Multi-Objective Optimization for the Low-Carbon Operation of Integrated Energy Systems Based on an Improved Genetic Algorithm

Abstract

:1. Introduction

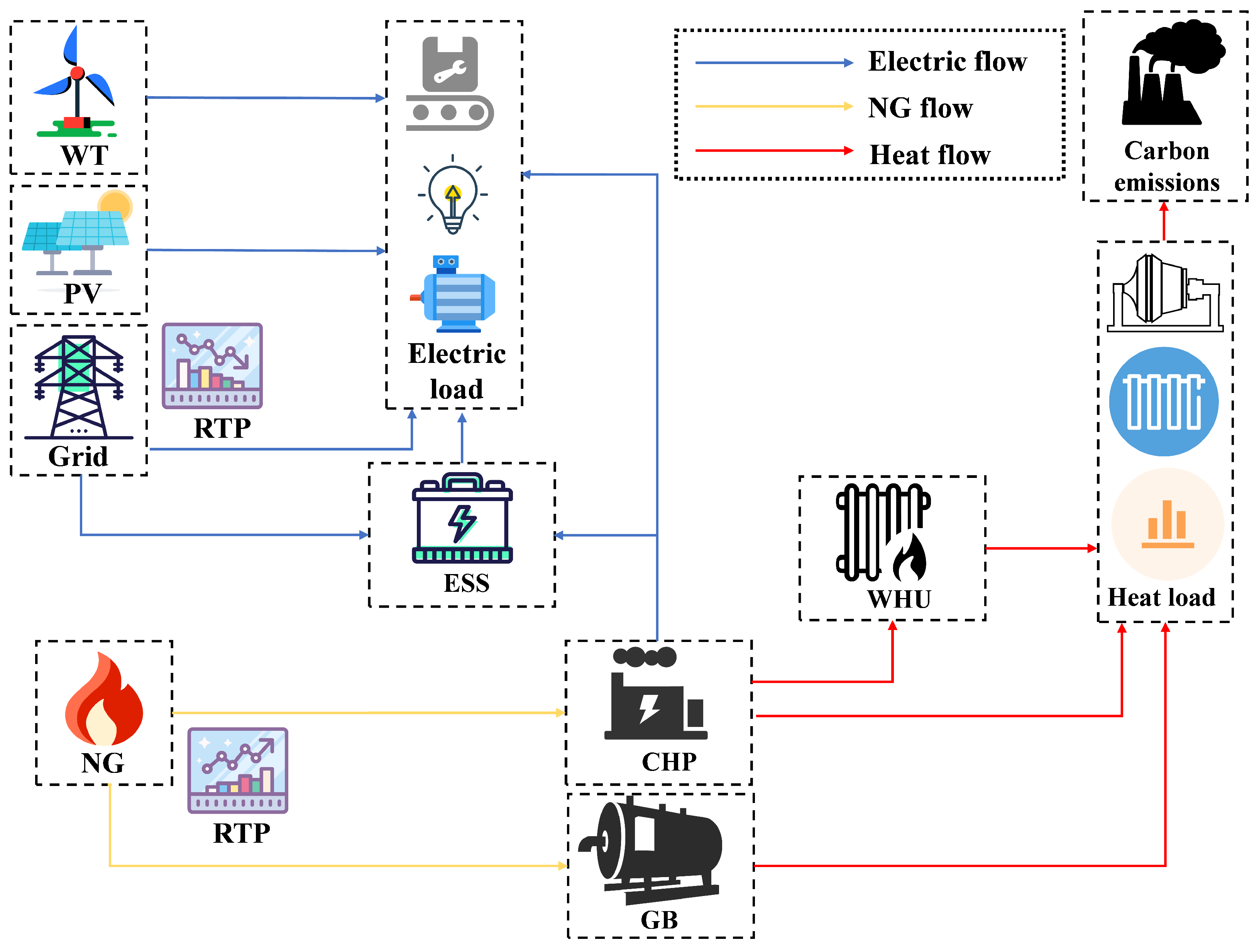

2. Modeling for IES Operation

2.1. Electricity–Heat–Gas IES Modeling

2.1.1. Mathematical Modeling of CHP Units

2.1.2. Mathematical Modeling of GB

2.1.3. Mathematical Modeling of Photovoltaic and Wind Power

2.1.4. Mathematical Model of ESSs

2.2. Operational Optimization Modeling of IES

2.2.1. Tiered Electricity Pricing Mechanism

2.2.2. Tiered Carbon Emission Pricing Mechanism

2.2.3. Tiered Natural Gas Pricing Mechanism

2.2.4. Optimization Modeling of IES Operation

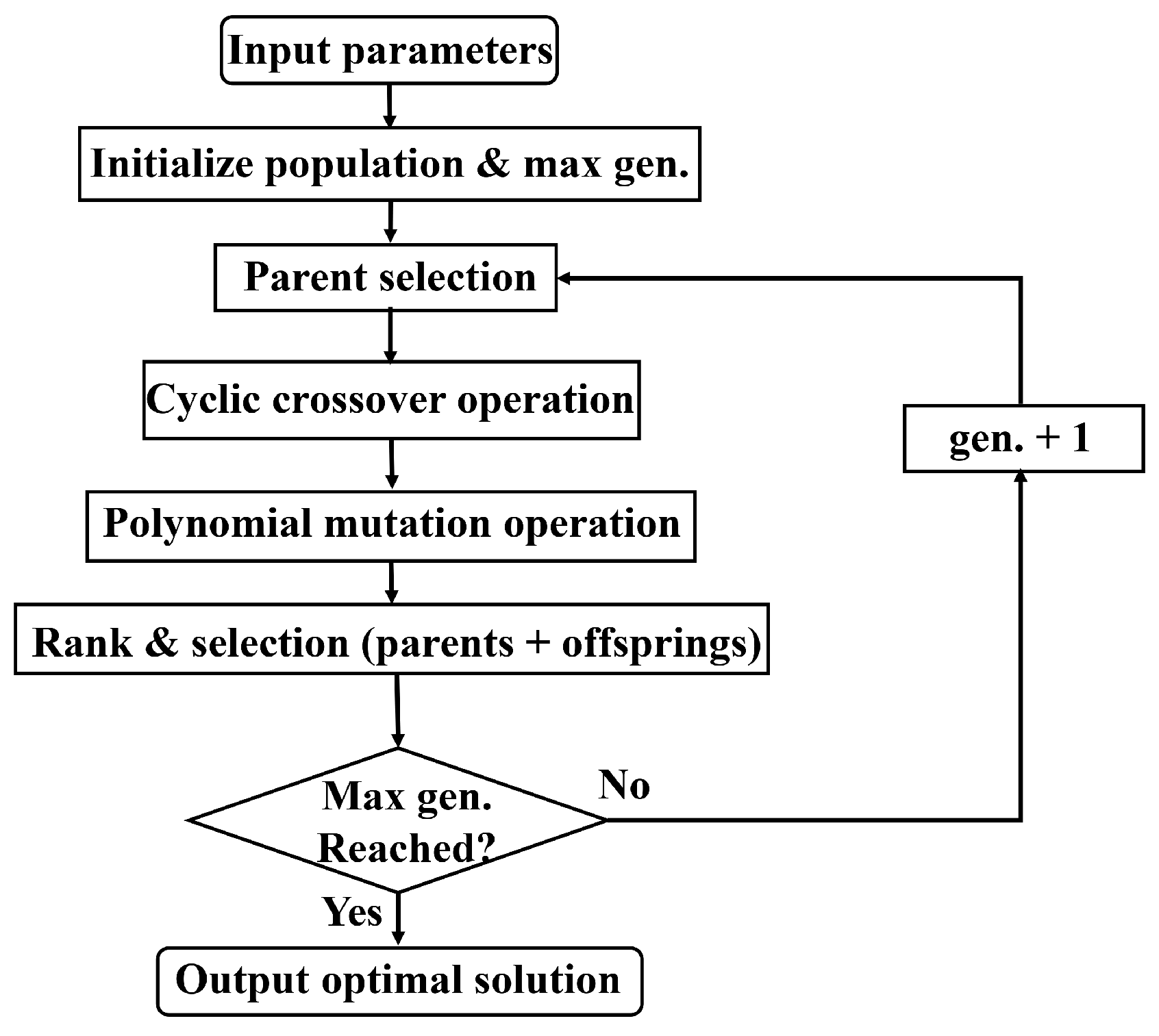

3. Improved Multi-Objective Genetic Algorithm

3.1. Population Initialization

3.2. Parent Selection

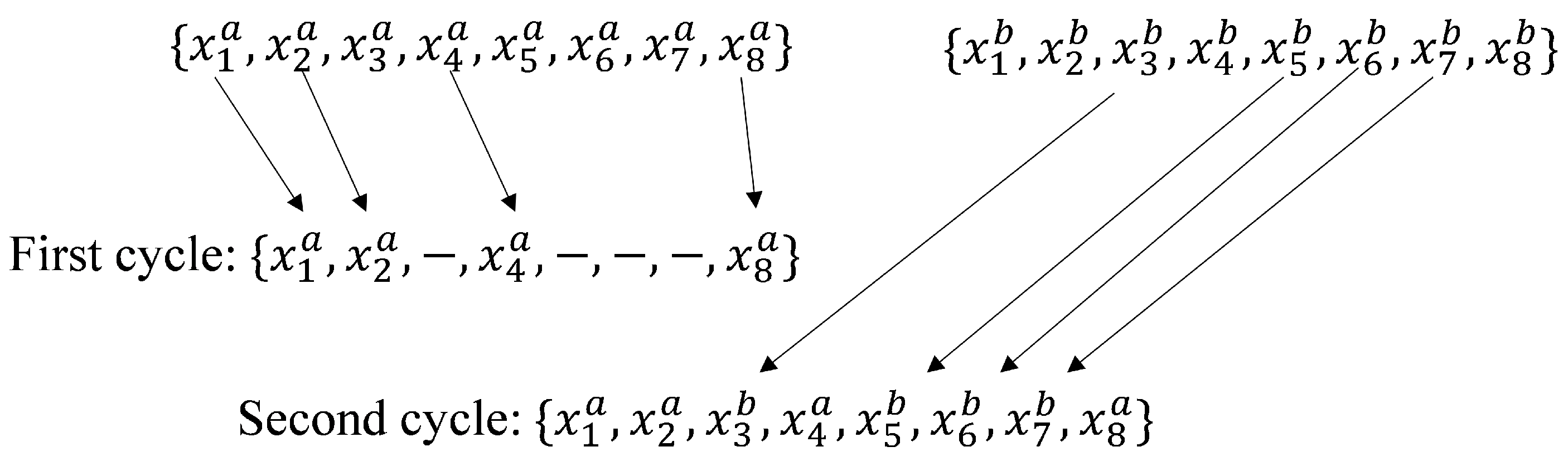

3.3. Cyclic Crossover Operation

3.4. Polynomial Mutation Operation

3.5. Selection Between Parents and Offspring

3.6. Fast Non-Dominated Sorting

3.7. Weight-Based Pareto Solution Selection

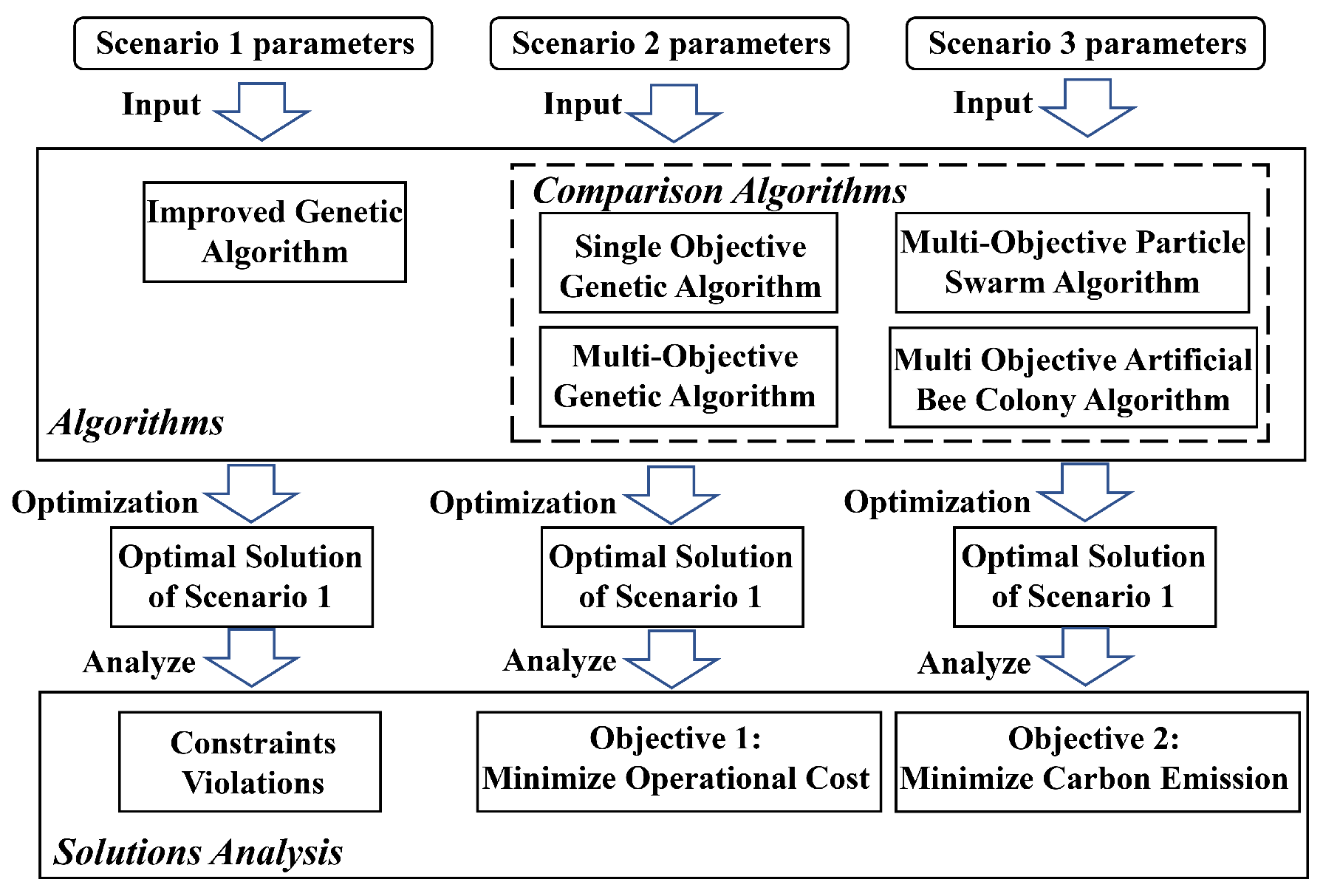

4. Case Study

4.1. Case Study Setup

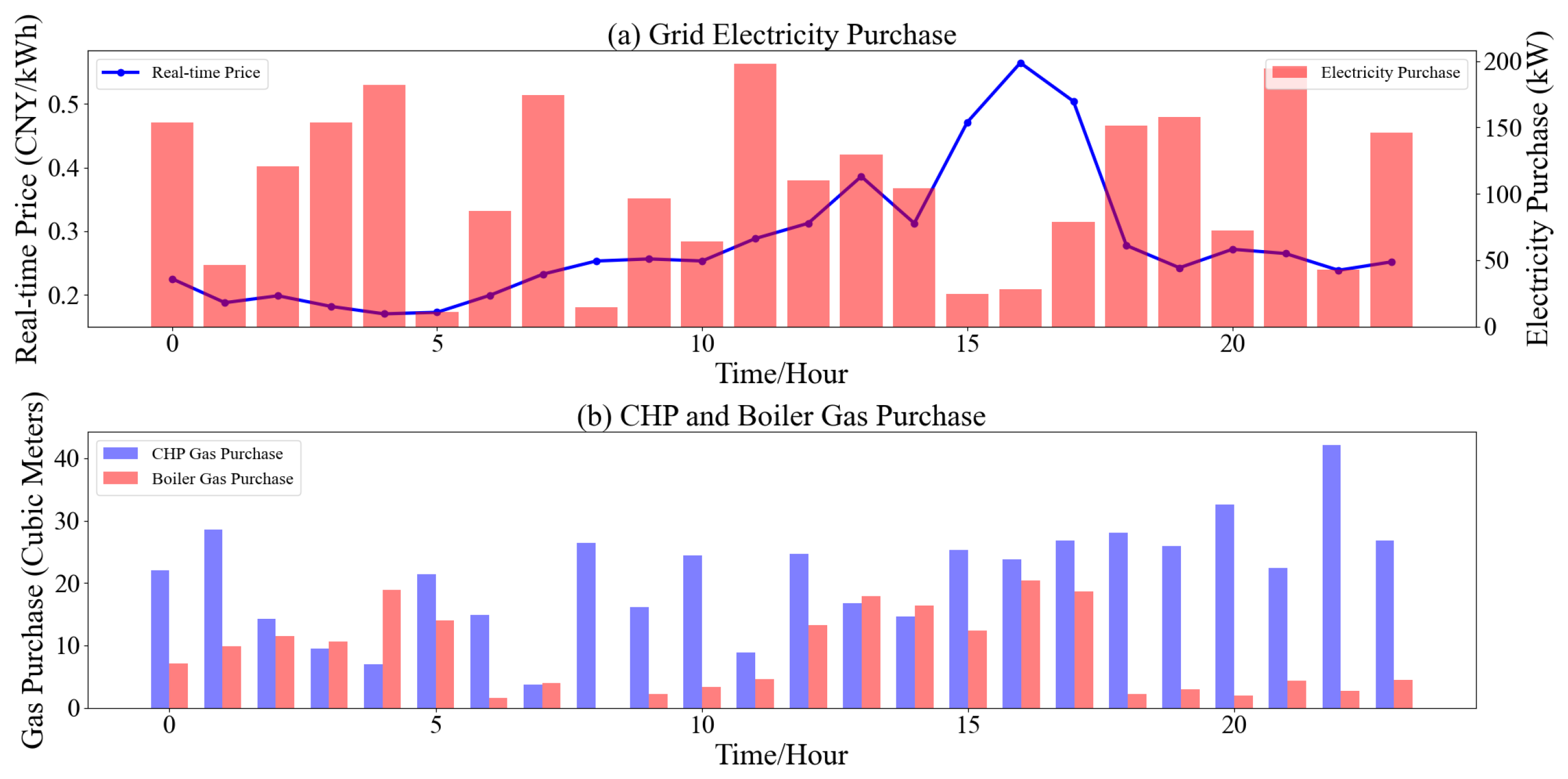

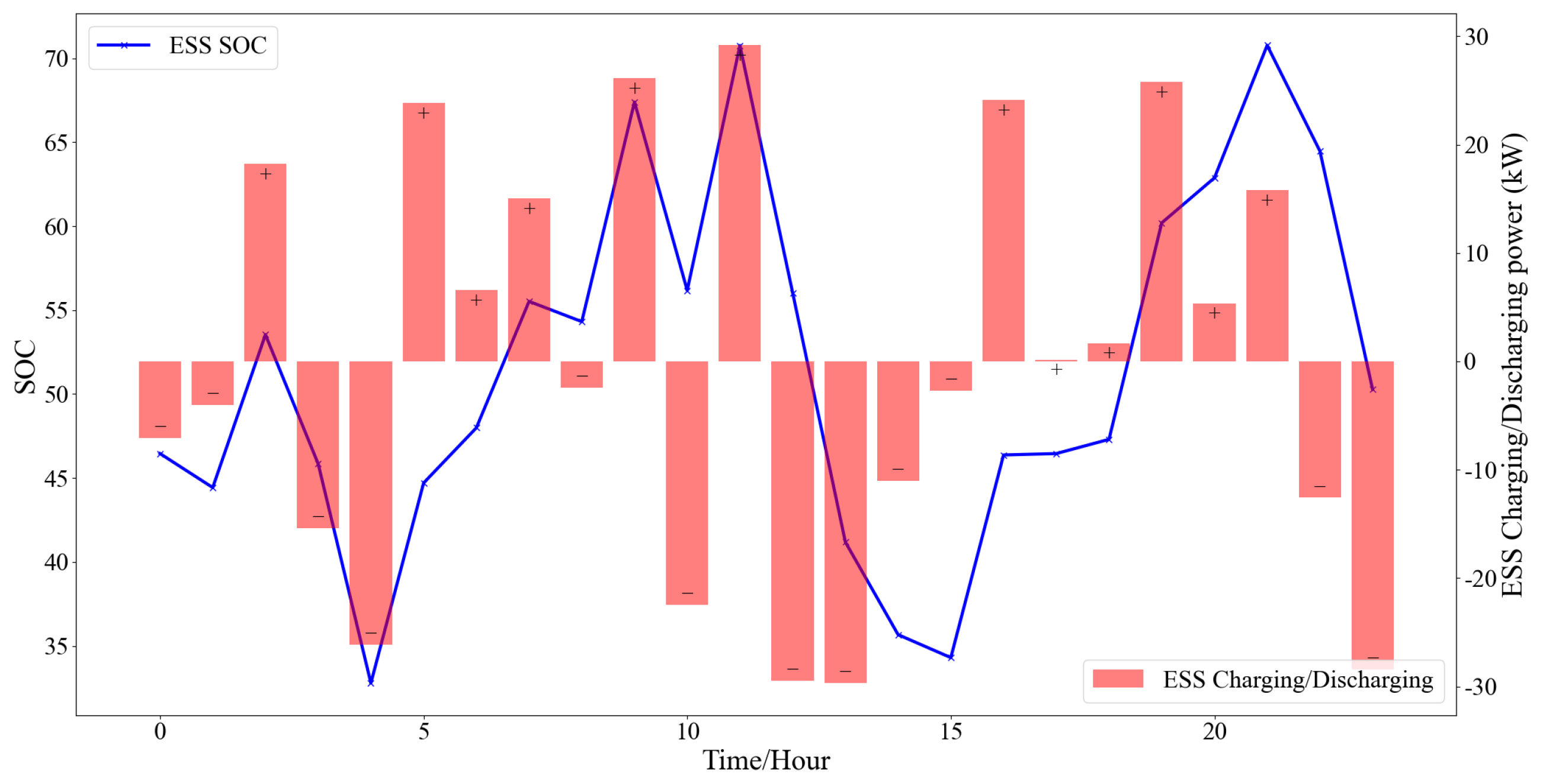

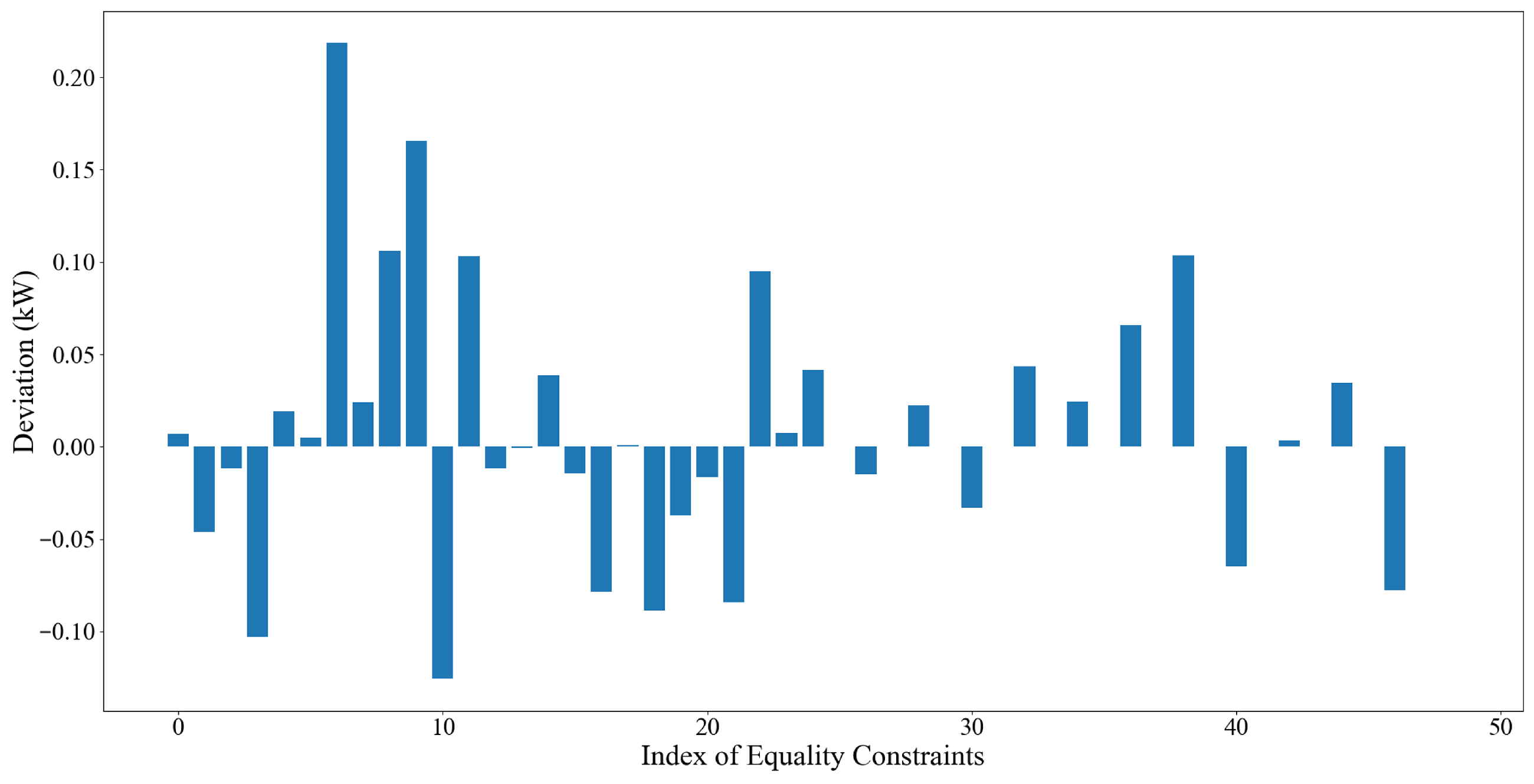

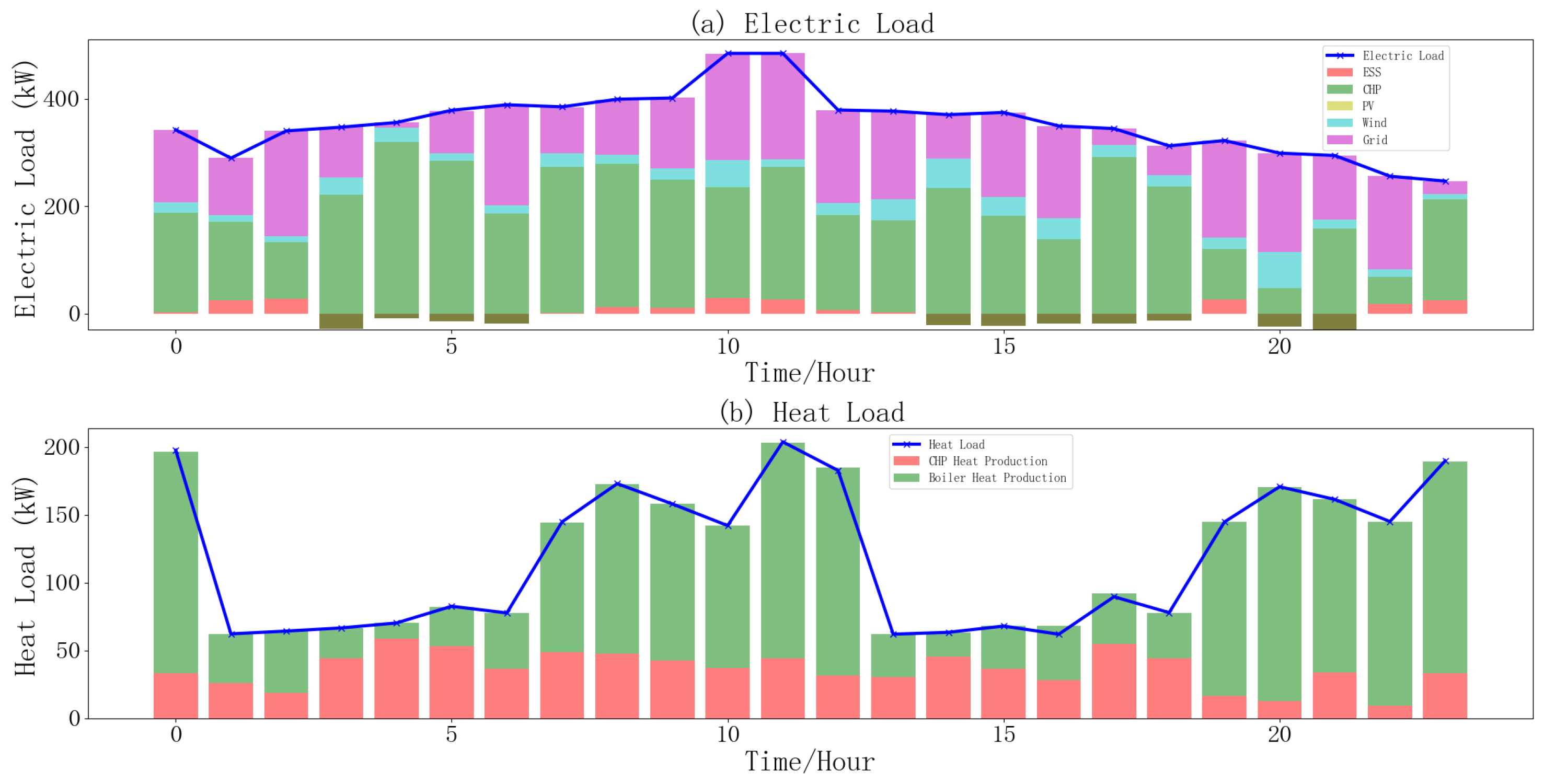

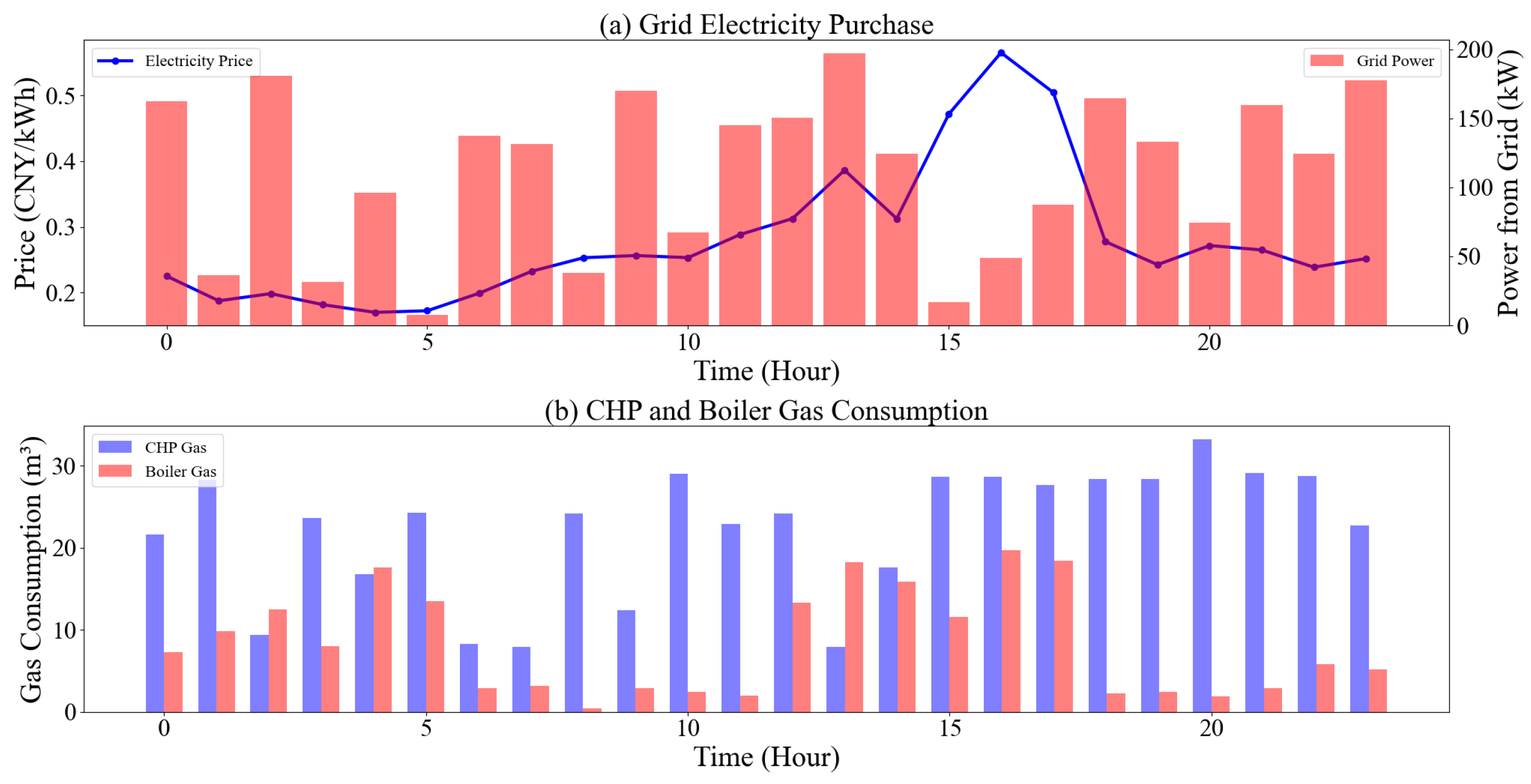

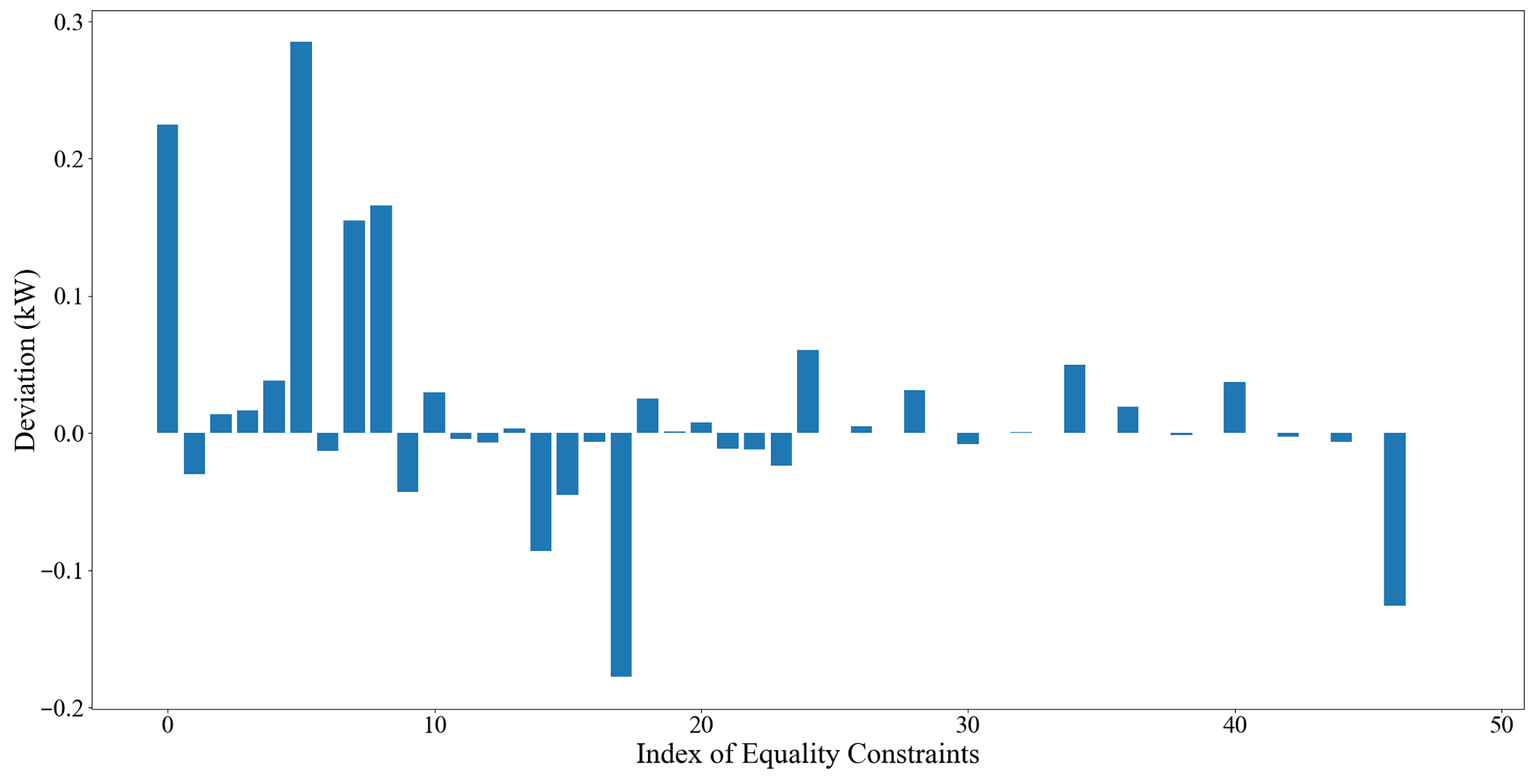

4.2. Optimization Results of the IES in Scenario 1

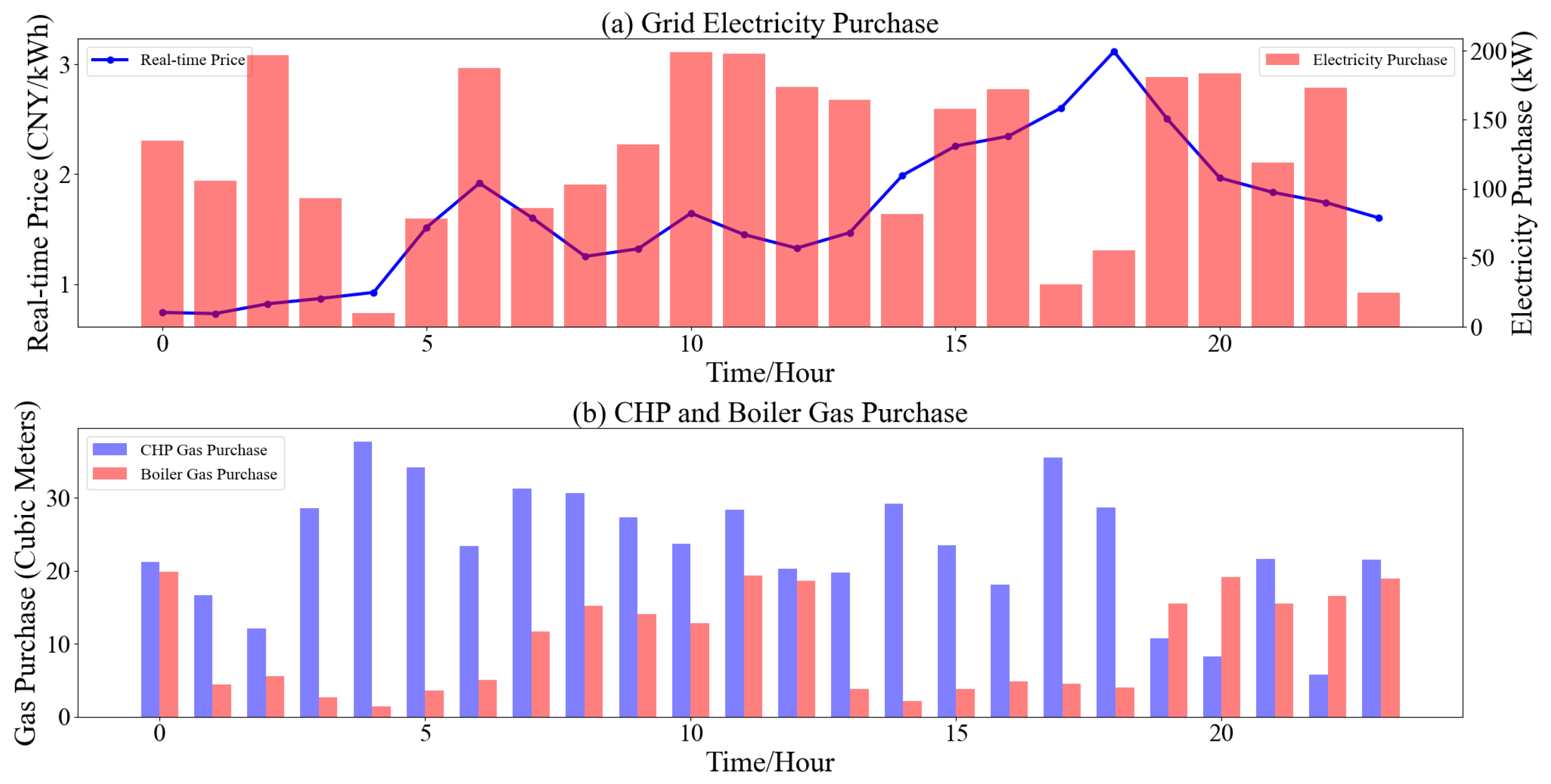

4.3. Optimization Results of the IES in Scenario 2

4.4. Optimization Results of the IES in Scenario 3

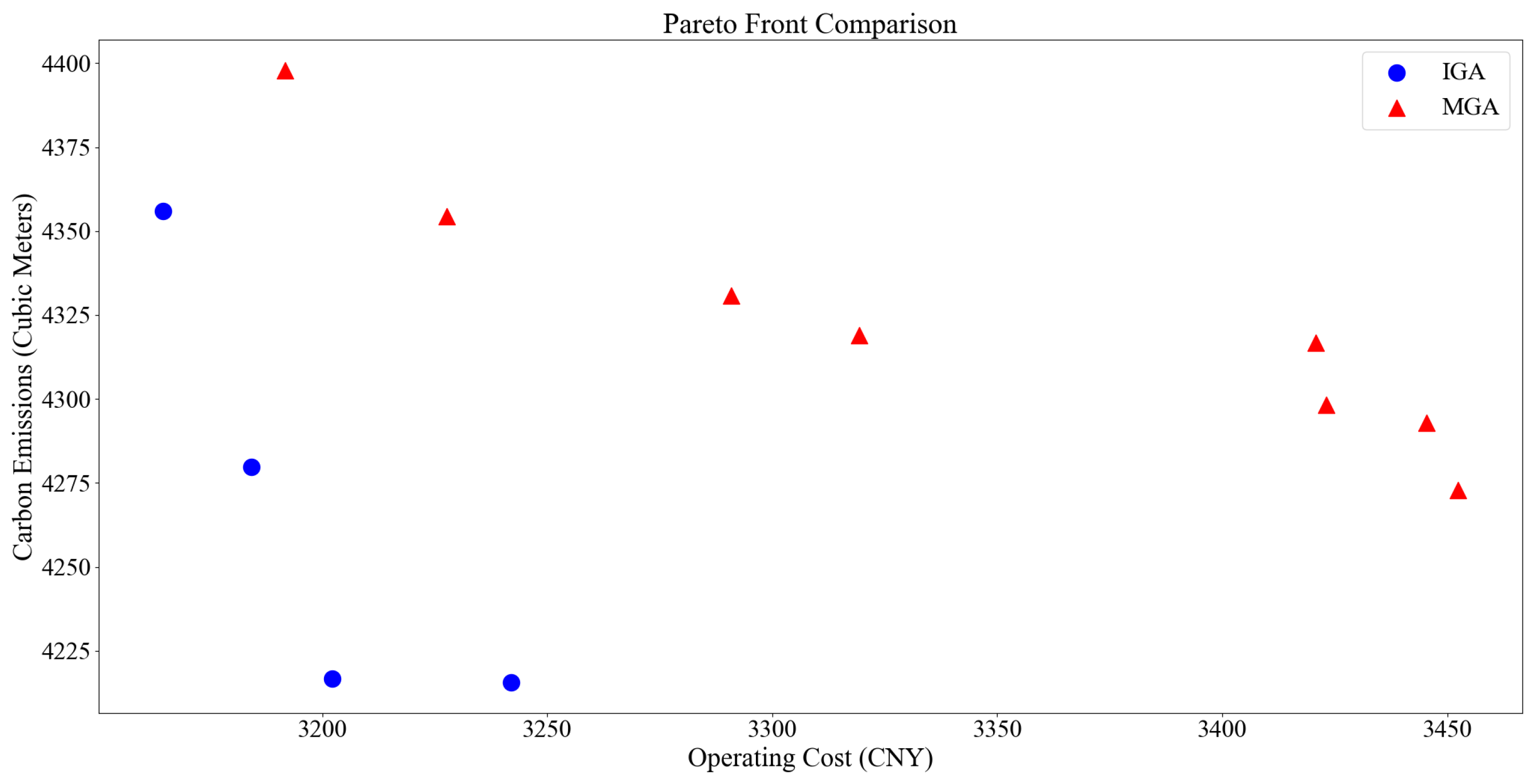

4.5. Comparison of the IGA with Other Heuristic Algorithms

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jia, C.; Liu, W.; He, H.; Chau, K.T. Deep reinforcement learning-based energy management strategy for fuel cell buses integrating future road information and cabin comfort control. Energy Convers. Manag. 2024, 321, 119032. [Google Scholar] [CrossRef]

- Jiang, B.; Yang, H.; Wang, Y.; Liu, Y.; Geng, H.; Zeng, H.; Ding, J. Dynamic Temporal Dependency Model for Multiple Steps Ahead Short-Term Load Forecasting of Power System. IEEE Trans. Ind. Appl. 2024, 60, 5244–5254. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, Y.; Wang, Q.; Geng, H. A Novel Interpretable Short-Term Load Forecasting Method Based on Kolmogorov-Arnold Networks. IEEE Trans. Power Syst. 2025, 40, 1180–1183. [Google Scholar] [CrossRef]

- Song, D.; Meng, W.; Dong, M.; Yang, J.; Wang, J.; Chen, X.; Huang, L. A critical survey of integrated energy system: Summaries, methodologies and analysis. Energy Convers. Manag. 2022, 266, 115863. [Google Scholar] [CrossRef]

- Berjawi, A.; Walker, S.; Patsios, C.; Hosseini, S. An evaluation framework for future integrated energy systems: A whole energy systems approach. Renew. Sustain. Energy Rev. 2021, 145, 111163. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, K.; Yang, S. A review of residential tiered electricity pricing in China. Renew. Sustain. Energy Rev. 2017, 79, 533–543. [Google Scholar] [CrossRef]

- Lv, G.; Zhang, Y.; Zhu, J.; Liu, L.; Wu, Y.; Wang, T. Low-carbon optimal operation of electricity—Heat—Gas systems based on bi-directional tiered-pricing carbon trading. Energy Rep. 2023, 9, 377–387. [Google Scholar] [CrossRef]

- Kuang, Y.; Lin, B. Performance of tiered pricing policy for residential natural gas in China: Does the income effect matter? Appl. Energy 2021, 304, 117776. [Google Scholar] [CrossRef]

- Keshavarzzadeh, A.H.; Ahmadi, P. Multi-objective techno-economic optimization of a solar based integrated energy system using various optimization methods. Energy Convers. Manag. 2019, 196, 196–210. [Google Scholar] [CrossRef]

- Yang, P.; Jiang, H.; Liu, C.; Kang, L.; Wang, C. Coordinated optimization scheduling operation of integrated energy system considering demand response and carbon trading mechanism. Int. J. Electr. Power Energy Syst. 2023, 147, 108902. [Google Scholar] [CrossRef]

- Chen, M.; Lu, H.; Chang, X.; Liao, H. An optimization on an integrated energy system of combined heat and power, carbon capture system and power to gas by considering flexible load. Energy 2023, 273, 127203. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, L.; Ma, Y.; Han, X.; Xing, J.; Miao, W.; Wang, H. Study on operation optimization of decentralized integrated energy system in northern rural areas based on multi-objective. Energy Rep. 2022, 8, 3063–3084. [Google Scholar] [CrossRef]

- Zhong, J.; Li, Y.; Cao, Y.; Tan, Y.; Peng, Y.; Zeng, Z.; Cao, L. Stochastic optimization of integrated energy system considering network dynamic characteristics and psychological preference. J. Clean. Prod. 2020, 275, 122992. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Yan, P.; Li, X.; Zhou, G.; Yu, D. Operation Optimization of Integrated Energy System under a Renewable Energy Dominated Future Scene Considering Both Independence and Benefit: A Review. Energies 2021, 14, 1103. [Google Scholar] [CrossRef]

- Zhang, A.; Zhang, H.; Qadrdan, M.; Yang, W.; Jin, X.; Wu, J. Optimal Planning of Integrated Energy Systems for Offshore Oil Extraction and Processing Platforms. Energies 2019, 12, 756. [Google Scholar] [CrossRef]

- Carvalho, É.C.; Bernardino, H.S.; Hallak, P.H.; Lemonge, A.C. An adaptive penalty scheme to solve constrained structural optimization problems by a Craziness based Particle Swarm Optimization. Optim. Eng. 2017, 18, 693–722. [Google Scholar] [CrossRef]

- Wang, Q.; Hobbs, W.B.; Tuohy, A.; Bello, M.; Ault, D.J. Evaluating Potential Benefits of Flexible Solar Power Generation in the Southern Company System. IEEE J. Photovoltaics 2022, 12, 152–160. [Google Scholar] [CrossRef]

- Niu, S.; Zhao, Q.; Niu, S.; Jian, L. A Comprehensive Investigation of Thermal Risks in Wireless EV Chargers Considering Spatial Misalignment from a Dynamic Perspective. IEEE J. Emerg. Sel. Top. Ind. Electron. 2024, 5, 1560–1571. [Google Scholar] [CrossRef]

- Li, W.; Wang, Q. A Linked Swing Contract Market Design with High Renewable Penetration and Battery Firming. IEEE Trans. Power Syst. 2024, 39, 2723–2734. [Google Scholar] [CrossRef]

- Yang, C.; Song, B.; Xie, Y.; Zheng, S.; Tang, X. Adaptive Identification of Nonlinear Friction and Load Torque for PMSM Drives via a Parallel-Observer-Based Network with Model Compensation. IEEE Trans. Power Electron. 2023, 38, 5875–5897. [Google Scholar] [CrossRef]

- Hong Kong Electric Company. Residential Electricity Price List. 2023. Available online: https://www.hkelectric.com/documents/zh/CustomerServices/Documents/HKE_Tariff_2023_Residential_zh.pdf (accessed on 24 April 2025).

- Michalewicz, Z.; Schoenauer, M. Evolutionary Algorithms for Constrained Parameter Optimization Problems. Evol. Comput. 1996, 4, 1–32. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T.A.M.T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, Y. A Multi-user Integrated Energy Service Sharing Method Considering Stepped Carbon Emission Cost. Mod. Electr. Power 2022, 38, 1–13. (In Chinese) [Google Scholar] [CrossRef]

- Coello, C.C.; Lechuga, M.S. MOPSO: A proposal for multiple objective particle swarm optimization. In Proceedings of the 2002 Congress on Evolutionary Computation. CEC’02 (Cat. No. 02TH8600), Honolulu, HI, USA, 12–17 May 2002; Volume 2, pp. 1051–1056. [Google Scholar]

- Akbari, R.; Hedayatzadeh, R.; Ziarati, K.; Hassanizadeh, B. A multi-objective artificial bee colony algorithm. Swarm Evol. Comput. 2012, 2, 39–52. [Google Scholar] [CrossRef]

| Algorithm | Scenario 1 | Scenario 2 | Scenario 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| V * | o1 * | o2 * | V * | o1 * | o2 * | V * | o1 * | o2 * | |

| IGA | 0.20 | 3202.13 | 4216.66 | 0.29 | 8094.54 | 5246.46 | 0.30 | 3381.65 | 4948.82 |

| MGA | 0.23 | 3290.70 | 4330.03 | 0.33 | 8156.91 | 5333.16 | 0.32 | 3447.34 | 4957.79 |

| MPSO | 17.6 | 3365.40 | 4524.81 | 13.4 | 8107.57 | 5348.40 | 10.91 | 3478.29 | 4965.16 |

| SGA | 0.18 | 3468.18 | 4463.21 | 0.32 | 8295.44 | 5453.69 | 0.30 | 3486.24 | 4975.41 |

| MABC | 2.5 | 3234.07 | 4253.31 | 4.8 | 8120.60 | 5309.64 | 3.74 | 3397.34 | 4955.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Y.; Gao, C.; Xu, Z.; Ren, S.; Wu, D. Multi-Objective Optimization for the Low-Carbon Operation of Integrated Energy Systems Based on an Improved Genetic Algorithm. Energies 2025, 18, 2283. https://doi.org/10.3390/en18092283

Duan Y, Gao C, Xu Z, Ren S, Wu D. Multi-Objective Optimization for the Low-Carbon Operation of Integrated Energy Systems Based on an Improved Genetic Algorithm. Energies. 2025; 18(9):2283. https://doi.org/10.3390/en18092283

Chicago/Turabian StyleDuan, Yao, Chong Gao, Zhiheng Xu, Songyan Ren, and Donghong Wu. 2025. "Multi-Objective Optimization for the Low-Carbon Operation of Integrated Energy Systems Based on an Improved Genetic Algorithm" Energies 18, no. 9: 2283. https://doi.org/10.3390/en18092283

APA StyleDuan, Y., Gao, C., Xu, Z., Ren, S., & Wu, D. (2025). Multi-Objective Optimization for the Low-Carbon Operation of Integrated Energy Systems Based on an Improved Genetic Algorithm. Energies, 18(9), 2283. https://doi.org/10.3390/en18092283