Day-Ahead Optimal Scheduling of an Integrated Electricity-Heat-Gas-Cooling-Hydrogen Energy System Considering Stepped Carbon Trading

Abstract

1. Introduction

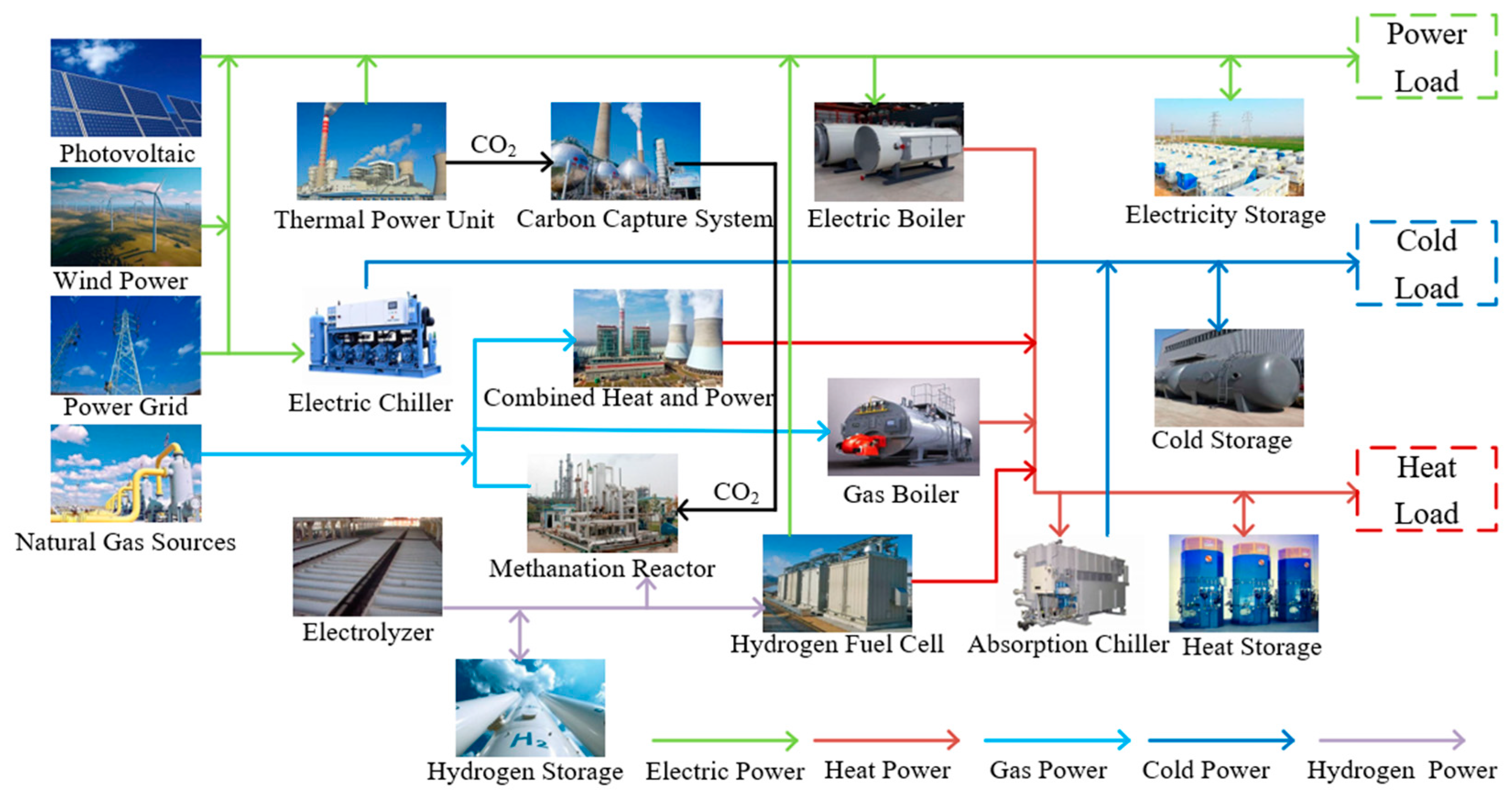

- The optimal scheduling model containing equipment such as P2G, hydrogen fuel cells, and cogeneration units is constructed, which enhances the coupling of electric, heat, gas, cold, and hydrogen subsystems.

- The refined modeling of P2G, together with the inclusion of hydrogen fuel cells and CCS, improves the utilization of renewable energy and solves the carbon source problem of the hydrogen-to-methane process while lowering the system’s carbon emissions even more.

- The implementation of a positive and negative tiered carbon trading mechanism, thereby establishing an effective market-based incentive system, demonstrates significant practical significance for advancing carbon-emission reduction through decreased CO2 emissions in integrated energy service systems at the market level.

2. IES Architecture and Mathematical Modelling

2.1. IES Model Establishment

2.1.1. Electrolyzer (EL)

2.1.2. Hydrogen Fuel Cell (HFC)

2.1.3. Methane Reactor (MR)

2.1.4. Carbon Capture Power Plants

2.1.5. Combined Heat and Power (CHP)

2.1.6. Gas Boiler (GB)

2.1.7. Electric Boiler (EB)

2.1.8. Electric Chillers (EC)

2.1.9. Absorption Chiller (AC)

2.1.10. Energy Storage Device

2.2. Carbon Emission Model

3. Objective Functions and Constraint Conditions

3.1. Objective Functions

3.2. Constraint Conditions

4. Case Study

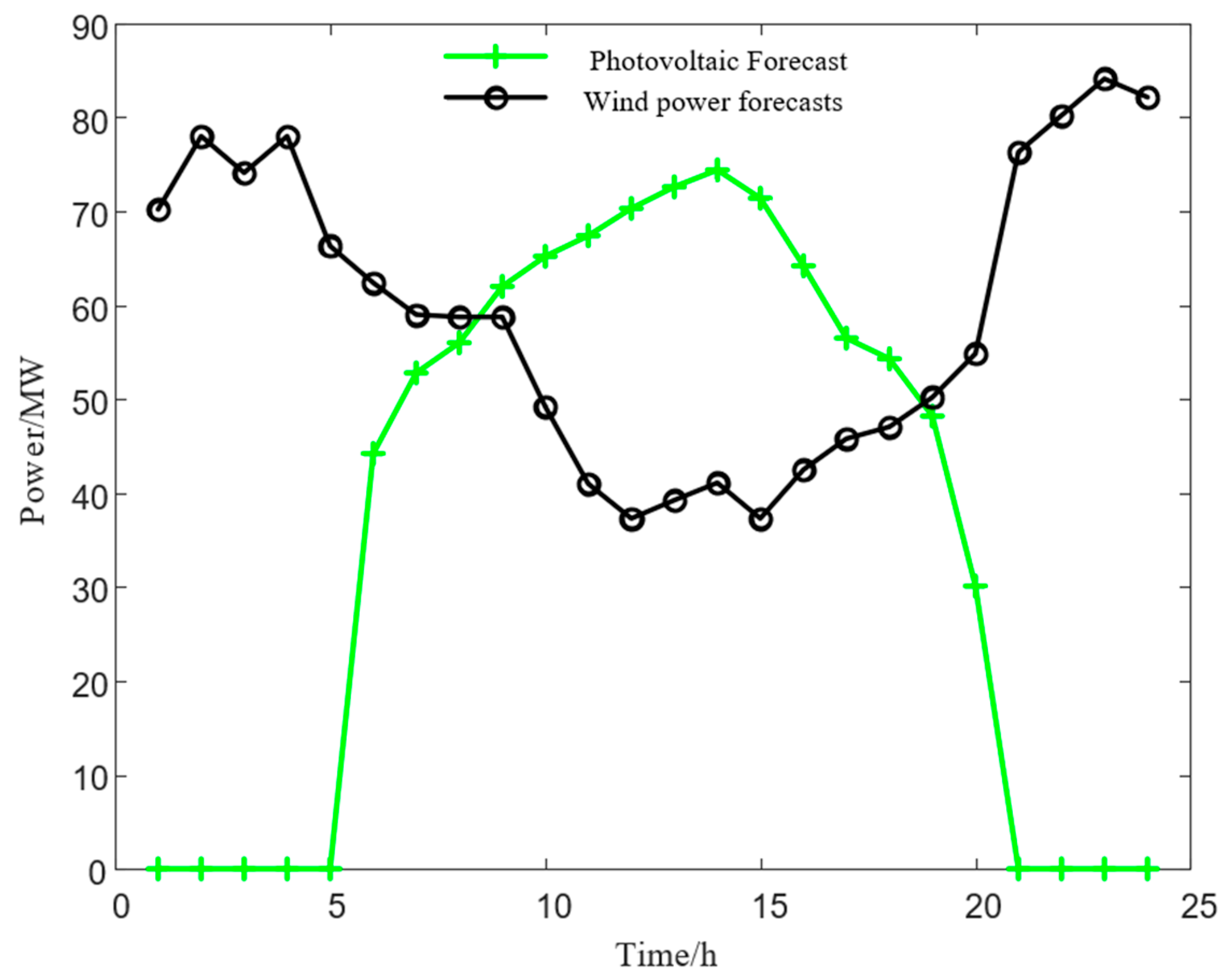

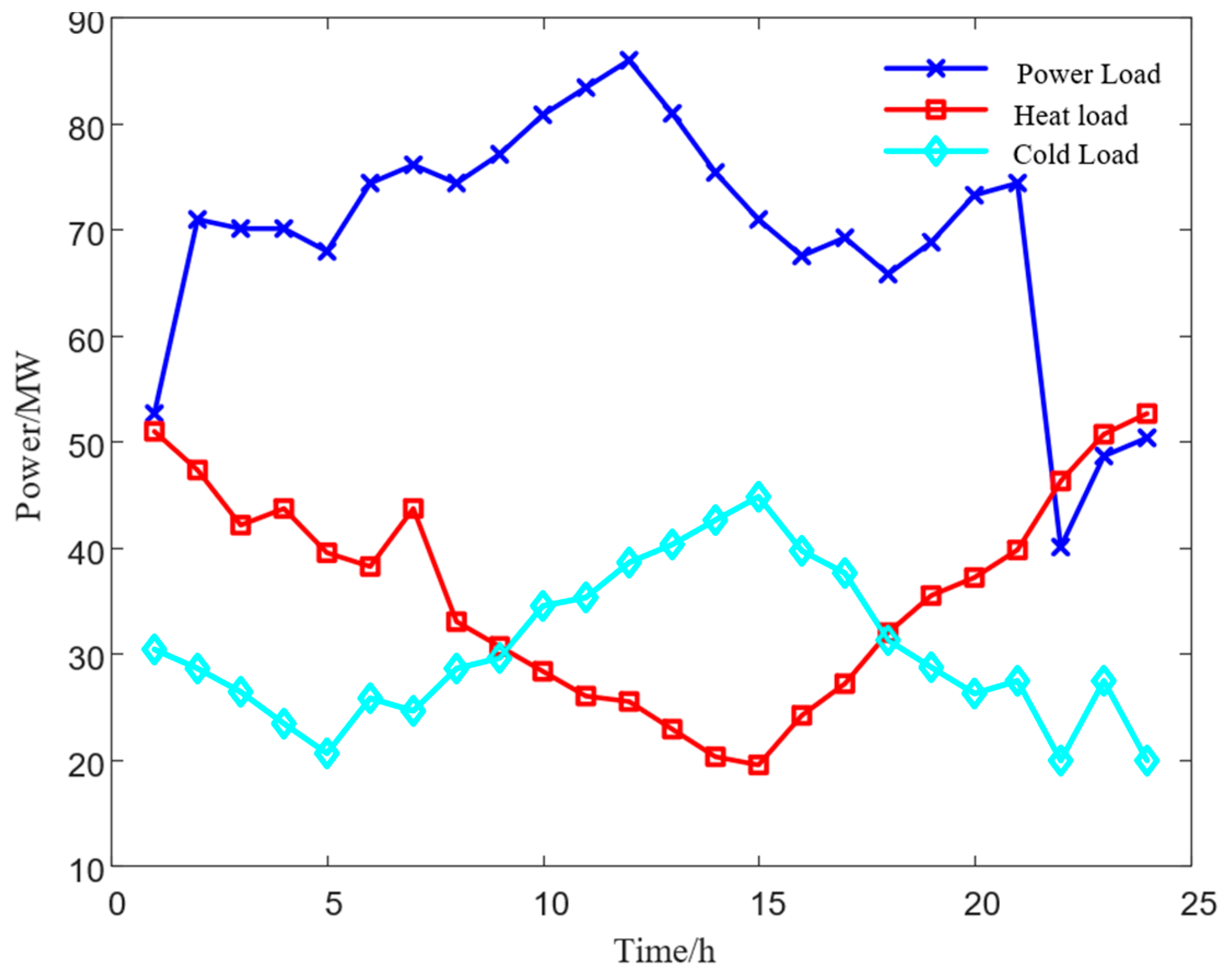

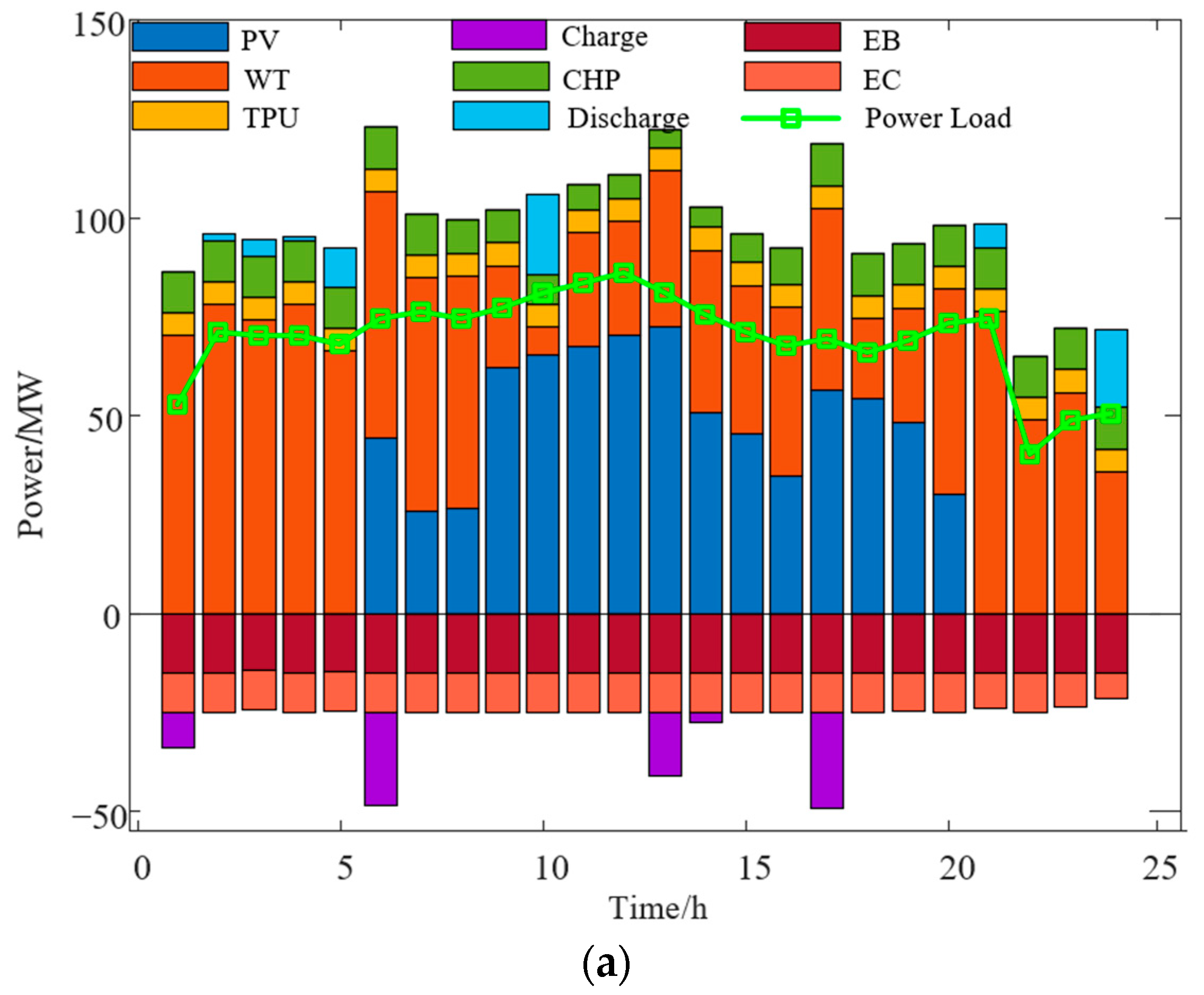

Basic Data

5. Conclusions

- The traditional P2G equipment is refined into two parts: an electrolyzer and an MR, and an HFC is introduced to reduce carbon emissions by utilizing the CO2 produced by the system while promoting wind energy consumption. Through arithmetic simulation, the renewable energy consumption rate is increased from 83.16% to 100%, and the carbon emission is reduced from 159.45 tonnes to 133 tonnes.

- Introduced a phased carbon trading mechanism to minimize emissions by adjusting the output of each part of the system, in which the penalty and reward mechanism of the market for trading in carbon can guide participants to prioritize the use of energy with minimal environmental impact, and the data reveal that the system’s releases of carbon have been decreased from 133 tonnes to 104.65 tonnes after implementing into consideration the phased trading of carbon.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| IES | integrated energy system | AC | absorption chiller |

| CHP | combined heat and power | EL | electrolyzer |

| PV | photovoltaic | HFC | hydrogen fuel cell |

| WT | wind turbine | MR | methane reactor |

| TPU | thermal power unit | ES | electricity storage |

| GB | gas boiler | H2S | hydrogen storage |

| EB | electric boiler | HS | heat storage |

| EC | electric chiller | CS | cold storage |

| P2G | power-to-gas | MILP | mixed-integer linear programming |

References

- Cheng, Y.; Liu, M.; Chen, H.; Yang, Z. Optimization of multi-carrier energy system based on new operation mechanism modelling of power-to-gas integrated with CO2-based electrothermal energy storage. Energy 2021, 216, 119269. [Google Scholar] [CrossRef]

- Chattopadhyay, A.; Witmer, A.-P.; Sauer, P.W. The Need for Teaching Place-Based Contextualization for Sustainable Power System Infrastructure Design. IEEE Trans. Power Syst. 2021, 36, 5846–5853. [Google Scholar] [CrossRef]

- Rabbi, M.F.; Popp, J.; Mate, D.; Kovacs, S. Energy Security and Energy Transition to Achieve Carbon Neutrality. Energies 2022, 15, 8126. [Google Scholar] [CrossRef]

- Gu, W.; Wang, Z.; Wu, Z.; Luo, Z.; Tang, Y.; Wang, J. An Online Optimal Dispatch Schedule for CCHP Microgrids Based on Model Predictive Control. IEEE Trans. Smart Grid 2017, 8, 2332–2342. [Google Scholar] [CrossRef]

- Qin, C.; Zhao, J.; Chen, L.; Liu, Y.; Wang, W. An adaptive piecewise linearized weighted directed graph for the modeling and operational optimization of integrated energy systems. Energy 2022, 244, 122616. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Huang, Y.; Yu, H.; Du, R.; Zhang, F.; Zhang, F.; Zhu, J. Optimal Scheduling of the Regional Integrated Energy System Considering Economy and Environment. IEEE Trans. Sustain. Energy 2019, 10, 1939–1949. [Google Scholar] [CrossRef]

- Zhang, J.; Kong, X.; Shen, J.; Sun, L. Day-ahead optimal scheduling of a standalone solar-wind-gas based integrated energy system with and without considering thermal inertia and user comfort. J. Energy Storage 2023, 57, 106187. [Google Scholar] [CrossRef]

- Ge, L.; Zhang, B.; Huang, W.; Li, Y.; Hou, L.; Xiao, J.; Mao, Z.; Li, X. A review of hydrogen generation, storage, and applications in power system. J. Energy Storage 2024, 75, 109307. [Google Scholar] [CrossRef]

- Laimon, M.; Yusaf, T. Towards energy freedom: Exploring sustainable solutions for energy independence and self-sufficiency using integrated renewable energy-driven hydrogen system. Renew. Energy 2024, 222, 119948. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Y.; Ji, T.; Cai, Z.; Li, L.; Xu, Z. Coordinated optimal dispatch and market equilibrium of integrated electric power and natural gas networks with P2G embedded. J. Mod. Power Syst. Clean Energy 2018, 6, 495–508. [Google Scholar] [CrossRef]

- Walker, S.B.; van Lanen, D.; Fowler, M.; Mukherjee, U. Economic analysis with respect to Power-to-Gas energy storage with consideration of various market mechanisms. Int. J. Hydrogen Energy 2016, 41, 7754–7765. [Google Scholar] [CrossRef]

- Guandalini, G.; Campanari, S.; Romano, M.C. Power-to-gas plants and gas turbines for improved wind energy dispatchability: Energy and economic assessment. Appl. Energy 2015, 147, 117–130. [Google Scholar] [CrossRef]

- Wang, S.; Wang, S.; Zhao, Q.; Dong, S.; Li, H. Optimal dispatch of integrated energy station considering carbon capture and hydrogen demand. Energy 2023, 269, 126981. [Google Scholar] [CrossRef]

- Chen, M.; Lu, H.; Chang, X.; Liao, H. An optimization on an integrated energy system of combined heat and power, carbon capture system and power to gas by considering flexible load. Energy 2023, 273, 127203. [Google Scholar] [CrossRef]

- Pan, C.; Jin, T.; Li, N.; Wang, G.; Hou, X.; Gu, Y. Multi-objective and two-stage optimization study of integrated energy systems considering P2G and integrated demand responses. Energy 2023, 270, 126846. [Google Scholar] [CrossRef]

- Zeng, Z.; Ding, T.; Xu, Y.; Yang, Y.; Dong, Z. Reliability Evaluation for Integrated Power-Gas Systems with Power-to-Gas and Gas Storages. IEEE Trans. Power Syst. 2020, 35, 571–583. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, H.; Hong, F.; Yang, J.; Chen, Z.; Cui, H.; Feng, J. Modeling and optimization of combined heat and power with power-to-gas and carbon capture system in integrated energy system. Energy 2021, 236, 121392. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Huang, Y.; Yang, J.; Ma, Y.; Yu, H.; Zeng, M.; Zhang, F.; Zhang, Y. Operation optimization of regional integrated energy system based on the modeling of electricity-thermal-natural gas network. Appl. Energy 2019, 251, 113410. [Google Scholar] [CrossRef]

- Lu, Z.; Bai, L.; Wang, J.; Wei, J.; Xiao, Y.; Chen, Y. Peer-to-Peer Joint Electricity and Carbon Trading Based on Carbon-Aware Distribution Locational Marginal Pricing. IEEE Trans. Power Syst. 2023, 38, 835–852. [Google Scholar] [CrossRef]

- Song, M.; Zheng, H.; Shen, Z. Whether the carbon emissions trading system improves energy efficiency-Empirical testing based on China’s provincial panel data. Energy 2023, 275, 127465. [Google Scholar] [CrossRef]

- Chen, X.; Lin, B. Towards carbon neutrality by implementing carbon emissions trading scheme: Policy evaluation in China. Energy Policy 2021, 157, 112510. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Z. Low carbon economic scheduling model for a park integrated energy system considering integrated demand response, ladder-type carbon trading and fine utilization of hydrogen. Energy 2024, 290, 130311. [Google Scholar] [CrossRef]

- Mochi, P.; Espegren, K.A.; Korpas, M. Short communication: Local electricity-hydrogen market. Int. J. Hydrogen Energy 2025, 116, 17–22. [Google Scholar] [CrossRef]

- Li, Y.; Bu, F.; Gao, J.; Li, G. Optimal dispatch of low-carbon integrated energy system considering nuclear heating and carbon trading. J. Clean Prod. 2022, 378, 134540. [Google Scholar] [CrossRef]

- Turner, J.; Sverdrup, G.; Mann, M.K.; Maness, P.-C.; Kroposki, B.; Ghirardi, M.; Evans, R.J.; Blake, D. Renewable hydrogen production. Int. J. Energy Res. 2008, 32, 379–407. [Google Scholar] [CrossRef]

- Mulky, L.; Srivastava, S.; Lakshmi, T.; Sandadi, E.R.; Gour, S.; Thomas, N.A.; Priya, S.S.; Sudhakar, K. An overview of hydrogen storage technologies—Key challenges and opportunities. Mater. Chem. Phys. 2024, 325, 129710. [Google Scholar] [CrossRef]

- Olabi, A.G.; Sayed, E.T. Developments in Hydrogen Fuel Cells. Energies 2023, 16, 2431. [Google Scholar] [CrossRef]

- Cui, Y.; Zeng, P.; Hui, X.; Li, H.; Zhao, J. Low-carbon Economic Dispatch Considering the Integrated Flexible Operation Mode of Carbon Capture Power Plant. Power Syst. Technol. 2021, 45, 1877–1885. [Google Scholar]

- Deng, Y.; Zeng, R.; Liu, Y. A novel off-design model to optimize combined cooling, heating and power system with hybrid chillers for different operation strategies. Energy 2022, 239, 122085. [Google Scholar] [CrossRef]

- Liu, M.; Cheng, Y.; Cheng, W.; Zhan, C. Dynamic performance analysis of a solar driving absorption chiller integrated with absorption thermal energy storage. Energy Conv. Manag. 2021, 247, 114769. [Google Scholar] [CrossRef]

- Shi, B.; Li, N.; Gao, Q.; Li, G. Market incentives, carbon quota allocation and carbon emission reduction: Evidence from China’s carbon trading pilot policy. J. Environ. Manag. 2022, 319, 115650. [Google Scholar] [CrossRef]

- Yang, C.; Dong, X.; Wang, G.; Lv, D.; Gu, R.; Lei, Y. Low-carbon economic dispatch of integrated energy system with CCS-P2G-CHP. Energy Rep. 2024, 12, 42–51. [Google Scholar] [CrossRef]

- Zhu, G.; Gao, Y. Multi-objective optimal scheduling of an integrated energy system under the multi-time scale ladder-type carbon trading mechanism. J. Clean Prod. 2023, 417, 137922. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| ηEL [22] | 0.87 | 0 MW | |

| 40 MW | Δ | −8 MW | |

| Δ | 8 MW | ηHFC,E | 0.87 |

| 15 MW | 0 MW | ||

| Δ | 3 MW | Δ | −3 MW |

| 1.2 | 0.5 | ||

| 0 MW | ηMR | 0.7 [22] | |

| Δ | −4 MW | 20 MW | |

| eg [28] | 1 (t/MW·h) | Δ | 4 MW |

| β [28] | 0.9 | δ [28] | 0.8 |

| ε [28] | 0.269 ((MW·h)/t) | η [28] | 1.05 |

| 10 MW | PD | 2 MW | |

| Δ | −60 | 55 MW | |

| 0 MW | Δ | 60 MW | |

| Δ | −4 MW | 20 MW | |

| 0.5 | Δ | −4 MW | |

| ηGB [22] | 0.9 | 1.8 | |

| 15 MW | 0 MW | ||

| Δ | 3 MW | Δ | −3 MW |

| 0 MW | ηEB,E | 0.99 | |

| Δ | −3 MW | 15 MW | |

| ηEC,E [22] | 3 | Δ | 3 MW |

| 10 MW | 0 MW | ||

| Δ | 2 MW | Δ | −2 MW |

| 0 MW | ηAC,H | 1.8 | |

| Δ | −6 MW | 15 MW | |

| Δ | 6 MW | l | 200 t |

| λ [33] | 250 RMB/t | α [33] | 0.25 |

| ηi,in [22] | 0.95 | ηi,in [22] | 0.95 |

| ηloss [15] | 0.01 | βcc [14] | 1.02 |

| Type | Time (h) | Price (RMB/MWh) |

|---|---|---|

| Peak data | 8:00–11:00 | 1000 |

| 19:00–24:00 | ||

| Off-peak data | 11:00–13:00 | 810 |

| 17:00–19:00 | ||

| 0:00–4:00 | ||

| Valley data | 4:00–8:00 | 670 |

| 13:00–17:00 |

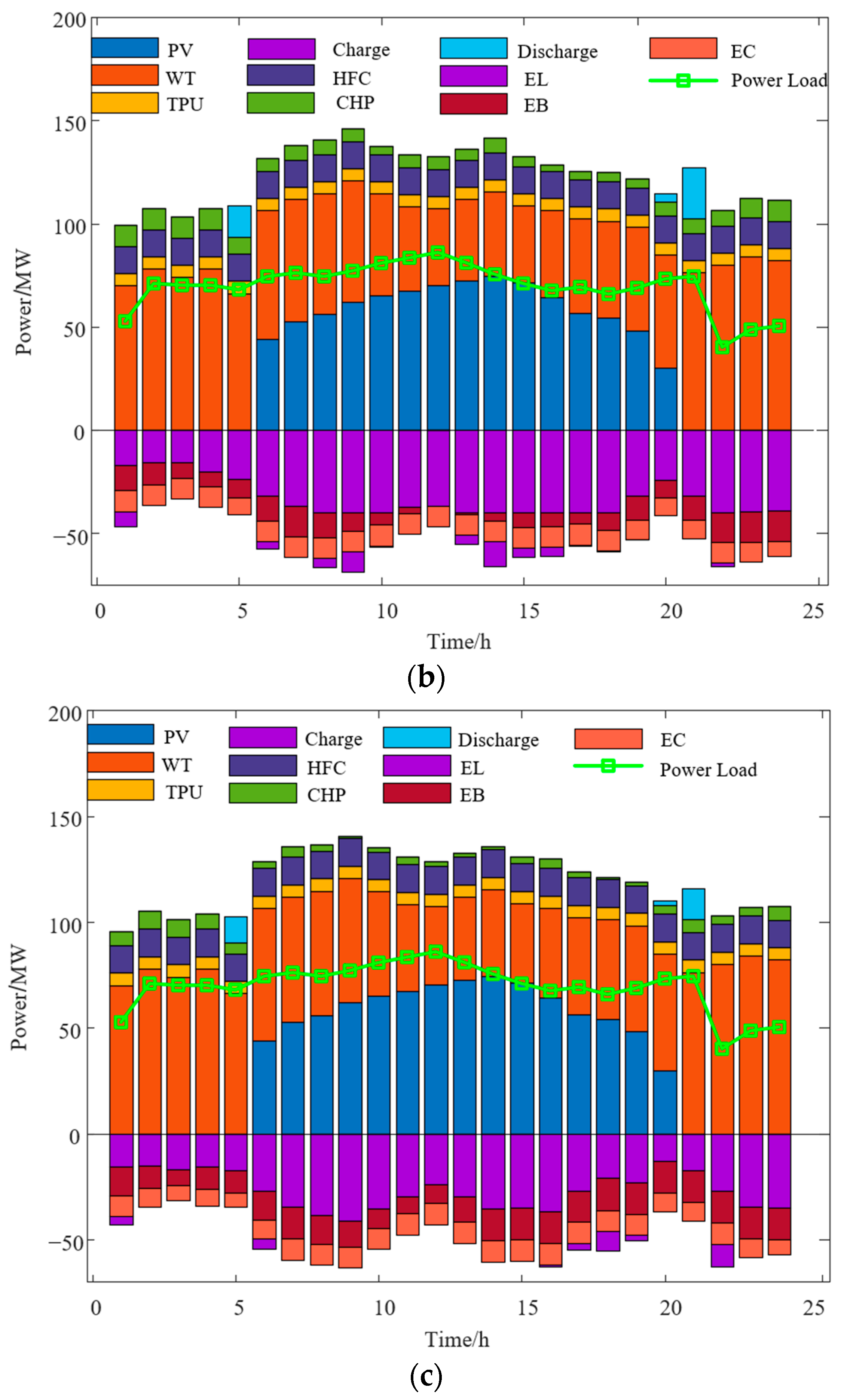

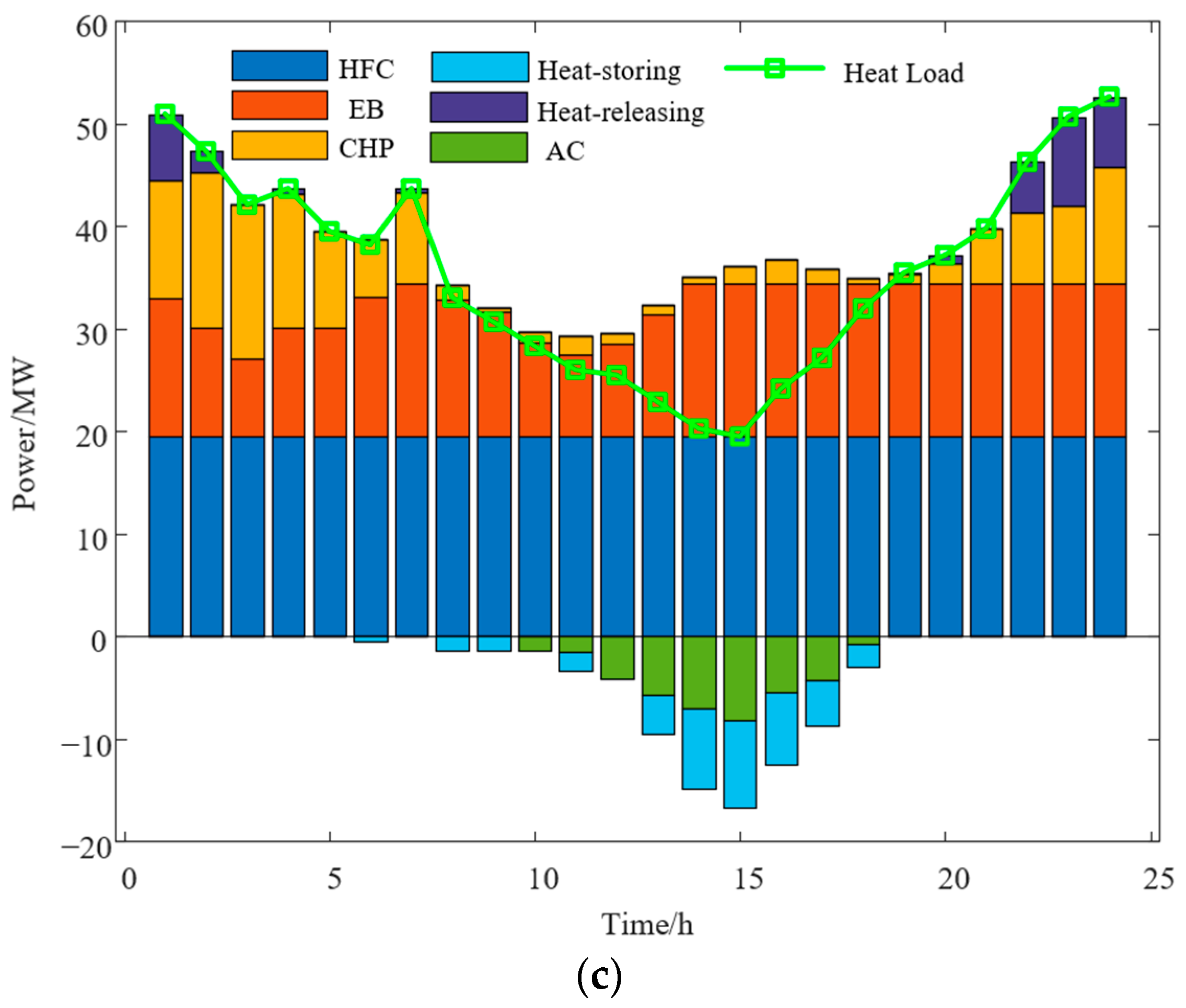

| Case | Condition |

|---|---|

| Case 1 | An IES do not take into account carbon trading and hydrogen participation |

| Case 2 | An IES consider hydrogen participation based on case 1 |

| Case 3 | An IES consider stepped carbon trading based on case 2 |

| Case | Renewable Energy Consumption/% | Cost/RMB | Carbon Emissions/t |

|---|---|---|---|

| 1 | 83.16% | 312,737.89 | 159.45 |

| 2 | 100.00% | 186,047.03 | 133.00 |

| 3 | 100.00% | 129,423.99 | 104.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Lin, W.; Bian, J.; Ren, X. Day-Ahead Optimal Scheduling of an Integrated Electricity-Heat-Gas-Cooling-Hydrogen Energy System Considering Stepped Carbon Trading. Energies 2025, 18, 2249. https://doi.org/10.3390/en18092249

Zhou Z, Lin W, Bian J, Ren X. Day-Ahead Optimal Scheduling of an Integrated Electricity-Heat-Gas-Cooling-Hydrogen Energy System Considering Stepped Carbon Trading. Energies. 2025; 18(9):2249. https://doi.org/10.3390/en18092249

Chicago/Turabian StyleZhou, Zhuan, Weifang Lin, Jiayu Bian, and Xuan Ren. 2025. "Day-Ahead Optimal Scheduling of an Integrated Electricity-Heat-Gas-Cooling-Hydrogen Energy System Considering Stepped Carbon Trading" Energies 18, no. 9: 2249. https://doi.org/10.3390/en18092249

APA StyleZhou, Z., Lin, W., Bian, J., & Ren, X. (2025). Day-Ahead Optimal Scheduling of an Integrated Electricity-Heat-Gas-Cooling-Hydrogen Energy System Considering Stepped Carbon Trading. Energies, 18(9), 2249. https://doi.org/10.3390/en18092249