Polarity-Dependent DC Dielectric Behavior of Virgin XLPO, XLPE, and PVC Cable Insulations

Abstract

1. Introduction

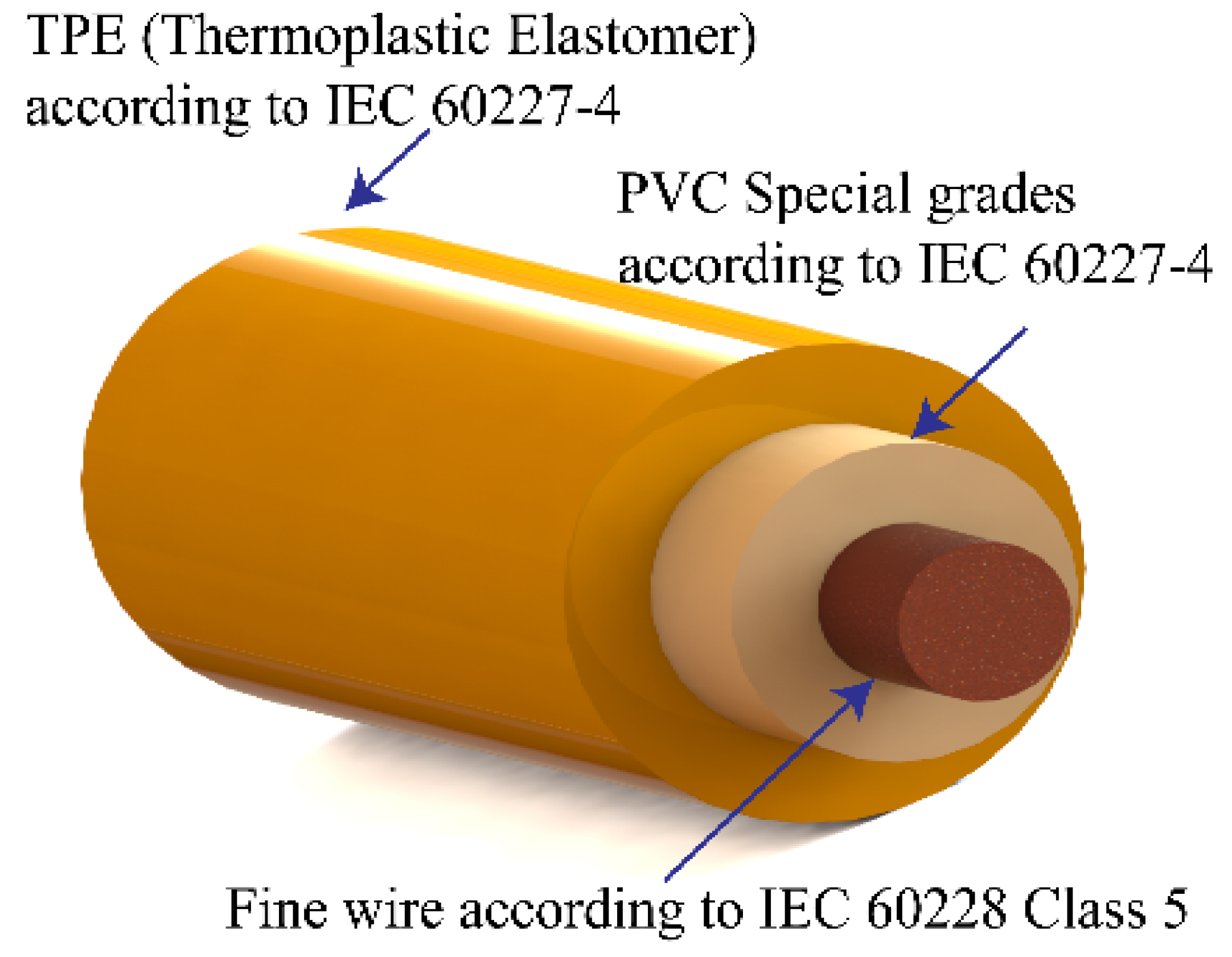

2. Materials and Methods

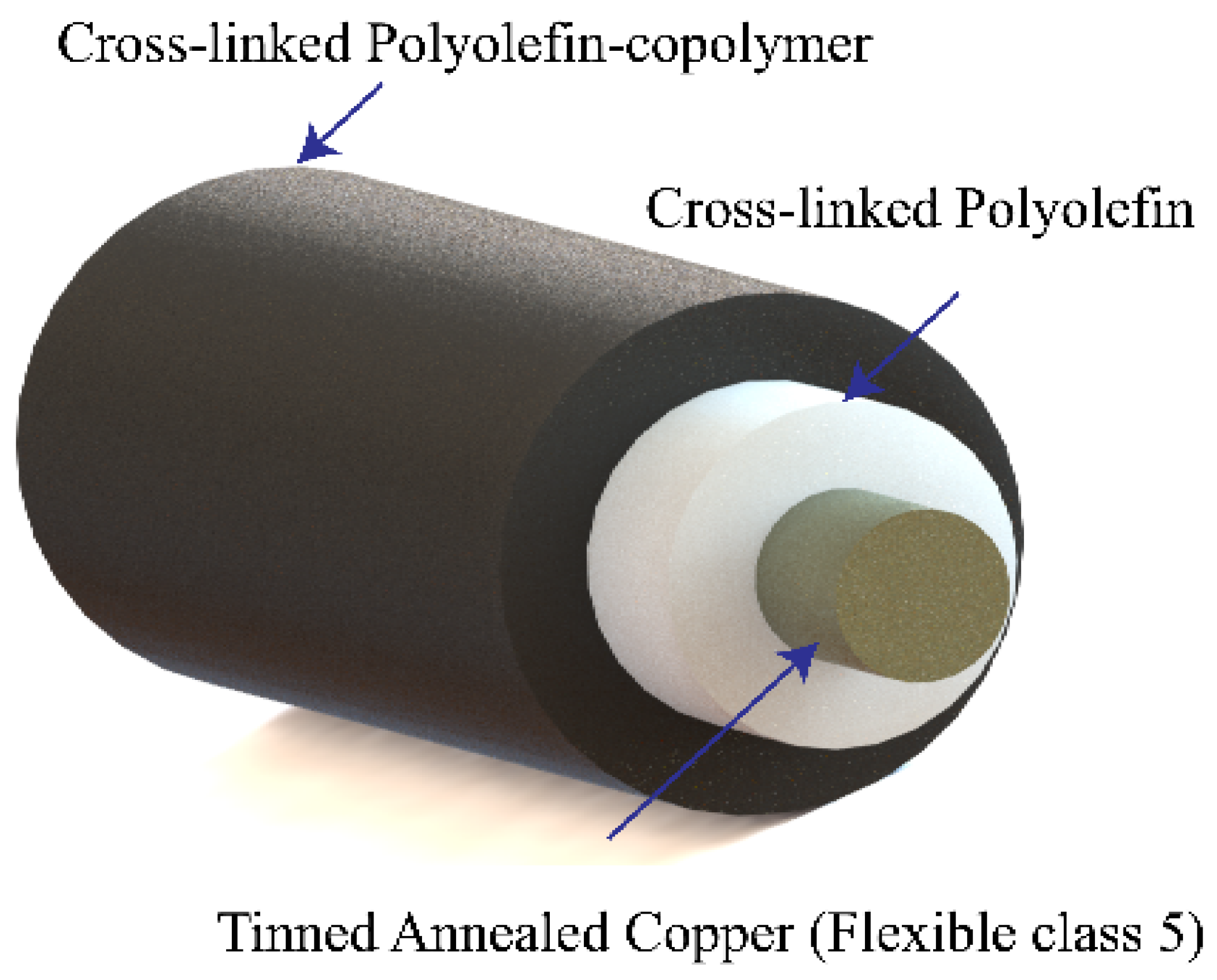

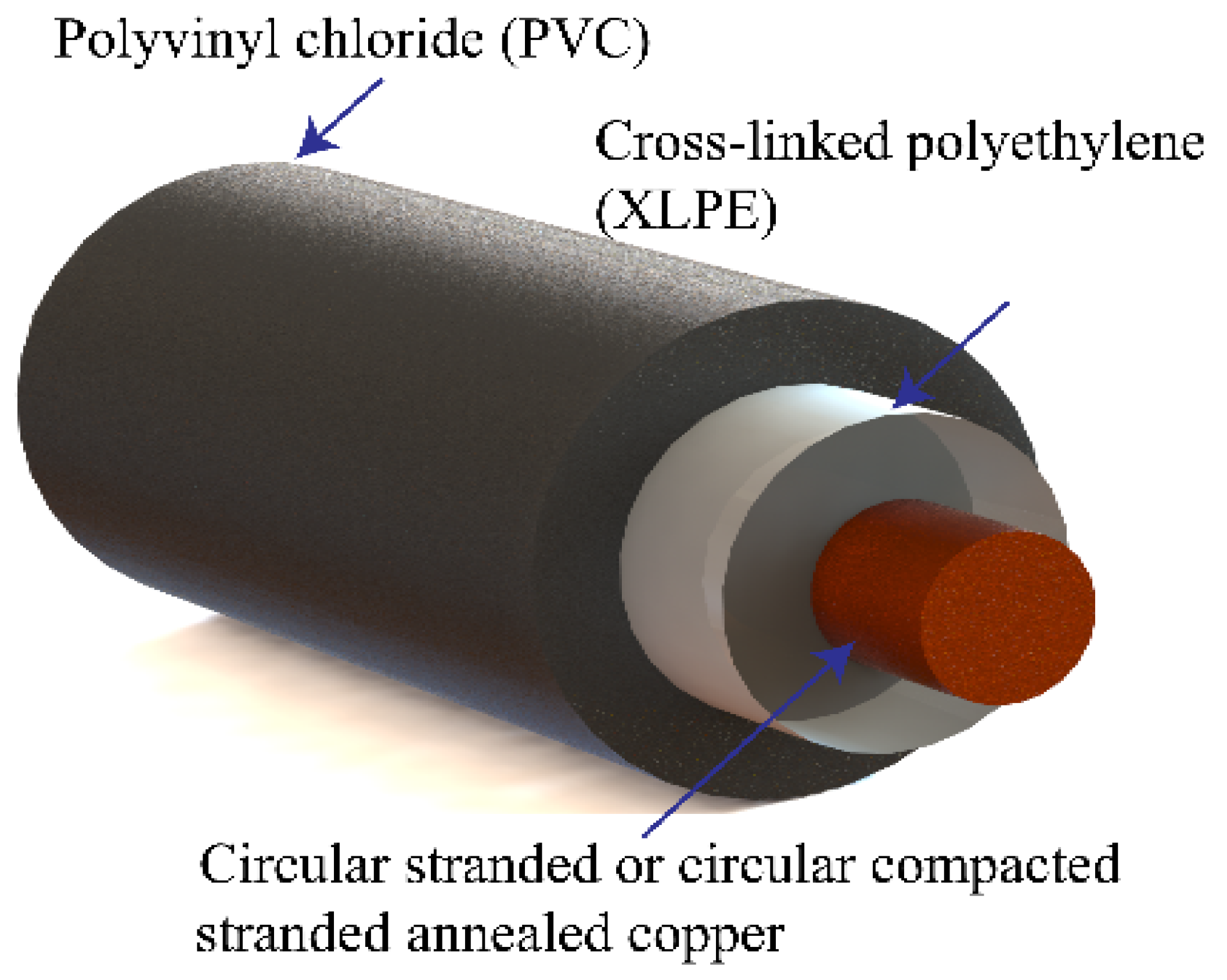

2.1. Preparation of Cables

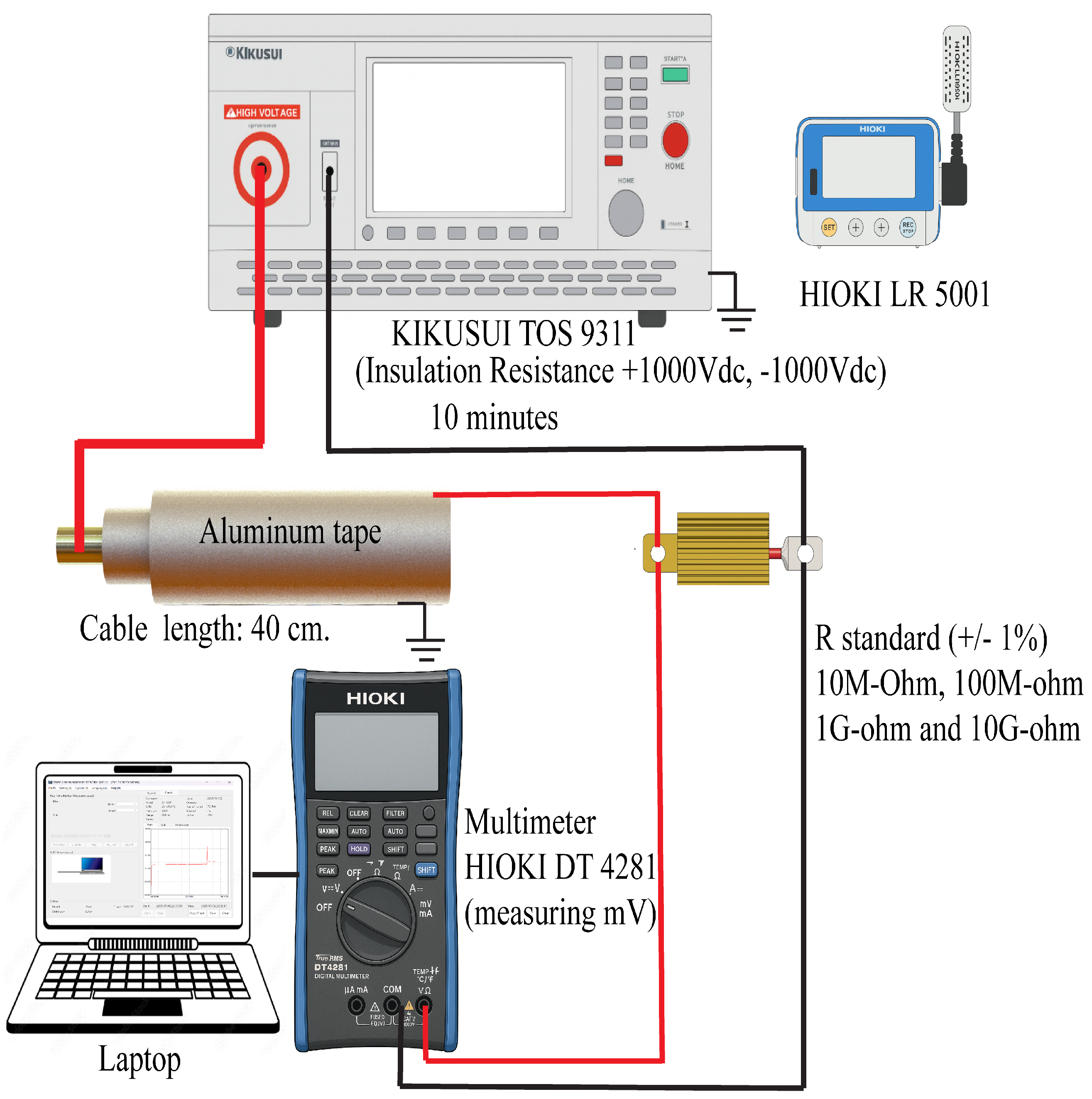

2.2. Insulation Resistance Measurement Setup

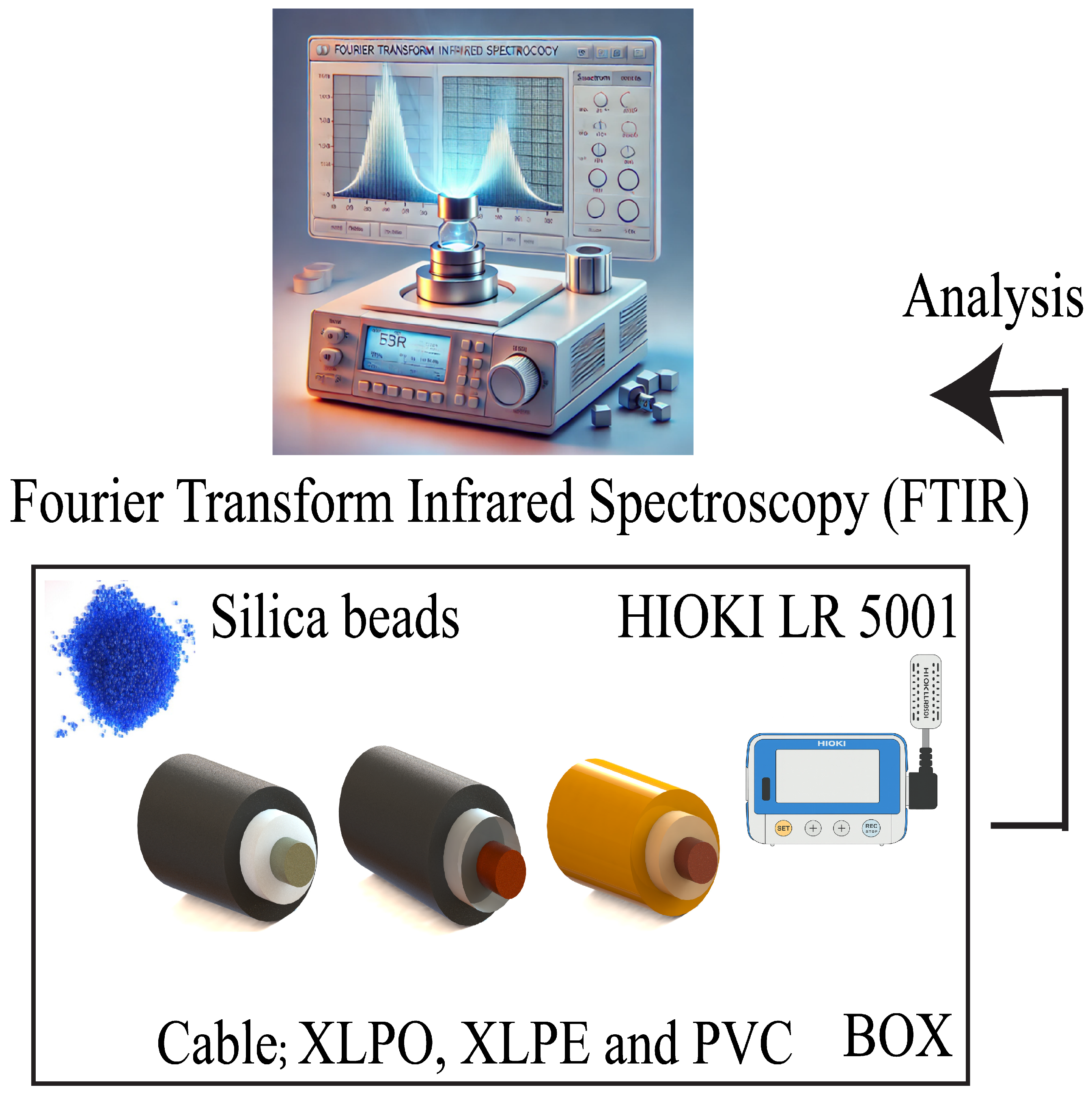

2.3. Sample Preparation for FTIR Analysis

3. Results

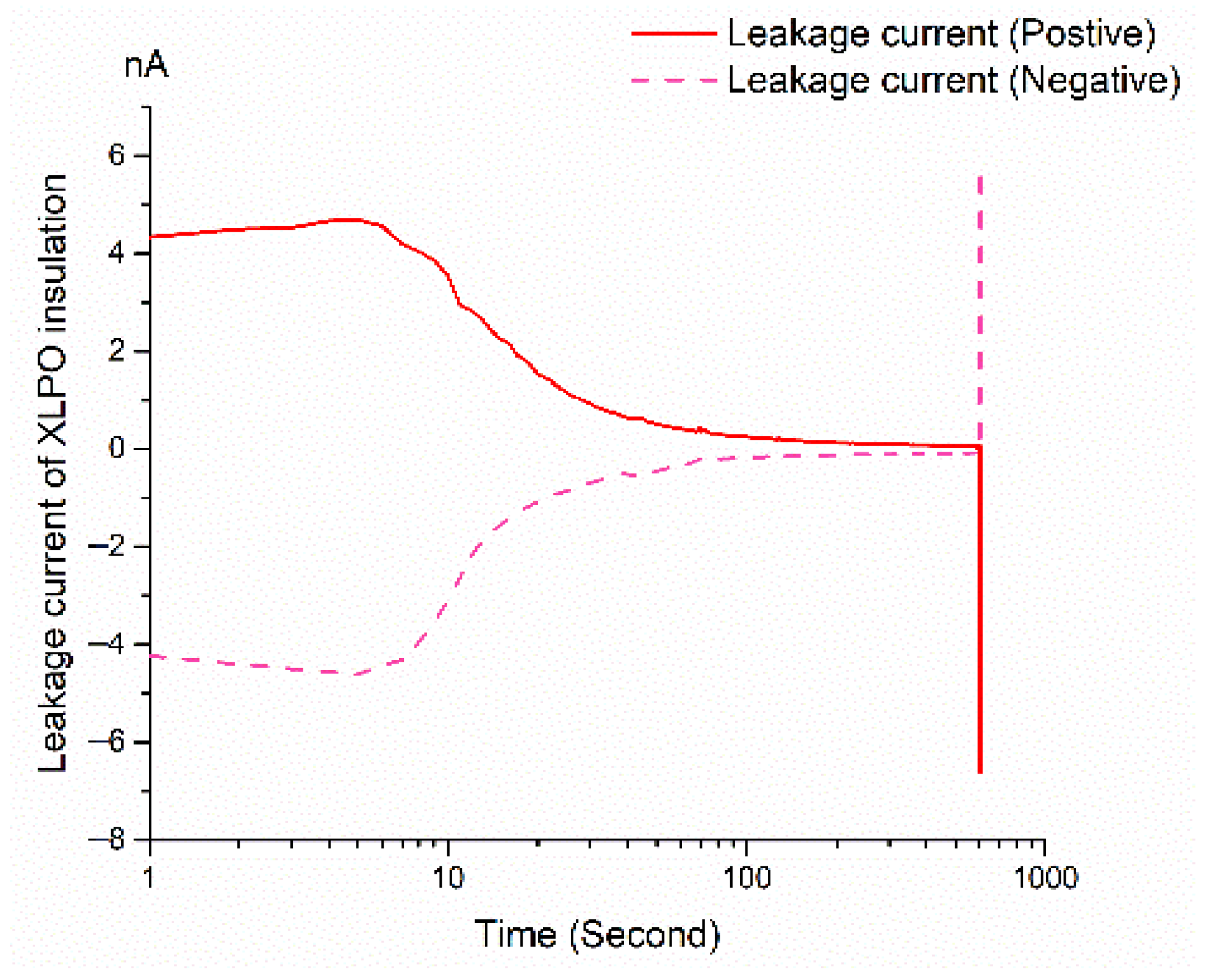

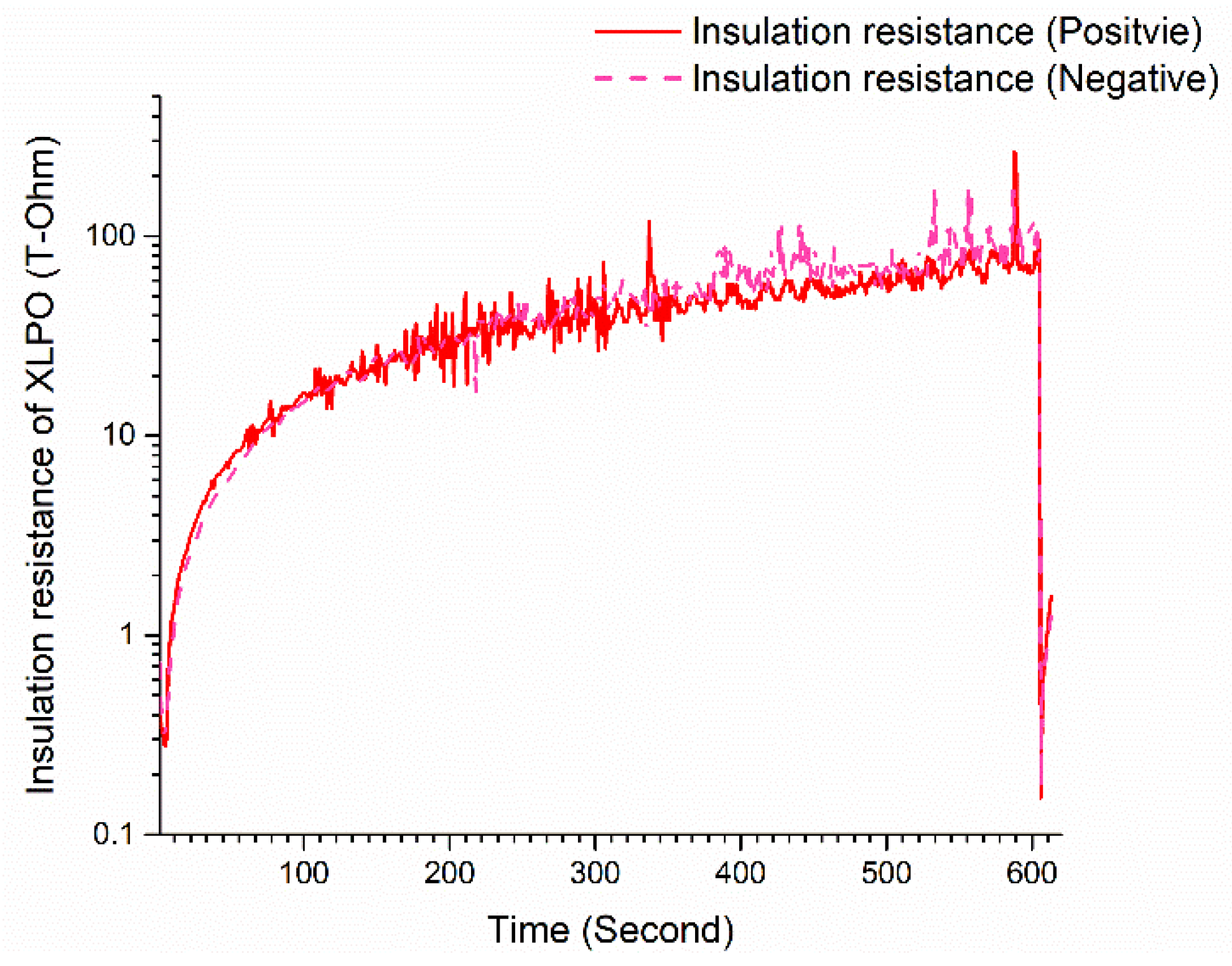

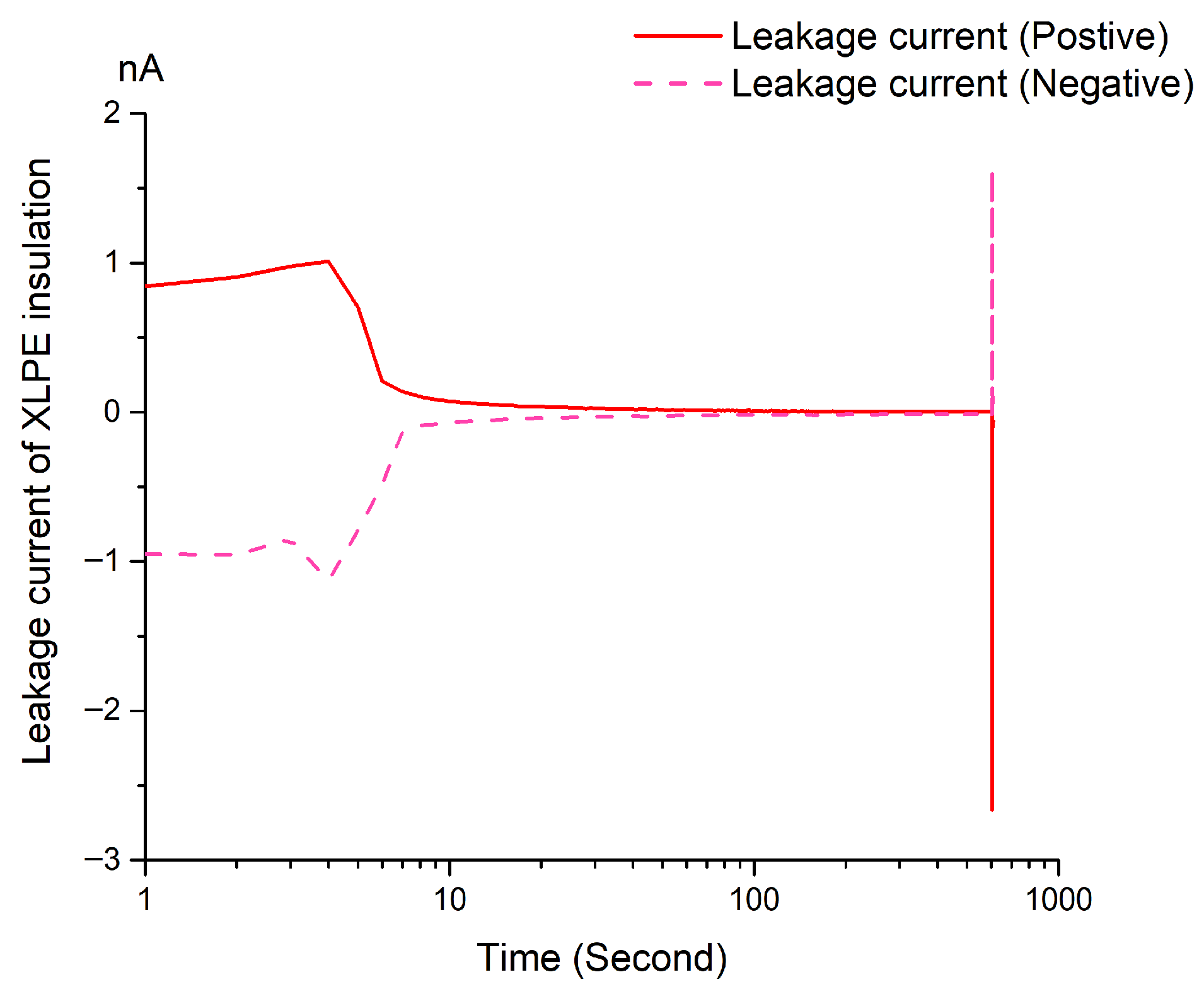

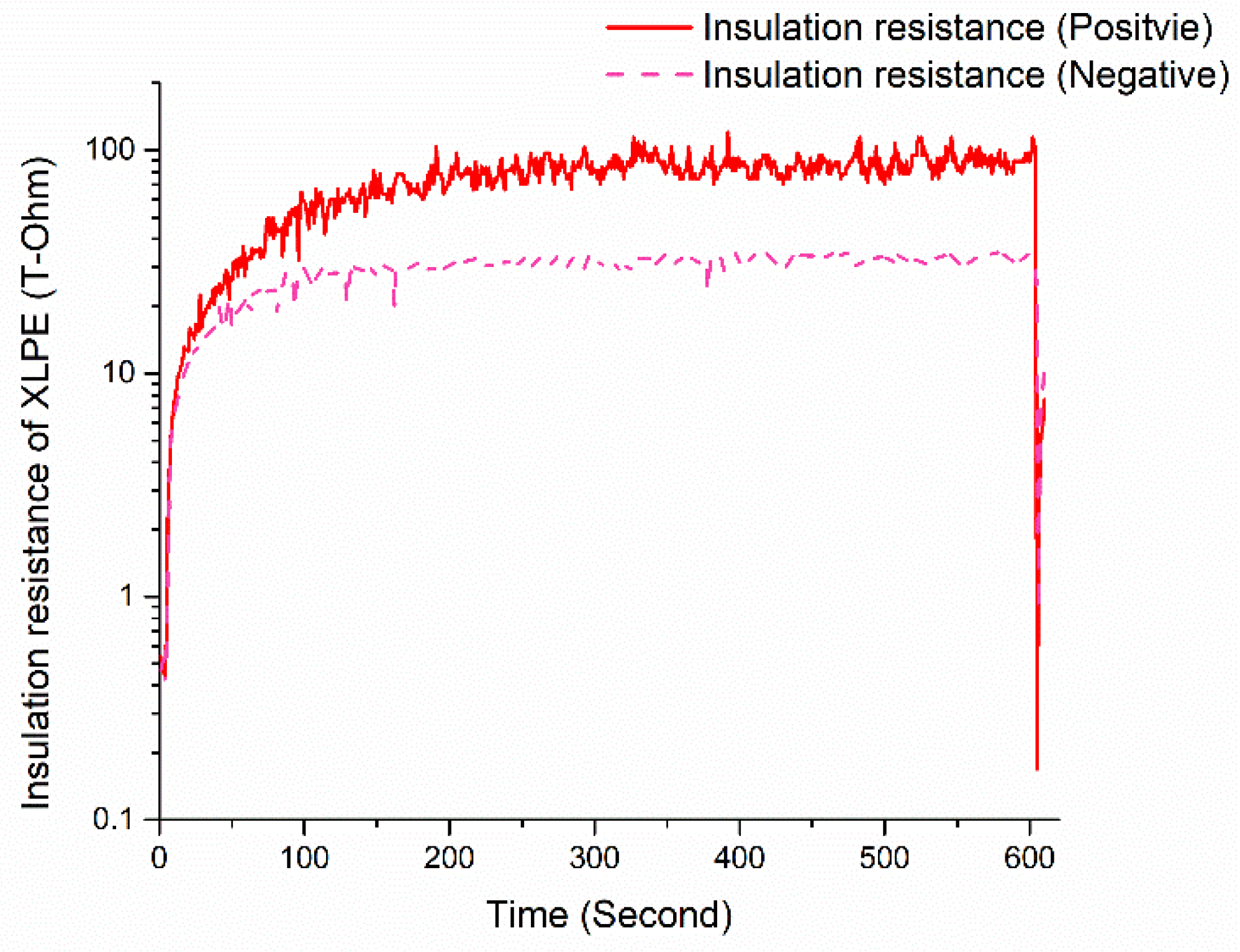

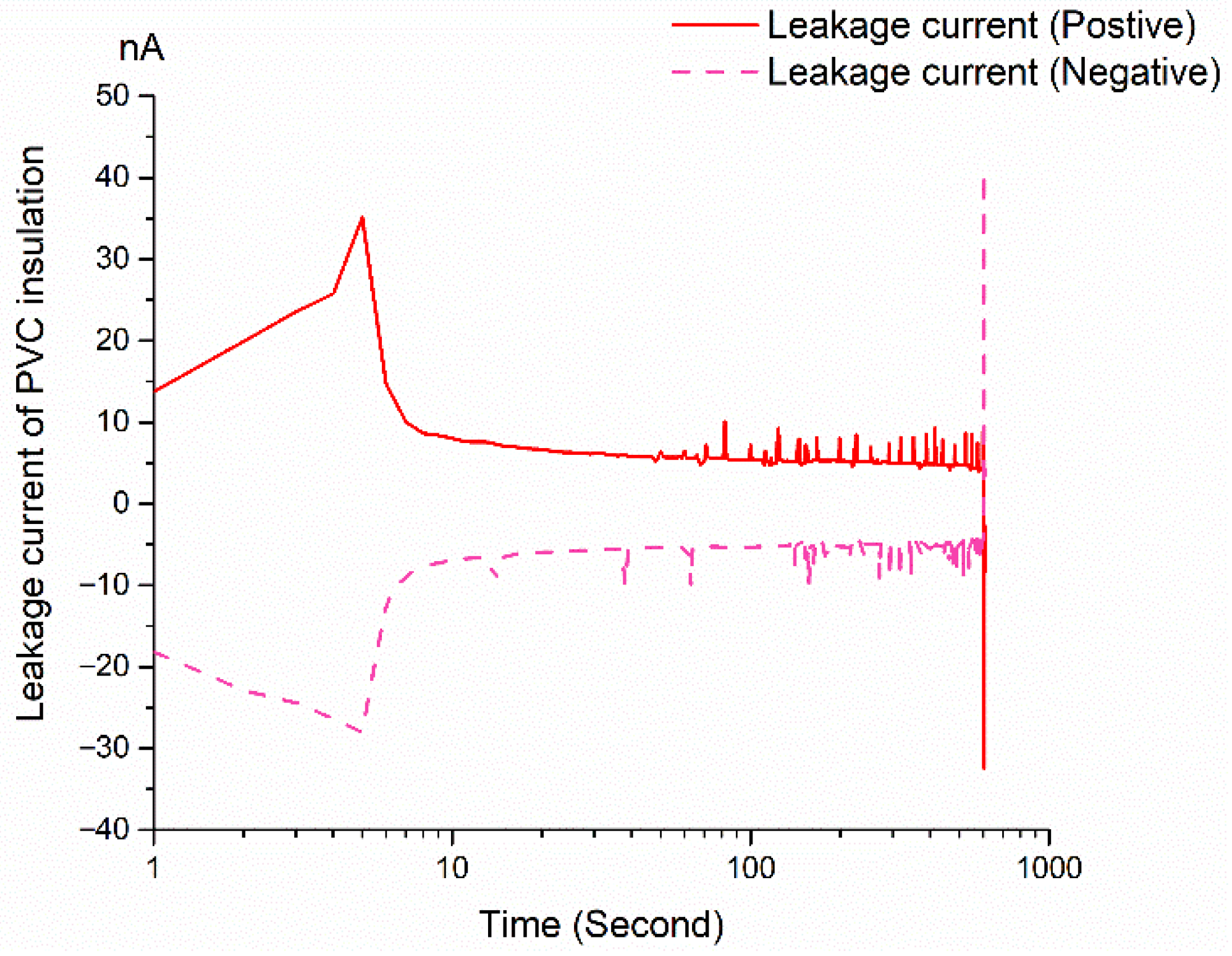

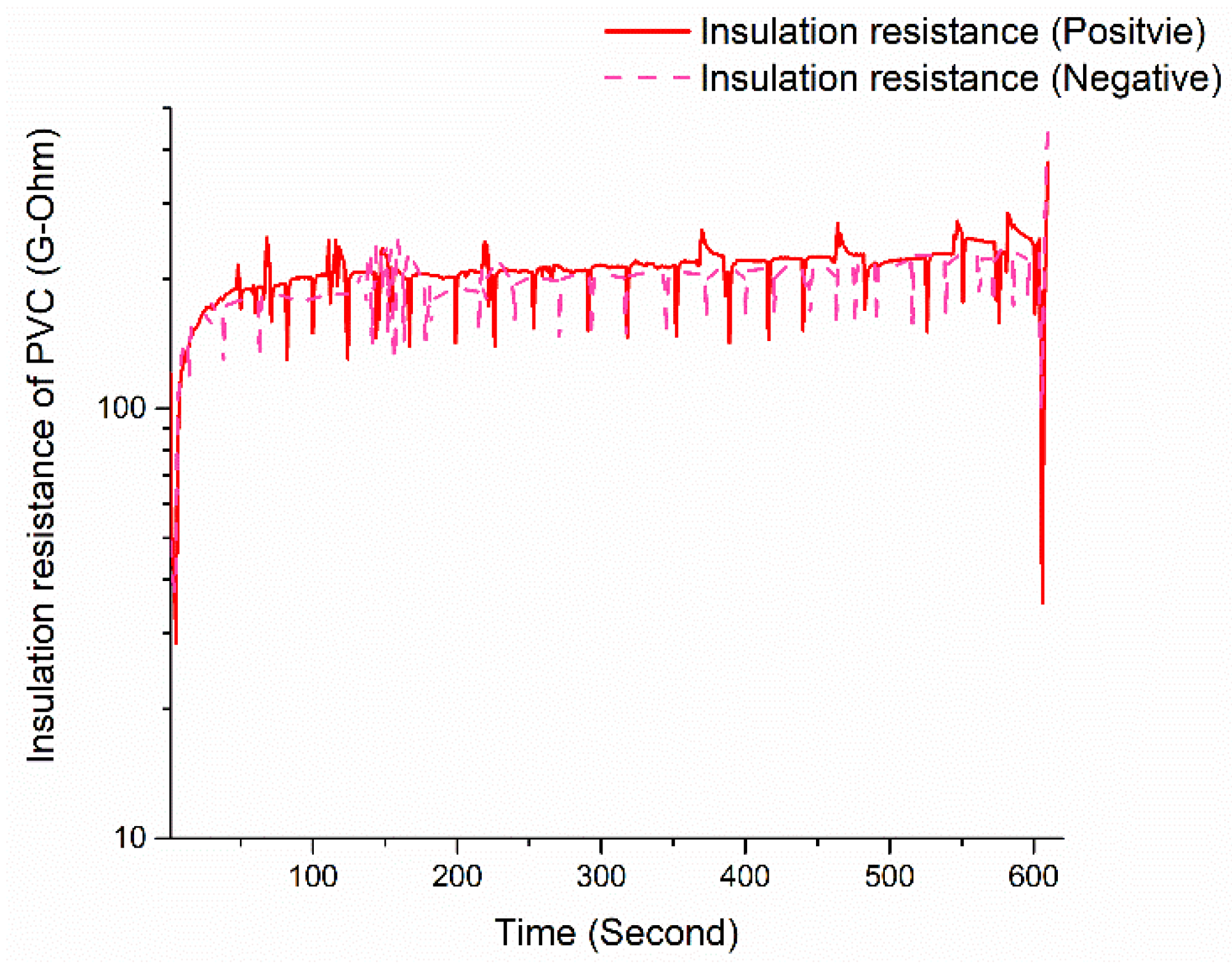

3.1. Leakage Current and Insulation Resistance Characteristics of Virgin Insulation Materials

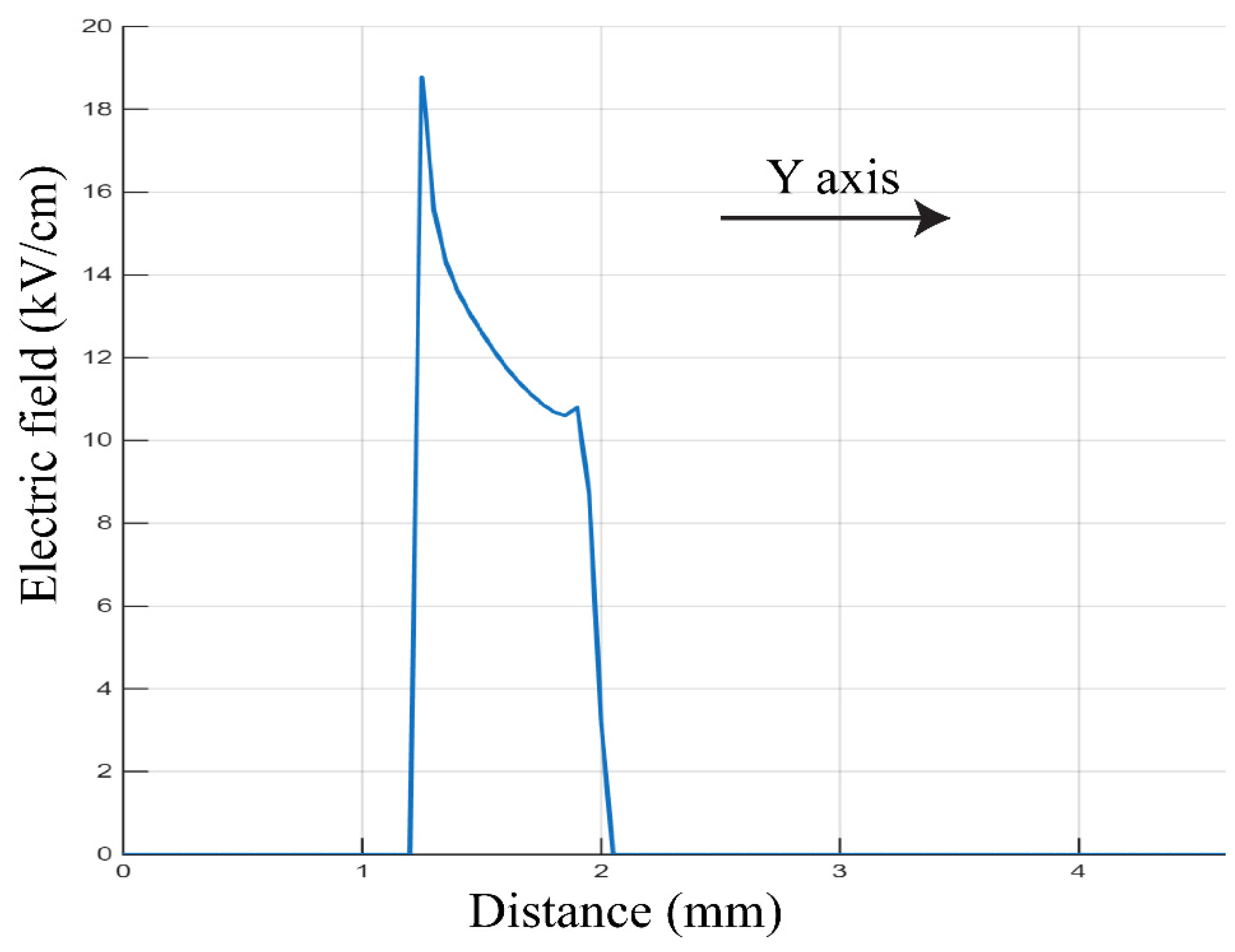

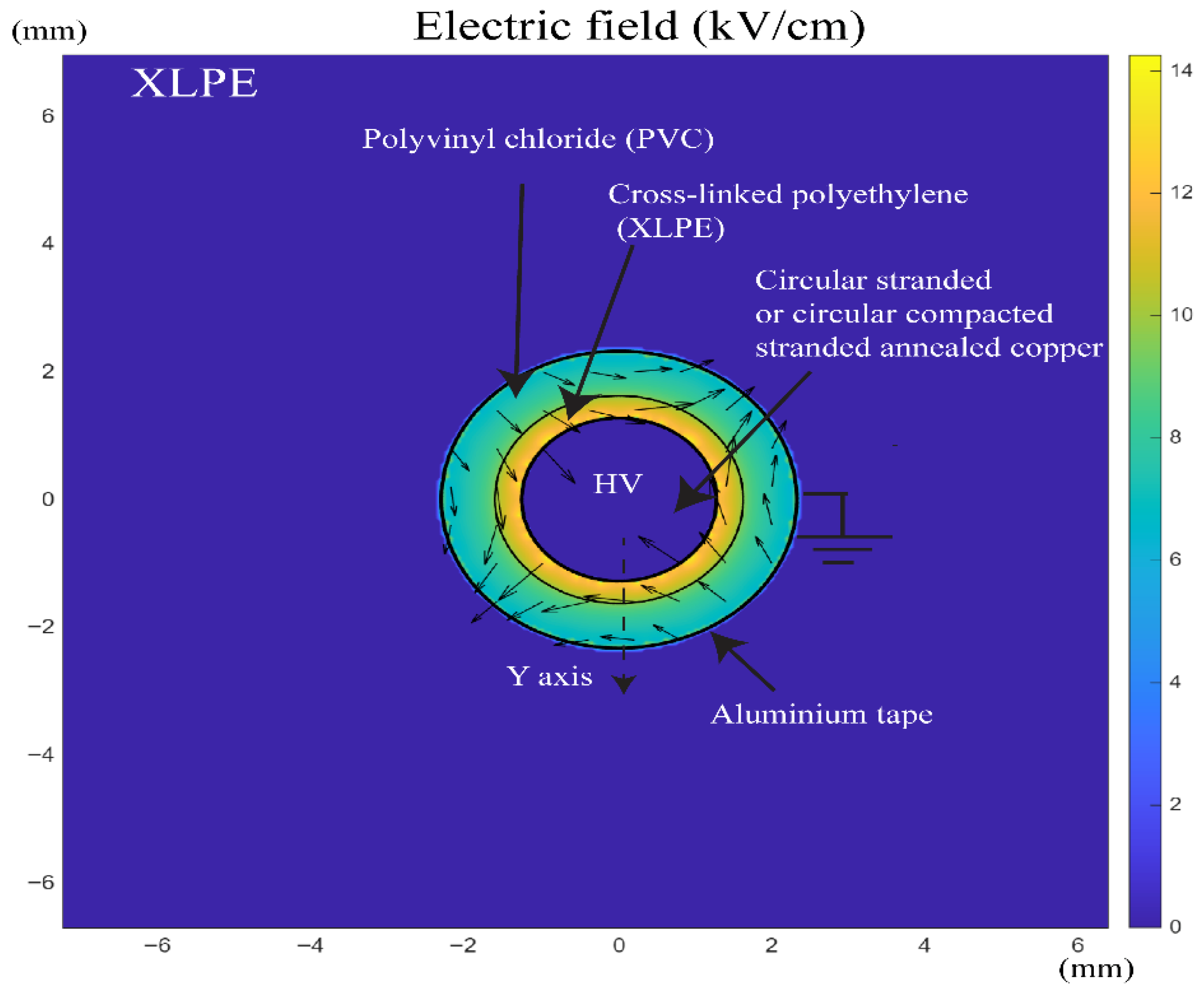

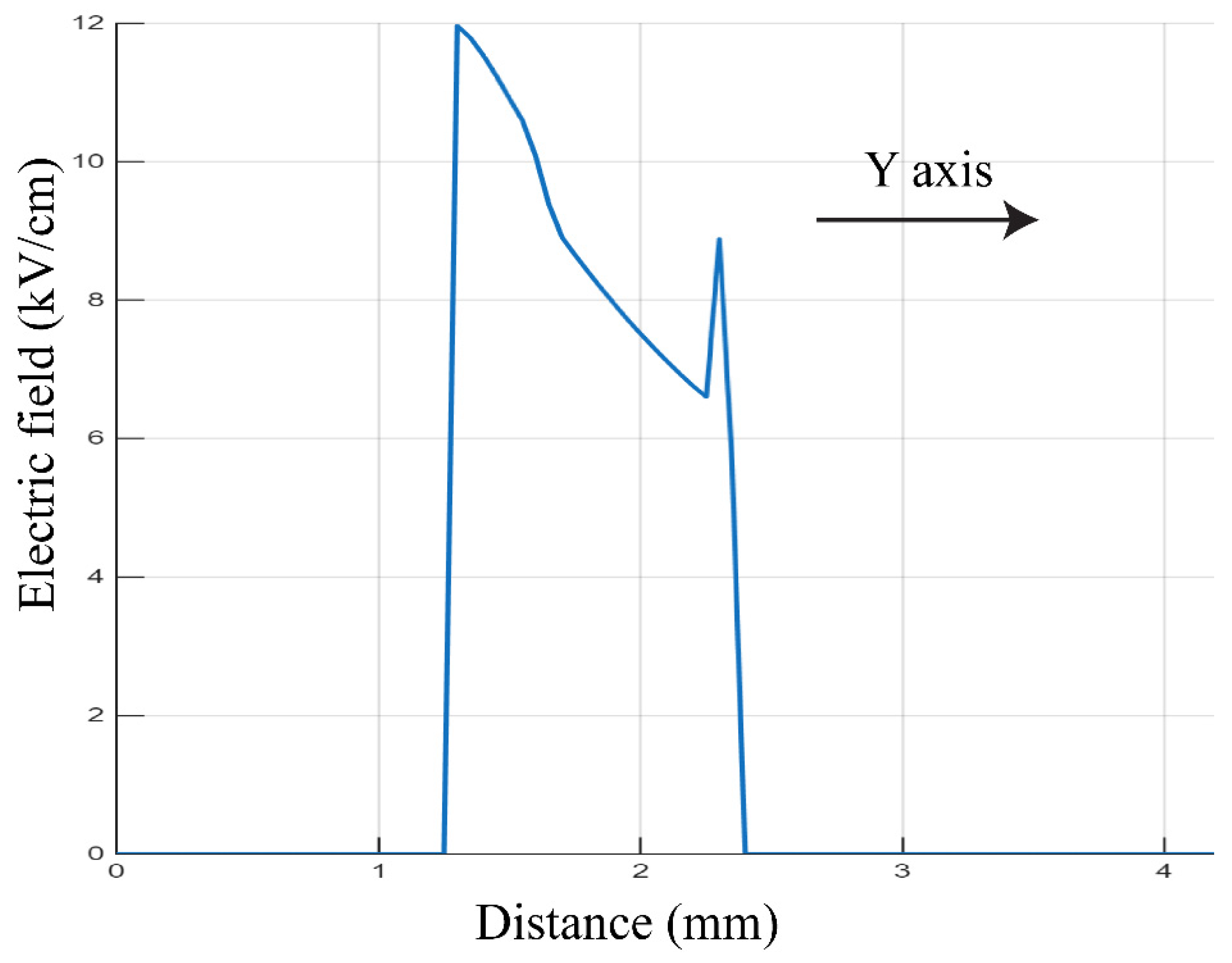

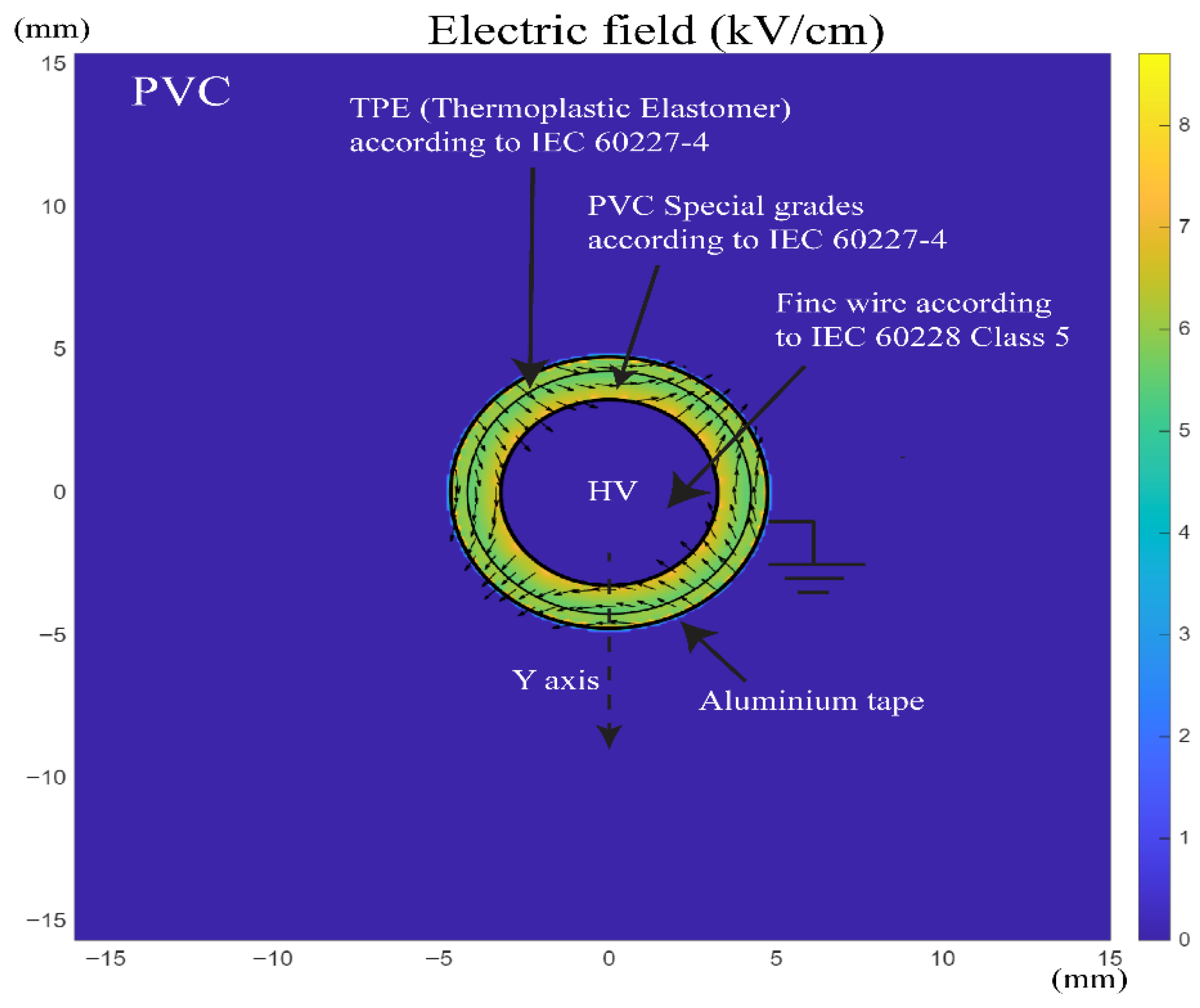

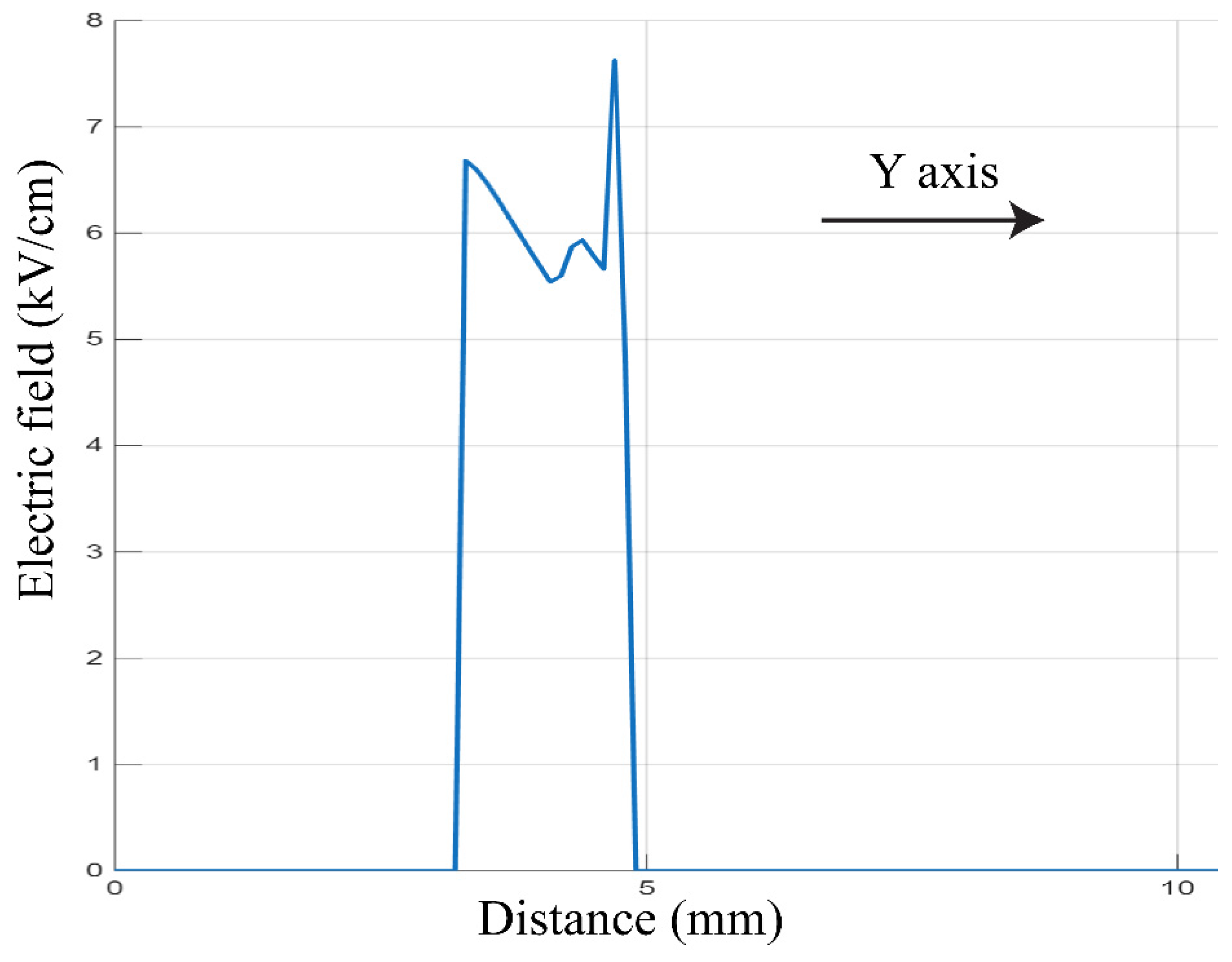

3.2. Electric Field Distribution

3.3. Analysis of Leakage Current, Insulation Resistance, and Electric Field in XLPO, XLPE, and PVC Under ±1 kV DC

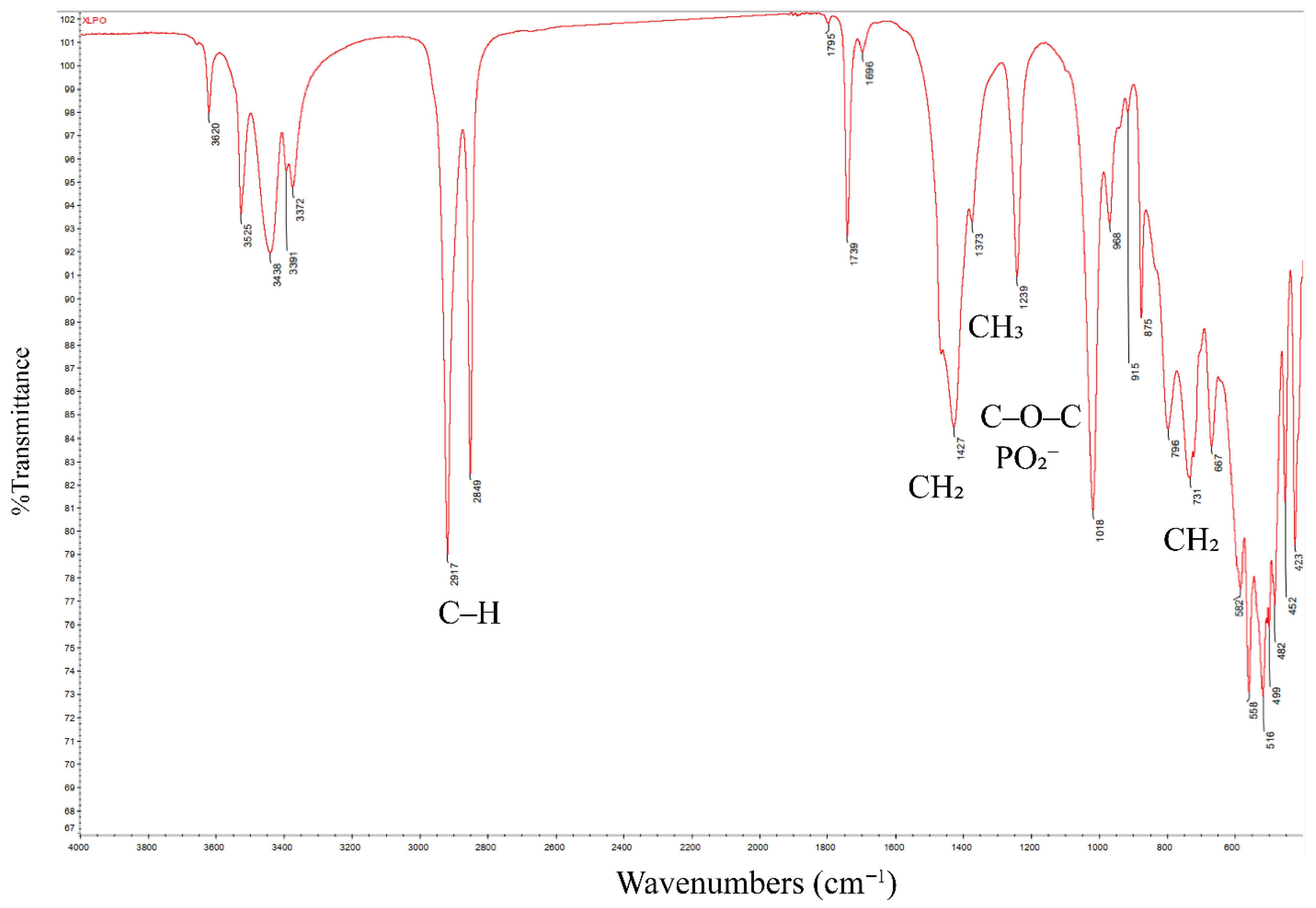

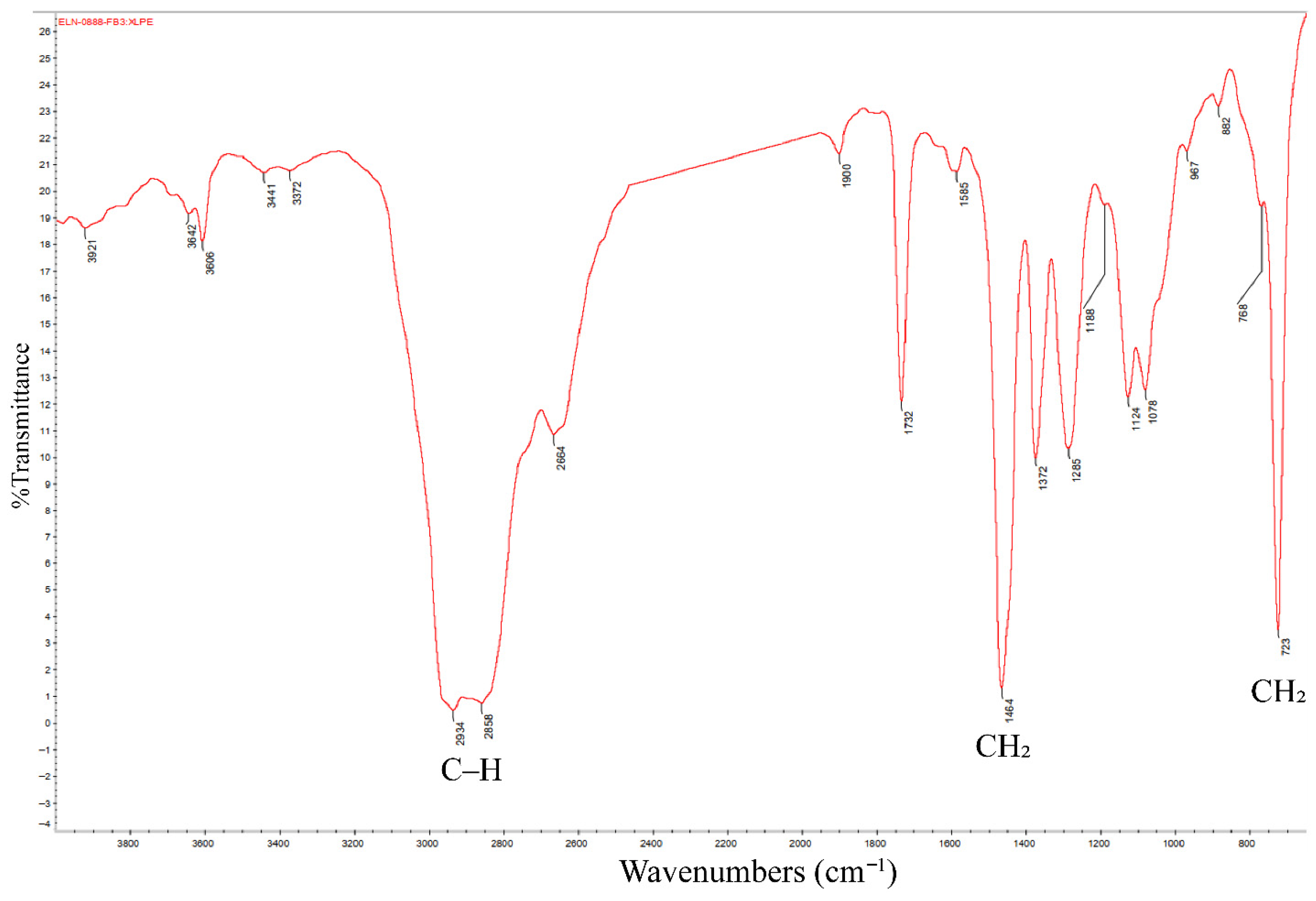

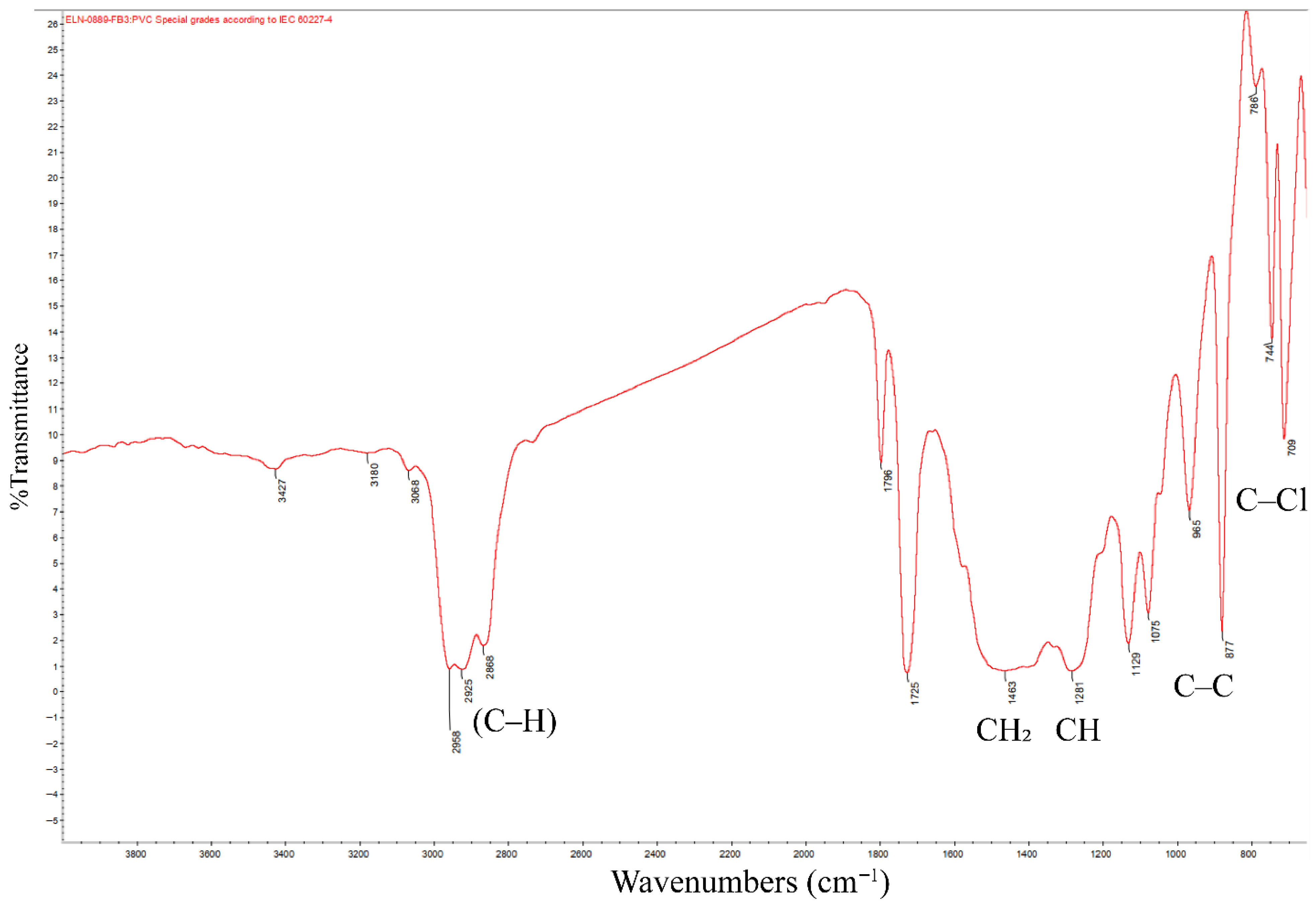

3.4. FTIR Spectral Analysis of Cable Insulation Materials

- C–H asymmetric and symmetric stretching: ~2920 and ~2850 cm−1

- Ester carbonyl (C=O): ~1747 cm−1 (vinyl acetate segment)

- CH2 and CH3 bending: ~1460 and ~1375 cm−1

- C–O–C stretching and PO2− (possible additives): ~1233 cm−1

- CH2 rocking (polyethylene backbone): ~720 cm−1

- C–H stretching: ~2916 and ~2848 cm−1

- CH2 scissoring: ~1472 and ~1462 cm−1

- CH2 rocking: ~720 and ~730 cm−1 (doublet due to crystallinity)

- C–H stretching: ~2910 and ~2850 cm−1

- CH2 bending: ~1430 cm−1 (lower than XLPE due to Cl substitution)

- CH wagging/twisting: ~1330 and ~1250 cm−1

- C–C stretching: ~960 cm−1

- C–Cl stretching: multiple peaks in 610–700 cm−1 (halogen signature)

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mustafa, E.; Afia, R.S.; Tamus, Z.Á. Investigation of complex permittivity of XLPO insulated photovoltaic DC cables due to thermal aging. In Proceedings of the International Symposium on High Voltage Engineering, Budapest, Hungary, 26–30 August 2019; pp. 261–269. [Google Scholar]

- Ohki, Y.; Hirai, N. Effects of the structure and insulation material of a cable on the ability of a location method by FDR. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 77–84. [Google Scholar] [CrossRef]

- Krause, C.; Drung, D.; Scherer, H. Measurement of sub-picoampere direct currents with uncertainties below ten attoamperes. Rev. Sci. Instrum. 2017, 88, 024711. [Google Scholar] [CrossRef] [PubMed]

- Jarrett, D.G.; Owen, M.C. Traceability for aerosol electrometer in the fA range. In Proceedings of the 19th IMEKO TC4 Symposium Measurements of Electrical Quantities, Barcelona, Spain, 18–19 July 2013; pp. 270–274. [Google Scholar]

- Haridoss, S.; Tobazéon, R.; Crine, J.-P. Estimation of water content in cross-linked polyethylene insulated cables by Fourier transform infrared spectroscopy. Appl. Spectrosc. 1988, 42, 186–188. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Oktiani, R.; Ragadhita, R. How to read and interpret FTIR spectroscope of organic material. Indones. J. Sci. Technol. 2019, 4, 97–118. [Google Scholar] [CrossRef]

- Bal, S.; Tamus, Z.A. Analyzing the Impact of Short-Term Cyclic Thermal Ageing on PVC Insulated Low Voltage Samples with Polarization/Depolarization Current Measurement. Acta Polytech. Hung. 2023, 20, 77–91. [Google Scholar] [CrossRef]

- Xu, X.M.; Smeers, J.; Vereecke, G.; Struyf, H. Investigation of the evaporation and wetting mechanism of IPA-DIW mixtures. Solid State Phenom. 2013, 195, 223–226. [Google Scholar] [CrossRef]

- Park, J.-G.; Lee, S.-H.; Ryu, J.-S.; Hong, Y.-K.; Kim, T.-G.; Busnaina, A.A. Interfacial and electrokinetic characterization of IPA solutions related to semiconductor wafer drying and cleaning. J. Electrochem. Soc. 2006, 153, G811. [Google Scholar] [CrossRef]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; IET: Stevenage, UK, 1992; Volume 9. [Google Scholar]

- Das-Gupta, D. Conduction mechanisms and high-field effects in synthetic insulating polymers. IEEE Trans. Dielectr. Electr. Insul. 2002, 4, 149–156. [Google Scholar] [CrossRef]

- Li, Z.; Chen, G. Space charge in thermally aged polyethylene and its electrical performance. Mater. Res. Express 2018, 6, 035308. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, L.; Bhutta, M.S.; Bian, H.; Khan, M.Z. Effect of thickness on the space charge behavior and dc breakdown strength of cross-linked polyethylene insulation. IEEE Access 2020, 8, 85552–85566. [Google Scholar] [CrossRef]

- Walker, R.C.; Hamedi, H.; Woodward, W.H.H.; Rajagopalan, R.; Lanagan, M. Impacts of crosslinking and degassing on the conductivity, dielectric loss, and morphology of low-density polyethylene and crosslinked polyethylene. In Broadband Dielectric Spectroscopy: A Modern Analytical Technique; ACS Publications: Washington, DC, USA, 2021; pp. 239–260. [Google Scholar]

- Kumara, S.; Hammarström, T.; Serdyuk, Y.V. Polarity effect on electric tree inception in HVDC cable insulation. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1819–1827. [Google Scholar] [CrossRef]

- Bartnikas, R.; Eichhorn, R. Engineering Dielectrics Volume IIA Electrical Properties of Solid Insulating Materials: Molecular Structure and Electrical Behavior; ASTM International: West Conshohocken, PA, USA, 1983. [Google Scholar]

- Nikam, P.N.; Deshpande, V.D. Dielectric behavior of plasticized PVC/alumina nanocomposites influenced with DC biasing field. Mater. Today Proc. 2018, 5, 2254–2262. [Google Scholar] [CrossRef]

- Gridnev, S. Dielectric relaxation in disordered polar dielectrics. Ferroelectrics 2002, 266, 171–209. [Google Scholar] [CrossRef]

- Carrión-Jaura, R.; Díaz-Sinche, D.; Castillo-Calderón, J.; Caraguay-Correa, C. Practical Approach to the Application of IEEE Standard 43-2013 in the Assessment of the Insulation of Rotating Machines. In Proceedings of the International Conference on Computer Science, Electronics and Industrial Engineering (CSEI), Ambato, Ecuador, 13–17 November 2023; pp. 920–932. [Google Scholar]

- Qu, J.; Wang, S.; Li, S. The XLPO cable insulation with synchronous-enhanced DC electrical and high-temperature mechanical properties. APL Mater. 2024, 12, 101122. [Google Scholar] [CrossRef]

- Tian, Z.; Sun, L.; Wang, J.; Bai, X. A Study of Simulation on Relationship Between Young’s Modulus of Cable joints and Interface Pressure Based on Finite Element Method. J. Phys. Conf. Ser. 2019, 1187, 022036. [Google Scholar] [CrossRef]

- Farshad, M.; Wildenberg, M.; Flüeler, P. Determination of shear modulus and Poisson’s ratio of polymers and foams by the anticlastic plate-bending method. Mater. Struct. 1997, 30, 377–382. [Google Scholar] [CrossRef]

- Berrag, A.; Madani, L.; Belkhiat, S. An Experimental Study of the Dielectric Parameters of PVC Nano-Composites under Corona Conditions. Eng. Technol. Appl. Sci. Res. 2023, 13, 10523–10528. [Google Scholar] [CrossRef]

- Abdel-Gawad, N.M.; El Dein, A.Z.; Mansour, D.-E.A.; Ahmed, H.M.; Darwish, M.; Lehtonen, M. Enhancement of dielectric and mechanical properties of polyvinyl chloride nanocomposites using functionalized TiO 2 nanoparticles. IEEE Trans. Dielectr. Electr. Insul. 2018, 24, 3490–3499. [Google Scholar] [CrossRef]

- Choudhury, S.N.; Nayak, J.; Das, P.; Pal, A.; Katheria, A.; Banerji, P.; Das, N.C. Enhancing electrical characteristics and electromagnetic interference shielding effectiveness in thermoplastic elastomeric polymer blends by utilizing the selective distribution of conductive black. Funct. Compos. Mater. 2024, 5, 4. [Google Scholar] [CrossRef]

- Salem, M.; Aldabbagh, O. numerical solution to poisson’s equation for estimating electrostatic properties resulting from an axially symmetric gaussian charge density distribution: Charge in free space. Mathematics 2024, 12, 1948. [Google Scholar] [CrossRef]

- Verma, A.R.; Subba, R.B. Understanding surface degradation on polymeric insulators using rotating wheel and dip test under DC stress. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2029–2037. [Google Scholar] [CrossRef]

- Murata, Y.; Sakamaki, M.; Abe, K.; Inoue, Y.; Mashio, S.; Kashiyama, S.; Matsunaga, O.; Igi, T.; Watanabe, M.; Asai, S. Development of high voltage DC-XLPE cable system. SEI Tech. Rev 2013, 101, 55–62. [Google Scholar]

- Du, B.; Han, C.; Li, Z.; Han, C.; Li, J.; Xiao, M.; Yang, Z. Effect of polarity-reversal voltage on charge accumulation and carrier mobility in silicone rubber/silicon carbide composites. IET Sci. Meas. Technol. 2021, 15, 184–192. [Google Scholar] [CrossRef]

- Bokobza, L. Some applications of vibrational spectroscopy for the analysis of polymers and polymer composites. Polymers 2019, 11, 1159. [Google Scholar] [CrossRef] [PubMed]

- Coates, J. Interpretation of infrared spectra, a practical approach. Encycl. Anal. Chem. 2000, 12, 10815–10837. [Google Scholar]

- Zhang, Z.; Wang, B.; Li, J. Effect of the synthesis initiation mode on the structure and properties of sulfadiazine molecularly imprinted polymers. J. Appl. Polym. Sci. 2011, 119, 3189–3198. [Google Scholar] [CrossRef]

- Liang, B.; Lan, R.; Zang, Q.; Liu, Z.; Tian, L.; Wang, Z.; Li, G. Influence of thermal aging on dielectric properties of high voltage cable insulation layer. Coatings 2023, 13, 527. [Google Scholar] [CrossRef]

- Gao, J.-G.; Liu, L.-W.; Sun, W.-F. Dielectric characteristics of crosslinked polyethylene modified by grafting polar-group molecules. Polymers 2023, 15, 231. [Google Scholar] [CrossRef]

| Material | Polarity | LI (=Idischarge/Icharge) |

|---|---|---|

| XLPO | +DC | 1.36 |

| XLPO | −DC | 1.53 |

| XLPE | +DC | 2.63 |

| XLPE | −DC | 1.46 |

| PVC | +DC | 0.98 |

| PVC | −DC | 1.45 |

| Material | Wavenumber (cm−1) | Band/Assignment |

|---|---|---|

| XLPO | 2920 | C–H asymmetric stretching (CH2, CH3) |

| XLPO | 2850 | C–H symmetric stretching (CH2) |

| XLPO | 1747 | Ester carbonyl (C=O) |

| XLPO | 1460 | CH2 bending (scissoring) |

| XLPO | 1375 | CH3 bending |

| XLPO | 1233 | C–O–C stretching; PO2− (additives) |

| XLPO | 720 | CH2 rocking |

| XLPE | 2916 | C–H stretching (asym.) |

| XLPE | 2848 | C–H stretching (sym.) |

| XLPE | 1472 | CH2 scissoring |

| XLPE | 1462 | CH2 scissoring |

| XLPE | 720 | CH2 rocking |

| XLPE | 730 | CH2 rocking |

| PVC | 2910 | C–H stretching |

| PVC | 2850 | C–H stretching |

| PVC | 1430 | CH2 bending |

| PVC | 1330 | CH wagging/twisting |

| PVC | 1250 | CH wagging/twisting |

| PVC | 960 | C–C stretching |

| PVC | 610–700 | C–Cl stretching (multiple) |

| PVC | ≈1730 (weak) | C=O (plasticizer) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruangwong, K.; Pattanadech, N.; Pannil, P. Polarity-Dependent DC Dielectric Behavior of Virgin XLPO, XLPE, and PVC Cable Insulations. Energies 2025, 18, 5404. https://doi.org/10.3390/en18205404

Ruangwong K, Pattanadech N, Pannil P. Polarity-Dependent DC Dielectric Behavior of Virgin XLPO, XLPE, and PVC Cable Insulations. Energies. 2025; 18(20):5404. https://doi.org/10.3390/en18205404

Chicago/Turabian StyleRuangwong, Khomsan, Norasage Pattanadech, and Pittaya Pannil. 2025. "Polarity-Dependent DC Dielectric Behavior of Virgin XLPO, XLPE, and PVC Cable Insulations" Energies 18, no. 20: 5404. https://doi.org/10.3390/en18205404

APA StyleRuangwong, K., Pattanadech, N., & Pannil, P. (2025). Polarity-Dependent DC Dielectric Behavior of Virgin XLPO, XLPE, and PVC Cable Insulations. Energies, 18(20), 5404. https://doi.org/10.3390/en18205404