase in the initial parameters leads to a decrease in the humidity of the steam, which reduces its effect on the internal relative efficiency. Thus, in [23] it is stated that the internal relative efficiency of the high- and low-pressure cylinder can reach 0.88–0.9, values that are strikingly different from their values in real installations.

In [24], the feedwater flow moving to the steam generator is divided into two. The water in the first flow evaporates in the steam generator and is sent to an external boiler-superheater. Water from the second flow is injected into the resulting superheated steam to perform the function of a steam cooler and regulate the flow temperature.

The patent [25] describes an external superheater, which, in addition to the function of the superheating steam, is capable of heating feedwater with exhaust gases from the burned fuel. This modification allows us to reduce the number of regenerative extractions and increase the turbine power. The thermal efficiency of such a scheme is 46%, which is much higher than the scheme without an external superheater, which is 34%. In such a scheme, there are no high-pressure heaters; therefore, steam with high parameters produces more energy and steam leaks from the high-pressure cylinder practically disappear.

In [26], a hybrid NPP scheme is considered, in which a new operating mode appears, where the exhaust gases of the gas turbine are used to heat the feedwater in a parallel line between the condenser and the steam generator (some regenerative heaters are switched off in this mode). The exhaust gases heat the condensate and feedwater using three counter-current heat exchangers, and due to the regulation of the valves, the temperature of the feedwater at the outlet remains constant.

Another modification of the combination of a nuclear power plant and a gas turbine is a unit with a waste heat boiler, which superheats saturated steam, intermediately superheats exhaust steam and heats feedwater [27]. This modification allows for deep utilization of the heat of the exhaust gases of the gas turbine and significantly increases the initial parameters of fresh steam. For example, the authors of one of the works [28], propose increasing the temperature at the inlet to the high-pressure cylinder from 282 °C to 560 °C, using the superheating surface of the waste heat boiler and thereby significantly increasing the net efficiency of the power unit from 33% to 49.4%, as well as reducing the final humidity of the steam; this is shown in [29]. The use of exhaust gases for heating the steam–water coolant in the Rankine cycle was considered. Replacing high-pressure heaters with gas–water heat exchangers and adding steam superheating to a temperature of 560 °C in the steam power section of the plant with an SVBR-100 reactor with a lead–bismuth coolant can ensure a net efficiency of the power unit of 45.39%, using two GE 6101 FA gas turbines.

Despite the large number of works devoted to the topic of steam superheating at nuclear power plants using additional hydrocarbon fuel installations, a comprehensive thermodynamic analysis of the schemes and their comparison under the same conditions has not been carried out.

This article proposes two fundamentally new approaches to steam superheating that complement traditional methods for increasing the efficiency of the NPP steam turbine cycle. The first approach implements a superheating scheme using a remote boiler unit, where steam superheating, feedwater heating and air preheating in front of the combustion chamber are carried out. This allows for the efficiency of the boiler unit to be increased, improving the fuel combustion process and replacing part of the traditional heat regeneration in the steam turbine circuit by using a gas condensate heater to utilize the heat of gases after the superheater. In the second approach, steam superheating is carried out by utilizing the heat of gases after the GTU. The main difference between the proposed solution and previously published studies is that a part of the high- and low-pressure heat regeneration is simultaneously replaced, which allows for increased capacity of the steam turbine cycle without changing the feedwater temperature in front of the steam generator.

In addition, for the first time, comparative assessments were made of all of the options for superheating steam at nuclear power plants under comparable conditions considered in this article, which further allows for an objective assessment of the effectiveness of the proposed schemes and their potential.

2. Research Object

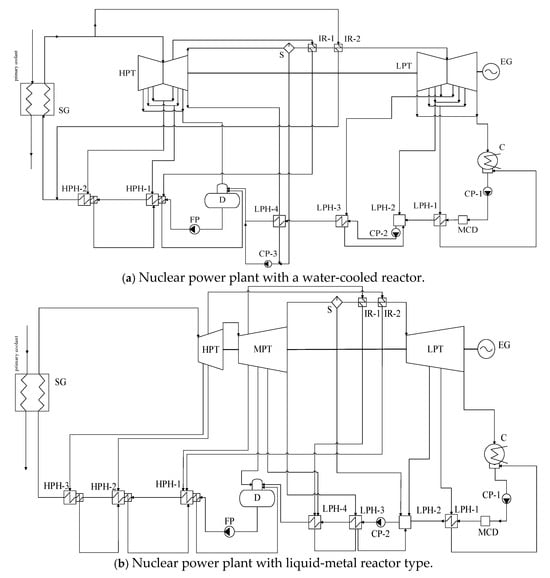

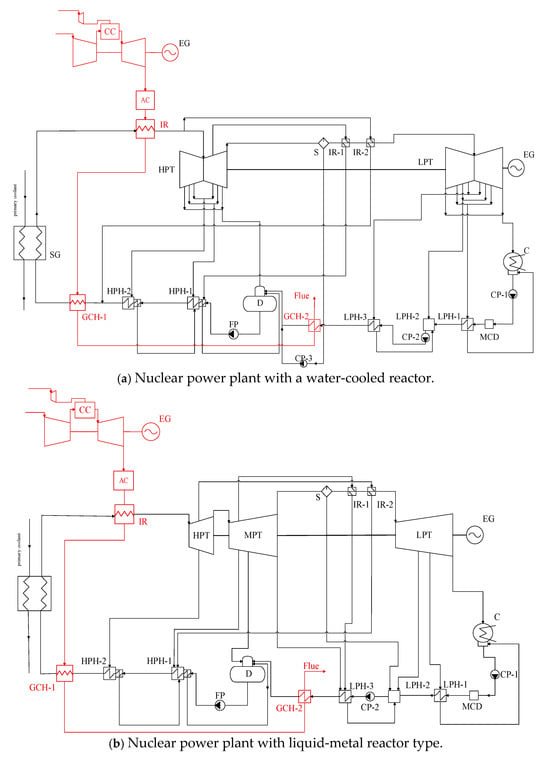

The basic objects considered are the schemes of a nuclear power plant with a water-cooled reactor (Figure 1a) and a nuclear power plant with a liquid-metal reactor (Figure 1b).

Figure 1.

Basic thermal diagrams of the studied basic power units of the NPP. SG—steam generator; HPT—high-pressure turbine; MPT—medium-pressure cylinder; D—deaerator; CP, FP—condensation and feed pumps; LPH—low-pressure heaters; HPH—high-pressure heaters; IR-1, IR-2—1st and 2nd stage superheaters.

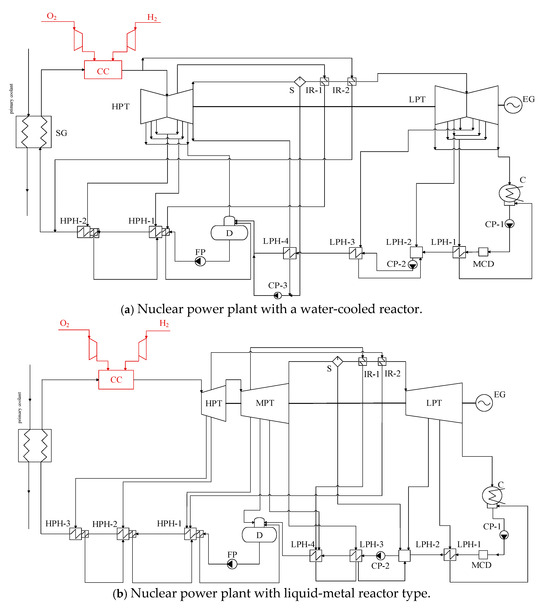

The use of a remote combustion chamber for superheating fresh steam after the steam generator is a topical issue in many research papers, and the implementation of such a solution will allow for preserving the traditional equipment layout, while avoiding the use of an excessive number of steam pipelines in the case of placing hydrogen combustion chambers in close proximity to the steam turbine. The advantage of hydrogen superheating is its environmental friendliness. Since the hydrogen burns in pure oxygen, the only combustion product is water vapor. It is also possible to use the combustion products to generate additional electricity, with their subsequent direction to the steam turbine, together with the main steam flow from the steam generator. These circumstances make it possible not only to significantly increase the initial temperature of the steam at the inlet of the steam turbine and achieve a higher level of efficiency of the power plant, but also to ensure minimal environmental impact.

The fundamental configurations of the proposed hybrid power units are illustrated in Figure 2. Steam generation occurs within the steam generator, after which the steam is directed to the remote combustion chamber (RCC), which operates on hydrogen fuel. In the RCC, the steam is combusted in pure oxygen with a stoichiometric mixture composition. Subsequently, the superheated steam is combined with the primary steam flow originating from the steam generator. Following further superheating within the RCC, the superheated steam is then directed to the steam turbine.

Figure 2.

Basic thermal diagrams of NPPs with steam superheating in the RCC.

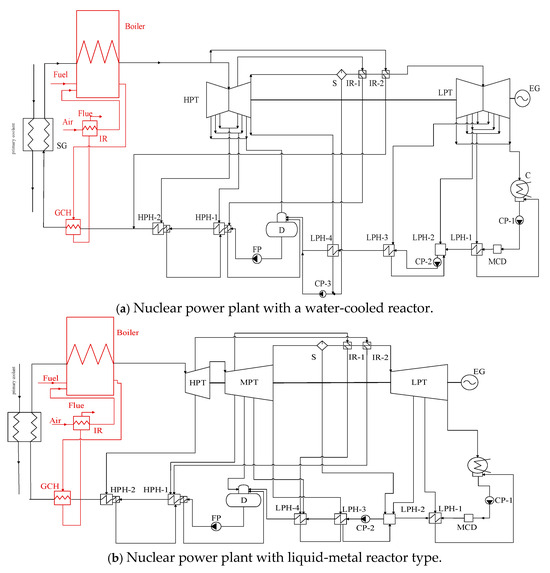

The basic diagrams of the studied hybrid power units with superheated steam in the heating surfaces of a boiler operating on natural gas are shown in Figure 3. Steam generation occurs in the steam generator, then the steam is sent to the remote steam superheater (RSH), which is a boiler, where heat is transferred from the combustion of organic fuel to steam through the superheater surface (SH). Then, the superheated steam is sent to the steam turbine. In order to increase the efficiency of the proposed steam superheating option, the exhaust gases, after the SH, were sent to the gas condensate heater (GCH), which replaces the first high-pressure heater (HPH–1) in the heat recovery system of the steam turbine part of the proposed thermal circuits and, therefore, eliminates the need to extract steam from the turbine to it, which, in turn, increases the generated useful power in the turbine. Further utilization of the heat of the exhaust gases occurred due to preheating of air in the air heater (AH) to 300 °C, which is sent to the combustion chamber.

Figure 3.

Basic thermal diagrams of a nuclear power plant with remote steam superheater.

It is worth noting that the initial temperature of combustion products in the boiler was set at 1000 °C and was controlled by having excess air in the furnace, equal to 3.86. The calculated ambient temperature was taken at 15 °C.

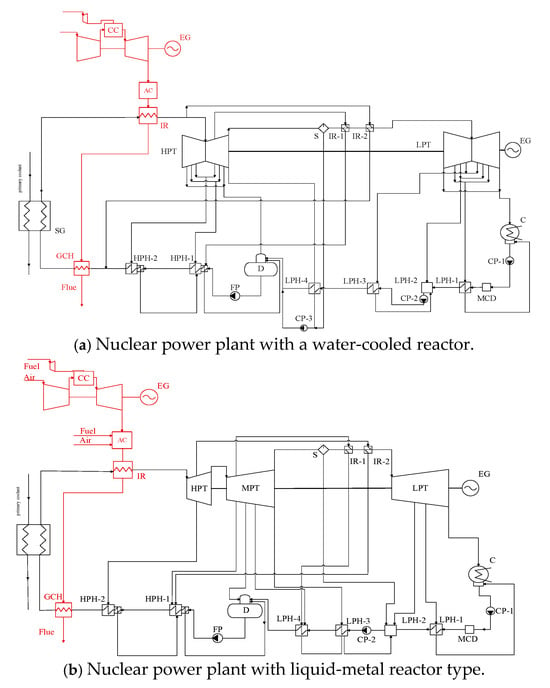

The study also considered the option of superheating steam after the steam generator by cooling the exhaust gas flow after the gas turbine unit (GTU). Utilization of the heat of the exhaust gases of the GTU, with their preliminary heating in the afterburner, is possible due to the sufficient content of the oxidizer in their composition to ensure the process of oxidation of natural gas and, as a result, additional heat supply. The use of the afterburner in the utilization of the heat of the exhaust gases after the GTU is due to the temperature level of both the gases themselves and the steam/condensate in the studied steam turbine cycles of NPPs. The work considered the utilization of the heat of gases after domestic gas turbines’ GTD-65 for NPPs with a liquid-metal reactor type and GTE-160 for water-moderated reactors; the operating parameters of these units are reflected in Table 1.

Table 1.

Operating parameters of the GTD-65 and GTE-160 installation.

The basic diagrams of the studied hybrid power units with superheating due to the utilization of the heat of exhaust gases after the GTU are shown in Figure 4. Steam generation occurs in the steam generator, then the steam is sent to the remote superheater, in which the steam is superheated by the exhaust gases of the GTU through the wall of the pipes. The superheated steam is sent to the turbine, and the exhaust gases are sent to the RCC and heat the main condensate before the steam generator to reach the required temperature level.

Figure 4.

Basic thermal diagrams of NPPs with steam superheating due to the utilization of heat from exhaust gases of gas turbine units.

After the first GCH, the temperature of the exhaust gases is at the level of 250 °C, which allows for additional heating of the condensate in the low-pressure regeneration system. Thus, for the studied NPPs with different types of reactors, it is advisable to heat the condensate instead of LPH-4 for water-cooled and liquid-metal reactor types, which in turn allows for the power generation in the steam turbine to increase without changing the temperature level in the low-pressure regenerative path of the steam turbine part of the NPP (Figure 5).

Figure 5.

Basic thermal diagrams of a nuclear power plant with superheated steam due to the utilization of heat from exhaust gases of a gas turbine plant with a developed utilization system.

3. Modeling Methods

To conduct the research, a mathematical model of basic NPPs with water-cooled and liquid-metal reactor units was developed. The models were also supplemented with an external, in relation to the nuclear unit, steam superheating path, including in different combinations of the scheme, which are as follows: RCC, RSH or GTU with AFB (after burner) and a remote steam superheater with a high-temperature turbine.

During the study, a comparison of the basic and hybrid schemes of the NPP was carried out by comparing the net power and the net efficiency of the turbine unit.

The enthalpy at the outlet of the turbine compartments was calculated using the following formula:

where hin and hout are the enthalpies at the turbine inlet and at the turbine outlet, kJ/kg;

∆H0 is the heat drop in the turbine compartment during isentropic expansion, kJ/kg;

ηoi is the internal relative efficiency of the compartment.

In the calculations, the internal efficiency in the turbine sections remained unchanged within the cylinder of one pressure level. The internal relative efficiency of the high- and medium-pressure cylinders was calculated by taking into account the humidity of the working steam, as follows:

where D is the steam flow rate through the cylinder, kg/s;

υcp is the average specific volume of steam, m3/kg, calculated using the following formula:

where υin and υout are the specific volumes at the inlet and outlet of the cylinder;

kwet is the coefficient, taking into account the work of the part of the cylinder in the wet steam region, as follows:

where γwet is a coefficient that takes into account moisture removal;

H0wet is the heat drop of the cylinder in the wet steam region kJ/kg;

yin and yout are the steam humidity at the inlet and outlet of the cylinder.

The internal relative efficiency of the low-pressure cylinder was calculated as follows:

where ∆ Hw.s. is the losses at the output speed, kJ/kg.

During the study, a model of a remote combustion chamber was developed, in which the stoichiometric process of hydrogen combustion in a pure oxygen environment was calculated (Formula (6)). The main initial data for the modeling are shown in Table 2. The model allows for us to obtain a certain value of the steam temperature at the outlet of the combustion chamber by calculating the required amount of pure oxygen and hydrogen through the equation of the heat balance of the combustion chamber flows.

Table 2.

Initial data for modeling the combustion process in the RCC.

A model of a remote superheater was also developed, in which the combustion process and its heat balance are calculated. The main assumptions are shown in Table 3. The model allows one to obtain the value of the oxidizer excess coefficient α, which makes it possible to determine the composition of the combustion products that are necessary to determine the thermodynamic properties of the medium and to calculate the efficiency of the superheater. It was assumed that the combustion reaction is stoichiometric (Formula (7)), and the oxidizer is air with a molar composition of 79% nitrogen and 21% oxygen.

Table 3.

Initial data for modeling the combustion process in the runway.

Heat balance of the combustion reaction is as follows:

where is the lower calorific value of fuel kJ/kg;

Ci is the heat capacity of gas under given conditions kJ/kg·K;

α is the excess air coefficient;

Li is the specific gas consumption, kg gas/kg fuel.

where µt is the molar mass of fuel, g/mol; µi is the molar mass of gas, g/mol;

n is the stoichiometric coefficient in the combustion reaction.

The efficiency of the superheater is calculated using the following formula:

where Gpg is the consumption of combustion products, kg/s;

hout is the enthalpy of combustion products at the outlet, kJ/kg;

hair is the enthalpy of combustion products at outside air temperature, kJ/kg;

Bt is the fuel consumption, kg/s.

To simulate the NPP schemes in which steam superheating occurs due to the utilization of heat from the exhaust gases of the GTU, a mathematical model of the afterburner was also compiled, in which a stoichiometric calculation of methane combustion in the exhaust gas environment was performed (Formula (7)). The composition of the exhaust gases after the GTU and other thermodynamic parameters required for the calculation are shown in Table 4.

Table 4.

Initial data for modeling the combustion process in the afterburning chamber.

The temperature of the gases at the outlet of the steam generator was determined based on the condition of heating the steam after the steam generator to a specified temperature level and maintaining the parameters of the condensate and feedwater unchanged in the high- and low-pressure regeneration system relative to the basic thermal schemes of the NPP.

Based on the calculation results, the net power of the turbo plant, the net efficiency of the turbo plant and the fuel consumption in the turbojet, runway and airspace were determined.

The net electrical power of the turbine plant was determined as follows:

where Nnet is the net capacity of the turbine unit, MW;

Ne is the electric power of the steam turbine, MW;

Npump is the power of all pumps in the cycle, MW;

is the net power of the gas turbine unit, MW;

NIP_ST is the internal power of the steam turbine, MW;

, is the efficiency of mechanical and electric generator, shares.

The net efficiency of the installation is determined by the following formula:

where Ni NET is the net capacity of the turbine unit under consideration, MW;

QTOT is the total heat supplied to the cycle, MW;

QST is the heat supplied to the cycle in the steam generator, MW;

QRCC, RSH, GTU are the heat supplied to the cycle, with steam superheating due to the RCC, RSH and exhaust gases of the gas turbine unit, MW;

BCH4,H2 is the fuel consumption, kg/s;

, are the higher and lower heat of combustion of hydrogen and methane, MJ/kg.

4. Results and Discussion

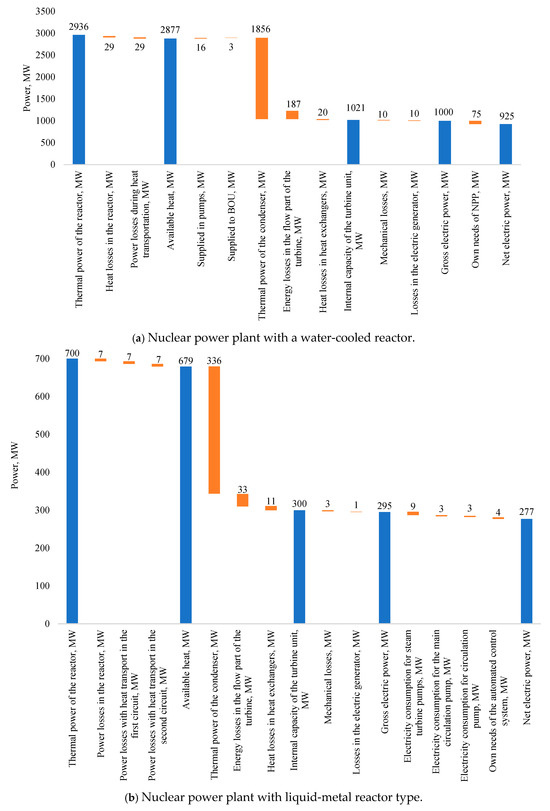

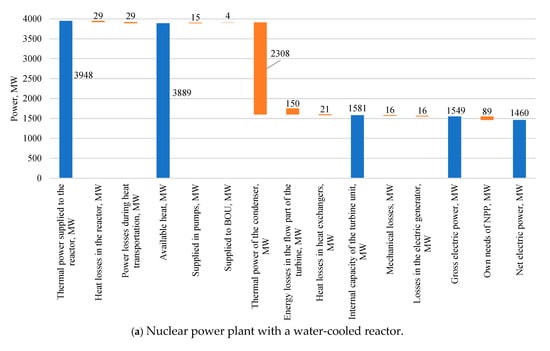

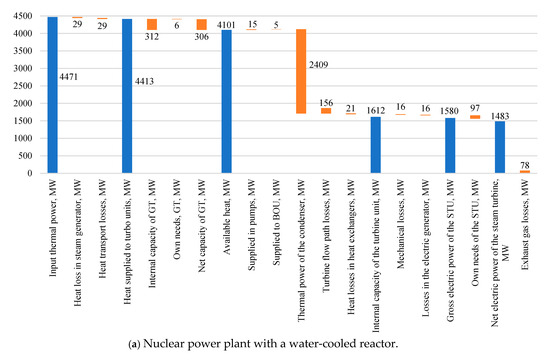

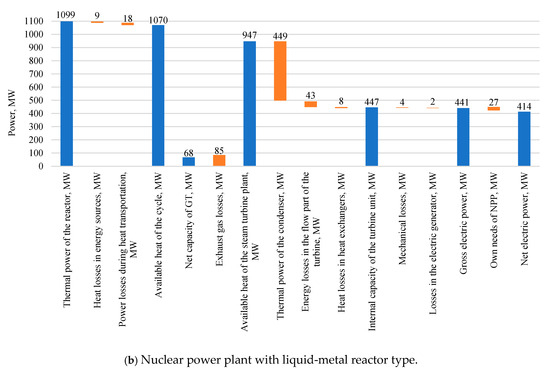

The results of modeling the basic schemes of NPPs with water-cooled and liquid-metal reactors showed that the net electric power generated by the cycle was 925 and 277 MW, respectively. The values of the net efficiency of the cycles were 31.52 and 39.24%, respectively, for the water-cooled and prospective liquid-metal reactors. The obtained efficiency estimates for the considered cycles are comparable with the data from [30], which indicates that the gross efficiency of such installations is in the range from 34 to 36% and from 41 to 43%, respectively, for PWR and BREST. The reduction of heat balances for the considered plants is shown in Figure 6. During the study, diagrams of the reduction of the heat balance of the turbine plant were also obtained for hybrid thermal schemes of NPPs with different types of plants. The principle of constructing the diagram is as follows: the diagram shows the energy scheme of the nuclear thermal cycle, which clearly reflects the distribution and losses of thermal energy at each stage. The initial thermal power coming from the reactor is transferred to the steam turbine circuit, but the heat reaches the steam generator with losses that occurred during transportation in the first and second circuits, which reduces the power supplied to the working fluid of the cycle. Additionally, energy costs for the operation of auxiliary equipment, such as pumps, are taken into account. The main energy losses occur in the condenser, as well as in the flow part of the turbine, where losses occur due to the internal relative efficiency of the turbine being less than 100%, while energy is additionally lost in the process of heat exchange between the environments in the high- and low-pressure heat regeneration systems of the steam turbine circuit. The total power generated by the turbine is z MW, from which, after subtracting the mechanical losses due to shaft friction and the operation of the oil supply system, as well as electrical losses in the electric generator for its cooling and in its stator windings, as well as energy costs for ensuring the operation of mechanisms for other auxiliary needs of the station, we obtain the absolute net electrical power of the cycle under study.

Figure 6.

Thermal balance of basic NPP schemes.

The use of a remote hydrogen combustion chamber leads to a simultaneous increase in the nominal steam consumption and an increase in its initial temperature before the turbine. This increases the potential power that the turbine is capable of developing, since, with an increase in temperature, the difference in enthalpies at the inlet and outlet increases, which enhances the conversion of the potential energy of the steam into the mechanical energy of rotor rotation. At the same time, an increase in the steam temperature is observed, at a constant pressure, in the extractions, which makes it possible to reduce the consumption of steam from the extractions for the heat recovery system (provided that the feedwater consumption after the condenser remains unchanged compared to the base cycle). Thus, despite the additional consumption of hydrogen fuel for heating the steam in the remote combustion chamber, the overall increase in power and net efficiency significantly improves the efficiency of the cycle, which is confirmed by the growth of indicators in a given range of superheated steam temperatures.

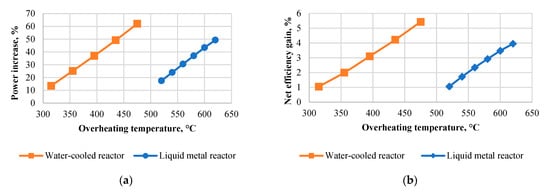

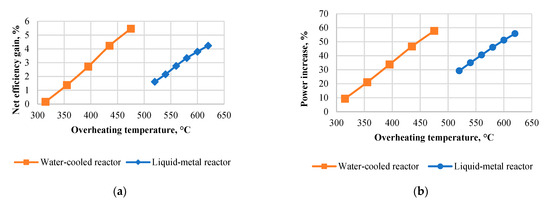

As a result of the conducted studies, it was established that the use of preliminary superheating of steam before the steam turbine in the RCC for water-cooled and liquid-metal reactor types of NPPs from 274 and 505 °C to 475 and 620 °C, respectively, ensures an increase in the net efficiency of the hybrid NPP by 5.43 and 3.82%, respectively; in addition, the electric power increases by 62 and 49%, relative to the basic schemes of the considered NPP types (Figure 7). The reduction of heat balances for hybrid plants with steam superheating in the RCC is shown in Figure 8.

Figure 7.

Dependence of power increase (a) and net efficiency (b) relative to the basic options of NPPs with superheating of fresh steam due to RCC.

Figure 8.

Heat balance of hybrid NPPs with steam superheating in the RCC.

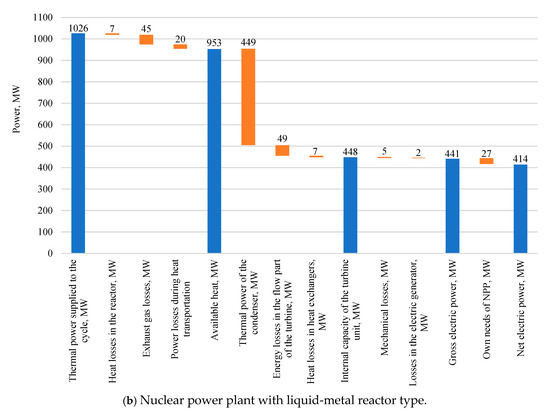

In RSH, fuel combustion heats up steam to the required temperatures (from 274 and 505 °C to 475 and 620 °C for water- and liquid-metal reactors, respectively). In this case, gases leaving the superheater are directed to the high-pressure regeneration system of the steam turbine complex, where the first regenerative extraction is completely replaced by a gas condensate heater. In this circuit solution, the feedwater in front of the steam generator is heated by the outgoing gases, and then they heat the air in front of the combustion chamber, which additionally improves the combustion process in the combustion chamber. An increase in the initial steam temperature increases the internal power of the steam turbine, while simultaneously increasing the steam flow through the turbine compartments due to the shutdown of the first regenerative extraction and reducing the steam flow to the regenerative extractions. As a result, due to the increase in heat conversion efficiency and the reduction in costs for regenerative extraction, there is a significant increase in net electric power (by 57.8 and 55.8%, relative to the base scheme for the considered types of NPPs), as well as a general increase in cycle efficiency of 5.47 and 4.23%, respectively, with an increase in the initial steam temperature from 274 and 505 °C to 475 and 620 °C for water and liquid-metal reactors, respectively, as described in (Figure 9). The heat balance of the calculated schemes is presented in Figure 10.

Figure 9.

Dependence of the increase in net efficiency (a) and power (b) relative to the basic options of NPPs with superheating of fresh steam in the runway.

Figure 10.

Heat balance of hybrid NPPs with steam superheating in the runway.

In the NPP with a gas turbine, the steam is preheated by utilizing the heat of the exhaust gases after the gas turbine, which allows for a deeper thermodynamic integration of the gas and steam cycles. The essence of the scheme is that the heat extracted from the exhaust gases of the gas turbine is directed to preheating the steam before the steam turbine, and is also used to replace the regenerative extractions in the feedwater heating system.

In the first variant, heat is used to replace the operation of one regenerative high-pressure heater (HPH). In this case, the feedwater is heated by gases after the superheater and not by extraction steam, which allows for the highest temperature and most energy-intensive extraction to be switched off. This also leads to an increase in the flow rate of steam passing through the flow path of the turbine, which additionally leads to an increase in the internal power of the turbine, in addition to an increase in the initial steam temperature.

In the second variant, a deeper version of utilization, part of the low-pressure regeneration is additionally replaced, i.e., two selection heaters (high- and low-pressure) are replaced by gas heat exchangers. This enhances the following effect: the proportion of steam sent to regeneration decreases, which means that an even larger volume of the working fluid passes through the turbine. At the same time, the temperature mode of the steam generator is maintained.

An increase in the initial steam temperature increases the heat drop in the turbine, and the replacement of selections increases the steam flow through the stages. In addition, the capacity of gas turbines also significantly increases the capacity of the NPP cycle with GTU. All of these three factors together lead to a significant increase in the net electric power of the hybrid NPP cycle.

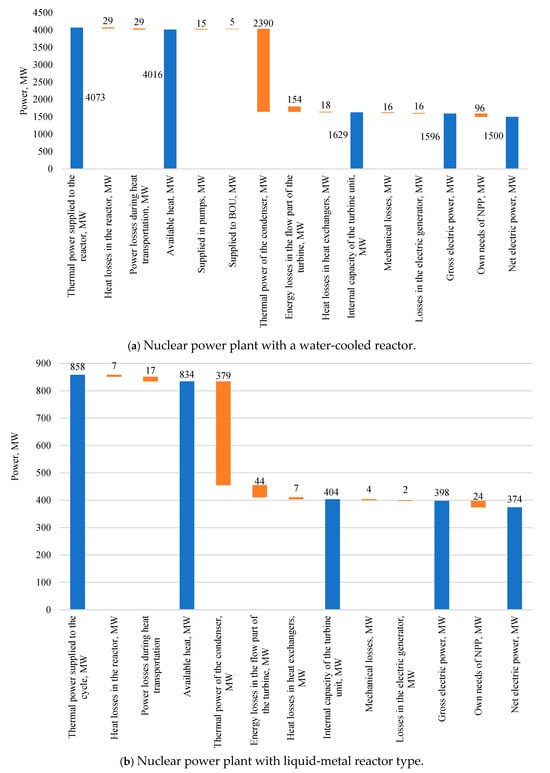

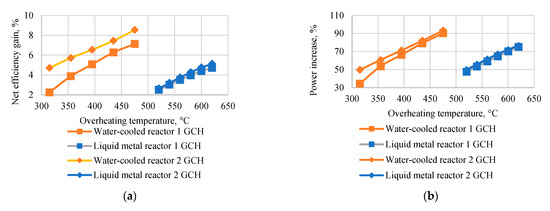

As a result of the conducted studies of the utilization of heat from exhaust gases of GTU with the replacement of LPH-1 with GCH, it was found that superheating of steam for water-cooled and liquid-metal types of NPP reactors from 274 and 505 °C to 475 and 620 °C, respectively, leads to an increase in the net efficiency of the hybrid NPP, relative to the basic version, by 7.12 and 4.71%, respectively (Figure 11a). In this case, the electric power increases by 90.3 and 75.2%, respectively, relative to the basic power levels of the considered NPP types (Figure 11b). With additional utilization of heat from exhaust gases after LPH in the low-pressure regeneration system, the net efficiency increase was 8.49 and 5.11% (Figure 11), respectively, for the water-cooled and liquid-metal types of reactor, while the power increased by 93.3 and 76.7%. The heat balance of the most efficient scheme for utilizing heat from a gas turbine in the cycles under study is shown in Figure 12.

Figure 11.

Dependence of the increase in net efficiency (a) and power (b) relative to the basic options of the NPP with superheating of fresh steam from the exhaust gases of the gas turbine unit.

Figure 12.

Heat balance of hybrid NPPs with superheating of steam by heat of exhaust gases of GTU.

Despite the increase in the efficiency of thermal schemes of nuclear power plants due to the use of installations on organic and hydrogen fuels, the final choice of certain technological solutions will be determined, first of all, by the technical and economic indicators of projects for the construction of new nuclear power units, as well as the safety and reliability indicators of power units.

5. Conclusions

This study developed hybrid NPP schemes in which steam is superheated after the steam generator by an external, in relation to the nuclear plant, built-on circuit using organic fuel. The results of the calculations were obtained for a scheme in which steam is superheated due to the use of a remote combustion chamber operating on hydrogen fuel; burning natural gas in a boiler unit in which fresh steam is superheated through a heating surface; utilization of heat from exhaust gases preheated in the boiler by burning natural gas.

It has been established that the use of a remote combustion chamber for superheating steam after the steam generator leads to an increase in the net efficiency of a hybrid NPP by 5.43 and 3.82% for water-cooled and liquid-metal types of NPP reactors, respectively, while the net electric power increases by 62 and 49%, relative to the basic schemes of the considered types of NPPs with steam superheating from 274 and 505 °C to 475 and 620 °C, respectively.

The use of a boiler unit for superheating steam after the steam generator leads to an increase in the net efficiency of the hybrid NPP by 5.47 and 4.23% for water-cooled and liquid-metal reactors, respectively, while the net electric power increases by 57.8 and 55.8%, relative to the basic schemes, with steam superheating from 274 and 505 °C to 475 and 620 °C, respectively.

The use of heat from the exhaust gases of the gas turbine, preheated in the pressurizer, for superheating the steam after the steam generator and further heating of the condensate in the high-pressure regeneration system leads to an increase in the net efficiency of the hybrid NPP by 7.12 and 4.71% for water-cooled and liquid-metal reactor types of NPPs, respectively, while the net electric power increases by 90.3 and 75.2%, relative to the basic schemes of the considered NPP types with steam superheating from 274 and 505 °C to 475 and 620 °C, respectively.

It was found that among the variants of schemes for superheating fresh steam after the steam generator considered in the study, the best solution is superheating, due to the utilization of heat from the exhaust gases of the GTU using the condensate heater. With partial replacement of high- and low-pressure heaters in the regeneration system with gas heaters of condensate and superheating of steam after the steam generator for water-cooled and liquid-metal reactor types, an increase in the net efficiency of the hybrid NPP by 8.49 and 5.11%, respectively, is observed, while the net electric power increases by 93.3 and 76.7%.

Author Contributions

Conceptualization, N.R. and V.K.; methodology, V.K.; software, M.O.; validation, R.Z.; formal analysis, I.M.; investigation, I.M.; resources, N.R.; data curation, R.Z.; writing—original draft preparation, M.O.; writing—review and editing, N.R.; visualization, R.Z.; supervision, V.K.; project administration, V.K.; funding acquisition, N.R. All authors have read and agreed to the published version of the manuscript.

Funding

This study conducted by National Research University “Moscow Power Engineering Institute” was supported by the Russian Science Foundation under Agreement No. 23-79-10235.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AFB | Afterburnering chamber |

| BWR | Boiling-Water-Reactor |

| C | Condenser |

| CP | Condensation pump |

| D | Deaerator |

| EG | Electric generator |

| FP | Feed pump |

| HPH | High pressure heaters |

| HPT | High pressure turbine |

| IR | Steam superheaters |

| LPH | Low pressure heaters |

| LPT | Low pressure turbine |

| MPT | Medium pressure turbine |

| NPP | Nuclear power plant |

| PWR | Pressurized-Water-Reactor |

| RCC | Remote combustion chamber |

| RSH | Remote steam superheater |

| S | Separator |

| SG | Steam generator |

| SVBR | Lead-bismuth fast reactor |

| GCH | Gas condensate heater |

| GTU | Gas turbine unite |

References

- Rahman, M.W.; Abedin, M.Z.; Chowdhury, M.S. Efficiency Analysis of Nuclear Power Plants: A Comprehensive Review. World J. Adv. Res. Rev. 2023, 19, 527–540. [Google Scholar] [CrossRef]

- Saltanov, E.; Pioro, I. World Experience in Nuclear Steam Reheat. In Nuclear Power; Tsvetkov, P., Ed.; IntechOpen: Rijeka, Croatia, 2011. [Google Scholar]

- Wibisono, A.F.; Shwageraus, E. Development of a Small Modular Boiling Water Reactor Combined with External Superheaters. Ann. Nucl. Energy 2021, 159, 108312. [Google Scholar] [CrossRef]

- Sam, R.; Sainati, T.; Hanson, B.; Kay, R. Licensing Small Modular Reactors: A State-of-the-Art Review of the Challenges and Barriers. Prog. Nucl. Energy 2023, 164, 104859. [Google Scholar] [CrossRef]

- Rogalev, N.; Rogalev, A.; Kindra, V.; Komarov, I.; Zlyvko, O. Structural and Parametric Optimization of S–CO2 Nuclear Power Plants. Entropy 2021, 23, 1079. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, J.; Wang, P. Study on Control Characteristics of a Nuclear Power Plant with Coupled Heat-Pipe Reactor and sCO2 Brayton Cycle. Nucl. Eng. Des. 2025, 432, 113819. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Technology Roadmap for Small Modular Reactor Deployment; International Atomic Energy Agency: Vienna, Austria, 2021; pp. 1–109. [Google Scholar]

- Bustos, J.; Vergara, J.A.; Correa, F.A. Development of a Concept Power Plant Using a Small Modular Reactor Coupled with a Supercritical CO2 Brayton Cycle for Sustainable Antarctic Stations. Prog. Nucl. Energy 2021, 132, 103606. [Google Scholar] [CrossRef]

- Li, J.; Hu, Y.; Zhan, H. Performance Study of Thermal-Nuclear Co-Generation System Based on Exergy and Thermal Economy Analysis. Case Stud. Therm. Eng. 2023, 48, 103119. [Google Scholar] [CrossRef]

- Bayramov, A. Comprehensive Assessment of System Efficiency and Competitiveness of Nuclear Power Plants in Combination with Hydrogen Complex. Int. J. Hydrogen Energy 2023, 48, 27068–27078. [Google Scholar] [CrossRef]

- Zaryankin, A.E. Hybrid NPP with Additional High-Temperature Steam Turbine. R.U. Patent 2661341, 28 November 2018. [Google Scholar]

- Aminov, R.Z.; Egorov, A.N. Assessment of Technical and Economic Efficiency of a Closed Hydrogen Cycle at NPP. Int. J. Hydrogen Energy 2020, 45, 15744–15751. [Google Scholar] [CrossRef]

- Kindra, V.; Maksimov, I.; Zlyvko, O.; Rogalev, A.; Rogalev, N. Thermodynamic Analysis and Comparison of Power Cycles for Small Modular Reactors. Energies 2024, 17, 1650. [Google Scholar] [CrossRef]

- Kindra, V.; Maksimov, I.; Patorkin, D.; Rogalev, A.; Rogalev, N. Thermodynamic Analysis and Optimization of Binary CO2-Organic Rankine Power Cycles for Small Modular Reactors. Energies 2024, 17, 2377. [Google Scholar] [CrossRef]

- Shirmanov, I.A.; Kostarev, V.S.; Litvinov, D.N.; Shcheklein, S.E. On the Possibility of Application of Compression and Non-Nuclear Steam Superheating on Fast Neutron Reactors with a Lead Coolant to Increase the Thermodynamic Efficiency of the Turbine Plant. Izvestiya Vuzov Fizika 2021, 64, 171–177. Available online: http://vital.lib.tsu.ru/vital/access/manager/Repository/koha:000719548 (accessed on 20 October 2021). [CrossRef] [PubMed]

- Makarov, S.A. Increasing the Efficiency of NPPs with BREST-300 by Using Natural Gas in the Environment. At. Energy 2023, 134, 119–124. [Google Scholar] [CrossRef]

- Lior, N. Energy, Exergy and Thermoeconomic Analysis of the Effects of Fossil-Fuel Superheating in Nuclear Power Plants. Energy Convers. Manag. 1997, 38, 1585–1593. [Google Scholar] [CrossRef]

- Wibisono, A.F.; Shwageraus, E. Thermodynamic Performance of Pressurized Water Reactor Power Conversion Cycle Combined with Fossil-Fuel Superheater. Energy 2016, 117, 190–197. [Google Scholar] [CrossRef]

- Schastlivtsev, A.I.; Duniko, D.O.; Borzenko, V.I.; Shmatov, D.P. Hydrogen-Oxygen Installations for the Energy Industry. High Temp. 2020, 58, 809–822. [Google Scholar] [CrossRef]

- Aminov, R.Z.; Bairamov, A.N. Estimation of the Efficiency of Combining a NPP with a Hydrogen Facility under Conditions of Safe Use of Hydrogen in a Steam Turbine Cycle. Power Eng. Res. Equip. Technol. 2021, 23, 56–69. [Google Scholar] [CrossRef]

- Aminov, R.Z.; Bairamov, A.N. Current State and Prospects of Hydrogen Production at NPPs. Therm. Eng. 2021, 68, 663–672. [Google Scholar] [CrossRef]

- Aminov, R.; Bairamov, A.; Garievskii, M. Assessment of the Performance of a Nuclear–Hydrogen Power Generation System. Therm. Eng. 2019, 66, 196–209. [Google Scholar] [CrossRef]

- Zaryankin, A.E.; Rogalev, N.D.; Lyskov, M.G.; Rogalev, A.N. NPP turbine plant with external superheater. Vestn. Mosk. Energeticheskogo Instituta 2011, 4, 12–18. [Google Scholar]

- Marie, M.P.E.J. Methods for the Operation of Nuclear Power Generating Stations. U.S. Patent 3,309,282, 14 March 1967. [Google Scholar]

- Wang, L.; Wu, F.; Yang, J.; Qi, J.; Liu, Y.; Hu, X.; Miao, J.; Sui, F.; Zhang, S.; Li, G. Nuclear energy and conventional energy resource coupling and decoupling belt reheating power generation system and method. C.N. Patent 10884341, 16 August 2018. [Google Scholar]

- Sedille, M.H.L. Kombinierte Gas-Dampf-Kraftanlage. D.E. Patent 1239890B, 6 December 1967. [Google Scholar]

- Veszely, K. Hybrid Combined Cycle Power Plant. In Advances in Nuclear Society of Slovenia, Proceedings of the International Conference Nuclear Energy for New Europe, Kranjska Gora, Slovenia, 9–12 September 2002; Nuclear Society of Slovenia: Ljubljana, Slovenia, 2002; pp. 0103.1–0103.8. [Google Scholar]

- Kasilov, V.F.; Dudolin, A.A.; Gospodchenkov, I.V. The effectiveness of using the combined-cycle technology in a nuclear power plant unit equipped with an SVBR-100 reactor. Therm. Eng. 2015, 62, 322–328. [Google Scholar] [CrossRef]

- Kasilov, V.F.; Dudolin, A.A.; Krasheninnikov, S.M. Development of a thermal scheme for a cogeneration combined-cycle unit with an SVBR-100 reactor. Therm. Eng. 2017, 64, 97–103. [Google Scholar] [CrossRef]

- Pioro, I.L. (Ed.) Handbook of Generation IV Nuclear Reactors, 2nd ed.; Woodhead Publishing (WP): Kidlington, UK, 2023; 1079 pages (hard copy) and 197 pages (Appendices 3–9) on website. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).