A State-of-the-Art Review on Nuclear Reactor Concepts and Associated Advanced Manufacturing Techniques

Abstract

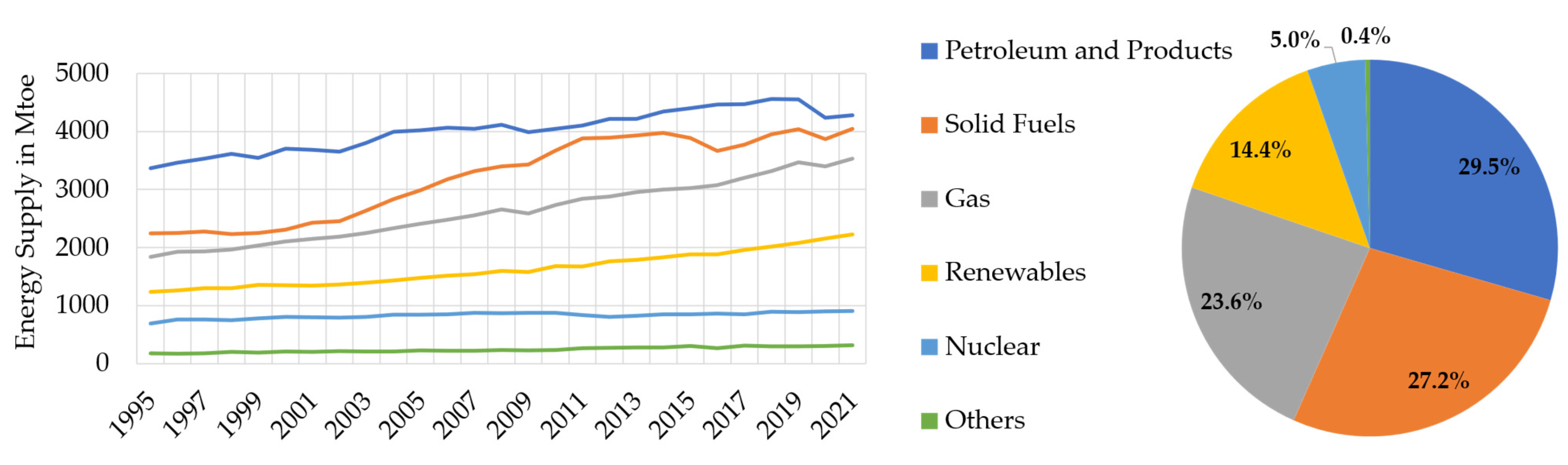

1. Introduction

2. Nuclear Energy

2.1. Technical Aspects of GEN-IV Nuclear Systems

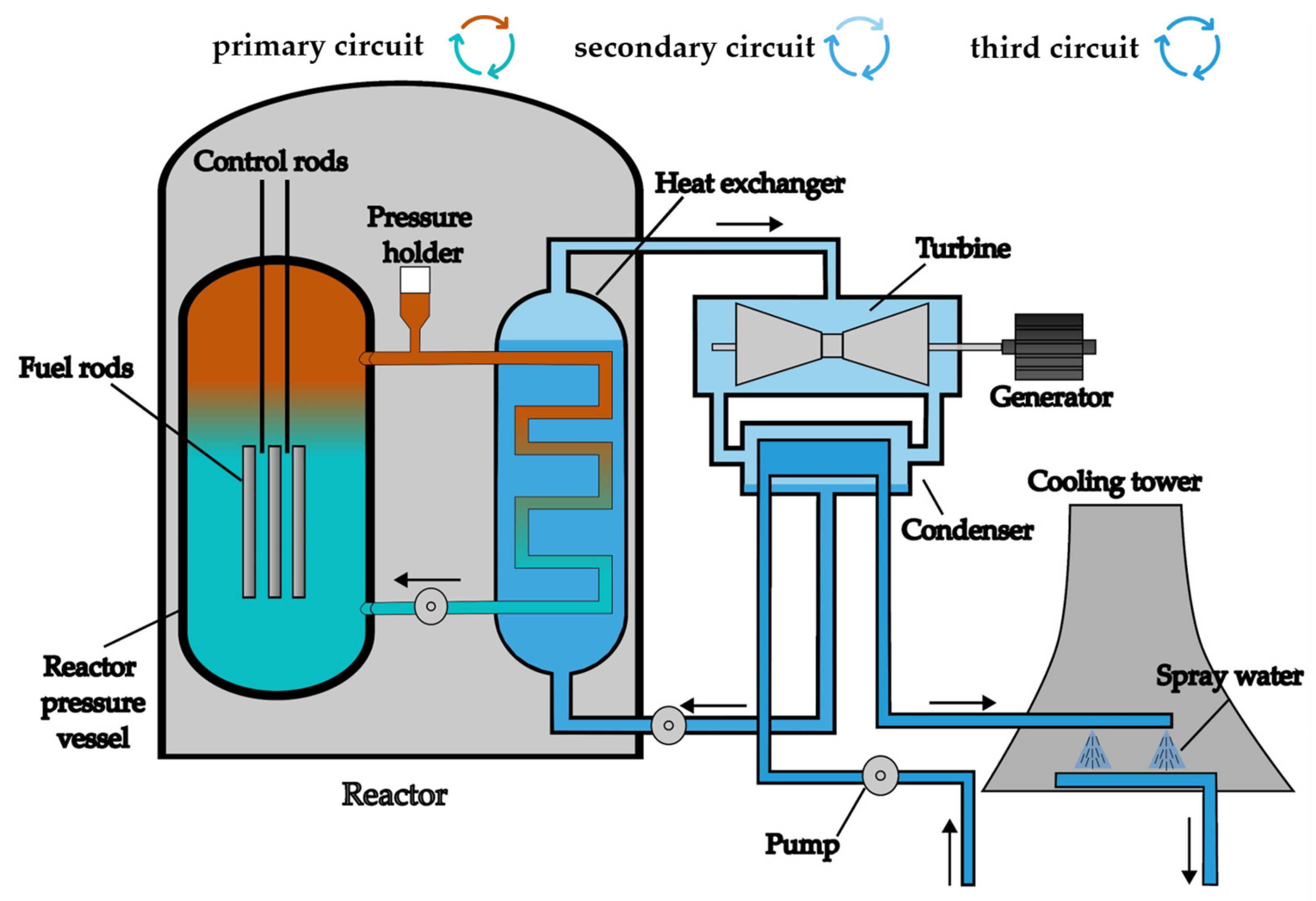

2.1.1. Light Water Reactors

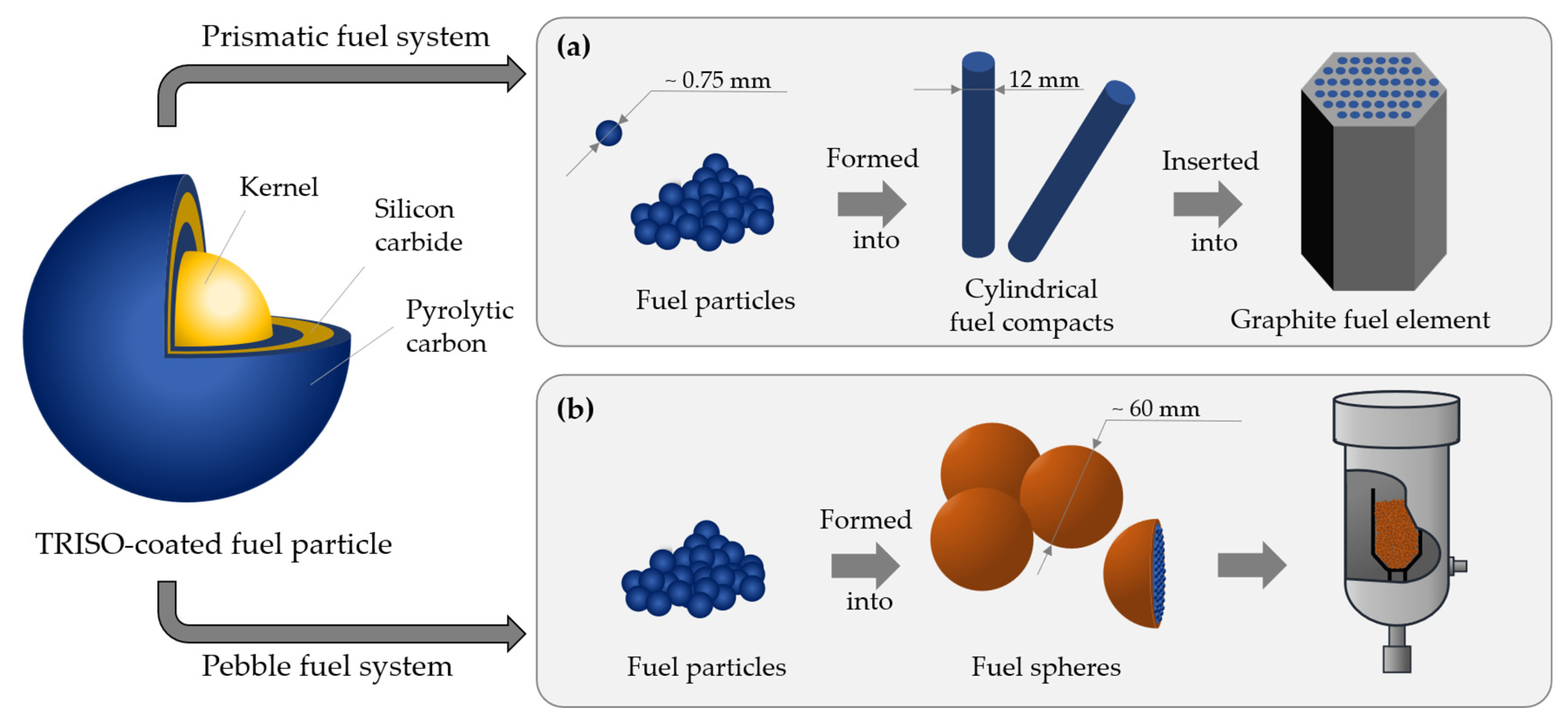

2.1.2. Very-High-Temperature Gas-Cooled Reactors

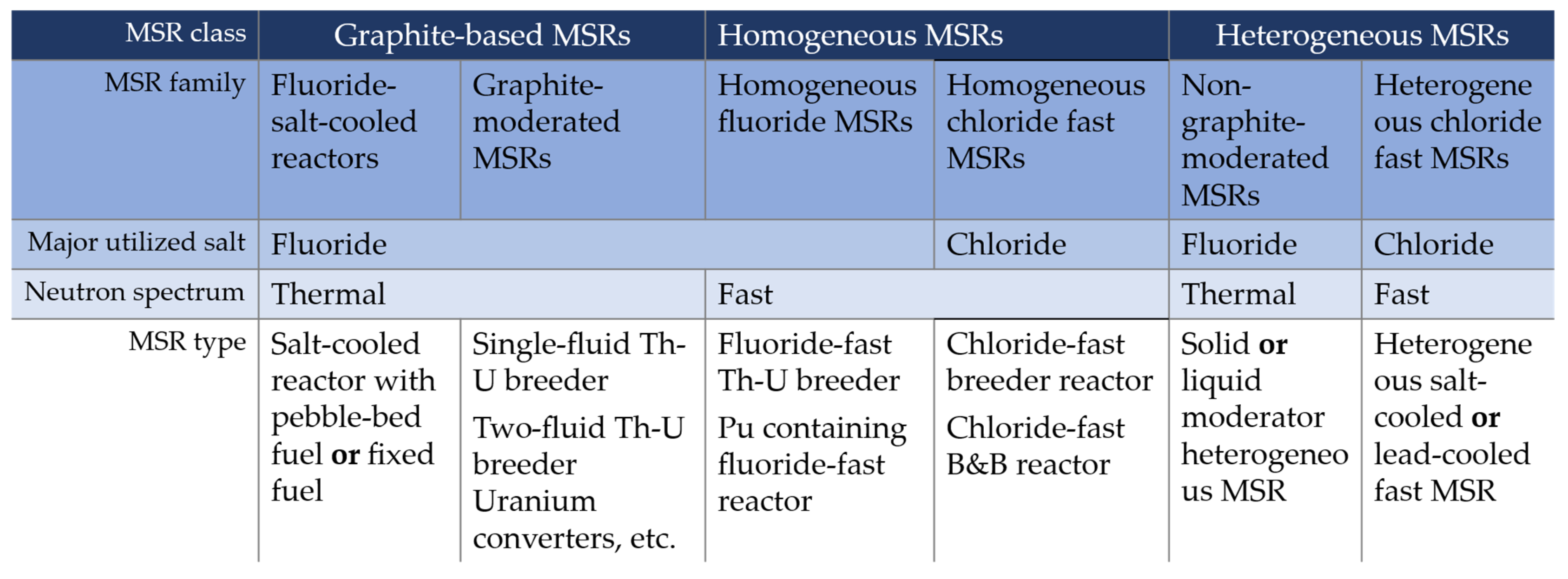

2.1.3. Molten Salt Reactors

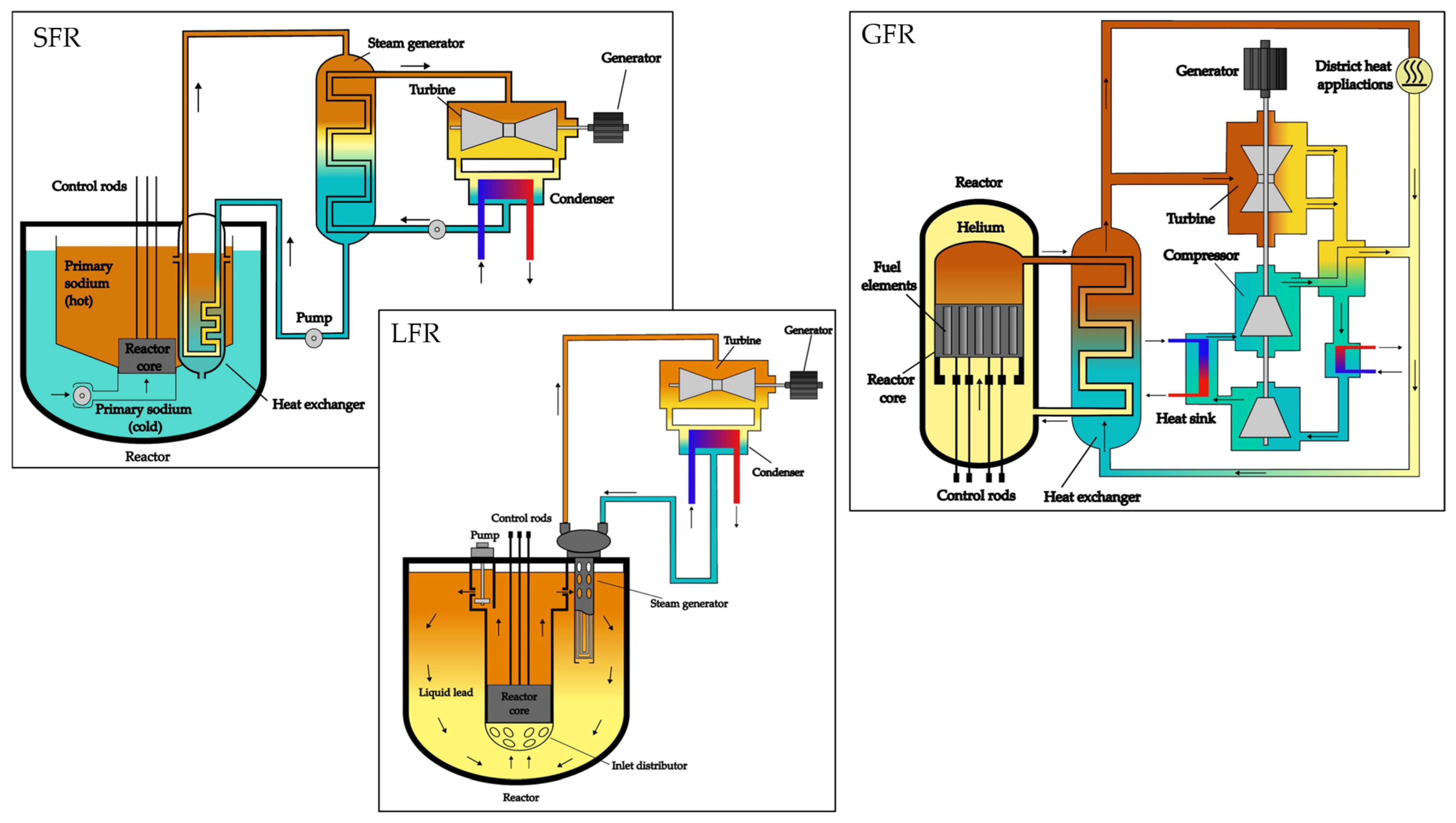

2.1.4. Fast Reactors (Gas-Cooled, Sodium-Cooled, Lead-Cooled)

2.1.5. Supercritical Water-Cooled Reactors

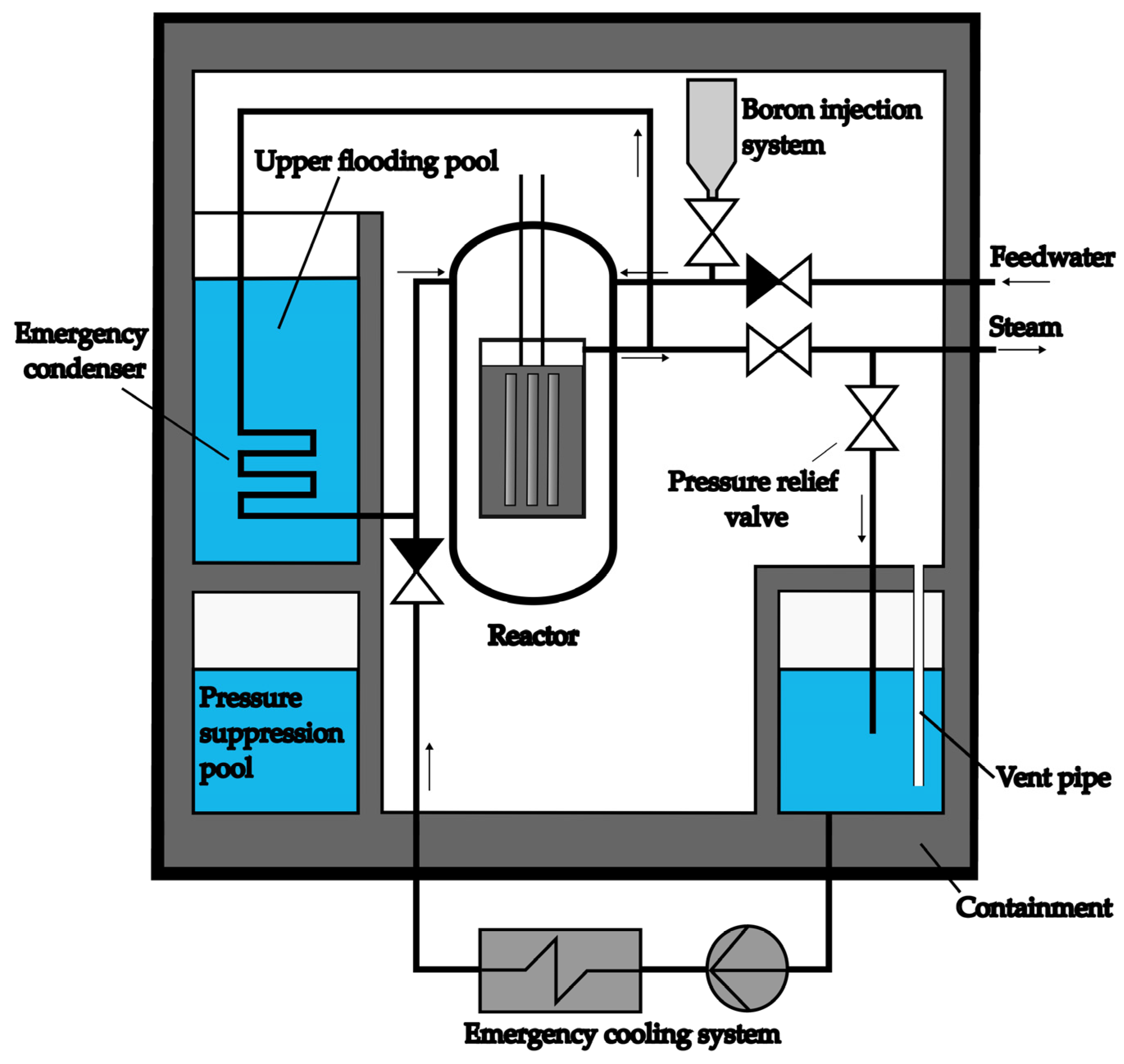

2.2. What About Safety?

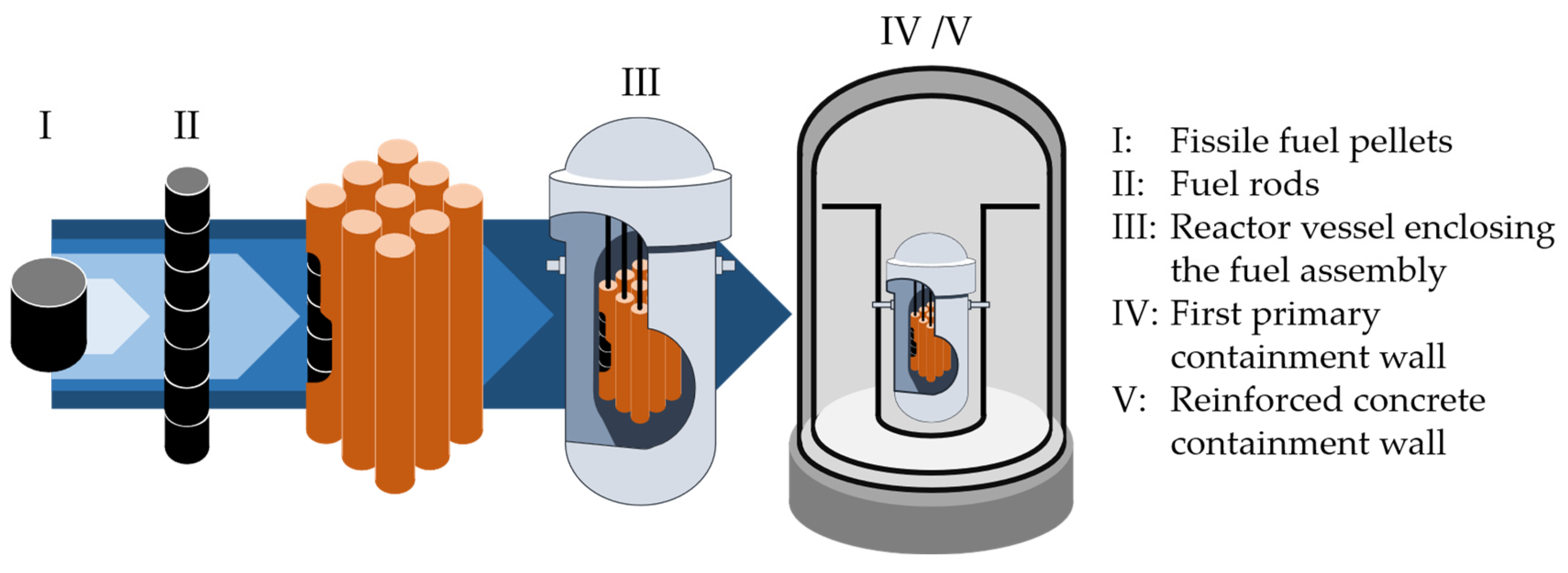

2.2.1. Fundamental Safety Functions

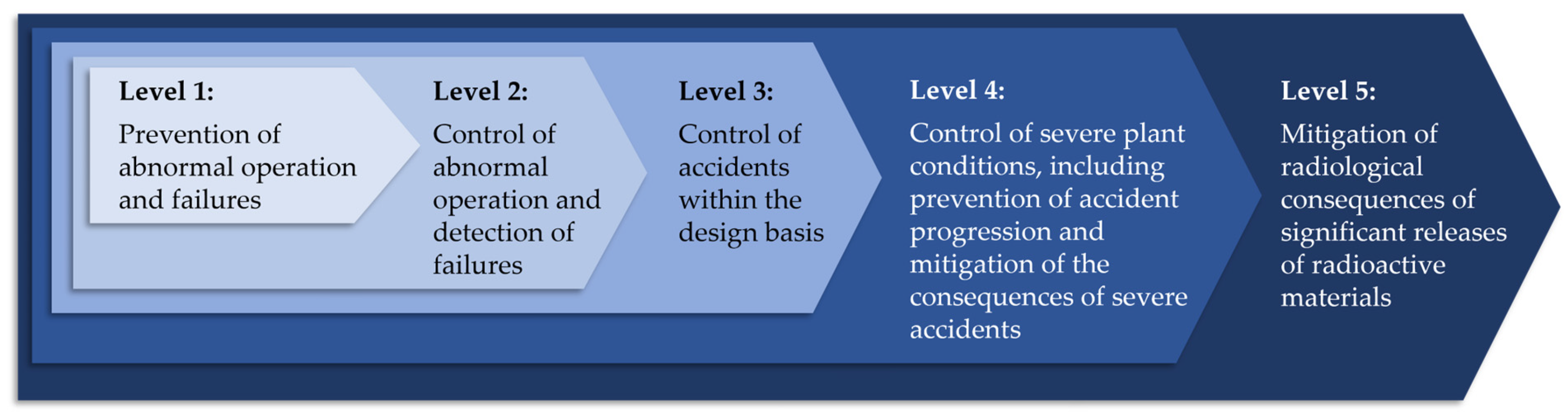

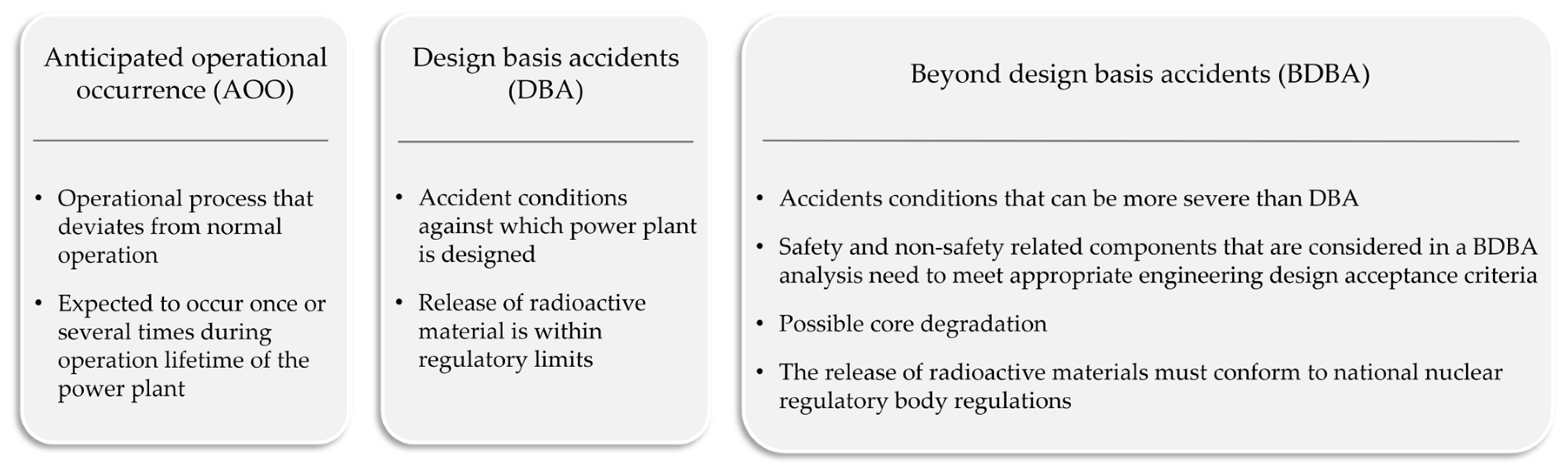

2.2.2. Safety Assessment

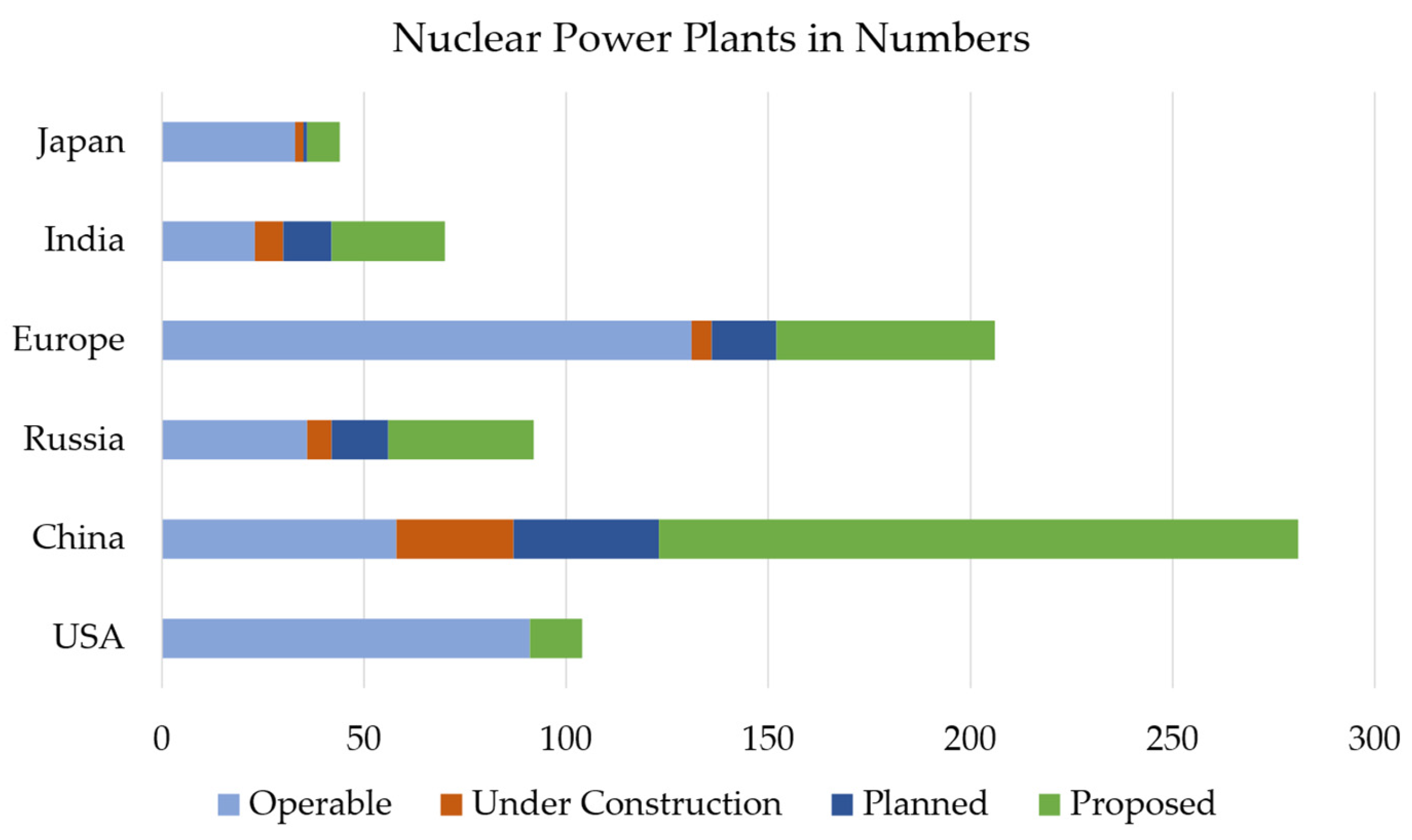

2.3. Global Trends

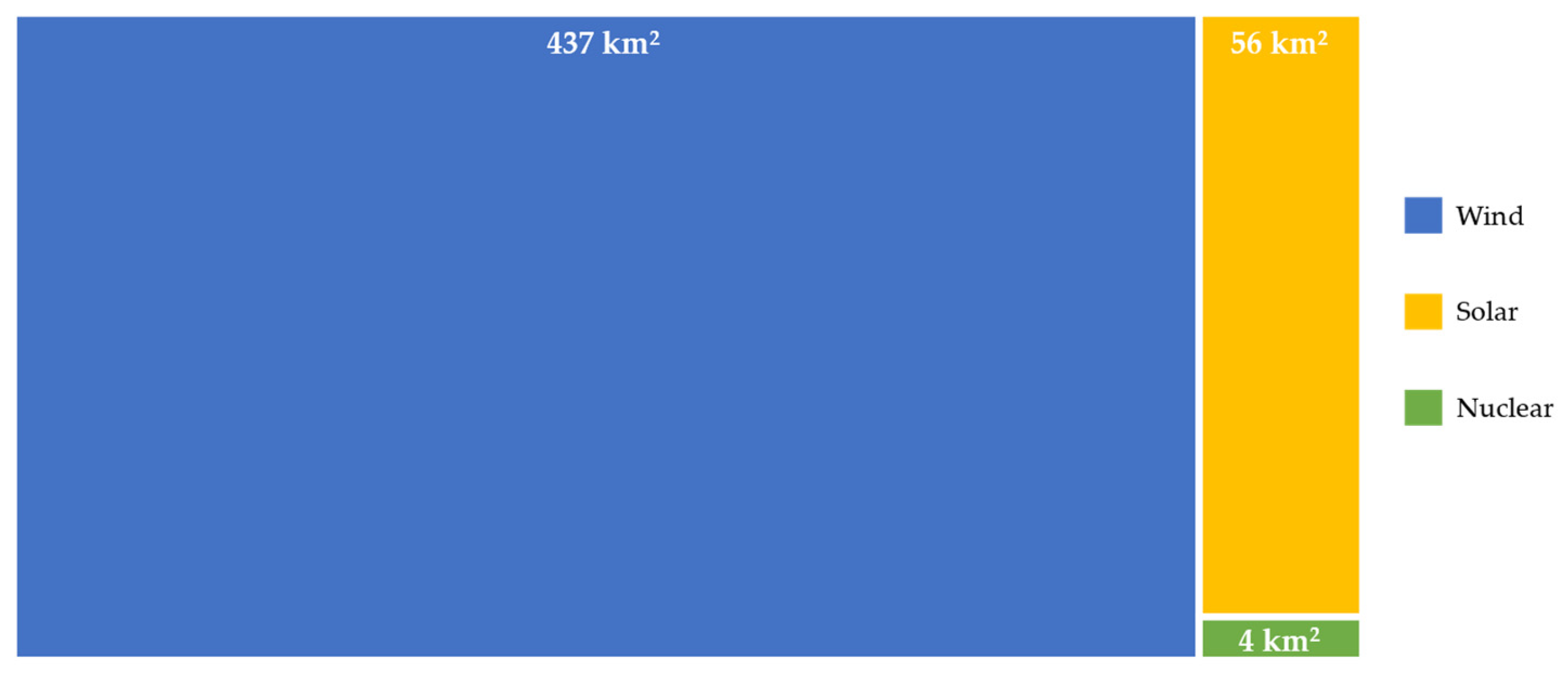

3. Bigger = Better?

3.1. Why Shift to Smaller Nuclear Reactors

| SMR | Country and Thermal Power, Outlet Temperature | License to Construct | Under Construction? | License to Operate | Operating? |

|---|---|---|---|---|---|

| CAREM SMR | Argentina 100 MWth, 326 °C | Yes | Yes | - | - |

| ACP100 | China 385 MWth, 320 °C | Yes | Yes | - | - |

| RITM-200N | Russia 396 MWth, 318 °C | Yes | Yes [89] | - | - |

| BREST-OD-300 | Russia 700 MWth, 350 °C | Yes | Yes | - | - |

| HTR-PM | China 500 MWth, 700 °C | Yes | Yes | Yes | Yes |

| KLT-40S | Russia 300 MWth, 316 °C | Yes | Yes | Yes | Yes |

| HTTR | Japan 30 MWth, 950 °C | Yes | Yes | Yes | Yes |

3.2. Advanced Manufacturing Techniques for the Nuclear Industry

3.2.1. Direct Energy Deposition

3.2.2. Powder Metallurgy–Hot Isostatic Pressing

3.2.3. Laser Powder Bed Fusion

3.2.4. Standardization

| AMT | Weight Limit | Size Limit | Potential Use in the Nuclear Industry |

|---|---|---|---|

| DED/WAAM | 230 kg [113] | Limited by the handling system [141] structural thickness ≥ 3 mm [115] | Heavy shielding, pressure vessel sections, piping, valves, components of nozzles or heat exchanger [118] |

| PM-HIP | larger HIP unit: 30 t [120] | Larger HIP unit: diameter up to 2.2 m, height of appr. 4 m [120] | Larger or thicker components [121] |

| LPBF | 23 kg [113] | Standards systems: 250 × 250 × 250 mm [141] | Fuel assembly components [113], channel fasteners, pump impellers, thimble plugging devices or valve bodies [142] |

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency. World Energy Outlook 2023; IEA: Paris, France, 2023. [Google Scholar]

- United States of America. The Long-Term Strategy of the United States: Pathways to Net-Zero Greenhouse Gas Emissions by 2050. 2021. Available online: https://unfccc.int/documents/308100 (accessed on 8 August 2025).

- Government of Canada. Net-Zero Emissions by 2050. Available online: https://www.canada.ca/en/services/environment/weather/climatechange/climate-plan/net-zero-emissions-2050.html (accessed on 23 April 2024).

- European Commission. The European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 18 April 2024).

- European Commission. Delivering the European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_en (accessed on 18 April 2024).

- Ezell, S. How Innovative Is China in Nuclear Power? 2024. Available online: https://itif.org/publications/2024/06/17/how-innovative-is-china-in-nuclear-power/ (accessed on 20 July 2025).

- Liou, J. 2023 Scientific Forum: Nuclear Innovations for Net Zero. Available online: https://www.iaea.org/newscenter/news/2023-scientific-forum-nuclear-innovations-for-net-zero (accessed on 24 April 2024).

- IPCC. Special Report on Renewable Energy Sources and Climate Change Mitigation; IPCC, Ed.; Prepared by Working Group III of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2011. [Google Scholar]

- IPCC (Ed.) Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Clack, C.; Choukulkar, A.; Coté, B.; McKee, S. Role of Electricity Produced by Advanced Nuclear Technologies in Decarbonizing the U.S. Energy System. Available online: https://vibrantcleanenergy.com/wp-content/uploads/2022/06/VCE-NEI-17June2022.pdf (accessed on 29 April 2024).

- Dolan, S.L.; Heath, G.A. Life Cycle Greenhouse Gas Emissions of Utility-Scale Wind Power. J. Ind. Ecol. 2012, 16, S136–S154. [Google Scholar] [CrossRef]

- Burkhardt, J.J.; Heath, G.; Cohen, E. Life Cycle Greenhouse Gas Emissions of Trough and Tower Concentrating Solar Power Electricity Generation. J. Ind. Ecol. 2012, 16, S93–S109. [Google Scholar] [CrossRef]

- Hsu, D.D.; O’Donoughue, P.; Fthenakis, V.; Heath, G.A.; Kim, H.C.; Sawyer, P.; Choi, J.-K.; Turney, D.E. Life Cycle Greenhouse Gas Emissions of Crystalline Silicon Photovoltaic Electricity Generation. J. Ind. Ecol. 2012, 16, S122–S135. [Google Scholar] [CrossRef]

- Kim, H.C.; Fthenakis, V.; Choi, J.-K.; Turney, D.E. Life Cycle Greenhouse Gas Emissions of Thin-film Photovoltaic Electricity Generation. J. Ind. Ecol. 2012, 16, S110–S121. [Google Scholar] [CrossRef]

- Warner, E.S.; Heath, G.A. Life Cycle Greenhouse Gas Emissions of Nuclear Electricity Generation. J. Ind. Ecol. 2012, 16, S73–S92. [Google Scholar] [CrossRef]

- NREL. Life Cycle Greenhouse Gas Emissions from Electricity Generation: Update. 2021. Available online: https://docs.nrel.gov/docs/fy21osti/80580.pdf (accessed on 15 July 2025).

- Bielen, K. Advanced Nuclear Energy. FAQ for Community Stakeholders. Available online: https://www.nei.org/CorporateSite/media/filefolder/resources/reports-and-briefs/Advanced-Nuclear-FAQ-for-Community-Stakeholders.pdf (accessed on 30 April 2024).

- International Atomic Energy Agency (Ed.) Terms for Describing Advanced Nuclear Power Plants; IAEA: Vienna, Austria, 2023; ISBN 978-92-0-146023-3. [Google Scholar]

- Elliott, D. Nuclear Power: Past, Present and Future, 2nd ed.; Version: 20220501; IOP Publishing: Bristol, UK, 2022; ISBN 9780750351522. [Google Scholar]

- European Commission. Small Modular Reactors Explained. Available online: https://energy.ec.europa.eu/topics/nuclear-energy/small-modular-reactors/small-modular-reactors-explained_en#eu-action-on-smrs (accessed on 18 April 2024).

- Marguet, S. (Ed.) A Brief History of Nuclear Reactor Accidents; Springer International Publishing: Cham, Switzerland, 2022. [Google Scholar]

- European Commission. Directorate General for Energy. In EU Energy in Figures: Statistical Pocketbook 2023; Publications Office: Luxembourg, 2023. [Google Scholar]

- World Nuclear Association. Nuclear Power in France. Available online: https://world-nuclear.org/information-library/country-profiles/countries-a-f/france (accessed on 24 January 2025).

- NRC Web. Backgrounder on the Three Mile Island Accident. Available online: https://www.nrc.gov/reading-rm/doc-collections/fact-sheets/3mile-isle.html (accessed on 4 August 2024).

- International Atomic Energy Agency. Frequently Asked Chernobyl Questions. Available online: https://www.iaea.org/newscenter/focus/chernobyl/faqs (accessed on 4 August 2024).

- Lovering, J.R.; Yip, A.; Nordhaus, T. Historical construction costs of global nuclear power reactors. Energy Policy 2016, 91, 371–382. [Google Scholar] [CrossRef]

- Gallup. Gallup Vault: Nuclear Power Plant Fears After Chernobyl. Available online: https://news.gallup.com/vault/191099/gallup-vault-nuclear-power-plant-fears-chernobyl.aspx (accessed on 14 July 2025).

- Gallup. 40 Years After Three Mile Island, Americans Split on Nuclear Power. Available online: https://news.gallup.com/poll/248048/years-three-mile-island-americans-split-nuclear-power.aspx?utm_source=chatgpt.com (accessed on 14 July 2025).

- IEA. World Energy Statistics and Balances. Available online: https://www.iea.org/data-and-statistics/data-product/world-energy-statistics-and-balances (accessed on 6 August 2025).

- Fisher, M. IAEA Milestones Guidance Updated to Include Considerations for SMRs. Available online: https://www.iaea.org/newscenter/news/iaea-milestones-guidance-updated-to-include-considerations-for-smrs (accessed on 10 August 2024).

- Zohuri, B.; McDaniel, P. Advanced Smaller Modular Reactors: An Innovative Approach to Nuclear Power; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar]

- International Atomic Energy Agency. Milestones in the Development of a National Infrastructure for Nuclear Power; IAEA: Vienna, Austria, 2024; ISBN 1995-7807. [Google Scholar]

- European Commission. Radiological Impacts. Available online: https://energy.ec.europa.eu/topics/nuclear-energy/radiation-protection/radiological-impacts_en (accessed on 18 April 2024).

- 2010/635/Euratom; Commission Recommendation of 11 October 2010 on the Application of Article 37 of the Euratom Treaty. European Commission: Luxembourg, 2010.

- International Atomic Energy Agency. Nuclear Power Reactors in the World: Reference Data Series No. 2; IAEA: Vienna, Austria, 2024. [Google Scholar]

- Generation IV International Forum. Technology Roadmap Update for Generation IV Nuclear Energy Systems; OECD Nuclear Energy Agency: Paris, France, 2014; Available online: https://www.gen-4.org/gif/upload/docs/application/pdf/2014-03/gif-tru2014.pdf (accessed on 12 July 2025).

- NEA. High-Temperature Gas-Cooled Reactors and Industrial Heat Applications; OECD Publishing: Paris, France, 2022. [Google Scholar]

- GRS gGmbH. Druckwasserreaktor (DWR). Available online: https://www.grs.de/de/glossar/druckwasserreaktor-dwr (accessed on 16 September 2024).

- BASE. Atomkraftwerke in Deutschland. Available online: https://www.base.bund.de/DE/themen/kt/kta-deutschland/kta-uebersicht/lwr/leichtwasserreaktoren.html (accessed on 16 September 2024).

- Frey, H. Kernenergie; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2021. [Google Scholar]

- International Atomic Energy Agency. Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and Documentation, 1st ed.; International Atomic Energy Agency: Vienna, Austria, 2022; ISBN 9789201325211. [Google Scholar]

- U.S. Department of Energy. Light Water Reactor Sustainability Program: Materials Aging and Degradation Technical Program Plan ORNL/LTR-2012/327. 2012. Available online: https://www.energy.gov/sites/prod/files/LWRS_Materials_Aging_%26_Degradation_Technical_Program_Plan_September2012.pdf?utm_source=chatgpt.com (accessed on 17 July 2025).

- Picot, W. Nuclear Innovations for Net Zero: Enhancing Nuclear Power Production with Artificial Intelligence. In Nuclear Innovations for Net Zero; IAEA: Vienna, Austria, 2023; pp. 18–19. [Google Scholar]

- Tetsuaki, T.; Yoshiyuki, I. High Temperature Gas-Cooled Reactors; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 978-0-12-821031-4. [Google Scholar]

- Reeve, K.D. Ceramics as nuclear reactor fuels. Ceramurg. Int. 1975, 1, 59–71. [Google Scholar] [CrossRef]

- Guimarães, C.; Laranjo de Stefani, G.; dos Santos, T. (Eds.) Use of Thorium for High Temperature Gas-Cooled Reactors. In Proceedings of the International Nuclear Atlantic Conference, Belo Horizonte, Brazil, 22–27 October 2017. [Google Scholar]

- Astute Analytica India Pvt. Ltd. Tri-Structural Isotropic (TRISO) Fuel Market Size, Report, 2033 AA05251304. 2025. Available online: https://www.astuteanalytica.com/industry-report/tri-structural-isotropic-fuel-market (accessed on 17 July 2025).

- Allen, T.; Busby, J.; Meyer, M.; Petti, D. Materials challenges for nuclear systems. Mater. Today 2010, 13, 14–23. [Google Scholar] [CrossRef]

- OECD; NEA. High-Temperature Gas-Cooled Reactors and Industrial Heat Applications; No. 7629; Nuclear Energy Agency: Paris, France, 2022; Available online: https://www.oecd-nea.org/upload/docs/application/pdf/2022-06/7629_htgr.pdf (accessed on 21 February 2025).

- The Generation IV International Forum. Very High Temperature Reactor (VHTR). Available online: https://www.gen-4.org/generation-iv-criteria-and-technologies/very-high-temperature-reactor-vhtr (accessed on 27 January 2025).

- Generation IV International Forum. Safety Design and Safety Characteristics of the VHTR: GIF VHTR Safety Assessment White Paper; 2018. Available online: https://www.gen-4.org/gif/upload/docs/application/pdf/2018-12/gifvhtr_safety_assessment_finaldec2018.pdf (accessed on 17 June 2025).

- National Academies of Sciences, Engineering, and Medicine (Ed.) Laying the Foundation for New and Advanced Nuclear Reactors in the United States; National Academies Press: Washington, DC, USA, 2023. [Google Scholar]

- The Generation IV International Forum. Molten Salt Reactors (MSR). Available online: https://www.gen-4.org/generation-iv-criteria-and-technologies/molten-salt-reactors-msr (accessed on 11 February 2025).

- The Generation IV International Forum. A Technology Roadmap for Generation IV Nuclear Energy Systems. 2002. Available online: https://www.gen-4.org/gif/jcms/c_40481/technology-roadmap (accessed on 15 February 2025).

- International Atomic Energy Agency. Status of Molten Salt Reactor Technology; TECDOC Series No. 489; IAEA: Vienna, Austria, 2022; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/STI-DOC-010-489_web.pdf (accessed on 16 February 2025).

- National Academies of Sciences, Engineering, and Medicine (Ed.) Merits and Viability of Different Nuclear Fuel Cycles and Technology Options and the Waste Aspects of Advanced Nuclear Reactors; National Academies Press: Washington, DC, USA, 2023. [Google Scholar]

- Schulenberg, T. The Fourth Generation of Nuclear Reactors; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- The Generation IV International Forum. Sodium Fast Reactor (SFR). Available online: https://www.gen-4.org/generation-iv-criteria-and-technologies/sodium-fast-reactor-sfr (accessed on 14 February 2025).

- The Generation IV International Forum. Gas-Cooled Fast Reactor (GFR). Available online: https://www.gen-4.org/generation-iv-criteria-and-technologies/gas-cooled-fast-reactor-gfr (accessed on 14 February 2025).

- The Generation IV International Forum. Lead Fast Reactors (LFR). Available online: https://www.gen-4.org/generation-iv-criteria-and-technologies/lead-fast-reactors-lfr (accessed on 14 February 2025).

- The Generation IV International Forum. Annual Report 2023; NEA: Paris, France, 2024. [Google Scholar]

- Wu, P.; Ren, Y.; Feng, M.; Shan, J.; Huang, Y.; Yang, W. A review of existing SuperCritical Water reactor concepts, safety analysis codes and safety characteristics. Prog. Nucl. Energy 2022, 153, 104409. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Safety of Nuclear Power Plants: Design; International Atomic Energy Agency: Vienna, Austria, 2016; ISBN 9789201093158. [Google Scholar]

- BAnz AT 15.03.2022 B3; Sicherheitsanforderungen an Kernkraftwerke. Bundesministerium für Umwelt, Naturschutz, nukleare Sicherheit und Verbraucherschutz: Berlin, Germany, 2022.

- International Atomic Energy Agency. Fundamental Safety Principles: Safety Fundamentals No. SF-1; IAEA: Vienna, Austria, 2006; ISBN 9201107064. [Google Scholar]

- ENGIE Electrabel. The Different Pillars of Nuclear Safety. Available online: https://nuclear.engie-electrabel.be/en/nuclear-energy/nuclear-power-plants-and-safety/different-pillars-nuclear-safety (accessed on 24 September 2024).

- International Atomic Energy Agency. Nuclear Safety and Security Glossary: Terminology Used in Nuclear Safety, Nuclear Security, Radiation Protection and Emergency Preparedness and Response, 2022 (interim) ed.; IAEA: Vienna, Austria, 2022; ISBN 9789201418227. [Google Scholar]

- International Atomic Energy Agency. Accident Analysis for Nuclear Power Plants with Modular High Temperature Gas Cooled Reactors; Publication/Division of Scientific and Technical Information; STI/PUB/1318; IAEA: Vienna, Austria, 2008. [Google Scholar]

- International Atomic Energy Agency. Seismic Hazards in Site Evaluation for Nuclear Installations; IAEA: Vienna, Austria, 2022; ISBN 9789201179210. [Google Scholar]

- NRC Web. Transportation of Spent Nuclear Fuel. Available online: https://www.nrc.gov/waste/spent-fuel-transp.html (accessed on 19 April 2024).

- NRC Web. Materials Transportation. Available online: https://www.nrc.gov/materials/transportation.html (accessed on 19 April 2024).

- U.S. Department of Energy. Atlas Railcar, 2020. Available online: https://www.energy.gov/sites/default/files/2020/10/f80/2020_10_ATLAS_Fact-Sheet_FINAL.pdf (accessed on 22 April 2024).

- U.S. Department of Energy. New Railcar Designed to Transport Spent Nuclear Fuel Completes Final Testing. Available online: https://www.energy.gov/ne/articles/new-railcar-designed-transport-spent-nuclear-fuel-completes-final-testing (accessed on 22 April 2024).

- International Atomic Energy Agency. Regulations for the Safe Transport of Radioactive Material, 2018 ed.; IAEA: Vienna, Austria, 2018; ISBN 9789201489197. [Google Scholar]

- Borowski, J.; Call, M.; Dunn, D.; Rigato, A.; Smith, J.; Solis, J.; Tapp, J.; White, B. NUREG-2216: Review Plan for Transportation Packages for Spent Fuel and Radioactive Material: Final Report; U.S. Nuclear Regulatory Commission—NRC: North Bethesda, MD, USA, 2020. [Google Scholar]

- Bajwa, C.S.; Easton, E.P.; Adkins, H.; Cuta, J.; Klymyshyn, N.; Suffield, S. Severe Transportation Accidents: Do Used Nuclear Fuel Transportation Packages Survive Real World Accidents? In Proceedings of the ASME 2011 Pressure Vessels and Piping Conference, Baltimore, MD, USA, 17–21 July 2011; Cheta, A., Ed.; ASME: New York, NY, USA, 2012; pp. 399–411, ISBN 978-0-7918-4457-1. [Google Scholar]

- U.S. Nuclear Regulatory Commission. NUREG/CR-6886, Rev 2: Spent Fuel Transportation Package Response to the Baltimore Tunnel Fire Scenario; U.S. Nuclear Regulatory Commission—NRC: North Bethesda, MD, USA, 2009. [Google Scholar]

- U.S. Department of Energy. Saving Existing Nuclear Fleet Brings Net-Zero Future Closer. Available online: https://www.energy.gov/articles/saving-existing-nuclear-fleet-brings-net-zero-future-closer (accessed on 11 July 2024).

- Ebner, S. Hinkley Point C: Wie Großbritanniens neues AKW zum Problemmeiler wird. RedaktionsNetzwerk Deutschland [Online], 8 February 2024. Available online: https://www.rnd.de/politik/hinkley-point-c-wie-grossbritanniens-neues-akw-zum-problemmeiler-wird-JATQRMGLYVHTFMKIDP45MO7WAQ.html (accessed on 11 July 2024).

- World Nuclear Association. Nuclear Power in the World Today. Available online: https://world-nuclear.org/information-library/current-and-future-generation/nuclear-power-in-the-world-today (accessed on 10 March 2025).

- NEA. Long-Term Operation of Nuclear Power Plants and Decarbonisation Strategies; OECD Publishing: Paris, France, 2021. [Google Scholar]

- Foro Nuclear. SALTO: Peer Review to Assess the Long-Term Operational Safety of Nuclear Power Plant. Available online: https://www.foronuclear.org/en/updates/in-depth/salto-peer-review-to-assess-the-long-term-operational-safety-of-nuclear-power-plant/ (accessed on 18 September 2024).

- Wendler, N. Zu teuer und zu langsam für die Dekarbonisierung: Kritik an Kernenergie hält Analyse nicht stand. atw—Int. J. Nucl. Power 2024, 69, 27–30. [Google Scholar]

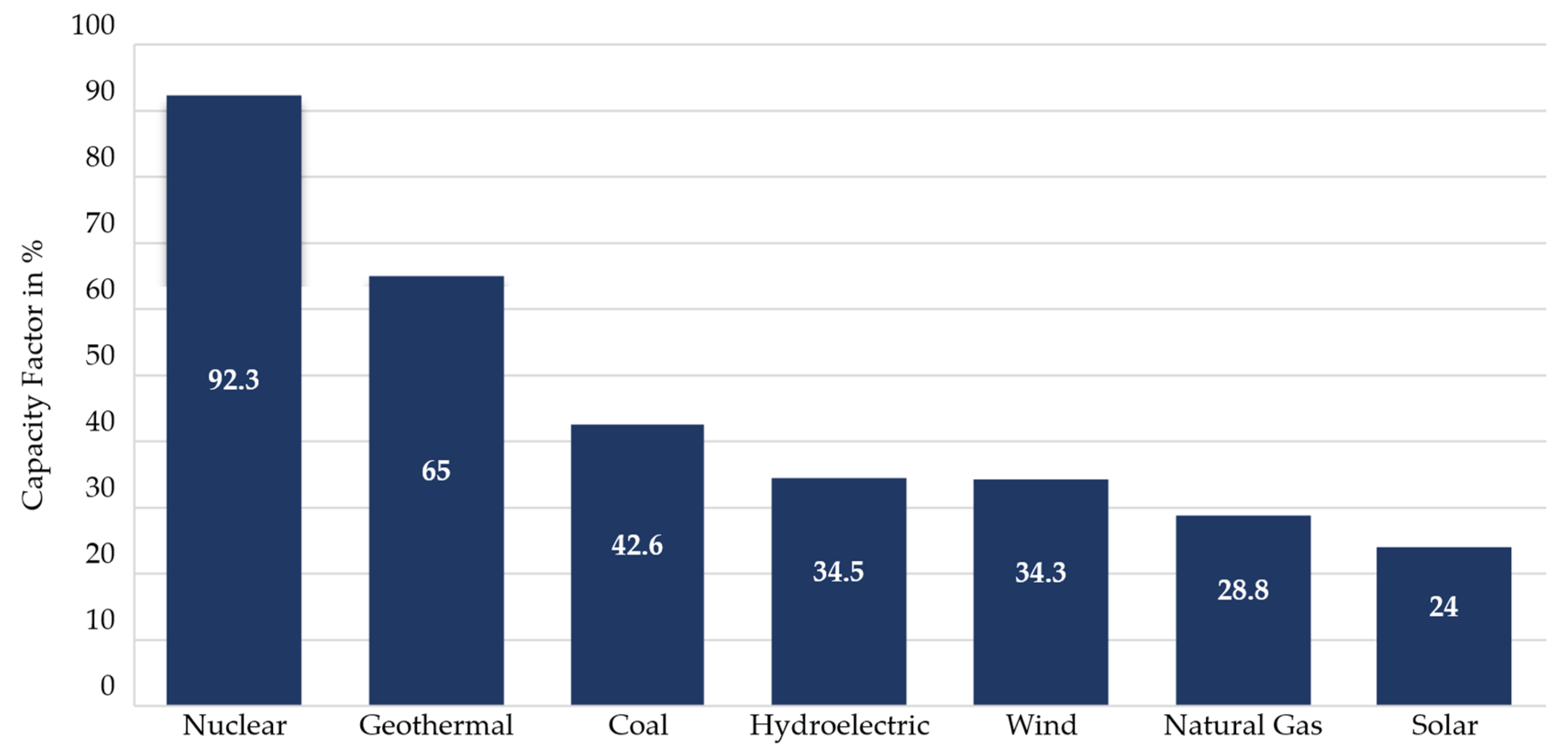

- U.S. Energy Information Administration. Electric Power Monthly; U.S. EIA: Washington, DC, USA, 2025. [Google Scholar]

- NEA. The NEA Small Modular Reactor Dashboard: Second Edition; OECD Publishing: Paris, France, 2024. [Google Scholar]

- Densmore, T.; Duffy, V.G. Systematic Literature Review of Nuclear Safety Systems in Small Modular Reactors. In HCI International 2021—Late Breaking Posters, Proceedings of the 23rd HCI International Conference, HCII 2021, Virtual Event, 24–29 July 2021, 1st ed.; Proceedings, Part I; Stephanidis, C., Antona, M., Ntoa, S., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 99–106. ISBN 978-3-030-90175-2. [Google Scholar]

- Westinghouse. eVinci™ Microreactor. Available online: https://westinghousenuclear.com/energy-systems/evinci-microreactor/ (accessed on 2 March 2025).

- Government of Saskatchewan. Westinghouse and Saskatchewan Research Council Advance Micro-Reactors in Canada. Available online: https://www.saskatchewan.ca/government/news-and-media/2022/may/18/westinghouse-and-saskatchewan-research-council-advance-micro-reactors-in-canada (accessed on 2 March 2025).

- World Nuclear News. Preparatory Work Stepped up for Russia’s First Land-Based SMR. Available online: https://www.world-nuclear-news.org/Articles/Preparatory-work-stepped-up-for-Russia-s-first-lan (accessed on 15 February 2025).

- World Nuclear News. Last Energy Plans Texan Microreactor Plant. Available online: https://www.world-nuclear-news.org/articles/last-energy-plans-texan-microreactor-plant (accessed on 2 March 2025).

- Carless, T.S.; Talabi, S.M.; Fischbeck, P.S. Risk and regulatory considerations for small modular reactor emergency planning zones based on passive decontamination potential. Energy 2019, 167, 740–756. [Google Scholar] [CrossRef]

- NuScale Power, LLC. NuScale SMR Technology: An Ideal Solution for Repurposing U.S. Coal Plant Infrastructure and Revitalizing Communities. Available online: https://www.nuscalepower.com/hubfs/Website/Files/Technical%20Publications/nuscale-smr-technology-an-ideal-solution-for-coal-plant-replacement.pdf (accessed on 2 July 2025).

- World Nuclear News. Uprated NuScale SMR Design Gets US Approval. Available online: https://www.world-nuclear-news.org/articles/uprated-nuscale-smr-design-gets-us-approval (accessed on 9 July 2025).

- Levinson, J. Nuclear Reactor Deal Collapse Challenges Portland Company’s Clean Energy plan. OPB [Online], 9 November 2023. Available online: https://www.opb.org/article/2023/11/09/nuscale-power-modular-nuclear-reactors-partnership-cancellation/ (accessed on 18 February 2025).

- Will Wade, B.N. First US Small Nuke Project Canceled After Costs Surge 53%. Financial Post [Online], 9 November 2023. Available online: https://financialpost.com/pmn/business-pmn/first-us-small-nuke-project-canceled-after-costs-climb-53 (accessed on 7 July 2025).

- Barber, G. The First Small-Scale Nuclear Plant in the US Died Before It Could Live. WIRED [Online], 9 November 2023. Available online: https://www.wired.com/story/first-small-scale-nuclear-plant-us-nuscale-canceled/ (accessed on 7 July 2025).

- Porter, K. The West’s only Licensed Small Reactor Project is Dead. It’s a Blow for Green Energy. The Telegraph [Online], 18 December 2023. Available online: https://www.telegraph.co.uk/news/2023/12/18/nuscale-smr-cancellation-green-energy-net-zero-blow/ (accessed on 7 July 2025).

- Fabian, E. Romania to host Europe’s First SMR with Newly Approved Design. CeenergyNews [Online], 30 May 2025. Available online: https://ceenergynews.com/nuclear/romania-to-host-europes-first-smr-with-newly-approved-design/ (accessed on 10 July 2025).

- World Nuclear News. NuScale SMR Meets Polish Safety Requirements, Says Regulator. Available online: https://www.world-nuclear-news.org/articles/nuscale-smr-meets-polish-safety-requirements,-says (accessed on 10 July 2025).

- World Nuclear News. Korea Considers Deployment of NuScale SMR for Hydrogen Production. Available online: https://world-nuclear-news.org/articles/korea-considers-deployment-of-nuscale-smr-for-hydr?utm_source=chatgpt.com (accessed on 10 July 2025).

- Business Korea. Doosan Enerbility to Supply SMR Components to Nuscale Power in US. Available online: https://www.businesskorea.co.kr/news/articleView.html?idxno=217802 (accessed on 10 July 2025).

- Nucleareurope. Infographics Pocket Guide; Nucleareurope: Brussels, Belgium, 2022. [Google Scholar]

- World Nuclear News. SMRs Cost-Effective in Hydrogen Production. Available online: https://www.world-nuclear-news.org/Articles/SMRs-cost-effective-in-hydrogen-production,-study (accessed on 21 May 2024).

- ULC Energy. Study Reveals Low Cost of Nuclear H2. Available online: https://www.ulc-energy.com/news/study-reveals-low-cost-of-nuclear-h2 (accessed on 21 May 2024).

- Midgley, E.; Fisher, M. Molten Salt Reactor Technology Development Continues as Countries Work Towards Net Zero. Available online: https://www.iaea.org/newscenter/news/molten-salt-reactor-technology-development-continues-as-countries-work-towards-net-zero (accessed on 26 September 2024).

- World Nuclear News. Polish Ministry Approves Plans for Rolls-Royce SMRs. Available online: https://www.world-nuclear-news.org/Articles/Polish-ministry-approves-plans-for-Rolls-Royce-SMR (accessed on 21 May 2024).

- GE Hitachi Nuclear. BWRX-300 Small Modular Reactor. Available online: https://www.gevernova.com/nuclear/carbon-free-power/bwrx-300-small-modular-reactor (accessed on 2 March 2025).

- Vinoya, C.L.; Ubando, A.T.; Culaba, A.B.; Chen, W.-H. State-of-the-Art Review of Small Modular Reactors. Energies 2023, 16, 3224. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Applicability of Design Safety Requirements to Small Modular Reactor Technologies Intended for Near Term Deployment: Light Water Reactors High Temperature Gas Cooled Reactors; IAEA: Vienna, Austria, 2020; ISBN 9789201309204. [Google Scholar]

- International Atomic Energy Agency. Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular Reactors; International Atomic Energy Agency: Vienna, Austria, 2023; ISBN 978-92-0-127323-9. [Google Scholar]

- International Atomic Energy Agency. Multi-Unit Probabilistic Safety Assessment, 1st ed.; IAEA: Havertown, PA, USA, 2023; ISBN 978-92-0-119422-0. [Google Scholar]

- Li, M.; Andersson, D.; Dehoff, R.; Jokisaari, A.; Van Rooyen, I.; Cairns-Gallimore, D. Advanced Materials and Manufacturing Technologies (AMMT): 2022 Roadmap; ANL-23/12; U.S. Department of Energy: Lemont, IL, USA, 2022. Available online: https://publications.anl.gov/anlpubs/2023/02/180691.pdf (accessed on 13 April 2025).

- Nuclear Energy Institute. Roadmap for Regulatory Acceptance of Advanced Manufacturing Methods in the Nuclear Energy Industry. 2019. Available online: https://www.nei.org/CorporateSite/media/filefolder/resources/reports-and-briefs/Report-NEI-Advanced-Manufacturing-Regulatory-Roadmap-Final-2019-05-13.pdf (accessed on 2 March 2025).

- Sperko Engineering Services, Inc. A History of Additive Manufacturing Using Conventional Welding Processes. 2023. Available online: https://sperkoengineering.com/html/Additive.pdf (accessed on 3 April 2025).

- Mayr, P.; Berger, M. (Eds.) FüMoTeC 2017: Tagungsband; Universitätsverlag Chemnitz: Chemnitz, Germany, 2017. [Google Scholar]

- Chen, X.; Shang, X.; Zhou, Z.; Chen, S.-G. A Review of the Development Status of Wire Arc Additive Manufacturing Technology. Adv. Mater. Sci. Eng. 2022, 2022, 5757484. [Google Scholar] [CrossRef]

- Tang, W.; Giuliano, D.; Martinez, O.; Banerjee, K.; Nycz, A.; Gussev, M.N.; Meyer, L.; Vaughan, D. 316L Stainless Steel Wire Arc Additive Manufacturing and Characterization for Potential SNF Canister Production. In Proceedings of the International High-Level Radioactive Waste Management Conference, IHLRWM 2022, Embedded with the 2022 ANS Winter Meeting, Phoenix, AZ, USA; pp. 43–52.

- Nag, S.; Paramanathan, M.; List, F.; Feldhausen, T.; Nycz, A.; Carter, B.; Brown, D.; Heinrich, L.; Fillingim, K.B.; Meyer, L.; et al. In Situ Monitoring Assisted Large-Scale Additive Manufacturing of Mild Steel and 316 Alloys for Nuclear Applications. ORNL/TM-2023/3090 M3CR-22OR0402031. 2023. Available online: https://info.ornl.gov/sites/publications/Files/Pub202570.pdf (accessed on 20 July 2025).

- Gardahaut, A.; Charau, A.; Le Bourdais, F.; Stolidi, A.; Sargeeva-Chollet, N. Implementation of Non Destructive Testing and in-line monitoring techniques on extra-large structures printed with WAAM technology. J. Nondestruct. Test. 2023, 28. [Google Scholar] [CrossRef] [PubMed]

- European Powder Metallurgy Association. Introduction to Hot Isostatic Pressing Technology: A guide for Designers and Engineers. 2019. Available online: http://www.cef3d.fr/COSS/wp-content/uploads/2019/02/27/EPMA-Introduction-to-PM-HIP-Technology-English.pdf (accessed on 21 July 2025).

- Hoelzer, D.T. The Use of Powder Metallurgy and Hot Isostatic Pressing for Fabricating Components of Nuclear Power Plants. ORNL/SPR-2022/2421. 2022. Available online: https://www.nrc.gov/docs/ML2216/ML22164A438.pdf (accessed on 9 April 2025).

- Sheinhartz, I.; Fugardi, J. Ceramic Fuel Elements Made By Hot Isostatic Pressing; SCNC-311; Sylvania-Corning Nuclear Corp.: Bayside, NY, USA, 1960. Available online: https://www.osti.gov/biblio/4015060 (accessed on 20 July 2025).

- Gandy, D.W.; Frew, B. Approach to Codifying New Manufacturing Methods (e.g., PM-HIP, LPBF, EBW); Electric Power Research Institute, Inc.: Palo Alto, CA, USA, 2020. [Google Scholar]

- Jiang, W.; Zhao, Y.; Lu, Y.; Wu, Y.; Frazer, D.; Guillen, D.P.; Gandy, D.W.; Wharry, J.P. Comparison of PM-HIP to forged SA508 pressure vessel steel under high-dose neutron irradiation. J. Nucl. Mater. 2024, 594, 155018. [Google Scholar] [CrossRef]

- Rolls-Royce. Rolls-Royce’s Experience of Applying the PM-HIP Process to the Manufacture of Nuclear Plant Components; U.S. Nuclear Regulatory Commission (NRC): Rockville, MD, USA, 2023. [Google Scholar]

- Rahman, M.; Evans, C.; Fox, J.; Miller, J.; Berez, J. Specification and Characterization of Laser Powder Bed Fusion Surface Textures for Heat Transfer in Internal Channels; Proceedings of the American Society for Precision Engineering (ASPE) and European Society for Precision Engineering and Nanotechnology (euspen) Special Interest Group Meeting: Advancing Precision in Additive Manufacturing, Golden, CO, USA, 2024. Available online: https://www.nist.gov/publications/specification-and-characterization-laser-powder-bed-fusion-surface-textures-heat?utm_source=chatgpt.com (accessed on 15 July 2025).

- Milewski, J.O. Additive Manufacturing of Metals: From Fundamental Technology to Rocket Nozzles, Medical Implants, and Custom Jewelry; Springer International Publishing: Cham, Switzerland, 2017; ISBN 9783319582054. [Google Scholar]

- Qian, C.; Zhang, K.; Zhu, J.; Liu, Y.; Liu, Y.; Liu, J.; Liu, J.; Yang, Y.; Wang, H. Effect of processing parameters on the defects, microstructure, and property evaluation of Ti-6Al-4V titanium alloy processed by laser powder bed fusion. AIP Adv. 2024, 14, 025246. [Google Scholar] [CrossRef]

- Evangelou, A.; Stylianou, R.; Loizou, A.; Kim, D.; Liang, A.; Reed, P.; Constantinides, G.; Kyratsi, T. Effects of process parameters and scan strategy on the microstructure and density of stainless steel 316 L produced via laser powder bed fusion. J. Alloys Metall. Syst. 2023, 3, 100027. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, W.; Sun, Y.; Ma, R.; Wang, Y.; Bai, J.; Xue, L.; Song, X.; Tan, C. Effects of Process Parameters and Heat Treatment on Microstructure and Mechanical Characteristics of Laser Powder Bed Fusion Alloy Inconel 718. Coatings 2023, 13, 189. [Google Scholar] [CrossRef]

- Diaz Vallejo, N.; Lucas, C.; Ayers, N.; Graydon, K.; Hyer, H.; Sohn, Y. Process Optimization and Microstructure Analysis to Understand Laser Powder Bed Fusion of 316L Stainless Steel. Metals 2021, 11, 832. [Google Scholar] [CrossRef]

- Sewalski, S.; Werz, M.; Weihe, S. Investigation of the Robustness of the PBF-LB/M process for AISI 316L in Context of Safety-Critical Components for Nuclear Applications. In Transactions of the SMiRT 27, Proceedings of the 27th International Conference on Structural Mechanics in Reactor Technology (SMiRT 27), Yokohama, Japan, 3–8 March 2024; SMiRT, Ed.; SMiRT 27 Secretariat: Yokohama, Japan, 2024. [Google Scholar]

- Mantri, S.; Zhang, X.; Chen, W.-Y. Laser Powder Bed Fusion of Steels for Nuclear Applications; Argonne National Laboratory: Lemont, IL, USA, 2024. [Google Scholar]

- Li, H.; Fu, X.; Zhang, L.; Zhang, Y.; Jiang, L.; Pu, Z. A Review of the Latest Developments in the Field of Additive Manufacturing Techniques for Nuclear Reactors. Crystals 2022, 12, 918. [Google Scholar] [CrossRef]

- McMurtrey, M.; Messner, M. Qualification Challenges for Additive Manufacturing in High Temperature Nuclear Applications. In Volume 4: Materials and Fabrication, Proceedings of the ASME 2021 Pressure Vessels & Piping Conference, Virtual online, 13–15 July 2021; American Society of Mechanical Engineers: New York, NY, USA, 2021; ISBN 978-0-7918-8534-5. [Google Scholar]

- Argonne National Laboratory. ASME Code Qualification Plan for LPBF 316 SS; ANL-AMMT-009. 2023. Available online: https://publications.anl.gov/anlpubs/2023/08/184225.pdf (accessed on 14 July 2025).

- GBR Consulting. ASME Additive Manufacturing Codification; U.S. Nuclear Regulatory Commission (NRC): Rockville, MD, USA, 2023. [Google Scholar]

- ASTM International. AM Materials Data—Challenges & Opportunities; U.S. Nuclear Regulatory Commission (NRC): Rockville, MD, USA, 2023. [Google Scholar]

- ISO/ASTM 52920:2023; ISO/ASTM. Additive Manufacturing—Qualification Principles—Requirements for Industrial Additive Manufacturing Processes and Production Sites. ISO: Genf, Switzerland, 2023.

- ISO/ASTM 52909:2024; ISO/ASTM. Additive Manufacturing of Metals—Finished Part Properties—Orientation and Location Dependence of Mechanical Properties for Metal Parts. ISO: Genf, Switzerland, 2024.

- European Powder Metallurgy Association. Introduction to Additive Manufacturing Technology: A Guide for Designers and Engineers; European Powder Metallurgy Association: Shrewsbury, UK, 2022. [Google Scholar]

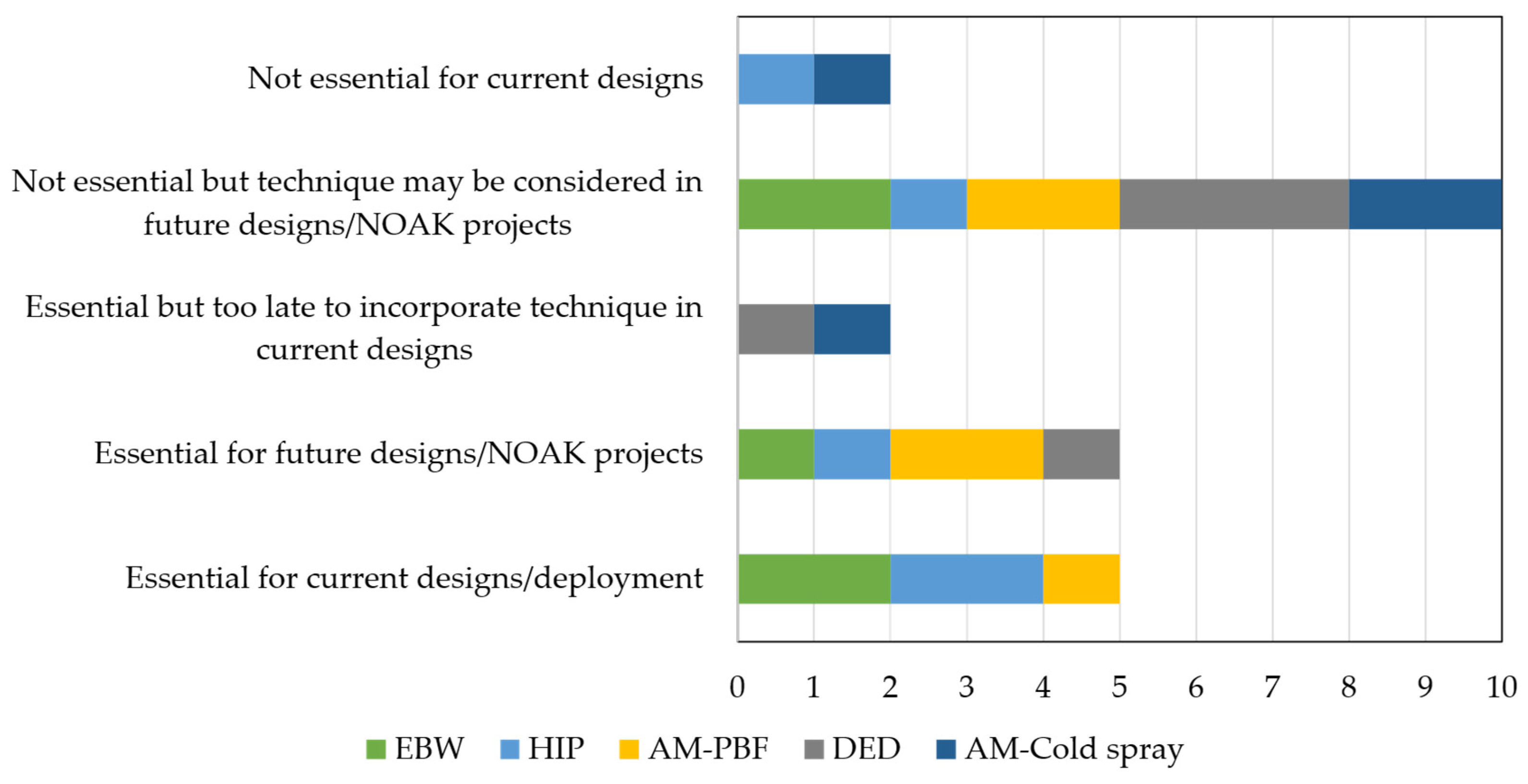

- Tanguy, R. CORDEL: A Perspective on Advanced Manufacturing Techniques [Workshop presentation], NEA Workshop on Advanced Construction and Manufacturing, Online. 16–17 March 2022. Available online: https://www.oecd-nea.org/jcms/pl_64903/advanced-construction-and-manufacturing-methodologies-for-new-nuclear-build (accessed on 16 March 2022).

- Bourgeois, M.; Petesch, C.; Verlet, R.; Misler, R. Some Challenges Regarding Qualification of Additive Manufacturing Components for a Nuclear Use—NUCOBAM Project. In Proceedings of the ASME 2024 Pressure Vessels & Piping Conference (PVP2024), Bellevue, WA, USA, 28 July–2 August 2024; The American Society of Mechanical Engineers: New York, NY, USA; Curran Associates Inc.: Little Falls, NJ, USA; Red Hook: New York, NY, USA, 2024; ISBN 978-0-7918-8850-6. [Google Scholar]

- Bertelle, N.; Hernandez, R.; Fernandez-Viña, A.; Nardone, S.; Hary, B.; Misler, R. Performance Assessment of Additive Manufacturing Components for an Ex-Core Nuclear User: Valve Component—NUCOBAM Project. In Proceedings of the ASME 2024 Pressure Vessels & Piping Conference (PVP2024), V004T06A029, Bellevue, WA, USA, 28 July–2 August 2024; ISBN 978-0-7918-8850-6. [Google Scholar]

- Mally, L.; Werz, M.; Weihe, S. Feasibility Study on Additive Manufacturing of Ferritic Steels to Meet Mechanical Properties of Safety Relevant Forged Parts. Materials 2022, 15, 383. [Google Scholar] [CrossRef]

- Werz, M.; Sewalski, S.; Mally, L.; May, L. Critical assessment of the safety of advanced manufacturing processes for internationally relevant SMR concepts—Project overview. In Transactions of the SMiRT 27, Proceedings of the 27th International Conference on Structural Mechanics in Reactor Technology (SMiRT 27), Yokohama, Japan, 3–8 March 2024; SMiRT 27 Secretariat: Yokohama, Japan, 2024. [Google Scholar]

- EPRI. Advancements in Electron Beam Welding for Heavy Section Components; [Workshop presentation], Workshop on Advanced Manufacturing Technologies (AMTs) for Nuclear Applications; U.S. Nuclear Regulatory Commission (NRC): Rockville, MD, USA, 2023. [Google Scholar]

- Lincoln Electric Corp. DED—Wire (aka Welding): Use Case Update; [Workshop presentation], Workshop on Advanced Manufacturing Technologies (AMTs) for Nuclear Applications; U.S. Nuclear Regulatory Commission (NRC): Rockville, MD, USA, 2023. [Google Scholar]

- Westinghouse. Additive Manufacturing at Westinghouse; [Workshop presentation], Workshop on Advanced Manufacturing Technologies (AMTs) for Nuclear Applications; U.S. Nuclear Regulatory Commission (NRC): Rockville, MD, USA, 2023. [Google Scholar]

- NEA. Unlocking Reductions in the Construction Costs of Nuclear: A Practical Guide for Stakeholders; OECD Publishing: Paris, France, 2020; Available online: https://www.oecd-nea.org/jcms/pl_30653/unlocking-reductions-in-the-construction-costs-of-nuclear?details=true (accessed on 10 February 2025).

- Saskatchewan Industrial and Mining Suppliers Association. Advanced Manufacturing for Small Modular Reactors: Implications for the Saskatchewan Supply Chain, Saskatchewan, Canada. 2024. Available online: https://simsa.ca/wp-content/uploads/Utilising-Advanced-Manufacturing-for-SMRs-SIMSA-April-2024-1.pdf (accessed on 20 April 2025).

| Reference | Year | Wind | Solar | Photovoltaic | Nuclear | Hydropower |

|---|---|---|---|---|---|---|

| IPCC SRREN [8] | 2011 | 12 | 22 | 46 | 16 | 4 |

| NREL | 2012 | 11 [11] | 12 [12] | 33 [13,14] | 12 [15] | - |

| NREL [16] | 2021 | 13 | 28 | 43 | 13 | 21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

May, L.; Werz, M. A State-of-the-Art Review on Nuclear Reactor Concepts and Associated Advanced Manufacturing Techniques. Energies 2025, 18, 4359. https://doi.org/10.3390/en18164359

May L, Werz M. A State-of-the-Art Review on Nuclear Reactor Concepts and Associated Advanced Manufacturing Techniques. Energies. 2025; 18(16):4359. https://doi.org/10.3390/en18164359

Chicago/Turabian StyleMay, Lisa, and Martin Werz. 2025. "A State-of-the-Art Review on Nuclear Reactor Concepts and Associated Advanced Manufacturing Techniques" Energies 18, no. 16: 4359. https://doi.org/10.3390/en18164359

APA StyleMay, L., & Werz, M. (2025). A State-of-the-Art Review on Nuclear Reactor Concepts and Associated Advanced Manufacturing Techniques. Energies, 18(16), 4359. https://doi.org/10.3390/en18164359