Abstract

Given the climate change observed in the past few decades, sustainable development and the use of renewable energy sources are urgent. In this scenario, hydrogen production through electrolyzers is a promising renewable source and energy vector because of its ultralow greenhouse emissions and high energy content. Hydrogen can be used in a variety of applications, from transportation to electricity generation, contributing to the diversification of the energy matrix. In this context, this paper presents an autonomous isolated DC microgrid system for generating and storing electrical energy to be exclusively used for feeding an electrolyzer hydrogen production plant, which has been retrofitted for green hydrogen production. Experimental verification was performed at Itaipu Parquetec, which consists of an alkaline electrolysis unit directly integrated with a battery energy storage system and renewable sources (e.g., photovoltaic and wind) by using an isolated DC microgrid concept based on DC/DC and AC/DC converters. Experimental results revealed that the new electrolyzer DC microgrid increases the system’s overall efficiency in comparison to the legacy thyristor-based power supply system by 26%, and it autonomously controls the energy supply to the electrolyzer under optimized conditions with an extremely low output current ripple. Another advantage of the proposed DC microgrid is its ability to properly manage the startup and shutdown process of the electrolyzer plant under power generation outages. This paper is the result of activities carried out under the R&D project of ANEEL program No. PD-10381-0221/2021, entitled “Multiport DC-DC Converter and IoT System for Intelligent Energy Management”, which was conducted in partnership with CTG-Brazil.

1. Introduction

Sustainable development combined with the adoption of renewable energy sources (RESs) is the goal to achieve net-zero emissions in the modern world. Given the severe climate changes faced and their current effects, several countries have been proposing increasingly bold measures and objectives for mass decarbonization in the coming years, with a focus on mitigating carbon emissions. The global energy transition is an urgent challenge and a critical priority to address climate change and achieve decarbonization. In this context, green hydrogen (), produced through the electrolysis of water utilizing electricity from RESs, such as solar and wind, has emerged as a promising energy vector and a fundamental solution for decarbonizing multiple sectors. Green hydrogen is considered particularly essential for hard-to-abate sectors and long-term energy storage [1,2,3,4,5,6].

Hydrogen has been safely used for over a century, primarily in industrial applications such as oil refinement, ammonia production, fertilizers, metallurgical applications, and the food industry [7]. Currently, over 99.9% of hydrogen demand is met by those traditional sectors, where hydrogen plays a fundamental role [4]. Green hydrogen is now being promoted for a broader range of new applications, aiming to decarbonize these and other sectors. These applications include heavy industry (e.g., steel, cement, and chemicals), mobility and transportation (e.g., fuel in electric vehicles and heavy-duty transportation like trucks, trains, ships, and long-haul transport), and civil applications such as heating and power generation in buildings [4]. Furthermore, green hydrogen is crucial for energy storage and grid balancing, acting as a versatile energy carrier and storage medium for surplus renewable energy [3,4].

However, the widespread implementation of green hydrogen faces significant drawbacks and challenges. The intermittent and stochastic nature of renewable energy sources can reduce the efficiency of hydrogen production and complicate its integration into energy systems [8,9,10]. This paper experimentally demonstrates that combining different RESs with battery energy storage systems (BESSs) enables the complete and proper management of the electricity provided to an electrolyzer, thereby mitigating the intermittent nature of RESs and increasing system reliability.

The water electrolysis process, a key method for green hydrogen generation, is inherently energy-intensive [8]. The entire hydrogen supply chain, from production to final use, is complex and can incur significant energy losses, potentially reducing overall efficiency to below 30–40% [4]. Uncertainties in proper CAPEX and OPEX estimations [4] with high production costs, which can be five to ten times more expensive than gray hydrogen [8] and currently range from USD 4.5 to USD 12 per kilogram for [11] (though projected to decrease significantly by the end of the decade [5]), conversion inefficiency, and dependence on specialized infrastructure are additional barriers to the widespread adoption of [8]. Existing infrastructure often requires substantial and costly modifications to accommodate hydrogen [3,12,13], presenting challenges related to storage (such as low density, significant compression energy requirements of 10–15% of the total energy input, and material degradation, including embrittlement [4]) and transportation (limited dedicated pipelines, with only about 5000 km globally compared to over 3 million km for natural gas [5]). Furthermore, many promising technological solutions are still far from industrial readiness, operating at low Technology Readiness Levels (TRLs) [3,4,5]. Safety considerations are paramount in hydrogen system design and deployment, given its highly flammable and explosive nature, which necessitates rigorous measures for leakage detection, explosion risk mitigation, and public perception management [7,13,14]. The current marginal presence of green hydrogen, making up just 0.1% of global hydrogen production by the end of 2023, highlights these ongoing challenges [4,5].

Despite these challenges, green hydrogen presents significant opportunities for a sustainable energy future. It offers a powerful tool for decarbonization, particularly in sectors where direct electrification is difficult. One key advantage is its ability to mitigate the intermittency and stochasticity of renewable energy sources by converting surplus electricity from wind and solar into hydrogen for storage and later use, thereby optimizing energy utilization and preventing curtailment. The advantages of mixing solar and wind, combined with storage, are particularly notable; these diverse renewable resources can complement each other by providing consistent energy during periods of low availability from one source, enhancing overall system reliability and supporting grid stability and resilience. This long-term energy storage capability goes beyond the capacities of batteries and extends the application of renewables to thermal energy systems and mobility [4,6,15,16,17]. However, as will be demonstrated in this work, combining BESSs with hydrogen production plants fed by RESs is essential for stabilizing hydrogen production, minimizing maintenance costs, and increasing the availability of electrolyzer plants throughout the year.

Green hydrogen offers potential economic benefits, including a projected 20–28% reduction in climate mitigation costs [5]. These costs are expected to decline further due to technological advancements and economies of scale. Targeted policies and bankable investment models are crucial for fostering the development of hydrogen ecosystems and accelerating their adoption [4]. Moreover, the development of approaches that allow for the retrofitting of already installed facilities presents a significant opportunity for widespread implementation, as shown in this work.

Hydrogen plants using alkaline electrolyzers are commercially mature for large-scale production, but there are continuous efforts to keep increasing their production efficiency and reducing their costs [2,4,5,8,12,15,16,17,18]. Alkaline electrolyzers are electrochemical systems composed of non-noble metallic electrodes (cathodes and anodes) embedded in an alkaline electrolyte (potassium hydroxide, KOH). In sum, the electrochemical reaction requires the supply of electrical energy in direct current (DC) between the electrodes, leading to the electrochemical conversion of water molecules into hydrogen () and oxygen () [19,20]. The power supply of commercial electrolyzers is usually based on Alternating-Current (AC) systems, employing rectifiers (AC/DC converters) to integrate DC electrolyzers into the electrical utility AC grid, with most of them mainly based on transformers associated with thyristor rectifiers or transistor and diode rectifiers [21,22,23]. Alkaline electrolyzers are recognized for their dynamic operation, efficiency, and rapid response times, making them ideal for integration with intermittent energy sources. Thyristor-based converters are the most widely used because of their cost, simplicity, and reliability. However, these AC/DC converters present technical limitations related to the energy quality of the power supplied and efficiency. The ripple factor of the direct current, frequency, and fluctuation of the current supplied by the rectifier to the electrolyzer can also impact the life cycle of the electrodes, resulting in degradation and/or efficiency decrease [21,22,23,24,25]. This work proposes a DC microgrid in which a retrofitted electrolyzer plant is powered by a DC power supply featuring an extremely low ripple current. This power supply, which employs three interleaved Phase-Shifted Full-Bridge converters, demonstrates experimental efficiency improvements of up to 26% in hydrogen production.

To achieve 100% , hydrogen plants need to run on renewable energy sources. Connecting these plants directly to DC power systems significantly boosts efficiency. This is because electrolyzers naturally use DC power, so a direct connection avoids the extra energy conversion steps that would be needed with an AC microgrid. There are not a large number of examples in the literature on isolated microgrids dedicated to green hydrogen production, but the work shown in [10] presents a design and analysis of stand-alone hydrogen energy systems integrated with different renewable energy sources (RESs) to supply electricity to a residential user in a mountain environment in Italy back in 2004. The study compared three types of systems, namely, a solar hydrogen energy system, micro-hydro hydrogen energy system, and wind hydrogen energy system, but a combination of more than one RES to feed the system was not investigated at that time. Back in 2004, the cost of RESs was considerably higher than that of conventional sources such as a micro-hydro power plant, which was identified as the best plant option at that time due to the system’s overall electrical efficiency and low investment cost. The study presented in [26] reviews the state of the art and investigates the benefits of using more than one RES to feed an electrolyzer in a DC microgrid concept for power grid stabilization application (tied to an AC utility grid by a DC/AC converter from the microgrid DC bus). Combining different renewable energy sources, like solar and wind power, can significantly enhance overall efficiency; for instance, it can increase Faradaic efficiency, which quantifies how effectively the electrical charge supplied to an electrochemical system is converted into the desired chemical product. When combining both PV and wind, it is possible to increase Faradaic efficiency above 85% compared to around 40% for PV only and 80% for wind power only [26]. The paper also shows that conventional Alkaline Water Electrolysis (AEL) electrolyzers have limitations when powered by fluctuating renewable energy because they are designed for fixed process conditions. A significant limitation is the increased gas impurity at low power availability (part-load range), which can lead to a safety shutdown if foreign gas contamination reaches 2 vol.% to prevent explosive mixtures. This limits the annual operation time and can accelerate electrode degradation due to frequent start/stop cycles. Optimal system design and operation strategies are crucial to mitigate issues like high gas impurity during low power availability and to maintain the optimal operating temperature (50–80 °C for KOH solutions) [26]. Investment costs for AEL (800–1500 EUR/kW) are currently lower than those for proton exchange membrane electrolysis (1400–2100 EUR/kW), and AEL also offers a higher lifetime and lower annual maintenance costs [26].

Considering the discussion presented above, the challenges of existing infrastructure, and the need for coherent and scalable strategies that connect technological development with practical implementation in the energy sector, this work presents and contributes to technology evolution, its adoption, and its TRL maturity improvement:

- A novel isolated DC microgrid concept for production to efficiently integrate RESs and BESSs into an industrial electrolyzer is proposed herein.

- This paper describes the operating aspects of an industrial electrolyzer, which drives the system requirements for the proposed DC microgrid to enhance electrolyzer operation, availability, and maintainability, potentially minimizing maintenance costs.

- Experimental verification of the proposed microgrid functionalities with RESs, a real PV array and an emulated wind turbine, a sodium BESS, and an industrial alkaline electrolyzer plant (retrofitted to produce ) is presented and discussed.

- Efficiency improvement is experimentally verified in hydrogen production with the proposed DC microgrid (up to 26%) when compared to legacy thyristor-based systems.

- The proposed DC microgrid showcases and contributes to technology maturity, elevating the Technology Readiness Level (TRL) for industrial applications. The presented work has been classified as TRL 5 (technology validated in a relevant environment). Still, it can be scaled up to TRL 8 when the system is completed, qualified, and passes certification.

2. Legacy Hydrogen Production Plant

Itaipu Parquetec, located in Brazil, focuses on applied research and was established in 2012 with the support of Itaipu Binational, the largest hydroelectric plant in the world in terms of annual energy production and the second in terms of generation capacity (14 GW) [27,28]. The center operates across the entire hydrogen technology value chain, and innovation in hydrogen production is one of its core expertise areas. Since its establishment in 2012, it has been developing new technologies and operating an production plant based on Alkaline Water Electrolysis (AEL); it is shown in Figure 1.

Figure 1.

Hydrogen facility dedicated to industrial-scale experimental stations for the entire hydrogen technology value chain.

2.1. Standard Electrical Power System of the Electrolyzer

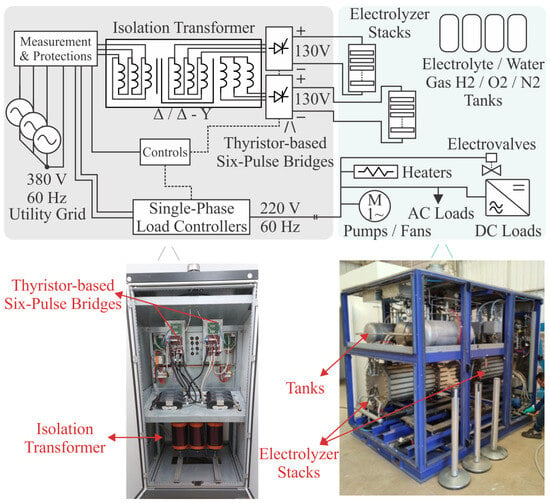

The industrial electrolyzer operating in Itaipu Parquetec was designed and manufactured by the former Italian company Nitidor. The electrolyzer’s technical parameters and electrical load data are shown in Table 1. An overview of the legacy electrolyzer’s electrical power system, showing the thyristor-based power supply and auxiliary electrical loads, can be seen in Figure 2.

Table 1.

Legacy electrolyzer technical parameters and data.

Figure 2.

Legacy electrical power system of the Nitidor AEL electrolyzer plant. Two thyristor-based six-pulse rectifiers provide the DC voltage for each cell stack. The auxiliary loads, such as pumps, fans, heaters, electrovalves, light AC fans, and DC loads (with a dedicated AC/DC rectifier), are fed with line-to-neutral voltages employing their dedicated load controller (contactor or relay). The DC loads comprise sensors ( leakage, pressure, flow, temperature, voltage, current, the Hall effect, etc.), a modem for communications, displays (human–machine interface), protective devices, emergency circuits, a Programmable Logic Controller (PLC) for process control, and power supplies (24 V/+15 V/−15 V).

One safety-related factor regarding hydrogen production systems is the plant’s earthing of the metal parts to avoid the risk of electrical discharges and the danger of explosions. Since metal live parts must be protective-earthed, the electrical system must include a galvanic isolation stage to protect the parts from electric grid hazards [21]. As can be seen in Figure 2, the legacy electrolyzer’s electrical power system features an isolation transformer to provide galvanic isolation between the electrical grid and the electrolyzer’s thyristor-based six-pulse rectifier, which is connected to the cell stack. This was one of the assessed requirements to define the new converter topology for feeding the G electrolyzer, as will be shown in the next section (galvanic isolation was provided at high frequency through an isolated DC/DC converter).

2.2. Hydrogen Production Process Based on AEL

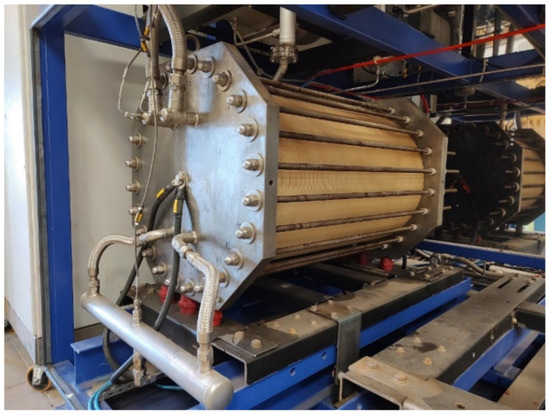

Hydrogen production is based on alkaline electrolysis technology. The process consists of the electrochemical conversion of water () into hydrogen () and oxygen () molecules through the electric field applied at the electrode interface by a DC power supply. The electrolysis cell has a multi-layer structure of anode, diaphragm, cathode, and electrolyte flow channels. Once the electrolysis cell is stacked up in a desired/designed number of cells, it forms a cell stack of the electrolyzer, which can be seen in Figure 3. More details on the AEL cell stack arrangement, as well as its physics phenomena, can be seen in [19,20].

Figure 3.

Electrolyzer cell stack comprising 80 AEL cells. The mechanical support/electric isolators can be seen in red at the bottom of the cell stack, separating it from the metal frame.

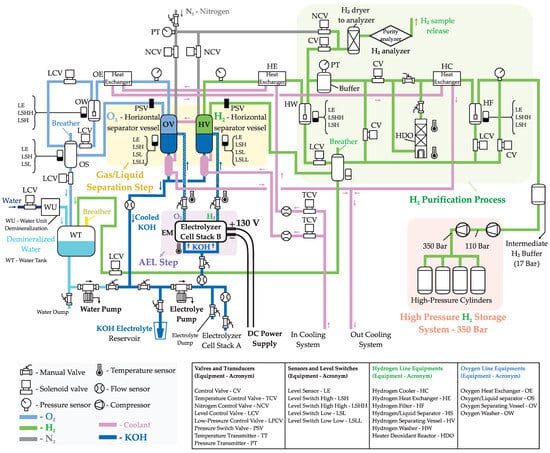

The control process of hydrogen production is based on several stages involving not only the electrolysis itself but also the separation, purification, compression, and storage processes. Each stage is automatically controlled via a Programmable Logic Controller (PLC) integrated into a Supervisory Control and Data Acquisition (SCADA) system, and then the plant’s operator supervises all production steps using SCADABR version 1.2 software on computers. Among the main embedded functionality of the test platform, precise control of pivotal process variables, such as electrolyte flow, pressure, temperature, and direct current electrical power supply, is essential to guarantee the overall production process quality. The experimental station also has integrated safety features, graphical supervision via a human–machine interface (HMI), automated execution of operational sequences through pre-configured scripts, and a functional expansion capacity via programmable interfaces. All operating data are automatically collected and stored, enabling traceability, comparative performance analysis, and support for the calibration of physical–computational models. The whole process is represented in Figure 4, and a summary of each step in hydrogen production is discussed in the following subsections.

Figure 4.

Electrolyzer plant diagram showing sensors, vessels, tanks, and equipment employed in each stage of hydrogen production.

2.2.1. Startup/Shutdown Purge and Inertization Phases with Nitrogen

Nitrogen is often used to purge the electrolyzer system, playing a subtle but important role in alkaline water electrolyzers keeping the system safe, especially during the startup, shutdown, and maintenance phases (idle time), as well as to prevent system oxidation, since the components inside the electrolyzer can corrode if exposed to oxygen or moisture when idle (electrodes or internal piping). Therefore, nitrogen helps create an oxygen-free environment to protect these parts during inertization phases.

After a whole cycle of the electrolysis process, the system contains a mixture of hydrogen and oxygen gases. If those gases are not removed from the piping and equipment, the mixture can become explosive. Thus, for safety reasons, an inert gas is used to carry the potentially explosive gas mixture out of the electrolyzer. Before restarting the system, nitrogen is employed to dry the internal components, ensuring that no reactive gases are present, maintaining hydrogen production at the highest purity levels.

2.2.2. Alkaline Water Electrolysis (AEL)

After the purge phase described in Section 2.2.1, all pipes are almost free of impurities, and nitrogen is collected. The automated process control initiates hydrogen production.

The water molecule is broken down into hydrogen and oxygen by applying DC voltage to the cell stack electrodes, while the electrolyte flowing through the anode and cathode, contacting the catalyst on both electrodes, facilitates the ionic conduction of the (cathode) and (anode) molecules out of the electrolyzer utilizing an aqueous solution of potassium hydroxide (). Each and molecule is properly routed to its horizontal separator vessels ( vessel—HV; vessel—OV) through the electrolyte, as shown in Figure 4.

The electrical equivalent model used in this work to model the AEL behavior, considering the lossy mechanisms (ohmic phenomena, activation phenomena, and double-layer effect) [9,20,29], is based on the model presented in [20]. The ideal thermoneutral voltage for the cell stack in this work is 118.4 V (80 cells times 1.48 V), but the stack voltage reaches 130 V on average due to the loss mechanisms. The electrolyzer voltage also depends on the power demand, as well as the environmental conditions (pressure and temperature) and transient variations, which may pull the voltage slightly above the average value, especially under high-current-ripple conditions or temperature shifts.

2.2.3. Gas/Liquid Separation (HVs and OVs)

The gases produced during electrolysis inside the cell stack, as previously described in Section 2.2.2, are conducted through the electrolyte to the separator tanks, where they are collected in two separate buffers and taken to the horizontal separator tanks: the hydrogen vessel (HV) and oxygen vessel (OV). The and gases are then separated from the liquid electrolyte, which is returned to the electrolyzer via the recirculation pump. The electrolyte level in the horizontal separator tanks must be at the midpoint to ensure good unit performance. The solution levels in the horizontal hydrogen and oxygen separator tanks are monitored in the SCADA system to guarantee the process performance. These separation stages are shown in Figure 4.

2.2.4. Heat Exchanger

A chiller is responsible for controlling the water temperature that circulates in the heat exchangers inside the production unit and in the compressor stage, which is also monitored.

2.2.5. Purification Process

During this stage, impurities are removed from the gases produced during the electrolysis process. The hydrogen goes through an advanced purification and drying stage to remove most impurities, while the oxygen is released into the atmosphere. The purification unit includes the following:

- Heater Deoxidant Reactor (HDO): The present in the line reacts with the hydrogen, thereby forming water, which is condensed and subsequently removed.

- Dryers: These remove the moisture contained in .

- Gas analyzers: These measure the amount of gas in the line, and vice versa. The gas concentrations must be below safety limits. The ISO 22734-1 [30] standard suggests stopping the process when the concentrations reach values such as 2% in and 1.6% in .

This entire process, represented in Figure 4, allows for achieving a high degree of purity in the produced . After purification, the hydrogen passes to the low-pressure storage step, which is described below.

2.2.6. Intermediate Buffer

The free of impurities is routed to an intermediate Hydrogen Buffer (HB) to stabilize the system pressure. The HB has a capacity of 700 L and operates up to 20 bar of pressure. It is located after the Hydrogen Filter (HF) vertical tank, as shown in Figure 4, where the electrolyte fraction and other impurities are removed from the final gas to be compressed and stored.

2.2.7. Compressor and Storage

When the pressure in the HB reaches 17 bar, the compressor is activated, compressing in two stages: from 17 bar to 110 bar and, subsequently, from 110 bar to 350 bar. The compressor is deactivated when the pressure in the HB decreases to 14 bar.

All of the produced hydrogen is then compressed and stored in high-pressure cylinders (350 bar) outside the hydrogen production building for safety reasons. The energy balance of the plant is also measured in terms of the amount of hydrogen produced and stored.

2.3. Operating and Maintenance Aspects

One important aspect when operating the hydrogen production plant is the purge time required to complete the startup and shutdown processes to avoid system contamination and safety issues, as already shown in the previous production process sections (especially in Section 2.2.1).

The startup and shutdown purge time is usually 15 min, which includes a complete cleaning cycle in all systems of the production plant and the ramp-up (startup) or ramp-down (shutdown) of the production powersets, usually between 70% and 100%. If the purge process is interrupted midway or if the electrolyzer suddenly loses electrical power while generating hydrogen, this can lead to safety risks or maintenance issues. Such events may reduce the plant’s life and operational availability, damage critical components, increase maintenance costs, and impair overall system performance.

The hydrogen plant is equipped with a 24 V Uninterruptible Power System (UPS) based on lead–acid battery technology with a 12 Ah capacity to keep some of the auxiliaries (presented in Figure 2) running in the case of electrical power loss, such as the emergency circuits (sensors and control valves), auxiliary power supplies, and PLC devices.

Suppose that the electrical power from the utility grid is suddenly lost when hydrogen is being generated. In that case, the system is not able to properly run the shutdown purge process (all auxiliary AC loads are shut down, including the electrolyte-circulating pumps, heaters, and fans). As a consequence, the system is contaminated, which leads to maintenance actions. In this case, since the system has a UPS to keep the emergency circuit running, the system is safely shut down, without concerns of overpressure or any other safety-related issue, driving maintenance but resulting in a longer production stop time.

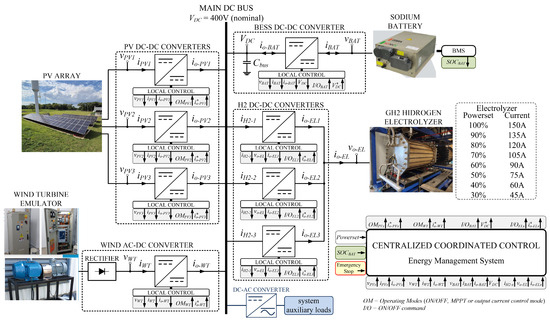

3. Isolated Microgrid Architecture for Production

Considering the legacy electrolyzer operating aspects presented in the previous section, especially in Section 2.3, Figure 5 shows a block diagram of the proposed isolated DC microgrid dedicated to feeding the plant, with RESs and BESSs, in substitution of the former/standard thyristor-based rectifier tied to the utility grid (non- production), as shown in Figure 2. This power structure is composed of seven input/output ports as follows: four current-controlled DC/DC converters fed by RESs, three with PV and one with a wind generator; a voltage-controlled DC/DC converter connected to the BESS (main DC bus voltage former); three dedicated current-controlled DC/DC converters, in interleaving mode, supplying the electrolyzer of the plant (DC power supply in Figure 4); and one DC/AC converter to supply all the AC and DC auxiliary loads (the DC ones have an input AC/DC conversion stage), presented in Figure 2 and Figure 4.

Figure 5.

Block diagram of the proposed DC microgrid.

One of the key advantages of the proposed microgrid architecture is its ability to maintain power supply to critical loads in the event of an abrupt interruption in energy generation. In such scenarios, the BESS can temporarily supply the electrolyzer and its auxiliary systems, ensuring that they remain powered for the necessary duration to execute a controlled and safe shutdown procedure, as discussed in Section 2.3. This represents a significant improvement over the legacy system, which relies solely on an Uninterruptible Power Supply (UPS) dedicated to the Programmable Logic Controller (PLC). In the previous setup, a utility grid outage would result in the immediate loss of power to all auxiliary loads, often leading to improper shutdown sequences and potential equipment damage or process instability. By contrast, the microgrid’s integrated storage and control enable more reliable operation, particularly under fault or emergency conditions.

3.1. Microgrid Control Strategy

The objectives behind implementing control in microgrids typically include the following:

- Power sharing: Ensuring that multiple distributed generation units proportionally share the load.

- Regulation: Maintaining a stable voltage level on the DC bus or managing the current from different sources.

- Energy management: Optimizing the use of energy resources and storage.

Control strategies for microgrids are typically divided into local and coordinated levels [31]. Local control, which relies on local measurements, manages individual converters and includes functions such as current, voltage, and droop control; source-dependent functions like Maximum Power Point Tracking (MPPT) for photovoltaic (PV) modules; and decentralized coordination functions like virtual resistance (VR), Distributed Bus Signaling (DBS), or Power Line Signaling (PLS). Coordinated control, which manages the overall operation of the microgrid, requires communication between units and includes decentralized, centralized, and distributed strategies. Decentralized control is an extension of local control using only local measurements, and it includes methods such as droop control and DBS. Centralized control uses a central controller (CC) that gathers data from distributed units, processes them, and sends commands, with master–slave control being a typical example. This approach is useful for optimizing power exchange with the main grid and between microgrids, managing local Distributed Generation (DG), optimizing energy storage, and minimizing operational costs. Distributed control involves communication between neighboring units through digital communication links (DCLs). Consensus and agent-based algorithms are frequently used in distributed control.

In this project, a hierarchical control strategy is implemented, combining local and coordinated control levels. At the local level, each power converter operates with a dedicated control loop based on its function. The electrolyzer port is controlled through an output current control loop to regulate hydrogen production. The BESS port employs dual-loop control: output current control and output voltage control to regulate the common 400 V DC bus, to which all converters are connected. For the PV and wind ports, two Operating Modes (OMs) are implemented: output current control mode for direct power regulation and Maximum Power Point Tracking mode using the Perturb and Observe (P&O) method to maximize energy extraction under varying conditions. In addition to the local control loops, a centralized coordinated control unit manages the power flow of the microgrid. This centralized controller receives as input data the desired powerset for the electrolyzer, measurements from the battery management system (BMS), and the power generated by the renewable sources. The centralized control determines whether the renewable sources will operate at the MPP or at a lower power level. The BESS converter always maintains the DC bus voltage at 400 V to ensure the proper operation of the other modules. As a result, this converter processes the residual power, which is the difference between the generated power and the consumed power. A CAN network is used for communication between the modules.

3.2. Power Interface for the Electrolyzer Port

The selection of the power converter for feeding the electrolyzer was based on the analysis of various technical criteria. First, the converter must operate with a gain in the range of 0.25 to step down the 400 V input voltage to approximately 100 V. Since the metal parts of the hydrogen production plant are earthed, isolation is required [21]. Modularity and current sharing are desirable characteristics that increase reliability and enable scalability to higher power ratings. Finally, a low output current ripple and high conversion efficiency are required to improve overall hydrogen production efficiency [21,22,24,25]. The basic specifications for the power converter to interface the DC microgrid to the hydrogen electrolyzer are summarized in Table 2.

Table 2.

Specifications of the power converter for the port.

Among high-frequency isolated DC/DC topologies, the literature highlights Half-Bridge and Full-Bridge topologies [23,32,33]. The Half-Bridge, although simple, presents excessive current stress and lacks redundancy, which may compromise its efficiency and reliability. Between the Full-Bridge topologies, Phase-Shifted Full-Bridge Zero-Voltage-Switching (PSFB-ZVS) and LLC converters arise as the most prominent converters, and they were chosen for a more detailed comparison.

The LLC resonant converter, while efficient at its optimal point, operates with a variable switching frequency. Although possible [34], this characteristic makes it more difficult to achieve synchronization and current sharing between parallel modules. The converter exhibits ZVS on the primary side and Zero-Current Switching (ZCS) on the secondary side. However, its efficiency is highly dependent on operating with a specific gain, while the conversion ratio is reported to change considerably during the electrolyzer’s lifetime [23]. The rectified sinusoidal output current is also a drawback for this application, since it requires a strong filtering effort to achieve a low ripple output current, resulting in large output capacitance [35]. Due to the ZCS on the secondary side, this topology does not require any additional circuit to protect the rectifier’s diodes against overvoltages.

Conversely, the Phase-Shifted Full-Bridge ZVS (PSFB-ZVS) converter with a center-tapped transformer was found to be more suitable for the project requirements. This topology operates with a fixed switching frequency, facilitating synchronization between parallel modules and the implementation of interleaving. Interleaved operation benefits from a reduced output current ripple and a higher-frequency ripple, both advantageous for increasing the hydrogen production efficiency [21,22,24,25] and reducing the filtering effort of the output stage, making it possible to even eliminate the output capacitor. The center-tapped topology reduces the number of semiconductor devices in the current path on the secondary side, thus reducing the power dissipation. The PSFB is designed to operate with soft switching (ZVS) for a certain load range, reducing switching losses and increasing converter efficiency [35,36]. As a drawback, this topology can suffer from high voltage stresses in the secondary diodes due to the hard switching.

Another important advantage of the PSFB topology is the possibility of employing synchronous rectification on the secondary side of the center-tapped transformer, replacing diodes with MOSFETs or GaNFET, for reduced conduction losses and enhanced efficiency. This technique is considered for future work.

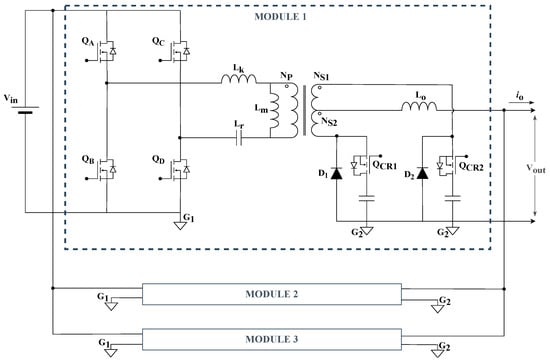

The adopted configuration, presented in Figure 6, includes three PSFB modules operating in interleaving mode, with an output inductance () that provides the current source characteristic. The capacitance () is included to prevent the circulation of an average current component through the transformer’s primary winding, avoiding core saturation. In the literature, this solution is often called a Phase-Shifted Full-Bridge Series Resonant converter [37,38]. In a well-executed project, the resonance frequency of the and circuit must be much lower than the switching frequency; thus, the influence of on converter operation is minimal, and its operating characteristics follow those of a classic PSFB-ZVS converter [37,38,39].

Figure 6.

Three interleaved PSFB converter modules employing active clamp circuits in the secondary stage.

It was chosen to build three identical 6.5 kW PSFB modules, achieving interleaved operation through a trigger signal between the modules (see Appendix A for the main components and construction details).

3.3. Power Interface for the BESS Port

The selection of the power topology for the BESS port is based on the specifications that it must meet. The battery employed in this project is a second-life Z37-620-38 battery from FZSoNick (Stabio, Switzerland) [40]. The battery voltage ranges from 414 V to 696 V, and its maximum allowed discharge current is 112 A. Since it is a second-life battery, it is chosen to limit the current considerably below the original limit and operate with a minimum voltage of 450 V. The battery used is a second-life unit, and, due to its unknown State of Health (SoH), a conservative operating range is adopted: charge and discharge are limited to the 450–696 V range and a maximum current of 33.3 A. This strategy aims to extend the battery lifespan and ensure safe operation despite potential degradation. Despite that, the battery can comfortably handle the maximum limit of 15 kW defined for this port. The output of the converter is the grid’s common DC bus, to which all converters are connected. This DC bus should be regulated by the BESS converter at 400 V with a small deviation during load/source transients. Table 3 summarizes the main specifications of the BESS converter.

Table 3.

Specifications of the interleaved buck converter for the BESS.

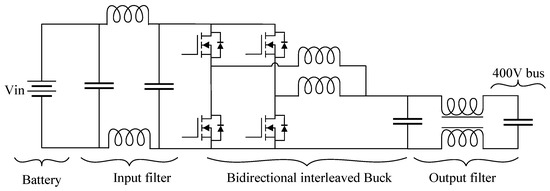

Due to its balanced characteristics, the interleaved bidirectional buck converter is one of the main topologies for bidirectional battery chargers in the range of cents of volts and a few tens of kilowatts. It counts with a reduced number of passive and active components, presents lower current efforts than three-level topologies [41,42,43], presents low voltage efforts [44], is efficient and modular, and does not require the design of complex magnetic components [45,46,47,48,49,50,51]. Figure 7 presents a schematic of the interleaved bidirectional buck converter. In addition to the main topology, an input filter was added to reduce the battery’s current ripple, and a common-mode filter was added to the output, between the converter and the microgrid common 400V DC bus connection point.

Figure 7.

Two-phase interleaved bidirectional buck converter with input and output filters.

3.4. Power Interface for the PV Port

The specifications for the PV converter are based on the photovoltaic power plant installed at the laboratory facilities where the system will be tested. The PV installation is composed of three individual strings, each connected to a power converter module. Table 4 presents the electrical specifications for the PV power converter, which form the basis for the design of the device.

Table 4.

Specifications of the PV converter.

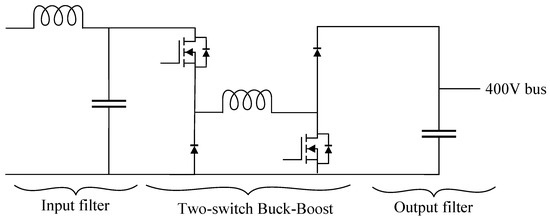

The review of the power topologies for the BESS port shows the advantages of the buck converter for the power ratings of this project. Unlike the BESS port, the PV input port requires a converter with the capacity to step up and step down the input voltage. The two-switch non-inverter buck–boost converter with two-carrier modulation is presented as a high-efficiency converter capable of meeting the project requirements [52]. This converter, presented in Figure 8, employs two active switches and two diodes. This modulation has significant advantages over a conventional buck–boost converter, since it reduces the current and voltage efforts in all components.

Figure 8.

Schematic of the non-inverter buck–boost converter for the PV input port.

3.5. Power Interface for the Wind Port

The wind port of the microgrid is designed to interface with small wind turbines, which are commonly used in distributed renewable energy systems. The specifications of a commercial small wind turbine form the basis for defining the input specifications of the wind power converter. To enable laboratory testing under controlled and repeatable conditions, a wind turbine emulator is constructed. This emulator consists of an electric motor mechanically coupled to a generator, allowing for the emulation of the dynamic behavior of a real wind turbine during various operating scenarios. Table 5 summarizes the specifications of the wind power converter.

Table 5.

Specifications of the wind converter.

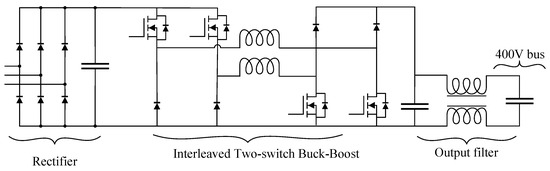

The wind port requires processing the variable-frequency AC power generated by the wind turbine, based on a permanent magnet generator, and delivering a regulated DC output current to the microgrid. Although the literature presents a variety of power conversion topologies for wind energy systems [53,54], these are predominantly boost-type converters, which do not apply to this project, since the input voltage can be higher than the output voltage. A two-stage topology is adopted. The first stage consists of a three-phase Graetz rectifier followed by a capacitive filter, responsible for converting the generator’s AC output into an unregulated DC voltage. The second stage is a two-phase interleaved two-switch non-inverter buck–boost converter [52]—the same topology used in the PV port—selected for its capacity to both step up and step down the input voltage, depending on the wind conditions. Figure 9 presents a schematic of the power topologies employed for the wind port.

Figure 9.

Schematic of the rectifier and non-inverter buck–boost converter for the wind input port.

4. Experimental Results

This section presents the main experimental results obtained from the tests with both hydrogen plants, one powered by the thyristor-based six-pulse rectifier (Figure 2) and the other by the proposed DC microgrid (Figure 5 and Figure 10).

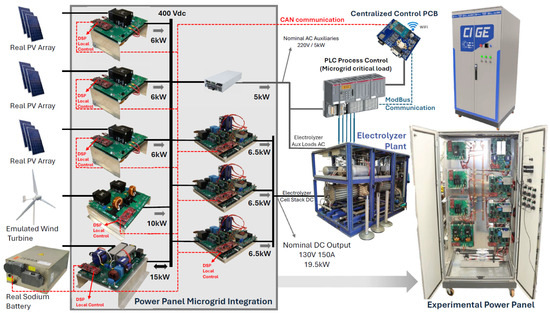

Figure 10.

Highly integrated microgrid experimental setup for retrofitted electrolyzer plant towards green hydrogen production.

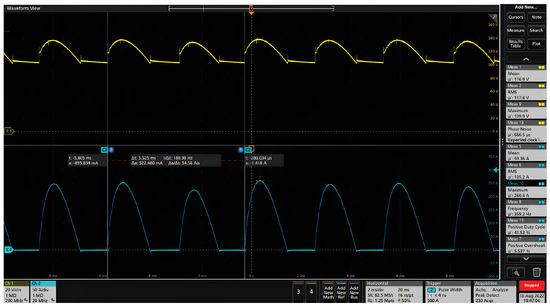

Figure 11 shows the output voltage and current waveforms of the legacy electrolyzer thyristor-based rectifier used to feed the electrolyzer cell stack. The electrical grid frequency is 60 Hz, while the output voltage/current ripple frequency is 360 Hz due to the six-pulse thyristor-based rectifier. When the grid voltage is higher than the load voltage, there is a transfer of energy from the grid to the electrolyzer, so there is a current flow, and the voltage follows the current behavior. However, when the grid voltage is lower than the load, there is no current, and the voltage is floating. This test is conducted at 70% of the powerset, with a total active power of 15.89 kW and an apparent power of 19.62 kVA, resulting in a power factor of approximately 0.8. The active power is the energy actually used for hydrogen generation. As can be seen, there is a significant ripple factor in the current and AC oscillations. These characteristics affect system operation and degrade the electrolytic cells, resulting in low efficiency of the electrolyzer and, consequently, a decrease in hydrogen production.

Figure 11.

Legacy electrolyzer thyristor-based rectifier voltage and current waveforms for an operating point with 70% of the full powerset. Yellow waveform: rectifier output voltage (maximum peak value is 139.9 V, mean value is 116.7 V, RMS value is 117.6 V). Blue waveform: rectifier output current (maximum peak value is 260.4 A, mean value is 93.36 A, RMS value is 135.2 A).

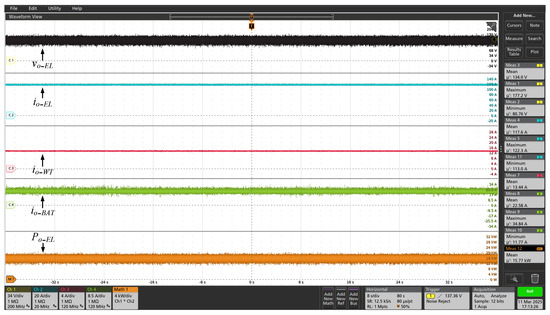

However, Figure 12 shows the voltage and current waveforms of the electrolyzer ( and ) when powered by the DC microgrid. This test is performed at 80% of the powerset, resulting in a total active power () close to 15.77 kW. As expected, the electrolyzer is powered by a DC current with a low ripple and is free from AC oscillations. This figure also shows the currents and , injected by the wind and BESS DC/DC converters, respectively, into the main DC bus. Complementarily, Figure 13 and Figure 14 show other electrical quantities of the DC microgrid at 70% and 60% of the full powerset, respectively.

Figure 12.

Voltage and current waveforms of DC microgrid at 80% of the full powerset ( = 134 V, and = 117 A, approximately).

Figure 13.

Voltage and current waveforms of DC microgrid at 70% of the full powerset ( = 126 V, and = 104 A, approximately).

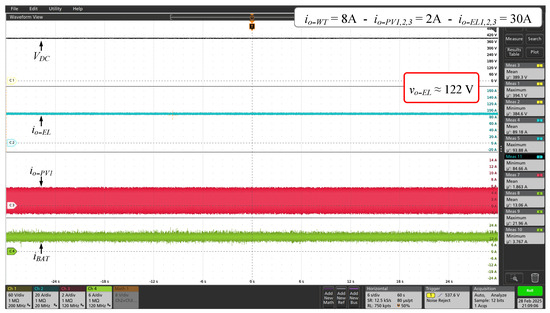

Figure 14.

Voltage and current waveforms of DC microgrid at 60% of the full powerset ( = 122 V, and = 89 A, approximately).

Table 6 summarizes the values of the voltage, current, and active power consumed by the electrolyzer for the results shown in Figure 11, Figure 12, Figure 13 and Figure 14. As expected, there is a significant reduction in the active power consumed by the electrolyzer when powered by the DC microgrid, for example, a reduction of approximately 18% for operation at 70% of the full powerset. In addition, Table 7 shows data related to hydrogen production and energy consumption, used to calculate the electrolyzer energy consumption (). It is noted that the DC microgrid enhances the system’s overall efficiency compared to the thyristor-based rectifier power supply, which was also the subject of discussion in [22], where simulation results showed efficiency improvements that are now being experimentally verified in this work.

Table 6.

Electrolyzer power consumption comparison.

Table 7.

Electrolyzer energy consumption () and efficiency () comparison based on methodology presented in [21,22]. The electrolyzer efficiency is calculated as the ratio of the higher heating value of hydrogen (HHV of = 3.5 kWh/Nm3) per energy consumption ().

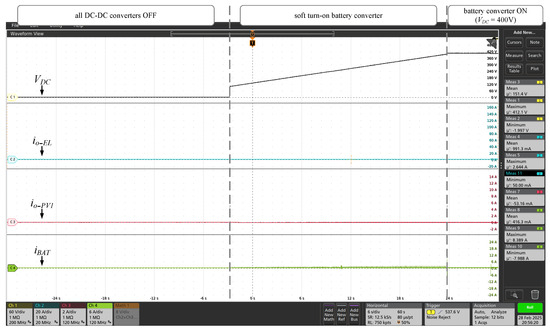

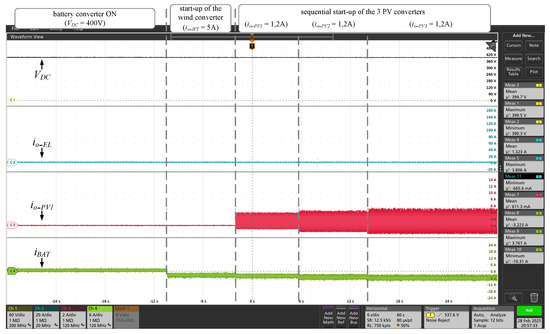

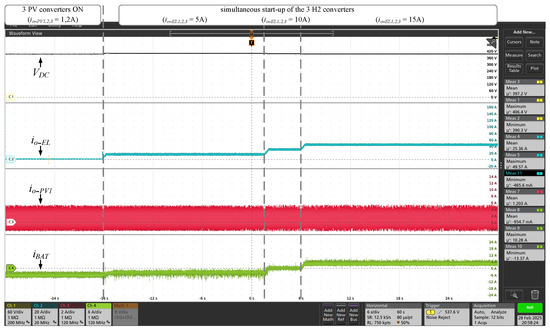

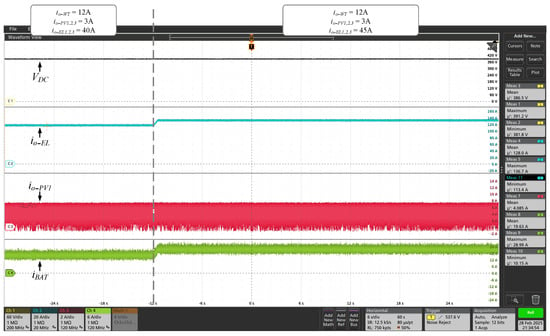

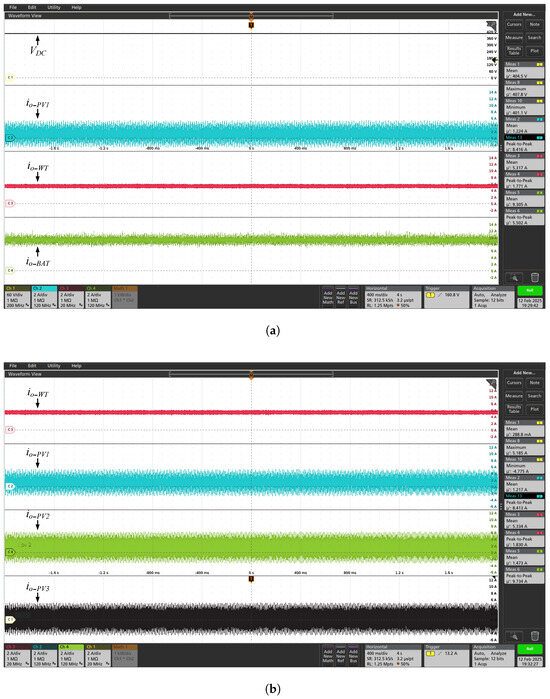

The experimental results for the DC microgrid initialization are shown in Figure 15, Figure 16, Figure 17 and Figure 18. Initially, the battery converter starts with a soft ramp until reaching the nominal voltage of the central DC bus ( = 400 V), as shown in Figure 15. After initializing the BESS converter, the wind converter is started in constant-current mode ( = 5 A), and, in sequence, the three PV converters are started also in constant-current mode ( = 1.2 A), as shown in Figure 16. Once the electrolyzer is turned off, all the energy produced by the RESs is absorbed by the BESS (negative indicates battery energy consumption). With the microgrid supply converters connected (wind and photovoltaic sources), the three converters are simultaneously activated, as shown in Figure 17, with control in constant-current mode and with an increase of 5 A in the value of the DC output current of each converter. It can be seen that, when exceeds 30 A, the direction of the current is reversed. In this case, the SAE supplies energy to the microgrid, together with the wind and photovoltaic sources, to power the electrolyzer. With all converters turned on, the current is increased up to 90% of the powerset (135 A), as shown in Figure 18. Simultaneously, in these tests, increases are made to the powers extracted from the wind and photovoltaic sources, according to the values of and indicated in the figures. The results presented prove that the converters of the proposed DC microgrid adequately extract energy from wind and photovoltaic sources, regulate the voltage of the central DC bus, process the energy globally, and store/supply the energy in/by the SAE. In addition, the system simultaneously supplies an appropriate DC current to the electrolyzer of the plant.

Figure 15.

Startup of the battery converter.

Figure 16.

Startup of the wind and three PV converters.

Figure 17.

Startup of the 3 converters.

Figure 18.

Nominal operation of the electrolyzer.

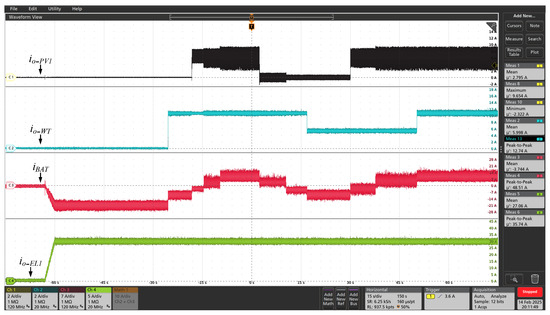

Figure 19 shows a case in which there is power generation from both RESs (PV and wind), the battery bank is partially charged, and the plant is turned off. Thus, all the energy produced is stored in the battery bank. For this test, PV generation is configured with = = = 1.2 A, close to 3.6 A of the current injected by the PV converters ( = 1.4 kW), and wind generation is configured with = 5.3 A ( = 2.1 kW). It can be observed that the BESS converter imposes the DC voltage on the main bus ( = 400 V), even with the energy injection by the RESs. Moreover, since the plant is turned off, all the produced energy is absorbed by the BESS converter ( = 9 A) and sent to the battery bank. This test shows the system’s ability to manage all energy produced by RESs. It is worth noting that the maximum power levels to be extracted from the PV and wind sources are directly linked to the consumption of the plant, as well as to the momentary storage capacity of the battery bank. Therefore, if there is a momentary surplus of energy, a deviation from the maximum power point of these sources must be made.

Figure 19.

Experimental tests of the DC microgrid with plant off: (a) Bus voltage and current waveforms at the battery, wind, and PV converters; (b) Current waveforms of the wind converter and PV converters.

To assess the system’s dynamic performance under renewable energy fluctuations, a test was carried out emulating the intermittent behavior of solar and wind sources, as shown in Figure 20. Initially, the electrolyzer was activated with all the required power supplied exclusively by the battery. Subsequently, the solar and wind converters were enabled and began injecting energy into the DC bus. Shortly after their activation, intermittent conditions were introduced, causing successive variations in the power delivered by both sources. The system maintained stable operation throughout these disturbances, with the BESS dynamically compensating for power deficits to ensure an uninterrupted current supply to the electrolyzer. The DC bus voltage remained within nominal levels, as well as the output current of the electrolyzer converters, and no instabilities were observed. These results demonstrate the system’s ability to manage renewable intermittency effectively, ensuring continuous and reliable hydrogen production under fluctuating generation scenarios.

Figure 20.

Dynamic behavior of the DC microgrid under renewable intermittency.

5. Conclusions

This paper successfully presents and experimentally verifies a novel isolated DC microgrid concept for green hydrogen () production, demonstrating comprehensive energy harvesting and storage capabilities, offering a significant opportunity to retrofit existing hydrogen production plants currently powered by the AC grid. The work pioneers an approach to integrate RESs directly into hydrogen production facilities, moving beyond traditional AC grid reliance. The experimental results show that the proposed DC microgrid significantly enhances the system’s overall efficiency. A remarkable reduction in active power consumption by the electrolyzer (e.g., approximately 18% at a 70% powerset) and an increase in electrolyzer efficiency (e.g., from 57.9% with the legacy system to 73.2% with the DC microgrid at an 80% powerset) were achieved compared to the legacy thyristor-based rectifier power supply. Furthermore, the system demonstrated stable operation and dynamic compensation by the BESS, even under intermittent renewable energy fluctuations, ensuring a continuous and reliable current supply to the electrolyzer. The hierarchical control strategy, combining local and coordinated control levels, was implemented. This centralized control unit efficiently managed the overall energy balance, dynamically overseeing power demand from the electrolyzer, generation from PV and wind, and the charge/discharge cycles of the BESS, ensuring stable DC bus voltage regulation. The comprehensive experimental results obtained from tests with the retrofitted electrolyzer integrated into the DC microgrid setup were crucial in proving the practical viability and efficiency improvements of this novel approach in the field of green hydrogen production.

This paper’s contributions are underscored by its successful implementation and validation of a DC microgrid that not only efficiently processes and manages renewable energy but also effectively stores excess energy and supplies stable DC power to the electrolyzer for production. This includes providing power to essential AC-powered auxiliary systems like pumps and heaters, thereby showcasing tangible improvements in operational efficiency and overall system performance. The detailed descriptions of the power interfaces for the electrolyzer (Phase-Shifted Full-Bridge Zero-Voltage-Switching (PSFB-ZVS) converter), BESS (interleaved bidirectional buck converter), PV (two-switch non-inverter buck–boost converter), and wind (two-stage topology with a rectifier and buck–boost interleaved converter) further highlight the practical engineering solutions developed to achieve a modular, efficient, and low-ripple system conducive to enhanced green hydrogen production efficiency.

Author Contributions

Conceptualization, R.L.d.S.J., F.T.C., L.B.G.C., G.G.P., T.G.J., A.A.Q., C.B.J., D.A.C., L.S.M., J.A.V. and F.M.O.; methodology, R.L.d.S.J., F.T.C., L.B.G.C., G.G.P., T.G.J., A.A.Q., C.B.J., D.A.C., L.S.M. and F.M.O.; software, R.L.d.S.J., F.T.C., L.B.G.C. and F.M.O.; validation, R.L.d.S.J., F.T.C., L.B.G.C., G.G.P., L.S.M., J.A.V. and F.M.O.; formal analysis, R.L.d.S.J., F.T.C., L.B.G.C., G.G.P., L.S.M. and F.M.O.; investigation, R.L.d.S.J., F.T.C., L.B.G.C., G.G.P., L.S.M. and F.M.O.; resources, T.G.J.; data curation, R.L.d.S.J., F.T.C., L.B.G.C., G.G.P., L.S.M. and F.M.O.; writing—original draft preparation, R.L.d.S.J., F.T.C., L.B.G.C., G.G.P., A.A.Q., C.B.J., D.A.C. and L.S.M.; writing—review and editing, R.L.d.S.J., F.T.C., L.B.G.C., T.G.J., A.A.Q., C.B.J. and D.A.C.; visualization, J.A.V. and F.M.O.; supervision, T.G.J., J.A.V. and F.M.O.; project administration, T.G.J. and F.M.O.; funding acquisition, J.A.V. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is the result of activities carried out under the R&D project of ANEEL program No. PD-10381-0221/2021, entitled “Multiport DC-DC Converter and IoT System for Intelligent Energy Management”, which was conducted in partnership with CTG-Brazil.

Data Availability Statement

The datasets presented in this article are not readily available because they are part of a R&D project in collaboration with CTG-Brasil and subject to confidentiality agreements. Requests to access the datasets should be directed to Fernando Marcos Oliveira (fernando.oliveira@itaipuparquetec.org.br).

Conflicts of Interest

Author Rogerio Luiz da Silva Junior, Filipe Tavares Carneiro, Leonardo Bruno Garcial Campanhol, Guilherme Gemi Pissaia, Tales Gottlieb Jahn, Angel Ambrocio Quispe, Carina Bonavigo Jakubiu, Daniel Augusto Cantane and Fernando Marcos Oliveira were employed by the company Itaipu Parquetec. Author Leonardo Sostmeyer Mai was employed by the company ISI Embarcados. Author Jose Alfredo Valverde was employed by the company CTG-Brazil.

Abbreviations

The following abbreviations are used in this manuscript:

| RES | Renewable Energy Source |

| Green Hydrogen | |

| TRLs | Technology Readiness Levels |

| AC | Alternating Current |

| DC | Direct Current |

| PLC | Programmable Logic Controller |

| SCADA | Supervisory Control and Data Acquisition |

| AEL | Alkaline Water Electrolysis |

| UPS | Uninterruptible Power System |

| BESS | Battery Energy Storage System |

| PV | Photovoltaic |

| WT | Wind Turbine |

| EL | Electrolyzer |

| BAT | Battery |

| SOC | State of Charge |

| BMS | Battery Management System |

| OM | Operating Mode |

Appendix A

Table A1.

Summary of components used in the ZVS-PSFB prototype.

Table A1.

Summary of components used in the ZVS-PSFB prototype.

| Component | Description |

|---|---|

| Half-Bridge module | 2× LMG3522EVM-042 |

| Rectifier diodes | 2× (2× IDW100E60) |

| MOSFETs for active clamping | 2× IPW60R045P7XKSA1 |

| ORing diodes | 2× IDW100E60FKSA1 |

| Input filter inductor | HF467-260M-45AH |

| Transformer | Custom made |

| Resonant capacitor (60 F) | 2× B32716H8306K000 |

| Output filter inductor | EK55246-800M-85AH |

| Output current sensor | CAS50-NP |

| Microcontroller | F28069 |

Table A2.

Summary of components used in the bidirectional interleaved buck prototype.

Table A2.

Summary of components used in the bidirectional interleaved buck prototype.

| Component | Description |

|---|---|

| SiC MOSFETs | 4× (2× E3M0075120K) |

| Heat sinks | 2× LAM 5 K 150 24 |

| Input filter inductors | 2× B82559A5682A033 |

| Interleaved inductors | 2× Custom made |

| Output filter choke inductor | B82727E6503A040 |

| Inductors’ current sensors | 2× CAS50-NP |

| Output voltage sensor | LV 20-P |

| Microcontroller | F28069 |

Table A3.

Construction characteristics of custom-made inductor for the BESS converter.

Table A3.

Construction characteristics of custom-made inductor for the BESS converter.

| Characteristic | Description |

|---|---|

| Inductance | 200 H |

| Core model | 2 × E65/32/27 |

| Core material | Ferroxcube 3C95 |

| Winding | 19 turns |

| Winding material | 2 × Litz wire 1325 × 0.05 mm |

| Gap | 1.6 mm |

| Dimensions | 65 mm × 65.6 mm × 79 mm |

| Weight | 1003.8 g |

References

- Cader, J.; Koneczna, R.; Olczak, P. The Impact of Economic, Energy, and Environmental Factors on the Development of the Hydrogen Economy. Energies 2021, 14, 4811. [Google Scholar] [CrossRef]

- Emonts, B.; Müller, M.; Hehemann, M.; Janßen, H.; Keller, R.; Stähler, M.; Stähler, A.; Hagenmeyer, V.; Dittmeyer, R.; Pfeifer, P.; et al. A Holistic Consideration of Megawatt Electrolysis as a Key Component of Sector Coupling. Energies 2022, 15, 3656. [Google Scholar] [CrossRef]

- Nayebossadri, S.; Walsh, M.; Smailes, M. An Overview of the Green Hydrogen Value Chain Technologies and Their Challenges for a Net-Zero Future. Hydrogen 2025, 6, 26. [Google Scholar] [CrossRef]

- Franco, A. Green Hydrogen and the Energy Transition: Hopes, Challenges, and Realistic Opportunities. Hydrogen 2025, 6, 28. [Google Scholar] [CrossRef]

- Elegbeleye, I.; Oguntona, O.; Elegbeleye, F. Green Hydrogen: Pathway to Net Zero Green House Gas Emission and Global Climate Change Mitigation. Hydrogen 2025, 6, 29. [Google Scholar] [CrossRef]

- Roucham, B.; Zaghdoud, O. Mapping Green Hydrogen and Renewable Energy Research in Extended BRICS (Brazil, Russia, India, China, South Africa and Others): A Bibliometric Approach with a Future Agenda. Hydrogen 2025, 6, 33. [Google Scholar] [CrossRef]

- Patil, R.R.; Calay, R.K.; Mustafa, M.Y.; Thakur, S. Artificial Intelligence-Driven Innovations in Hydrogen Safety. Hydrogen 2024, 5, 312–326. [Google Scholar] [CrossRef]

- Barbosa, L.T.; Vasconcelos, S.D.; Rosas, P.A.C.; Castro, J.F.C.; Barbosa, D.C.P. Assessment of Green Hydrogen as Energy Supply Alternative for Isolated Power Systems and Microgrids. Energies 2024, 17, 4774. [Google Scholar] [CrossRef]

- Carmo, M.; Stolten, D. Chapter 4—Energy Storage Using Hydrogen Produced From Excess Renewable Electricity: Power to Hydrogen. In Science and Engineering of Hydrogen-Based Energy Technologies; de Miranda, P.E.V., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 165–199. [Google Scholar] [CrossRef]

- Santarelli, M.; Calì, M.; Macagno, S. Design and analysis of stand-alone hydrogen energy systems with different renewable sources. Int. J. Hydrogen Energy 2004, 29, 1571–1586. [Google Scholar] [CrossRef]

- Schelling, K. Green Hydrogen to Undercut Gray Sibling by End of Decade; Technical Report; BloombergNEF: New York City, NY, USA, 2023. [Google Scholar]

- Quintos Fuentes, J.E.; Santos, D.M.F. Technical and Economic Viability of Underground Hydrogen Storage. Hydrogen 2023, 4, 975–1000. [Google Scholar] [CrossRef]

- Sun, Y.Q. Explosions of Hydrogen Storages and the Safety Considerations in Hydrogen-Powered Railway Applications—A Review. Hydrogen 2024, 5, 901–918. [Google Scholar] [CrossRef]

- Kazemi, M.; Brennan, S.; Molkov, V. Hydrogen Safety by Design: Exclusion of Flame Blow-Out from a TPRD. Hydrogen 2024, 5, 280–292. [Google Scholar] [CrossRef]

- Franco, A.; Carcasci, C.; Ademollo, A.; Calabrese, M.; Giovannini, C. Integrated Plant Design for Green Hydrogen Production and Power Generation in Photovoltaic Systems: Balancing Electrolyzer Sizing and Storage. Hydrogen 2025, 6, 7. [Google Scholar] [CrossRef]

- Wang, W.; Qi, Y.; Zhang, X.; Xie, P.; Guo, Y.; Sun, H. Carbon Emission Optimization of the Integrated Energy System in Industrial Parks with Hydrogen Production from Complementary Wind and Solar Systems. Hydrogen 2025, 6, 8. [Google Scholar] [CrossRef]

- Ali, D.; Stewart, C.; Qadir, K.; Jalisi, I. Design and Optimal Sizing of a Hydrogen Uninterruptable Power Supply (UPS) System for Addressing Residential Power Cutoffs. Hydrogen 2025, 6, 3. [Google Scholar] [CrossRef]

- Li, K.; Zhang, H.; Zheng, X.; Liu, C.; Chen, Q. Hydrogen Production by Water Electrolysis with Low Power and High Efficiency Based on Pre-Magnetic Polarization. Energies 2022, 15, 1878. [Google Scholar] [CrossRef]

- Zhong, Z.; Fang, J.; Hu, K.; Huang, D.; Ai, X.; Yang, X.; Wen, J.; Pan, Y.; Cheng, S. Power-to-Hydrogen by Electrolysis in Carbon Neutrality: Technology Overview and Future Development. CSEE J. Power Energy Syst. 2023, 9, 1266–1283. [Google Scholar] [CrossRef]

- Ursúa, A.; Sanchis, P. Static–dynamic modelling of the electrical behaviour of a commercial advanced alkaline water electrolyser. Int. J. Hydrogen Energy 2012, 37, 18598–18614. [Google Scholar] [CrossRef]

- Ursúa, A.; Sanchis, P.; Marroyo, L. Chapter 14—Electric Conditioning and Efficiency of Hydrogen Production Systems and Their Integration with Renewable Energies. In Renewable Hydrogen Technologies; Gandía, L.M., Arzamendi, G., Diéguez, P.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 333–360. [Google Scholar] [CrossRef]

- Koponen, J.; Ruuskanen, V.; Kosonen, A.; Niemela, M.; Ahola, J. Effect of Converter Topology on the Specific Energy Consumption of Alkaline Water Electrolyzers. IEEE Trans. Power Electron. 2019, 34, 6171–6182. [Google Scholar] [CrossRef]

- Chen, M.; Chou, S.F.; Blaabjerg, F.; Davari, P. Overview of Power Electronic Converter Topologies Enabling Large-Scale Hydrogen Production via Water Electrolysis. Appl. Sci. 2022, 12, 1906. [Google Scholar] [CrossRef]

- Ursúa, A.; Marroyo, L.; Gubía, E.; Gandía, L.M.; Diéguez, P.M.; Sanchis, P. Influence of the Power Supply on the Energy Efficiency of an Alkaline Water Electrolyser. Int. J. Hydrogen Energy 2009, 34, 3221–3233. [Google Scholar] [CrossRef]

- Ursúa, A.; San Martín, I.; Sanchis, P. Design of a Programmable Power Supply to Study the Performance of an Alkaline Electrolyser under Different Operating Conditions. In Proceedings of the 2012 IEEE International Energy Conference and Exhibition (ENERGYCON), Florence, Italy, 9–12 September 2012; pp. 259–264. [Google Scholar] [CrossRef]

- Brauns, J.; Turek, T. Alkaline Water Electrolysis Powered by Renewable Energy: A Review. Processes 2020, 8, 248. [Google Scholar] [CrossRef]

- Slater-Thompson, N.; Johnson, S. The World’s Nine Largest Operating Power Plants Are Hydroelectric Facilities; Technical Report; U.S. Energy Information Administration: Washington, DC, USA, 2016.

- Lu, M. These Are the World’s Largest Hydroelectric Dams; Technical Report; World Economic Forum: Cologny, Switzerland, 2022. [Google Scholar]

- LeRoy, R.L.; Bowen, C.T.; LeRoy, D.J. The Thermodynamics of Aqueous Water Electrolysis. J. Electrochem. Soc. 1980, 127, 1954. [Google Scholar] [CrossRef]

- ISO 22734-1:2025; Hydrogen Generators Using Water Electrolysis—Part 1: Safety. ISO: Geneva, Switzerland, 2025.

- Dragičević, T.; Lu, X.; Vasquez, J.C.; Guerrero, J.M. DC Microgrids—Part I: A Review of Control Strategies and Stabilization Techniques. IEEE Trans. Power Electron. 2016, 31, 4876–4891. [Google Scholar] [CrossRef]

- Guilbert, D.; Collura, S.; Scipioni, A. DC/DC converter topologies for electrolyzers: State-of-the-art and remaining key issues. Int. J. Hydrogen Energy 2017, 42, 23966–23985. [Google Scholar] [CrossRef]

- Williamson, S.S.; Rathore, A.K.; Musavi, F. Industrial Electronics for Electric Transportation: Current State-of-the-Art and Future Challenges. IEEE Trans. Ind. Electron. 2015, 62, 3021–3032. [Google Scholar] [CrossRef]

- Shah, S.S.; Rastogi, S.K.; Bhattacharya, S. Paralleling of LLC Resonant Converters. IEEE Trans. Power Electron. 2021, 36, 6276–6287. [Google Scholar] [CrossRef]

- Gillmor, C. Phase Shifted Full Bridge (PSFB) vs. Full Bridge LLC (FB-LLC) for High Power DC/DC Conversion; Video Presentation Series; Texas Instruments: Dallas, TX, USA, 2018; Available online: https://www.ti.com/video/series/phase-shifted-full-bridge-psfb-vs-full-bridge-llc-fb-llc.html#tab-1 (accessed on 12 April 2025).

- Barbi, I.; Pöttker, F. Soft Commutation Isolated DC-DC Converters; Springer: Berlin/Heidelberg, Germany, 2019; Volume 1. [Google Scholar]

- Yazdani, M.R.; Farzanehfard, M. Evaluation and Comparison of Conducted EMI in Three Full-Bridge DC-DC Switching Converters. In Proceedings of the 2019 10th International Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Shiraz, Iran, 12–14 February 2019; pp. 439–444. [Google Scholar] [CrossRef]

- Lenke, R.U.; Hu, J.; De Doncker, R.W. Unified Steady-State Description of Phase-Shift-Controlled ZVS-operated Series-Resonant and Non-Resonant Single-Active-Bridge Converters. In Proceedings of the 2009 IEEE Energy Conversion Congress and Exposition, San Jose, CA, USA, 20–24 September 2009; pp. 796–803. [Google Scholar] [CrossRef]

- Rospirski, A.; Zancanaro, L.G.; Mai, L.S.; De Oliveira, F.M.; Da Silva, R.L.; Carneiro, F.T.; Hernández, S.G.; Rigo, C.A.; Jahn, T.G.; De Araujo, P.G. Enhanced Three-Phase Interleaving Phase-Shifted Full Bridge Converter with Active Clamp Using GaNFET for Green Hydrogen Production. In Proceedings of the 2023 IEEE 8th Southern Power Electronics Conference (SPEC), Florianopolis, Brazil, 26–29 November 2023; pp. 1–6. [Google Scholar] [CrossRef]

- FZSONICK. Z Range—Z37 (Technical Brochure); FZSoNick S.A.: Stabio, Switzerland, 2017; Available online: https://fzsonick.ru/upload/iblock/726/ZETA_37_range.pdf (accessed on 25 May 2025).

- Hao, Z.; Jing-hua, Z.; Bing, H.; Chao-nan, T. A New Interleaved Three-Level Boost Converter and Neutral-Point Potential Balancing. In Proceedings of the 2013 2nd International Symposium on Instrumentation and Measurement, Sensor Network and Automation (IMSNA), Toronto, ON, Canada, 23–24 December 2013; pp. 1093–1096. [Google Scholar] [CrossRef]

- Dusmez, S.; Hasanzadeh, A.; Khaligh, A. Comparative Analysis of Bidirectional Three-Level DC–DC Converter for Automotive Applications. IEEE Trans. Ind. Electron. 2015, 62, 3305–3315. [Google Scholar] [CrossRef]

- Dusmez, S.; Hasanzadeh, A.; Khaligh, A. Loss Analysis of Non-Isolated Bidirectional DC/DC Converters for Hybrid Energy Storage System in EVs. In Proceedings of the 2014 IEEE 23rd International Symposium on Industrial Electronics (ISIE), Istanbul, Turkey, 1–4 June 2014; pp. 543–549. [Google Scholar] [CrossRef]

- de Sá, M.V.D.; Andersen, R.L. Dynamic Modeling and Design of a Cúk Converter Applied to Energy Storage Systems. In Proceedings of the 2015 IEEE 13th Brazilian Power Electronics Conference and 1st Southern Power Electronics Conference (COBEP/SPEC), Fortaleza, Brazil, 29 November–2 December 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Fahem, K.; Chariag, D.E.; Sbita, L. On-Board Bidirectional Battery Chargers Topologies for Plug-in Hybrid Electric Vehicles. In Proceedings of the 2017 International Conference on Green Energy Conversion Systems (GECS), Hammamet, Tunisia, 23–25 March 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Yilmaz, M.; Krein, P.T. Review of Battery Charger Topologies, Charging Power Levels, and Infrastructure for Plug-In Electric and Hybrid Vehicles. IEEE Trans. Power Electron. 2013, 28, 2151–2169. [Google Scholar] [CrossRef]

- Gorji, S.A.; Sahebi, H.G.; Ektesabi, M.; Rad, A.B. Topologies and Control Schemes of Bidirectional DC–DC Power Converters: An Overview. IEEE Access 2019, 7, 117997–118019. [Google Scholar] [CrossRef]

- Bascope, G.; Barbi, I. Generation of a Family of Non-Isolated DC-DC PWM Converters Using New Three-State Switching Cells. In Proceedings of the 2000 IEEE 31st Annual Power Electronics Specialists Conference. Conference Proceedings (Cat. No.00CH37018), Galway, Ireland, 23–23 June 2000; Volume 2, pp. 858–863. [Google Scholar] [CrossRef]

- Kwon, M.; Oh, S.; Choi, S. High Gain Soft-Switching Bidirectional DC–DC Converter for Eco-Friendly Vehicles. IEEE Trans. Power Electron. 2014, 29, 1659–1666. [Google Scholar] [CrossRef]

- Peraça, M.T. Conversores Utilizando Células de Comutação de Quatro Estados. Ph.D. Thesis, Universidade Federal de Santa Catarina, Florianópolis, Brazil, 2008. [Google Scholar]

- Tofoli, F.L.; Tavares, D.d.A.; Saldanha, J.I.d.A. Survey on Topologies Based on the Three-State and Multi-State Switching Cells. IET Power Electron. 2019, 12, 967–982. [Google Scholar] [CrossRef]

- Martins Junior, J. Power Equalization of Parallel Converters via Droop Control for Battery Charging. Master’s Thesis, Universidade Federal de Santa Catarina, Florianópolis, Brazil, 2020. [Google Scholar]

- Chen, Z.; Guerrero, J.M.; Blaabjerg, F. A Review of the State of the Art of Power Electronics for Wind Turbines. IEEE Trans. Power Electron. 2009, 24, 1859–1875. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Liserre, M.; Ma, K. Power Electronics Converters for Wind Turbine Systems. IEEE Trans. Ind. Appl. 2012, 48, 708–719. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).