3.2.4. Energy Recovery Mechanism

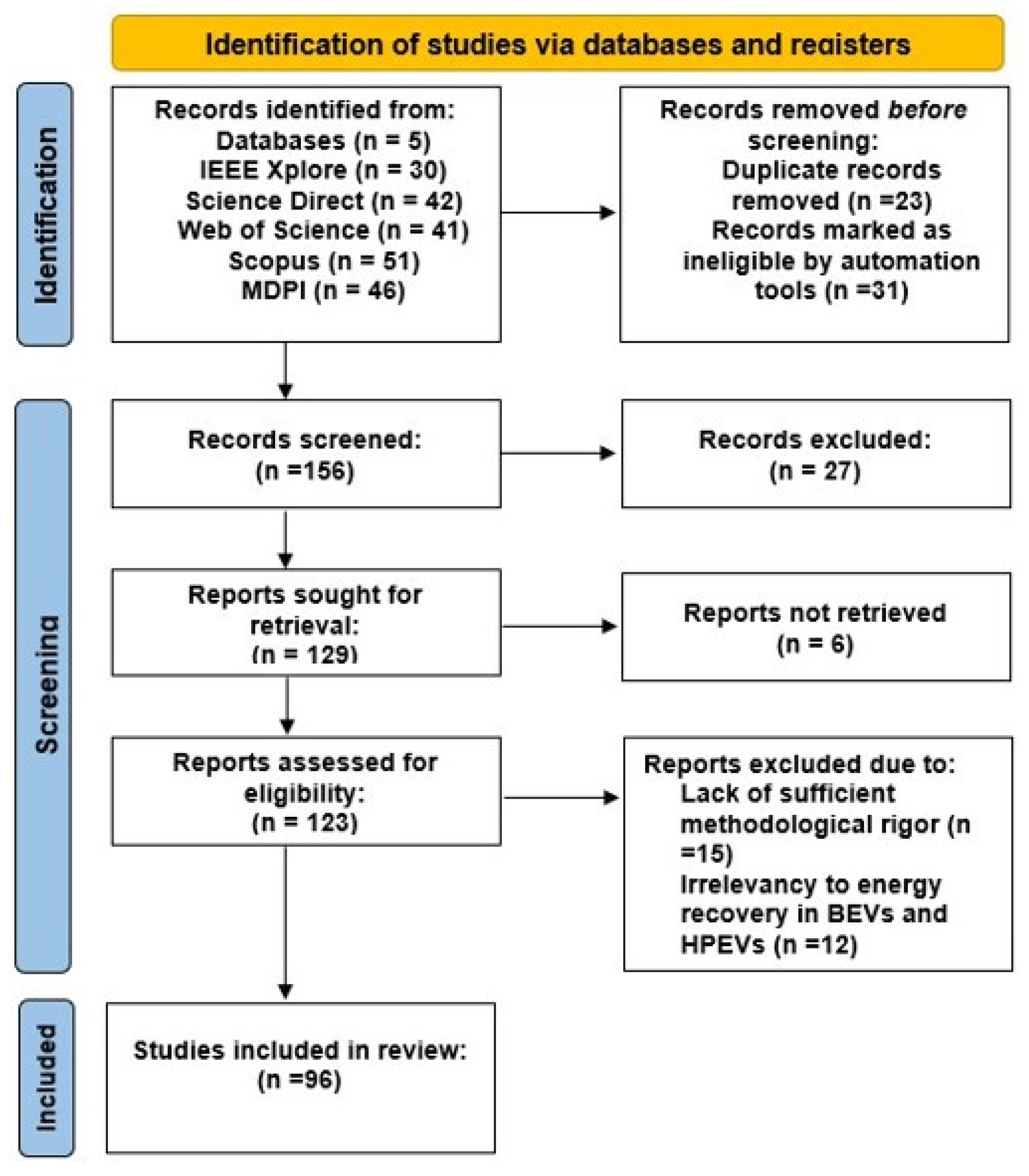

As reported in the studies of [

10,

18,

20], energy recovery mechanisms refer to systems or technologies designed to capture and reuse energy that would otherwise be lost during a process, typically during vehicle operation. The authors in [

5,

20] further underscored the importance of these mechanism in improving efficiency by converting wasted energy into a usable form and consequently, contributing to reducing the consumption of hydrogen, as in the case of HPEVs.

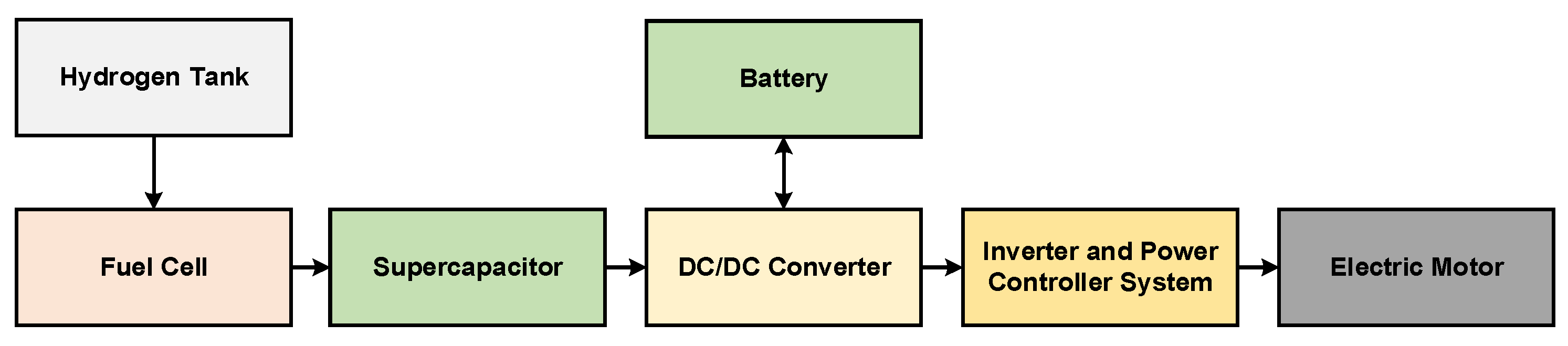

Although limited studies have been conducted on energy recovery in HPEVs, it is essential to note that most HPEVs are equipped with either a battery storage system or a supercapacitor, or both, to store the recovered energy [

5,

18]. While the battery capacity is smaller compared to those found in full BEVs, many energy recovery systems used in BEVs can also be applied to HPEVs [

5]. Therefore, this current review focused more on the literature incorporating different energy recovery in both BEVs and HPEVs.

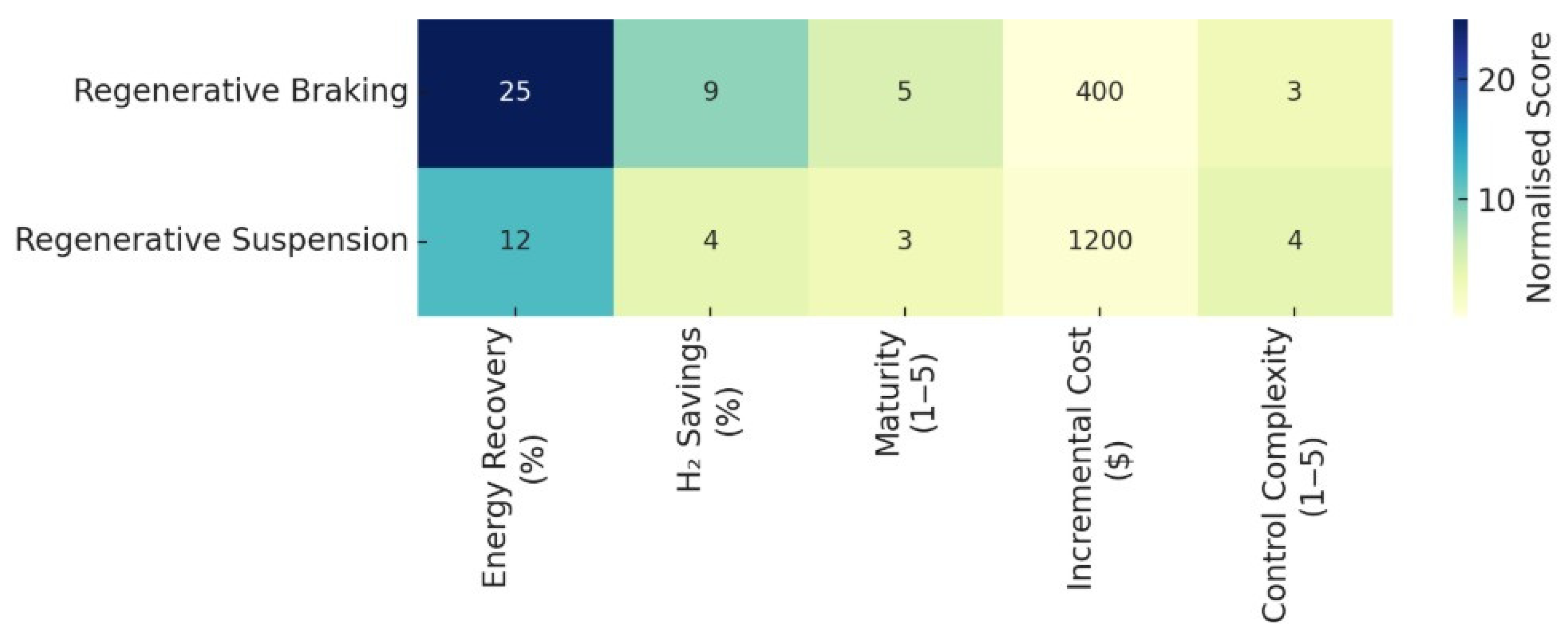

Generally, the two most discussed energy recovery mechanisms in the literature are the RBS and RSS [

5,

18]. However, many studies have focused solely on the use of RBS in the design of EVs [

14,

16,

17,

31,

32]. A few studies have also considered the use of RSSs, while very few studies have proposed the hybridization of the two approaches [

33,

34,

35]. The performance comparison of RBSs and RSSs as found in the literature is depicted in

Figure 6.

Other energy recovery mechanisms in EVs include regenerative fuel cells, flywheel energy storage, and various forms of energy harvesting, such as solar, wind, thermoelectric, piezoelectric, and radio frequency [

5,

18]. Nonetheless, since most of the studies have focused on the use of an RBS and RSS for energy recovery in BEVs and HPEVs, these two mechanisms are explored in detail in the subsequent sections.

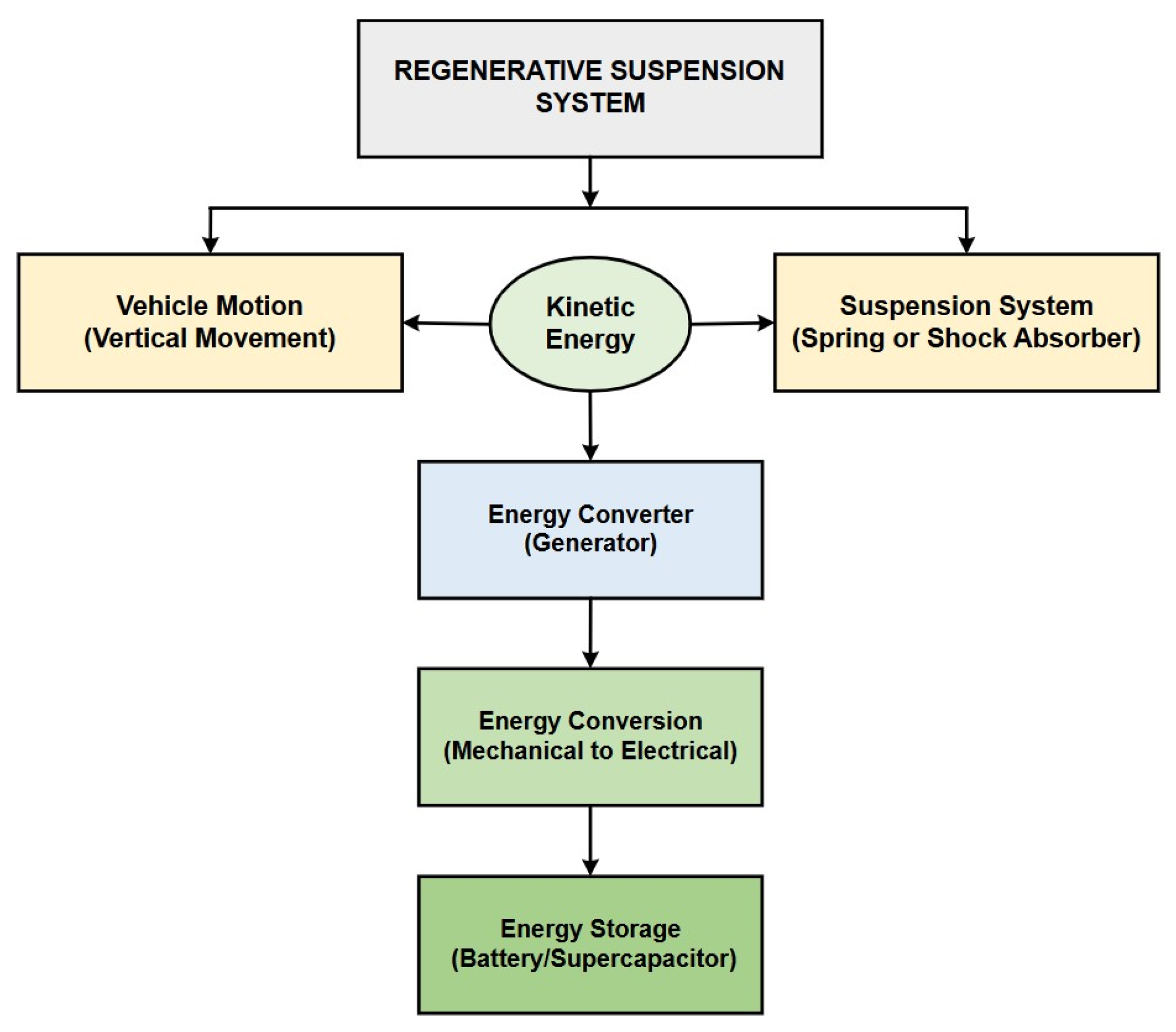

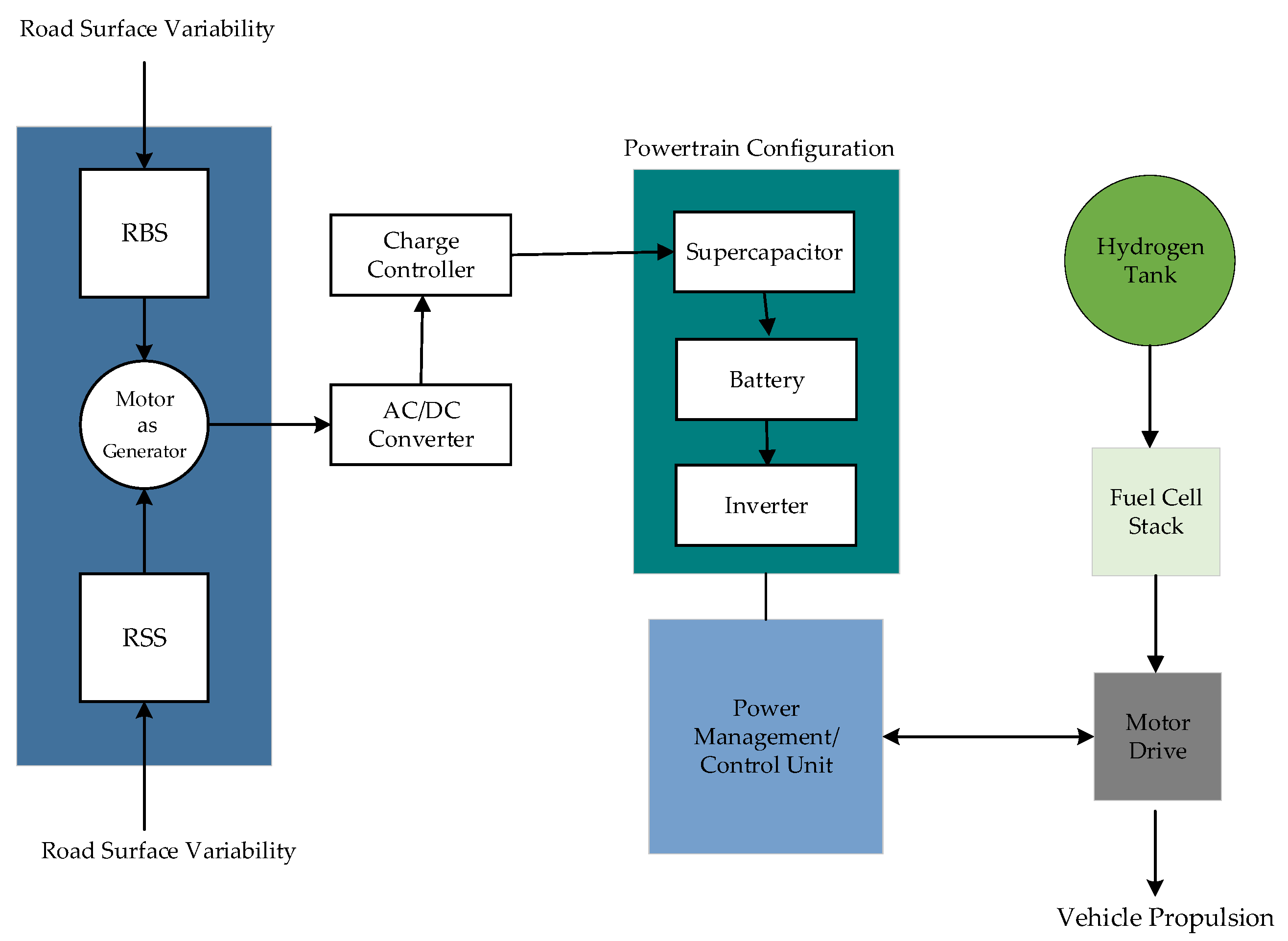

A regenerative suspension system as defined by [

36] is an innovative energy recovery method used in EVs that aims to harness the kinetic energy generated by the vehicle’s suspension system during motion [

5,

34,

36] In RSSs, the suspension components, such as shock absorbers or dampers, are integrated with a mechanism that converts the vertical movement of the wheels (caused by road irregularities and bumps) into electrical energy, as depicted in

Figure 7.

The total energy recovered through the RSS of an EV can be expressed using the principles of mechanical energy conversion, where the kinetic energy of the suspension components due to vertical movement is converted into electrical energy [

5,

37,

38,

39]. When the suspension system moves vertically due to road irregularities such as bumps and dips, among others, it absorbs mechanical energy. This mechanical energy is captured and converted into electrical energy using either a transducer, electromagnetic system, or hydraulic mechanism [

5,

39].

Hence, the energy recovered

in RSSs is related to the mechanical work performed by the suspension system as it undergoes a vertical movement and can be expressed using Equation (1) [

40].

where

is the force exerted by the suspension system as it compresses or rebounds;

is the velocity of the suspension components (shock absorbers) at time

and

represent the time intervals during the movement of the suspension system.

The force

exerted by the suspension is related to the spring constant

of the suspension and the displacement (deflection)

of the suspension components is given as follows:

Similarly, velocity can be associated with the rate of change in displacement, as given in Equation (3).

Substituting Equations (2) and (3) into Equation (1), the total energy recovered over time intervals

to

as the suspension moves vertically is expressed as follows:

Practically, the energy recovered in an electric vehicle using the RSS is usually considered the efficiency of the generator/hydraulic systems and road irregularities. Thus, for periodic motions common in most practical EVs, the energy recovered is given as follows:

Therefore, the total energy recovered by the RSS scheme is given as follows:

The recovered energy in Equation (6) is then stored in the vehicle’s battery for later use, improving overall energy efficiency [

37,

38,

40]. RSSs typically incorporate electromagnetic or hydraulic technology to capture the energy, which is then transformed into usable power, reducing the total dependence on hydrogen for HPEVs and subsequently enhancing the driving range energy [

5,

39]. It should, however, be noted from Equations (5) and (6) that the recovered energy in the RSS is influenced by four major factors as follows [

5,

38,

39,

40]:

Suspension Displacement (Vertical Motion): The vertical displacement of the suspension components due to road irregularities plays a significant role in energy recovery. The larger the displacement (amplitude) of the suspension, the more mechanical energy available to be converted into electrical energy.

Spring Constant (Stiffness of the Suspension): The spring constant determines the stiffness of the suspension system. It defines the amount of force required to compress the suspension by a given amount. A stiffer suspension (one with a higher spring constant) will resist vertical displacement more effectively than a softer suspension.

Velocity of Suspension Movement: The speed at which the suspension components move (velocity) during compression or rebound directly impacts the amount of kinetic energy available for conversion into electrical energy. This velocity depends on factors like vehicle speed and road conditions.

Efficiency of the Energy Conversion Mechanism: The different categories of RSSs also play a crucial role in determining how much mechanical energy (from the suspension) is successfully converted into electrical energy.

Several categories of RSSs exist in the literature; depending on the mode of operation, RSSs are categorized into three main categories: electromagnetic, hydraulic, and piezoelectric [

5,

40]. The performance comparison of the three categories in terms of efficiency, cost, amount of recovered energy, and maturity level, as found in most of the literature, is presented in

Table 6.

Moreover, depending on different degrees of control and energy recovery capability, the RSS is also categorized into active, semi-active, and passive systems. Passive RSSs are considered the simplest because the suspension components, such as dampers or shock absorbers, passively convert the energy generated from the vertical motion of the wheels into electrical energy using mechanical or electromagnetic piezoelectric [

5,

40]. This category of system has been reported to have minimal complexity and does not actively control the damping force but still recovers some energy. A semi-active RSS offers a higher level of control by adjusting the suspension’s damping properties in response to road conditions and driving behavior and therefore optimizing both ride comfort and energy recovery. This type of system typically utilizes actuators or variable damping mechanisms, which enable controlled energy harvesting while maintaining vehicle stability [

5,

18].

The most advanced among these categories of RSSs is the active system, which incorporates fully adjustable components that can independently control the suspension forces of each of the vehicle wheels. By actively controlling the suspension’s response to road conditions, this category of RSSs maximizes energy recovery, providing both superior ride quality and efficient energy capture. Blended RSSs can also adjust to varying driving conditions in real-time [

5,

18,

40]. Each of these systems has been reported to progressively enhance the vehicle’s ability to recover energy and improve overall performance, with active systems offering the most significant potential for energy efficiency and ride comfort [

5,

38,

39,

40].

- 2.

Regenerative Braking System

The author in [

18] defined an RBS as a groundbreaking technology that enhances energy efficiency in EVs by capturing and reusing the vehicle’s kinetic energy, which would typically be lost as heat in the conventional braking systems found in most ICE vehicles. The principle of operation of an RBS is such that upon the application of braking force by the driver, the electric motor switches to generator mode, converting the vehicle’s motion into electrical energy, as depicted in

Figure 8 [

5,

12,

18].

The recovered energy is then sent back to the battery or supercapacitor, helping to recharge it for future use [

5]. By recovering energy during braking, the system not only boosts the vehicle’s overall range but also reduces wear on traditional braking components, thereby contributing to a more sustainable and cost-effective driving experience [

5,

12,

18]. Mathematically, the energy recovered

in a typical EV. An RBS is modeled using Equations (7)–(13) [

12].

The vehicle kinetic energy is expressed as follows:

where

represents the mass of the vehicle, while

and

are the initial and final speeds of the vehicle.

Since the kinetic energy is converted into recovered electrical energy, Equation (7) can be rewritten as follows:

where

represents the recovered energy and is given as follows:

where

is the output current;

is the output voltage; and

is the efficiency of the electric motor when acting as a generator.

Equating (7) and (9), the values of the voltage and current across the generator can be obtained as follows:

Provided the electric generator supplies a constant voltage, and considering the generated current depends on the rank of kinetic energy, Equation (10) can be reformulated as follows:

Considering different steps in the kinetic energy loss process for time intervals of

; for short time intervals, Equation (11) can be rewritten as follows:

Equation (12) is applicable in flat terrain where there are no significant changes in elevation, or where such changes are minimal. In this context, the variation in kinetic energy is primarily linked to a decrease in vehicle speed, either because of braking or when the accelerator pedal is released.

However, if the route is downhill, the variation in kinetic energy can be linked to changes in the elevation of the terrain; Equation (12) can be expressed in terms of the altitude z of the route.

It has been reported in many existing studies that the recovered energy in any EV using the RBS depends significantly on its speed and mass [

13,

17,

32,

41,

42]. However, several other factors have been identified that must be considered when designing an efficient RBS for implementation in HPEVs for deployment in developing nations. Some of the most important factors identified in the recent literature include [

5,

12,

13,

18] the following:

Vehicle Speed: Higher speeds generally result in more kinetic energy, but at certain speeds, the RBS may become less effective or inefficient. The efficiency of energy recovery tends to be higher at lower to moderate speeds, where braking occurs more frequently.

Vehicle Weight: A heavier vehicle requires more energy to slow down, potentially increasing the amount of energy that can be recovered through the RBS. However, this also means more energy is required to overcome inertia and maintain motion.

Driving Conditions: The terrain and driving style can impact energy recovery. For instance, driving on hilly terrain or in stop-and-go traffic allows for more frequent opportunities for the RBS. In contrast, constant high-speed driving on flat roads may offer fewer opportunities for energy recovery.

Battery State of Charge (SoC): The level of charge in the vehicle’s battery impacts how much energy can be recovered. If the battery is near full charge, it may not be able to accept additional energy, reducing recovery efficiency.

Brake Pedal Usage: The interaction of the driver with the brake pedal can also influence energy recovery. If the driver uses the brakes aggressively, more energy may be lost as heat rather than being recovered, whereas smooth braking tends to maximize energy regeneration.

Motor and Controller Technology: The design and capabilities of the electric motor and the energy management system can greatly impact the efficiency of the regenerative braking process. Advanced systems may allow for better control and improved energy conversion.

Temperature Conditions: Environmental temperature can also affect both battery performance and regenerative braking efficiency. Cold temperatures, for example, can reduce the battery’s ability to accept charge, limiting energy recovery, while hot temperatures can affect motor and braking system performance.

Regenerative Braking Efficiency: The effectiveness of the RBS in converting kinetic energy into electrical energy plays a significant role. Factors like the braking force, motor efficiency, and the battery’s ability to accept charge can influence the amount of energy recovered.

The regenerative braking system is principally categorized into three main types: a series, parallel, and blended RBS. In a series RBS, the electric motor acts as the primary braking mechanism, converting kinetic energy into electrical energy before any mechanical braking is applied [

18]. This system maximizes energy recovery but may require additional braking support at low speeds. In contrast, a parallel RBS allows both the regenerative and mechanical brakes to operate simultaneously, with the braking force divided between them based on system design and vehicle conditions. This ensures reliable braking even when regenerative capacity is limited, such as during a fully charged battery [

5,

18].

A blended RBS, as revealed in the study of [

5], optimally integrates both methods using an advanced control strategy. It dynamically adjusts the proportion of regenerative and mechanical braking for seamless operation. This hybrid approach has been reported to enhance braking stability, maximizes energy recovery, and ensures driver comfort by mitigating abrupt transitions between braking [

5,

13,

16,

18]. Generally, blended systems have been reported to offer the best balance of efficiency and safety, making them ideal for modern EVs such as HPEVs [

13,

16]. A general comparison of the three major categories of the RBS in terms of braking mechanism, efficiency of energy recovered, braking stability, scalability, and complexity as reported in the literature is presented in

Table 7.

Another important category of the RBS reported in the literature is based on the type of technology used in the design of the system. Under this category, the RBS is categorized as an electromagnetic (battery)-based RBS, supercapacitor-based RBS, flywheel-based RBS, and hydraulic-based RBS [

5,

18]. The performance comparison of this category in terms of energy recovery efficiency, cost, power density, and maturity level are presented in

Table 8a,b.

To further illustrate how different factors affect the performance of energy recovery in an RBS and RSS, a conceptual meta-regression model depicted in

Figure 9 is developed using synthesized data derived from the literature [

13,

15,

16,

17,

32,

33,

34,

35,

38,

39,

40]. From the diagram in

Figure 9, the recovery efficiency of an RBS increases with vehicle speed. It decreases as the battery approaches full charge, reflecting the constraints of both the controller and the battery [

15,

16,

17,

32,

39]. On the other hand, RSS performance is positively correlated with suspension displacement and velocity, indicating its greater suitability for rough or uneven road profiles [

33,

34,

35,

38,

40]. These insights reinforce the importance of context-specific optimization when integrating energy recovery systems into HPEVs.

3.2.5. Storage Solutions in Electric Vehicles

Energy storage plays a crucial role in maximizing the benefits of energy recovered in EVs [

5,

18]. As reported in several studies, the efficiency of any energy recovery mechanism depends on the storage system’s ability to capture, store, and release energy when needed quickly [

2,

4,

7,

9]. This section provides brief findings on the major energy storage technologies used in EVs, highlighting their advantages, limitations, and potential future improvements. Storage technologies are designed to efficiently store and release energy when needed, ensuring that the energy captured during the energy recovery process is effectively utilized [

2,

4,

5,

7,

9,

18]. The performance comparison in terms of energy density, power density, efficiency, response time, lifespan, and cost of the most popular storage technologies in BEVs and HPEVs, as reported in the literature, is presented in

Table 9, followed by a brief description of each storage technology.

Among the various storage technologies in EVs, lithium-ion batteries dominate due to their superior energy density, ranging from 150 to 250 Wh/kg, high charge/discharge efficiency, and a life cycle of 1000 to 5000 cycles [

5,

18,

43]. The electrochemical composition of a lithium-ion battery primarily consists of lithium cobalt oxide, lithium iron phosphate, or nickel manganese cobalt cathodes, paired with graphite or silicon anodes. Recent advances in silicon-dominant anodes have reportedly pushed energy densities beyond 300

, subsequently leading to high efficiency and a more extended range in EVs [

2,

4,

7,

9,

44].

Similarly, advancements in solid-state batteries are reshaping the landscape of many EV power sources. Solid-state batteries are reported to the liquid electrolyte in Li-ion cells with a solid electrolyte, offering higher energy density (400

and have improved safety and a longer lifespan. Nonetheless, challenges include high production costs, electrolyte stability, and scalability [

2,

4,

5,

7,

9,

18].

The findings also revealed that the battery size in BEVs is significantly larger than that of HPEVs due to the differing energy storage and power delivery mechanisms. BEVs rely solely on battery packs, often ranging from 40

to over 100

, to power the drivetrain, whereas HPEVs use smaller battery packs (typically 1–10

) as a buffer to support peak power demands and the RBS [

5,

18,

45,

46]. HPEVs primarily store energy in hydrogen fuel tanks and convert it into electricity using fuel cells, thereby reducing reliance on ample battery storage but requiring additional space for hydrogen storage and fuel cell stacks [

5,

43,

44]. Consequently, while BEVs emphasize higher energy density battery solutions, it is essential to optimize power management in HPEVs through hybridization of fuel cells and small battery packs and/or supercapacitors.

- 2.

Supercapacitors

Supercapacitors have been widely studied for their role in energy recovery in both BEVs and HPEVs due to their high-power density and rapid charge–discharge capabilities. Several studies have indicated that supercapacitors can significantly enhance the energy recuperation process by efficiently capturing high-power surges during regenerative braking [

13,

16,

47]. Unlike lithium-ion batteries, which have limited charge acceptance rates at high currents, supercapacitors can absorb and release energy almost instantaneously, making them ideal for transient power applications [

5,

18]. Studies have reported that integrating supercapacitors with conventional battery storage in EVs can improve energy efficiency by up to 15% to 25% while also reducing stress on battery cells, thereby extending their lifespan [

5,

18,

32,

47].

In HPEVs, supercapacitors have been reported as playing a crucial role in managing power fluctuations and peak energy demands [

32,

47]. Studies have also revealed that HPEVs equipped with hybrid energy storage systems, consisting of fuel cells, batteries, and supercapacitors, demonstrate improved fuel economy, efficiency, driving range, and dynamic response [

5,

18,

32,

47]. Hence, supercapacitors are capable of effectively bridging the gap between the slow response of fuel cells and the instantaneous power demands of acceleration and regenerative braking. The hybridization of fuel cells with supercapacitors can reduce hydrogen consumption by optimizing energy utilization, resulting in a more efficient and sustainable vehicle design [

5,

18].

- 3.

Flywheel

Flywheels have also been explored as a viable solution for enhancing energy recovery, particularly in BEVs, due to their ability to store kinetic energy with high efficiency [

5]. The literature findings suggest that flywheels offer rapid energy absorption and release, making them particularly effective in RBSs [

18,

20,

45,

48,

49]. Unlike batteries, which rely on electrochemical storage, flywheels store energy mechanically in a rotating mass, reducing issues related to charge degradation and cycle life [

5,

50]. Studies have also reported that flywheel-integrated energy recovery systems can improve energy efficiency by 20% to 30%, particularly in heavy-duty and high-performance vehicle applications [

5,

18,

45,

49,

50].

For HPEVs, flywheel energy storage offers an effective means of managing transient power demands and reducing reliance on hydrogen fuel during peak load conditions [

5,

18,

45,

48,

49]. Research has indicated that integrating flywheels with fuel cell systems can enhance vehicle performance by stabilizing power fluctuations and improving the overall efficiency of hydrogen utilization [

5,

48,

49]. Furthermore, the combination of flywheels with other energy storage technologies, such as batteries and supercapacitors, has been reported to optimize energy distribution and extend the lifespan of fuel cell stacks [

5,

18]. These advancements underscore the potential of the flywheel in improving the sustainability and operational efficiency of HPEVs in developed and developing nations.

- 4.

Hydraulic Accumulator

Hydraulic accumulator energy storage systems have been investigated as an effective means of energy recovery in both BEVs and HPEVs, particularly for applications requiring high power bursts and efficiency in the RBS [

5,

51]. The literature suggests that hydraulic accumulators, which store energy in the form of pressurized fluid, offer superior power density compared to batteries and can rapidly absorb and release energy with minimal losses. Studies have also reported that integrating hydraulic accumulators in EVs can enhance braking energy recovery efficiency by up to 25% to 35%, particularly in heavy-duty applications such as buses and industrial vehicles [

45,

51].

In HPEVs, hydraulic accumulators have demonstrated potential for complementing fuel cells by smoothing power fluctuations and providing additional energy during acceleration [

51]. The literature findings indicate that hybrid energy storage configurations incorporating hydraulic accumulators can help reduce stress on both batteries and fuel cells. Consequently, this improves overall system efficiency and extends the lifetime of components. Additionally, advancements in lightweight materials and compact accumulator designs are making hydraulic energy storage systems increasingly viable for a wider range of vehicle applications [

5,

51].

- 5.

Compressed Air Energy Storage

Compressed air energy storage (CAES) has been investigated as an alternative method for energy recovery storage in BEVs and HPEVs due to its high-power density and sustainability [

52,

53]. The literature suggests that CAES systems are capable of efficiently capturing and storing excess energy by compressing air, which can later be expanded to generate mechanical or electrical power. Studies have also reported that integrating CAES with electric drivetrains enhances braking energy recovery by up to 30%, particularly in stop-and-go urban traffic conditions, making them suitable for vehicle deployment in developing nations [

18,

52,

53].

In HPEVs, CAES has been explored to assist hydrogen fuel cells in handling peak power demands. The research indicates that hybrid CAES–fuel cell systems improve overall efficiency by smoothing power fluctuations and reducing fuel cell degradation. Furthermore, advancements in isothermal and adiabatic compression techniques have been identified as key factors in increasing CAES efficiency and making it a viable energy storage solution for sustainable transportation [

52,

53].

- 6.

Magnetic Energy Storage

Magnetic energy storage, particularly superconducting magnetic energy storage (SMES), has been explored for its potential in energy recovery applications in BEVs and HPEVs [

54]. SMES systems store energy in the magnetic field created by the flow of direct current in a superconducting coil, offering rapid charge and discharge capabilities with minimal energy loss. The literature findings indicate that SMES can enhance the RBS efficiency by quickly absorbing and delivering high-power surges, thereby reducing energy wastage and improving vehicle performance [

5,

18,

54].

For HPEVs, SMES plays a crucial role in stabilizing power fluctuations and improving transient response. The research highlights that hybridizing SMES with fuel cells can lead to increased energy efficiency, reduced fuel consumption, and improved system reliability [

54]. Studies have also suggested that advancements in high-temperature superconductors and cryogenic cooling technologies are key to making SMES a viable solution for automotive applications, addressing challenges such as cost and operational complexity [

5,

54].

- 7.

Hybrid Energy Storage Systems (HESSs)

Hybrid energy storage systems, which combine different energy storage technologies such as batteries, supercapacitors, and flywheels, have been extensively studied for their benefits in BEVs and HPEVs [

55]. The literature findings indicate that HESSs can significantly enhance energy recovery efficiency by optimizing power distribution and reducing the stress on individual storage components. Studies reported that HESSs can improve RBS efficiency by up to 30% by allowing for fast energy capture and controlled energy release, thus maximizing overall system performance [

5,

18,

55].

Hybrid energy storage systems have been reported to play a crucial role in balancing power fluctuations and enhancing overall energy efficiency in EVs. Research has highlighted that integrating supercapacitors or flywheels with fuel cells can enhance the transient response and reduce hydrogen consumption in HPEVs, leading to improved vehicle efficiency and sustainability. Additionally, advancements in power management algorithms and energy control strategies are essential in optimizing HESS performance for both BEVs and HPEVs [

5,

55].

Moreover, integrating intelligent energy management systems with supercapacitor-battery hybrid storage has been reported to enhance the effectiveness of the RBS, particularly in urban driving cycles with frequent stop-and-go conditions [

5,

18,

55,

56]. These findings emphasize that a well-designed control strategy and power management optimization technique are critical for improving the RBS performance, extending battery lifespan, and ensuring seamless braking transitions, ultimately leading to a more energy-efficient and sustainable vehicle system.

The findings have also shown that without an optimized control mechanism, the energy recovered in any category of EV can be inconsistent. This can lead to inefficient power distribution and excessive reliance on mechanical braking, which typically results in increased wear and tear and a reduction in the vehicle’s lifespan [

18,

56]. The next section highlights the various categories of control strategies used to improve the efficiency of energy recovery in EVs, utilizing either an RBS or RSS.

3.2.6. Control Strategies in Energy Recovery Systems

As reported in the study of [

21], control strategies are crucial in energy recovery systems for effectively managing the conversion of mechanical energy into electrical energy while ensuring vehicle safety and performance. Effective control strategies are fundamental to optimizing the performance and efficiency of the powertrains of HPEVs, particularly in configurations involving multiple energy sources such as fuel cells, batteries, and supercapacitors [

42,

47,

57].

In an RBS, the control system must enable real-time adjustments to braking torque distribution between regenerative and friction brakes, optimizing energy recovery while maintaining vehicle safety. The literature has also highlighted the need for strategies to account for factors such as battery state-of-charge (SOC), road conditions, and driver behavior to dynamically adjust the braking force and prevent regenerative braking saturation [

42,

57].

Similarly, in RSSs, the control strategy must accurately sense and filter road-induced vibrations and vehicle dynamic responses in real-time; it must also modulate the suspension’s damping and stiffness characteristics accordingly to maintain ride comfort and vehicle dynamics while harvesting energy from road-induced vibrations [

33,

58,

59]. Moreover, studies have also reported that control strategies need to incorporate predictive and adaptive algorithms that can anticipate changes in road conditions and adjust the energy recovery process without compromising safety [

42,

57,

59].

The need for these strategies arises from the inherent trade-offs between maximizing energy recovery and maintaining dynamic stability and comfort, particularly in the presence of system nonlinearities, uncertainties, and varying driving conditions both in developed and developing countries [

42,

57]. A range of control strategies has been explored in the literature to address these challenges. A broad view of the hierarchical structure of control strategies for regeneration systems (RBSs or RSSs) in BEVs and HPEVs, as reported in the literature, is illustrated in

Table 10.

Techniques such as the linear quadratic regulator, model predictive control (MPC), and adaptive or fuzzy logic controllers (FLCs) have been applied to both RBSs and RSSs [

60,

61]. The use of MPC in predicting future vehicle states and optimizing control actions over a horizon is well-documented in several studies, while sliding mode control offers robustness against system uncertainties [

39,

62]. Recent studies have also demonstrated that FLC can be an effective tool for optimizing control strategies in both single and dual wheel configurations in EVs [

32,

56,

57].

For single-wheel applications, FLCs have been reported as handling the inherent non-linearities and uncertainties present in vehicle dynamics, particularly under varying road conditions and friction coefficients [

56,

63]. By employing linguistic rules that encapsulate expert knowledge, FLCs dynamically adjust parameters such as braking force or motor torque to optimize energy recovery and improve traction. This adaptive behavior has been found to not only enhance energy recuperation efficiency during regenerative braking but also contribute to improved ride stability and safety in real-world driving scenarios [

32,

56,

57].

In dual wheel configurations, FLC offers the added advantage of coordinating control actions between the wheels to achieve balanced performance [

32]. Research findings have indicated that when FLC is applied to dual-wheel systems, it can effectively manage the distribution of forces, thereby reducing wheel slip and enhancing overall regenerative efficiency [

32,

56,

57,

61]. The controller’s ability to seamlessly integrate feedback from both wheels enables real-time adjustments that better account for differences in road contact and load distribution [

32,

61]. While these benefits contribute to improved energy efficiency and vehicle stability, challenges such as increased computational complexity and the fine-tuning of fuzzy membership functions for diverse driving conditions remain areas for further investigation.

Nevertheless, several studies have also reported the significant benefits of various control strategies for regeneration systems in EVs, which include extended vehicle range and improved integration of energy recovery functions into the overall vehicle dynamics [

32,

56,

57,

61]. However, challenges persist in terms of controller complexity, real-time computational demands, and the need to finely balance energy recovery with safety and vehicle performance [

64,

65].

Table 11 presents a performance comparison of the most common control strategies in terms of efficiency, computational complexity, adaptability, and cost, as found in the literature.

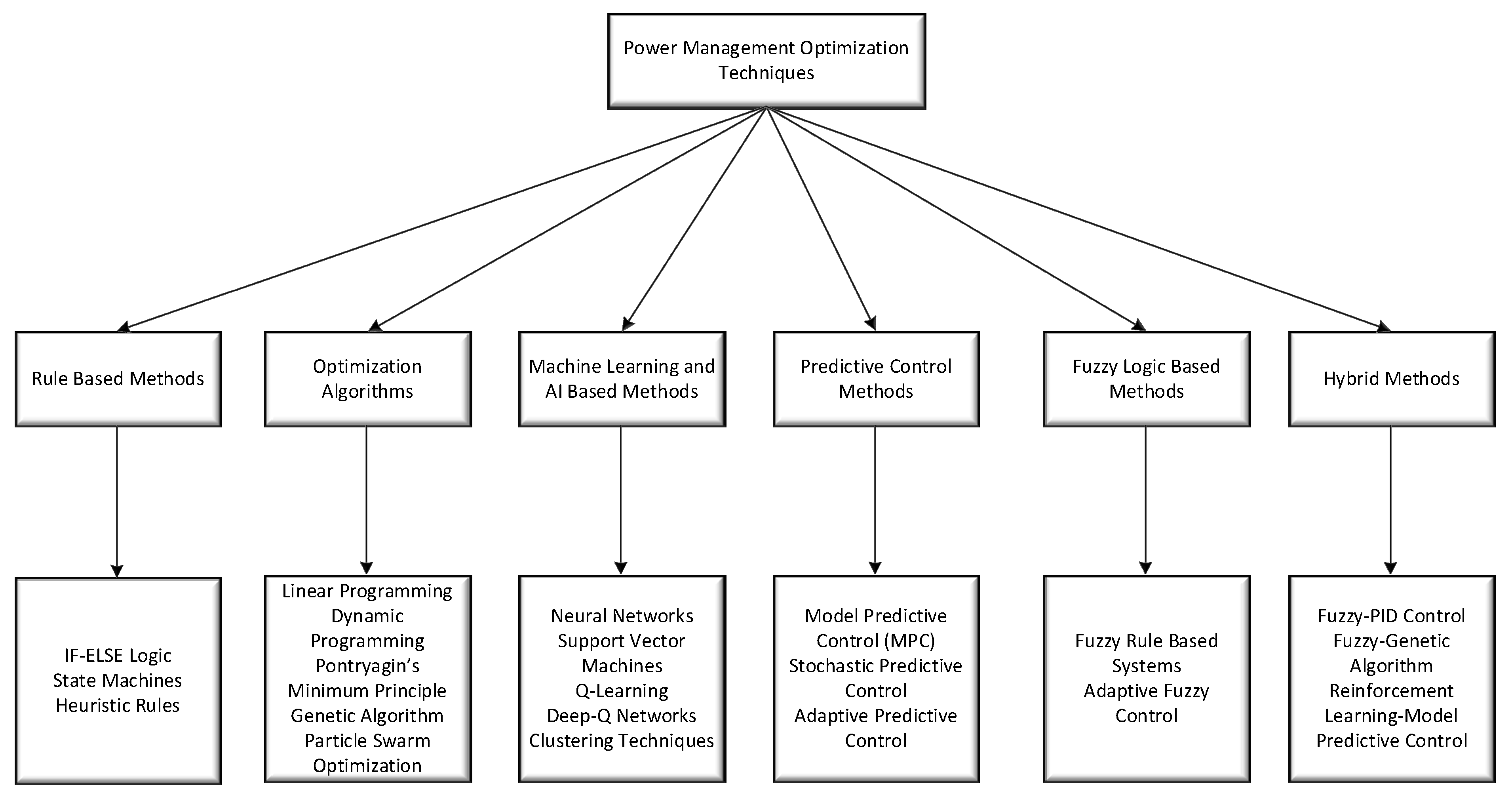

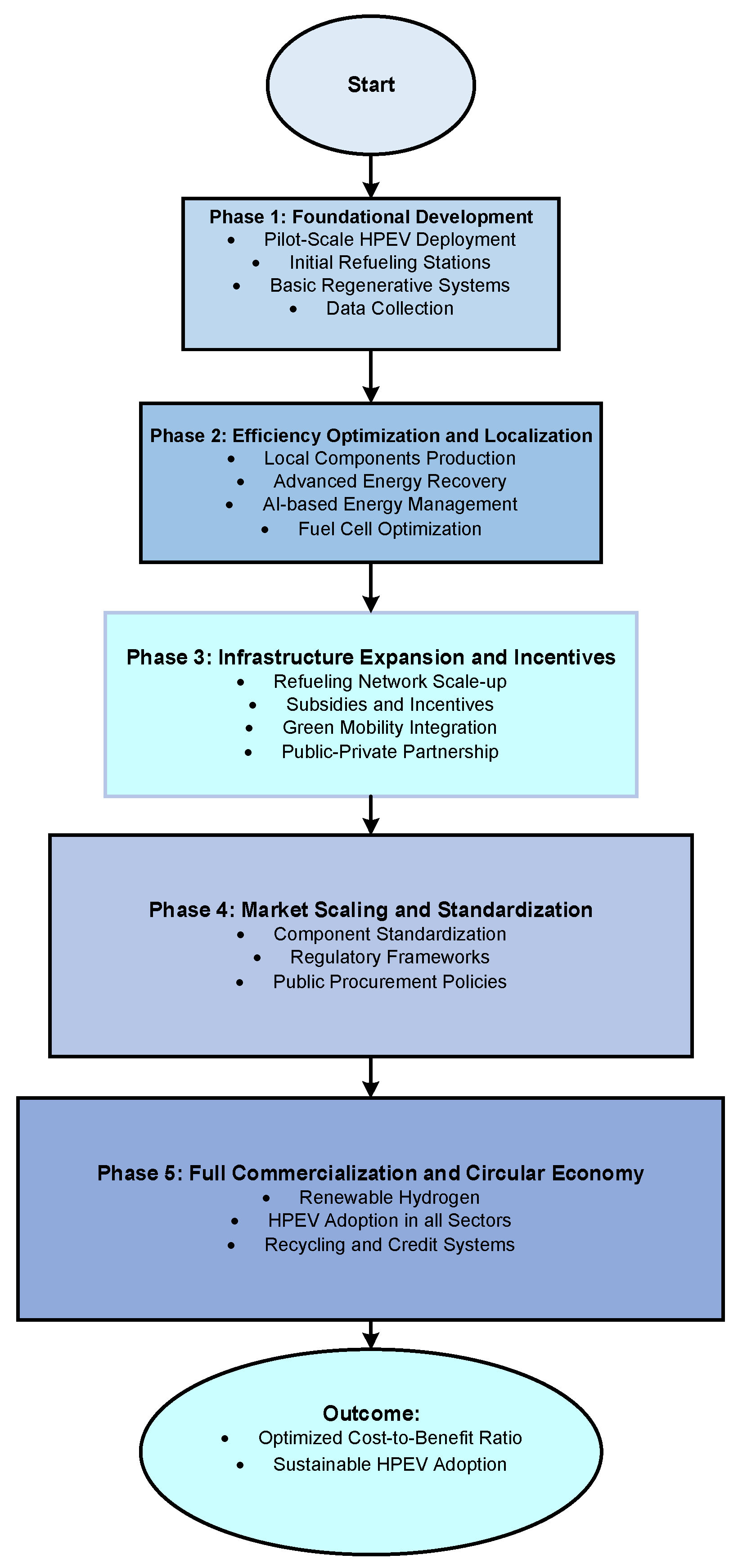

3.2.7. Power Management Optimization Techniques in BEVs and HPEVs

The findings have also revealed that efficient power management is crucial to maximizing the performance, efficiency, and longevity of EVs. Different researchers have developed various optimization techniques to ensure optimal energy utilization, reduce energy losses, and enhance driving range [

1,

3,

4,

5,

66,

67,

68,

69,

70]. These techniques are broadly categorized into several categories, including rule-based, model-based, artificial intelligence (AI)-based methods, among others, as illustrated in

Figure 10. A brief description of some of these techniques is subsequently presented.

The rule-based power management strategy has been widely employed in various studies. It operates using a set of heuristic or deterministic control rules that govern the power distribution among the fuel cell, battery, and supercapacitor within HPEVs’ powertrains [

5,

67]. These rules are typically formulated based on expert knowledge and system thresholds such as state of charge, load demand, and offline simulations. Although they are computationally light and suitable for real-time control, rule-based strategies lack adaptability and optimization capability under dynamic and uncertain driving conditions, often resulting in sub-optimal fuel cell utilization and increased degradation of energy storage components [

3,

5,

69,

70].

- 2.

Artificial Intelligence-Based Optimization

Artificial intelligence-based optimization techniques, such as neural networks, reinforcement learning, and fuzzy inference systems, have also been employed as powerful tools for power management in the powertrains of HPEVs. They can improve energy recovery efficiency and enhance vehicle driving range [

20,

70,

71]. These methods enable the system to learn optimal power distribution strategies through data-driven modeling and adaptive control, even under highly nonlinear and uncertain driving conditions. Unlike rule-based or fixed-logic approaches, AI-based optimization can continuously improve its performance over time, offering superior adaptability, real-time decision-making, and enhanced energy efficiency [

5,

20]. However, findings have revealed that challenges such as computational complexity, training data requirements, and real-time feasibility need to be carefully addressed for practical deployment [

5,

70,

71].

- 3.

Model-Based Optimization Techniques

Model-based optimization techniques, also known as predictive control methods, were reported to rely mainly on mathematical models of the powertrain in HPEVs to determine the optimal power split among the fuel cell, battery, and supercapacitor [

5,

72,

73]. These techniques typically involve the formulation of an objective function such as minimizing hydrogen consumption or maximizing system efficiency subject to dynamic and operational constraints [

1,

4,

66,

73]. Methods like dynamic programming (DP), MPC, and Pontryagin’s minimum principle fall under this category. While it was argued in most of the literature that model-based approaches can yield globally or near-globally optimal solutions, they often require accurate system modeling and may involve high computational overhead, limiting their real-time applicability in embedded vehicle systems [

1,

5,

73].

- 4.

Fuzzy Logic Controller

A fuzzy logic controller offers a robust and flexible framework for power management in HPEV powertrains by mimicking human decision-making through linguistic rules and fuzzy inference [

61,

74]. It effectively handles system uncertainties and non-linearities without requiring precise mathematical models. Several studies have reported that FLC can regulate the power flow among various energy sources in HPEVs, based on input variables such as state of charge, load demand, and acceleration [

41,

57,

60,

61,

65]. Its rule-based structure enables real-time implementation; however, the design of membership functions and rule sets requires expert knowledge, and performance may degrade if not properly tuned or adapted to varying driving profiles [

57,

60,

61].

- 5.

Hybrid Power Management Strategies

A novel technique common in different optimization problems is to hybridize two or more strategies such that the merits of one can compensate for the flaws of the other and vice versa. Hybrid power management is also peculiar in the design of HPEVs; this strategy combines multiple control techniques, such as rule-based methods, fuzzy logic, and optimization algorithms, to leverage the strengths of each approach for managing the power split in HPEV powertrains [

3,

5,

75,

76,

77].

The findings have also revealed that the primary objective of this strategy is to strike a balance between computational efficiency and optimal performance by selecting the most suitable technique based on the current system state or operating conditions [

3,

5,

55,

75,

77,

78]. For example, FLC may be used for real-time adjustments, while optimization algorithms such as particle swarm optimization (PSO) or DP have been employed for global performance enhancement. Hybrid strategies have also been reported in several studies to improve energy efficiency and system robustness but may introduce increased complexity and computational demands in real-time applications [

3,

5,

25,

27,

79,

80].

)

)