1. Introduction

Climate change presents a universal challenge demanding a global response. Within this context, China, in 2020, committed to its “Dual Carbon” objectives, targeting a carbon emissions peak by 2030 and neutrality by 2060. This period saw the nation’s aggregate energy consumption rise from 4.98 to 5.72 billion tons of standard coal equivalent between 2020 and 2023 [

1]. During the same period, traditional fossil fuels such as coal and oil continued to dominate the energy consumption structure, driving a persistent rise in carbon emissions [

2,

3]. Given that China has maintained its status as the world’s foremost producer of steel for many years, it is notable that the industry’s operations are responsible for a substantial portion of the national carbon output, constituting an estimated 15% of the total [

4]. Guided by the “Dual Carbon” goals, the iron and steel industry—a sector characterized by high energy consumption and high emissions—urgently needs to undergo a green and low-carbon transformation through technological upgrades and structural optimization [

5,

6]. Targeting the 2024–2025 period, the “Special Action Plan for Energy Conservation and Carbon Reduction in the Iron and Steel Industry” was collaboratively released by five key Chinese governmental agencies, including the National Development and Reform Commission and the Ministry of Industry and Information Technology. The Plan sets forth clear objectives to save approximately 20 million tons of standard coal equivalent and cut carbon dioxide emissions by around 53 million tons, primarily through retrofitting existing facilities for improved energy efficiency and carbon reduction and upgrading energy-consuming equipment [

7]. As a vital pillar of the national economy, the iron and steel industry not only generates carbon emissions through the combustion of fossil fuels but also emits atmospheric pollutants. Therefore, achieving synergistic reductions in greenhouse gases and atmospheric pollutants is of great significance for advancing the green transformation of the steel industry and enhancing emission reduction efficiency [

8].

In the green and low-carbon transition of the iron and steel industry, ultra-low emission retrofits and clean energy alternatives play a critical role [

9,

10]. Studies have shown that ultra-low-emission retrofits can effectively reduce emissions of pollutants such as particulate matter, sulfur dioxide (SO

2), and nitrogen oxides (NOx) [

11], while clean energy alternatives help diminish reliance on fossil fuels by increasing the share of renewable energy in the production process [

12]. In recent years, a growing number of scholars have focused on the green transformation of the steel industry. Research on end-of-pipe treatment has primarily centered on ultra-low-emission retrofits. Yu et al. [

9] systematically analyzed the generation mechanisms of particulate matter, SO

2, NOx, and CO

2 during steel production and compared the principles and effectiveness of major emission reduction technologies. Zhang et al. [

13] investigated the emission reduction efficiency achieved through ultra-low-emission retrofits in China’s iron and steel industry, demonstrating that such retrofits significantly lower the concentration of pollutant emissions. Some scholars have also begun to evaluate the co-benefits of pollution reduction and carbon mitigation from ultra-low-emission retrofits in the sector. For instance, Zheng et al. [

14] quantified the emission reduction effects using air quality models based on a typical steel enterprise. In terms of process control, researchers have focused on adjusting the energy structure [

15,

16]. Many studies have assessed the application potential of low-carbon technologies, such as hydrogen metallurgy and electric furnace short-process steelmaking, from the perspective of clean energy substitution, suggesting that these technologies hold broad prospects for deep decarbonization of the iron and steel industry in the future [

17,

18,

19]. Additionally, the synergistic effects of pollution reduction and carbon mitigation in the steel sector have begun to attract attention. Liu et al. [

20] and Zhang et al. [

21] explored the synergistic effects of current emission reduction policies using scenario simulations, while Ma et al. [

22] compared the emission reduction potential and costs of different technological measures based on their energy-saving potential, thereby evaluating the co-benefits of policies. Collectively, these studies indicate that the synergistic role of various emission reduction measures is crucial for enhancing overall mitigation outcomes [

23,

24].

A review of domestic and international research on pollution and carbon reduction in the iron and steel industry reveals three main limitations in current studies: First, most policy evaluation studies focus on assessing single emission reduction policies, lacking comparative analysis of the synergies among multiple policies; second, the range of pollutants covered is relatively limited, with very few studies addressing the emission reduction effects of volatile organic compounds (VOCs) resulting from unorganized emission control; finally, existing research has not sufficiently explored or discussed pathways for the synergistic reduction in greenhouse gases and air pollutants. Furthermore, a thorough review of the literature indicates that potential pathways for achieving the co-reduction in greenhouse gases and air pollutants have not been investigated in depth. To bridge this identified gap, the primary goal of this systematic assessment is to answer four fundamental questions: (a) How do the synergistic outcomes of the five principal emission reduction strategies adopted in China’s iron and steel sector between 2020 and 2023 differ, specifically regarding their effects on air pollutants versus CO2? (b) What synergistic directions and characteristics do these policies exhibit within the synergistic control effect coordinate system? (c) How should the priority for promoting these emission reduction technologies be determined based on the synergistic emission reduction equivalent (APeq) indicator? (d) What are the policy implications of comparing end-of-pipe treatment with clean energy alternative pathways for the industry’s future green and low-carbon transition?

Based on these observations, this study selects major emission reduction policies in China’s iron and steel industry as its research focus, categorizing these policies into two broad types: ultra-low-emission retrofits and clean energy alternatives. These specifically include sintering machine desulfurization and denitrification retrofit (SDD), dust removal equipment upgrades (DRE), unorganized emission control (UEC), electric furnace short-process steelmaking (ES), and hydrogen metallurgy (HM). The study covers the period from 2020 to 2023, examining the synergistic effects of pollution reduction and carbon mitigation brought about by major emission reduction measures in the steel industry following the introduction of the “Dual Carbon” goals.

This study offers several innovative contributions: First, by selecting 2020 as the starting year, “hydrogen metallurgy” technology is incorporated into the study, making the policy coverage more comprehensive; second, the range of pollutants covered is more extensive, including not only conventional particulate matter, SO2, and NOX but also unorganized emissions of VOCs; third, the study integrates an analytical framework combining a synergistic control effect coordinate system and a synergistic emission reduction equivalent metric, which not only visually illustrates the marginal relationship between pollutant reduction and carbon emission control but also unifies the effects of multi-pollutant reduction, providing a scientific basis for policy formulation and optimization.

2. Materials and Methods

The emission accounting scope of this study covers the total national production of China’s iron and steel industry. The activity data are based on the nationally reported total crude steel output, allocated according to the penetration rates of various emission reduction technologies nationwide, thereby reflecting the mixed structure of different processes such as BF-BOF and EAF. This study selects 2020—the year when the “Dual Carbon” goals were introduced—as the baseline year to analyze the synergistic effects of major emission reduction policies and measures implemented in China’s iron and steel industry on air pollutants control and greenhouse gas reduction, following the same accounting scope. First, the emission reduction effects and carbon emission reductions achieved by each policy measure from 2020 to 2023 are calculated. Using an emission factor methodology based on authoritative and publicly available data, a quantitative analysis is conducted for five specific policies: sintering machine desulfurization and denitrification retrofit (SDD), dust removal equipment upgrades (DRE), unorganized emission control (UEC), electric furnace short-process steelmaking (ES), and hydrogen metallurgy (HM). It should be clarified that the indirect accounting method employed in this study aims to capture the total change in energy-system-related emissions, covering both direct and indirect sources, induced by iron and steel production activities, rather than separately distinguishing direct emissions from process routes. This framework choice ensures consistency in cross-policy comparison. Next, a synergistic control effect coordinate system is constructed, with pollutant reduction and carbon reduction as the two-dimensional indicators, to evaluate the synergistic performance of each policy in reducing both pollution and carbon emissions. Furthermore, a synergistic emission reduction equivalent indicator is introduced to unify the reduction effects of multiple pollutants into a standard equivalent, facilitating a comparative analysis of the comprehensive emission reduction benefits across different policy measures. This provides data support and a scientific basis for optimizing emission reduction policy combinations and enhancing synergistic governance efficiency. The five technical measures selected for this study cover the full spectrum from mature end-of-pipe treatments to emerging low-carbon technologies. Although hydrogen metallurgy (HM) was at the demonstration stage during the study period, its inclusion aims to provide baseline performance data for emerging low-carbon technologies, capturing their early-stage development characteristics and offering a reference for future technological pathways. This comprehensive coverage facilitates the comparison of synergistic emission reduction characteristics across technologies at different maturity levels. The air pollutants covered in this study mainly include: NOx, SO

2, PM, and VOCs, while the greenhouse gas primarily refers to CO

2. The major emission reduction policies are categorized into two types: ultra-low-emission retrofits and clean energy alternatives. The specific technical measures are in

Table 1 below.

2.1. Calculation Method for Emission Reduction

The accounting in this study is conducted at the national level, aiming to evaluate the overall effect of policies across the country. The accounting of emissions for various pollutants follows an indirect estimation approach based on energy consumption. First, the crude steel output associated with each emission reduction technology measure is converted into standard coal consumption using the comprehensive energy consumption coefficient per ton of steel stipulated in the General Rules for Calculation of Comprehensive Energy Consumption (GB/T 2589-2020) [

25]. Due to the lack of officially published emission factors for standard coal that can be directly linked to steel production endpoints, this study adopts an intermediate energy conversion pathway by further converting standard coal consumption into equivalent electricity generation. The identification and allocation of the ‘crude steel output associated with each emission reduction technology measure’ in this study followed this principle: it refers to the annual crude steel production from facilities where the specific technology was implemented. Specifically, based on publicly available data (China Iron and Steel Industry Yearbook, industry association reports), this study obtained the annual national retrofit penetration rate or capacity/production adoption rate for each technology (e.g., the proportion of sintering capacity equipped with desulfurization and denitrification, the share of EAF steel production). This rate was then applied to the annual national total crude steel output (or the relevant production base) to estimate the steel output attributed to that technological measure. This method ensures that, even when multiple measures are implemented concurrently, the output base for each measure is independently accounted for based on its actual application scale, avoiding double-counting.

To ensure the comparability of the emission reduction effects of the five policies under a consistent benchmark for the period 2020–2023, the conversion coefficient is selected based on the standard coal consumption limit (set at 302 g/kWh) specified in the updated Energy Consumption Limit per Unit Product of Coal-Fired Power-Generating Sets (GB 21258-2024) [

26] issued by the Standardization Administration of China. This approach aims to isolate the interference from interannual efficiency changes in the power system itself, thereby more clearly revealing the relative effectiveness of the emission reduction policies within the steel industry. Emissions of various pollutants (SO

2, NOx, PM, VOCs) and CO

2 are calculated by multiplying the equivalent electricity generation by the corresponding power emission factors from the latest Baseline Emission Factors for Regional Power Grids in China (2023) [

27], published by the Ministry of Ecology and Environment. The CO

2 emission factor refers to the national average value (0.6205 kgCO

2/kWh), while the emission factors for other pollutants (SO

2, NOx, PM, VOCs) are derived using a fuel-structure weighting method. By comparing and analyzing data from 2020 and 2023, the emission reduction effects of each policy since the introduction of the carbon neutrality goal are quantified. The specific calculation method is shown in Equation (1) below.

where Δ

,

,

, CEF,

, t

1 and t

2 are the emission reduction in the j-th type of pollutant by the i-th technical measure, the technical measures corresponding to steel production in year t, the comprehensive energy consumption coefficient per ton of steel in year t, the ton standard coal equivalent power generation conversion coefficient, the emission factor of the jth type of pollutant, and the two time nodes used for comparative analysis, respectively.

2.2. Measurement Methods of Synergistic Effects

The synergistic control effect coordinate system method is employed to visualize the impact of emission reduction measures on various pollutants within a two-dimensional coordinate framework. In this system, the abscissa (x-axis) represents the emission reduction effect on a specific air pollutant, while the ordinate (y-axis) indicates the corresponding effect on carbon reduction. Each point within the coordinate system corresponds to an individual emission reduction measure, with its position reflecting both the magnitude and direction of the emission control performance. Points located in the first quadrant denote measures that effectively reduce emissions of both air pollutants and greenhouse gases simultaneously. Points in the second quadrant indicate measures that reduce carbon emissions but may increase emissions of atmospheric pollutants. Points falling within the third quadrant suggest that the measure may lead to an increase in emissions for both categories. Points in the fourth quadrant represent measures that reduce atmospheric pollutant emissions but may result in increased greenhouse gas emissions. The relative effectiveness of a measure in reducing air pollutants versus CO2 can be quantitatively expressed by the angle β formed between the line connecting the data point to the origin and the horizontal or vertical axis.

- 2.

Normalization of emission reduction effect

When evaluating synergistic effects, a normalization method is required to quantify the co-control effects of multiple pollutants. This approach, through the construction of a synergistic emission reduction equivalent, enables a comprehensive evaluation of the co-control effects of different pollutants on a unified scale. The air pollutant equivalence indicator (AP

eq) is used to reflect the overall effectiveness of synergistic reduction between air pollutants and greenhouse gases. Taking SO

2, NOx, PM, VOCs, and CO

2—key emission reduction targets in the current urban iron and steel industry’s energy conservation and emission reduction efforts—as examples, the normalized calculation formula is presented as Equation (2) below:

where ΔE, α, β, γ,

,

represent the emission reduction in each type of pollutant and the equivalent coefficients corresponding to various air pollutants (dimensionless).

The calculation of this indicator primarily employs the ambient air quality standard values of various pollutants. Since air quality standards are based on the comprehensive impact of different pollutants, a higher concentration limit indicates a lower environmental impact of the pollutant, while a lower concentration limit suggests a greater environmental impact. Using the air pollutant equivalence coefficient of SO

2, denoted as α, as the baseline (α = 1), the equivalence coefficients for other pollutants are derived from the ratio of the 24-h average SO

2 concentration to that of each respective pollutant under the Class II standards specified in the “Ambient Air Quality Standards (GB 3095-2012)” [

28]. Here, PM refers to the sum of PM

10 and PM

2.5. The concentration limits and corresponding equivalence coefficients for various air pollutants and greenhouse gases are provided in

Table 2.

Based on the results presented in

Table 2, the calculation formula for AP

eq can be expressed as Equation (3):

where ΔE represent the emission reduction for each type of pollutant.

3. Results and Discussion

3.1. Research Context and Case Scope

Prior to presenting the specific emission reduction accounting results, this section first clarifies the macro context and specific case scope underpinning this empirical analysis. Given its high energy consumption and emission levels, the iron and steel sector is the dominant source of major air pollutants such as particulate matter and sulfur dioxide within non-power industries, besides being a significant greenhouse gas emitter [

29]. Against this backdrop, China, which produced 1.029 billion tons of crude steel in 2023—representing 54.2% of global production [

1,

30]—has rolled out a series of emission reduction policies. To tackle this challenge and foster a green transition, initiatives including the Ministry of Ecology and Environment’s “Guidelines on Promoting Ultra-Low Emissions in the Iron and Steel Industry (2019)” and the “Technical Specification for Ultra-Low Emission Engineering in Sintering Flue Gas Treatment” have been implemented. These documents define pollutant emission limits and control technology pathways for the industry, with a focus on ultra-low-emission retrofits and energy structure adjustment. Using 2020 as the baseline year, this study evaluates the synergistic effects of five major emission reduction policies in the steel industry by comparing data between 2020 and 2023. The policies examined include: sintering machine desulfurization and denitrification retrofit (SDD), dust removal equipment upgrade (DRE), unorganized emission control (UEC), electric furnace short-process steelmaking (ES), and hydrogen metallurgy (HM). Given the significant regional disparities in the distribution of steel production and the substantial influence of local economic and technological conditions on policy implementation, a nationwide study on the synergistic effects of pollution reduction and carbon mitigation in the steel industry can not only provide critical policy optimization pathways for achieving China’s “Dual Carbon” goals but also accurately identify the synergies and potential trade-offs among different technological routes. This will thereby offer a scientific basis for regionally differentiated regulatory strategies.

3.2. Emission Reduction Accounting and Policy Priority Ranking

3.2.1. Emission Reduction Accounting

Using Equation (1), the emission reductions of pollutants and greenhouse gases under different policy scenarios can be calculated by comparing the baseline year with each target year.

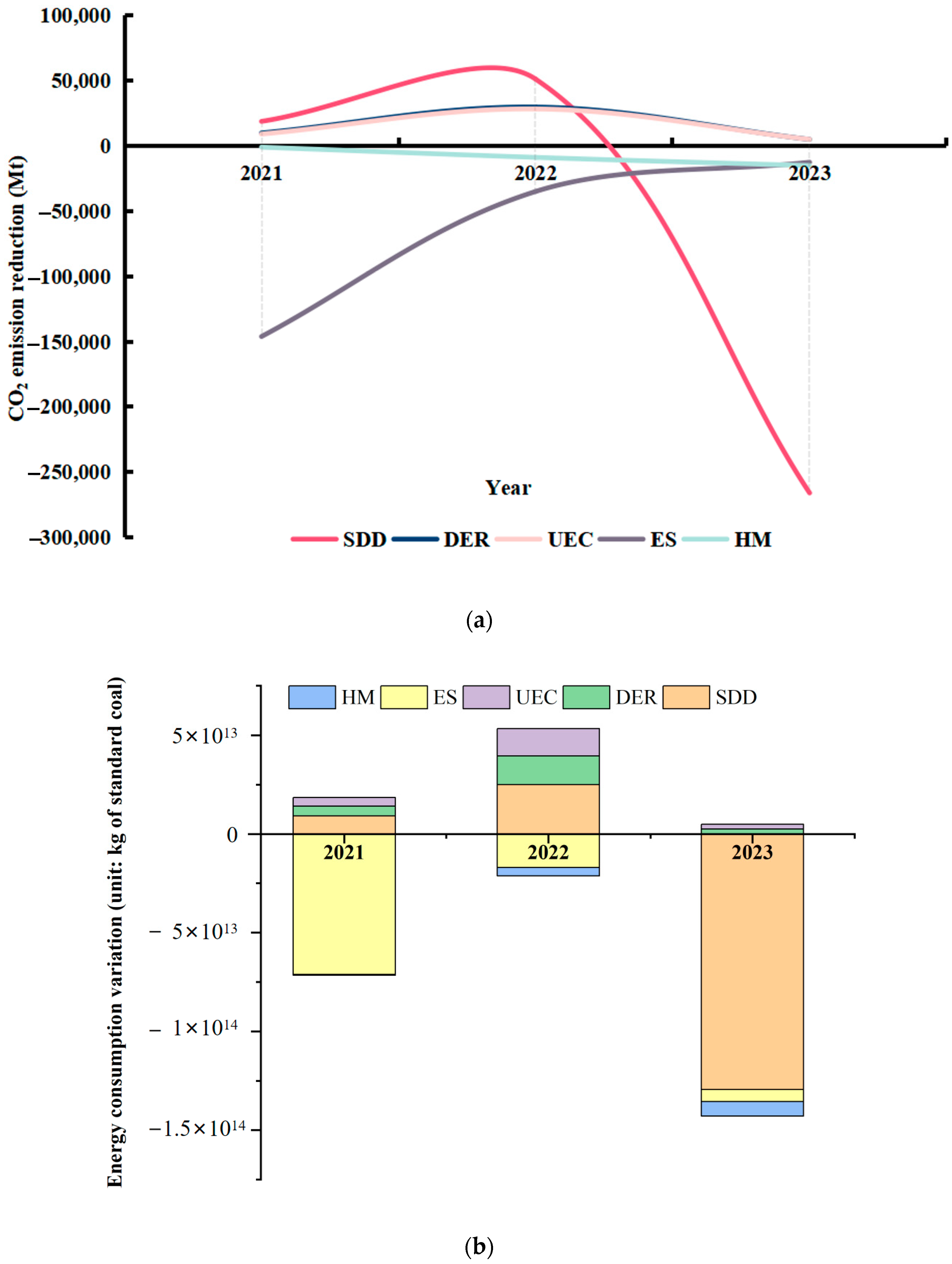

Figure 1 presents the annual CO

2 emission reductions and the energy consumption variation for the five emission reduction policies in 2021–2023 relative to 2020, calculated based on national macro-data (Detailed data can be found in

Appendix A Table A1). The calculations are all based on activity data at the national level and unified emission factors, reflecting the overall effect of the policies at the national scale. As illustrated, the emission reduction trends vary significantly among the policies. Specifically, the sintering machine desulfurization and denitrification retrofit (SDD) demonstrated strong greenhouse gas reduction effects prior to 2022. However, in 2023, not only did it fail to contribute to emission reductions, but it also resulted in a significant increase in carbon emissions compared to 2020. The reversal is primarily because, to comply with stricter emission standards, some enterprises implemented high-energy-consuming end-of-pipe treatment technologies, (such as activated coke desulfurization and denitrification, in the later stages of policy implementation. The operation of these technologies resulted in additional energy consumption, which in turn led to an increase in CO

2 emissions [

9]. Although the record-high crude steel output in 2023 also impacted total emissions, the significant rise in carbon emission intensity in the corresponding SDD links suggests that energy efficiency factors are crucial. The accounting framework of this study captures this shift in emissions driven by increased energy consumption. In contrast, the dust removal equipment upgrade (DRE) and unorganized emission control (UEC) consistently delivered stable greenhouse gas reduction effects over the three-year period. This is primarily because these two technological approaches boast relatively low energy consumption and high processing efficiency. They achieve energy conservation by minimizing additional energy losses within the production system—such as those caused by dust dispersion or increased system resistance—thereby indirectly leading to a reduction in carbon emissions. On the other hand, electric furnace short-process steelmaking (ES) and hydrogen metallurgy (HM) have not yet demonstrated significant advantages in greenhouse gas reduction compared to 2020. The main reasons include their currently limited scale of application and the fact that hydrogen metallurgy (HM) technology is still in the pilot and demonstration phase, yet to be widely implemented. Nevertheless, both technologies hold substantial emission reduction potential in the long term. Hydrogen metallurgy (HM), in particular, is expected to achieve deep decarbonization in the future through hydrogen production from renewable energy sources. Furthermore, electric furnace short-process steelmaking (ES) relies on scrap steel resources. With improvements in the scrap recycling system and technological advancements, the greenhouse gas emissions associated with this process had already decreased noticeably by 2023.

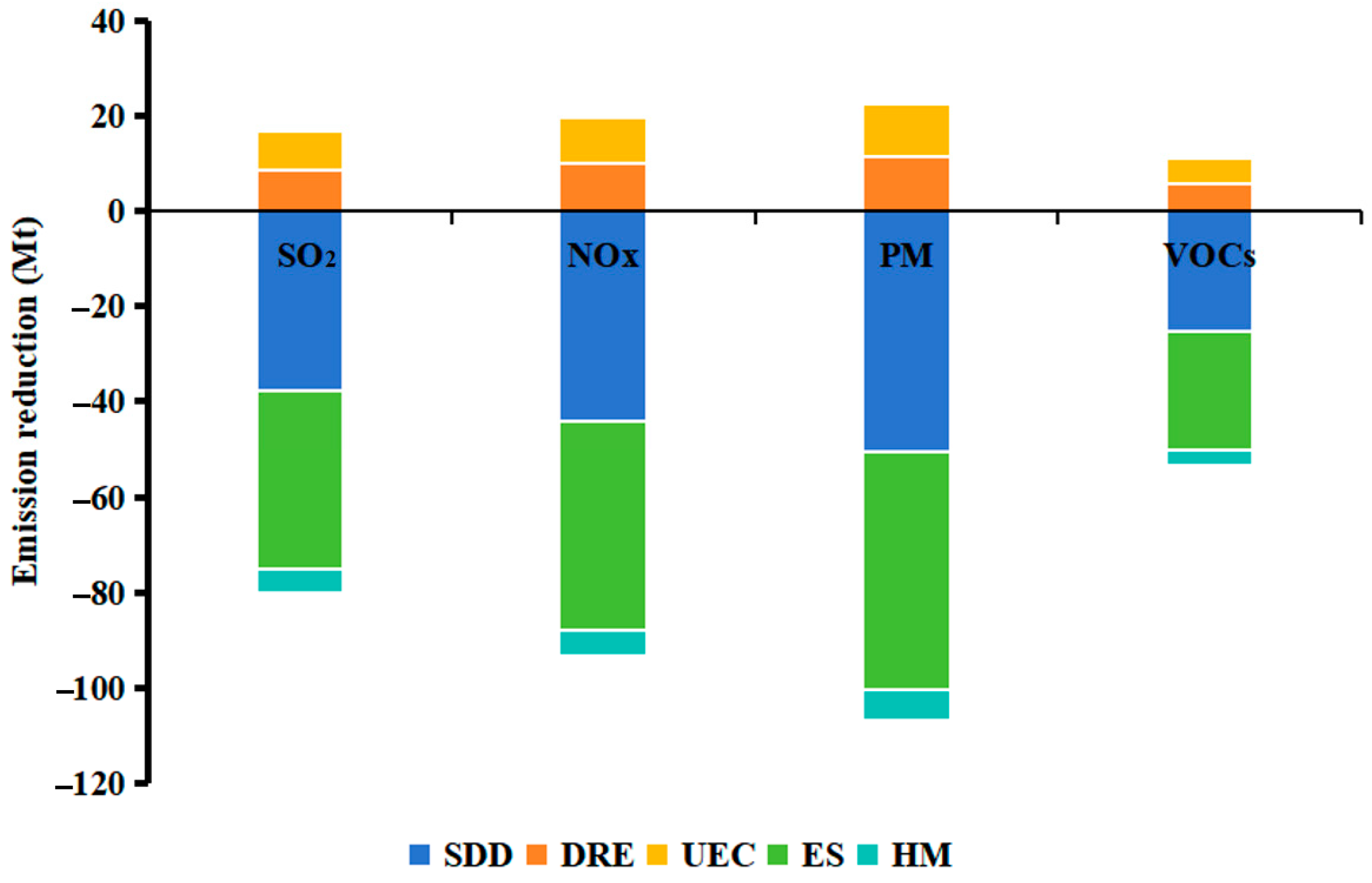

In terms of air pollutants emission reduction, by aggregating the emission reductions achieved from 2021 to 2023 relative to 2020, it can be observed that all five policies exhibited varying degrees of effectiveness in reducing different pollutants, as shown in

Figure 2 (Detailed data can be found in

Appendix A Table A2). Among them, the Dust Removal Equipment upgrade (DRE) and Unorganized Emission Control (UEC) demonstrated significant emission reduction effects across all pollutant categories, particularly in reducing particulate matter emissions. This reflects the ability of these two policies to effectively control dust emission sources during production processes. In contrast, the other three policies did not yield net emission reductions compared to 2020. Specifically, the Sintering machine Desulfurization and Denitrification retrofit (SDD) and Electric furnace short-process Steelmaking (ES) performed poorly in reducing various pollutants. This is primarily due to secondary pollution issues generated during the operation of SDD technology, while ES remains heavily dependent on fossil fuel-based energy structure, resulting in limited pollutant reduction benefits. Additionally, although Hydrogen Metallurgy (HM) theoretically possesses low emission characteristics during its experimental stage, its practical application has been constrained by technological immaturity and supporting infrastructure limitations, preventing it from demonstrating significant advantages in emission reduction performance. It should be noted that all policies faced certain implementation discrepancies and technical compatibility issues during execution, which directly affected the stability and sustainability of pollutant emission reductions.

3.2.2. Policy Priority Ranking

According to the calculation method for synergistic emission reduction equivalents provided in the research methodology section, the AP

eq values for the five emission reduction measures in the steel industry were calculated separately. The measures were then ranked from the highest to lowest based on their synergistic emission reduction equivalents for CO

2 and air pollutants, with the results shown in

Table 3.

As shown in

Table 3, the Sintering machine Desulfurization and Denitrification retrofit (SDD) exhibits the highest synergistic emission reduction equivalent among the five measures, indicating its significant contribution to carbon emission reduction while effectively controlling air pollutants emissions. Hydrogen Metallurgy (HM) and Electric furnace short-process Steelmaking (ES) follow closely, ranking second and third, respectively. The high synergistic effects of these three measures primarily stem from the dual role of their technological pathways in optimizing the energy structure and improving process flows. In contrast, Unorganized Emission Control (UEC) and Dust Removal Equipment upgrade (DRE) demonstrate relatively lower synergistic emission reduction equivalents. Their emission reduction contributions are mainly focused on localized environmental quality improvements, with limited direct impact on carbon emission reduction. Therefore, during policy implementation, priority should be given to promoting SDD, HM, and ES technologies to achieve synergistic enhancement in both pollution and carbon reduction.

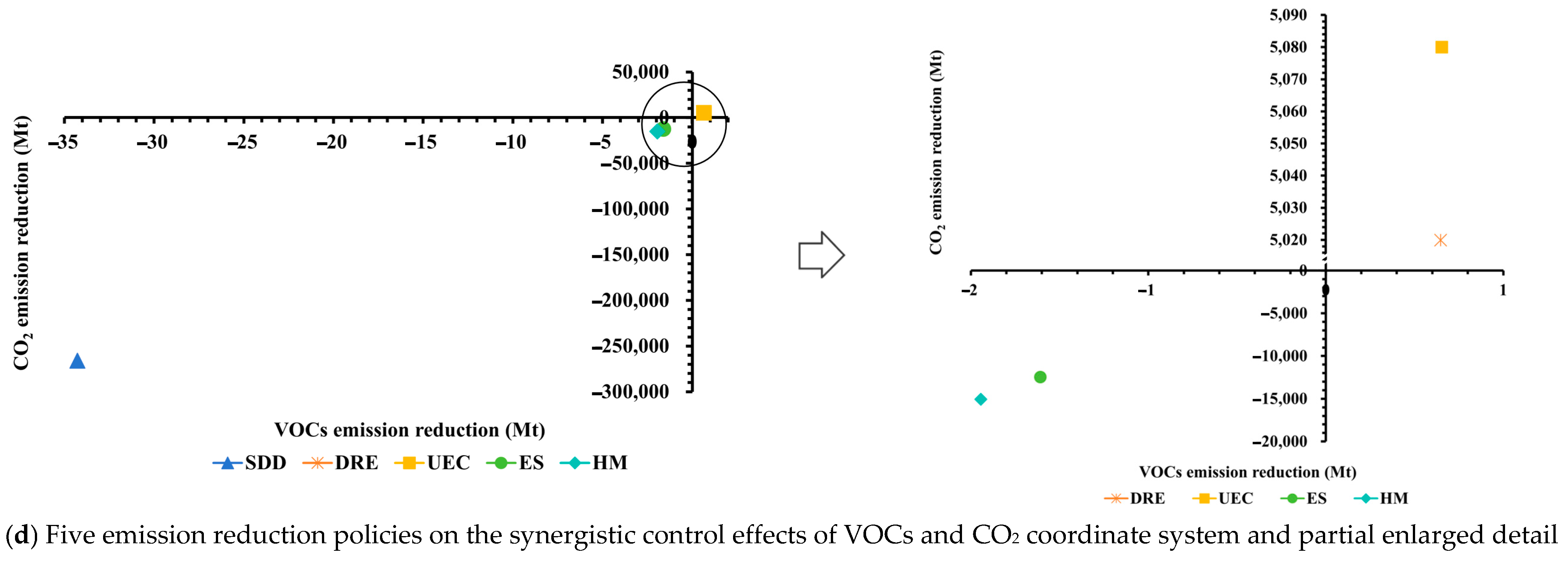

3.3. Results from the Synergistic Control Effect Coordinate System

The synergistic emission reduction coordinate system for the five emission reduction policies was constructed using the synergistic control effect coordinate system method, as shown in

Figure 3. The table below (

Table 4) also helps summarize the positional characteristics of different policies in

Figure 3. The coordinate system clearly indicates that the data points for Dust Removal Equipment upgrade (DRE) and Unorganized Emission Control (UEC) are both located in the first quadrant. This means that both policies exhibit positive synergistic effects in reducing air pollutants (SO

2, NOx, PM, VOCs) and CO

2, simultaneously lowering emissions of multiple pollutants and greenhouse gases. Furthermore, it demonstrates that these two policies not only directly capture particulate matter and control VOCs but also optimize the operational efficiency of the production system, reducing additional energy consumption caused by material dispersal and increased system resistance. Thus, they achieve synergistic carbon reduction while reducing pollution. Moreover, the angle between the line connecting the data point for Unorganized Emission Control (UEC) to the origin and the coordinate axes is larger than that for Dust Removal Equipment upgrade (DRE). This indicates that, when reducing the same amount of air pollutants, the Unorganized Emission Control (UEC) contributes more significantly to greenhouse gas reduction. In contrast, the data points for Sintering machine Desulfurization and Denitrification retrofit (SDD), Electric furnace short-process Steelmaking (ES), and Hydrogen Metallurgy (HM) are all located in the third quadrant. This suggests that, as of 2023 relative to 2020, these policies have neither reduced air pollutant emissions nor lowered greenhouse gas emissions, indicating that they have not yet achieved the expected synergistic effects. One reason is that Sintering machine Desulfurization and Denitrification retrofit (SDD), as an end-of-pipe treatment technology, directly or indirectly increases energy consumption while aiming to reduce air pollutants. On the other hand, Electric furnace short-process Steelmaking (ES) and Hydrogen Metallurgy (HM) are still in the early stages of application, requiring an adaptation and adjustment period, which has limited their emission reduction performance. Additionally, the implementation of these three policies may be constrained by economic costs, technological levels, or production scales, further affecting their emission reduction efficacy.

Analysis using the synergistic control effect coordinate system and the synergistic emission reduction equivalent (APeq) revealed significant differences in the effects of different technological pathways on the reduction in air pollutants (SO2, NOx, PM, VOCs) and CO2. Although the Sintering machine Desulfurization and Denitrification retrofit (SDD) showed the highest APeq value (988,604,352.2), indicating strong synergistic emission reduction capability, its CO2 emissions increased significantly in 2023 compared to 2020 due to rising energy consumption. This suggests that end-of-pipe treatment technologies may undermine carbon reduction effects due to high energy costs. In contrast, the Dust Removal Equipment upgrade (DRE) and Unorganized Emission Control (UEC) consistently remained in the first quadrant of the synergistic coordinate system, demonstrating their ability to reduce both particulate matter and VOCs while simultaneously decreasing CO2 emissions, reflecting relatively stable synergistic performance. Although Electric furnace short-process Steelmaking (ES) and Hydrogen Metallurgy (HM) have not yet exhibited significant synergistic emission reduction effects due to limitations in technological maturity and scale of application, their technical attributes position them as critical pathways for deep decarbonization in the future.

Based on the APeq indicator, the ranking of positive synergistic effects among the five policies is as follows: Sintering machine Desulfurization and Denitrification retrofit (SDD), Hydrogen Metallurgy (HM), Electric furnace short-process Steelmaking (ES), Unorganized Emission Control (UEC), and Dust Removal Equipment upgrade (DRE). This sequence provides a basis for phased policy promotion but also highlights the need to consider potential energy costs associated with high-APeq policies. In the short term, it is advisable to continue advancing robust technologies such as dust removal upgrades and unorganized emission control to ensure air quality. In the medium to long term, emphasis should be placed on fundamental low-carbon technologies like Hydrogen Metallurgy (HM) and Electric furnace short-process Steelmaking (ES), supported by green power supply and industrial chain development, to achieve structural decarbonization. Evaluating HM at the demonstration stage alongside mature technologies holds significant methodological value. Its characteristic of high APeq value but limited actual emission reduction effect clearly reveals the critical role of technological maturity in achieving synergistic effects, providing a dynamic perspective for understanding policy effectiveness along technological evolution pathways.

A comparison between the AP

eq ranking in

Table 3 and the coordinate system analysis in

Figure 3 reveals a noteworthy phenomenon: the Sintering machine Desulfurization and Denitrification retrofit (SDD) policy, which ranks highest in terms of synergistic emission reduction equivalent (AP

eq), does not exhibit a positive synergistic direction in the coordinate system. This seemingly contradictory finding actually highlights the different focuses of the two evaluation methods. The AP

eq indicator emphasizes the aggregate environmental utility or ‘magnitude’ of a policy’s effect; SDD scores high due to its substantial reduction in key air pollutants (e.g., SO

2, NOx). In contrast, the coordinate system analysis focuses on revealing the ‘directionality’ and ‘balance’ between the dual objectives of pollution reduction and carbon reduction. The position of SDD in the coordinate system clearly identifies its potential drawback as an end-of-pipe technology: it may achieve pollutant reduction at the expense of increased carbon emissions. Therefore, the two methods jointly illustrate that while SDD contributes significantly to short-term air quality improvement, it is not an ideal synergistic pathway from a long-term deep decarbonization perspective. This finding underscores the importance of employing multiple assessment tools in multi-objective policy decision-making.

4. Conclusions

This study systematically evaluates the synergistic effects of five emission reduction policies in China’s iron and steel industry from 2020 to 2023 in terms of pollution and carbon reduction, providing an empirical basis and policy insights for the green transition of the industry. The results show significant differences in the synergistic emission reduction effects of different technological pathways, which stem not only from the energy-dependent nature of the technologies themselves but also from factors such as policy implementation cycles, corporate execution capabilities, and the background energy structure.

End-of-pipe treatment technologies can significantly reduce pollutant emissions in the short term, but their synergistic carbon reduction effects are constrained by increased energy consumption, particularly in the case of sintering machine desulfurization and denitrification retrofits (SDD). These results indicate that relying solely on end-of-pipe treatment cannot achieve systematic emission reduction and may even lead to a rebound in carbon emissions due to energy feedback effects. Therefore, while promoting ultra-low-emission retrofits, supporting measures such as energy efficiency improvements and operational optimization should be implemented to reduce the carbon cost of the treatment process itself.

Clean-energy-driven technologies, such as electric furnace short-process steelmaking (ES) and hydrogen metallurgy (HM), have not yet demonstrated significant emission reduction effects but represent core pathways for deep decarbonization in the iron and steel industry. Their current limitations mainly arise from low technological maturity, insufficient green power supply, and high costs, with hydrogen metallurgy (HM) still in the demonstration stage. As renewable energy costs decline, hydrogen production technologies advance, and carbon constraint policies strengthen, the emission reduction potential of these processes will gradually be realized. Thus, their leading role should be emphasized at the strategic level, with enhanced efforts in technology research and development, infrastructure investment, and market mechanism design to create conditions for large-scale application.

Energy structure transformation is a critical prerequisite for supporting the low-carbon development of the iron and steel industry. This study highlights the constraints posed by the current carbon emission factor of electricity on the emission reduction effectiveness of electric furnace processes and the limitations imposed by green hydrogen shortages on the hydrogen metallurgy pathway. In the future, coordinated energy and steel transition should be promoted by accelerating the development of direct green power supply and energy storage systems for steel enterprises while fostering the entire hydrogen chain, including production, storage, transportation, and application. Particular attention should be paid to regional synergy between renewable energy bases and steel production capacity.

Policy formulation must balance synergistic benefits and implementation feasibility. The APeq ranking provided in this study offers a basis for prioritizing policies but also indicates the need for dynamic adjustments based on technological maturity, regional capabilities, and enterprise differences. It is recommended to establish a three-level adaptation mechanism encompassing technology, policy, and region. This includes setting overall emission reduction targets and technical guidelines at the national level, formulating key technology promotion lists at the regional level, and providing customized transformation plans and financial support at the enterprise level to optimize the allocation of policy resources.

This study employed both the Synergistic Emission Reduction Equivalent (APeq) and the Synergistic Control Effect Coordinate System for evaluation. It is crucial to emphasize that the APeq ranking reveals the ‘magnitude’ of the comprehensive environmental benefit generated by policies over the specific period, while the coordinate system diagnoses the ‘direction’ and ‘sustainability’ of their synergistic reduction. For instance, the different insights provided by the two methods for the SDD policy are not contradictory but complementary: SDD offers high immediate environmental benefits (high APeq), but its technical characteristics may lead to increased carbon emissions (non-synergistic direction shown in the coordinate system). Consequently, policymakers should integrate these two perspectives: the APeq indicator can be referenced for achieving rapid short-term air quality improvements, while planning long-term low-carbon transition pathways must prioritize technologies located in the first quadrant of the coordinate system, which possess genuine synergistic potential (such as DRE, UEC, and future mature ES and HM).

5. Limitations and Future Research

This study provides a systematic evaluation of the synergistic effects of key emission reduction policies in China’s iron and steel industry, several limitations should be acknowledged, which also present directions for future research. The emission accounting framework in this study relies on an indirect calculation method based on energy consumption, applying unified grid emission factors and fixed energy conversion coefficients. Although this approach ensures consistency in cross-policy comparison, it does not strictly distinguish between direct process emissions and indirect emissions from purchased electricity, nor can it reflect plant-level emission heterogeneity resulting from differences in equipment efficiency, operating conditions, and raw materials. This study focuses more on assessing energy-system emissions induced by steel production rather than direct emissions at the facility level. Future research could, when data availability permits, develop more granular emission inventories that distinguish between direct and indirect emission sources, coupled with parameter uncertainty and sensitivity analyses.

The emission accounting framework relies on an indirect calculation method based on energy consumption, applying unified grid emission factors and fixed energy conversion coefficients. Although this approach ensures consistency in cross-policy comparison, it does not strictly distinguish between direct process emissions and indirect emissions from purchased electricity. Furthermore, to maintain a consistent benchmark, uncertainty analysis for key parameters was not conducted, which might affect the precision of absolute emission reduction estimates. However, the conclusions regarding the relative ranking of policies are robust. The weighting scheme for the Air Pollutant Equivalent (APeq) indicator is based on the concentration limits from the Ambient Air Quality Standards. This method offers an objective perspective grounded in environmental capacity but does not directly reflect the differences in health impacts or socio-economic costs among pollutants. The simultaneous use of the synergistic control effect coordinate system in this study partially mitigates this limitation by providing multi-dimensional insights for policymakers.

Future research could be deepened in the following areas:

- (1)

Developing more granular emission inventories that distinguish between direct and indirect emission sources, coupled with parameter uncertainty and sensitivity analyses, when data availability permits;

- (2)

Exploring the integration of multiple weighting systems, such as health impacts or the social cost of carbon (SCC), into the synergistic effect assessment framework for multi-criteria decision analysis;

- (3)

Applying the evaluation framework constructed in this study to regional or enterprise levels and combining it with dynamic scenario simulations to investigate long-term emission reduction potential and transition pathways under different technological roadmaps.