1. Introduction

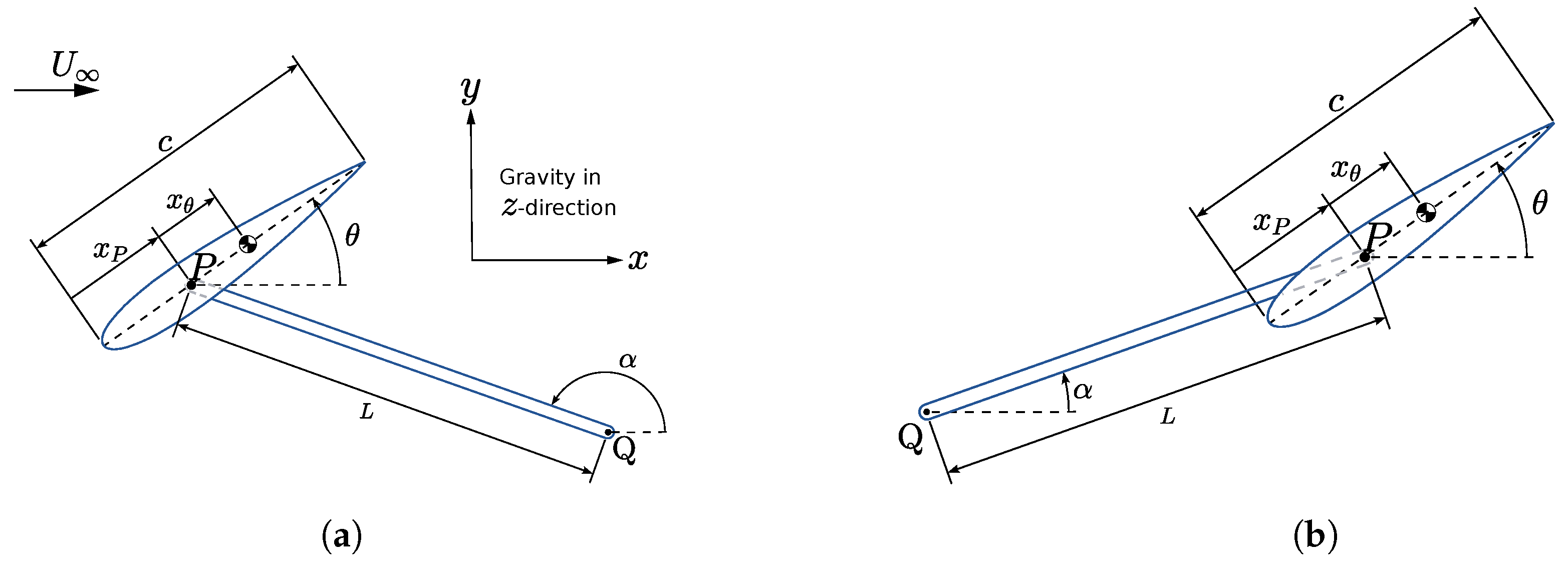

In order to diminish pollution and its many undesirable consequences on human and animal health and on the Earth’s environment, advances in renewable energy technologies are crucial. In the field of hydrokinetic energy, promising developments regarding oscillating-foil turbines (OFTs) have been realized in recent years. An OFT uses a combination of linear heave and pitch motions about a pivot point along the chord line (typically located at around a third of the foil’s chord from the leading edge). This type of turbine is particularly well suited for extracting energy from rivers and tidal flows and holds its own advantages compared to the classical horizontal-axis turbine. Notably, it has a simpler blade geometry, which could reduce fabrication costs, and it operates across a rectangular extraction plane rather than a circular one, making it an attractive option for shallow waters without compromising on power production. In addition, the OFT concept has been demonstrated by many CFD and experimental studies [

1] to reach performances comparable to modern rotor blade turbines. In this study, we refer to the efficiency and the power coefficient when discussing performance.

The first model of the OFT, developed in the early 1980s by McKinney and DeLaurier [

2] had fully constrained sinusoidal motions in both heave and pitch degrees of freedom. Thereafter, efforts from several groups have allowed us to identify the best parameters for such a device, leading to the acknowledgment of the great potential of this turbine concept for energy extraction [

3,

4,

5].

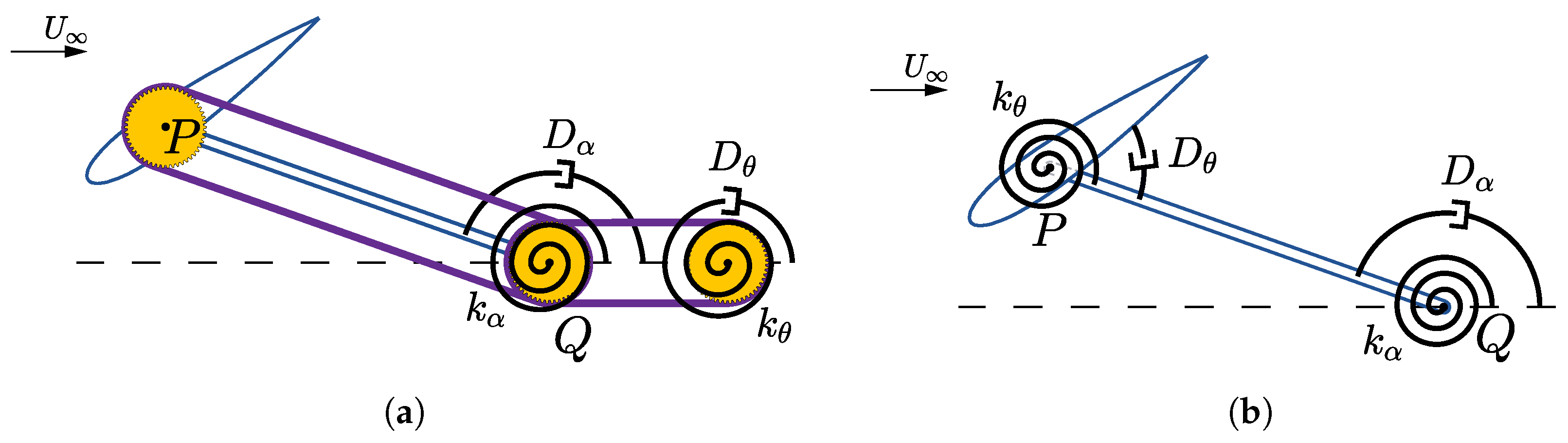

As the research progressed, attention was given to alternate versions of the concept, of which the three main versions are said to be fully-constrained (FC-OFTs), semi-passive (SP-OFTs), and fully-passive OFTs (FP-OFTs). Much interest has been given to both passive models for which the pitch motion or both the pitch and heave motions are only restricted by springs and dampers, rather than being kinetically constrained by bar links. In the case of the SP-OFT, the typical design choice is to control the pitching while allowing the heaving motion to respond passively to the pitching input. However, it is possible to control the heaving while allowing the pitching motion to be the passive response. Indeed, in a two-dimensional CFD study on the SP-OFT with a prescribed heave motion and a passive pitch motion, Boudreau et al. [

6] found a maximum efficiency of 45.4%. They further noted that the efficiency of the turbine was increased when no leading-edge vortices (LEVs) were shed at high Reynolds numbers.

Boudreau et al. [

7] then used the insight from their work on the SP-OFTs to find optimal structural parameters for the FP-OFT, where both heave and pitch motions are left unconstrained. Their best configuration, reaching an efficiency value as high as 51%, used similar structural parameters to those of their SP-OFT study. This showed that letting the whole system respond passively to the incoming flow, given carefully chosen parameters, can perform better than its semi-passive counterpart with sinusoidal heaving.

Experimental studies have also been carried out to validate the performance of the FP-OFT. Indeed, from their initial CFD analysis of the FP-OFT, Duarte et al. [

8] constructed an experimental apparatus to validate the simulated results. They found that, though the turbine could attain self-sustained oscillations, the friction between physical components was a serious challenge. Following these results, they also investigated the dynamic behavior of a FP-OFT with respect to the location of its pitching axis along its chord, as well as its pitch spring stiffness [

9] and the pitching viscous damping [

10]. Their results showed that the turbine could reach four distinct responses of self-sustained oscillations, showing the high sensitivity of the turbine with respect to its structural parameters.

Mann et al. [

11] and Gunther et al. [

12] assessed, both experimentally and numerically, the effects of confinement on the performance of the FP-OFT. By varying the lateral distance between the walls of the channel, they found that the ratio of the swept area of the turbine to the cross-sectional area of the channel was optimal at 0.45. Beyond this optimal value, the performance of the FP-OFT rapidly decreased, providing insight into how sensitive the FP-OFT is to blockage.

Lee et al. [

13] studied the effects of the sweep angle of the foil (or a plate in their study) at different inflow velocities. They showed that, while the unswept plate saw a decrease in performances at higher inflow velocities, the swept plate kept relatively constant performances even at higher velocities.

Other experimental studies on the FP-OFT focused on the nature of the incoming flow. Oshkai et al. [

14] studied the reliability of an FP-OFT operating in a periodically perturbed inflow. By controlling the frequency and the heave and pitch amplitudes of an FC-OFT upstream of the FP-OFT, they controlled the incoming vortices and verified their effects on the FP-OFT. Under a certain frequency threshold, the FP-OFT performed adequately with steady-state oscillations.

Theodorakis et al. [

15] investigated the effects of a sheared incoming flow, suggesting that the performance of the turbine can be slightly increased under such flow conditions and that the standard uniform flow might not be the ideal one. The relevance of such an investigation stems from the fact that in shallow water applications, such as in rivers, the flow may very well be sheared due to the presence of a boundary layer at its bottom.

The complex motion of a passive OFT is solely determined by its structural parameters and the interaction of the foil with the incoming flow. Therefore, its advantage lies in a much simpler design that, ultimately, may yield increased robustness and less maintenance. Also, it is expected to reduce friction by eliminating the bar links present in the fully constrained contraption, while also eliminating the flow perturbations caused by the bar links. The semi- and fully passive OFTs also have the potential to be adaptable to different flow conditions, as they could be designed with adjustable structural parameters (springs’ stiffness, dampers’ coefficient, and pivot position).

Having 8 structural parameters [

7], the FP-OFT is quite complex to tune. It is thus critical to determine efficient sets of parameters that lead to stable cyclical motions. In recent years, two distinct FSI instabilities have been identified as possible driving mechanisms for OFTs [

16,

17], leading to two different turbine behaviors. In the first type of instability, dubbed the stall-flutter instability, the turbine’s pitch motion stems from the divergence instability, whereby the position of the pitch axis being downstream of the pressure center of the foil increases the angle of attack continuously. As the foil eventually reaches its instantaneous stalling angle of attack, a leading-edge vortex (LEV) is shed, and, as the heave motion comes to a maximum, the pitch spring brings the foil in the opposite pitching direction. This instability is very robust and achieves limit-cycle oscillations (LCOs) rapidly. Results from 2D URANS CFD simulations, placing the pitch axis at one-third of the chord length

, also report efficiency values near 35% [

18]. In the second type of instability, named the coupled-flutter instability, the motion is driven by the coupling of the pitching and heaving inertial components. This instability, which does not lead to the shedding of LEVs, is less robust against flow perturbations and takes longer to reach steady-state oscillations, but it offers excellent efficiency, with values as high as 53.8% obtained via 2D URANS CFD simulations [

7], with the pitch axis placed at one-quarter of the chord length

. These two instabilities have been studied for purely linear heaving motions, as would occur on a prototype on rails [

19], but they have not yet been studied specifically for arched heave motions. The term “railed” is used in this current study to denote a linear heaving motion.

For the OFT on a swinging arm (OFT-SA), most studies have been performed with fully constrained motions. This obviously stems from the fact that OFTs on rails with fully constrained motions have been the subject of exhaustive research in the last decades, making it possible to compare the new results of OFT-SAs with those of the OFT on rails.

Among these studies is the work of Huxham et al. [

20], who obtained, for a fixed damping coefficient, an efficiency value of 23.8%. Karbasian et al. [

21], on the other hand, studied the performance of a NACA0012 airfoil at a moderate Reynolds number (

) and observed that the position of the blade (upstream or downstream) had a significant impact on the performance of the OFT-SA. Indeed, a few years later, a comparison of the upstream, downstream, and rail configurations at a higher Reynolds number (

) was carried out by Sitorus and Ko [

22]. This numerical investigation, in which the length of the swinging arm was fixed to two chords, allowed them to state that the upstream configuration offered better performance compared to the downstream and railed configurations.

Some experimental investigations have also been carried out with an FP-OFT-SA. For instance, Sitorus et al. [

23] conducted tests for which the extracted power reached a maximum efficiency of 17%. Then, a numerical and experimental study was conducted by Liu et al. [

24] using a semi-passive OFT-SA with a prescribed pitch motion in the downstream configuration. They surprisingly observed that their 2D numerical model was just as qualified as their 3D model to adequately predict the results obtained experimentally.

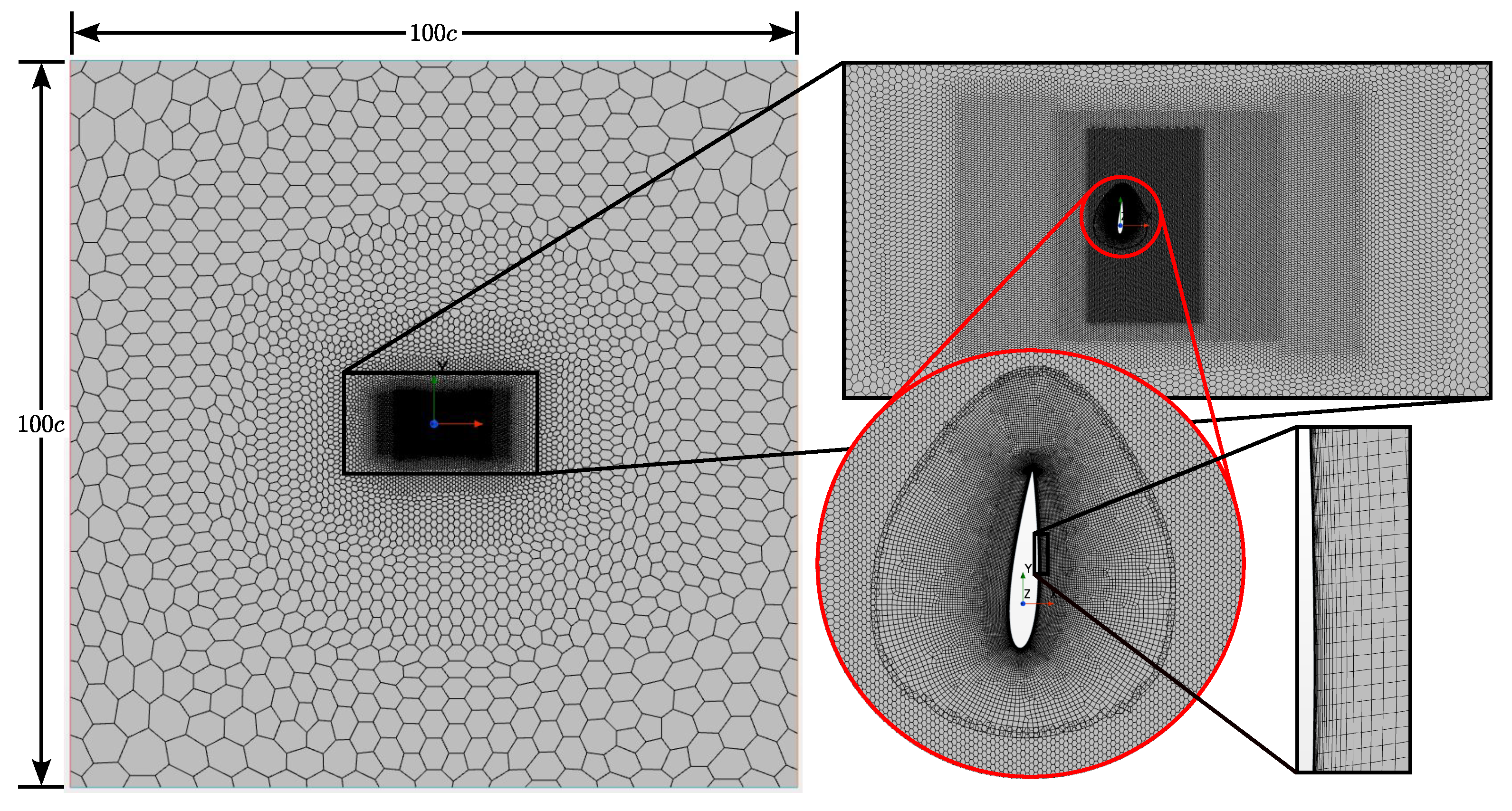

In this study, a new variant of the FP-OFT is investigated, where the foil is placed upon a swinging arm rather than on rails. This FP-OFT on a swinging arm (FP-OFT-SA) thus has the advantage of being mechanically much simpler. Indeed, a single pivot offers fewer mechanical constraints than rails, which have to be perfectly aligned to ensure proper sliding of the foil in the heaving motion. However, the effects of the foil’s circular trajectory are not well documented for the FP-OFT, thus motivating this research. Upstream and downstream rest positions are investigated with two variants regarding the setup for the pitch spring and damper. In order to assess the performance of this turbine concept, 2D URANS CFD simulations are carried out to evaluate its efficiency and power coefficient when using structural parameters derived from those of railed configurations from Boudreau et al. [

7] and Veilleux and Dumas [

18], while operating under, respectively, the coupled-flutter and stall-flutter instabilities. Indeed, the main contribution of this paper is to provide a better understanding of the swinging-arm oscillating-foil turbine and to determine operating configurations that reproduce or even improve the high performances predicted for the railed configurations that undergo a similar but linear motion.

4. Conclusions

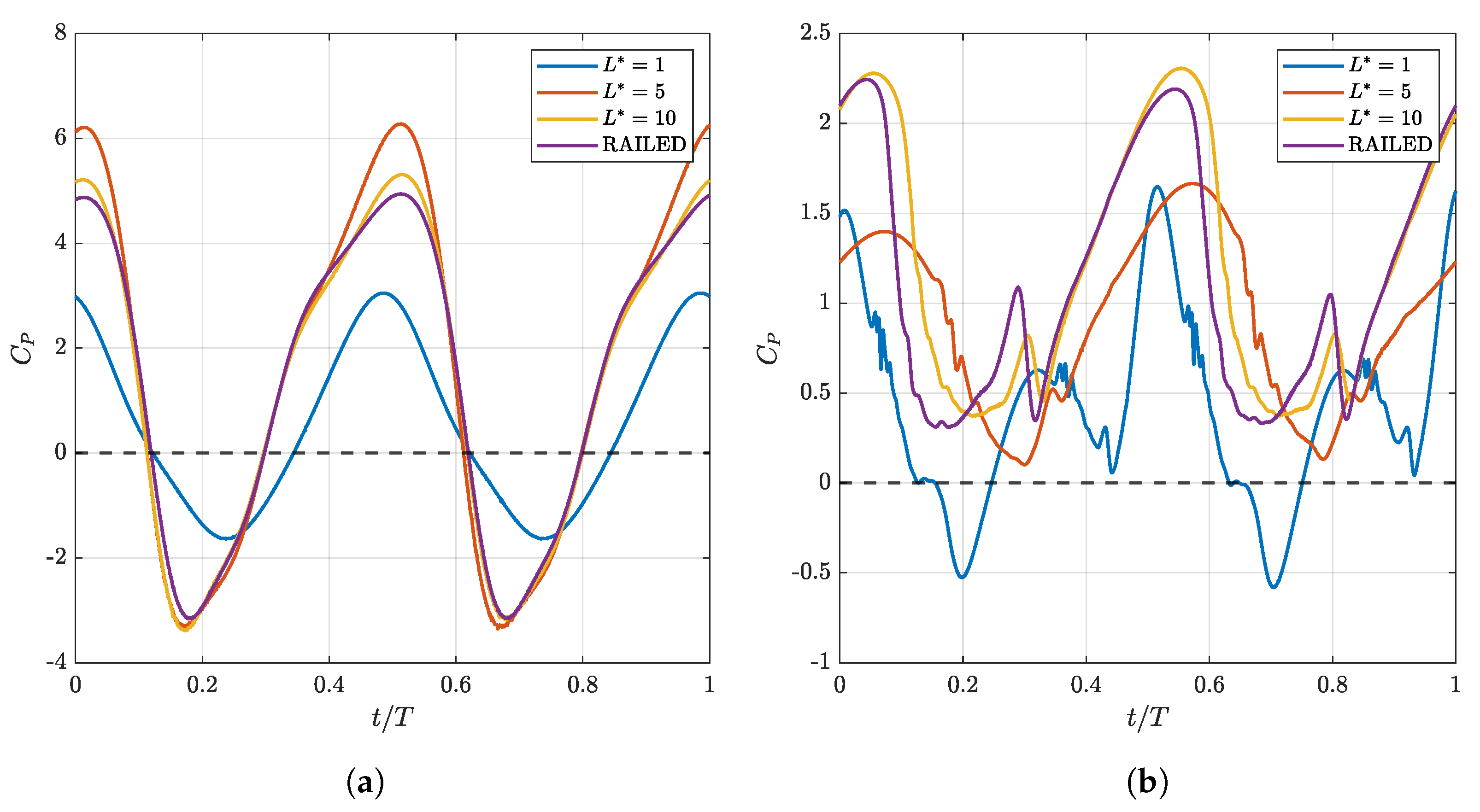

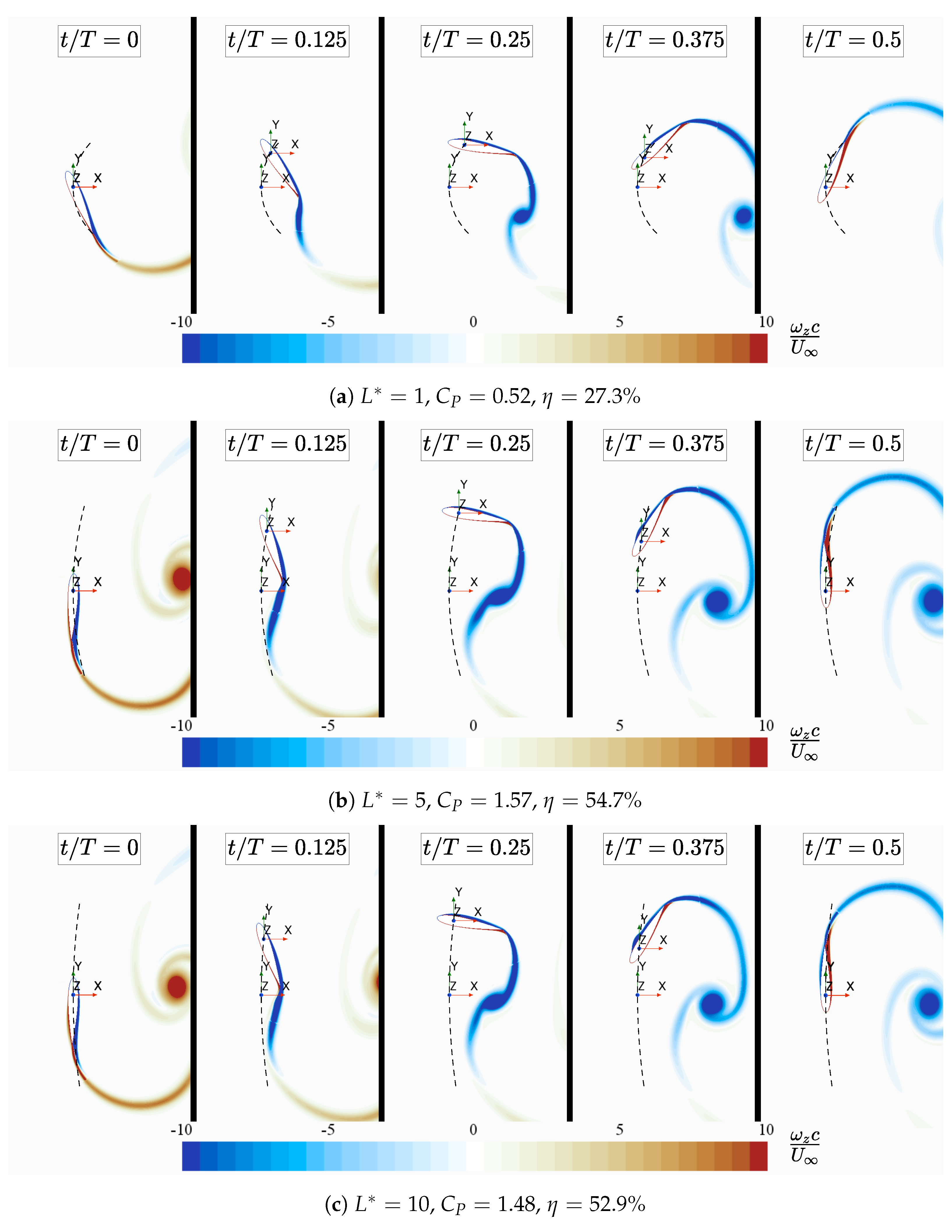

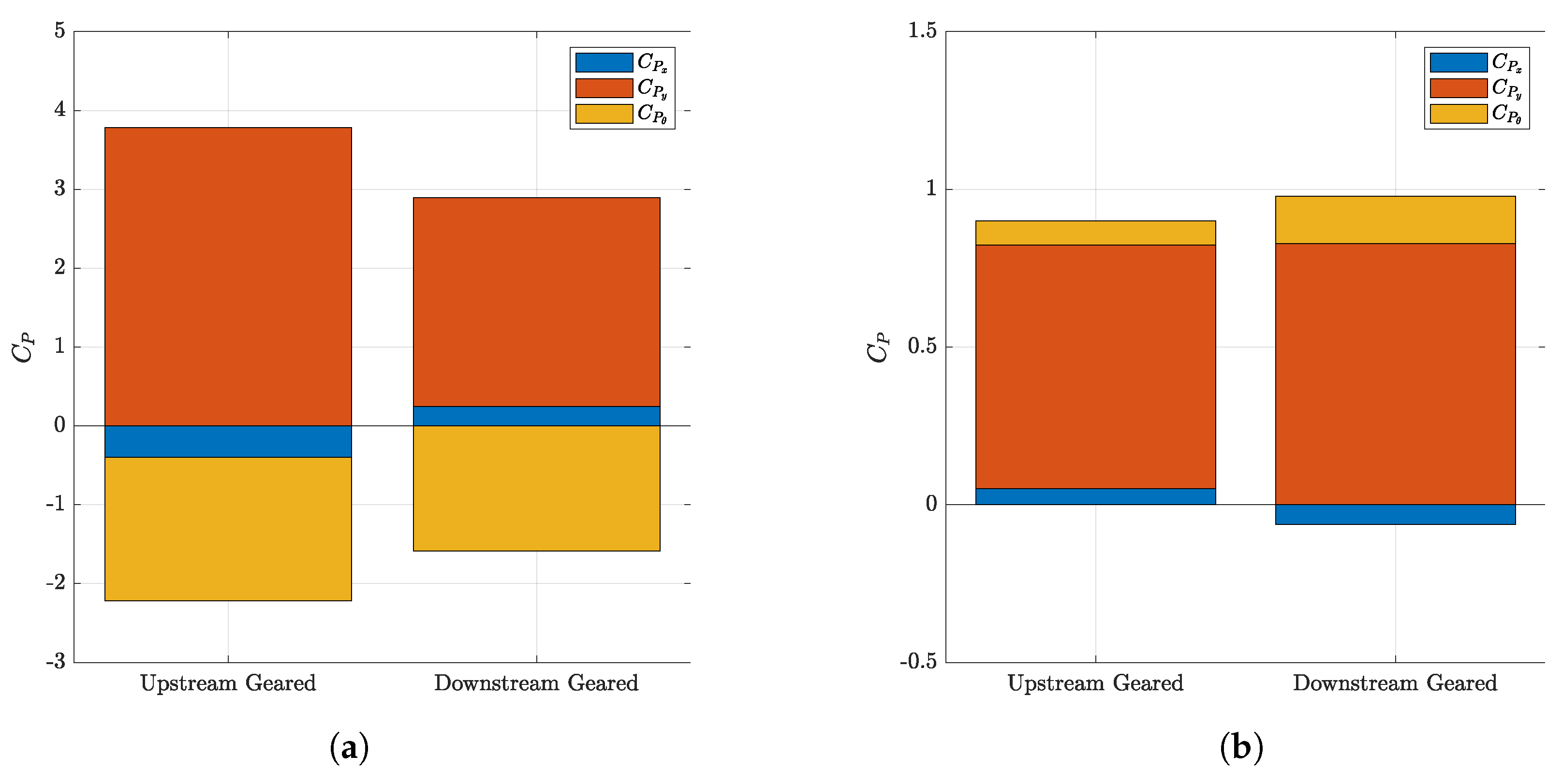

This paper presents an investigation of the energy harvesting potential of the fully passive oscillating-foil turbine on a swinging arm. This research was driven by the need to investigate different and simpler mechanical configurations than the fully passive oscillating-foil turbine on rails. Therefore, two different mechanisms, geared and gearless, were investigated in both downstream and upstream rest positions for different lengths of the swinging arm using 2D URANS CFD simulations. Furthermore, two different sets of optimized parameters yielding railed turbines operating under two different instability mechanisms, i.e., the coupled-flutter and stall-flutter instabilities, were used to establish equivalent parameters for the fully passive oscillating-foil turbines on a swinging arm of different lengths.

The results obtained are promising, showing that the fully passive oscillating-foil turbines on a swinging arm offer performances, i.e., efficiency values and power coefficients, comparable to or even better than those of the fully passive railed oscillating-foil turbines if the arm length is chosen carefully depending on the instability mechanism. For instance, when operating under the coupled-flutter instability and with the use of gears in an upstream configuration, an arm length of 5 chords offers a power coefficient and an efficiency value of and , respectively. When compared to the fully passive railed oscillating-foil turbine, which has a power coefficient of and an efficiency value of , the oscillating-foil turbine on a swinging arm therefore offers relatively similar performance metrics to those of the railed configuration, with increases of about and , respectively. Such a configuration of the fully passive oscillating-foil turbine on a swinging arm would be a good prototype for experimental investigations.

Firstly, when operating under the coupled-flutter instability, the upstream configuration is always slightly better than its downstream counterpart, and the use of gears offers better performance metrics if the structural parameters of the railed configuration are scaled with respect to the arm length. Following this result, the initially unresponsive gearless model was adapted to become responsive and, thus, to provide viable performance metrics.

Secondly, it was found that both the geared and gearless configurations are well suited when the turbine is operating under the stall-flutter instability. Although intrinsically less efficient than when operating under the coupled-flutter instability, the robustness of the turbine when operating under the stall-flutter instability makes it suitable for use with all configurations analyzed, without requiring adjustment of the optimized railed structural parameters.

Therefore, given the current findings, a practical prototype should be based on the upstream geared configuration, operating under the coupled-flutter instability, with an arm length of more than five chords.

For future work, 3D simulations would provide insight into how such a turbine would operate when subjected to the tip effects of finite blade spans. An experimental study, as well as a sensitivity study, would also be very valuable to complement the simulations presented in this paper. It would also be of great interest to assess the performance of a turbine combining on the same arm the upstream and downstream FP-OFT-SA configurations in a tandem configuration. Some studies have looked into the fully-constrained and the semi- and fully-passive configurations in tandem configurations, showing strong interactions between the upstream foil’s wake and the downstream foil. However, most studies make use of an array of railed turbines rather than a single turbine consisting of two foils on a single rigid arm. Simulations using two fully-passive foils on a single arm might provide insight into whether greater power outputs and efficiency values can be reached if such tandem systems are carefully optimized. From an engineering point of view, building such a tandem apparatus seems to benefit from a swinging arm perspective. Indeed, it is a simpler solution than having two railed turbines in an array, and it permits a direct link between the heaving positions upstream and downstream, ensuring that both foils operate in a mirror pattern height-wise.