Study on the Propagation Law of CO2 Displacement in Tight Conglomerate Reservoirs in the Mahu Depression, Xinjiang, China

Abstract

1. Introduction

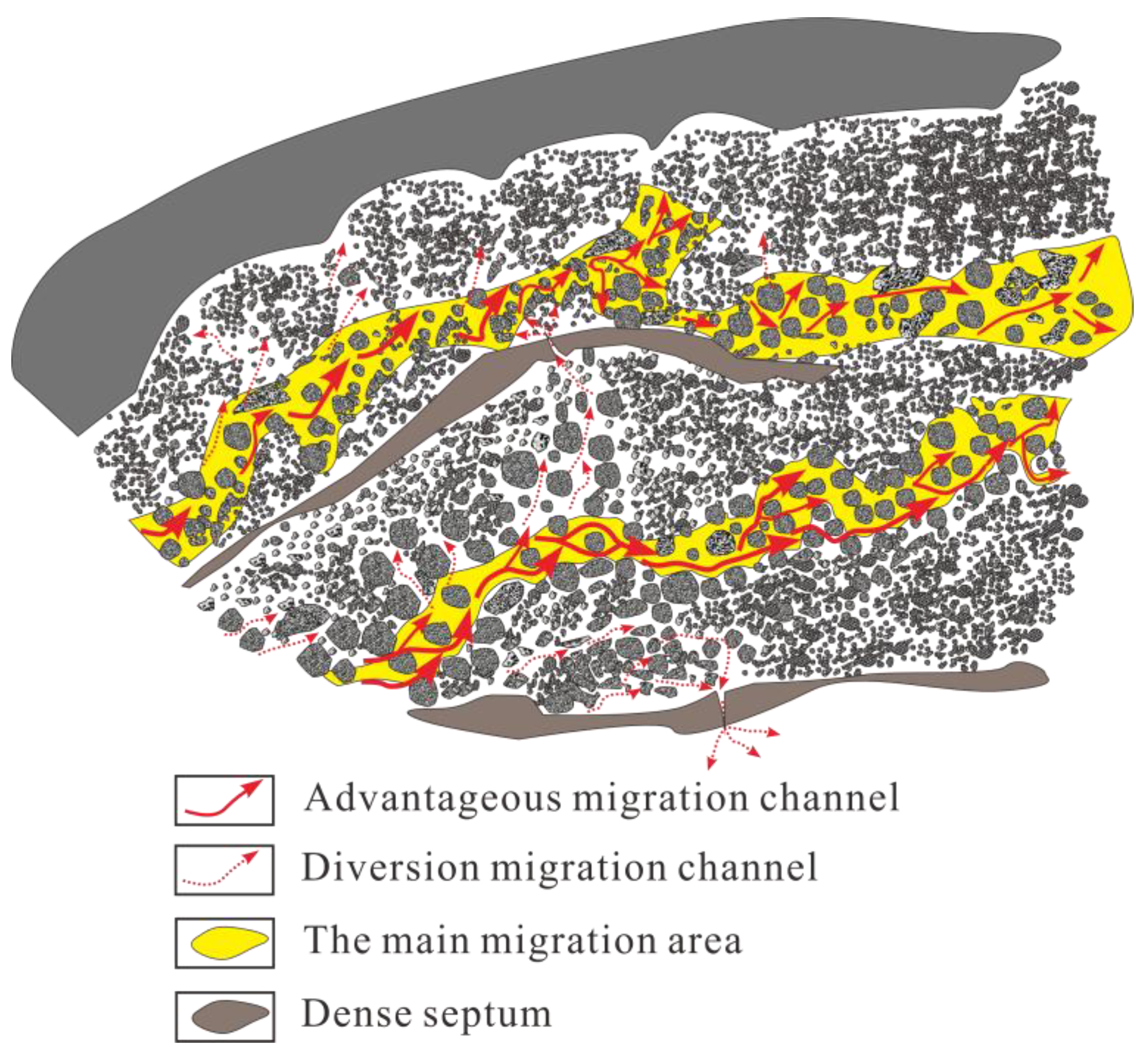

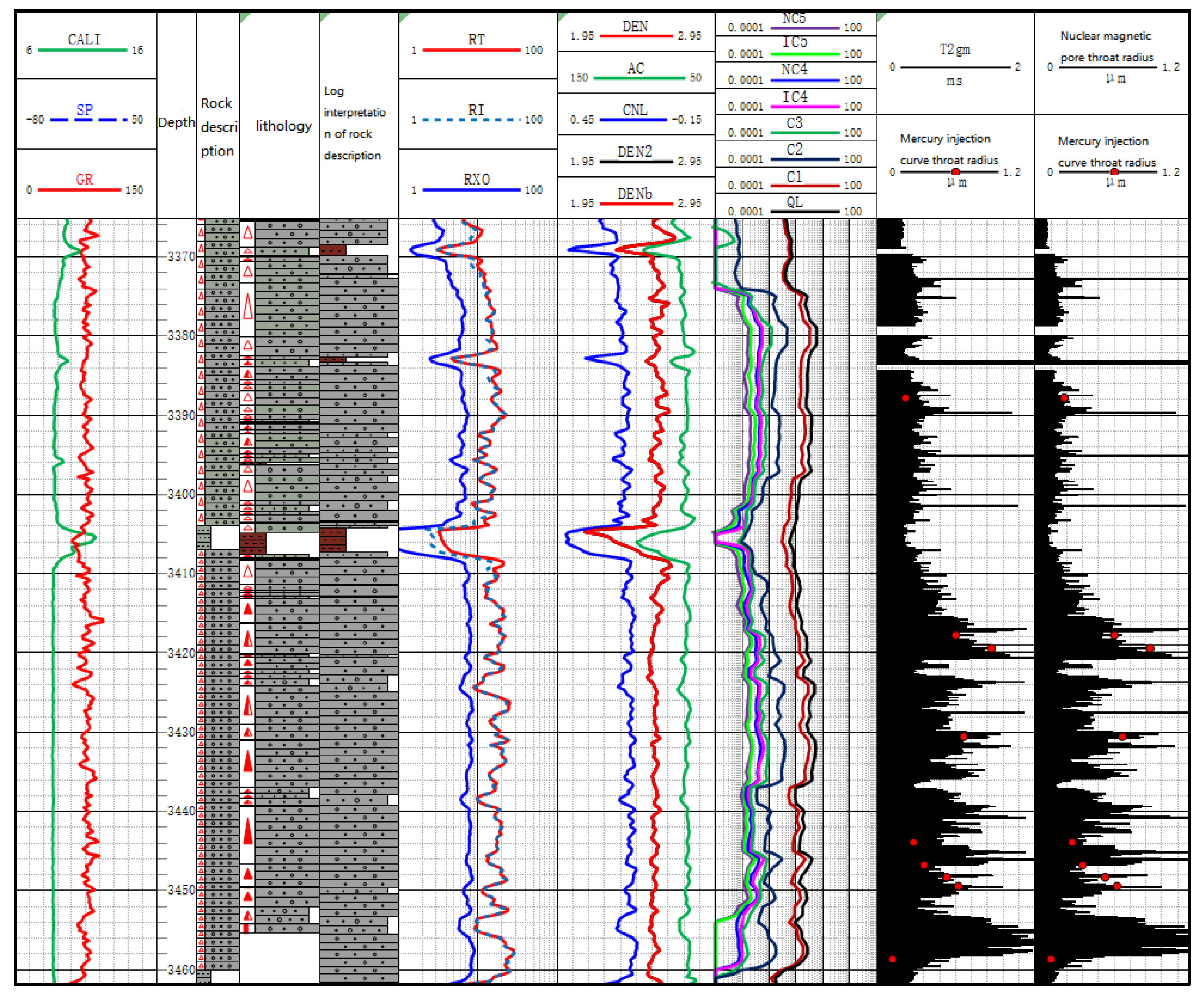

2. Distribution Pattern of Pore Throats

2.1. Core Experiment

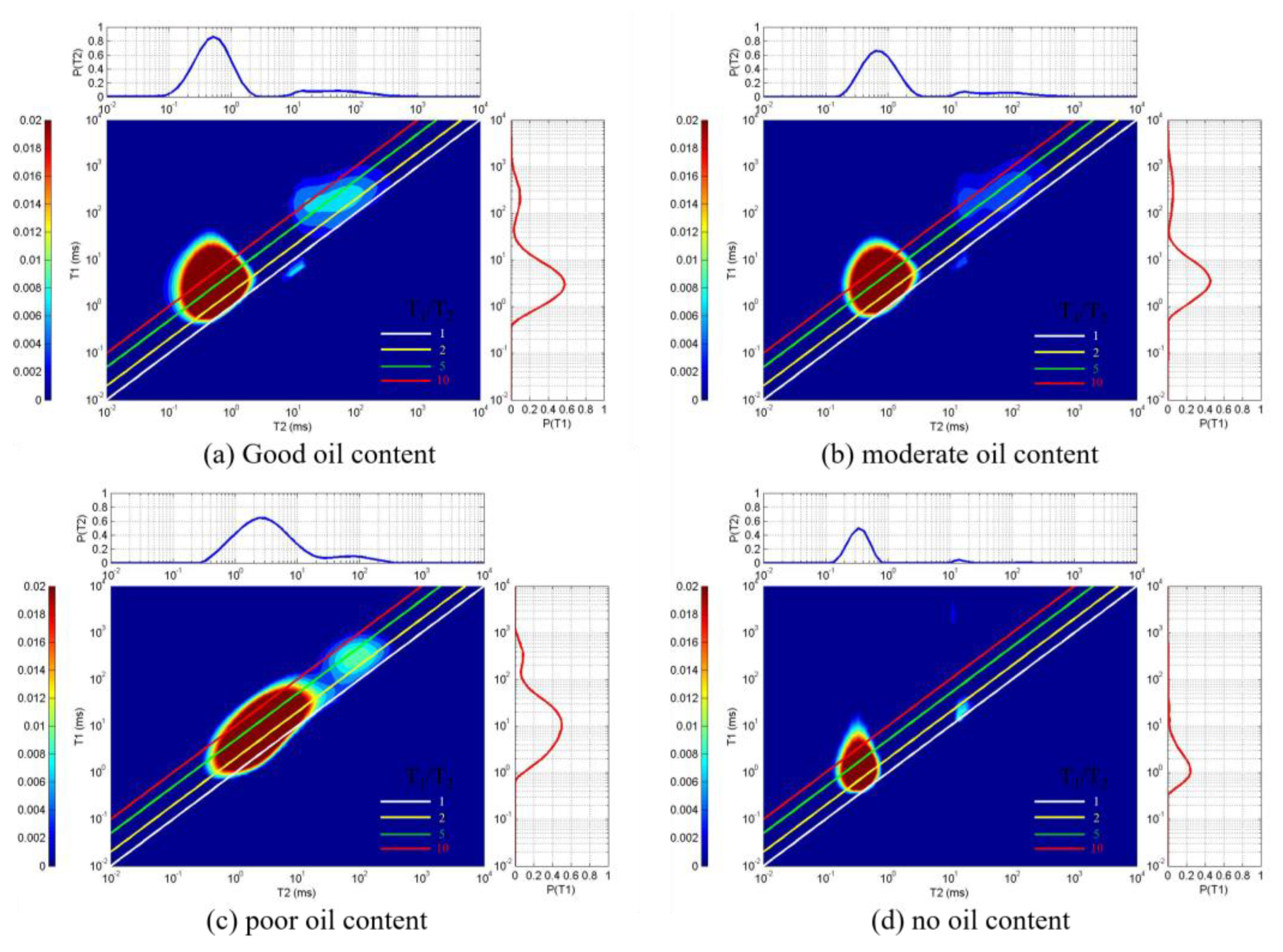

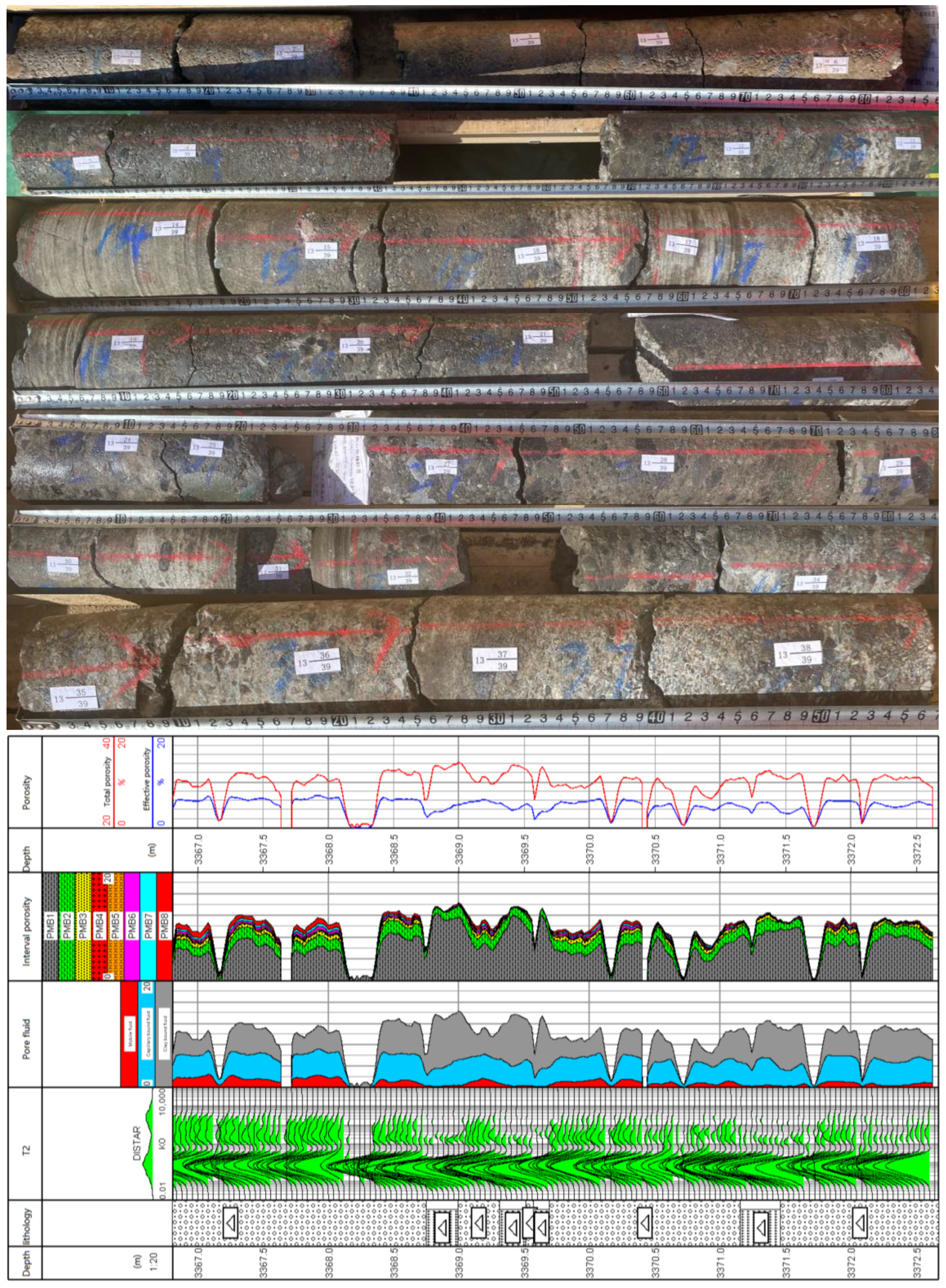

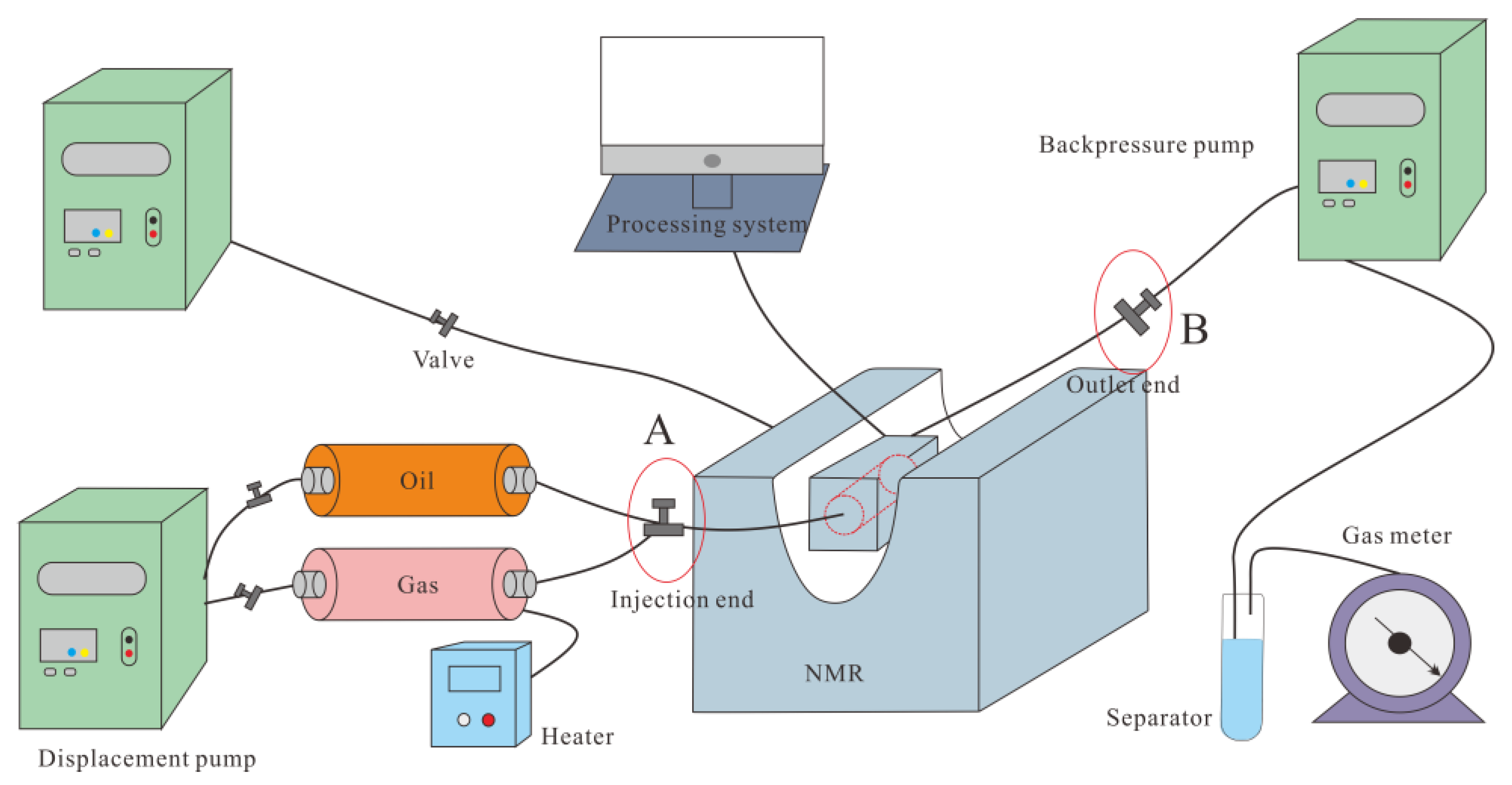

2.2. Full-Diameter Core Nuclear Magnetic Resonance Scanning

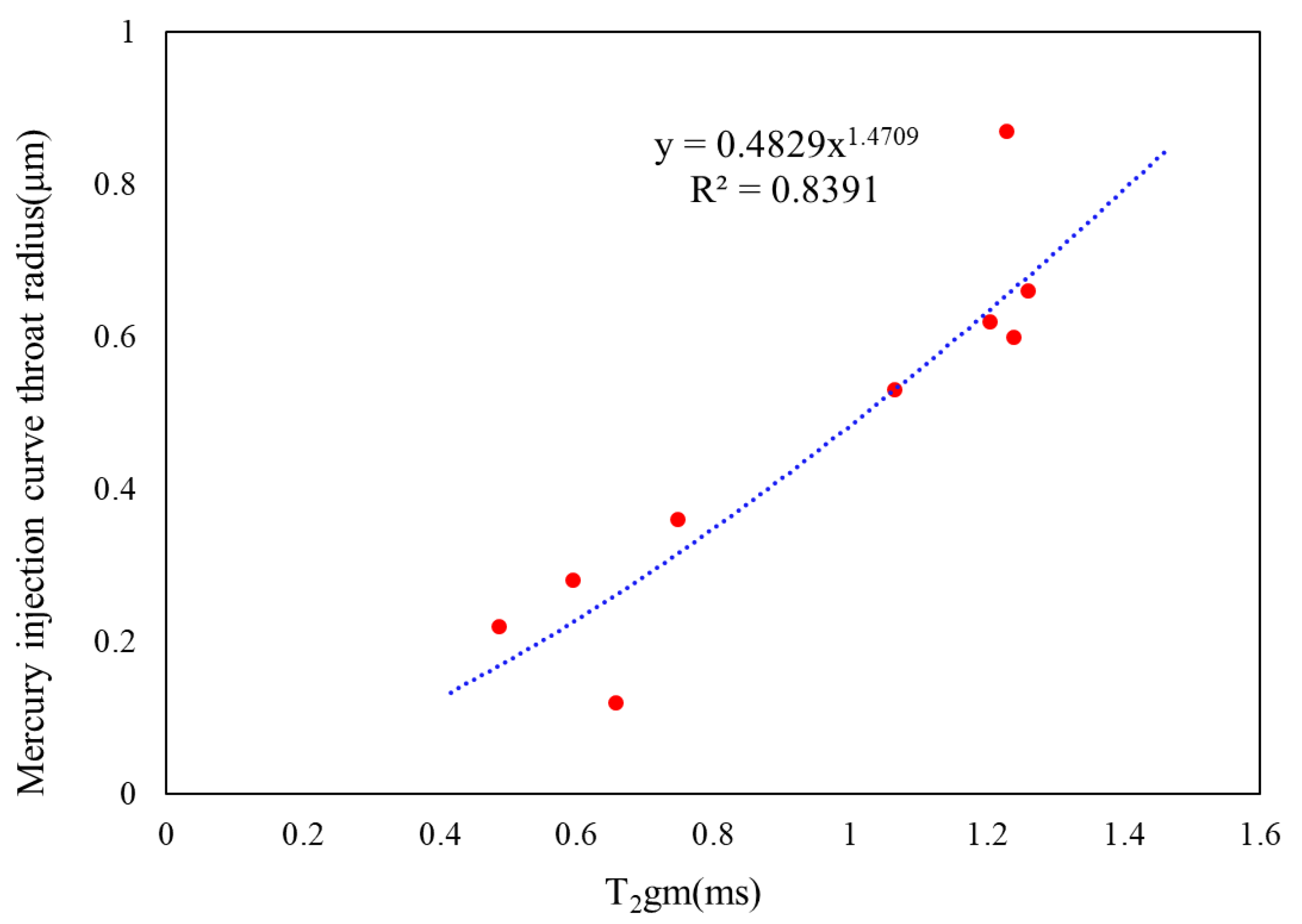

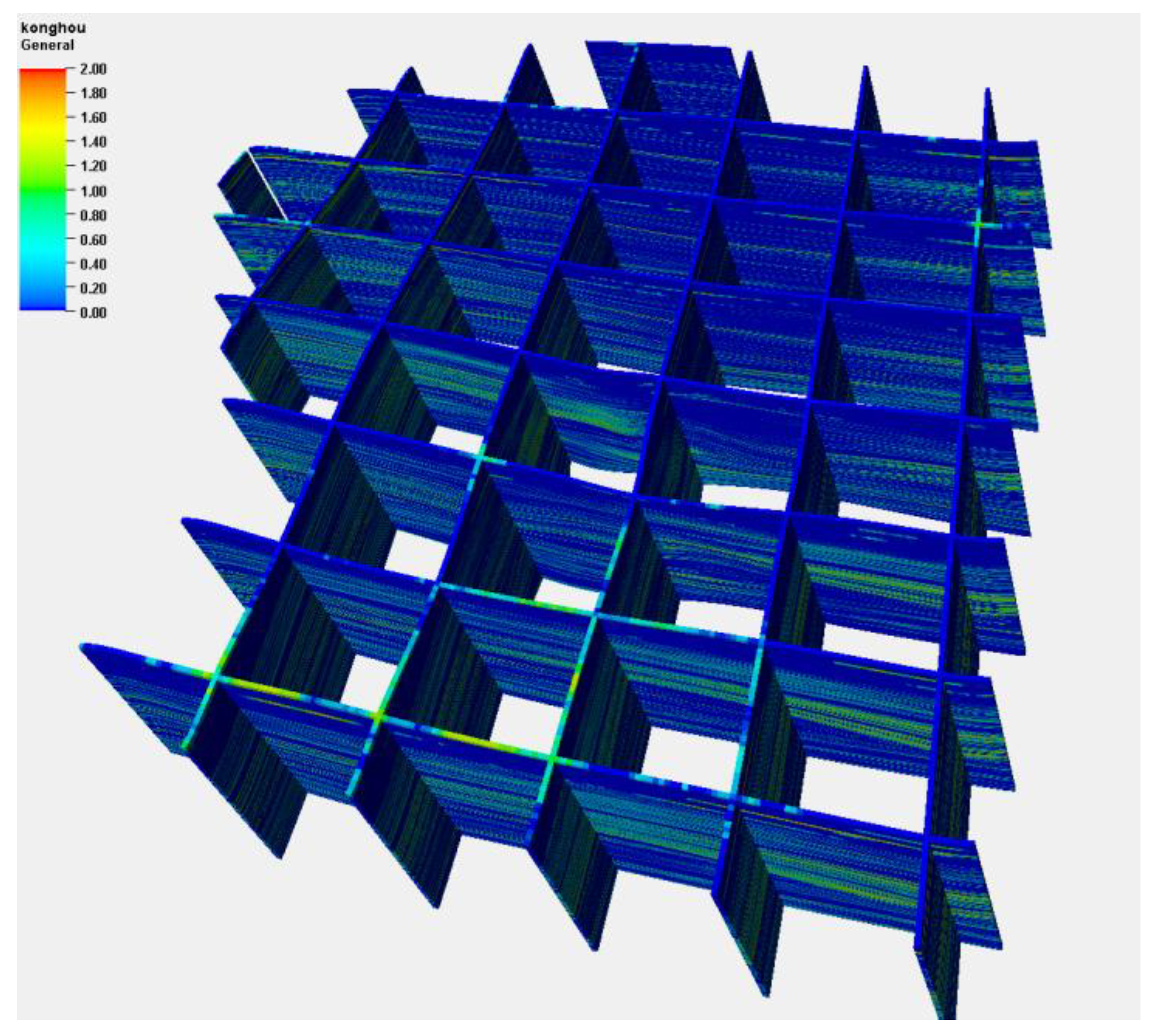

2.3. Calculation of Average Pore-Throat Radius

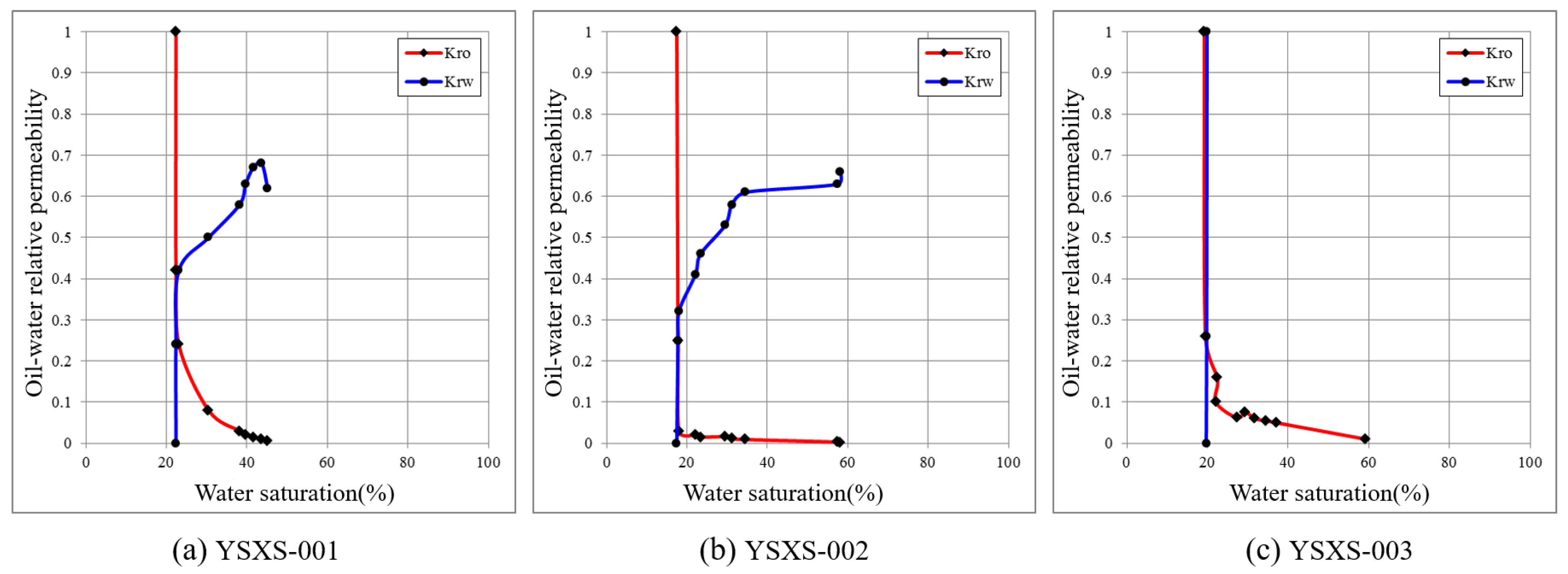

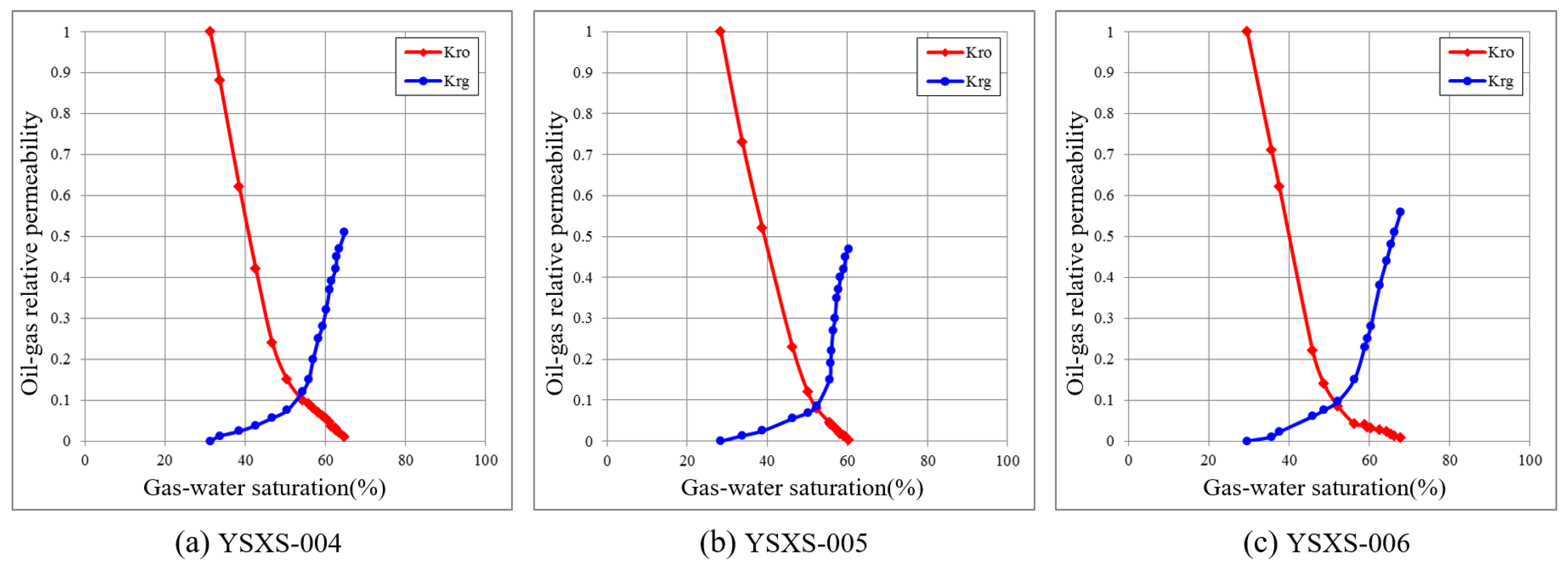

3. The Law of Two-Phase Fluid Flow

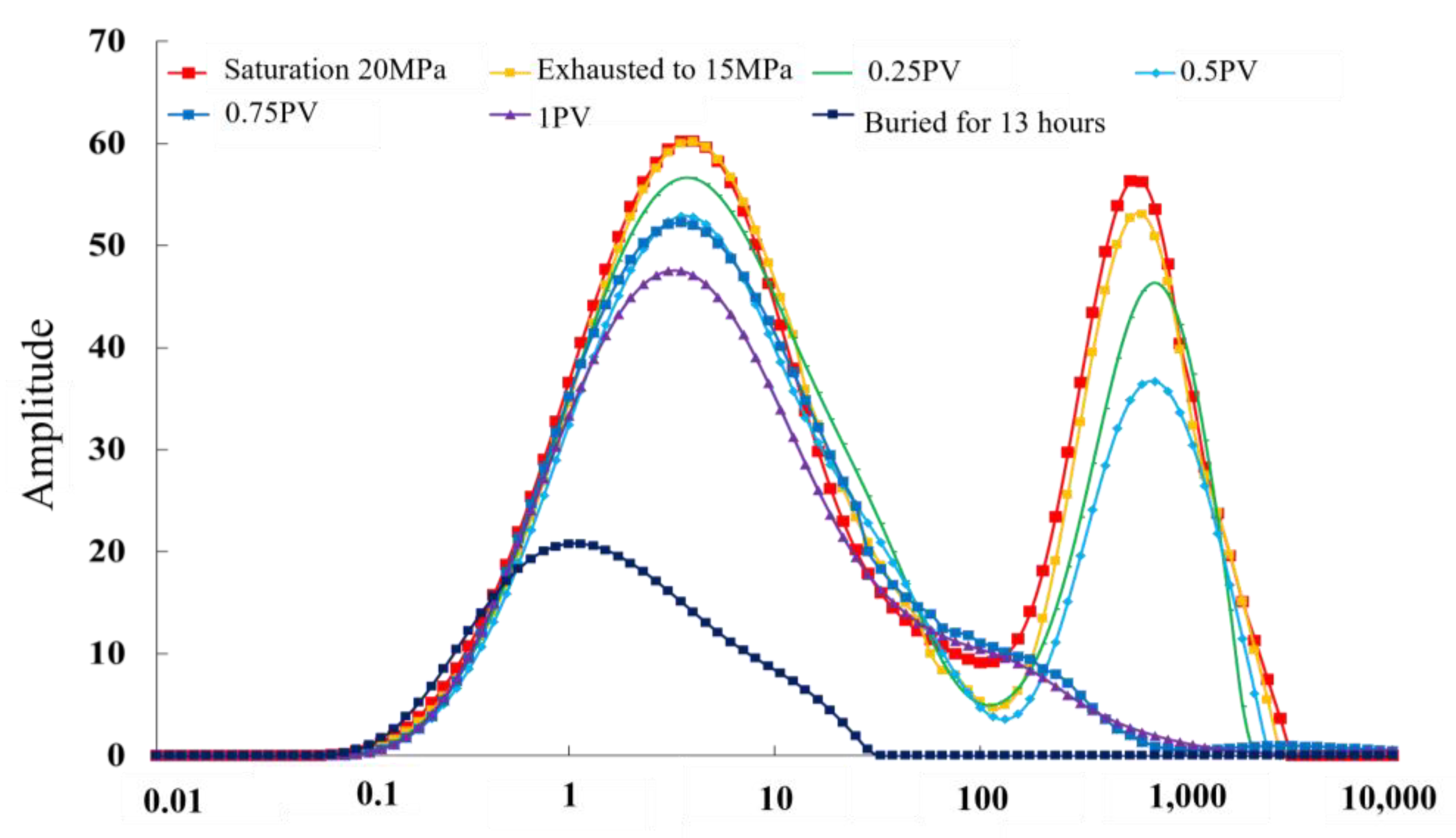

4. The Utilization Law of T2 Spectrum in CO2 Continuous Displacement

5. Support Dynamic Analysis

6. Conclusions

- (1)

- The pore-throat coordination number of the Wuerhe Formation reservoir space is low, with a proportion of 86.3% of its pore throats being below 1 μm. The on-site full-diameter core NMR scanning results of the entire well section show that the total porosity of the Wuerhe Formation is 10–14%, and the effective porosity is only 4–6%;

- (2)

- A correlation between the movable porosity parameters determined by NMR of the full-diameter core and the calculated average pore-throat radius can be established, thus allowing us to establish a formula for calculating the pore-throat radius of movable porosity. In addition, based on the three-dimensional geological attribute model of the research area, an average pore-throat radius three-dimensional model can be established to explain the reservoir pore-throat radius of 0.01~4.36 μm, which has an average of 0.33 μm and is concentrated in 0.03–0.9 μm areas;

- (3)

- The low-permeability conglomerate reservoir of the Wuerhe Formation in the Mahu oil area has strong water sensitivity [19], and the oil–water permeability of the experimental core will rapidly decrease after it encounters water. The oil–gas two-phase permeability experiment shows that, with an increase in gas saturation in the rock core, the relative permeability of the oil phase decreases, and the final increase in the relative permeability of the gas phase is 0.55, indicating that gas displacement has good oil displacement potential;

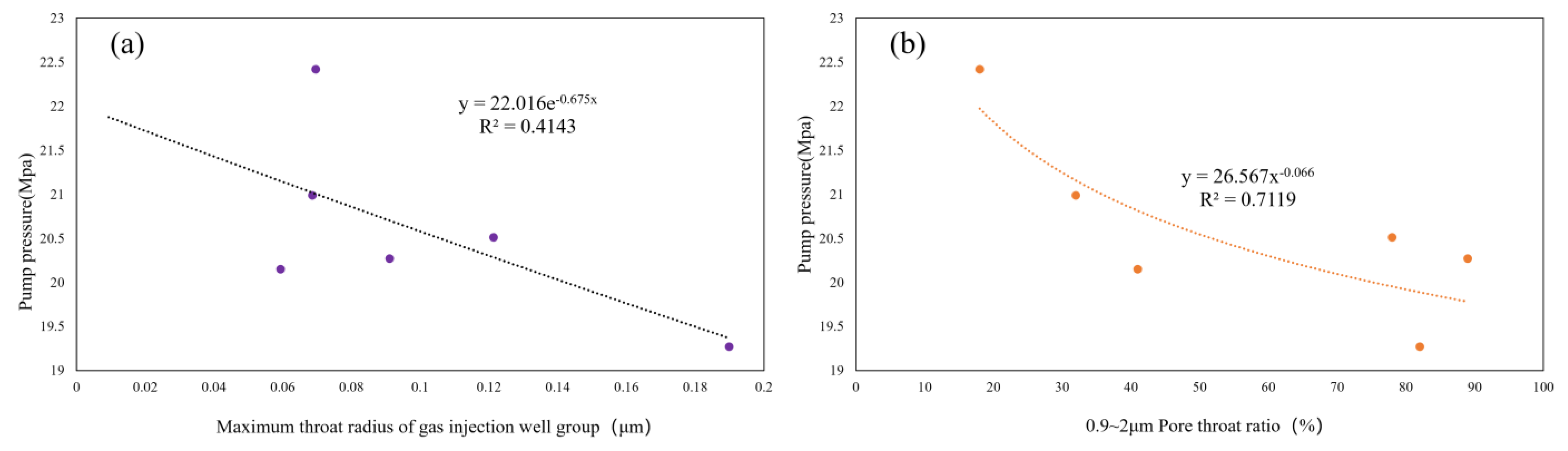

- (4)

- By employing online NMR CO2 displacement experiments in conjunction with a three-dimensional pore-throat model, the oil recovery rate for CO2 displacement in the Wuerhe Formation reservoir was calibrated to currently be at 43.9% based on the microscopic pore-throat utilization patterns observed during the gas displacement experiments. The primary pore-throat range utilized by CO2 displacement spans from 0.3 to 9 μm, encompassing 60.77% of the reservoir’s storage capacity. An ongoing analysis of injection pressures across various well groups indicates a negative correlation of the injection pressure with the average pore-throat radius of the injection well groups, as well as a negative correlation of the injection pressure with the proportion of pore throats falling within the 0.9–2 micrometer range within each injection well group. The microscopic pore-throat characteristics of tight conglomerate reservoirs serve as the fundamental controlling factors influencing the sweep efficiency of CO2 displacement and the associated injection-production parameters [26].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qian, M.; Wang, X.; Li, M.; Li, Z.; Leng, J.; Sun, Z. Oil-bearing properties and hydrocarbon occurrence states of Fengcheng formation shale in Well Maye-1, Mahu sag. Xinjiang Pet. Geol. 2022, 43, 693–703. [Google Scholar]

- Wu, J.; Yang, S.; Li, Q. Movable pore limits of tight glutenite reservoir in Mahu sag of Junggar basin. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 167–174. [Google Scholar]

- Li, G.; Qin, J.; Xian, C.; Fan, X.; Zhang, J.; Ding, Y. Theoretical understandings, key technologies and practices of tight conglomerate oilfield efficient development: A case study of the Mahu oilfield, Junggar Basin, NW China. Pet. Explor. Dev. 2020, 47, 1185–1197. [Google Scholar] [CrossRef]

- Tang, Y.; Song, Y.; Guo, X.; Zhao, J.; Wu, T.; Huang, L.; He, W.; Wu, W.; Wu, H. Main controlling factors of tight conglomerate oil enrichment above source kitchen in Ma hu sag, Junggar Basin. Acta Pet. Sin. 2022, 43, 192–206. [Google Scholar]

- Zheng, X.; He, C.; Yang, N.; Weng, D.; Cai, B.; Yi, X. Volumetric fracturing 2.0 process for unconventional oil and gas reservoirs and R&D suggestions. Pet. Sci. Techonology Forum 2022, 41, 1–9. [Google Scholar]

- Kuang, H.; Zhou, R.; Wang, J.; Liu, H.; Tan, X.; Cai, X.; Xiao, Z. Differences and genesis of upper Wuerhe formation reservoirs in Mahu sag and Shawan Sag. Xin Jiang Pet. Geol. 2023, 44, 18–24. [Google Scholar]

- Ye, Y.; Jiang, Q.; Liang, C.; Xiong, Q.; Qiu, Z.; Li, S.; Zhang, H. Experimental study on the mechanism of water-sensitive injury in Upper Urho formation sand and gravels of the Mahu well area. Sci. Technol. Eng. 2022, 22, 11895–11903. [Google Scholar]

- Song, P.; Cui, C.; Zhang, J.; Liu, K.; Deng, Z.; Tan, L.; Yu, X. Simultaneous CO2 huff-n-puff test in highly sensitive reservoirs in upper Wuerhe formation, Mahu sag. Xinjiang Pet. Geol. 2024, 45, 355–361. [Google Scholar]

- Deng, Z.; Wang, X.; Tan, L.; Zhang, J.; Chen, C.; Song, P. Enhancing oil recovery of tight conglomerate reservoirs by asynchronous CO2 huff and puff in Mahu sag. Xinjiang Pet. Geol. 2022, 43, 200–205. [Google Scholar]

- Huang, X.; Jia, X.; Zhou, X.; Zheng, S.; Yan, W.; Yua, Y. Optimization of long core CO2 huff-n-puff experimental parameters in low permeability reservoir, Yanchang Oilfield. XinJiang Pet. Geol. 2015, 36, 313–316. [Google Scholar]

- Li, S.; Lei, S.; Chen, Z. Further discussion on reservoir engineering concept and development mode of CO2 flooding-EOR technology. Reserv. Eval. Dev. 2020, 10, 1–14. [Google Scholar]

- Wang, G.; Zheng, X.; Zhang, Y.; Lü, W.; Wang, F.; Yin, L. A new screening method of low permeability reservoirs suitable for CO2 flooding. Pet. Explor. Dev. 2015, 42, 358–363. [Google Scholar]

- Shi, L.; Zhu, S.; Ma, J.; Yang, M.; Peng, Y.; Ye, Z. Numerical simulation of tight oil extraction with supercritical CO2. Pet. Geol. Recovery Effic. 2019, 9, 25–31. [Google Scholar]

- Tan, F.; Ma, C.; Li, X.; Jing, Y. Application and prospect of fluid mobility in oilfield development. J. Southwest Pet. Univ. 2024, 46, 1–20. [Google Scholar]

- Qiao, J.; Zeng, J.; Xia, Y.; Cai, J.; Chen, D.; Jiang, S.; Han, G.; Cao, Z.; Feng, X.; Feng, S. A three dimensional visualized physical simulation for natural gas chargingin the micro-nano pore system. Pet. Explor. Dev. 2022, 49, 306–318. [Google Scholar] [CrossRef]

- Master, J.A. Deep basin gas trap, western Canada. AAPG Bull. 1979, 63, 152–181. [Google Scholar]

- Bai, Z.; Wang, Q.; Song, W. Lower limits of pore throat producing in natural gas drive reservoirs based on nuclear magnetic resonance. Xinjiang Pet. Geol. 2023, 44, 58–63. [Google Scholar]

- Lv, L.; Zhang, T.; Li, J.; Sun, J.; Zheng, H.; Wang, G. Influence of reservoir mineral types on CO2 displacement effect of tight reservoir. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 1–10. [Google Scholar]

- Shi, L.; Zhang, Y.; Ye, Z. Field test effect analysis of CO2, huff and puff for FOR of horizontal wells in tight glutenite reservoir of Mahu Oilfield. Pet. Reserv. Eval. Dev. 2021, 11, 871–877. [Google Scholar]

- Pu, W.; Wang, Y.; Li, L.; Gao, H.; Shan, D.; Wang, W. Feasibility of supercritical CO2 huff-puff development of tight conglomerate reservoirs. Xinjiang Pet. Geol. 2021, 42, 456–461. [Google Scholar]

- Kirizov, H.X.; Murzakaev, V.M. Application of complex nuclear magnetic resonance measurements to supervicious oil deposits in Russian republic of Tatarstan. Well Logging Technol. 2017, 41, 506–511. [Google Scholar]

- Zhao, W. Estimation of average pore throat radius by NMR log data. Pet. Geol. Recovery Effic. 2009, 16, 43–45. [Google Scholar]

- Qin, J.; Li, Y.; Du, G.; Zhou, Y.; Deng, Y.; Peng, S.; Xiao, D. NMR logging based productivity analysis and sweet spot evaluation for shale oil. Xin Jiang Pet. Geol. 2024, 45, 317–326. [Google Scholar]

- Cong, Y.; Fan, Y.; Deng, S.; Ye, Q.; Chen, F. The research on pore structure in tight sand reservoir based on the three-component decomposition Theory of the NMR T2 Spectrum. Well Logging Technol. 2013, 37, 600–604. [Google Scholar]

- Li, T.; Zheng, W.; Geng, Z.; Lee, J.-F.; Wu, T. Formation mechanism and flow limits of residual oil based on microscopic pore throat structure. Sci. Technol. Eng. 2023, 23, 12892–12899. [Google Scholar]

- Song, X.; Liu, Y.; Yang, X. Numerical simulation of CO2 miscible displacement at pore scale. Pet. Geol. Recovery Effic. 2024, 31, 1–13. [Google Scholar]

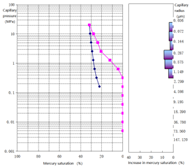

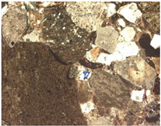

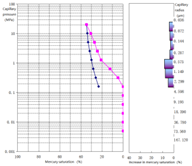

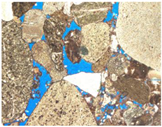

| Depth/m | Horizon | Characteristic Parameters of Porosity and Permeability | Structural Parameters of Porosity and Permeability | Mercury Pressure Capillary Force Curve and Pore Throat Distribution Histogram | Cast Thin Sheet |

|---|---|---|---|---|---|

| 3419.39 | P3w22−1 | Porosity (%): 8.5 Penetration rate (10−3 μm2): 0.945 Displacement/median pressure (MPa): 0.18/14.67 Median radius (μm): 0.05 Maximum pore-throat radius (μm): 4.06 Visual pore-throat volume ratio: 3.89 Average capillary radius (μm): 0.87 Homogeneity coefficient: 0.11 Unsaturated pore volume percentage (%):47.15 | Pore type and relative content (%): gravel hole: 50; intergranular dissolved pores: 40; dissolved pores in gravel: 10 Average pore diameter (μm): 8.0 |  |  |

| 3432.87 | P3w22−2 | Porosity (%):7.3 Penetration rate (10−3 μm2): 0.346 Visual pore-throat volume ratio: 2.27 Unsaturated pore volume percentage (%): 68.27 | Pore type and relative content(%): dissolved pores in gravel: 50; construction seam: 50 Average pore diameter (μm): 21.5 Average crack width (μm): 2.1 Crack surface density (strips/mm2): 0.2 Crack rate (%): 0.041 |  |  |

| 3448.28 | P3w22−3 | Porosity (%): 10.8 Penetration rate (10−3 μm2): 0.432 Displacement pressure (MPa): 0.34 Maximum pore-throat radius (μm): 2.15 Visual pore-throat volume ratio: 2.78 Average capillary radius (μm): 0.53 Homogeneity coefficient: 0.12 Unsaturated pore volume percentage (%): 61.33 | Pore type and relative content (%): gravel hole: 93; intergranular dissolved pores: 5; dissolved pores in gravel: 2 Average pore diameter (μm): 175.6 Average throat width (μm): 5.2 Average pore-throat ratio: 9.1 Average coordination number: 0.14 |  |  |

| 3454.4 | P3w22−4 | Porosity (%): 10.5 Penetration rate (10−3 μm2): 0.469 Visual pore-throat volume ratio: 1.99 Unsaturated pore volume percentage (%): 65.26 | Pore type and relative content (%): gravel hole: 92; intergranular dissolved pores: 5; dissolved pores in gravel: 3 Average pore diameter (μm): 135.1 Average throat width (μm): 11.5 Average pore-throat ratio: 6.6 Average coordination number: 0.11 |  |  |

| T2 Cutoff Value (ms) | Pore-Throat Radius (μm) | Proportion of Reserves (%) | Inject the Extraction Degree Under Different PV Conditions | |||

|---|---|---|---|---|---|---|

| 0~0.25 | 0.25~0.5 | 0.5~0.75 | 0.75~1 | |||

| 0.1~0.3 | 0.01–0.03 | 20.93 | 8.3 | 17.7 | 31.7 | 38.2 |

| 0.3~9 | 0.03–0.9 | 60.77 | 11.2 | 22.3 | 42.5 | 48.9 |

| 9~2 | 0.9–2 | 18.3 | 0.3 | 5.3 | 19.9 | 34.1 |

| total | / | / | 8.6 | 18.2 | 36.1 | 43.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, L.; Zhang, J.; Zhang, J.; Jiang, R.; Qin, J.; Dong, Y.; Deng, Z.; Song, P.; Cui, C.; Zhai, W.; et al. Study on the Propagation Law of CO2 Displacement in Tight Conglomerate Reservoirs in the Mahu Depression, Xinjiang, China. Energies 2025, 18, 990. https://doi.org/10.3390/en18040990

Tan L, Zhang J, Zhang J, Jiang R, Qin J, Dong Y, Deng Z, Song P, Cui C, Zhai W, et al. Study on the Propagation Law of CO2 Displacement in Tight Conglomerate Reservoirs in the Mahu Depression, Xinjiang, China. Energies. 2025; 18(4):990. https://doi.org/10.3390/en18040990

Chicago/Turabian StyleTan, Long, Jigang Zhang, Jing Zhang, Ruihai Jiang, Jianhua Qin, Yan Dong, Zhenlong Deng, Ping Song, Chenguang Cui, Wenya Zhai, and et al. 2025. "Study on the Propagation Law of CO2 Displacement in Tight Conglomerate Reservoirs in the Mahu Depression, Xinjiang, China" Energies 18, no. 4: 990. https://doi.org/10.3390/en18040990

APA StyleTan, L., Zhang, J., Zhang, J., Jiang, R., Qin, J., Dong, Y., Deng, Z., Song, P., Cui, C., Zhai, W., & Tan, F. (2025). Study on the Propagation Law of CO2 Displacement in Tight Conglomerate Reservoirs in the Mahu Depression, Xinjiang, China. Energies, 18(4), 990. https://doi.org/10.3390/en18040990