Abstract

The transition toward renewable-powered greenhouse agriculture offers opportunities for reducing operational costs and environmental impacts, yet challenges remain in managing fluctuating energy loads and optimizing agricultural inputs. While second-life lithium-ion batteries provide a cost-effective energy storage option, their thermal and electrical characteristics under real-world greenhouse conditions are poorly documented. Similarly, although plasma-activated water (PAW) shows potential to reduce chemical fertilizer usage, its integration with renewable-powered systems requires further investigation. This study develops an adaptive monitoring and modeling framework to estimate the thermal resistances (Ru, Rc) and internal resistance (Rint) of second-life lithium-ion batteries using operational data from greenhouse applications, alongside a field trial assessing PAW effects on beefsteak tomato cultivation. The adaptive control algorithm accurately estimated surface temperature (Ts) and core temperature (Tc), achieving a root mean square error (RMSE) of 0.31 °C, a mean absolute error (MAE) of 0.25 °C, and a percentage error of 0.31%. Thermal resistance values stabilized at Ru ≈ 3.00 °C/W (surface to ambient) and Rc ≈ 2.00 °C/W (core to surface), indicating stable thermal regulation under load variations. Internal resistance (Rint) maintained a baseline of ~1.0–1.2 Ω, with peaks up to 12 Ω during load transitions, confirming the importance of continuous monitoring for performance and degradation prevention in second-life applications. The PAW treatment reduced chemical nitrogen fertilizer use by 31.2% without decreasing total nitrogen availability (69.5 mg/L). The NO3−-N concentration in PAW reached 134 mg/L, with an initial pH of 3.04 neutralized before application, ensuring no adverse effects on germination or growth. Leaf nutrient analysis showed lower nitrogen (1.83% vs. 2.28%) and potassium (1.66% vs. 2.17%) compared to the control, but higher magnesium content (0.59% vs. 0.37%), meeting Japanese adequacy standards. The total yield was 7.8 kg/m2, with fruit quality comparable between the PAW and control groups. The integration of adaptive battery monitoring with PAW irrigation demonstrates a practical pathway toward energy efficient and sustainable greenhouse operations.

1. Introduction

Global warming and the greenhouse effect pose significant threats to agricultural production, particularly in densely populated, land-scarce island nations like Taiwan. Taiwanese agriculture, characterized by intensive farming practices, faces challenges such as an aging population, labor shortages, and rising input costs. Excessive nitrogen fertilizer use has led to soil acidification, water eutrophication, and increased emissions of greenhouse gases such as nitrous oxide (N2O), which has a global warming potential 298 times greater than carbon dioxide (CO2) [1,2,3,4]. These impacts exacerbate the conflict between agricultural productivity and environmental sustainability [5]. Agriculture accounts for approximately 10–14% of anthropogenic greenhouse gas emissions, with agricultural soils contributing 60–70% of global anthropogenic N2O emissions, primarily from fertilizer application and livestock manure management [6,7,8].

To address these challenges, recent research highlights strategies such as high efficiency fertilizers, slow-release technologies, and alternative nitrogen sources to improve nitrogen use efficiency while reducing N2O emissions. One promising approach is plasma-activated water (PAW) technology, which uses plasma reactions to convert nitrogen oxides from air and water into plant-absorbable nitrogen nutrients. This eco-friendly alternative to chemical fertilizers supports crop growth while reducing reliance on synthetic nitrogen fertilizers, thereby lowering greenhouse gas emissions and supporting sustainable agricultural practices [9].

In parallel, the adoption of renewable energy systems in agriculture particularly in controlled-environment greenhouses has accelerated as part of the global transition toward net-zero emissions [10]. Photovoltaic (PV) power generation, combined with battery energy storage systems (BESS), enables reliable off-grid operation, reduces dependence on fossil fuels, and supports critical agricultural processes [11,12,13]. Lithium-ion batteries (LIBs) are widely preferred in these systems due to their high energy density, long cycle life, and low self-discharge rates [14]. However, in greenhouse applications, LIBs face significant operational challenges: frequent charge–discharge cycles combined with fluctuating ambient temperatures can cause uneven internal heating, changes in internal resistance, and accelerated degradation especially when second-life batteries are used [15,16,17,18].

The accurate estimation of both thermal states and internal resistance is crucial for ensuring safety, maximizing usable capacity, and extending the lifespan of LIBs under such demanding conditions [19]. Internal resistance directly influences power output, efficiency, and heat generation, making it a key parameter for predicting performance in dynamic agricultural energy systems. Conventional methods often rely on static parameters or simplified models that fail to capture real-time variations caused by fluctuating loads and environmental changes [20].

Globally, the reuse of second-life lithium-ion batteries has become an important research focus within the circular economy and renewable energy transition [21,22,23]. In Europe, initiatives under the EU Green Deal framework have demonstrated the potential of integrating retired EV batteries into agricultural microgrids and smart grid storage systems [24]. In the United States, the Department of Energy has launched pilot projects deploying second-life batteries for grid stabilization and microgrid support, while Japan and South Korea have developed commercial applications for reusing repurposed batteries in smart farming and renewable-powered facilities [25,26]. These international efforts highlight the worldwide relevance and scalability of second-life battery applications, reinforcing the need for adaptive control strategies that ensure operational safety, efficiency, and long-term sustainability across diverse environments [5,27].

To overcome these limitations, this study proposes a real-time adaptive control algorithm that dynamically estimates and regulates both the thermal behavior and the internal resistance of a 48V lithium-ion battery operating in a greenhouse energy system [28,29]. The algorithm uses a lumped thermal model with two key thermal resistances, Ru (surface ambient) and Rc (core surface), while also tracking internal resistance changes in real time. Model parameters are continuously updated based on feedback from operational data, ensuring robustness under realistic, non-ideal greenhouse conditions [30].

Beyond improving battery performance, this research integrates a crop growth case study using PAW technology for beefsteak tomato cultivation. By ensuring a stable and efficient energy supply to the greenhouse including the uninterrupted operation of PAW systems this work demonstrates how advanced battery management directly supports sustainable agriculture. The dual focus on thermal stability and internal resistance tracking not only enhances battery reliability but also enables consistent, low-carbon crop production, linking energy optimization to tangible agricultural and environmental benefits.

2. Materials and Methods

This section describes the materials and experimental procedures employed in this study, focusing on the integration of a second-life lithium-ion battery energy storage system with a greenhouse microgrid powered by a photovoltaic (PV) profile load. The methodology covers battery characterization, thermal and internal resistance estimation, control system implementation, and the operational framework for supporting plasma-activated water (PAW) production for sustainable crop cultivation.

2.1. System Overview

The experimental setup was designed to replicate the real operating conditions of a greenhouse energy system in a controlled laboratory environment. Real-time operational data including ambient temperature, charging/discharging current profiles, and solar power generation were collected from an actual greenhouse facility. This approach allowed for a controlled yet highly representative evaluation of battery performance, while minimizing the variability and uncertainty associated with in-field measurements. The battery was connected to a charging–discharging machine, as shown in Figure 1 and placed under typical greenhouse operation conditions, where solar panels were the main charging source and loads included ventilation, lighting, and environmental control systems including the ambient temperature variation range (28–36 °C).

Figure 1.

Charge–Discharge Machine and Reused Battery.

As shown in Figure 2, the data acquisition process followed three main stages: (1) data collection during the battery’s charge–discharge cycles within the greenhouse system, (2) automation and control using a charge–discharge unit to ensure consistency, and (3) data storage in XLS and DAT formats for detailed analysis. Key parameters such as voltage, current, and surface temperature were continuously monitored throughout both charging and discharging phases.

Figure 2.

Experimental Workflow.

The greenhouse was equipped with monitoring sensors (current, voltage, surface temperature) connected to a centralized database. The stored data were then retrieved and used to simulate and validate battery thermal behavior under actual greenhouse operating profiles.

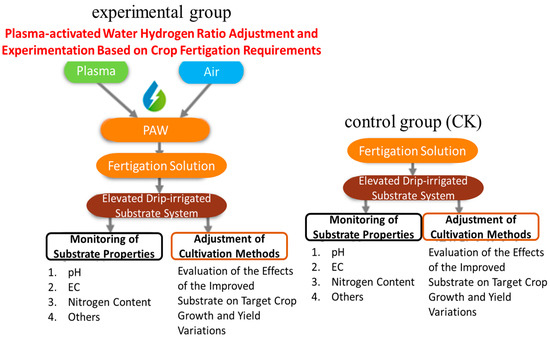

Among the major loads in the greenhouse, the plasma-activated water (PAW) system, as shown in Figure 3 plays a significant role in shaping the battery’s load profile. The PAW unit, used for nutrient solution activation and disinfection, operates in scheduled cycles that require short bursts of high electrical power [8]. These load pulses impose dynamic discharge conditions on the battery, influencing both its internal resistance behavior and thermal response.

Figure 3.

PAW Hydrogen Ratio Adjustment Based on Crop Fertigation Requirements.

All electrical and environmental parameters—including battery voltage, current, surface temperature, and ambient conditions—are measured in real time using an integrated sensor network. These measurements are automatically logged in the greenhouse supervisory control and data acquisition (SCADA) system and stored in a structured database. The recorded profiles are then replicated in the laboratory using programmable load equipment to ensure that the simulated conditions match the actual field operation. This approach allows for a controlled and repeatable evaluation of the battery’s performance under representative operating scenarios while avoiding the operational risks of direct on-site testing.

A microgrid system was developed to power a greenhouse module by integrating solar PV panels with grid electricity. The experimental site, covering approximately 285 m2, has an average monthly electricity consumption of 70 kWh, equivalent to 2.3 kWh per day. To accommodate the additional energy demand from introducing a PAW system, the assessment was scaled to a larger field of 1000 m2, with an estimated monthly electricity consumption of 200 kWh, or 6.6 kWh per day. The region’s annual average solar radiation is approximately 1138 kWh/kWp. Based on an installation requirement of approximately 9.9 m2 per kWp of solar panels, the 39.6 m2 rooftop of the experimental site can support at least a 4 kWp solar system, projected to generate 3965 kWh annually.

The solar PV system is integrated with a small gasoline generator and an energy storage system to ensure a stable power supply. An energy management system (EMS) governs control strategies, prioritizing the direct use of solar energy or charging the storage system during sunny conditions. On cloudy or rainy days, the EMS determines whether to draw power from the grid, solar system, or activate the gasoline generator for supplementary power. The power supply hierarchy prioritizes solar energy over storage, and storage over grid electricity. This design aims to establish a demonstration of energy self-sufficiency for the experimental site while offering a scalable, off-grid power solution for remote areas with unreliable grids, such as in Southeast Asia. The ultimate goal is to achieve zero grid electricity consumption (0 kWh) for the facility.

2.2. Battery Characterization

The energy storage system employed in this study consisted of a second-life 48 V lithium-ion polymer battery pack, originally designed for high-power applications. The battery pack has a nominal voltage of 51.8 V and a rated capacity of 33 Ah. Thermal properties include a core thermal capacity (Cc) of 67 J/K and a surface thermal capacity (Cs) of 4.5 J/K.

Prior to experimental integration, the battery underwent preliminary characterization to determine its electrical and thermal performance under controlled laboratory conditions using real-world operating profiles obtained from the greenhouse system. Voltage, current, and surface temperature were measured in both charge and discharge phases. The internal electrical resistance was verified using the voltage drop method during controlled current pulses, while the thermal resistances (Rc and Ru) were validated through steady state temperature measurements under a constant load.

2.3. Themal Modeling of Battery

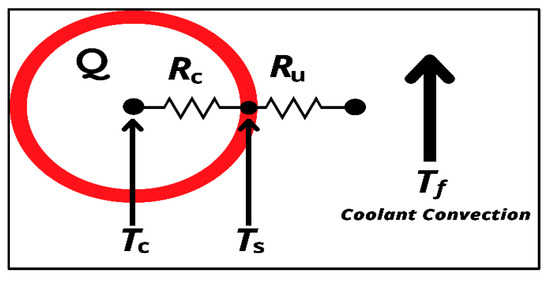

As shown in Figure 4, we present the thermal modeling approach for a lithium-ion battery, focusing on two key thermal resistances: Ru (thermal resistance from the environment to the battery surface) and Rc (thermal resistance from the core to the battery surface) [9,31].

Figure 4.

Thermal Modeling of Reuse Battery.

By analyzing the energy balance equations for both the core and surface of the battery, we can derive relationships that help in estimating these thermal resistances and implementing effective thermal management strategies [32,33]. Additionally, we can estimate the surface temperature of the battery, which is a critical factor in determining the overall thermal behavior of the battery.

- Model Parameters

The model parameters used in the simulations are crucial for accurately reflecting the thermal dynamics of the lithium-ion battery. The parameters used in this study are summarized in Table 1.

Table 1.

Model Parameters.

- Energy Balance Equations

The battery is modeled using two thermal capacitances: core temperature Tc and surface temperature Ts. The thermal system is subjected to internal heat generation and two thermal resistances Rc (core to surface) and Ru (surface to ambient). The energy balance equations are as follows:

These equations describe the first order thermal behavior of the battery. Through mathematical manipulation (differentiation and substitution), the system can be represented in second order form for adaptive estimation

or, in extended form that includes internal temperature influence

Two different model formulations were used in the implementation. Equation (3) was used for estimating the thermal resistance Ru, as it directly relates to the environmental influence on surface temperature. Meanwhile, Equation (4) was employed for estimating Rc, allowing a more flexible parameterization suitable for the adaptive estimation of internal heat transfer.

- Parameter Estimation Model

Equations (3) and (4) are structured to estimate unknown thermal parameters θᵢ. The parameters have the following physical interpretation, as summarized in Table 2.

Table 2.

Estimation Model.

- Sliding Surface and Lyapunov Stability

To guarantee the stability of the estimation process, a sliding surface is defined as

where is the tracking error. The Lyapunov candidate function is

The derivative of the Lyapunov function is

To ensure < 0, a control input u is applied

- Parameter Update Laws

The parameter estimates are updated in real-time using adaptation laws derived from Lyapunov stability as follows:

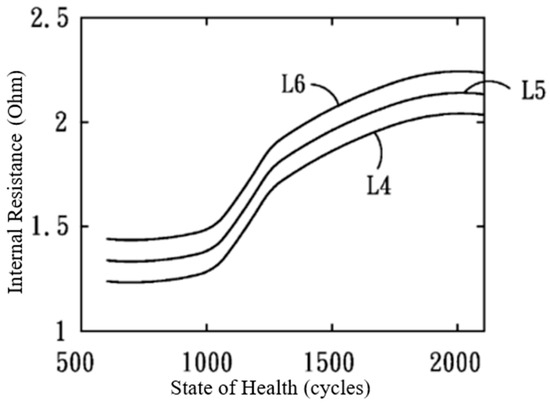

2.4. Internal Resistance

Internal resistance is a critical parameter for assessing the performance and health of batteries, as it quantifies the opposition to current flow within the battery and reflects internal losses during charge and discharge processes, as shown in Figure 5. The internal resistance of a battery is influenced by various factors, including the materials used for the electrodes, the composition of the electrolyte, the characteristics of the separator, and the overall design of the cell [10,11].

Figure 5.

Internal Resistance [11].

The internal resistance measurement begins with data collection, where real-time voltage and current are recorded during the discharge process. Additionally, the open circuit voltage is measured at corresponding state of charge (SoC) and temperature (T) conditions. Using these measurements, we apply the formula

Several factors affect internal resistance according to the equation. Temperature variations impact ion mobility, where lower temperatures increase resistance, and higher temperatures can accelerate degradation. State of charge (SoC) also influences resistance, with values tending to peak at very low or high SoC levels. Additionally, battery aging processes, such as the growth of the solid electrolyte interphase (SEI) layer, lithium plating, and loss of active material, contribute to increased resistance over time.

2.5. Data Acquisition and Modeling

Data acquisition was conducted through an integrated monitoring system installed in the greenhouse energy network. Electrical parameters—battery voltage (V), current (I), and power (P)—were measured using high accuracy DC sensors connected to the battery and inverter terminals. Thermal parameters, including the surface temperature of the battery module (Ts) and ambient environmental conditions (Ta, relative humidity), were measured using digital temperature sensors and environmental probes.

All sensor signals were transmitted to the supervisory control and data acquisition (SCADA) platform via Modbus TCP/IP, where they were timestamped and stored in a MySQL database. Data logging was configured at a 1 s sampling rate to capture the short-term dynamic variations in battery loading, particularly during high-power events such as irrigation pumping or plasma-activated water (PAW) operation.

The recorded datasets were exported and used as input profiles for laboratory simulations. By replaying the real-world current and voltage profiles on programmable load equipment, the laboratory setup reproduced the same thermal and electrical stress experienced by the battery in the greenhouse. This ensured consistency between field and laboratory conditions, allowing for the accurate estimation of internal resistance and thermal resistance under realistic operating scenarios.

3. Results

This section presents the experimental results obtained from the greenhouse energy storage system, followed by the analysis of battery internal and thermal resistance. The analysis begins with the characterization of the electrical load profile derived from real-time greenhouse operation data, which was used as the basis for the laboratory simulation. Subsequently, the internal resistance (Rint) is estimated and evaluated to assess its influence on battery performance and efficiency. The thermal behavior of the battery is then examined, including the comparison between measured and estimated surface temperatures (Ts), as well as the estimation of thermal resistances (Ru and Rc) that describe heat dissipation to the environment and within the battery core. Finally, the coupling between electrical and thermal parameters is discussed to highlight the operational implications for greenhouse energy management.

3.1. Current and Thermal Power Results

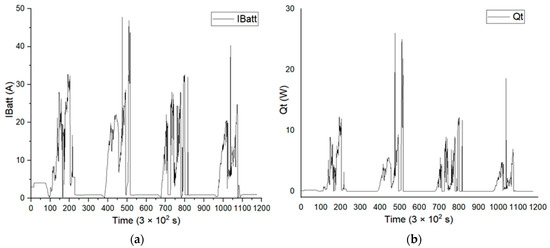

The results presented here focus on the current () flowing through the battery and the thermal power () generated by the battery over time, as shown in Figure 6.

Figure 6.

Current and Thermal Power (a) The current flowing through the battery (b) The thermal power generated by the battery.

Current (Ib) Profile:

- As shown in Figure 6a, the battery current exhibits dynamic fluctuations, ranging from near 0 A during idle phases to peak values exceeding 45 A during high-demand periods.

- The average current throughout the simulation is approximately 9.8 A, with intermittent bursts lasting between 100–300 s per cycle.

- These fluctuations mirror the on–off cycling of real-world greenhouse systems—such as ventilation motors, irrigation pumps, and lighting—highlighting dynamic energy consumption patterns.

- Periods of sustained current draw correlate with greenhouse load surges, while zero-current intervals represent natural pauses in energy demand (e.g., nighttime or non-operational phases).

Power (Qt) Profile:

- Figure 6b shows the estimated thermal power dissipated due to internal resistance, peaking at around 25 W.

- The total accumulated thermal energy over the simulation (by integrating Qt over time) is estimated at approximately 5.6 kWh, reflecting the heat loss that must be managed to prevent thermal runaway.

- The thermal power curve closely follows the current pattern, due to the quadratic relationship , indicating that even short bursts of high current can cause significant heat generation.

These findings emphasize the importance of dynamic thermal management in second-life battery applications for agriculture.

3.2. Temperature Profile

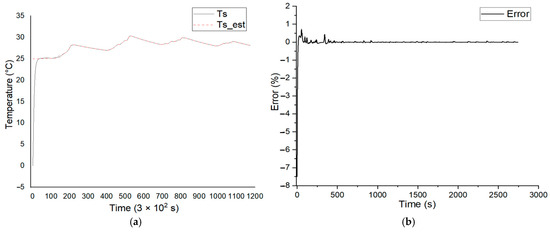

The performance of the adaptive control algorithm was evaluated by comparing the estimated and experiment temperature profiles. The validation process involved running simulations to observe how well the model predictions matched the actual thermal behavior of the battery under various operating conditions.

Figure 7a displays the surface temperature Ts along its estimated counterpart The estimation closely follows the actual temperature after an initial transient phase. This indicates that the control algorithm adapts effectively to thermal changes and maintains accurate surface tracking. Figure 7b shows the percentage error between Ts and , which remains within 0.31% after stabilization. Additionally, the root mean square error (RMSE) and mean absolute error (MAE) were calculated as 0.31 °C and 0.25 °C, respectively.

Figure 7.

(a) Surface Temperature Profile (b) Error.

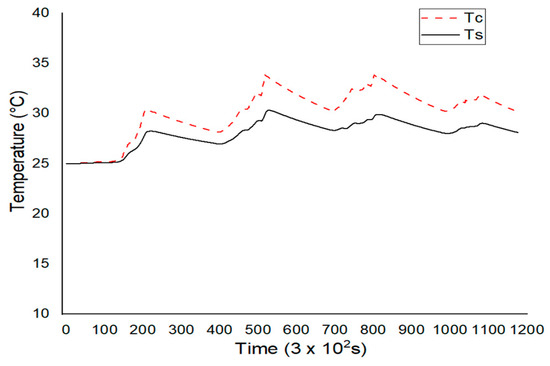

Figure 8 compares the estimated core temperature (Tc) with the surface temperature (Ts). While direct measurement of Tc is not feasible, its dynamic behavior aligns with physical expectations. The estimated Tc exhibits a delayed thermal response and greater amplitude compared to Ts, which is consistent with internal heat accumulation during high current discharge periods. These trends validate the thermal inertia captured by the model and further support its physical consistency. This inertia is expected due to the higher heat capacity of the battery core.

Figure 8.

Estimate Core Temperature and Surface Temperature.

In summary, the adaptive control algorithm not only achieves an accurate real-time estimation of Ts but also predicts the internal thermal behavior () logically. The maximum core temperature reached 34.8 °C, remaining within the safe thermal range for lithium-ion batteries and reflecting expected thermal inertia.

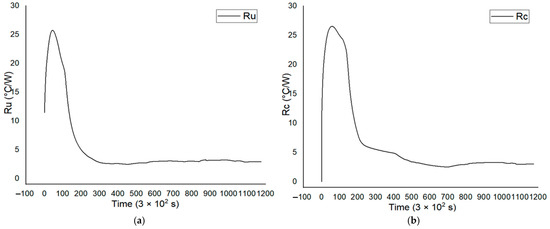

3.3. Thermal Resistance Estimation

The adaptive control system’s effectiveness in estimating thermal resistances Ru and Rc was evaluated through two case studies, each focusing on different aspects of the battery’s thermal dynamics. These estimations were performed by conditioning the parameters within the control algorithm. As shown in Figure 9, the adaptive control algorithm’s effectiveness in estimating thermal resistances Ru (surface to ambient) and Rc (core to surface).

Figure 9.

Thermal Resistance Estimation (a) Estimating Ru (b) Estimating Rc.

The effectiveness of the adaptive control algorithm in estimating the thermal resistances Ru (surface to ambient) and Rc (core to surface) is illustrated in Figure 9a,b.

- Estimation of Ru

Figure 9a shows that rapidly decreases from ~25 °C/W to ~3 °C/W within the early stage of operation. This steep decline indicates the system’s ability to adapt to environmental thermal fluctuations (e.g., greenhouse ambient changes), stabilizing the heat transfer at the surface level.

- Estimation of Rc

Figure 9b reveals a similar sharp drop in Rc, which stabilizes around 2 °C/W. This behavior reflects internal heat regulation from the battery core, influenced by charging and discharging cycles.

- Practical implications

The rapid convergence and stability of and directly contribute to maintaining stable surface and core temperatures (Ts, Tc). This correlation validates the adaptive model’s effectiveness in capturing thermal dynamics and ensuring operational safety in second-life battery applications.

- Seasonal Variation of Thermal Resistance

As shown in Table 3, the long-term monitoring of thermal resistance across different months revealed seasonal trends that complement the short-term analysis. During cooler months (September–December), thermal resistance stabilized more rapidly after the initial transient phase, indicating efficient heat dissipation under lower ambient temperatures. Conversely, in warmer months such as May and June, the resistance curves showed slower stabilization and slightly higher steady-state values (~5.1–5.2 °C/W), reflecting increased thermal stress due to elevated environmental temperatures and load demands.

Table 3.

Average Steady-State Thermal Resistance.

The majority of steady-state values ranged between 2.9–3.8 °C/W, suggesting a consistent dissipation capacity across seasons. Importantly, no month exceeded 6 °C/W, confirming that the reused battery system maintained safe thermal performance under varying operating conditions. These seasonal observations highlight the adaptability of the adaptive control model to real greenhouse environments, supporting its long-term feasibility for second-life battery deployment.

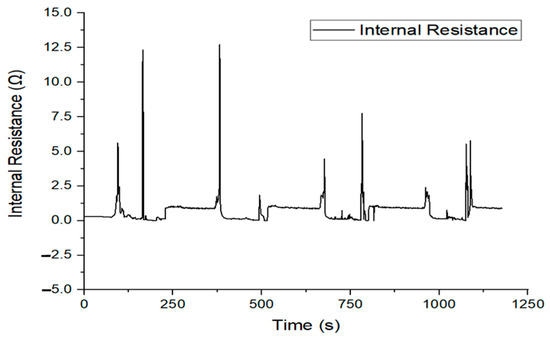

3.4. Internal Resistance Estimation

The internal resistance (Rint) of the second-life lithium-ion polymer battery was determined using the voltage drop method under dynamic load conditions representative of greenhouse operations. Figure 10 shows the variation of Rint over a measurement period.

Figure 10.

Internal Resistance.

As shown in Figure 10, the results indicate that Rint remained relatively stable at around 1.0–1.2 Ω during normal operation, with occasional sharp spikes reaching up to ~12 Ω. These transient peaks were typically associated with abrupt load changes, such as the activation of high-current devices (e.g., ventilation motors or irrigation pumps). Such spikes are likely due to short term electrochemical polarization and measurement response delay during rapid current transitions.

However, the presence of repeated transient peaks highlights the importance of monitoring Rint in real time, as persistent or increasing spike magnitude over time could signal the early stages of contact degradation, electrolyte drying, or internal connection faults.

From an operational perspective, maintaining Rint close to its nominal range is critical for minimizing resistive heating, reducing energy loss, and prolonging battery life. The integration of Rint monitoring into the adaptive control strategy can enable predictive maintenance, allowing for timely intervention before performance deterioration impacts the greenhouse’s energy supply reliability.

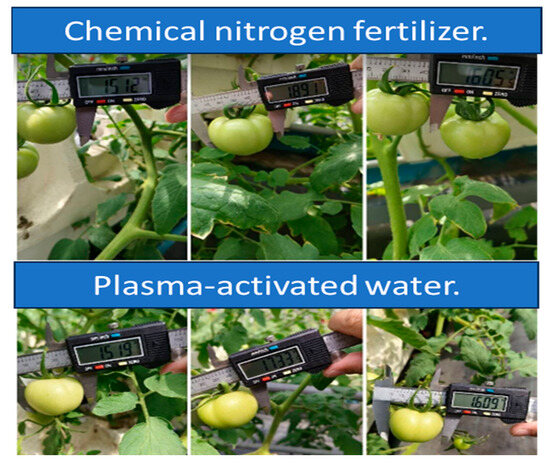

3.5. Crop Growth and Nutrient Response Under PAW Treatment

An in-depth evaluation of PAW technology was conducted for beefsteak tomato cultivation, aiming to reduce chemical nitrogen fertilizer use while maintaining crop yield and quality.

In terms of nutrient response, the system successfully reduced the use of chemical nitrogen fertilizers by 31.2% (as shown in Table 4). The concentration of nitrate-nitrogen (NO3−-N) in the plasma-activated water was confirmed by third-party testing to reach 134 mg/L within one hour. Although the average pH of the plasma-activated water stock solution was 3.04, dilution prior to application brought the solution close to neutral, and germination tests confirmed that it had no adverse effects on crop growth. To address concerns about nitrite (NO2−), samples tested by Eurofins Food Testing Company showed no detectable levels in tomatoes.

Table 4.

Nutrient Ratio in Plasma-Activated Water Fertilizer for Beef Tomato.

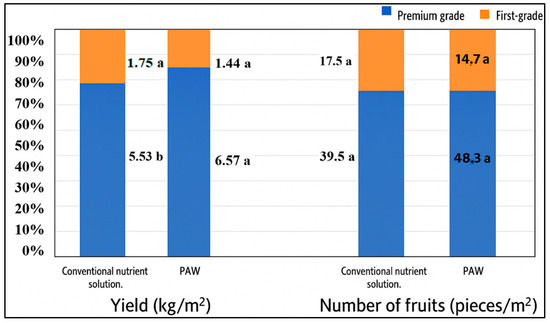

Leaf nutrient content analysis at the end of the tomato growth cycle revealed differences compared to the conventional nutrient solution group. As shown in Figure 11, the PAW-treated group exhibited a leaf nitrogen content of 1.83% (versus 2.28% in the control group) and a potassium content of 1.66% (versus 2.17% in the control group), both significantly lower than the control and below Japanese adequacy standards. However, the magnesium content in the PAW-treated group was 0.59%, significantly higher than the 0.37% in the control group, meeting Japanese adequacy standards. Phosphorus content (0.53% to 0.57%) and calcium content (3.02% to 3.35%) showed no significant differences between groups, with phosphorus levels slightly elevated and calcium levels meeting adequacy standards.

Figure 11.

Trial Scale Production of 700 Beefsteak Tomato Plants Using Fertigation (Nitrogen Fertilizer) and Plasma-Activated Water via Drip Irrigation (October 2024).

Statistical analysis of harvest results revealed that beefsteak tomatoes under controlled facility conditions achieved a total yield of 7.8 kg/m2. Regarding growth traits, measurements of plant height, stem diameter, leaf length, and leaf width taken in the second month after transplanting showed no statistically significant differences between the conventional nutrient solution group and the PAW treatment group, indicating that PAW had no adverse effects on vegetative growth, as shown in Figure 12.

Figure 12.

Effects of different tomato grades on fruit yield and fruit number in greenhouse grown tomatoes during the 2024 autumn season. Letters (a, b) indicate statistical differences between treatments.

4. Conclusions

This study evaluated the integration of an adaptive battery thermal management framework with a greenhouse microgrid, combining real-world operational data, laboratory simulations, and field trials with plasma-activated water (PAW) technology. The key findings are summarized as follows:

- System Performance

The developed experimental and simulation framework successfully integrated real-time data acquisition from a greenhouse microgrid into a laboratory-based adaptive control model. This integration enabled the simultaneous monitoring of electrical and thermal parameters, providing reliable insights into the battery’s operational behavior under dynamic agricultural energy demands.

- Thermal and Internal Resistance Analysis

The adaptive control algorithm accurately estimated surface temperature (Ts) and core temperature (Tc), achieving a root mean square error (RMSE) of 0.31 °C, a mean absolute error (MAE) of 0.25 °C, and a percentage error of 0.31%. Thermal resistance values converged to approximately Ru ≈ 3.00 °C/W (surface to ambient) and Rc ≈ 2.00 °C/W (core to surface), demonstrating stability under fluctuating loads. Internal resistance (Rint) maintained a baseline of ~1.0–1.2 Ω, with peaks up to 12 Ω during load transitions, confirming the need for continuous monitoring to prevent performance degradation and ensure safety in second-life battery applications.

- Plasma-Activated Water (PAW) Impact

The use of PAW enabled a 31.2% reduction in chemical nitrogen fertilizer usage without decreasing the total nitrogen available to plants. The NO3−-N concentration in PAW reached 134 mg/L, with an initial pH of 3.04 neutralized before application, ensuring no negative effects on germination or plant growth. Leaf nutrient analysis showed reduced nitrogen (1.83% vs. 2.28%) and potassium (1.66% vs. 2.17%) content compared to the control, but increased magnesium content (0.59% vs. 0.37%), meeting Japanese adequacy standards. Phosphorus and calcium levels showed no significant differences. The total yield reached 7.8 kg/m2, with fruit quality comparable between the PAW-treated and control groups.

Overall, this work demonstrates the potential feasibility of combining adaptive battery thermal modeling with agricultural PAW applications to enhance resource efficiency. However, the scalability and broader applicability of this approach require further empirical validation.

5. Future Work

While the results of this study demonstrate the potential of integrating adaptive battery thermal management with plasma-activated water (PAW) technology to support sustainable greenhouse operations, several directions remain open for further research. First, the present work was conducted within a single greenhouse environment with short-term monitoring. Future studies should extend the evaluation to multiple greenhouse types and climatic conditions to validate the robustness of the proposed system under diverse operational settings.

Second, crop trials should be expanded to include multiple species, soil conditions, and varying irrigation strategies in order to validate the generalizability of the PAW-based fertilizer reduction outcomes. Broader trials will also enable a more comprehensive evaluation of input efficiency and yield stability.

Finally, scalability and system-level integration remain important directions for further investigation. Future work should explore the feasibility of deploying this combined framework at larger commercial greenhouse facilities, incorporating real-time control with grid-connected and off-grid renewable energy systems. This would further strengthen the practical applicability and sustainability claims of integrating energy, water, and fertilizer optimization strategies.

Author Contributions

Conceptualization, M.B.A.; methodology, C.-Y.T. and Y.F.R.; software, Y.F.R.; validation, M.B.A., Y.F.R. and C.-Y.T.; data curation, A.A.F.; writing—original draft preparation, M.B.A., Y.F.R. and C.-Y.T.; writing—review and editing, C.-H.W. and W.-J.C.; visualization, A.A.F.; supervision, W.-Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

Special thanks to all those who contributed to this research. Their support, insights, and feedback were invaluable in shaping the project. We also appreciate the assistance provided by colleagues, mentors, and institutions who supported us throughout the study.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PAW | Plasma-Activated Water |

| Rint | Internal Resistance |

| Rth | Thermal Resistance |

| SoC | State of Charge |

| Ts | Surface Temperature |

| Tc | Core Temperature |

References

- Hu, A.H.; Chen, C.-H.; Huang, L.H.; Chung, M.-H.; Lan, Y.-C.; Chen, Z. Environmental Impact and Carbon Footprint Assessment of Taiwanese Agricultural Products: A Case Study on Taiwanese Dongshan Tea. Energies 2019, 12, 138. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, K.; Guo, K.; Liu, L.; Zhang, T.; Xu, M.; Yan, X.; Gao, X. Multifactor effects on the N2O emissions and yield of potato fields based on the DNDC model. Environ. Sci. Pollut. Res. 2022, 29, 25448–25460. [Google Scholar] [CrossRef]

- Ahmed, D.; Maraz, K.M. Revolutionizing energy storage: Overcoming challenges and unleashing the potential of next generation Lithium-ion battery technology. Mater. Eng. Res. 2023, 5, 265–278. [Google Scholar] [CrossRef]

- Chaoui, H.; Gualous, H. Adaptive State of Charge Estimation of Lithium-Ion Batteries with Parameter and Thermal Uncertainties. IEEE Trans. Control Syst. Technol. 2017, 25, 752–759. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, M.; Zhang, B.; Wang, X.; Liu, D.; Wang, J.; Bai, P.; Liu, C.; Sun, Y.; Zhu, Y. Review of Lithium-Ion Battery Fault Features, Diagnosis Methods, and Diagnosis Procedures. IEEE Internet Things J. 2023, 11, 18936–18950. [Google Scholar] [CrossRef]

- Zhang, N.; Deng, T.; Zhang, S.; Wang, C.; Chen, L.; Wang, C.; Fan, X. Critical Review on Low-Temperature Li-Ion/Metal Batteries. Adv. Mater. 2022, 34, 2107899. [Google Scholar] [CrossRef] [PubMed]

- Shahjalal, M.; Shams, T.; Islam, E.; Alam, W.; Modak, M.; Bin Hossain, S.; Ramadesigan, V.; Ahmed, R.; Ahmed, H.; Iqbal, A. A review of thermal management for Li-ion batteries: Prospects, challenges, and issues. J. Energy Storage 2021, 39, 102518. [Google Scholar] [CrossRef]

- Wankhade, S. Review on Role of Energy Storage System in Integration of Renewable Energy Sources in Microgrid. No. October, pp. 1–8. 2023. Available online: https://www.researchgate.net/publication/374757652 (accessed on 4 August 2025).

- Dey, S.; Biron, Z.A.; Tatipamula, S.; Das, N.; Mohon, S.; Ayalew, B.; Pisu, P. Model-based real-time thermal fault diagnosis of Lithium-ion batteries. Control Eng. Pract. 2016, 56, 37–48. [Google Scholar] [CrossRef]

- Mathew, A.; van Ekeren, W.; Andersson, R.; Lacey, M.J.; Heiskanen, S.K.; Younesi, R.; Brandell, D. Limitations of Polyacrylic Acid Binders When Employed in Thick LNMO Li-ion Battery Electrodes. J. Electrochem. Soc. 2024, 171, 020531. [Google Scholar] [CrossRef]

- Chiang, Y.-H.; Wu, Y.-S.; Huang, C.-Y. Apparatus for Estimating Battery State of Health. U.S. Patent 2011/0148424 A1, 23 June 2011. [Google Scholar]

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ali, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Munoz-Condes, P.; Gomez-Parra, M.; Sancho, C.; Andres, M.A.G.S.; Gonzalez-Fernandez, F.J.; Carpio, J.; Guirado, R. On Condition Maintenance Based on the Impedance Measurement for Traction Batteries: Development and Industrial Implementation. IEEE Trans. Ind. Electron. 2013, 60, 2750–2759. [Google Scholar] [CrossRef]

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Ralls, A.M.; Leong, K.; Clayton, J.; Fuelling, P.; Mercer, C.; Navarro, V.; Menezes, P.L. The Role of Lithium-Ion Batteries in the Growing Trend of Electric Vehicles. Materials 2023, 16, 6063. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, C.; Hu, X.; Lin, X.; Zhang, Y.; Li, W. An MPC-Based Control Strategy for Electric Vehicle Battery Cooling Considering Energy Saving and Battery Lifespan. IEEE Trans. Veh. Technol. 2020, 69, 14657–14673. [Google Scholar] [CrossRef]

- Amir, M.; Deshmukh, R.G.; Khalid, H.M.; Said, Z.; Raza, A.; Muyeen, S.; Nizami, A.-S.; Elavarasan, R.M.; Saidur, R.; Sopian, K. Energy storage technologies: An integrated survey of developments, global economical/environmental effects, optimal scheduling model, and sustainable adaption policies. J. Energy Storage 2023, 72, 108694. [Google Scholar] [CrossRef]

- Gao, Y.; Pan, Z.; Sun, J.; Liu, Z.; Wang, J. High-energy batteries: Beyond lithium-ion and their long road to commercialisation. Nano-Micro Lett. 2022, 14, 94. [Google Scholar] [CrossRef]

- Khan, F.N.U.; Rasul, M.G.; Sayem, A.; Mandal, N. Maximizing energy density of lithium-ion batteries for electric vehicles: A critical review. Energy Rep. 2023, 9, 11–21. [Google Scholar] [CrossRef]

- Mekonnen, Y.; Sundararajan, A.; Sarwat, A.I. A review of cathode and anode materials for lithium-ion batteries. In Proceedings of the SoutheastCon 2016, Norfolk, VA, USA, 30 March–3 April 2016; pp. 1–6. [Google Scholar]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, H.; Zhang, G.; Dai, Z.; Wen, Y.; Jiang, L. Cycle life studies of lithium-ion power batteries for electric vehicles: A review. J. Energy Storage 2024, 93, 112231. [Google Scholar] [CrossRef]

- Ghaeminezhad, N.; Ouyang, Q.; Wei, J.; Xue, Y.; Wang, Z. Review on state of charge estimation techniques of lithium-ion batteries: A control-oriented approach. J. Energy Storage 2023, 72, 108707. [Google Scholar] [CrossRef]

- Christensen, J.; Newman, J. Effect of Anode Film Resistance on the Charge/Discharge Capacity of a Lithium-Ion Battery. J. Electrochem. Soc. 2003, 150, A1416. [Google Scholar] [CrossRef]

- Tao, M. Review—Electrochemistry for Sustainable Solar Photovoltaics. ECS J. Solid State Sci. Technol. 2020, 9, 125007. [Google Scholar] [CrossRef]

- Aris, A.M.; Shabani, B. An Experimental Study of a Lithium Ion Cell Operation at Low Temperature Conditions. Energy Procedia 2017, 110, 128–135. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Z.; Xie, Z.; Wang, Y. Parametric Investigation on the Performance of a Battery Thermal Management System with Immersion Cooling. Energies 2022, 15, 2554. [Google Scholar] [CrossRef]

- Sundin, D.W.; Sponholtz, S. Thermal Management of Li-Ion Batteries With Single-Phase Liquid Immersion Cooling. IEEE Open J. Veh. Technol. 2020, 1, 82–92. [Google Scholar] [CrossRef]

- Mahmud, S.; Rahman, M.; Kamruzzaman; Ali, O.; Alam Emon, S.; Khatun, H.; Ali, R. Recent advances in lithium-ion battery materials for improved electrochemical performance: A review. Results Eng. 2022, 15, 100472. [Google Scholar] [CrossRef]

- Larkins, D.B.; Harvey, W. Introductory computational science using MATLAB and image processing. Procedia Comput. Sci. 2012, 1, 913–919. [Google Scholar] [CrossRef][Green Version]

- Zhang, H.; Bai, M.; Wang, X.; Gai, J.; Shu, C.-M.; Roy, N.; Liu, Y. Thermal runaway incidents-a serious cause of concern: An analysis of runaway incidents in China. Process Saf. Environ. Prot. 2021, 155, 277–286. [Google Scholar] [CrossRef]

- Olabi, A.; Maghrabie, H.M.; Adhari, O.H.K.; Sayed, E.T.; Yousef, B.A.; Salameh, T.; Kamil, M.; Abdelkareem, M.A. Battery thermal management systems: Recent progress and challenges. Int. J. Thermofluids 2022, 15, 100171. [Google Scholar] [CrossRef]

- Kim, D.Y.; Lee, B.; Kim, M.; Moon, J.H. Thermal assessment of lithium-ion battery pack system with heat pipe assisted passive cooling using Simulink. Therm. Sci. Eng. Prog. 2023, 46, 102230. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).