Modern Systems for Nuclear Fuel Storage and Monitoring: An Analysis of Technological Trends, Challenges, and Future Perspectives

Abstract

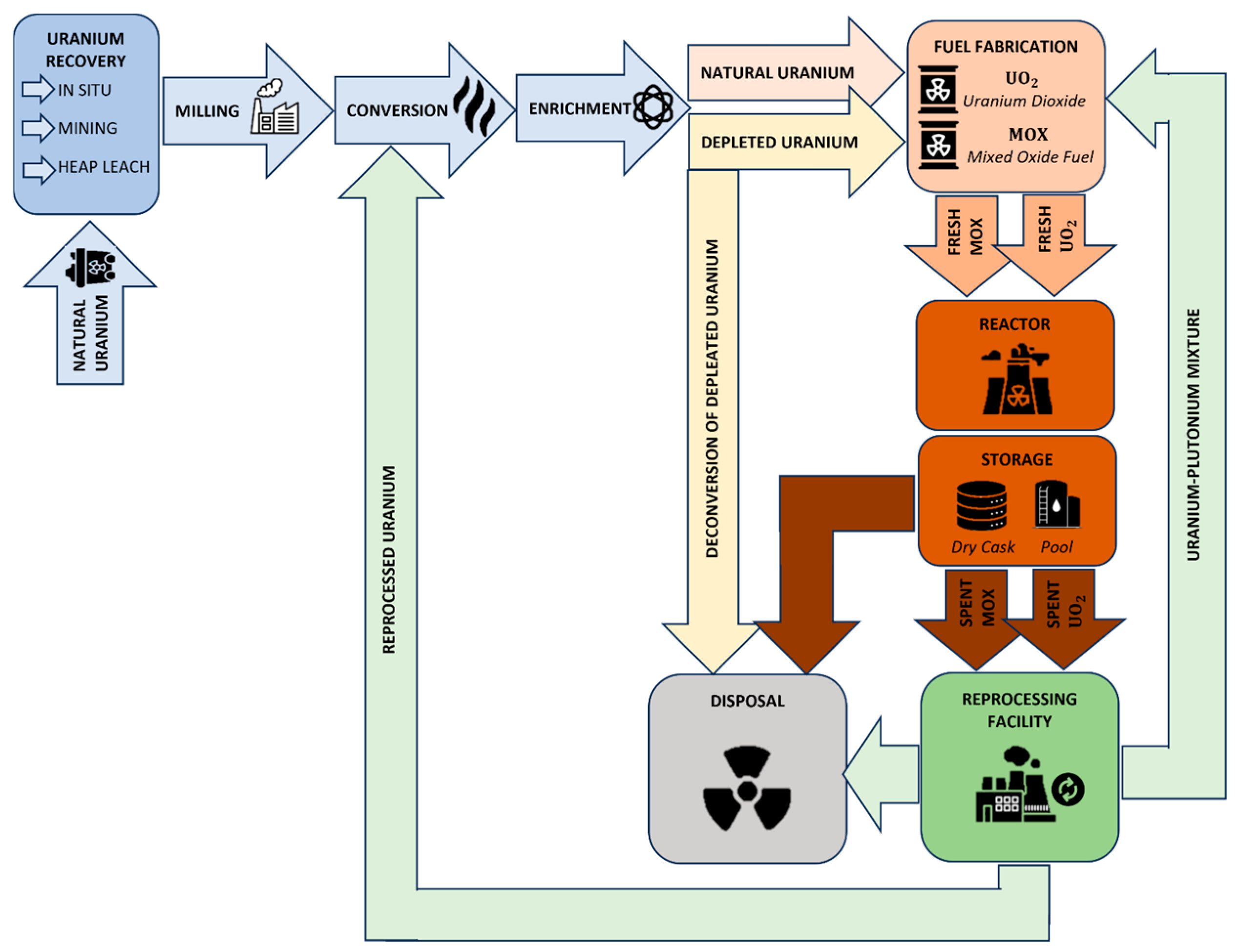

1. Introduction

2. Nuclear Fuel Storage Systems Types

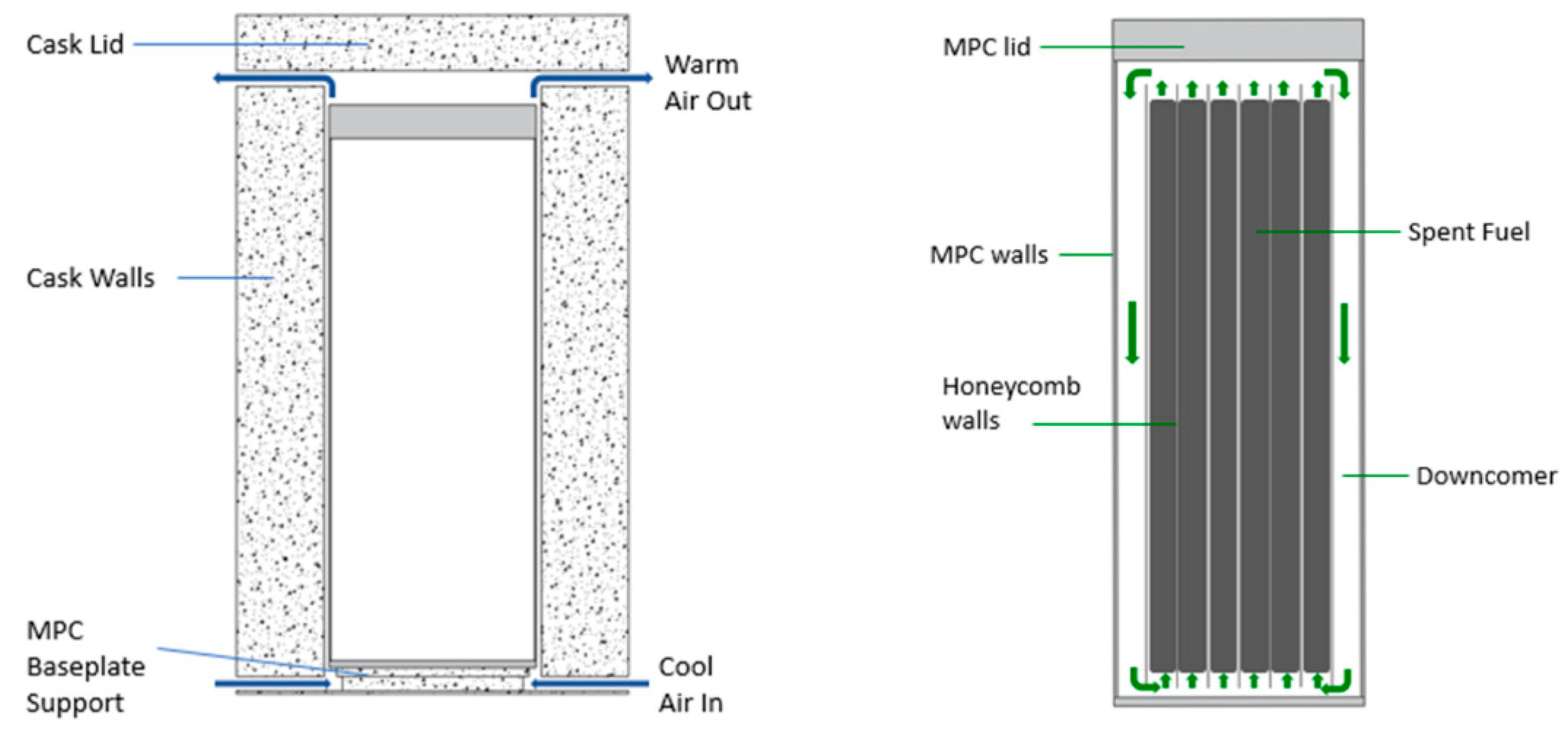

2.1. Dry Storage Systems

- Storage in an inert atmosphere prevents fuel corrosion issues;

- Natural cooling without maintenance;

- Low probability of environmental impact contamination;

- Safety measures are simple to put into practice.

- Storage buildings or containers are costly; prices vary based on the volume and kind of waste;

- Repairing equipment is complicated when containers are damaged;

- Continuous monitoring with pressure sensors is necessary to detect leaks caused by sealing failures.

2.2. Wet Storage Systems

- Storage pools are already accessible nearby reactor;

- Proven technology, all spent fuel is temporarily stored in pools cooling;

- Low-cost storage.

- Corrosive environment;

- Potential fuel damage from storage corrosion containers;

- Water purification by filtration;

- The importance of controlling water quality;

- Maintenance of mechanical equipment, such as coolers or pumps, must be conducted over a long period;

- Possibility of radioactive material leaking into the environment pool;

- Possibility of contamination spreading into the environment;

- Before fuel is transported, it must be dried when it is packed in a container.

3. Monitored Parameters and Monitoring Methods

3.1. Critical Parameters During Storage

3.2. Monitoring Technologies

4. Technological Trends in Storage Systems

4.1. Automated Process Control Using Digital Technologies

4.2. Advanced Diagnostic Technologies and Non-Invasive Sensors

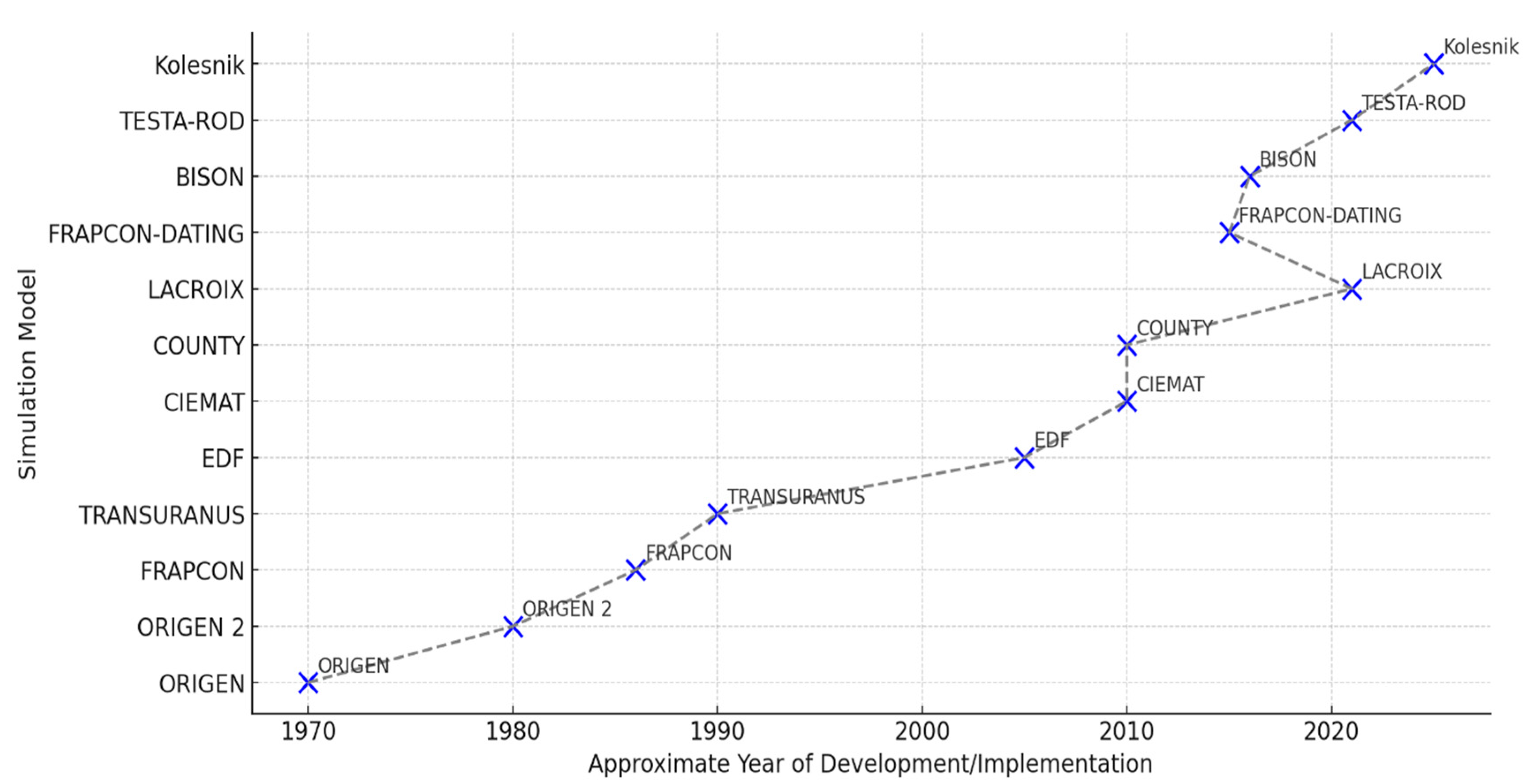

4.3. Advanced Modeling and Simulation for Designing Storage Systems

5. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| CNN | Convolutional Neural Network |

| DCS | Distributed Control Systems |

| DES | Detached Eddy Simulation |

| DT | Digital Twin |

| EDS | Energy Dispersive X-Ray Spectroscopy |

| FTIR | Fourier Transform Infrared Spectroscopy |

| IAEA | International Atomic Energy Agency |

| ICP-MS | Inductively Coupled Plasma Mass Spectrometry |

| IoT | Internet of Things |

| LES | Large Eddy Simulation |

| MOX | Mixed Oxide |

| PWR | Pressurized Water Reactor |

| RANS | Reynolds-Averaged Navier–Stokes |

| SCADA | Supervisory Control and Data Acquisition |

| SEM | Scanning Electron Microscope |

| SNF | Combustibil nuclear uzat/Spent Nuclear Fuel |

| SSG | Specific Safety Guide |

| SFP | Spent Fuel Pool |

| STORM | Storage Module |

| STORM FW | Storage Module Flow Wind |

| UF6 | Uranium Hexafluoride |

| UO2 | Uranium Dioxide |

| U3O8 | Triuranium Octoxide |

| UAV | Unmanned Aerial Vehicles |

| XRD | X-Ray Diffraction |

| YSECT | Yonsei Single-photon Emission Computed Tomography |

References

- Liu, B.; Peng, B.; Lu, F.; Hu, J.; Zheng, L.; Bo, M.; Shang, X.; Liu, W.; Zhang, Y.; Zhou, X.; et al. Critical Review of Nuclear Power Plant Carbon Emissions. Front. Energy Res. 2023, 11, 1147016. [Google Scholar] [CrossRef]

- International Energy Agency. Nuclear Power and Secure Energy Transitions: From Today’s Challenges to Tomorrow’s Clean Energy Systems; IEA: Paris, France, 2022; Available online: https://www.iea.org/reports/nuclear-power-and-secure-energy-transitions (accessed on 11 May 2025).

- El-Samrah, M.G.; Tawfic, A.F.; Chidiac, S.E. Spent Nuclear Fuel Interim Dry Storage; Design Requirements, Most Common Methods, and Evolution: A Review. Ann. Nucl. Energy 2021, 160, 108408. [Google Scholar] [CrossRef]

- Ratiko, R.; Sumarbagiono, R.; Aisyah, A.; Wati, W.; Heriyanto, K.; Mirawaty, M.; Artiani, P.A.; Purwanto, Y.; Saputra, D.L.I.; Rachmadetin, J.; et al. Theoretical and Experimental Analysis on Influence of Natural Airflow on Spent Fuel Heat Removal in Dry Cask Storage. Sustainability 2022, 14, 1859. [Google Scholar] [CrossRef]

- Papamarkou, T.; Guy, H.; Kroencke, B.; Miller, J.; Robinette, P.; Schultz, D.; Hinkle, J.; Pullum, L.; Schuman, C.; Renshaw, J.; et al. Automated Detection of Corrosion in Used Nuclear Fuel Dry Storage Canisters Using Residual Neural Networks. arXiv 2020, arXiv:2003.03241. Available online: https://arxiv.org/abs/2003.03241 (accessed on 9 May 2025). [CrossRef]

- Yessenbayev, O.; Nguyen, D.C.D.; Jeong, T.; Kang, K.J.; Kim, H.R.; Ko, J.; Park, J.Y.; Roh, M.S.; Comuzzi, M. Combining Blockchain and IoT for Safe and Transparent Nuclear Waste Management: A Prototype Implementation. J. Ind. Inf. Integr. 2024, 39, 100596. [Google Scholar] [CrossRef]

- Xu, C.; Wang, Z.; Tang, S.; Chi, X.; Zhu, X.; Li, Y.; Wang, N. Research Progress on Thermal Hydraulic Characteristics of Spent Fuel Pools: A Review. Energies 2023, 16, 3990. [Google Scholar] [CrossRef]

- Sindelar, R.L. Molecular Fuel Cycle: Safe Management of Spent Nuclear Fuel. J. South Carol. Acad. Sci. 2022, 20, 7. [Google Scholar]

- Nakagawa, N.; Kosai, S.; Yamasue, E. Life Cycle Resource Use of Nuclear Power Generation Considering Total Material Requirement. J. Clean. Prod. 2022, 363, 132530. [Google Scholar] [CrossRef]

- Tsai, T.L.; Chiou, Y.F.; Tsai, S.C. Overview of the Nuclear Fuel Cycle Strategies and the Spent Nuclear Fuel Management Technologies in Taiwan. Energies 2020, 13, 2996. [Google Scholar] [CrossRef]

- Angelucci, M.; Paci, S.; Feria, F.; Herranz, L.E. Uncertainty and Sensitivity Analysis of a Dry Cask for Spent Nuclear Fuel. Energies 2022, 15, 1216. [Google Scholar] [CrossRef]

- Vira, J. Geological Repository for High-Level Nuclear Waste Becoming Reality in Finland. In Geological Repository Systems for Safe Disposal of Spent Nuclear Fuels and Radioactive Waste; Woodhead Publishing: Cambridge, UK, 2017; pp. 645–666. [Google Scholar] [CrossRef]

- Di Bella, C.A.W.; Duquette, D.J.; Rigby, D.B. Very Long-Term Dry Storage Systems for Spent Nuclear Fuel: Effect of Canister Weld Corrosion on System Integrity. Mater. Res. Soc. Symp. Proc. 2012, 1475, 143–150. [Google Scholar] [CrossRef]

- Dong-Gyu Lee, N.-H.S.J.-H.P.S.-H.C. An Assessment of Temperature History on Concrete Silo Dry Storage System for CANDU Spent Fuel. Ann. Nucl. Energy 2016, 94, 263–271. [Google Scholar]

- Singh, K.P. Nuclear Waste Storage Canisters. U.S. Patent US10872707B2, 22 December 2022. [Google Scholar]

- European Patent Office. Nuclear Waste Storage Canisters. EP3363021B1, 5 July 2023. [Google Scholar]

- Funke, T.; Henig, C. CASTOR® 1000/19: Development and Design of a New Transport and Storage Cask. In Proceedings of the Annual Meeting on Nuclear Technology 2008, Jahrestagung Kerntechnik 2008, Hamburg, Germany, 27–29 May 2008; Inforum Verlag: Bonn, Germany, 2008; pp. 368–374. [Google Scholar]

- Gartz, R.; Diersch, R.; Gluschke, K. CONSTOR® Transport and Storage Cask for Spent Fuel and for High Active Waste. In Proceedings of the PATRAM 2001—14th International Symposium on the Packaging and Transportation of Radioactive Materials, Berlin, Germany, 20–24 September 2001; Available online: https://resources.inmm.org/system/files/patram_proceedings/2001/33413.PDF (accessed on 9 May 2025).

- Bajwa, C.S.; Adkins, H.E.; Cuta, J.M. Spent Fuel Transportation Cask Response to a Tunnel Fire Scenario. In Proceedings of the PATRAM 2004—14th International Symposium on the Packaging and Transportation of Radioactive Materials, Berlin, Germany, 20–24 September 2004. Available online: https://resources.inmm.org/system/files/patram_proceedings/2004/2-8_247.pdf (accessed on 9 May 2025).

- Jeong, G.E.; Choi, W.S.; Cho, S.S. Topology Optimization of Tie-down Structure for Transportation of Metal Cask Containing Spent Nuclear Fuel. Nucl. Eng. Technol. 2021, 53, 2268–2276. [Google Scholar] [CrossRef]

- Lee, S.G.; Cheong, J.H. Neutron Activation of Structural Materials of a Dry Storage System for Spent Nuclear Fuel and Implications for Radioactive Waste Management. Energies 2020, 13, 5325. [Google Scholar] [CrossRef]

- NAC International. MAGNASTOR® – Modular Advanced Generation Nuclear All-Purpose Storage System; NAC International: Peachtree Corners, GA, USA, 2018; Available online: https://www.nacintl.com/solutions/storage-technologies/magnastor (accessed on 28 May 2025).

- Higley, M.; Hadj-Nacer, M.; Greiner, M. Effect of Basket/Rail Gap on Temperature Prediction in the TN-32 Cask under Storage and Drying Conditions. Nucl. Eng. Des. 2023, 407, 112296. [Google Scholar] [CrossRef]

- Grgic, D.; Matijevic, M.; Duckic, P.; Jecmenica, R. Radiation Shielding Analysis of the HI-STORM FW Storage Cask. Nucl. Eng. Des. 2022, 396, 111878. [Google Scholar] [CrossRef]

- National Research Council. Safety and Security of Commercial Spent Nuclear Fuel Storage: Public Report; The National Academies Press: Washington, DC, USA, 2006. [Google Scholar]

- Rosner, R.; Lordan, R. Why America Should Move toward Dry Cask Consolidated Interim Storage of Used Nuclear Fuel. Bull. At. Sci. 2014, 70, 48–62. [Google Scholar] [CrossRef]

- Electric Power Research Institute. Roadmap for the Industrywide Learning Aging Management Program (i-LAMP) for Neutron Absorber Materials in Spent Fuel Pools; EPRI: Palo Alto, CA, USA, 2018. Available online: https://www.nrc.gov/docs/ML1822/ML18226A291.pdf (accessed on 20 April 2025).

- Gu, Z.; Jia, X.; Su, J. Analysis of the Layout of Passive Safety Systems When the Spent Fuel Pool Is Built in the Containment. Energies 2025, 18, 906. [Google Scholar] [CrossRef]

- Liu, Y.Y. Wet Storage of Spent Nuclear Fuel. In Safe and Secure Transport and Storage of Radioactive Materials; Woodhead Publishing: Cambridge, UK, 2015; pp. 299–310. [Google Scholar] [CrossRef]

- Kain, V.; De, P.K.; Agarwal, K.; Seetharamaih, P. Environmental Degradation of Materials during Wet Storage of Spent Nuclear Fuels. J. Mater. Eng. Perform. 2000, 9, 317–323. [Google Scholar] [CrossRef]

- Swedish Radiation Safety Authority. Study of Degradation of Spent Fuel’s Structural Material and Core Components Under Long-Term Wet Storage; SSM Report 2023:11; SSM: Stockholm, Sweden, 2023; Available online: https://www.stralsakerhetsmyndigheten.se/contentassets/40e1dc0556dc4920903bd0f64c88e76a/202311-study-of-degradation-of-spent-fuels-structural-material-and-core-components-under-long-term-wet-storage.pdf (accessed on 18 April 2025).

- Dolin, V.; Lo Frano, R.; Cancemi, S.A. Assessment of Spent Nuclear Fuel in Ukrainian Storage System: Inventory and Performance. Energies 2024, 17, 1945. [Google Scholar] [CrossRef]

- Harper, C.O.; Brown, J.L.; Amos, R.T. Corrosion Processes Affecting Copper-Coated Used Fuel Containers for the Disposal of Spent Nuclear Fuel: Critical Review of the State-of-Knowledge. Npj Mater. Degrad. 2024, 8, 124. [Google Scholar] [CrossRef] [PubMed]

- Milena-Pérez, A.; Bonales, L.J.; Emblico, L.; Serrano-Purroy, D.; Rodríguez-Villagra, N. Spent Nuclear Fuel Oxidation under Dry Storage Controlled Conditions for Studying Its Radial Oxidation Behavior. J. Nucl. Mater. 2024, 589, 154831. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S. Simplified Model of a High Burnup Spent Nuclear Fuel Rod under Lateral Impact Considering a Stress-Based Failure Criterion. Metals 2021, 11, 1631. [Google Scholar] [CrossRef]

- Yoo, H.S.; Yoo, S.H.; Kim, E.S. Heat Transfer Enhancement in Dry Cask Storage for Nuclear Spent Fuel Using Additive High Density Inert Gas. Ann. Nucl. Energy 2019, 132, 108–118. [Google Scholar] [CrossRef]

- Lochbaum, D. Independent Spent Fuel Storage Installations: Comforts and Concerns. In Department of Public Service; State of New York: Albany, NY, USA, November 2023. Available online: https://dps.ny.gov/system/files/documents/2023/11/20231100-lochbaum-isfsi-comforts-and-concerns.pdf (accessed on 12 April 2025).

- Jang, K.N.; Cha, H.J.; Kim, K.T. Allowable Peak Heat-up Cladding Temperature for Spent Fuel Integrity during Interim-Dry Storage. Nucl. Eng. Technol. 2017, 49, 1740–1747. [Google Scholar] [CrossRef]

- Morales-Hidalgo, M.; Povedano-Priego, C.; Martinez-Moreno, M.F.; Ruiz-Fresneda, M.A.; Lopez-Fernandez, M.; Jroundi, F.; Merroun, M.L. Insights into the Impact of Physicochemical and Microbiological Parameters on the Safety Performance of Deep Geological Repositories. Microorganisms 2024, 12, 1025. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Cho, H.; Lissenden, C.J. Nondestructive Inspection of Spent Nuclear Fuel Storage Canisters Using Shear Horizontal Guided Waves. Nucl. Eng. Technol. 2018, 50, 890–898. [Google Scholar] [CrossRef]

- Yeh, C.P.; Tsai, K.C.; Huang, J.Y. Effects of Relative Humidity on Crevice Corrosion Behavior of 304l Stainless-Steel Nuclear Material in a Chloride Environment. Metals 2019, 9, 1185. [Google Scholar] [CrossRef]

- Brdar, V.; Huber, P.; Kopp, J. Antineutrino Monitoring of Spent Nuclear Fuel. Phys. Rev. Appl. 2017, 8, 054050. [Google Scholar] [CrossRef]

- Oettingen, M. Assessment of the Radiotoxicity of Spent Nuclear Fuel from a Fleet of Pwr Reactors. Energies 2021, 14, 3094. [Google Scholar] [CrossRef]

- Sun, M.; Li, Q.; Wei, C.; Xu, S.; Zou, S.; Huang, Y.; Lei, Y. Research on Radiation Monitoring Strategy for Spent Fuel Reprocessing Plant Based on Coordination of Nuclear Security Risk and Facility Importance Evaluation. Sustainability 2024, 16, 1495. [Google Scholar] [CrossRef]

- Chen, J.H.; Zou, S.L. An Intelligent Condition Monitoring Approach for Spent Nuclear Fuel Shearing Machines Based on Noise Signals. Appl. Sci. 2018, 8, 838. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Design of Fuel Handling and Storage Systems for Nuclear Power Plants; IAEA Safety Standards Series No. SSG-63; IAEA: Vienna, Austria, 2020; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/P1897_web.pdf (accessed on 10 April 2025).

- International Atomic Energy Agency. IAEA Safety Glossary: Multilingual, 2007 Edition* and *Fundamental Safety Principles; IAEA: Vienna, Austria, 2008; ISBN 9201107064. [Google Scholar]

- International Atomic Energy Agency. Environmental and Source Monitoring for Purposes of Radiation Protection; IAEA Safety Standards Series No. RS-G-1.8; IAEA: Vienna, Austria, 2005; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1216_web.pdf (accessed on 8 May 2025).

- Sharp, E.H.; Bernard, R.; Bolton, G.; Dixon, S. Pressure Monitoring of Special Nuclear Material Containment. NDT E Int. 2023, 133, 102760. [Google Scholar] [CrossRef]

- Zhuang, B.; Gencturk, B.; Sinkov, A.; Good, M.; Meyer, R.; Oberai, A. Non-Invasive Ultrasonic Sensing of Internal Conditions on a Partial Full-Scale Spent Nuclear Fuel Canister Mock-Up. NDT E Int. 2024, 148, 103242. [Google Scholar] [CrossRef]

- Spykman, G. Dry Storage of Spent Nuclear Fuel and High Active Waste in Germany—Current Situation and Technical Aspects on Inventories Integrity for a Prolonged Storage Time. Nucl. Eng. Technol. 2018, 50, 313–317. [Google Scholar] [CrossRef]

- Guo, X.; Gin, S.; Frankel, G.S. Review of Corrosion Interactions between Different Materials Relevant to Disposal of High-Level Nuclear Waste. Npj Mater. Degrad. 2020, 4, 34. [Google Scholar] [CrossRef]

- Misra, N.L. Advanced X-Ray Spectrometric Techniques for Characterization of Nuclear Materials: An Overview of Recent Laboratory Activities. Spectrochim. Acta Part. B At. Spectrosc. 2014, 101, 134–139. [Google Scholar] [CrossRef]

- Wen, C.; Yun, D.; He, X.; Xin, Y.; Li, W.; Sun, Z. Applying Multi-Scale Simulations to Materials Research of Nuclear Fuels: A Review. Mater. Rep. Energy 2021, 1, 100048. [Google Scholar] [CrossRef]

- Zhang, Y.; Myhre, K.G.; Bilheux, H.Z.; Johnson, J.A.; Bilheux, J.C.; Parish, C.M.; Miskowiec, A.J.; Hunt, R.D.; Lin, J.Y.Y. Non-Destructive Characterization of Advanced Nuclear Fuel Materials Using Neutron Imaging. Nucl. Mater. Energy 2023, 35, 101434. [Google Scholar] [CrossRef]

- Chajduk, E.; Kalbarczyk, P.; Dudek, J.; Polkowska-Motrenko, H. Isotope Ratio Measurements for Uranium by Quadrupole-Based Inductively Coupled Plasma Mass Spectrometry. Application in Thorium Fuel Research. Procedia Chem. 2012, 7, 660–665. [Google Scholar] [CrossRef][Green Version]

- Chae, K.Y.; Ahn, S.; Bardayan, D.W.; Chipps, K.A.; Manning, B.; Pain, S.D.; Peters, W.A.; Schmitt, K.T.; Smith, M.S.; Strauss, S.Y. Construction of a Fast Ionization Chamber for High-Rate Particle Identification. Nucl. Instrum. Methods Phys. Res. A 2014, 751, 6–10. [Google Scholar] [CrossRef]

- Li, F.; Lv, S.; Qi, S.; Cheng, P.; Zeng, G.Q.; Xiao, M.; Sempau, J. Optimization of Energy Compensation Layered Structure of Geiger- Müller Counters. Nucl. Eng. Technol. 2024, 57, 103300. [Google Scholar] [CrossRef]

- Kelley, R.P.; Enqvist, A.; Jordan, K.A. Pulse Shape Discrimination in Helium-4 Scintillation Detectors. Nucl. Instrum. Methods Phys. Res. A 2016, 830, 44–52. [Google Scholar] [CrossRef]

- Milena-Pérez, A.; Rodríguez-Villagra, N.; Feria, F.; Aguado, C.; Herranz, L.E. Critical Review of Fuel Oxidation Database under Dry Storage Conditions. Prog. Nucl. Energy 2023, 165, 104914. [Google Scholar] [CrossRef]

- Xu, Y.; Yu, W.; Wan, Y.; Zhang, Z. Review of Blockchain-Based Approaches to Spent Fuel Management in Nuclear Power Plants. arXiv 2025, arXiv:2506.00677. Available online: https://arxiv.org/abs/2506.00677 (accessed on 9 May 2025).

- Liu, Z.; Fang, M.; George, J.; Meng, L.-J.; Di Fulvio, A. Neutron Tomography of Spent Fuel Casks. arXiv 2021, arXiv:2110.08939. Available online: https://arxiv.org/abs/2110.08939 (accessed on 9 May 2025). [CrossRef]

- Fulpagare, Y.; Yao, T.; Li, C.J.; Wang, C.C. CFD Analysis of Spent Fuel Dry Cask Storage System for High Burnup Nuclear Fuel. Prog. Nucl. Energy 2023, 161, 104713. [Google Scholar] [CrossRef]

- Choi, H.-j.; Cheon, B.W.; Baek, M.K.; Chung, H.; Chung, Y.H.; You, S.H.; Min, C.H.; Choi, H.J. Experimental Evaluation of Fuel Rod Pattern Analysis in Fuel Assembly Using Yonsei Single-Photon Emission Computed Tomography (YSECT). Nucl. Eng. Technol. 2022, 54, 1982–1990. [Google Scholar] [CrossRef]

- Hu, M.; Zhang, X.; Peng, C.; Zhang, Y.; Yang, J. Current Status of Digital Twin Architecture and Application in Nuclear Energy Field. Ann. Nucl. Energy 2024, 202, 110491. [Google Scholar]

- Gohel, H.A.; Upadhyay, H.; Lagos, L.; Cooper, K.; Sanzetenea, A. Predictive Maintenance Architecture Development for Nuclear Infrastructure Using Machine Learning. Nucl. Eng. Technol. 2020, 52, 1436–1442. [Google Scholar] [CrossRef]

- Alipio, M.; Bures, M. Current Testing and Performance Evaluation Methodologies of LoRa and LoRaWAN in IoT Applications: Classification, Issues, and Future Directives. Internet Things 2024, 25, 101053. [Google Scholar] [CrossRef]

- Jing, Y.G.; Liu, H.; Cheng, M.M.; Fang, H.; Xu, K.; Lan, Y. A New-Generation Nuclear Power Industrial Internet Platform Based on Cloud-Edge-Terminal Network Architecture. In Proceedings of the Proceedings—2024 IEEE 4th International Conference on Digital Twins and Parallel Intelligence, DTPI 2024, Wuhan, China, 18–20 October 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024; pp. 693–699. [Google Scholar]

- Xu, H.; Duo, Y.; Tang, T. Development of an Edge-Cloud Collaboration Framework for Fission Battery Management System. Int. J. Adv. Nucl. React. Des. Technol. 2022, 4, 177–186. [Google Scholar] [CrossRef]

- Song, J.G.; Lee, J.W.; Lee, C.K.; Kwon, K.C.; Lee, D.Y. A Cyber Security Risk Assessment for the Design of L&C Systems in Nuclear Power Plants. Nucl. Eng. Technol. 2012, 44, 919–928. [Google Scholar] [CrossRef]

- Hernández-Gutiérrez, C.A.; Delgado-del-Carpio, M.; Zebadúa-Chavarría, L.A.; Hernández-de-León, H.R.; Escobar-Gómez, E.N.; Quevedo-López, M. IoT-Enabled System for Detection, Monitoring, and Tracking of Nuclear Materials. Electronics 2023, 12, 3042. [Google Scholar] [CrossRef]

- Xu, Y.; Peng, Y.; Wang, H.; Wang, X. A Short Text Similarity Calculation Method Based on Deep Learning. UPB Sci. Bull. Ser. C 2024, 86, 2024. [Google Scholar]

- Huurman, J.; Mondal, K.; Martinez, O. An Overview of Emerging Nuclear Sensor Technologies: Challenges, Advancements and Applications. Appl. Sci. 2025, 15, 2338. [Google Scholar] [CrossRef]

- Lingampalle, D.; Dhabal, M.; Ullas, O.P. Design and Implementation of PLC and SCADA Based Monitoring and Control System for Radiological Once-through Ventilation System at BARC. Int. J. Innov. Sci. Res. Technol. 2022, 7, 132–148. [Google Scholar] [CrossRef]

- de Brito, I.B.; de Sousa, R.T. Development of an Open-Source Testbed Based on the Modbus Protocol for Cybersecurity Analysis of Nuclear Power Plants. Appl. Sci. 2022, 12, 7942. [Google Scholar] [CrossRef]

- Bandala, M.; Chard, P.; Cockbain, N.; Dunphy, D.; Eaves, D.; Hutchinson, D.; Lee, D.; Ma, X.; Marshall, S.; Murray, P.; et al. Digital Twin Challenges and Opportunities for Nuclear Fuel Manufacturing Applications. Nucl. Eng. Des. 2024, 420, 113013. [Google Scholar] [CrossRef]

- Sowers, S.; Yankee, M.; Plante, P. Wall-Climbing Robots Inspect Nuclear Storage Casks Field Tests Demonstrate Robots’ Ability to Inspect Facilities That Store Used Fuel Extracting Value from R&D EPRI and Robotic Technologies of Tennessee Designed Robots for Inspecting Used Nuclear Fuel. EPRI J. 2019, 2, 22–26. Available online: https://eprijournal.com/wp-content/uploads/2019/05/EPRI-Journal-2019-No2-MarApr.pdf (accessed on 11 June 2025).

- Ali, M.A.H.; Baggash, M.; Rustamov, J.; Abdulghafor, R.; Abdo, N.A.D.N.; Abdo, M.H.G.; Mohammed, T.S.; Hasan, A.A.; Abdo, A.N.; Turaev, S.; et al. An Automatic Visual Inspection of Oil Tanks Exterior Surface Using Unmanned Aerial Vehicle with Image Processing and Cascading Fuzzy Logic Algorithms. Drones 2023, 7, 133. [Google Scholar] [CrossRef]

- Guedes, J.V.F.; Meira, G.d.S.; Bias, E.d.S.; Pitanga, B.; Lisboa, V. Performance of Sensors Embedded in UAVs for the Analysis and Identification of Pathologies in Building Façades. Buildings 2025, 15, 875. [Google Scholar] [CrossRef]

- Pallas Enguita, S.; Chen, C.H.; Kovacic, S. A Review of Emerging Sensor Technologies for Tank Inspection: A Focus on LiDAR and Hyperspectral Imaging and Their Automation and Deployment. Electronics 2024, 13, 4850. [Google Scholar] [CrossRef]

- Das, A.; Dorafshan, S.; Kaabouch, N. Autonomous Image-Based Corrosion Detection in Steel Structures Using Deep Learning. Sensors 2024, 24, 3630. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development Nuclear Energy Agency. Best Practice Guidelines for the Use of CFD in Nuclear Reactor Safety Applications—Revision; NEA/CSNI/R(2014)11. OECD Publishing: Paris, France, 2015. Available online: https://www.oecd-nea.org/jcms/pl_19548/best-practice-guidelines-for-the-use-of-cfd-in-nuclear-reactor-safety-applications-revision (accessed on 4 June 2025).

- Yun, M.; Christian, R.; Kim, B.G.; Almomani, B.; Ham, J.; Lee, S.; Kang, H.G. A Software Tool for Integrated Risk Assessment of Spent Fuel Transportation and Storage. Nucl. Eng. Technol. 2017, 49, 721–733. [Google Scholar] [CrossRef]

- Madruga, F.J.; González, D.A.; Mirapeix, J.M.; López Higuera, J.M. Application of Infrared Thermography to the Fabrication Process of Nuclear Fuel Containers. NDT E Int. 2005, 38, 397–401. [Google Scholar] [CrossRef]

- Ratiko, R.; Samudera, S.A.; Hindami, R.; Siahaan, A.T.; Naldi, L.; Hapsari, D.; Mahlia, T.M.I.; Nasruddin, N. Optimization of Dry Storage for Spent Fuel from G.A. Siwabessy Nuclear Research Reactor. Int. J. Technol. 2018, 9, 55–67. [Google Scholar] [CrossRef]

- Konarski, P.; Cozzo, C.; Khvostov, G.; Ferroukhi, H. Spent Nuclear Fuel in Dry Storage Conditions—Current Trends in Fuel Performance Modeling. J. Nucl. Mater. 2021, 555, 153138. [Google Scholar] [CrossRef]

- Park, J.Y.; Kang, S.; Baek, K.; Kim, S.; Yang, Y.S. Areas of Improvement in FRAPCON and FRAPTRAN Codes for Applications to Fuels with Cladding Material Change. Nucl. Eng. Des. 2023, 414, 112615. [Google Scholar] [CrossRef]

- Lassmann, K.; Schubert, A.; Van De Laar, J.; Van Uffelen, P. The “Fuel Rod Analysis ToolBox”: A General Program for Preparing the Input of a Fuel Rod Performance Code. Ann. Nucl. Energy 2015, 81, 332–335. [Google Scholar] [CrossRef]

- Barani, T.; Bruschi, E.; Pizzocri, D.; Pastore, G.; Van Uffelen, P.; Williamson, R.L.; Luzzi, L. Analysis of Transient Fission Gas Behaviour in Oxide Fuel Using BISON and TRANSURANUS. J. Nucl. Mater. 2017, 486, 96–110. [Google Scholar] [CrossRef]

- Raynaud, P.A.C.; Einziger, R.E. Cladding Stress during Extended Storage of High Burnup Spent Nuclear Fuel; NUREG/CR-7198; U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2015. Available online: https://www.nrc.gov/docs/ML1514/ML15141A557.pdf (accessed on 2 July 2025).

- Cappelaere, C.; Decroix, G.-M.; Howald, O.; Duigou, P.; Moitrelle, L.; Bredel, T.; Maury, R. Long Term Internal Pressure Creep Test Device in K6 LECI Hot Cell. In Proceedings of the 41st Plenary Meeting of the European Working Group on Hot Laboratories and Remote Handling, Saclay, France, 22–24 September 2003; pp. 167–183. [Google Scholar]

- Choi, G.H.; Shin, C.H.; Kim, J.Y.; Kim, B.J. Circumferential Steady-State Creep Test and Analysis of Zircaloy-4 Fuel Cladding. Nucl. Eng. Technol. 2021, 53, 2312–2322. [Google Scholar] [CrossRef]

- Courty, O.; Motta, A.T.; Hales, J.D. Modeling and Simulation of Hydrogen Behavior in Zircaloy-4 Fuel Cladding. J. Nucl. Mater. 2014, 452, 311–320. [Google Scholar] [CrossRef]

- Passelaigue, F.; Lacroix, E.; Pastore, G.; Motta, A.T. Implementation and Validation of the Hydride Nucleation-Growth-Dissolution (HNGD) Model in BISON. J. Nucl. Mater. 2021, 544, 152683. [Google Scholar] [CrossRef]

- Kolesnik, M. Comparison of Two Kinetic Approaches for Modeling of Radial Hydride Fraction in Zirconium-Based Fuel Rod Cladding. Nucl. Eng. Technol. 2025, 57, 103479. [Google Scholar] [CrossRef]

- Dufek, J.; Arzhanov, V.; Gudowski, W. Nuclear Spent Fuel Management Scenarios: Status and Assessment Report; SKI Report 2006:37. Swedish Nuclear Power Inspectorate (SKI): Stockholm, Sweden, 2006. Available online: https://www.stralsakerhetsmyndigheten.se/contentassets/84f9d5a763aa4089931d40c6e7d7c169/200637-nuclear-spent-fuel-management-scenarios-status-and-assessment-report (accessed on 8 July 2025).

- Alyokhina, S. The Information System Concept for Thermal Monitoring of a Spent Nuclear Fuel Storage Container. Nucl. Eng. Technol. 2023, 55, 3898–3906. [Google Scholar] [CrossRef]

| No. | Name/ Manufacturer | Purpose | Construction Materials | Monitored Parameters | Key Aspects | Ref. |

|---|---|---|---|---|---|---|

| 1 | CASTOR 1000/19 GNS | transport and storage | -Steel; -Shielding: ductile cast iron; -Neutron moderator: polyethylene rods; -Capacity: 19 fuel assemblies. | -Temperature; -Internal pressure; -Sealing; -Lid integrity. | It offers a high level of radiological safety during storage or transport. Adequate protection is provided by using suitable construction materials. The modular structure facilitates easier handling and storage. | [17] |

| 2 | CONSTOR/GNS | transport and storage | -Walls are of sandwich type: steel–concrete–steel; -Designed for high-level radioactive waste. | -Temperature; -Heat load distribution; -Mechanical deformation. | These systems offer excellent shielding and provide strong protection against thermal and mechanical stresses. | [18] |

| 3 | HI STAR 100/Holtec International | transport and storage | -Cylindrical body made of carbon steel; -Shielding with lead. | -Temperature; -Leak detection indicated by helium loss; -Structural stresses. | A dependable storage system operated under pre-set vacuum conditions. Shows high performance in accident scenario tests. | [19] |

| 4 | Korad 21 | transport and storage | -Structure made of stainless steel; -Protective concrete layers against radiation. | -Temperature; -Structural integrity; -Radiation shielding; -Subcriticality. | Modular system allows for efficient and safe storage, with a durable structure that provides protection under extreme external conditions. | [20] |

| 5 | Hi STORM 100/ Holtec International | storage | -Body made of steel and concrete; -Inner storage canister made of stainless steel. | -Temperature; -Airflow in the passive cooling system; -Corrosion due to external environmental exposure. | Robust system with highly effective passive cooling. Nuclear fuel integrity is properly maintained over an extended period. | [21] |

| 6 | MAGNASTOR/ NAC International | storage | -Body made of carbon steel; -Storage canister made of aluminum alloy; -Lead shielding; -High storage capacity. | -Temperature; -Internal pressure; -Radiation level; -Leak detection | The system is designed to ensure the secure long-term storage of large quantities. | [22] |

| 7 | TN 32/ Transnuclear INC | storage | -Body made of carbon steel; -Lead shielding; -Capacity: 32 PWR fuel assemblies. | -Temperature; -Radiation level; -Pressure; -Mechanical integrity through periodic inspections. | Reliable long-term system operating under controlled environmental conditions, retaining its protective functions even after extended periods of use. | [23] |

| 8 | HI-STORM FW/ Holtec International | storage | -Body made of steel and concrete; -Designed with high resistance to flooding and strong winds. | -Temperature; -Integrity under external factors (wind, rain). | System with excellent stability and long-lasting reliability, tested under harsh weather conditions. | [24] |

| No. | Criterium | Wet Storage | Dry Storage | Ref. |

|---|---|---|---|---|

| 1 | Radiological Security | Good, immediately after removal from the reactor, water offers cooling and gamma shielding. | Very good in the long term; Containers provide shielding and protection tight sealing. | [7,32] |

| 2 | Corrosion Risk | High water is a corrosive environment that needs filtration and chemical treatments. | Low–inert atmosphere (helium/nitrogen) and corrosion-resistant containers. | [27,33] |

| 3 | Estimated Storage Period | Temporary solution lasting years to decades for initial cooling. | Long-term solution (lasting decades to centuries) until final geological disposal. | [3,12] |

| 4 | Costs | Relatively lower initially (pools already available); However, high maintenance costs. | High initial costs, but low when considering long-term maintenance. | [25,26] |

| 5 | Maintenance | High: pumps, filters, continuous water quality monitoring. | Low: passive ventilation systems and periodic structural monitoring. | [4,23] |

| No. | Monitored Parameter | Description | Ref. |

|---|---|---|---|

| 1 | The temperature of the fuel and the container in which it is stored | The temperature must stay below 400 °C to avoid degrading the fuel rods. Exceeding these values may cause chemical reactions like oxidation, followed by the breaking of the fuel rods. Monitoring this parameter is crucial, especially in dry casks, because heat dissipates passively. | [38] |

| 2 | The dose of radiation | It must be monitored for the safety of the operators. They should not receive more than the maximum allowable dose to avoid any adverse health effects. Radiation monitoring must also be conducted to detect any breaches in the integrity of the containers. An increase in radiation levels indicates the containers are degrading. | [39] |

| 3 | The internal pressure of the container | If the tightness of the container is affected, the pressure changes. This phenomenon suggests that accumulations of radioactive gases or hydrogen are produced from reactions with residual water. The increase in pressure is due to modifications to the vessel’s structure. | [40] |

| 4 | Corrosion of exterior surfaces | If containers are stored outdoors, particles from the environment can cause corrosion of stainless steel or other metal materials. Corrosion reduces the strength of the container structure. When stored in a damp climate, these problems can occur much more frequently. Therefore, this storage method is not recommended for prolonged periods. | [33] |

| 5 | Humidity | If moisture exists inside the container, corrosion could happen. That is why it is vacuumed several times. If this vacuum drying process is not performed properly, the leftover moisture can also impact the fuel tubes and generate H2, which can become hazardous in large quantities. | [41] |

| 6 | Fuel integrity | If the nuclear fuel cladding is compromised, fission products may escape. Quickly detecting structural degradation is crucial because the cladding can crack under thermal stresses. | [34] |

| No. | Monitored Characteristics | Fresh Fuel | Spent Fuel |

|---|---|---|---|

| 1 | Radioactivity | Reduced emissions. | High radioactivity: requires shielding, cooling, and personnel protection [42]. |

| 2 | Heat generation | Very small. | A prolonged period must be applied to a cooling method due to residual heat [43]. |

| 3 | Physical-chemical state | Excellent stability; the material remains unchanged mainly unless external factors intervene. | The potential for chemical reactions caused by gases and fission products [32]. |

| 4 | Risk of contamination | Very low. | Raised because of potential cracks in the fuel tanks [44]. |

| 5 | Storage period | Small: until their introduction into the reactor. | Considerable: decades of years [32]. |

| 6 | The objective of monitoring | Ensuring the environmental conditions and fuel traceability. | Maintaining container integrity to prevent radioactive leaks and support continuous assessment [44]. |

| 7 | Monitored parameters | Temperature, humidity, internal pressure, and traceability of fuel rods. | Temperature, emitted radiation, pressure, corrosion, tube and container integrity, vibrations [44]. |

| 8 | The complexity of monitoring | Reduced: sensors and automation equipment are used for everyday working environments. | Raised: continuous monitoring is implemented with complex and redundant equipment [44]. |

| 9 | Monitoring equipment | Thermocouples, thermoresistances, humidity sensors, tables, or RFID for traceability. | Gamma/neutron detectors, acoustic and vibration systems, gas monitoring systems, etc. [45]. |

| No. | Parameter | Device | Description | Ref. |

|---|---|---|---|---|

| 1 | Temperature | Thermocouples/ Temperature Sensors | Preventing the contraction or expansion of materials that could compromise the integrity of nuclear fuel. | [46] |

| 2 | Humidity | Humidity sensors | The metal components and casings are exposed to corrosion, and humidity must be monitored to prevent it from contributing to the phenomenon. | |

| 3 | Internal pressure | Pressure sensors | Gas accumulations can be observed when the internal pressure changes. A sign of seal failure in the system is when the internal pressure drops. | |

| 4 | The level of radiation | Radiation detectors | To prevent personnel in the storage area from being exposed to a high dose of radiation, the radiation level must be checked, and any potential contamination in that area must be identified. | [47] |

| 5 | Positioning and inventory of the fuel | Fuel traceability systems | The production batch, technical details, and other information about the nuclear material must not be lost during storage or transportation. That is why traceability must be maintained with strict precision. | [48] |

| 6 | Structural integrity | Visual inspection | The integrity of the structure and the absence of cracks or deformations must be checked regularly. |

| No. | Equipment | Method Description | Ref. |

|---|---|---|---|

| 1 | Raman spectrometer | Using the spectrometer, the chemical composition of uranium oxide (UO2) is monitored. It can lose oxygen at high temperatures, which may lead to the formation of triuranium octoxide (U3O8), indicating fuel degradation. | [34] |

| 2 | EMAT system | The EMAT system generates waves within the metal walls of the container and measures the vibration frequencies. These frequencies increase as internal pressure rises. A precision acoustic microphone can detect vibrations near the container. This method is contactless and non-destructive, making it an ideal choice. | [49] |

| 3 | Ultrasonic sensors | Using ultrasonic sensors allows for non-invasive monitoring of a canister’s internal conditions. This enables the observation of whether a proper vacuum has been achieved, the detection of temperature variations, or the identification of residual water vapors that could compromise the container’s integrity. | [50] |

| 4 | Thermocouples/ Temperature Sensors | To prevent fuel degradation, monitor the temperature to avoid reaching levels that could compromise its structural integrity. | [51] |

| 5 | Electronic microscopy (SEM) | SEM microscopy is used for detailed analysis of fuel cladding surfaces. It reveals defects that are not visible with traditional methods and provides detailed images of the microstructure of nuclear materials. | [52] |

| 6 | XRD Analysis | XRD analysis is used to study the crystal structure of nuclear materials. | [53] |

| 7 | FEM | The finite element method is employed to analyze the mechanical and thermal behaviors of nuclear fuel. | [54] |

| 8 | EDS | A non-destructive technique used to analyze the elemental chemical composition of surface oxides on nuclear fuel cladding. | [55] |

| 9 | FTIR + vacuum drying | Creating a vacuum and generating heat are used to remove moisture, thereby preventing corrosion. | [53] |

| 10 | ICP-MS | For nuclear fuel analysis, ICP-MS with an ultrasonic nebulizer is employed. It checks the purity of the fuel and analyzes the isotopic ratios. For samples with very low uranium concentrations, this method remains effective and can be used to analyze all elements from the periodic table, not just uranium. | [56] |

| 11 | Ionization chamber | The ionization chamber is designed to detect particles produced in nuclear reactions involving radioactive ions. Using inclined electrodes improves the detector’s response time. | [57] |

| 12 | Geiger-Muller Counter | Geiger-Muller counters are used to improve the accuracy of radiation monitoring. | [58] |

| 13 | Scintillation detector | Scintillation detectors are crucial for identifying nuclear materials. Their precision improves because they efficiently distinguish between signals from neutrons and gamma radiation. | [59] |

| 14 | Muon detector | The trajectories of cosmic muons are diverted when they pass through materials of different densities. Using algorithms and 3D reconstruction, an image of the internal structure of the cask can be created without opening it. This helps determine if nuclear fuel is present. | [60] |

| No. | Name | Developer | Model Type | Notes | Remarks | Ref. |

|---|---|---|---|---|---|---|

| 1 | FRAPCON | PNNL– Pacific Northwest National Laboratory | Fuel performance modeling tool | It is used to simulate key parameters, including the internal pressure within fuel rods, the release of fission gases, and the resulting mechanical responses stresses. | Provides time-evolution predictions of nuclear fuel performance for PWR and BWR reactor types. | [87] |

| 2 | TRANSURANUS | JRC– Comisia Europeană | Fuel performance modeling tool | It is used to simulate the behavior of spent nuclear fuel. | It is used to study the post-irradiation behavior of materials. | [88] |

| 3 | BISON | Idaho National Laboratory | Fuel performance modeling tool | Used for advanced fuel simulation, assessing the impact of temperature on the fuel cladding, as well as the effects of creep and mechanical stresses. | Detailed 3D simulations | [89] |

| 4 | TESTA-ROD | Pennsylvania State University | Fuel performance modeling tool | Used for analyzing hydrogen migration within the fuel cladding. | Confirms the presence and retention of hydrogen in the material structure. | [86] |

| 5 | FRAPCON-DATING | ORNL– Oak Ridge National Laboratory | Creep behavior simulation model | Advanced FRAPCON model used for fuel lifetime evaluation. | Beyond the standard FRAPCON capabilities, additional functions have been integrated to enable the prediction of creep behavior under dry storage conditions. | [90] |

| 6 | EDF | Electricite de France | Creep behavior simulation model | Model used to assess the long-term creep behavior of Zircaloy-4 cladding. | Provides essential design input data for storage development containers. | [91] |

| 7 | CIEMAT | Centro de Investigaciones Energeticas, Medioambiantales y Tecnologicas | Creep behavior simulation model | Simplified version of the EDF model, optimized for fuel performance analysis | Low-temperature optimized model for experimental evaluation. | [92] |

| 8 | COUNTY | County et al. | Hydrogen diffusion and hydride precipitation model | Examines hydrogen diffusion and precipitation from the cladding. | Validates hydrogen accumulation | [93] |

| 9 | LACROIX | Lacroix et al. | Hydrogen diffusion and hydride precipitation model | An improved version of the County model was developed to better observe hydrogen-induced swelling, as the previous model failed to capture this behavior. | Enables estimation of hydrogen-induced swelling and cladding expansion. | [94] |

| 10 | Kolesnik | Kolesnik | Hydrogen diffusion and hydride precipitation model | Investigates hydride behavior under mechanical stress. | Investigates the combined effects of creep and hydrogenation on structures integrity. | [95] |

| 11 | ORIGEN | Chemical Technology Division of ORNL | Decay and depletion model | Assesses nuclear fuel irradiation and its life cycle. | Delivers accurate estimations of residual heat generation. | [96] |

| 12 | ORIGEN 2 | Chemical Technology Division of ORNL | Decay and depletion model | An enhanced version of the Origen code that analyzes composition and radioactivity. | Includes data for materials, shielding, and transport. | [96] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Godea, B.-T.; Gogorici, A.; Iordache, D.-M.; Șchiopu, A.-G.; Anghel, D.-C.; Deaconu, M. Modern Systems for Nuclear Fuel Storage and Monitoring: An Analysis of Technological Trends, Challenges, and Future Perspectives. Energies 2025, 18, 5030. https://doi.org/10.3390/en18185030

Godea B-T, Gogorici A, Iordache D-M, Șchiopu A-G, Anghel D-C, Deaconu M. Modern Systems for Nuclear Fuel Storage and Monitoring: An Analysis of Technological Trends, Challenges, and Future Perspectives. Energies. 2025; 18(18):5030. https://doi.org/10.3390/en18185030

Chicago/Turabian StyleGodea, Bogdan-Teodor, Ana Gogorici, Daniela-Monica Iordache, Adriana-Gabriela Șchiopu, Daniel-Constantin Anghel, and Mariea Deaconu. 2025. "Modern Systems for Nuclear Fuel Storage and Monitoring: An Analysis of Technological Trends, Challenges, and Future Perspectives" Energies 18, no. 18: 5030. https://doi.org/10.3390/en18185030

APA StyleGodea, B.-T., Gogorici, A., Iordache, D.-M., Șchiopu, A.-G., Anghel, D.-C., & Deaconu, M. (2025). Modern Systems for Nuclear Fuel Storage and Monitoring: An Analysis of Technological Trends, Challenges, and Future Perspectives. Energies, 18(18), 5030. https://doi.org/10.3390/en18185030