Simulation and Economic Benefit Analysis of Carburetor Combined Transport in Winter at a Liquefied Natural Gas Receiving Station

Abstract

1. Introduction

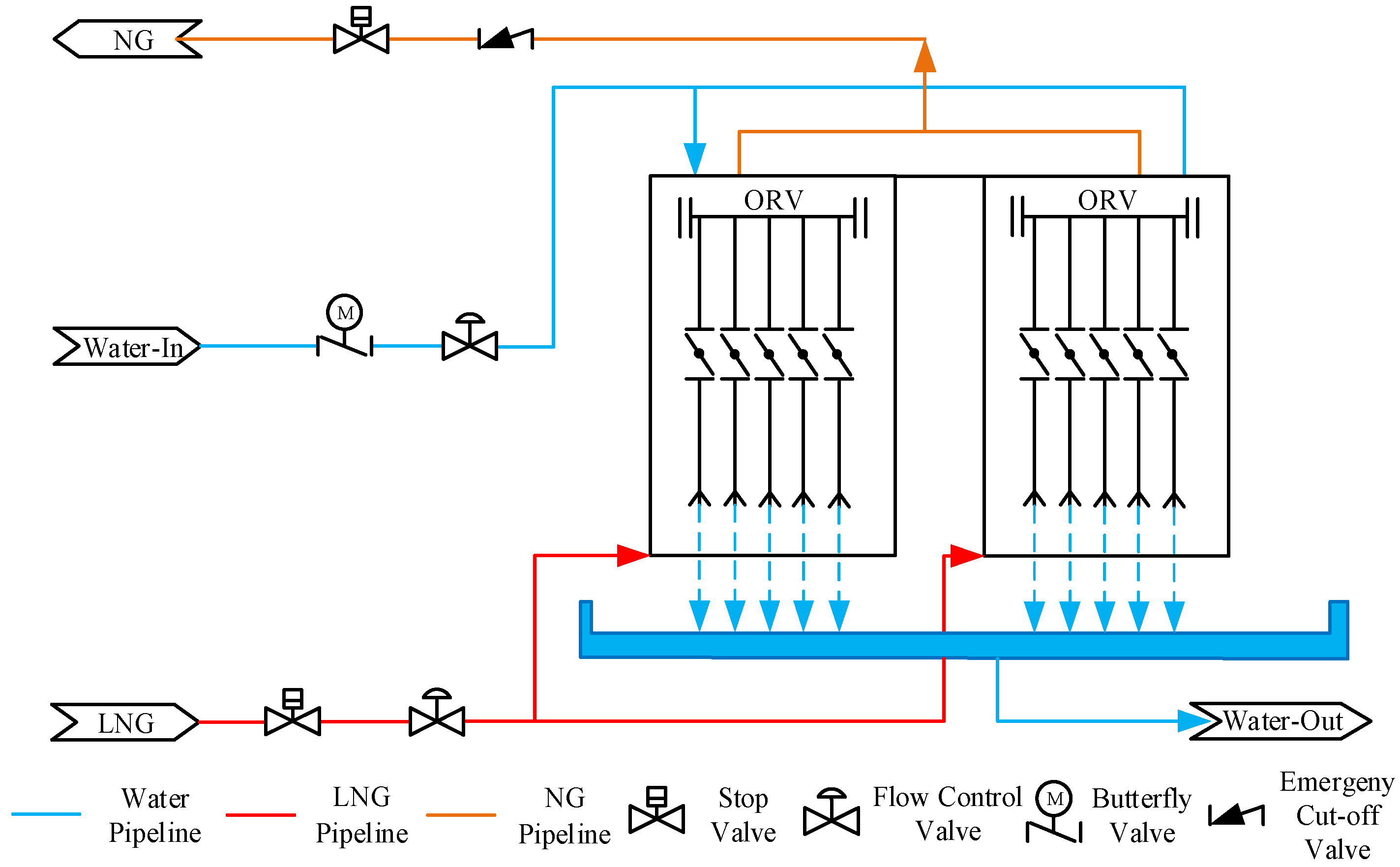

2. Technical Equipment Configuration

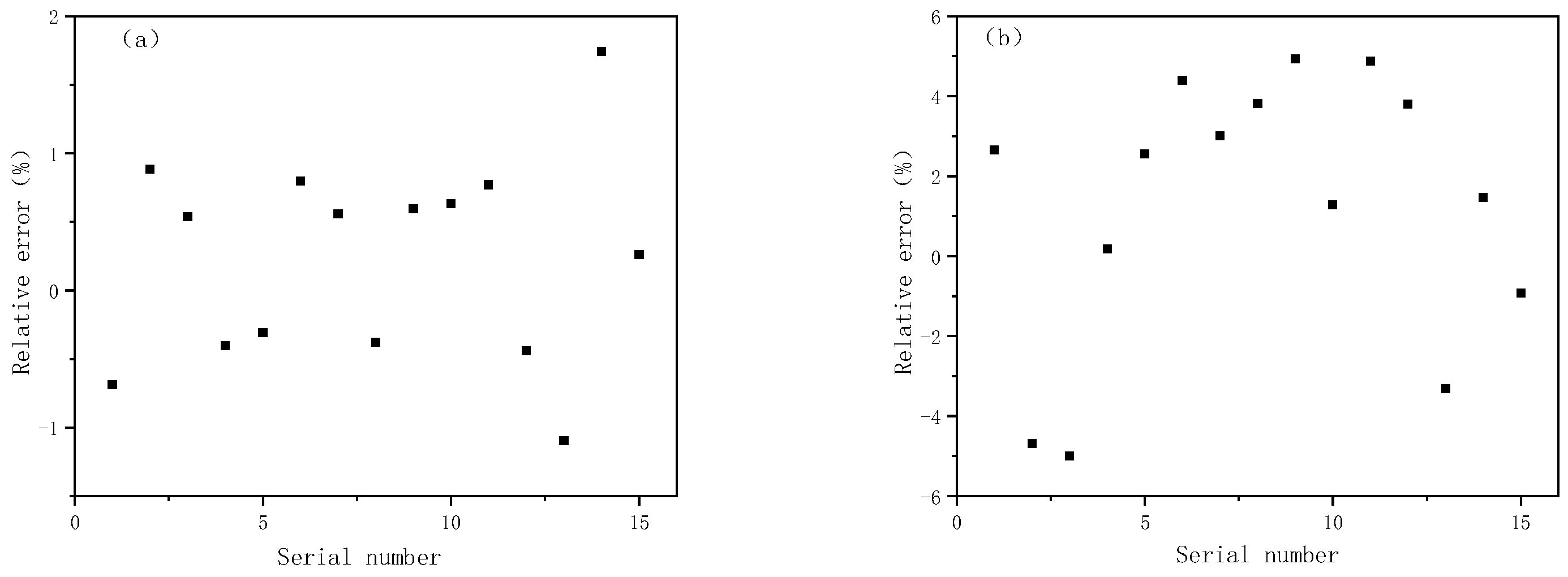

3. Establishment and Verification of Gasification Unit Model

- (1)

- Neglecting Pressure Drop and Heat Loss in the Piping System: It is assumed that the pressure drop and heat loss in the system’s piping are neglected, which simplifies the simulation and calculation process.

- (2)

- Heat Source Assumption: The external environment of the vaporizer is considered to have no heat exchange with the system. All heat required for the vaporization process is provided by external heat sources, such as seawater heating or water bath heating.

- (3)

- Heat Source Efficiency Assumption: The heat efficiency of the heat source is assumed to be known and fixed, simplifying the calculation of heat requirements for the vaporizer.

- (4)

- Assumption of No Chemical Reactions: It is assumed that the vaporization process within the vaporizer involves only physical changes, with no chemical reactions occurring during the LNG vaporization.

- (5)

- LNG Composition Assumption: The LNG is assumed to be a mixture of methane, ethane, propane, and other hydrocarbon gases, with the composition remaining constant throughout the process.

4. Simulation Optimization Research

4.1. Gasification Unit Operation Research Under Different Conditions for ORV and SCV

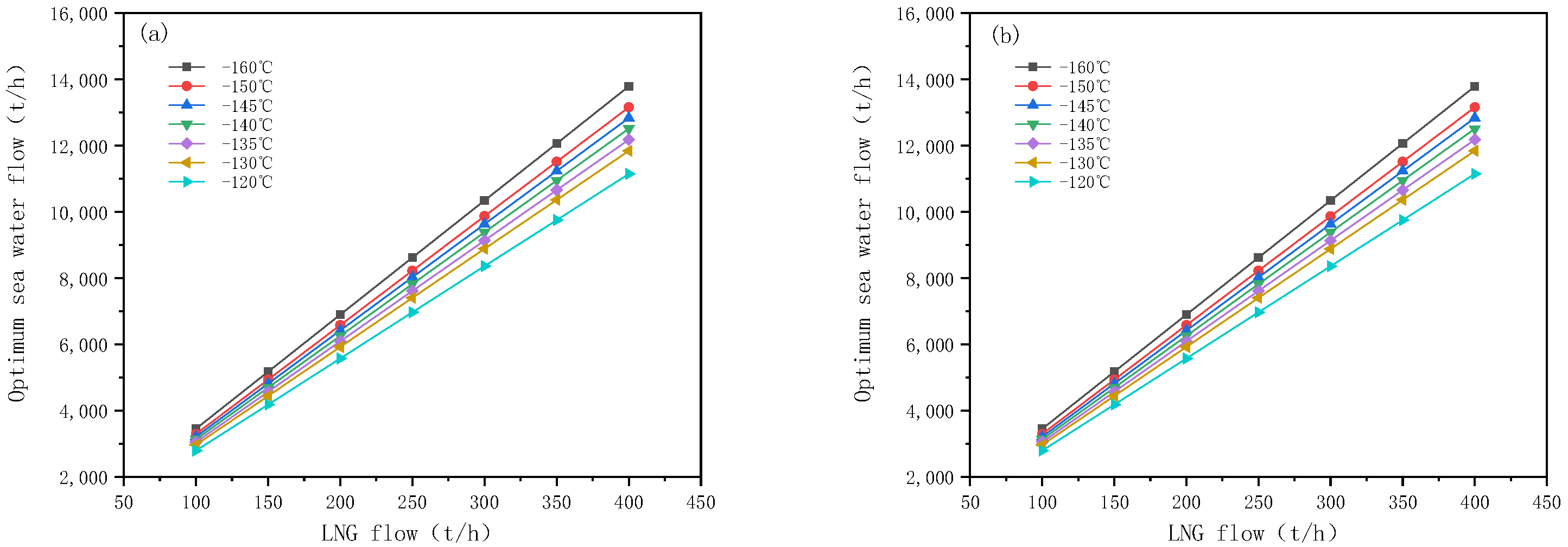

4.2. ORV Operation Optimization Characteristics Under Non-Winter Conditions

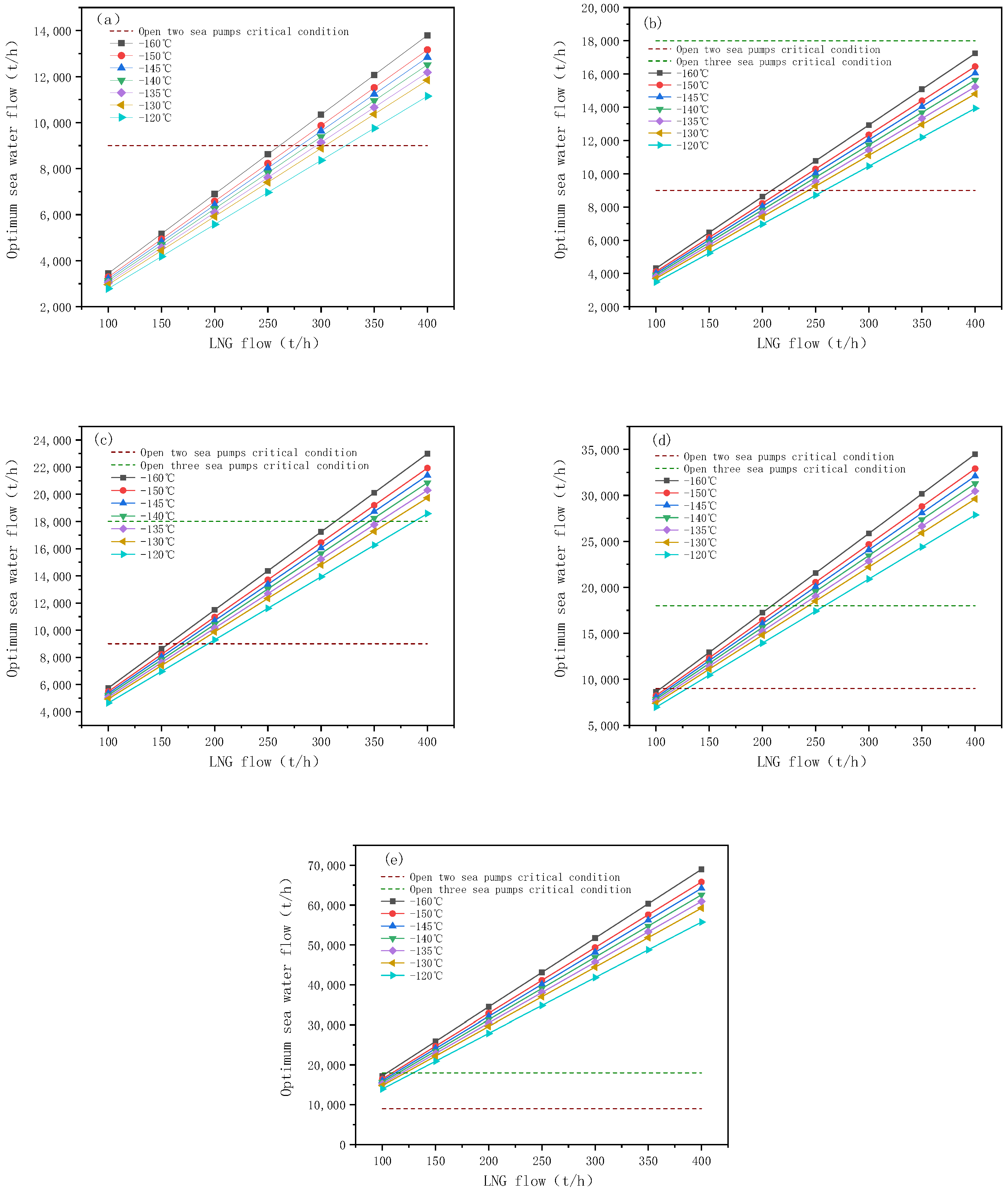

4.3. ORV Operation Research Under Winter Conditions

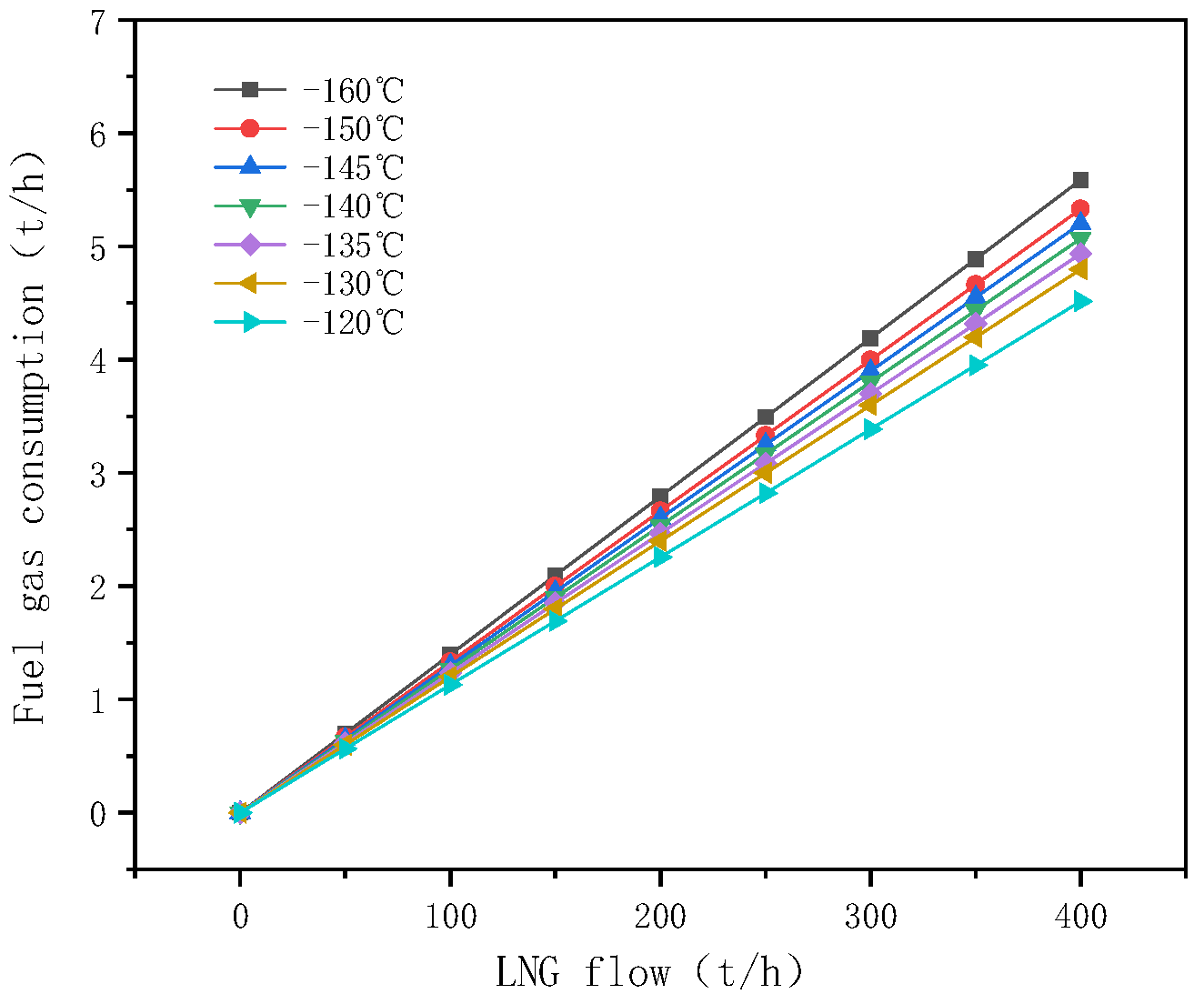

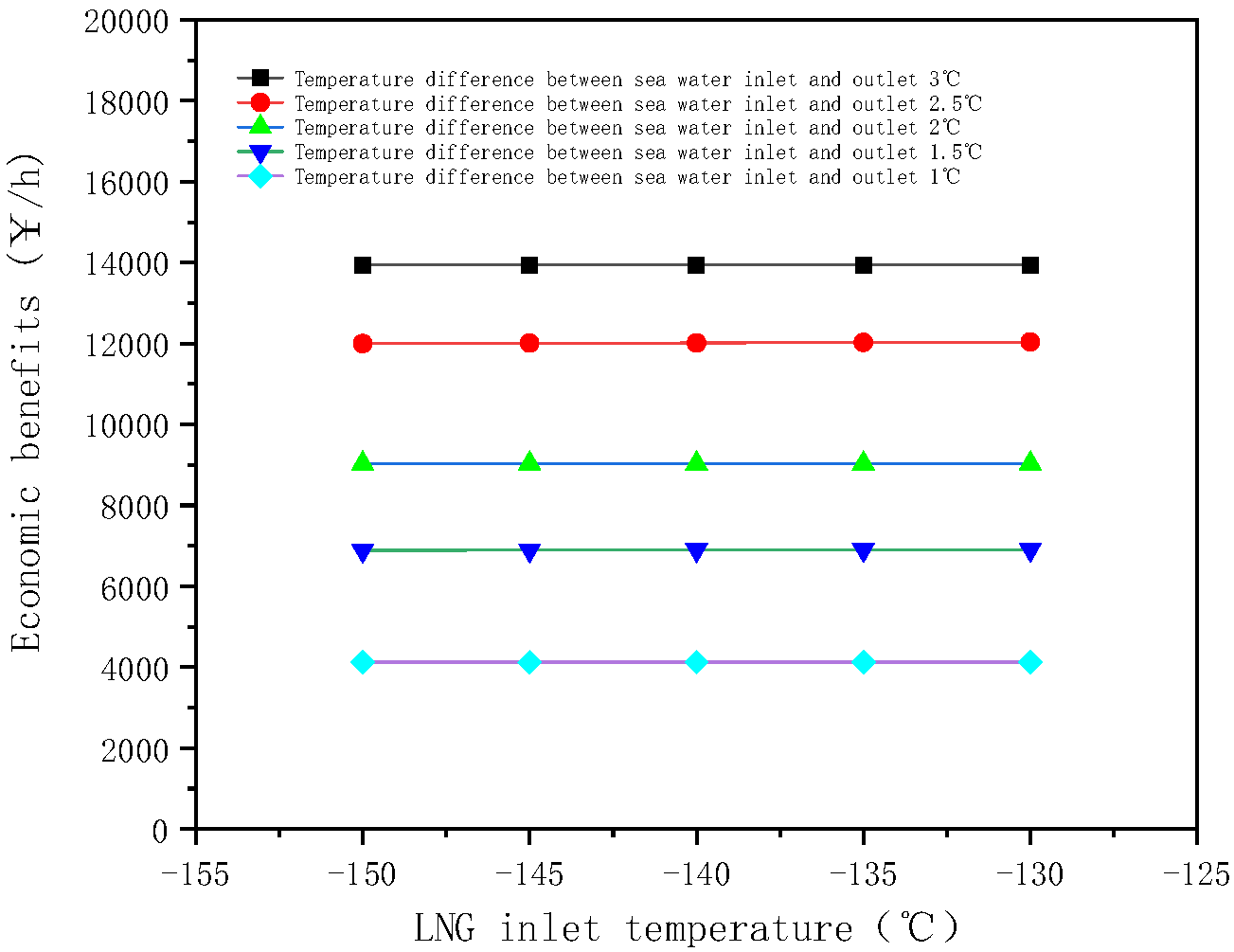

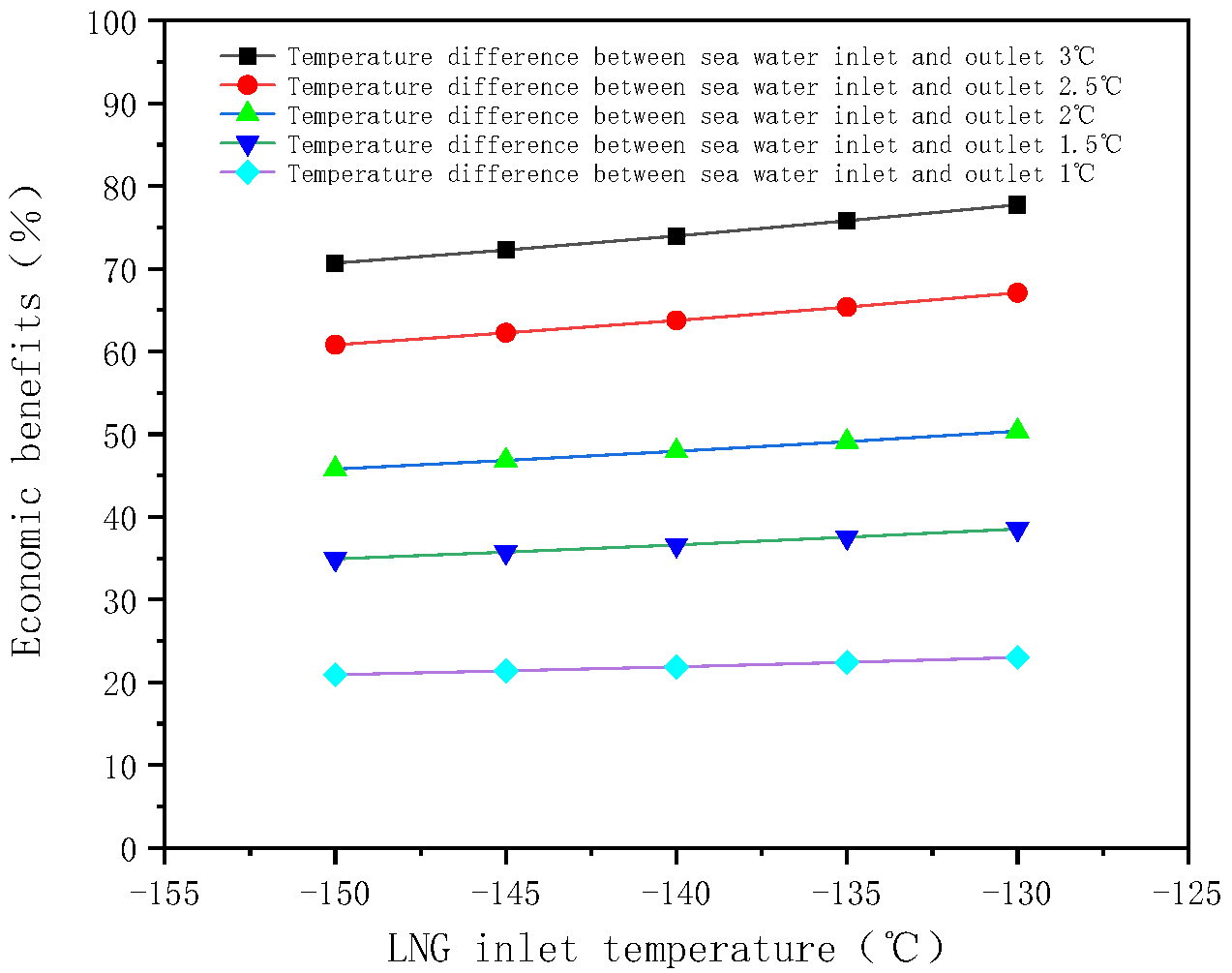

4.4. ORV + SCV Joint Operation Mode Optimization Research

5. Conclusions

- (1)

- Under non-winter conditions, the number of operating ORV seawater pumps should be adjusted according to different LNG export volumes to achieve energy-saving objectives.

- (2)

- For winter conditions, an ORV + SCV joint operation scheme was designed. When the seawater inlet–outlet temperature difference is less than 4 °C, choosing the joint operation scheme shows significant cost savings compared to SCV operation alone. When the seawater inlet–outlet temperature difference is 3 °C, under different LNG inlet temperatures, the joint operation mode saves 70–77% in costs compared to SCV operation alone; at 2.5 °C difference, it saves 60–67%; at 2 °C difference, it saves 45–50%; at 1.5 °C difference, it saves 35–38%; and at 1 °C difference, it saves 20–23%.

- (1)

- Energy Efficiency Improvement: The finding that the number of operating ORV seawater pumps should be adjusted according to different LNG export volumes (under non-winter conditions) is crucial for reducing energy consumption. By optimizing the seawater flow requirements, the LNG terminal can operate more efficiently, ensuring that the energy consumption is in line with actual demand. This not only reduces operational costs but also contributes to the sustainability of the terminal’s operations.

- (2)

- Cost Reduction in Winter Conditions: As LNG terminals typically operate in varying temperature conditions, especially during winter, the results of this study provide a practical framework for adjusting operational strategies to minimize costs while maintaining optimal gasification performance. This flexible operational strategy ensures that LNG terminals can adapt to changing environmental conditions and continue to operate cost-effectively, improving the overall economic viability of LNG import operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Li, Q.; Han, Y. A Numerical Investigation on Kick Control with the Displacement Kill Method during a Well Test in a Deep-Water Gas Reservoir: A Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The Carrying Behavior of Water-Based Fracturing Fluid in Shale Reservoir Fractures and Molecular Dynamics of Sand-Carrying Mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Zhou, S.W.; Zhu, J.; Shan, T.; Fu, Q.; Zhang, D.; Wang, J. Development status and outlook of natural gas and LNG industry in China. China Offshore Oil Gas 2022, 34, 1–8. [Google Scholar]

- Dong, L.W.; Wang, H.R. Research on energy consumption of LNG terminal based on E-P analysis method. Energy Conserv. Pet. Petrochem. Ind. 2023, 13, 10–14. [Google Scholar]

- Gao, Z.Y.; Gao, P.; Liu, Q.; Zhou, Y.; Li, T.Y.; Sun, S.C. LNG industry in China and some suggestions on its development. Nat. Gas Technol. Econ. 2019, 13, 14–19. [Google Scholar]

- Wu, B.; Yu, X.; Liu, J.J.; Tang, J.F.; Yao, B.L.; Li, T. Simulation and optimization of combined transportation of IFV and ORV after capacity expansion of Qingdao LNG terminal. Nat. Gas Chem. Ind. 2022, 47, 134–141. [Google Scholar]

- Wang, X.S.; Chen, W.J.; Li, X.T.; Tang, J.F.; Liu, Q.Y.; Shi, Y. Simulation study on optimized operation of gasification unit in Qingdao LNG terminal. Nat. Gas Chem. Ind. 2019, 44, 63–69. [Google Scholar]

- Liang, Y.; Zhou, Y.X.; Yuan, S.J.; Meng, F.P.; Zhang, S.M.; Wei, S.R.; Leng, X. Analysis on comprehensive utilization scheme of circulating water in LNG terminal and power plant. Nat. Gas Chem. Ind. 2021, 46, 96–101. [Google Scholar]

- Chen, S.; Zhang, Z.X. Energy-saving operation of ORV under low seawater temperatures at LNG terminals. Nat. Gas Ind. 2016, 36, 106–114. [Google Scholar]

- Liu, J.C.; Ju, Y.L.; Fu, Y.Z. Heat transfer model and calculation method for three types of LNG seawater vaporizers. Cryog. Supercond. 2014, 42, 56–61. [Google Scholar]

- Xu, Y.; Ma, M.J.; Zhu, M.; Ji, M.L. Research of the open rack vaporizer operation. Chem. Eng. Oil Gas 2019, 48, 57–60+68. [Google Scholar]

- Shi, H.Q.; Chen, B.; Chen, S.; Jing, X.L. Minimum Seawater Flow Calculation of Open Rack Vaporizer in Different Working Conditions. Autom. Petro-Chem. Ind. 2017, 53, 50–55. [Google Scholar]

- Sun, Q.D.; Chen, S.P.; Yao, S.T.; Zhao, T.; Jin, S.F.; Liu, D.Y.; Meng, G.L. Numerical simulation of freezing on the surface of ORV. Cryog. Supercond. 2016, 44, 16–19+54. [Google Scholar]

- Wang, Y.J.; Li, S.Y.; Chen, W.J.; Tang, J.F.; Li, X.T.; Wang, D.X.; Yu, X. Heat transfer behaviors and operation optimization of LNG submerged combustion vaporizers. Nat. Gas Ind. 2021, 41, 134–143. [Google Scholar]

- Wang, T.J.; Chen, W.J.; Zhao, J.R.; Wang, J.K. Optimization of the operation mode of vaporizers at LNG terminals in winter. Oil Gas Storage Transp. 2018, 37, 1272–1279. [Google Scholar]

- Qi, C.; Yi, C.; Wang, B.; Wang, W.; Xu, J. Thermal performance analysis and the operation method with low temperature seawater of super open rack vaporizer for liquefied natural gas. Appl. Therm. Eng. 2019, 150, 61–69. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, X.; Lei, Z.; Wang, J.; Fan, Z.; Liu, S. Economic Feasibility of LNG Business: An Integrated Model and Case Study Analysis. Energies 2024, 17, 3351. [Google Scholar] [CrossRef]

- Jiao, Y.M.; Chen, S.; Yang, L.; Zhou, H.; Wang, Z.; Li, Q. Operation efficiency and cost check of energy consumption of submerged combustion vaporizer. Chem. Eng. Oil Gas 2014, 43, 505–511. [Google Scholar]

- Peng, C.; Wang, H.D.; Hou, X.G.; Wang, H.S.; Lyu, H.S.; Liu, P.P.; Wei, J.R.; Chen, A.M. Optimization of operation scheme with combined BOG treatment process in LNG terminals. Oil Gas Storage Transp. 2023, 42, 624–631. [Google Scholar]

- Xie, X.G.; Sun, N. Calculation method of greenhouse gas emission from LNG terminals. Oil Gas Storage Transp. 2023, 42, 276–282+312. [Google Scholar]

- Li, X.; Chen, S. Energy saving analysis on variable-frequency seawater pump and high-pressure pump in LNG terminal. Chem. Eng. Oil Gas 2016, 45, 100–106. [Google Scholar]

- Chen, F.; Xie, X.G.; Sun, N.; Gao, Z. Sequential measurement and economic evaluation of carbon emissions from LNG terminals. Oil Gas Storage Transp. 2023, 42, 509–516. [Google Scholar]

- Khan US, S.; Khaliq, M.M.; Shakeel, M.A. Simulation Analysis of Novel Integrated LNG Regasification-Organic Rankine Cycle and Anti-Sublimation Process to Generate Clean Energy. Energies 2023, 16, 2824. [Google Scholar] [CrossRef]

| Designation | Parameter |

|---|---|

| LNG quantity of flow | 207.26 t/h |

| LNG inlet temperature | −160 °C |

| NG outlet temperature | 3 °C |

| Design temperature | −165 °C/50 °C |

| LNG inlet pressure (design/operation) | 15.7 MPaG/10.1 MPaG |

| Rated sea water pump flow | 9000 t/h |

| Seawater inlet temperature (design/operation) | 50 °C/8–37.8 °C |

| Seawater outlet temperature | ≥3 °C |

| Designation | Parameter |

|---|---|

| LNG quantity of flow | 207.26 t/h |

| LNG inlet temperature | −160 °C |

| NG outlet temperature | 3 °C |

| Design temperature | −165 °C/50 °C |

| LNG inlet pressure (design/operation) | 15.7 MPaG/10.1 MPaG |

| Design heat transfer efficiency | 98% |

| Design temperature of water bath | 22 °C |

| High calorific value of fuel gas | 54,330 kj/kg |

| Name | CH4 | C2H6 | N2 |

|---|---|---|---|

| Mole Fraction | 99.8% | 0.07% | 0.13% |

| Parameter | ORV Actual Operation Value | SCV Actual Operation Value |

|---|---|---|

| LNG quantity of flow | 162.246 t/h | 134.001 t/h |

| LNG inlet temperature | −148.61 °C | −147.67 °C |

| LNG inlet pressure | 7.3 MPaG | 8.08 MPaG |

| NG outlet temperature | 4.65 °C | 8.5 °C |

| NG outlet pressure | 7.3 MPaG | 8 MPaG |

| ORV seawater inlet temperature | 9.04 °C | —— |

| ORV seawater outlet temperature | 5.42 °C | —— |

| SCV tube area water bath temperature | —— | 13.17 °C |

| SCV combustion area water bath temperature | —— | 13.19 °C |

| Name | Parameter | Name | Parameter |

|---|---|---|---|

| LNG export volume | 0~400 t/h | NG outlet temperature | ≥1 °C |

| Seawater inlet–outlet temperature drop | ≤5 °C | Seawater outlet temperature | ≥0 °C |

| Fin plate freezing height | ≤1 m | Minimum seawater film-forming flow | 3742.5 t/h |

| Seawater Inlet–Outlet Temperature Difference/°C | LNG Inlet Temperature/°C | Maximum LNG Gasification Rate/(t/h) |

|---|---|---|

| 4 | −130 | 487.2 |

| −135 | 473.717 | |

| −140 | 461.184 | |

| −145 | 449.481 | |

| −150 | 438.504 | |

| 3 | −130 | 365.43 |

| −135 | 355.316 | |

| −140 | 345.916 | |

| −145 | 337.137 | |

| −150 | 328.905 | |

| 2 | −130 | 243.64 |

| −135 | 236.897 | |

| −140 | 230.63 | |

| −145 | 224.777 | |

| −150 | 219.288 | |

| 1 | −130 | 121.831 |

| −135 | 118.459 | |

| −140 | 115.325 | |

| −145 | 112.398 | |

| −150 | 109.654 |

| Seawater Inlet–Outlet Temperature Difference | ORV Units | ORV Gasification Rate | SCV Units | SCV Gasification Rate |

|---|---|---|---|---|

| 3 °C | 2 | 345.916 t/h | 1 | 54.094 t/h |

| 2.5 °C | 2 | 300.698 t/h | 1 | 99.302 t/h |

| 2 °C | 2 | 230.630 t/h | 1 | 169.370 t/h |

| 1.5 °C | 2 | 180.539 t/h | 2 | 219.461 |

| 1 °C | 2 | 115.325 t/h | 2 | 284.675 t/h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, S.; Luan, T.; Zuo, P.; Si, X.; Xie, P.; Guo, Y. Simulation and Economic Benefit Analysis of Carburetor Combined Transport in Winter at a Liquefied Natural Gas Receiving Station. Energies 2025, 18, 276. https://doi.org/10.3390/en18020276

Cao S, Luan T, Zuo P, Si X, Xie P, Guo Y. Simulation and Economic Benefit Analysis of Carburetor Combined Transport in Winter at a Liquefied Natural Gas Receiving Station. Energies. 2025; 18(2):276. https://doi.org/10.3390/en18020276

Chicago/Turabian StyleCao, Song, Tao Luan, Pengliang Zuo, Xiaolei Si, Pu Xie, and Yingjun Guo. 2025. "Simulation and Economic Benefit Analysis of Carburetor Combined Transport in Winter at a Liquefied Natural Gas Receiving Station" Energies 18, no. 2: 276. https://doi.org/10.3390/en18020276

APA StyleCao, S., Luan, T., Zuo, P., Si, X., Xie, P., & Guo, Y. (2025). Simulation and Economic Benefit Analysis of Carburetor Combined Transport in Winter at a Liquefied Natural Gas Receiving Station. Energies, 18(2), 276. https://doi.org/10.3390/en18020276