Abstract

This study presents the technological, technical, and economic basis of the solution developed by the authors for the production of biomethane based on the pretreatment of organic substrates at low temperature using solidified CO2 captured during biogas upgrading in a closed cycle (TeCH4BiogasUp). TeCH4BiogasUp integrates the disintegration of organic substrates, biogas upgrading and the sequestration and utilization of CO2 in a closed cycle. The multifunctional and hybrid nature of TeCH4BiogasUp sets it apart from other available solutions that only perform selected, individual technological processes. This is a significant advantage and a competitive market edge; however, it also poses challenges in conducting comparative analyses with existing solutions on the market. The technology has been compared with traditional substrate pretreatment techniques and biogas purification technologies. Considering the origin of the solidified CO2, this method can be regarded as material recycling, which aligns fully with the principles of the circular economy. This technology supports the reduction in CO2 emissions by capturing the CO2 and introducing it into the closed process. This novel approach to the production and utilization of solidified CO2 largely overcomes previous limitations associated with the low profitability of the process. TeCH4BiogasUp could serve as a viable alternative to other methods, particularly in light of economic trends and the imperative to reduce CO2 emissions through the development of renewable energy sources.

1. Introduction

Taking into account the assumptions of the circular economy, the practical implementation of the “zero waste” policy and the requirements related to the development of renewable energy sources (RESs) and the reduction in greenhouse gas emissions, the development of clean technologies becomes a priority [1,2]. The solutions most expected by the market should be characterized by universality, the possibility of comprehensive and multidirectional satisfaction of expectations related to the production of clean energy, saving of materials, protection of the environment and compliance with the principles of sustainable development [3]. It is also important that these solutions are effective and simple and are already characterized by a high technological readiness level (TRL). This enables the projection and reliable prediction of the technological and economic impact achieved, which directly determines the possibility of their implementation on a technical scale. This is important given the need to reduce greenhouse gas emissions into the atmosphere and the ambitious European and global plans in this area. The issues of improving technological efficiency and meeting increasingly stringent environmental criteria also affect the area of biogas/biomethane production and utilization [4].

Despite numerous challenges related to the development of renewable energies, the energy production sector based on the use of biogas has been very limited in many countries of the European Union (EU) and will certainly develop dynamically. This is evident from the available forecasts and analyses [5]. This should have a direct impact on the growth of interest and demand for innovative and competitive solutions. Their implementation will contribute to the growth of biogas production, the possibility of producing more valuable and universal biomethane and the reduction in pollutant emissions into the environment [6]. Biogas produced in the anaerobic digestion (AD) process is recognized by EU directives as a renewable energy source that can significantly increase its share in the energy mix [7]. This fact will reduce greenhouse gas emissions into the atmosphere, make the economy less dependent on conventional energy sources and reduce the negative impact of energy crises on macroeconomic phenomena [8]. This view is justified because the technologies for the production and utilization of biogas are universal and well known [9].

Technologies aimed at intensifying the processes of biogas production and its refinement into biomethane are important and in need of further development and improvement [10]. The expected progress relates to functionality, universality of use, profitability and environmental neutrality. Biomethane is a second-generation biofuel that is included in the EU’s development strategy for so-called biofuels of the future. It plays a key role in the implementation of the REPowerEU plan. REPowerEU is a European Commission initiative aimed at ending dependence on Russian fossil fuels before 2030. The plan targets the achievement of 600 GW of solar photovoltaic capacity by 2030 and aims to simplify and accelerate permitting procedures for the use of biomethane and green hydrogen. The goal is to reach a production level of 35 billion Nm3 of biomethane in the EU by 2030 [11]. This is due to the possibility of universal utilization of this biogas component. Biomethane can serve as a starting substrate for H2 production, it can be used in transport or mixed with natural gas and distributed to end consumers and stored [12]. Biomethane can be produced in practically any location with sufficient access to organic substrates. In Europe, over 3 billion Nm3 of biomethane is already being produced in more than 1000 plants. The leaders are France with 306 biomethane plants and Germany with 242 biomethane plants [13]. In Poland, on the other hand, there has so far been no legal regulation in this area, but the Act of 17 August 2023 on renewable energy sources introduced numerous changes aimed at creating the biomethane market and accelerating its development [14]. The first biomethane plant in Poland, which is being built by the Orlen SA Group, is located in Głąbów. The project will enable the production of 7 million Nm3 of biomethane per year, which will then be converted into BioLNG fuel [15].

There are currently no hybrid and multifunctional solutions on the market that integrate and utilize many individual processes in a closed cycle, which ultimately has a positive effect on the technological and economic impact of biogas and biomethane production systems. Normally, the processes of pretreatment of organic substrates and biogas upgrading have to be carried out in separate installations. The energy balance resulting from their use is usually negative, and there are also high investment and operating costs. This is confirmed by previous studies by Elalami et al. [16], Garlicka et al. [17], Kainthola et al. [18], Kovacic et al. [19], and Zupanc et al. [20]. Methods based on advanced technologies require qualified personnel and are characterized by considerable process complexity, which very often limits the effects achieved. Solutions that combine many processes that previously required separate plants in a functionally justified way are still sought and expected by the biogas sector. There is, therefore, a justified need to search for and commercialize innovative solutions, the use of which will increase the market advantage of biogas production and upgrading systems to biomethane. Their competitiveness will be based on high technological efficiency, economic justification and pro-ecological values. The answer to these expectations could be an original technology in which the decomposition of organic substrates, biogas upgrading and CO2 sequestration and use take place in a closed cycle (TeCH4BiogasUp). TeCH4BiogasUp enables the practical implementation of circular economy assumptions and supports the achievement of CO2 emission reduction levels set in international agreements and fulfils the requirements related to increasing the share of renewable energy sources.

The aim of the work was to present the technological, technical and economic basis of the solution developed by the authors for the production of biomethane based on the low-temperature disintegration of organic substrates using solidified CO2 captured during the upgrading of biogas in a closed cycle (TeCH4BiogasUp). This is an original idea that has not yet been applied in practice. The solution in question is unlike existing ones in that it is comprehensive and makes it possible to increase the efficiency of fermentation processes, utilize the captured CO2, reduce CO2 emissions into the atmosphere and operate continuously.

2. Biomass Pretreatment—Short Evaluation

The methods for pretreatment of organic substrates prior to anaerobic digestion are dynamically developing technologies. Their aim is to break down the structure of the substrate by fragmenting and damaging the cells of the biomass and releasing organic matter and extracellular polymers into the dissolved phase [21]. These technologies use various approaches, including mechanical methods [22], high-pressure methods [23], ultrasound [24], microwaves [25], cavitation generators [26], biological methods [27], chemical methods (acidification [28], alkalization [29], oxidation [30], ozonization [31]) and thermal methods such as heat treatment [32] and freeze–thaw [33]. Hybrid methods, in which different techniques are combined to maximize the effect, are also increasingly being used [34].

Most of the methods tested produce satisfactory technological effects, which are reflected in an improved efficiency of the methane fermentation process [35]. Among other things, a significant increase in the efficiency of biogas production, the CH4 content and a higher degree of mineralization and biodegradation of organic material is observed [36]. In many cases, however, the energy balance when using these technologies remains negative, which means that the amount of net energy obtained does not offset the operating costs of the equipment used for pretreatment [37]. Another frequently raised issue is the high investment costs and expenses for maintenance, servicing and repairs of disintegration systems [38]. Methods based on the use of advanced technologies require qualified personnel and are characterized by considerable process complexity, which very often causes operational difficulties and significantly limits the final results obtained [39]. In addition, none of the technologies allows an increase in biogas production of more than 30%, which was observed in preliminary tests with TeCH4BiogasUp [40,41].

Of all the known and described methods of biomass preparation prior to the anaerobic digestion process, mechanical shredding is one of the most frequently used. It essentially consists of the destruction of the substrate structures by the impact of shear forces or periodic pressure changes that cause destructive stresses [42]. Mechanical decomposition methods include the following: centrifuges, homogenizers, ball mills, ultrasound, electrical pulses, hydrodynamic methods and methods using the cavitation phenomenon [43]. The basic disadvantages of mechanical methods are operational problems caused by the fibrous structure of the biomass, which leads to clogging and rapid wear of the components [44]. The ultrasonic method, which is used by the Austrian company VTA Technologie GmbH (Rottenbach, Austria), among others, is associated with high energy requirements, deterioration of water removal from the sludge and operational problems (erosion of the probes and associated frequent replacement and repairs). On the other hand, technology using electrical pulses is a method that has not yet been fully researched and is characterized by high energy requirements and electrode erosion [44].

Another solution for the pretreatment of organic substrates is thermal disintegration (thermal and low-temperature hydrolysis method) [45]. It is used by the company Cambi (Asker, Norway), among others. In hydrothermal depolymerization, the biomass is briefly exposed to steam at high temperatures and pressures (approx. 160–170 °C, approx. 10–15 bar). A similar effect can be achieved with low-temperature disintegration at a temperature of approx. 50 °C, which takes approx. 2.5 h [46]. The disadvantages of these methods are operational problems—corrosion, odor formation, high amount of suspensions in the effluent and the required high concentration of dry mass of organic substrates [44]. A competitive method is biological hydrolysis [47]. This technology is characterized by high costs for the preparations and the lack of tests on an industrial scale [44]. Chemical disintegration methods, on the other hand, utilize the energy of chemical reactions using O2, O3, H2O2, HCl, NaOH or H2SO4. Chemical hydrolysis causes operational problems such as corrosion, odor formation, a high proportion of suspended solids in the effluent, the required high concentration of dry matter in the sludge, high operating costs and the need to neutralize the pH value before the next processing stage. High investment costs, high energy requirements, foaming and increased concentrations of nitrogen and phosphorus in the mixture after dewatering are also mentioned [44]. A summary of the strengths and weaknesses of existing biomass preprocessing technologies is presented in Table 1.

Table 1.

Summary of the strengths and weaknesses of existing biomass pretreatment technologies.

In light of the above-mentioned techniques described in the literature and currently used in practice for the pre-shredding of biomass prior to anaerobic digestion, the TeCH4BiogasUp solution appears to be a justified and competitive alternative. Due to its stability under atmospheric conditions and its broad applicability, the favored approach for CO2 capture and recovery from biogas is the production of SCO2 [72]. A promising strategy involves the separation of impurities and a depressurized cryogenic liquefaction plant that converts raw biogas from anaerobic digesters into liquefied biomethane (LBM) and industrially usable SCO2 [73]. In the first stage, the raw biogas is converted into an almost pure mixture of methane and carbon dioxide. The gas purification process begins with complete desulfurization by adsorption, using agents such as ferric chloride. Ammonia is then removed by absorption, e.g., in the form of ammonium sulfate, followed by precise gas desulfurization using adsorption techniques such as an activated carbon column [74]. The biogas is then dried using a gas cooler (7 °C) and passed through a silica gel and/or zeolite column. In the next stage, the biogas is pre-cooled using a heat exchanger immersed in an alcohol solution (e.g., ethanol or methanol). This heat exchanger also acts as a reserve unit by freezing the gas impurities remaining after the previous purification. This process is particularly effective for components such as H2O and NH3 [75]. The theoretical feasibility of using an alcohol-based heat exchanger (e.g., ethanol or methanol) has been considered. Approximately 20% of the SCO2 produced is required for pre-cooling. At this stage, the gas temperature reaches about −80 °C. In the third stage, methane (CH4) and carbon dioxide (CO2) are separated: the CO2 is selectively flocculated out of the gas stream by further lowering the temperature via another heat exchanger.

The processes used for the purification and treatment of biogas and the simultaneous production of SCO2 must be individually selected based on the qualitative composition of the raw biogas. The concentration of impurities, including H2S, NH3 and H2O, is determined by the substrates used in the process and the anaerobic digestion technology applied. The effective removal of biogas impurities is critical to the purity, application and commercial value of the recovered SCO2. The high purity and quality of this product are essential for applications in the food industry [76]. Due to the intersection of the vapor pressure curves of CO2 and H2S, even minimal H2S residues in the purified gas will combine with SCO2 during the cooling process. Since H2S is highly toxic and has an extremely low odor threshold for humans, the gas purification process must achieve almost complete H2S removal [77]. However, ensuring an exceptionally high SCO2 purity is directly linked to increased process costs, which may make the process economically uncompetitive. Therefore, there is a justified need to explore cost-effective alternatives or other applications for SCO2 generated in biogas plants that do not require such high purity levels. One promising direction is the use of SCO2 in pretreatment techniques that could improve the technological efficiency of biogas systems and at the same time simplify the pre-cleaning system for biogas prior to SCO2 production. According to studies by the authors [78], a 43% increase in biogas yield was observed following the disintegration of dairy wastewater sludge with solid CO2, from 440.7 ± 21.5 mL/gVS (raw sludge) to 630.20 ± 45.5 mL/gVS (SCO2 dosage to sludge at a ratio of 0.3/1). The CH4 content increased accordingly from 61.2 ± 1.3% to 68.7 ± 1.5% [78]. Pretreatment of AGS with solid CO2 (dosage 0.3/1) led to an increase in biogas yield of about 54%, from 309 ± 21 mL/gVS to 476 ± 20 mL/gVS, with the CH4 content increasing from 68.84 ± 2.2% to 71.58 ± 1.7% [40].

Considering the origin of the solidified CO2, this method can be considered as material recycling, which is fully in line with the principles of the circular economy. This technology supports the reduction in CO2 emissions by sequestering it and its introduction into the closed-loop process. The production and utilization of solidified CO2 in biomass disintegration processes is undoubtedly an environmentally friendly approach, especially as the CO2 is recovered in the biogas upgrading process. This method also avoids secondary pollutants often produced by chemical decomposition and the additional energy required in mechanical processing. This new approach to the production and utilization of solidified CO2 largely eliminates the previous limitations resulting from the low profitability of the process [79]. TeCH4BiogasUp could prove to be a justifiable alternative to other methods, taking into account the trends of economic transformation and the need to reduce CO2 emissions through the development of renewable energy sources.

3. Biogas Upgrading—Short Evaluation

The most common technologies for biogas upgrading are pressure swing adsorption (PSA) and water scrubbers [80]. Both solutions have been used in over 60 installations in Europe alone. Other methods, including membrane separation, cryogenic separation, adsorption on limed sediments or ash and in situ upgrading by air injection, have only been tested in individual facilities. Each of the technologies available on the market is imperfect, which is why each application is preceded by a detailed technological and economic analysis. PSA utilizes the phenomenon of adsorption of CO2 and other molecules in a bed of activated carbon or on zeolite molecular sieves. The main provider of this technology is the company NeoZeo AB (Stockholm, Sweden). The disadvantage is that it is a periodic process that must be stopped when the sorption capacity of the adsorbent is exhausted. To ensure the continuity of the process, it is therefore common to build several parallel adsorption–desorption columns. H2S and H2O can also be adsorbed on activated carbon, which leads to deactivation and a reduction in the efficiency of the bed. In addition, the biogas must be pre-cleaned before it is fed into the columns [81].

The second most popular technology for biogas upgrading is the use of water scrubbers. This technology is implemented by the company Biorega AB (Långaryd, Sweden). The separation of CH4 and CO2 in this type of plant utilizes the phenomenon of greater solubility of CO2 and its absorption in water or alkaline solutions compared to CH4. This process is carried out under increased pressure conditions, which results in other gaseous components such as H2S or NH3 dissolving in water in addition to CO2. The disadvantage of this type of solution is the rapid exhaustion of the sorption capacity, the difficulties in regenerating the absorption liquid and the limited possibilities of continuous operation. Another technology is the use of organic scrubbers, which work on a similar principle to water scrubbers, with the difference that the CO2 is absorbed in an organic solvent such as polyethylene glycol. The polyethylene glycol solution is regenerated by heating and/or gradually lowering the pressure. In addition to CO2, substances such as H2S, H2O, O2 and N2 can also be removed. However, they are usually removed before the purification process begins. Organic scrubbers are a far less popular solution than water scrubbers. Chemical scrubbers, also known as amine scrubbers, are also used, which operate on the principle of a chemical reaction of CO2 with monoethanolamine or dimethylethanolamine. The reaction is very selective, so that CH4 losses are insignificant (<0.1%). Part of the liquid is lost during the process through evaporation and must be replenished. The liquid in which the CO2 is chemically bound is regenerated by heating. If H2S is present in the raw gas, it is absorbed into the solution in the amine scrubber, which means that higher temperatures are required to regenerate the solution. It is therefore advisable to remove H2S before the absorption process begins in the amine scrubber [81].

Membrane techniques are also being developed [80]. Suppliers of these technologies include the company Duttwiler Energietechnik (Flurlingen, Switzerland) and the company MemfoACT AS (Trondheim, Norway). The membranes usually take the form of so-called capillary fibers. These fibers have a very small diameter, which means that the solution can only flow through the membrane under high pressure. High pressures in turn require considerable mechanical strength of the membrane, as the capillary channels can be blocked very easily. This leads to a significant increase in the cost of the process. The wet membrane used for biogas purification consists of materials that only allow CO2, H2O and NH3 to pass through. Compounds such as H2S or O2 only penetrate the membrane to a certain extent, while the permeability of N2 and CH4 is insignificant. The purification process in which membranes are involved often takes place in two stages. Before the gas penetrates the membrane, it first passes through a filter that retains water, oil droplets and aerosols, which have a negative effect on the function of the membrane and can damage it [81].

Other biogas purification technologies include in situ CH4 enrichment and cryogenic separation. In biogas purification with simultaneous in situ CH4 enrichment, the medium is first channeled from the fermentation tanks into a desorption column and then back into the fermentation tank. In the desorption column, the CO2 is desorbed by passing a dose of air through the medium [81]. The continuous CO2 removal process leads to an increase in the CH4 concentration in the biogas leaving the fermentation tank. Process simulations have shown that it is possible to obtain biogas with a 75% CH4 content, with a loss of less than 2% during purification. The use of this technology is currently limited to small installations where a high CH4 content in the biogas (>75%) is not required. The technology was developed and realized by KTH and JTI with financial support from FUTURA and Göteborgs Energi (Gothenburg, Sweden). The cryogenic separation process, which is mainly carried out by the Swedish company Biofrigas Sweden AB (Göteborg, Sweden), takes place at very low temperatures (down to −100 °C) and high pressures (approx. 40 bar). Raw biogas is cooled to a temperature at which the CO2 it contains condenses or sublimates and can be separated from the biogas as a liquid or solid, while CH4 remains in the gas phase. Cooling usually takes place in several stages in order to thoroughly remove various undesirable substances contained in the biogas, such as water vapor and siloxanes, and to optimize energy production. The main advantage of cryogenic separation is the possibility of obtaining biogas with a high CH4 content of up to 99% [81]. A summary of the strengths and weaknesses of current biogas enrichment technologies is presented in Table 2.

Table 2.

Summary of the strengths and weaknesses of existing biogas upgrading technologies.

The TeCH4BiogasUp solution does not require a complex technological system for the extraction of high-purity, solidified CO2, as its primary application focuses on biomass disintegration. This approach significantly simplifies the technological process, leading to reduced investment and operational costs. Limited information exists in the global literature regarding the feasibility of biomass pretreatment at low temperatures prior to anaerobic digestion using solidified carbon dioxide (SCO2). Consequently, this technology remains relatively unknown. Based on available data, it can be assumed that SCO2-based pretreatment is an environmentally sustainable technology. This is supported by the fact that SCO2 can be recovered during the biogas upgrading and enrichment processes. Additional advantages include the prevention of secondary contamination of organic substrates, which is a common issue in chemical disintegration methods, and the absence of additional energy requirements, as seen in mechanical pretreatment techniques.

Even when this technology is used to intensify the production of renewable energy in the form of biogas from waste substrates such as sewage sludge, it should be recognized as environmentally friendly. This is because it indirectly contributes to reducing the use of fossil fuels. An important environmental benefit of this technology is the production of biomethane, which is a more versatile fuel than biogas and allows more efficient utilization of its stored potential energy. The use of carbon dioxide for pretreatment represents a material utilization that contributes to the reduction in CO2 emissions.

The TeCH4BiogasUp technology, which uses solidified carbon dioxide for the disintegration of sewage sludge prior to AD, is undeniably environmentally friendly due to several key factors. Firstly, it enables a reduction in greenhouse gas emissions as the CO2 used in the process comes from emission capture, meaning it is reused and not released into the atmosphere. In addition, this method improves the efficiency of AD, resulting in a 10–50% increase in biogas production compared to conventional techniques. A higher biogas yield means greater potential for renewable energy production, which is in line with the goals of a low-carbon economy.

Another important factor is the reduction in digestate volume by 20–40%, which minimizes the need for further disposal and reduces transport and processing costs. In addition, this technology consumes less energy than other disintegration methods, such as ultrasonic, chemical or thermal processes, and no additional chemical substances are introduced into the sludge, minimizing the risk of toxic by-products. It is also worth noting that the use of solidified CO2 is consistent with the principles of a closed carbon cycle. In addition, part of the CO2 can be bound in the sludge structure, which further reduces emissions. Due to these advantages, this technology not only improves the efficiency of sewage sludge processing, but also supports sustainable resource management and the reduction in the carbon footprint.

4. TeCH4BiogasUp—Technological Basics

The previous studies [41,78] have demonstrated that the pretreatment of biomass with solidified CO2 (SCO2) significantly influences the initiation and efficient progression of microbial cell lysis. This process leads to the disruption of activated sludge flocs, promotes biomass fragmentation, facilitates the efficient dispersion of molecular associations, and induces changes in cell morphology as well as macromolecular denaturation. These effects result in an increased concentration of organic and biogenic substances, along with molecular material, in the dissolved phase.

The aforementioned phenomena have practical applications in various processes, including sewage sludge sanitization, dewatering techniques, and sludge biomass pretreatment technologies designed for aerobic or anaerobic stabilization [79,106]. Such applications enable multi-stage processing, final neutralization, and/or the safe management of sludge. Furthermore, many of the mechanisms proven effective in the treatment of sewage sludge with SCO2 can be adapted for processing biomass with differing characteristics and properties.

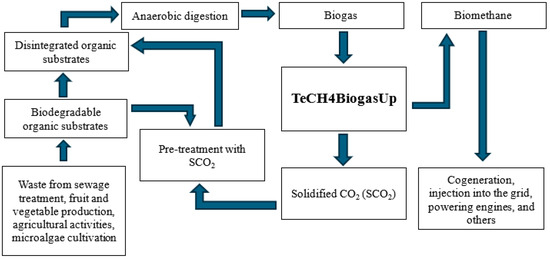

Given the direct effects of SCO2 use in biomass processing technologies, its application as a pretreatment method to enhance the efficiency of methane and hydrogen fermentation processes is well justified. This approach is particularly advantageous as it supports the implementation of a closed CO2 cycle, encompassing the following stages: biogas production → biogas enrichment → SCO2 production → sludge disintegration → anaerobic digestion → biogas production. This closed-loop system not only improves the economic and technological efficiency of fermentation processes but also aligns with the environmental imperative to reduce CO2 emissions into the atmosphere (Figure 1).

Figure 1.

Conceptual process of the technological solution TeCH4BiogasUp.

The new approach to the production and utilization of solidified CO2 (SCO2) largely addresses previous limitations, which were primarily associated with the low economic efficiency of production processes [79]. However, in light of current trends emphasizing the reduction in CO2 emissions and the adoption of circular economy principles, the application of SCO2 in biomass processing prior to methane fermentation emerges as an increasingly viable and justifiable alternative to conventional methods.

5. TeCH4BiogasUp—Results of Preliminary Research

The effects of freeze/thaw processes on the methane fermentation of industrial and municipal sewage sludge have been explored by only a few researchers. For instance, Meyer et al. [107] examined the impact of freeze/thaw pretreatment on the AD of sludge from pulp and paper mills. Their study revealed that biogas production increased to 310 mL/g of chemical oxygen demand (COD) for pretreated sludge compared to 111 mL/g COD for untreated sludge. Similarly, Montusiewicz et al. [108] treated a mixture of primary and biological sludge (60:40 ratio) at −25 °C, reporting biogas production of 1.31 L/g of volatile solids (VSs) removed—over 1.5 times higher than untreated sludge. The freeze/thaw pretreatment also doubled the concentration of soluble COD (sCOD) on average, accompanied by the release of nitrogen and phosphorus compounds. Wang et al. [109] further confirmed a 27% increase in methane production from municipal sewage sludge treated at −10 °C. Jan et al. [110] reported a COD removal efficiency of 30%—a significant improvement compared to 18% for untreated sludge—following the freeze/thaw treatment of food industry wastewater sludge at −17 °C and subsequent methane fermentation.

A promising innovation for enhancing fermentation efficiency is the thermal modification of sludge using solidified CO2 (SCO2). The disintegration of excess sludge with SCO2 induces microbial cell denaturation supported by mechanical effects. Crystallization during this process causes a “thermal shock” to microorganisms. Zawieja [106] demonstrated that SCO2 disintegration enhances sludge biodegradability, initiating hydrolysis and increasing sCOD, volatile fatty acids (VFAs), and total organic carbon (TOC). The optimal SCO2-to-sludge ratio of 0.35:1 achieved a decomposition degree of 6.6%, with improved biogas production observed during fermentation.

Additional studies [33] examined the effects of SCO2 disintegration on methane fermentation using SCO2 granules (0.6 mm diameter) mixed with excess sludge at various volumetric ratios (0.15/1 to 0.75/1). Fermentation under mesophilic conditions (37 °C) showed that a 0.55/1 ratio yielded optimal results, including 2.7- to 3.0-fold increases in TOC and sCOD, a 2.8-fold increase in VFA concentrations, a 33% higher fermentation degree, and a 31% increase in biogas production efficiency. Kazimierowicz et al. [78] investigated low-temperature conditioning of dairy sewage sludge with SCO2. A volume ratio of 0.3 yielded the highest biogas production (630.2 ± 45.5 mL/gVS) with 68.7 ± 1.5% methane content, while further SCO2 increases did not significantly enhance biogas or methane production. For unconditioned sludge, the COD concentration was 400.5 ± 23.8 mg/L. The applied method increased the concentration of ammonium nitrogen from 155.2 ± 10.2 to 185.9 ± 11.1 mg/L and that of orthophosphates from 198.5 ± 23.1 to 300.6 ± 35.9 mg/L [78].

In previous studies by the authors [40], the effect of aerobic granular sludge (AGS) disintegration using SCO2 on its AD efficiency under mesophilic conditions (42 °C) was investigated. The impacts of this disintegration method on the structure and properties of sewage sludge, changes in the concentration of organic and biogenic compounds in the dissolved phase, the taxonomic structure of anaerobic bacteria, and the efficiency and kinetics of biogas production and CH4 content were also evaluated. The results demonstrated that with the increase in the SCO2/AGS volume ratio from 0.1 to 0.3, a proportional increase in the concentrations of COD, N-NH4+ and P-PO43− in the supernatant was observed. However, higher doses of SCO2 did not lead to significant changes in the concentrations of these indicators in the dissolved phase. The highest efficiencies in biogas and CH4 production were achieved at 476 ± 20 mL/gVS and 341 ± 13 mL/gVS, respectively, at an SCO2/AGS ratio of 0.3. It was shown that the use of SCO2 doses higher than 0.3 significantly lowered the pH of the AGS (below 6.5), leading to a reduction in the proportion of methanogenic bacteria in the community of anaerobic microorganisms. This, in turn, resulted in a decrease in the methane content of the biogas [40]. Researchers [111] have demonstrated that the use of AGS disintegration with SCO2 under thermophilic conditions (55 °C) yields the best technological results with an SCO2/AGS ratio of 0.3. The biogas amount was reported at 482 ± 21 mL/gVS and 337 ± 14 mLCH4/gVS [111].

Researchers [41] investigated the effects of long-term pretreatment of municipal sewage sludge (MSS) with SCO2 on AD conditions, the anaerobic bacterial community, and the composition and yield of biogas in continuous reactors. The effect of organic loading rate (OLR) on the methane fermentation performance of MSS was studied under mesophilic conditions at 38 ± 1 °C. The SCO2/MSS ratio was 1:3, and the OLR values tested ranged from 2.0 to 5.0 gCOD/L·day. The results showed that pretreatment of MSS with SCO2 improved AD efficiency with an OLR value of 3.0 to 4.0 gVS/L·day. The best biogas production efficiency was achieved at an OLR of 3.0 gVS/L·day, where the average daily biogas production was 29 ± 1.3 L/day and the efficiency per added VS reached 0.49 ± 0.02 L/gVS. Additionally, the highest CH4 content in the biogas was observed in this variant, which was 70.1 ± 1.0%. Pretreatment with SCO2 had no effect on pH, FOS/TAC, or anaerobic bacteria composition. These variables were primarily influenced by the OLR [41].

In other studies [112], a hybrid chemical–thermal disintegration of activated sludge with NaOH and SCO2 was tested prior to thermophilic anaerobic stabilization. This approach promotes the intensification of the degradation of organic compounds and improves the efficiency of anaerobic stabilization compared to the fermentation of raw sludge. The study utilized a hybrid pretreatment system that included alkalization to pH 9.5 and SCO2 conditioning at a volume ratio of 1:1 to sewage sludge. This method showed a synergistic effect, leading to increased disintegration of the microbial biomass and the structure of excess sludge flocs. This effect resulted in a significant release of soluble organic matter, manifested in an increase in SCOD of 2000 mg/L in the hybrid process. Thermophilic fermentation of sludge subjected to this process led to increased biogas production. This intensification resulted from the increased amount of disintegrated activated sludge (DAS) in the digesters. For samples containing 50% of the volume of DAS, an increase in biogas production of approximately 59% was observed compared to the control sample. Moreover, the hybrid process proved beneficial for improving the hygienization of the digested sludge [112].

This is confirmed by the results of the study by Grübel and Machnicka [113] on the effects of the hybrid disintegration process using alkalization (pH ≈ 9) and the freezing/thawing of SCO2 (volume dose of SCO2 to sludge 1:0.75) on excess activated sludge and the mesophilic methane fermentation process. It was found that the COD value of the sludge that was not disintegrated was on average 100 mg/L, while the application of the chemical–thermal disintegration process led to a significant increase in the concentration of organic matter in the supernatant liquid, expressed as SCOD, reaching about 1890 mg/L. The addition of disintegrated sludge to the fermentation reactors contributed to the increase in biogas production and the unit efficiency of the process, depending on the volume fraction of this sludge. The highest increase in biogas production was observed with a 50% addition of sludge after hybrid disintegration, reaching 2.933 L, which corresponded to an increase of 15.2% compared to raw sludge. The highest efficiency of biogas production per unit—0.482 L/gVS removed—was obtained for the sample with a 30% volume fraction of sludge after hybrid disintegration [113]. The summary of the technological effects of sewage sludge pretreatment in technologies based on the use of SCO2 is shown in Table 3.

Table 3.

Summary of research results on the use of SCO2 in the pretreatment of sewage sludge with anaerobic digestion.

6. SCO2—Impact on the Properties of Sewage Sludge

The application of freeze/thaw processes with SCO2 for sewage sludge treatment has a significant impact on the improvement of dewaterability [114]. Studies have demonstrated a substantial reduction in sludge dewatering parameters, such as capillary suction time (CST) and specific filtration resistance (R). Low-temperature treatment changes the structure of the activated sludge flocs and makes them more compact, reducing the amount of bound water and facilitating its removal from the cells [115]. This technology significantly reduces the water content of the sludge, thereby reducing its volume, minimizing the space required for storage and disposal and reducing transport and disposal costs. A sudden change in temperature leads to a thermal shock that directly attacks both the outer and inner cell structures of the microorganisms. Freezing leads to partial mechanical destruction of the bacterial cells, which is crucial for the subsequent processing stages of the sludge [116]. This process leads to the formation of ice crystals both inside and outside the cells, which cause physical damage. As a result, the concentration of degraded microorganisms increases, which promotes the release of lipoproteins and other organic substances as well as the transition of the originally bound water into the dissolved phase. The next step is the gradual heating of the sewage sludge, which leads to the expansion of the water originating from the ice, which further intensifies the degradation of the bacterial cells and increases the efficiency of the subsequent treatment processes [117].

Thermal disintegration, which involves rapid freezing and gradual thawing, contributes to the destruction of activated sludge flocs, biomass fragmentation and dissolution of molecular bonds. This leads to morphological changes in the cells and denaturation of macromolecules. Consequently, this process effectively initiates microbial cell lysis and increases the amount of organic substances in the dissolved phase [33]. This technology has practical applications in the hygienization and dewatering of sewage sludge and as a pretreatment step for biomass destined for aerobic or anaerobic stabilization, which facilitates the final neutralization and management of the sludge. The efficiency of the freeze/thaw process depends on the cell structure and microbiological composition of the sewage sludge biomass. The formation and distribution of ice crystals within the cells are determined by the water activity, the properties of the biological membranes and other physicochemical parameters. The destruction of microorganisms caused by SCO2 leads to an increase in dissolved phase indicators such as dissolved COD, proteins, orthophosphates, ammonium nitrogen and carbohydrates [78]. In addition, an increase in supernatant turbidity and a decrease in capillary suction time are observed, confirming the improvement in sludge dewatering ability. FTIR spectroscopy studies have shown effective digestion of the sludge, as evidenced by absorption changes corresponding to the presence of amines, amino acids, proteins and phosphates. The separation of these substances in the supernatant confirms microbial destruction and effective cell lysis [117].

The sludge conditioning technology based on SCO2 is characterized by its environmental friendliness. SCO2 can be recovered during biogas upgrading, eliminating the secondary sludge contamination associated with chemical disintegration processes. Furthermore, this technology does not require any additional energy input, as is the case with mechanical sludge treatment. Despite their numerous advantages, freezing and thawing technologies are not widely used on an industrial scale. The main barriers to their adoption are the high operating costs and limited economic efficiency [118]. However, in the context of current trends focusing on the reduction in CO2 emissions and circular economy principles, the use of SCO2 could be an attractive alternative [119]. The use of this method in sludge treatment could help to reduce the cost of CO2 production from waste gases, as additional cleaning is no longer required. A practical example of the use of SCO2 in sewage sludge processing is its application in the conditioning of sludge generated in wastewater treatment plants. Experiments have shown that this technology significantly improves the dewatering properties of various types of sludge, including primary, excess, chemical and flotation fat-containing sludges. The settling velocity of volatile suspensions decreased to 76–150 μm/s, while the capillary suction time did not exceed 36 s after conditioning. These results indicate a significant improvement in the sludge dewatering parameters [120].

In addition, the biochemical analysis confirmed the effect of SCO2 on sewage sludge. The most effective variants showed a 14-fold increase in dissolved COD, a 5-fold increase in total nitrogen and protein concentration, a 7-fold increase in carbohydrates and a 23-fold increase in ammonium nitrogen. The concentration of orthophosphates increased 27-fold, while the turbidity of the supernatant increased more than 7-fold. In addition, the RNA content in the dissolved phase increased by 2.23 mg L−1 [117]. The SCO2 treatment proved to be an effective alternative to the conventional sludge conditioning methods and increased the biodegradation of organic matter by 48% compared to the raw biomass [117]. Studies on improving the sanitary conditions of sewage sludge have shown that the SCO2 method effectively reduces the level of pathogens. Compared to hydrodynamic disintegration, the application of SCO2 resulted in a 7.8–14.9% reduction in pathogenic bacteria (Salmonella sp., E. coli, Clostridium perfringens) and coliphages [121]. The highest efficiency was achieved with a hybrid method (hydrodynamic cavitation + SCO2), which reduced pathogens by up to 69.7% [121]. Microbial inactivation during SCO2 freezing results from the expansion of freezing water in the cytoplasm, mechanical damage to cellular structures and osmotic shock [122]. Based on the available studies, LTC-SCO2 technology could be a cost-effective alternative to other sludge treatment methods [123].

7. TeCH4BiogasUp—Application Concept Based on Sewage Sludge

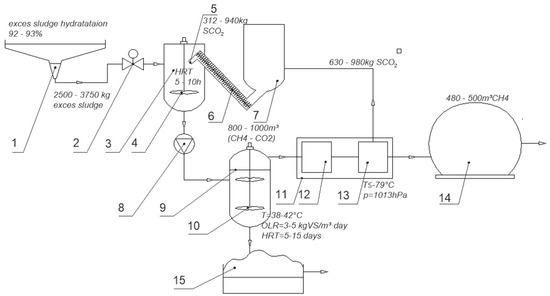

The core innovation of the TeCH4BiogasUp system lies in its process for producing biogas from sewage sludge pretreated with solidified CO2 (SCO2) (Figure 2). The process operates within a closed-loop system to enhance efficiency and sustainability.

Figure 2.

Diagram of the technological system for biogas production and pretreatment of sewage sludge (1—settling tank; 2—pump; 3—pretreatment reactor; 4—mixing system; 5—SCO2 dispenser; 6—screw conveyor; 7—storage tank; 8—pump; 9—sealed methane fermentation chamber; 10—full mixing system; 11—biogas upgrading module; 12—biogas pretreatment section; 13—cryogenic separation section; 14—biomethane tank; 15—fermentation sludge).

Excess sewage sludge, pre-thickened in the settling tank (1), is transferred via a pump (2) into the pretreatment reactor (3), which is equipped with a complete mixing system (4). Within this reactor, the disintegration of microbial cell structures occurs through a low-temperature depolymerization process using SCO2. The disintegrated sludge is then conveyed (8) to a sealed methane fermentation chamber (9), equipped with a full mixing system (10), where the biological decomposition of organic matter into biogas is facilitated. The biogas produced in the fermentation chamber is directed to a biogas upgrading module (11), where CO2 is removed through a cryogenic separation process. This upgrading module consists of two key sections:

- –

- A biogas pretreatment section (12), which performs biogas drying and the removal of gaseous ammonia and hydrogen sulfide;

- –

- A cryogenic separation section (13), which extracts SCO2 at temperatures below −79 °C under standard atmospheric pressure (1013 hPa).

The resulting biomethane is stored in a dedicated tank (14), while the recovered SCO2 is collected in a storage tank (7). The SCO2 is subsequently extracted using a screw conveyor (6) and precisely dosed (5) into the pretreatment reactor (3), thus maintaining a closed-loop system that optimizes resource utilization.

Excess sewage sludge fed to the pretreatment reactor is pre-thickened to a hydration degree of 92–93%. The volume of the pretreatment reactor ensures a hydraulic retention time of the disintegrated excess sewage sludge ranging from 5 to 10 h. The mass ratio of excess sewage sludge to SCO2 is between 4:1 and 8:1. The volume of the closed fermentation chamber provides a hydraulic retention time ranging from 5 to 15 days. The load of organic compounds in the fermentation chamber is between 3.0 and 5.0 kg of organic dry matter/m3·day. The closed fermentation chamber maintains a temperature between 35 and 55 °C, ensuring complete mixing of the chamber contents. Solidified carbon dioxide is collected in a storage tank in the form of pellets with a diameter of 1–3 mm.

This technological solution is unique in that it utilizes CO2 captured during the biogas upgrading process in a closed cycle to disintegrate excess sewage sludge, thereby intensifying the methane fermentation process. Unlike existing methods, this process can be performed continuously in a closed system, reducing CO2 emissions into the atmosphere. The technology is environmentally friendly and offers a competitive alternative both economically and in terms of the final outcomes of fermentation processes. Given the origin of the solidified CO2, this method can be viewed as material recycling, fully aligned with the principles of the circular economy. This technology contributes to the reduction in CO2 emissions through sequestration and utilization in a closed-loop process. The production and use of solidified CO2 in sewage sludge disintegration are environmentally friendly, particularly because CO2 is recovered during the biogas upgrading process. This method also prevents secondary pollution, often associated with chemical decomposition, and avoids the additional energy input required for mechanical processing.

An essential feature of this method is its versatility and broad applicability for the disintegration of sewage sludge with various properties, toxicity levels, chemical compositions and origins, including granulated sludge, which is increasingly popular. This approach is used for the pretreatment of excess sludge, which includes the growing biomass of activated sludge microorganisms periodically removed from the wastewater treatment plant’s technological system. Due to their cell structure and properties, these microorganisms present operational challenges in digester chambers and are less susceptible to anaerobic decomposition compared to easily biodegradable initial sludge. The use of the disintegration method for excess sludge results from the quantitative balance of solidified carbon dioxide that can be achieved.

The process described leads to a closed CO2 cycle. Organic carbon is a component of excess sludge biomass (solid phase Corg.), which is partially transferred to the dissolved phase through disintegration with SCO2. The CO2 stream cyclically changes phases:

- –

- Presence of gaseous CO2 in biogas as a result of fermentation of disintegrated excess sludge (CO2 in the gas phase);

- –

- Removal of CO2 from biogas through solidification in the upgrading process and short-term storage (CO2 in the solid phase);

- –

- Use of solidified CO2 for disintegration of excess sewage sludge;

- –

- Dissolution of CO2 in the liquid phase of this substrate (CO2 in the liquid/dissolved phase) and transfer of Corg. into the dissolved phase;

- –

- Fermentation of the disintegrated excess sludge and re-transfer of CO2 into biogas (CO2 in the gas phase).

- –

- In the described technology, a portion of C undergoes the following:

- –

- Discharge in the dissolved phase into the fermented sludge outside the technological system;

- –

- Assimilation by anaerobic bacteria and incorporation into their growing biomass;

- –

- Loss through sublimation during short-term storage and disintegration of excess sludge;

- –

- Conversion into methane (CH4) in reduction methanogenic processes following the reaction CO2 + 2H2 = CH4 + O2.

Table 4 presents the average unit values (per 1 tonne of mixed sludge) of the essential components of the described technology and the mass balance of sludge in municipal wastewater treatment facilities, including biogas and carbon dioxide produced, along with technological parameters of the disintegration and fermentation process characteristic of the method according to the invention.

Table 4.

Estimated mass balance of the main process components and the initial technological parameters of the process determined on the basis of previous research.

8. Estimated Economic Analysis

Evaluating the energy efficiency of innovative technological solutions is crucial for assessing their feasibility for large-scale implementation. Based on previous studies [40,78], an estimated energy balance was calculated, incorporating the energy demand for SCO2 production, methane (CH4) production efficiency, and its energy value (9.17 Wh/L).

The specific energy input (Es) was determined using Equation (1). The parameters required for the calculation, including the power of the SCO2 generator (PSCO2), the SCO2 mass (MSCO2), and the generator yield (YSCO2), were derived based on data from the P3000 Pelletizer device (Cold Jet, Loveland, CO, USA) [124]:

where the following definitions hold:

Es = (PSCO2 × MSCO2)/YSCO2 (kWh)

- PSCO2—power consumption of the SCO2 generator (kW);

- MSCO2—mass of produced SCO2 (kg);

- YSCO2—yield capacity of the SCO2 generator (kg/h).

The energy output (Eout) associated with methane production was computed following Equation (2):

where the following definitions hold:

Eout = YMethane × CVMethane × MSL (kWh/MgVS)

- YMethane—methane yield (m3/MgVS);

- CVMethane—calorific value of methane (kWh/m3);

- MSL—mass of sludge (MgVS).

The net energy gain (Enet) was derived from Equation (3):

where the following definitions hold:

Enet = Enout − Es (kWh/MgVS)

- Enout—net energy output (kWh/MgVS);

- Es—specific energy input (kWh/MgVS).

The energy value (EV) was determined using Equation (4):

where the following definitions hold:

EV = Enet × EP (€/MgVS)

- Enet—net energy gain (kWh/MgVS);

- EP—energy price (EUR/kWh), calculated as the average value from 2020 to mid-2022 based on Eurostat data [29].

The monetary value of SCO2 (SCO2V) was assessed using Equation (5):

where the following definitions hold:

SCO2V = MSCO2 × CPP (€)

- MSCO2—mass of SCO2 (kg/MgVS);

- CPP—price of EU Carbon Permits (EUR/kg), averaged for the period between 2020 and mid-2022, as per Trading Economics data [30].

The total profit was obtained from Equation (6):

where the following definitions hold:

Profit = EV + SCO2V (€)

- EV—energy value (EUR/MgVS);

- SCO2V—financial valuation of SCO2 (EUR/MgVS).

The calculations of the net energy output achieved do not include the energy consumption for other process units required for the proper operation of large-scale anaerobic digesters. These primarily include the operation of pumps that feed the sewage sludge into the anaerobic reactors and discharge the fermented substrate, systems for mixing and heating the contents of the bioreactors or control and measurement equipment. However, it should be noted that regardless of the fact that the TeCH4BiogasUp technology is implemented in the technological system, the energy consumption for the above-mentioned process will be analogous. Therefore, this has no influence on the determination of the energy efficiency of the proposed pretreatment method. For this reason, these power receivers were not taken into account in the energy balance presented and in the determination of the final obtained net power.

Considering the methane production yield and its energy value of 9.17 Wh/dm³, the highest total energy gain was achieved in variant V4, amounting to 3053 ± 100 kWh/MgVS (Table 5). In contrast, in the control variant (V1), the gain was only 1950 ± 110 kWh/MgVS [40]. An essential factor influencing the economic viability of fermentation processes is the potential reduction in CO2 emissions to the atmosphere. The estimated economic analysis demonstrated potential profits ranging from 630 ± 40 EUR/MgVS (ratio 0.1) to 1332 ± 30 EUR/MgVS (ratio 0.3) [40].

Table 5.

Energy and economic analysis of the application of sewage sludge disintegration using SCO2 prior to methane fermentation under batch conditions.

Further tests on excess sludge from a dairy wastewater treatment plant [78] also indicated a positive net energy balance for SCO2/sewage sludge ratios between 0.1 and 0.3. These tests showed an increase in energy gain, ranging from 2700 ± 110 kWh/MgVS (ratio 0.1) to 2800 ± 100 kWh/MgVS (ratio 0.3). An economic analysis for these scenarios showed potential profits ranging from 770 ± 30 EUR/MgVS to 1240 ± 30 EUR/MgVS, corresponding to SCO2/sewage sludge ratios of 0.1 to 0.5 [78]. The detailed results of this analysis are presented in Table 5.

However, in the long-term use of SCO2 conditioning of sewage sludge prior to anaerobic digestion in continuous reactors [41], the highest gross energy gain was achieved at an organic loading rate (OLR) of 3.0 gVS/L·day, amounting to 187.07 ± 1.5 Wh/day (Table 6). In contrast, for the variant without disintegration, only 148.55 ± 1.3 Wh/day was achieved. The application of SCO2 pretreatment to intensify the methane fermentation process is well justified when these solutions utilize a closed CO2 cycle. This approach serves as a significant factor for improving the economic, technological and environmental efficiency of anaerobic sewage sludge fermentation [41].

Table 6.

Energy analysis of the application of sewage sludge disintegration using SCO2 before its AD under continuous conditions.

9. Summary and Conclusions

In light of the facts presented, there is a growing need to develop new, environmentally friendly technologies for the pretreatment of biomass with varying characteristics and origins, including sewage sludge. These technologies should offer a competitive alternative in terms of both the economics of the process and the final outcomes of methane fermentation. They contribute directly to the circular economy concept by supporting CO2 sequestration and utilization in a closed cycle. An important aspect is the versatility and the broad applicability of these new solutions for the digestion of biomass with different properties, toxicities, chemical compositions and origins—such as the increasingly popular granular sludge or microalgae biomass.

Given the techniques described in the literature and currently used in practice for pretreating biomass before methane fermentation, the TeCH4BiogasUp solution emerges as a justified and competitive alternative. Respirometric studies have shown that pretreatment of excess dairy sludge with solidified CO2 provides an increase in net energy gain of about 12%, compared to almost 36% for anaerobic granular sludge. For dairy sludge, the net energy gain increased from 2480 ± 190 kWh/MgVS for the variant without pretreatment to 2800 ± 100 kWh/MgVS at a volume ratio of SCO2/dairy sludge of 0.3. For aerobic granular sludge, the energy gain increased from 1950 ± 110 kWh/MgVS to 3053 ± 100 kWh/MgVS. When operating the continuous bioreactors, the highest CH4 yield was achieved at an organic load rate of 3.0 gVS/L d and totaled 20.4 ± 1.5 L/day. In the variant without pretreatment with SCO2, it was 16.2 ± 1.3 LCH4/day.

Considering the origin of the solidified CO2, this method can be regarded as material recycling, fully aligned with the principles of the circular economy. This technology promotes the reduction in CO2 emissions through sequestration and integration into a closed-loop process. The production and use of solidified CO2 in biomass disintegration is undoubtedly an environmentally friendly approach, particularly as the CO2 is recovered in the biogas upgrading process. This method also avoids secondary pollutants often generated during chemical decomposition and the additional energy input required for mechanical processing.

This novel approach to the production and utilization of solidified CO2 largely addresses previous limitations related to the low profitability of the process. TeCH4BiogasUp may prove to be a valid alternative to other methods, considering the evolving economic landscape and the necessity to reduce CO2 emissions through the advancement of renewable energy sources.

TeCH4BiogasUp is an original idea that has yet to be described or applied in practice. This innovative technology can be implemented to intensify biomethane production in fermentation processes. It is important to note that TeCH4BiogasUp integrates three previously separate processes: disintegration of organic substrates, biogas upgrading, and sequestration and utilization of CO2 in a closed cycle. The multifunctional and hybrid nature of TeCH4BiogasUp sets it apart from other available solutions that perform only specific, isolated technological functions. While this presents a significant advantage and market potential, it also poses challenges in conducting comparative analyses with existing competitive solutions. Due to the lack of integrated installations, the existing technologies were utilized to realize the two primary goals of TeCH4BiogasUp—pretreatment of organic substrates for fermentation and biogas upgrading to biomethane.

Author Contributions

Conceptualization, J.K. and M.D.; methodology, J.K., M.D. and M.Z.; formal analysis, J.K. and M.D.; investigation, J.K., M.D. and M.Z.; resources, J.K., M.D. and M.Z.; writing—original draft preparation, J.K. and M.D.; writing—review and editing, J.K. and M.D.; visualization, J.K. and M.D.; supervision, J.K. and M.D.; project administration, J.K.; funding acquisition, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by works WZ/WB-IIŚ/3/2022 of the Bialystok University of Technology and No. 29.610.023-110 of the University of Warmia and Mazury in Olsztyn, funded by the Ministry of Science and Higher Education.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Campoli, J.S.; Alves Junior, P.N.; Kodama, T.K.; Nagano, M.S.; Burnquist, H.L. G20 Countries’ Progress on the 7th SDG under Circular Economy DEA Model. Environ. Sci. Policy 2024, 160, 103839. [Google Scholar] [CrossRef]

- Teleszewski, T.J.; Hożejowski, L. Estimating Sludge Deposition on the Heat Exchanger in the Digester of a Biogas Plant. Sustainability 2024, 16, 7981. [Google Scholar] [CrossRef]

- Yu, Z.; Kamran, H.W.; Amin, A.; Ahmed, B.; Peng, S. Sustainable Synergy via Clean Energy Technologies and Efficiency Dynamics. Renew. Sustain. Energy Rev. 2023, 187, 113744. [Google Scholar] [CrossRef]

- Vasan, V.; Sridharan, N.V.; Feroskhan, M.; Vaithiyanathan, S.; Subramanian, B.; Tsai, P.C.; Lin, Y.C.; Lay, C.H.; Wang, C.T.; Ponnusamy, V.K. Biogas Production and Its Utilization in Internal Combustion Engines—A Review. Process Saf. Environ. Prot. 2024, 186, 518–539. [Google Scholar] [CrossRef]

- Pavičić, J.; Mavar, K.N.; Brkić, V.; Simon, K. Biogas and Biomethane Production and Usage: Technology Development, Advantages and Challenges in Europe. Energies 2022, 15, 2940. [Google Scholar] [CrossRef]

- Rodrigues, B.C.G.; de Mello, B.S.; Grangeiro, L.C.; Dussan, K.J.; Sarti, A. The Most Important Technologies and Highlights for Biogas Production Worldwide. J. Air Waste Manag. Assoc. 2024, 75, 87–108. [Google Scholar] [CrossRef] [PubMed]

- Mignogna, D.; Ceci, P.; Cafaro, C.; Corazzi, G.; Avino, P. Production of Biogas and Biomethane as Renewable Energy Sources: A Review. Appl. Sci. 2023, 13, 10219. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Biogas Production and Applications in the Sustainable Energy Transition. J. Energy 2022, 2022, 1–43. [Google Scholar] [CrossRef]

- Jameel, M.K.; Mustafa, M.A.; Ahmed, H.S.; Mohammed, A.J.; Ghazy, H.; Shakir, M.N.; Lawas, A.M.; Mohammed, S.K.; Idan, A.H.; Mahmoud, Z.H.; et al. Biogas: Production, Properties, Applications, Economic and Challenges: A Review. Results Chem. 2024, 7, 101549. [Google Scholar] [CrossRef]

- Corigliano, O.; Iannuzzi, M.; Pellegrino, C.; D’Amico, F.; Pagnotta, L.; Fragiacomo, P. Enhancing Energy Processes and Facilities Redesign in an Anaerobic Digestion Plant for Biomethane Production. Energies 2023, 16, 5782. [Google Scholar] [CrossRef]

- Sulewski, P.; Ignaciuk, W.; Szymańska, M.; Wąs, A. Development of the Biomethane Market in Europe. Energies 2023, 16, 2001. [Google Scholar] [CrossRef]

- Rogala, Z.; Stanclik, M.; Łuszkiewicz, D.; Malecha, Z. Perspectives for the Use of Biogas and Biomethane in the Context of the Green Energy Transformation on the Example of an EU Country. Energies 2023, 16, 1911. [Google Scholar] [CrossRef]

- Now Environment. Biogas in Poland in 2023. Available online: https://www.teraz-srodowisko.pl/publikacje/biogaz-w-polsce-2023/teraz-srodowisko-publikacja-biogaz-w-polsce-2023.pdf (accessed on 13 November 2024).

- Journal of Laws 2023 Item 1762. Act of 17 August 2023 Amending the Act on Renewable Energy Sources and Certain Other Acts. 2023. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20230001762 (accessed on 13 November 2024).

- PGNiG Bioevolution. Biogas Plant in Głąbów. Available online: https://bioevolution.orlen.pl/pl/o-spolce/nasze-biogazownie/biogazownia-w-glabowie (accessed on 11 November 2024).

- Elalami, D.; Carrere, H.; Abdelouahdi, K.; Garcia-Bernet, D.; Peydecastaing, J.; Vaca-Medina, G.; Oukarroum, A.; Zeroual, Y.; Barakat, A. Mild Microwaves, Ultrasonic and Alkaline Pretreatments for Improving Methane Production: Impact on Biochemical and Structural Properties of Olive Pomace. Bioresour. Technol. 2020, 299, 122591. [Google Scholar] [CrossRef]

- Garlicka, A.; Zubrowska-Sudol, M.; Umiejewska, K.; Roubinek, O.; Palige, J.; Chmielewski, A. Effects of Thickened Excess Sludge Pre-Treatment Using Hydrodynamic Cavitation for Anaerobic Digestion. Energies 2020, 13, 2483. [Google Scholar] [CrossRef]

- Kainthola, J.; Shariq, M.; Kalamdhad, A.S.; Goud, V.V. Enhanced Methane Potential of Rice Straw with Microwave Assisted Pretreatment and Its Kinetic Analysis. J. Environ. Manag. 2019, 232, 188–196. [Google Scholar] [CrossRef] [PubMed]

- Kovačič, A.; Škufca, D.; Zupanc, M.; Gostiša, J.; Bizjan, B.; Krištofelc, N.; Dolenc, M.S.; Heath, E. The Removal of Bisphenols and Other Contaminants of Emerging Concern by Hydrodynamic Cavitation: From Lab-Scale to Pilot-Scale. Sci. Total Environ. 2020, 743, 140724. [Google Scholar] [CrossRef]

- Zupanc, M.; Humar, B.B.; Dular, M.; Gostiša, J.; Hočevar, M.; Repinc, S.K.; Krzyk, M.; Novak, L.; Ortar, J.; Pandur, Ž.; et al. The Use of Hydrodynamic Cavitation for Waste-to-Energy Approach to Enhance Methane Production from Waste Activated Sludge. J. Environ. Manag. 2023, 347, 119074. [Google Scholar] [CrossRef] [PubMed]

- Mancuso, G.; Langone, M.; Andreottola, G.; Bruni, L. Effects of Hydrodynamic Cavitation, Low-Level Thermal and Low-Level Alkaline Pre-Treatments on Sludge Solubilisation. Ultrason. Sonochem. 2019, 59, 104750. [Google Scholar] [CrossRef] [PubMed]

- Zubrowska-Sudol, M.; Podedworna, J.; Sytek-Szmeichel, K.; Bisak, A.; Krawczyk, P.; Garlicka, A. The Effects of Mechanical Sludge Disintegration to Enhance Full-Scale Anaerobic Digestion of Municipal Sludge. Therm. Sci. Eng. Prog. 2018, 5, 289–295. [Google Scholar] [CrossRef]

- Nabi, M.; Zhang, G.; Li, F.; Zhang, P.; Wu, Y.; Tao, X.; Bao, S.; Wang, S.; Chen, N.; Ye, J.; et al. Enhancement of High Pressure Homogenization Pretreatment on Biogas Production from Sewage Sludge: A Review. Desalin. Water Treat. 2018, 175, 341–351. [Google Scholar] [CrossRef]

- Zieliński, M.; Dȩbowski, M.; Krzemieniewski, M.; Rusanowska, P.; Zielińska, M.; Cydzik-Kwiatkowska, A.; Głowacka-Gil, A. Application of an Innovative Ultrasound Disintegrator for Sewage Sludge Conditioning before Methane Fermentation. J. Ecol. Eng. 2018, 19, 240–247. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Wang, J. Enhanced Sewage Sludge Disintegration and Hydrogen Production by Ionizing Radiation Pretreatment in the Presence of Fe2+. ACS Sustain. Chem. Eng. 2019, 7, 15548–15557. [Google Scholar] [CrossRef]

- Rózycki, S.; Banas, M. Exergy Analysis of Cavitation Pretreatment of Sludge. E3S Web Conf. 2018, 49, 00089. [Google Scholar] [CrossRef]

- Waclawek, S.; Grübel, K.; Silvestri, D.; Padil, V.V.T.; Waclawek, M.; Cerník, M.; Varma, R.S. Disintegration of Wastewater Activated Sludge (WAS) for Improved Biogas Production. Energies 2018, 12, 21. [Google Scholar] [CrossRef]

- Yesil, H.; Molaey, R.; Calli, B.; Tugtas, A.E. Removal and Recovery of Heavy Metals from Sewage Sludge via Three-Stage Integrated Process. Chemosphere 2021, 280, 130650. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.; Xiao, X.; Wang, J.; Hong, M.; Deng, C.; Li, Y.Y.; Liu, J. Enhancing Phosphorus Recovery from Sewage Sludge Using Anaerobic-Based Processes: Current Status and Perspectives. Bioresour. Technol. 2021, 341, 125899. [Google Scholar] [CrossRef] [PubMed]

- Zawieja, I.; Worwąg, M. Biogas Production from Excess Sludge Oxidized with Peracetic Acid (PAA). Energies 2021, 14, 3434. [Google Scholar] [CrossRef]

- Tuncay, S.; Akcakaya, M.; Icgen, B. Ozonation of Sewage Sludge Prior to Anaerobic Digestion Led to Methanosaeta Dominated Biomethanation. Fuel 2022, 313, 122690. [Google Scholar] [CrossRef]

- Koupaie, E.H.; Lin, L.; Lakeh, A.B.; Azizi, A.; Dhar, B.; Hafez, H.; Elbeshbishy, E. Performance Evaluation and Microbial Community Analysis of Mesophilic and Thermophilic Sludge Fermentation Processes Coupled with Thermal Hydrolysis. Renew. Sustain. Energy Rev. 2021, 141, 110832. [Google Scholar] [CrossRef]

- Zawieja, I.E. The Course of the Methane Fermentation Process of Dry Ice Modified Excess Sludge. Arch. Environ. Prot. 2019, 45, 50–58. [Google Scholar] [CrossRef]

- Khanh Nguyen, V.; Kumar Chaudhary, D.; Hari Dahal, R.; Hoang Trinh, N.; Kim, J.; Chang, S.W.; Hong, Y.; Duc La, D.; Nguyen, X.C.; Hao Ngo, H.; et al. Review on Pretreatment Techniques to Improve Anaerobic Digestion of Sewage Sludge. Fuel 2021, 285, 119105. [Google Scholar] [CrossRef]

- Atelge, M.R.; Atabani, A.E.; Banu, J.R.; Krisa, D.; Kaya, M.; Eskicioglu, C.; Kumar, G.; Lee, C.; Yildiz, Y.; Unalan, S.; et al. A Critical Review of Pretreatment Technologies to Enhance Anaerobic Digestion and Energy Recovery. Fuel 2020, 270, 117494. [Google Scholar] [CrossRef]

- Ampese, L.C.; Sganzerla, W.G.; Di Domenico Ziero, H.; Mudhoo, A.; Martins, G.; Forster-Carneiro, T. Research Progress, Trends, and Updates on Anaerobic Digestion Technology: A Bibliometric Analysis. J. Clean. Prod. 2022, 331, 130004. [Google Scholar] [CrossRef]

- Lippert, T.; Bandelin, J.; Xu, Y.; Liu, Y.C.; Robles, G.H.; Drewes, J.E.; Koch, K. From Pre-Treatment to Co-Treatment—How Successful Is Ultrasonication of Digested Sewage Sludge in Continuously Operated Anaerobic Digesters? Renew. Energy 2020, 166, 56–65. [Google Scholar] [CrossRef]

- Yildiz, S.; Oran, E. Sewage Sludge Disintegration by Electrocoagulation. Int. J. Environ. Heal. Res. 2018, 29, 531–543. [Google Scholar] [CrossRef] [PubMed]

- Zhen, G.; Lu, X.; Kato, H.; Zhao, Y.; Li, Y.Y. Overview of Pretreatment Strategies for Enhancing Sewage Sludge Disintegration and Subsequent Anaerobic Digestion: Current Advances, Full-Scale Application and Future Perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M. Technological, Ecological, and Energy-Economic Aspects of Using Solidified Carbon Dioxide for Aerobic Granular Sludge Pre-Treatment Prior to Anaerobic Digestion. Int. J. Environ. Res. Public Health 2023, 20, 4234. [Google Scholar] [CrossRef] [PubMed]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M. Long-Term Pre-Treatment of Municipal Sewage Sludge with Solidified Carbon Dioxide (SCO2)—Effect on Anaerobic Digestion Efficiency. Appl. Sci. 2023, 13, 3075. [Google Scholar] [CrossRef]

- Wang, X.; Gao, C.; Qi, X.; Zhang, Y.; Chen, T.; Xie, Y.; Zhang, A.; Gao, J. Enhancing Sludge Fermentation and Anaerobic Digestion by Mechanical Cutting Pretreatment. J. Water Process Eng. 2021, 40, 101812. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M. Gospodarka Osadowa Oczyszczalni Ścieków. Intensyfikacja Wybranych Problemów i Propozycja Rozwiązań; Verlag Dashofer Sp. zoo: Warsaw, Poland, 2011. [Google Scholar]

- Stępień, M.; Krawczyk, P.; Wołowicz, M.; Mikołajczak, A. Dezintegracja Substratów Biologicznych Przed Procesem Fermentacji. Przegląd Stosow. Technol. 2018, 138, 5. [Google Scholar]

- Myszograj, S.; Płuciennik-Koropczuk, E. Thermal Disintegration of Sewage Sludge as a Method of Improving the Biogas Potential. Energies 2023, 16, 559. [Google Scholar] [CrossRef]

- Sahu, A.K.; Mitra, I.; Kleiven, H.; Holte, H.R.; Svensson, K. Cambi Thermal Hydrolysis Process (CambiTHP) for Sewage Sludge Treatment. In Clean Energy and Resource Recovery; Elsevier: Amsterdam, The Netherlands, 2022; Volume 2, pp. 405–422. [Google Scholar] [CrossRef]

- Wang, M.; Chen, H.; Chang, S. Impact of Combined Biological Hydrolysis and Anaerobic Digestion Temperatures on the Characteristics of Bacterial Community and Digestate Quality in the Treatment of Wastewater Sludge. Bioresour. Technol. 2022, 362, 127796. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, H.C.; Buffiere, P.; Bayard, R. Understanding the Role of Mechanical Pretreatment before Anaerobic Digestion: Lab-Scale Investigations. Renew. Energy 2022, 187, 193–203. [Google Scholar] [CrossRef]

- Coarita Fernandez, H.; Amaya Ramirez, D.; Teixeira Franco, R.; Buffière, P.; Bayard, R. Methods for the Evaluation of Industrial Mechanical Pretreatments before Anaerobic Digesters. Molecules 2020, 25, 860. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xie, Y.; Qi, X.; Chen, T.; Zhang, Y.; Gao, C.; Zhang, A.; Ren, W. A New Mechanical Cutting Pretreatment Approach towards the Improvement of Primary Sludge Fermentation and Anaerobic Digestion. J. Environ. Chem. Eng. 2022, 10, 107163. [Google Scholar] [CrossRef]

- De Crescenzo, C.; Marzocchella, A.; Karatza, D.; Molino, A.; Ceron-Chafla, P.; Lindeboom, R.E.F.; van Lier, J.B.; Chianese, S.; Musmarra, D. Modelling of Autogenerative High-Pressure Anaerobic Digestion in a Batch Reactor for the Production of Pressurised Biogas. Biotechnol. Biofuels Bioprod. 2022, 15, 20. [Google Scholar] [CrossRef]

- Nabi, M.; Liang, J.; Zhang, P.; Wu, Y.; Fu, C.; Wang, S.; Ye, J.; Gao, D.; Shah, F.A.; Dai, J. Anaerobic Digestion of Sewage Sludge Pretreated by High Pressure Homogenization Using Expanded Granular Sludge Blanket Reactor: Feasibility, Operation Optimization and Microbial Community. J. Environ. Chem. Eng. 2021, 9, 104720. [Google Scholar] [CrossRef]

- Xiao, H.; Liang, J.; Zhang, Y.; Chang, J.; Zhang, R.; Zhang, P. Conversion of Materials and Energy in Anaerobic Digestion of Sewage Sludge with High-Pressure Homogenization Pretreatment. Processes 2023, 11, 2467. [Google Scholar] [CrossRef]

- Dauknys, R.; Mažeikienė, A.; Paliulis, D. Effect of Ultrasound and High Voltage Disintegration on Sludge Digestion Process. J. Environ. Manag. 2020, 270, 110833. [Google Scholar] [CrossRef]

- Dębowski, M.; Kisielewska, M.; Zieliński, M.; Kazimierowicz, J. The Influence of the Ultrasound Disintegration of Microalgal–Bacterial Granular Sludge on Anaerobic Digestion Efficiency. Appl. Sci. 2023, 13, 7387. [Google Scholar] [CrossRef]

- Sridhar, P.; Tyagi, R.D.; Bhunia, P.; Rout, P.R.; Zhang, T.C.; Surampalli, R.Y. Greenhouse Gas Emissions in Sludge Ultrasonication Followed by Anaerobic Digestion Processes. Bioresour. Technol. 2021, 341, 125754. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Song, G.; Lu, C.; Wang, J.; Liu, R.; Hu, C. Ultrasonication as Anaerobic Digestion Pretreatment to Improve Sewage Sludge Methane Production: Performance and Microbial Characterization. J. Environ. Sci. 2024, 146, 15–27. [Google Scholar] [CrossRef] [PubMed]

- Szaja, A.; Szulżyk-Cieplak, J.; Łagód, S.; Kuzioła, E. Recent Developments in the Application of Ultrasonication in Pre-Treatment of Municipal Sewage Sludge. J. Ecol. Eng. 2023, 24, 223–234. [Google Scholar] [CrossRef] [PubMed]

- Elagroudy, S.; Radwan, A.G.; Banadda, N.; Mostafa, N.G.; Owusu, P.A.; Janajreh, I. Mathematical Models Comparison of Biogas Production from Anaerobic Digestion of Microwave Pretreated Mixed Sludge. Renew. Energy 2020, 155, 1009–1020. [Google Scholar] [CrossRef]

- Kocbek, E.; Garcia, H.A.; Hooijmans, C.M.; Mijatović, I.; Lah, B.; Brdjanovic, D. Microwave Treatment of Municipal Sewage Sludge: Evaluation of the Drying Performance and Energy Demand of a Pilot-Scale Microwave Drying System. Sci. Total Environ. 2020, 742, 140541. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhao, M.; Lv, C.; Yue, P. The Effect of Microwave Pretreatment on Anaerobic Co-Digestion of Sludge and Food Waste: Performance, Kinetics and Energy Recovery. Environ. Res. 2020, 189, 109856. [Google Scholar] [CrossRef] [PubMed]

- Zieliński, M.; Dębowski, M.; Rusanowska, P.; Kazimierowicz, J. Influence of Microwave Radiation on Pollutant Removal and Biomethane Production Efficiency in Anaerobic Treatment of High-Load Poultry Wastewater. Appl. Sci. 2023, 13, 3553. [Google Scholar] [CrossRef]

- Abdelrahman, A.M.; Tebyani, S.; Talabazar, F.R.; Tabar, S.A.; Berenji, N.R.; Aghdam, A.S.; Koyuncu, I.; Kosar, A.; Guven, H.; Ersahin, M.E.; et al. The Flow Pattern Effects of Hydrodynamic Cavitation on Waste Activated Sludge Digestibility. Chemosphere 2024, 357, 141949. [Google Scholar] [CrossRef] [PubMed]

- Dębowski, M.; Kazimierowicz, J.; Nowicka, A.; Dudek, M.; Zieliński, M. The Use of Hydrodynamic Cavitation to Improve the Anaerobic Digestion of Waste from Dairy Cattle Farming—From Laboratory Tests to Large-Scale Agricultural Biogas Plants. Energies 2024, 17, 1409. [Google Scholar] [CrossRef]

- Vilarroig, J.; Martínez, R.; Zuriaga-Agustí, E.; Torró, S.; Galián, M.; Chiva, S. Design and Optimization of a Semi-Industrial Cavitation Device for a Pretreatment of an Anaerobic Digestion Treatment of Excess Sludge and Pig Slurry. Water Environ. Res. 2020, 92, 2060–2071. [Google Scholar] [CrossRef] [PubMed]

- Ding, H.H.; Chang, S.; Liu, Y. Biological Hydrolysis Pretreatment on Secondary Sludge: Enhancement of Anaerobic Digestion and Mechanism Study. Bioresour. Technol. 2017, 244, 989–995. [Google Scholar] [CrossRef]

- Mehari, B.B.; Chang, S.; Hong, Y.; Chen, H. Temperature-Phased Biological Hydrolysis and Thermal Hydrolysis Pretreatment for Anaerobic Digestion Performance Enhancement. Water 2018, 10, 1812. [Google Scholar] [CrossRef]

- Menzel, T.; Neubauer, P.; Junne, S. Role of Microbial Hydrolysis in Anaerobic Digestion. Energies 2020, 13, 5555. [Google Scholar] [CrossRef]

- Akhlisah, Z.N.; Yunus, R.; Abidin, Z.Z.; Lim, B.Y.; Kania, D. Pretreatment Methods for an Effective Conversion of Oil Palm Biomass into Sugars and High-Value Chemicals. Biomass Bioenergy 2021, 144, 105901. [Google Scholar] [CrossRef]

- Sidana, A.; Yadav, S.K. Recent Developments in Lignocellulosic Biomass Pretreatment with a Focus on Eco-Friendly, Non-Conventional Methods. J. Clean. Prod. 2022, 335, 130286. [Google Scholar] [CrossRef]

- Zeng, Y.; Tang, X.; Fan, C.; Tang, L.; Zhou, M.; Zhang, B.; Wang, R.; Li, G. Evaluating the Effects of Different Pretreatments on Anaerobic Digestion of Waste Activated Sludge Containing Polystyrene Microplastics. ACS Environ. Sci. Technol. Water 2022, 2, 117–127. [Google Scholar] [CrossRef]

- Nguyen, L.N.; Kumar, J.; Vu, M.T.; Mohammed, J.A.H.; Pathak, N.; Commault, A.S.; Sutherland, D.; Zdarta, J.; Tyagi, V.K.; Nghiem, L.D. Biomethane Production from Anaerobic Co-Digestion at Wastewater Treatment Plants: A Critical Review on Development and Innovations in Biogas Upgrading Techniques. Sci. Total Environ. 2021, 765, 142753. [Google Scholar] [CrossRef] [PubMed]

- Chandra, R.; Isha, A.; Kumar, S.; Khan, S.A.; Subbarao, P.M.V.; Vijay, V.K.; Chandel, A.K.; Chaudhary, V.P. Potentials and Challenges of Biogas Upgradation as Liquid Biomethane. Biogas Prod. 2020, 307–328. [Google Scholar] [CrossRef]