Research on Thermal Performance of the Microchannel with Internal Cavities Under Al2O3-Water Nanofluid

Abstract

1. Introduction

2. Experimental Methodology

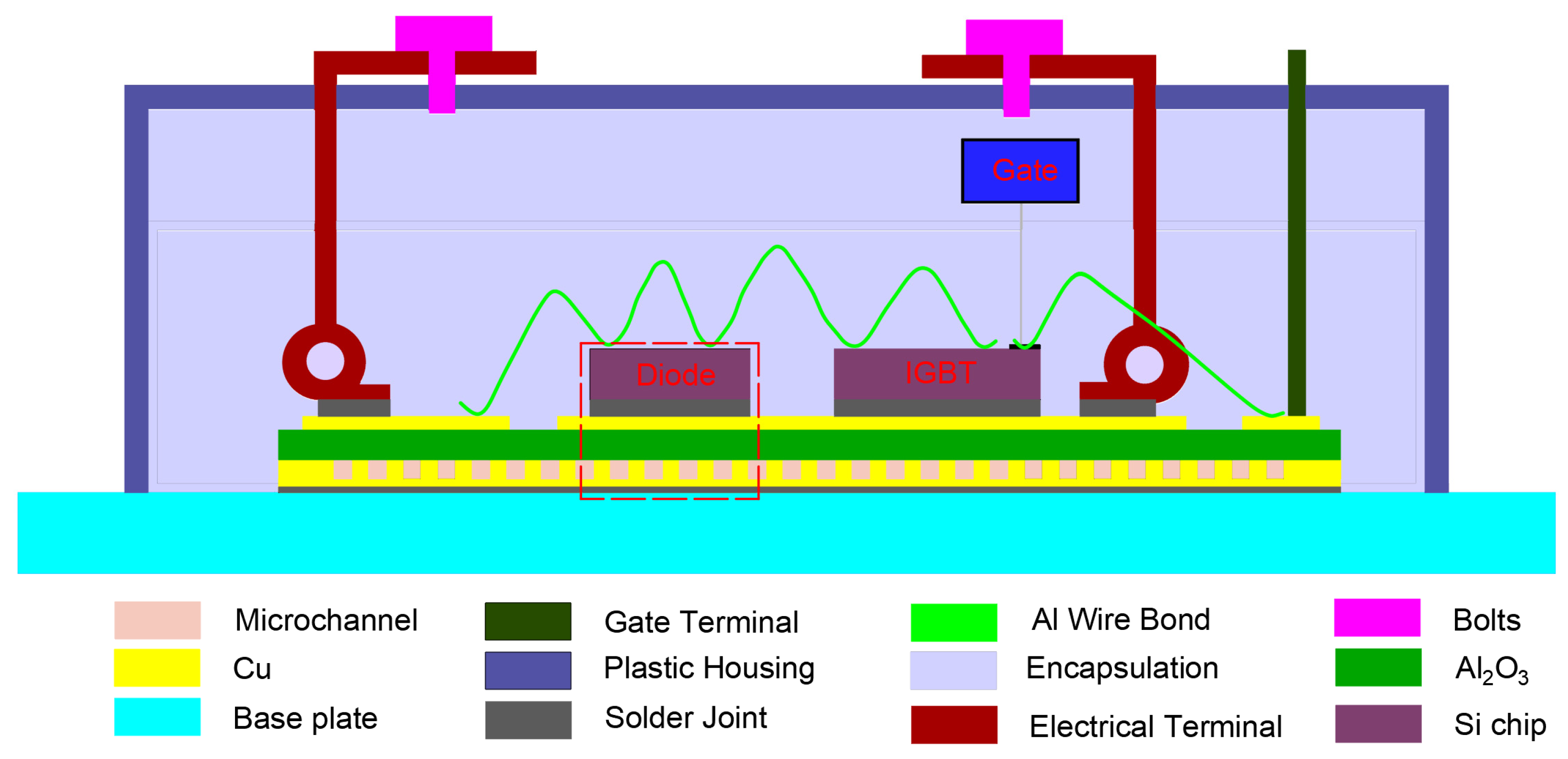

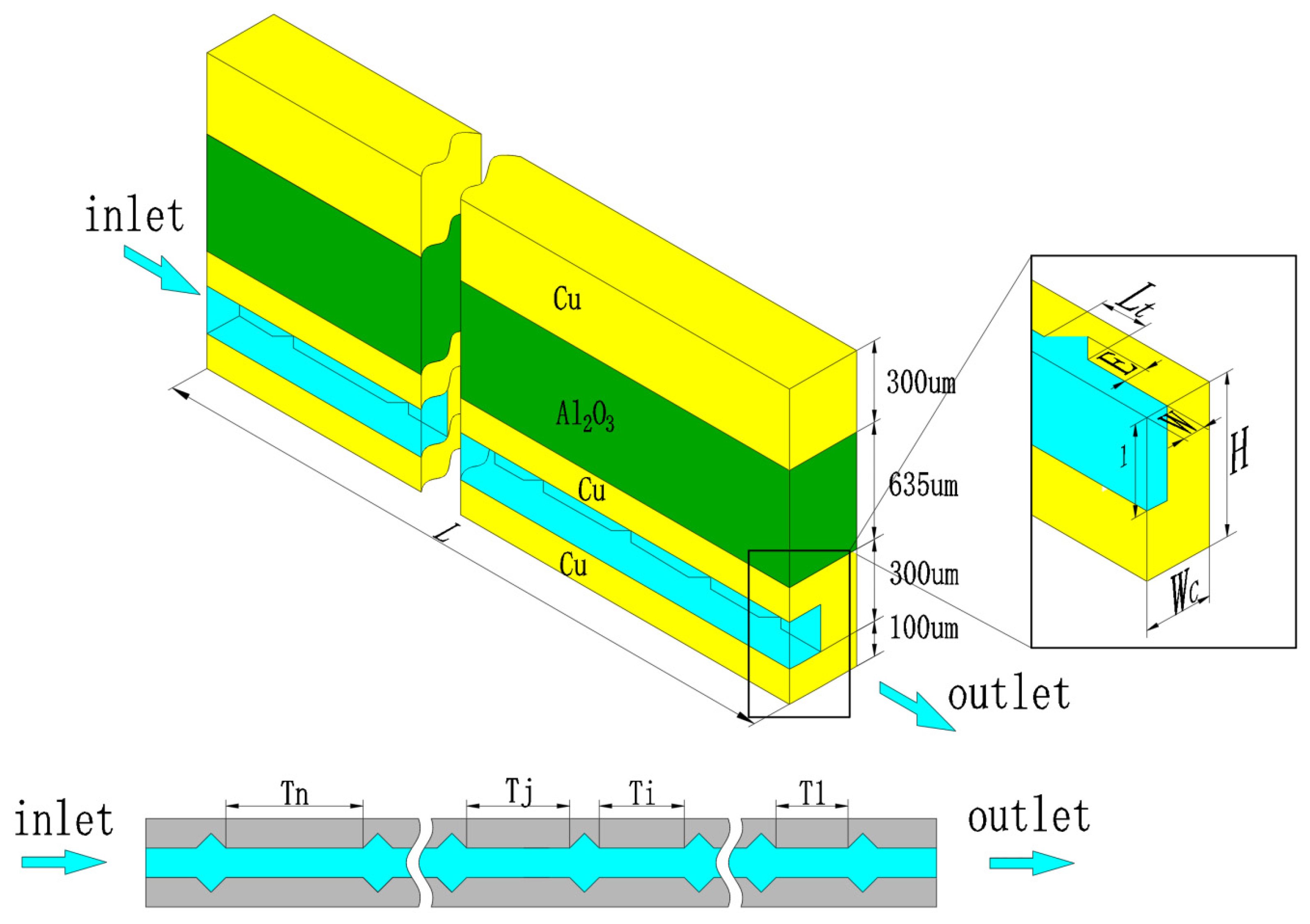

2.1. Geometric Model Establishment

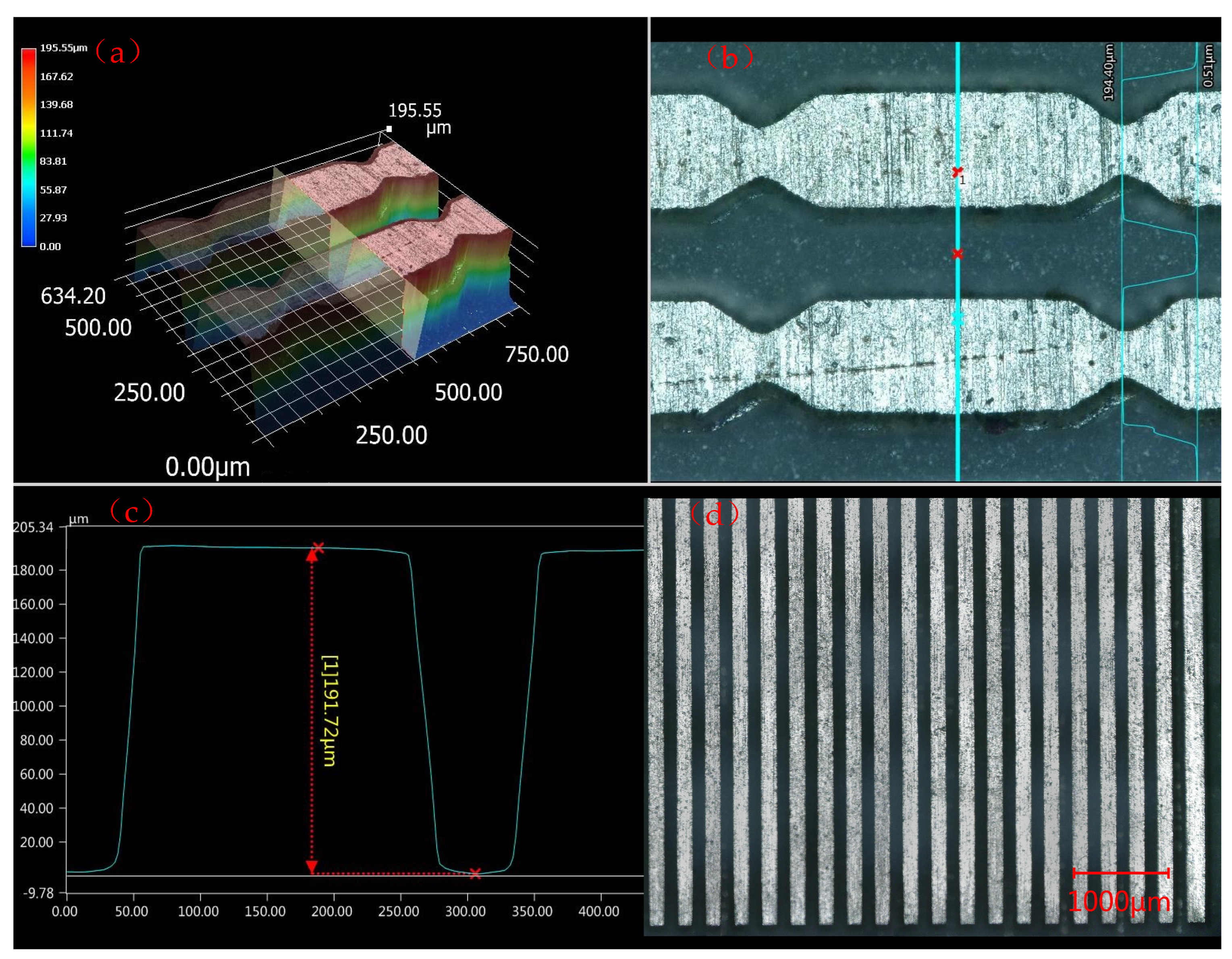

2.2. Microchannel Manufacturing and Nanofluids Preparation

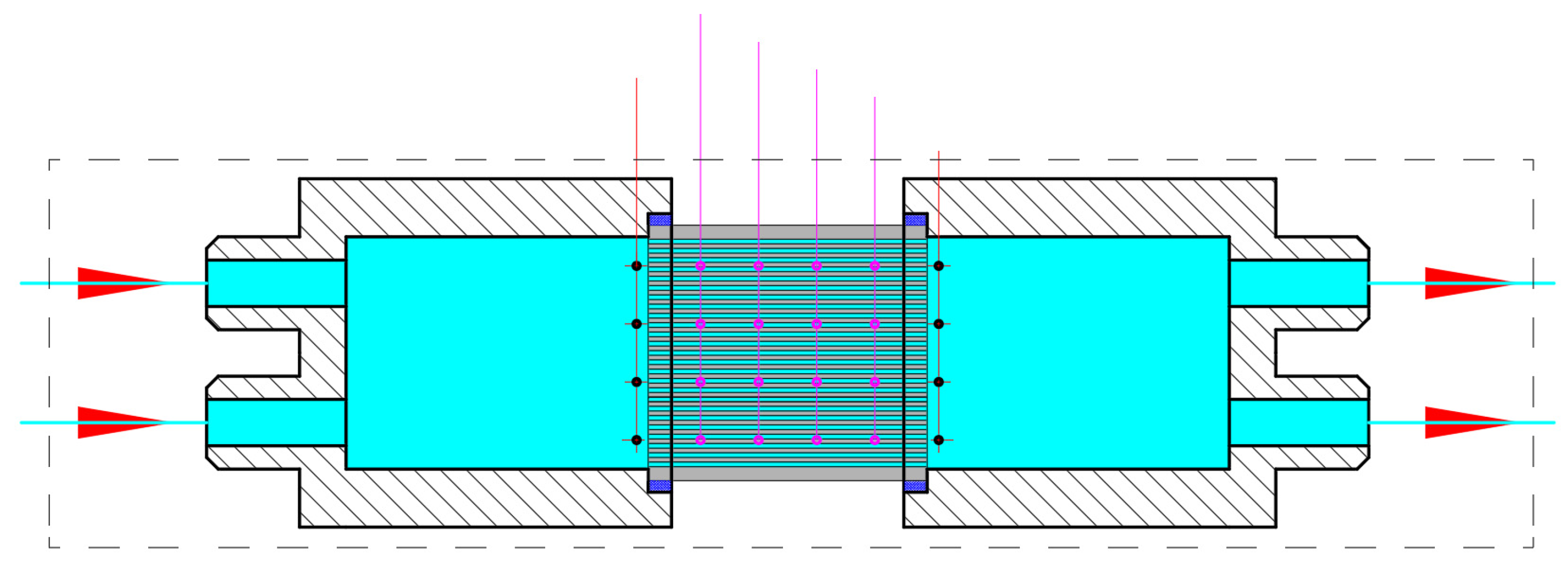

2.3. Testing Systems Setup

3. Numerical Simulation

4. Discussion

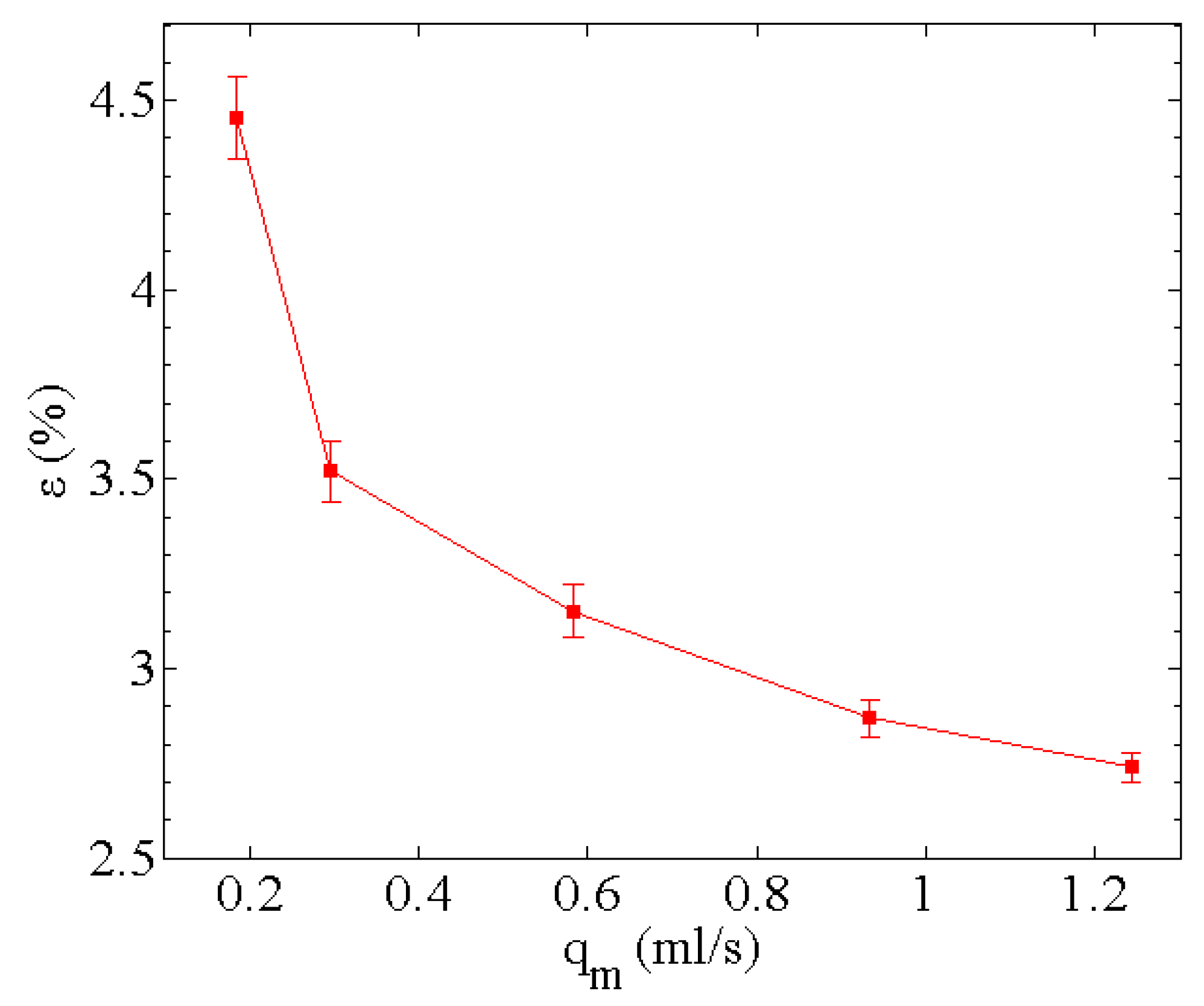

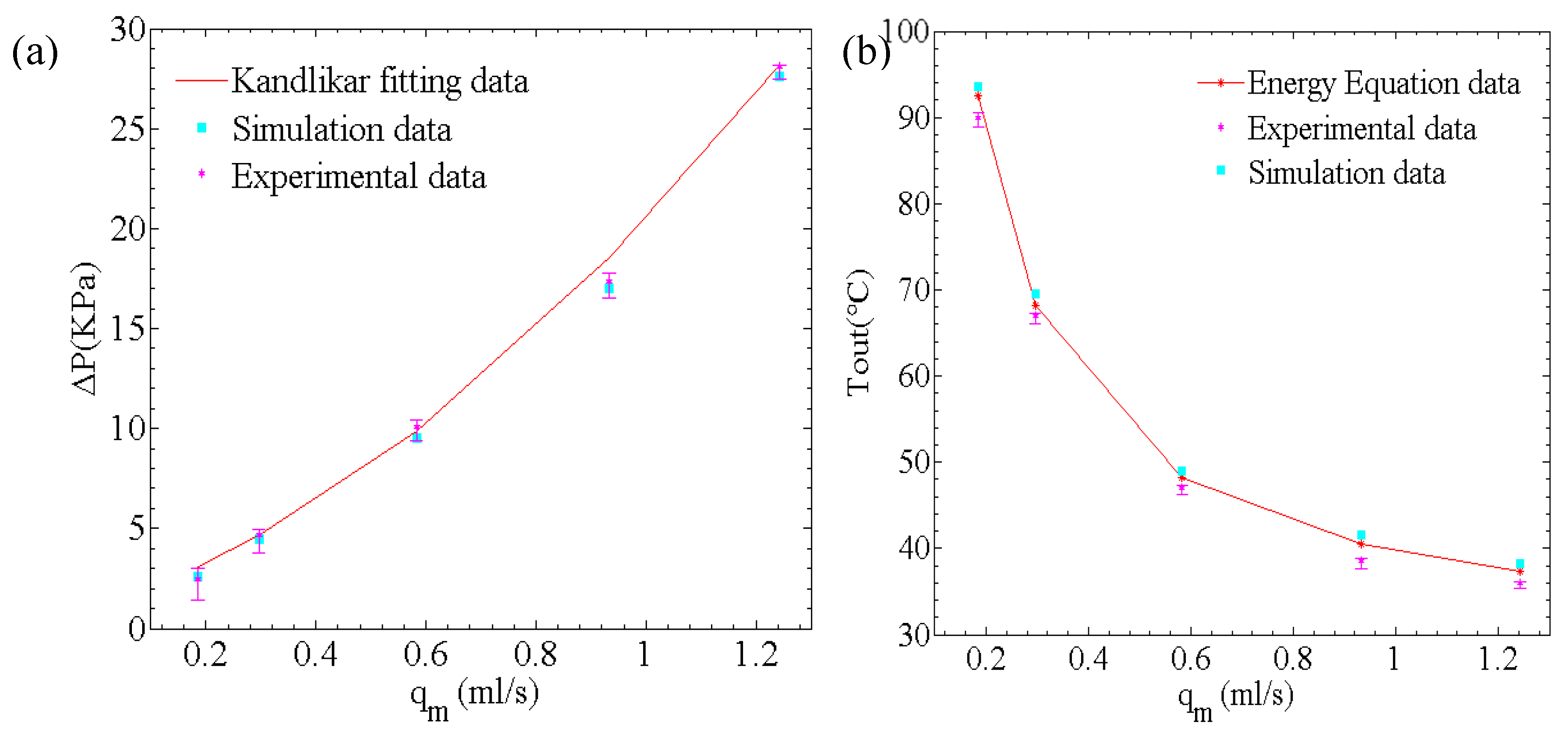

4.1. Data Processing and Thermal Balance Analysis

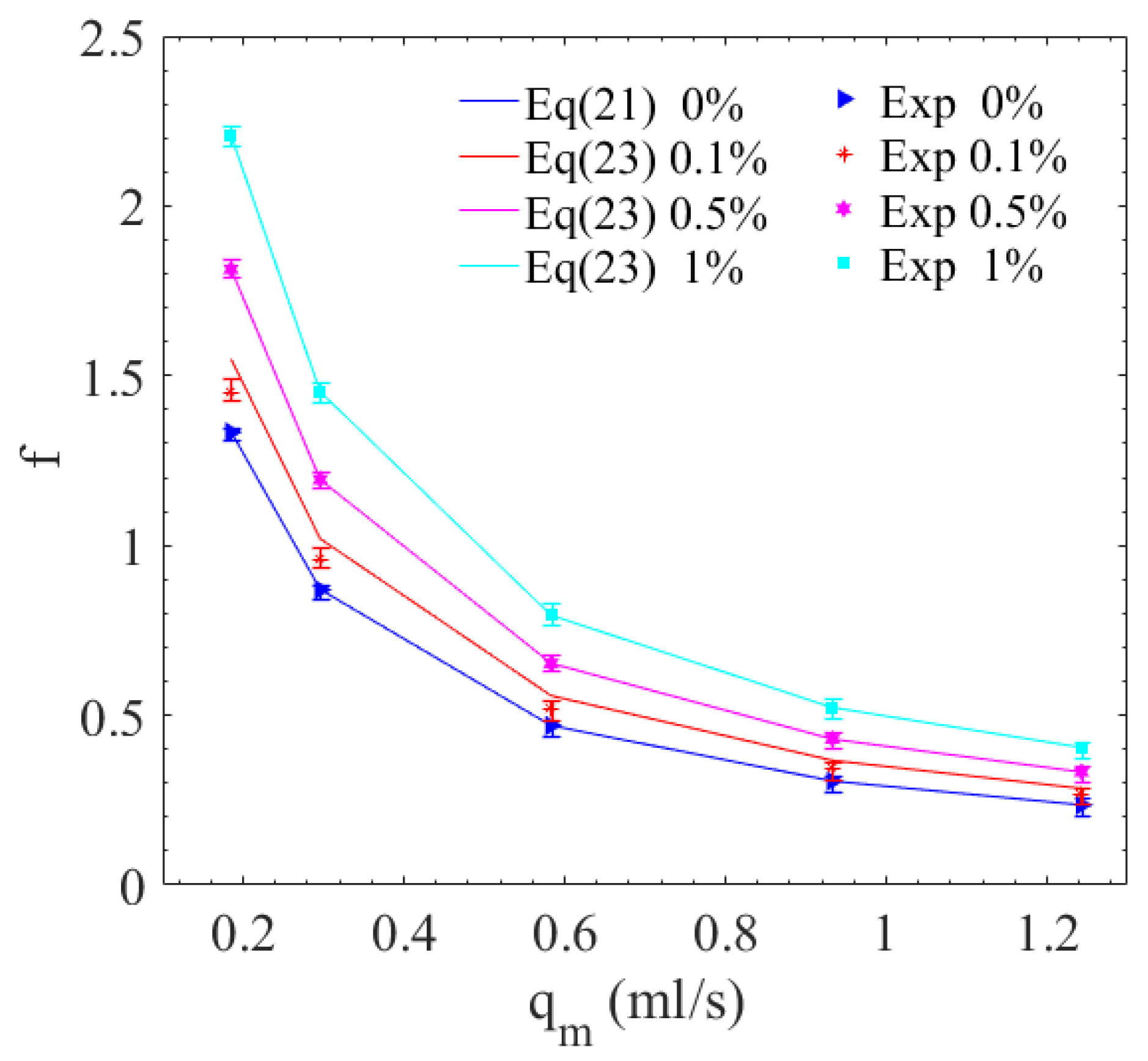

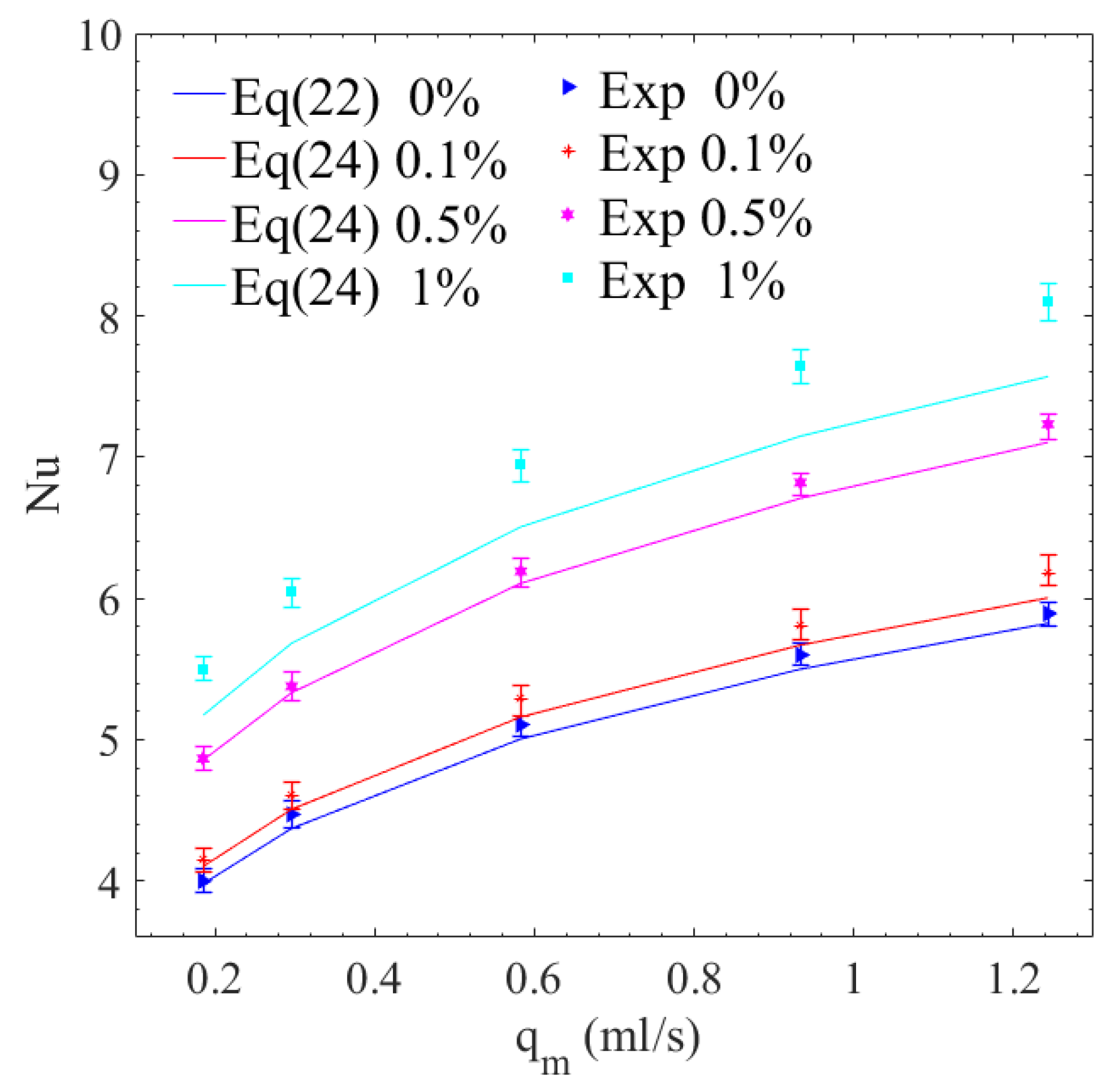

4.2. The Flow and Heat Transfer Characteristics Analysis

5. Conclusions

- By comparing experimental results with numerical simulation data, the reliability of the three-dimensional conjugate heat transfer model in analyzing the flow and heat transfer characteristics of the microchannel was verified. Additionally, the configuration of internal cavities in the microchannel was optimized based on the field synergy principle, and the feasibility and reliability of this optimization strategy were demonstrated.

- Experiments were conducted to explore the feasibility of applying the novel microchannel structure to IGBT devices, providing critical experimental data to support the translation of this optimized design from theoretical research to engineering applications.

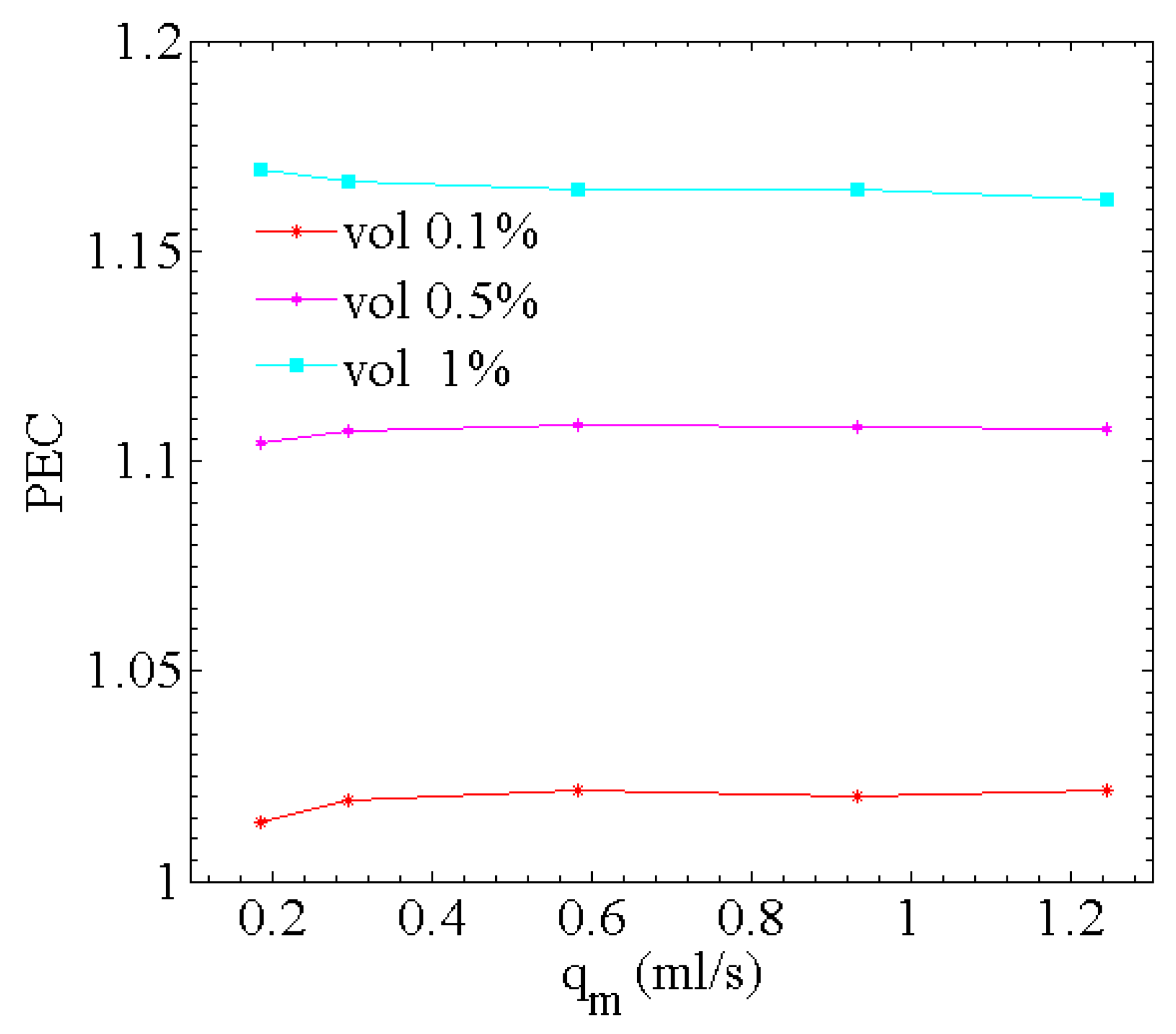

- Based on the optimized microchannel structure, experimental results validated the heat transfer enhancement effect of nanofluids: Under the same microchannel configuration, when the flow rate was 0.6 mL/min and the heat flux of the cooled device was 100 W/cm2, the heat dissipation efficiency was improved by 38% using nanofluids compared to deionized water.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The International Technology Roadmap for Semiconductors (TIRS); Semiconductor Industry Association: Washington, DC, USA, 2006.

- Huang, R.; Wei, G.; Wang, X.; Jiang, B.; Zhu, J.; Chen, J.; Wei, X.; Dai, H. Revealing the low-temperature aging mechanisms of the whole life cycle for lithium-ion batteries (nickel-cobalt-aluminum vs. graphite). J. Energy Chem. 2025, 106, 31–43. [Google Scholar] [CrossRef]

- Du, L.; Hu, W. An overview of heat transfer enhancement methods in microchannel heat sinks. Chem. Eng. Sci. 2023, 280, 119081. [Google Scholar] [CrossRef]

- Tang, X.; Huang, H.; Zhong, X.; Wang, K.; Li, F.; Zhou, Y.; Dai, H. On-Line Parameter Identification and SOC Estimation for Lithium-Ion Batteries Based on Improved Sage–Husa Adaptive EKF. Energies 2024, 17, 5722. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, X.; Zhou, Y.; Huang, H.; Dai, H. Experimental and Modeling Analysis of Thermal Runaway for LiNi0.5Mn0.3Co0.2O2/Graphite Pouch Cell Triggered by Surface Heating. Energies 2024, 17, 826. [Google Scholar] [CrossRef]

- Ben Hamida, M.B. Thermal management of square light emitting diode arrays: Modeling and parametric analysis. Multidiscip. Model. Mater. Struct. 2024, 20, 363–383. [Google Scholar] [CrossRef]

- Hamida, M.; Hatami, M. Optimization of fins arrangements for the square light emitting diode (LED) cooling through nanofluid-filled microchannel. Sci. Rep. 2021, 11, 12610. [Google Scholar] [CrossRef]

- Ben Hamida, M.B.; Almeshaal, M.A.; Hajlaoui, K.; Rothan, Y.A. A three-dimensional thermal management study for cooling a square Light Edding Diode. Case Stud. Therm. Eng. 2021, 27, 101223. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, F.W. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Dong, W.; Zhang, X.; Liu, B.; Wang, B.; Fang, Y. Research progress on passive enhanced heat transfer technology in microchannel heat sink. Int. J. Heat Mass Transf. 2024, 220, 125001. [Google Scholar] [CrossRef]

- Zhu, Q.; Jin, Y.; Chen, J.; Su, R.; Zhu, F.; Li, H.; Wan, J.; Zhang, H.; Sun, H.; Cui, Y.; et al. Computational study of rib shape and configuration for heat transfer and fluid flow characteristics of microchannel heat sinks with fan-shaped cavities. Appl. Therm. Eng. 2021, 195, 117171. [Google Scholar] [CrossRef]

- Derakhshanpour, K.; Kamali, R.; Eslami, M. Effect of rib shape and fillet radius on thermal-hydrodynamic performance of microchannel heat sinks: A CFD study. Int. Commun. Heat Mass Transf. 2020, 119, 104928. [Google Scholar] [CrossRef]

- Narendran, G.; Mallikarjuna, B.; Nagesha, B.K.; Gnanasekaran, N. Experimental investigation on additive manufactured single and curved double layered microchannel heat sink with nanofluids. Heat Mass Transf. 2023, 59, 1311–1332. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, L.; Zhang, X.; Xu, H.; Zhang, H.; Zhou, S.; Cao, Y. Thermohydraulic performance of the microchannel heat sinks with three types of double-layered staggered grooves. Int. J. Therm. Sci. 2024, 201, 109032. [Google Scholar] [CrossRef]

- Mezzanzanica, G.; Français, O.; Mariani, S. Surface Acoustic Wave-Based Microfluidic Device for Microparticles Manipulation: Effects of Microchannel Elasticity on the Device Performance. Micromachines 2023, 14, 1799. [Google Scholar] [CrossRef]

- Tian, Z.; Huang, Z.; Zhou, Y.; Cao, Z.; Gao, W. Design and experimental study on wave-type microchannel cooling plates for marine large-capacity battery thermal management. Appl. Therm. Eng. 2024, 236, 121571. [Google Scholar] [CrossRef]

- Zhang, X.; Ji, Z.; Wang, J.; Lv, X. Research progress on structural optimization design of microchannel heat sinks applied to electronic devices. Appl. Therm. Eng. 2023, 235, 121294. [Google Scholar] [CrossRef]

- Feng, Z.; Hu, Z.; Lan, Y.; Huang, Z.; Zhang, J. Effects of geometric parameters of circular pin-fins on fluid flow and heat transfer in an interrupted microchannel heat sink. Int. J. Therm. Sci. 2021, 165, 106956. [Google Scholar] [CrossRef]

- Foong, A.J.L.; Ramesh, N.; Chandratilleke, T.T. Laminar convective heat transfer in a microchannel with internal longitudinal fins. Int. J. Therm. Sci. 2009, 48, 1908–1913. [Google Scholar] [CrossRef]

- Shen, H.; Wang, C.; Xie, G. A parametric study on thermal performance of microchannel heat sinks with internally vertical bifurcations in laminar liquid flow. Int. J. Heat Mass Transf. 2018, 117, 487–497. [Google Scholar] [CrossRef]

- Chakraborty, R.A.S. Effect of micro-structures in a microchannel heat sink—A comprehensive study. Int. J. Heat Mass Transf. 2020, 154, 119617. [Google Scholar]

- Jung, S.Y.; Park, J.H.; Lee, S.J.; Park, H. Heat transfer and flow characteristics of forced convection in PDMS microchannel heat sink. Exp. Therm. Fluid Sci. 2019, 109, 109904. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Y.; Li, J.; Shi, D.; Xin, G. Flow and heat transfer characteristics of manifold microchannels with different microchannel arrangements. Therm. Sci. Eng. Prog. 2025, 59, 103354. [Google Scholar] [CrossRef]

- Xia, G.D.; Chai, L.; Wang, H.; Zhou, M.; Cui, Z. Optimum thermal design of microchannel heat sink with triangular reentrant cavities. Appl. Therm. Eng. 2011, 31, 1208–1219. [Google Scholar] [CrossRef]

- Xia, G.; Chai, L.; Zhou, M.; Wang, H. Effects of structural parameters on fluid flow and heat transfer in a microchannel with aligned fan-shaped reentrant cavities. Int. J. Heat Mass Transf. 2011, 50, 411–419. [Google Scholar] [CrossRef]

- Xia, G.D.; Zhai, Y.; Cui, Z. Numerical investigation of thermal enhancement in a micro heat sink with fan-shaped reentrant cavities and internal ribs. Appl. Therm. Eng. 2013, 58, 52–60. [Google Scholar] [CrossRef]

- Zhai, Y.L.; Xia, G.D.; Liu, X.F.; Li, Y.F. Heat transfer in the microchannels with fan-shaped reentrant cavities and different ribs based on field synergy principle and entropy generation analysis. Int. J. Heat Mass Transf. 2014, 68, 224–233. [Google Scholar] [CrossRef]

- Bi, C.; Tang, G.H.; Tao, W.Q. Heat transfer enhancement in mini-channel heat sinks with dimples and cylindrical grooves. Appl. Therm. Eng. 2013, 55, 121–132. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing thermal conductivity of fluids with nanoparticles. In Proceedings of the ASME International Mechanical Engineering Congress & Exposition, San Francisco, CA, USA, 12–17 November 1995. [Google Scholar]

- Xuan, Y.; Roetzel, W. Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Investigation on Convective Heat Transfer and Flow Features of Nanofluids. J. Heat Transf. 2003, 125, 151–155. [Google Scholar] [CrossRef]

- Ho, C.J.; Wei, L.C.; Li, Z.W. An experimental investigation of forced convective cooling performance of a microchannel heat sink with Al2O3/water nanofluid. Appl. Therm. Eng. 2010, 30, 96–103. [Google Scholar] [CrossRef]

- Ho, C.J.; Chen, W.C. An experimental study on thermal performance of Al2O3/water nanofluid in a minichannel heat sink. Appl. Therm. Eng. 2013, 50, 516–522. [Google Scholar] [CrossRef]

- Wang, X.; An, B.; Xu, J. Optimal geometric structure for nanofluid-cooled microchannel heat sink under various constraint conditions. Energy Convers. Manag. 2013, 65, 528–538. [Google Scholar] [CrossRef]

- Wang, X.; An, B.; Lin, L.; Lee, D. Inverse geometric optimization for geometry of nanofluid-cooled microchannel heat sink. Appl. Therm. Eng. 2013, 55, 87–94. [Google Scholar] [CrossRef]

- Bianco, V.; Scarpa, F.; Tagliafico, L.A. Numerical analysis of the Al2O3-water nanofluid forced laminar convection in an asymmetric heated channel for application in flat plate PV/T collector. Renew. Energy 2018, 116, 9–21. [Google Scholar] [CrossRef]

- Bianco, V.; Marchitto, A.; Scarpa, F.; Tagliafico, L.A. Numerical investigation on the forced laminar convection heat transfer of Al2O3-water nanofluid within a three-dimensional asymmetric heated channel. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 1132–1152. [Google Scholar] [CrossRef]

- Marseglia, G.; De Giorgi, M.G.; Pontes, P.; Solipa, R.; Souza, R.R.; Moreira, A.L.N.; Moita, A.S. Enhancement of microchannel heat sink heat transfer: Comparison between different heat transfer enhancement strategies. Exp. Therm. Fluid Sci. 2024, 150, 111052. [Google Scholar] [CrossRef]

- Omri, M.; Smaoui, H.; Frechette, L.; Kolsi, L. A new microchannel heat exchanger configuration using CNT-nanofluid and allowing uniform temperature on the active wall. Case Stud. Therm. Eng. 2022, 32, 101866. [Google Scholar] [CrossRef]

- Jamshidmofid, M.; Abbassi, A.; Bahiraei, M. Efficacy of a novel graphene quantum dots nanofluid in a microchannel heat exchanger. Appl. Therm. Eng. 2021, 189, 116673. [Google Scholar] [CrossRef]

- Vinoth, R.; Sachuthananthan, B. Flow and heat transfer behavior of hybrid nanofluid through microchannel with two different channels. Int. Commun. Heat Mass Transf. 2021, 123, 105194. [Google Scholar] [CrossRef]

- Ajeeb, A.W.; Oliveira, M.S.A.; Martins, N.; Murshed, S.M.S. Forced convection heat transfer of non-Newtonian MWCNTs nanofluids in microchannels under laminar flow. Int. Commun. Heat Mass Transf. 2021, 127, 105495. [Google Scholar] [CrossRef]

- Wang, Y.; Li, W.; Qi, C.; Yu, J. Thermal management of electronic components based on hierarchical microchannels and nanofluids. Therm. Sci. Eng. Prog. 2023, 42, 101910. [Google Scholar] [CrossRef]

- Massoudi, M.D.; Hamida, M.B.B. Enhancement of MHD radiative CNT-50% water + 50% ethylene glycol nanoliquid performance in cooling an electronic heat sink featuring wavy fins. Waves Random Complex Media 2022, 16, 1–26. [Google Scholar] [CrossRef]

- Ben Hamida, M.B.; Hatami, M. Investigation of heated fins geometries on the heat transfer of a channel filled by hybrid nanofluids under the electric field. Case Stud. Therm. Eng. 2021, 28, 101450. [Google Scholar] [CrossRef]

- Ben Hamida, M.B.; Charrada, K.; Almeshaal, M.A.; Chamkha, A. A three-dimensional thermal analysis and optimization of square light edding diode subcomponents. Int. Commun. Heat Mass Transf. 2021, 120, 105016. [Google Scholar] [CrossRef]

- Li, F.; Zhu, W.; He, H. Numerical optimization on microchannel flow and heat transfer performance based on field synergy principle. Int. J. Heat Mass Transf. 2019, 130, 375–385. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Li, D.Y.; Wang, B.X. A novel concept for convective heat transfer enhancement. Int. J. Heat Mass Transf. 1998, 41, 2221–2225. [Google Scholar] [CrossRef]

- Tao, W.Q.; He, Y.L.; Wang, Q.W.; Qu, Z.G.; Song, F.Q. A unified analysis on enhancing single phase convective heat transfer with field synergy principle. Int. J. Heat Mass Transf. 2002, 45, 4871–4879. [Google Scholar] [CrossRef]

- Tao, W.Q.; He, Y.L.; Chen, L. A comprehensive review and comparison on heatline concept and field synergy principle. Int. J. Heat Mass Transf. 2019, 135, 436–459. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Investigations of thermal conductivity and viscosity of nanofluids. Int. J. Therm. Sci. 2008, 47, 560–568. [Google Scholar] [CrossRef]

- Lin, Q.; Li, Q.; Xu, P.; Zheng, R.; Bao, J.; Li, L.; Tan, D. Transport Mechanism and Optimization Design of LBM–LES Coupling-Based Two-Phase Flow in Static Mixers. Processes 2025, 13, 1666. [Google Scholar] [CrossRef]

- Albojamal, A.; Vafai, K. Analysis of single phase, discrete and mixture models, in predicting nanofluid transport. Int. J. Heat Mass Transf. 2017, 114, 225–237. [Google Scholar] [CrossRef]

- Li, F.; Zhu, W.; He, H. Field synergy analysis on flow and heat transfer characteristics of nanofluid in microchannel with non-uniform cavities configuration. Int. J. Heat Mass Transf. 2019, 144, 118617. [Google Scholar] [CrossRef]

- Steinke, M.E.; Kandlikar, S.G. Single-phase liquid friction factors in microchannels. Int. J. Therm. Sci. 2006, 45, 1073–1083. [Google Scholar] [CrossRef]

- Moraveji, M.K.; Ardehali, R.M. CFD modeling (comparing single and two-phase approaches) on thermal performance of Al2O3/water nanofluid in mini-channel heat sink. Int. Commun. Heat Mass Transf. 2013, 44, 157–164. [Google Scholar] [CrossRef]

- Zhai, Y.L.; Xia, G.D.; Liu, X.F.; Li, Y.F. Heat transfer enhancement of Al2O3-H2O nanofluids flowing through a micro heat sink with complex structure. Int. Commun. Heat Mass Transf. 2015, 66, 158–166. [Google Scholar] [CrossRef]

| Vol % | Density (kg/m3) | Specific Heat () | Thermal Conductivity ) | Dynamic Viscosity () | Prandtl Number Pr |

|---|---|---|---|---|---|

| 0.1 | 1001.9 | 4169.3 | 0.6415 | 0.0010152 | 6.65 |

| 0.5 | 1013.5 | 4112.5 | 0.6435 | 0.0010231 | 6.55 |

| 1 | 1026.2 | 4043.6 | 0.6518 | 0.0010352 | 6.41 |

| No. | Equipment Name | Type | Measuring Range | Precision |

|---|---|---|---|---|

| 1 | Pump | Customization, GB/T7782-2008 | 0–10 MPa | 0.166 mL/min |

| 2 | Filter | 400 eyes | -- | 40 μm |

| 3 | Thermocouple | TTJ36-CASS-010G-2 | −40–250 °C | 0.0075 T |

| 4 | Digital pressure gauge | GJM-120 | 0–200 KPa | 0.05% |

| 5 | Electronic scales | FA1104N | 0–110 g | 0.1 mg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Tan, Z.; He, H.; Zhou, Y.; Tang, X.; Zhu, W. Research on Thermal Performance of the Microchannel with Internal Cavities Under Al2O3-Water Nanofluid. Energies 2025, 18, 4419. https://doi.org/10.3390/en18164419

Li F, Tan Z, He H, Zhou Y, Tang X, Zhu W. Research on Thermal Performance of the Microchannel with Internal Cavities Under Al2O3-Water Nanofluid. Energies. 2025; 18(16):4419. https://doi.org/10.3390/en18164419

Chicago/Turabian StyleLi, Fang, Zewen Tan, Hu He, Youhang Zhou, Xuan Tang, and Wenhui Zhu. 2025. "Research on Thermal Performance of the Microchannel with Internal Cavities Under Al2O3-Water Nanofluid" Energies 18, no. 16: 4419. https://doi.org/10.3390/en18164419

APA StyleLi, F., Tan, Z., He, H., Zhou, Y., Tang, X., & Zhu, W. (2025). Research on Thermal Performance of the Microchannel with Internal Cavities Under Al2O3-Water Nanofluid. Energies, 18(16), 4419. https://doi.org/10.3390/en18164419