Influence of the Configurations of Fuel Injection on the Flame Transfer Function of Bluff Body-Stabilized, Non-Premixed Flames

Abstract

1. Introduction

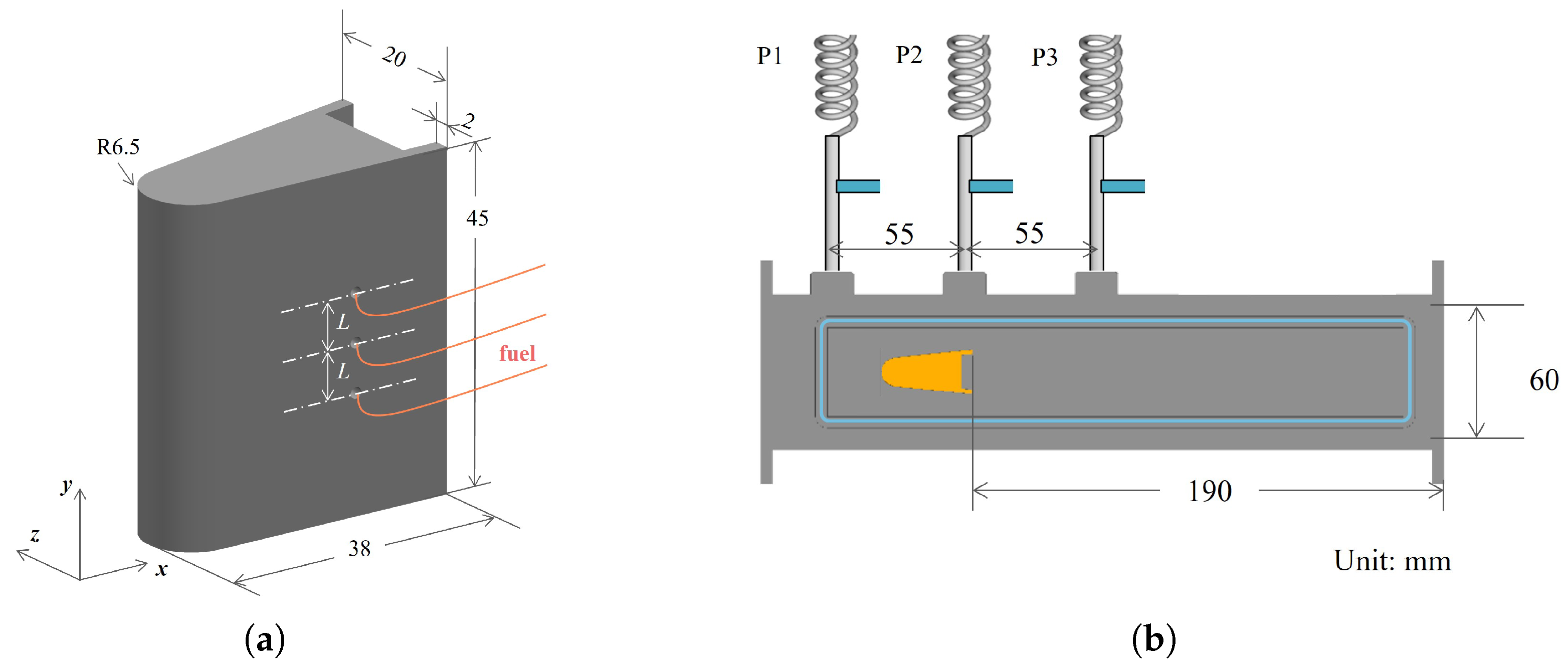

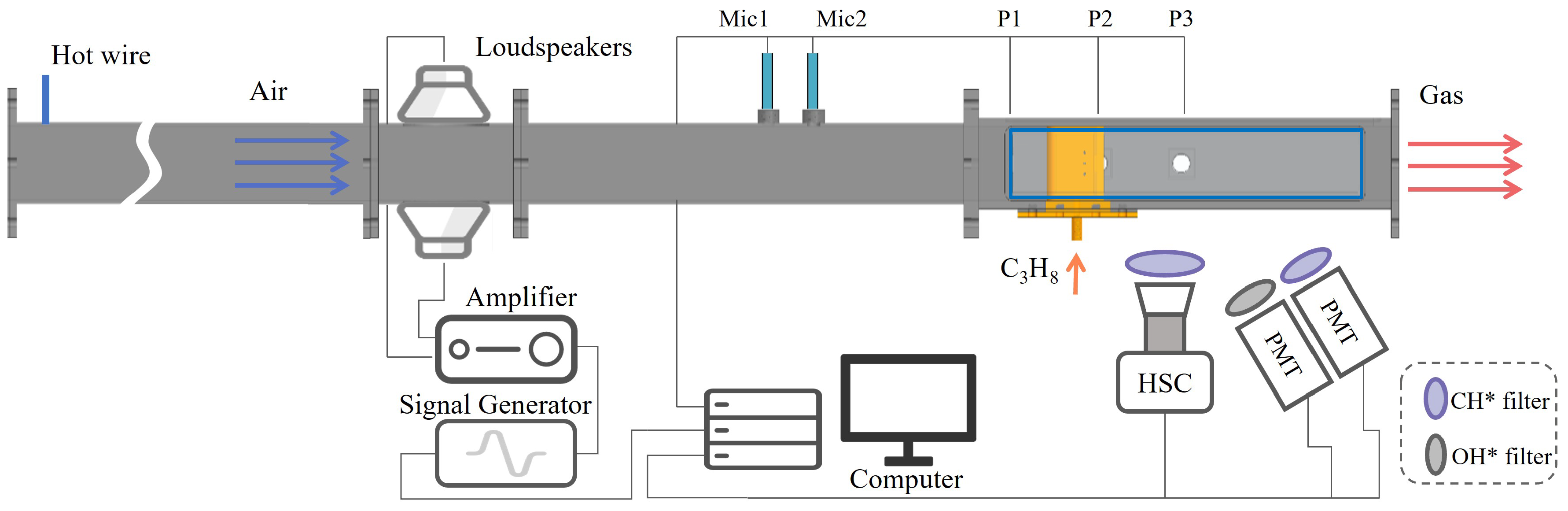

2. Experimental Setup

2.1. Combustion Rig

2.2. Diagnostic Techniques

2.3. Operating Conditions

3. Results and Discussion

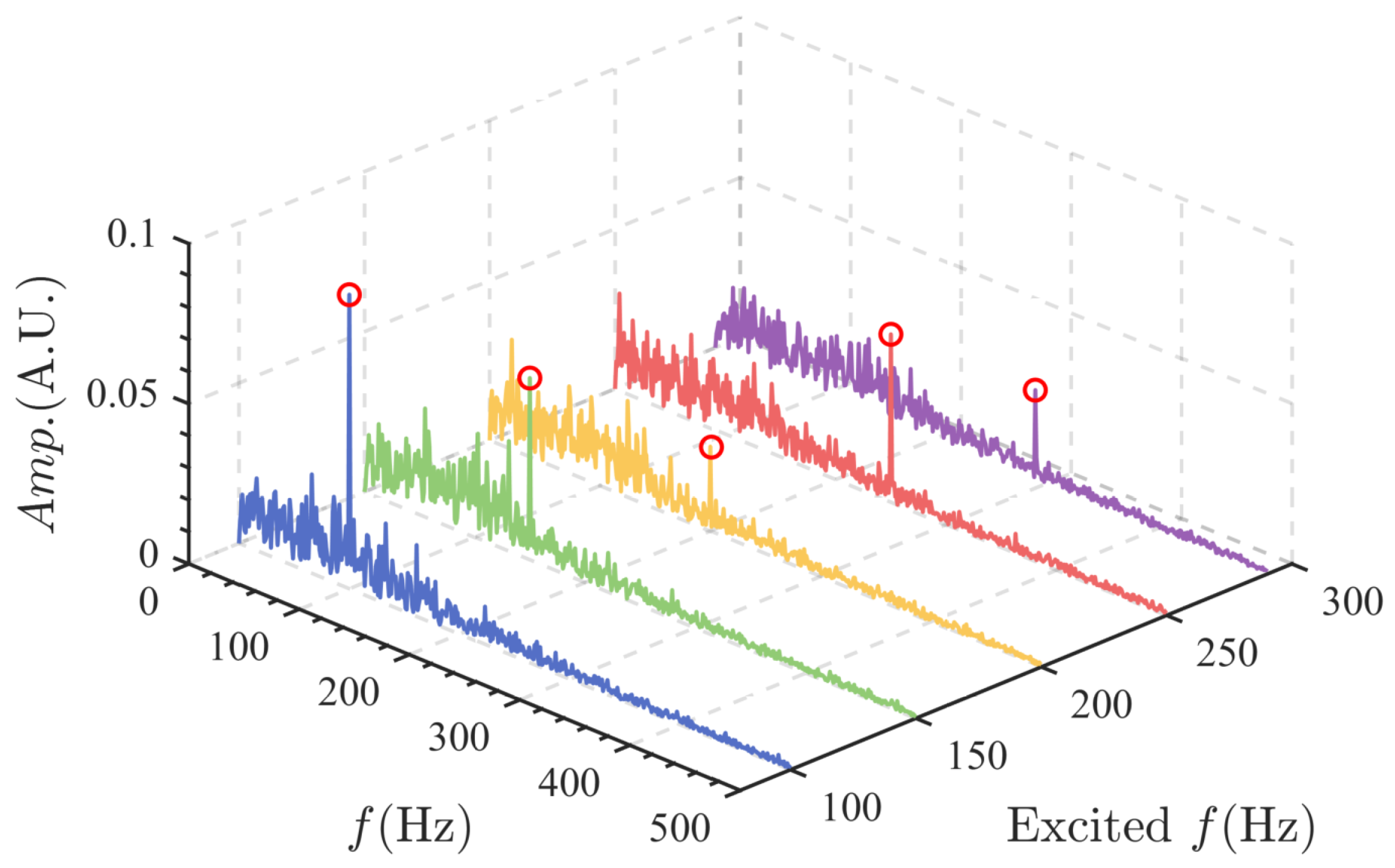

3.1. Flame Transfer Function

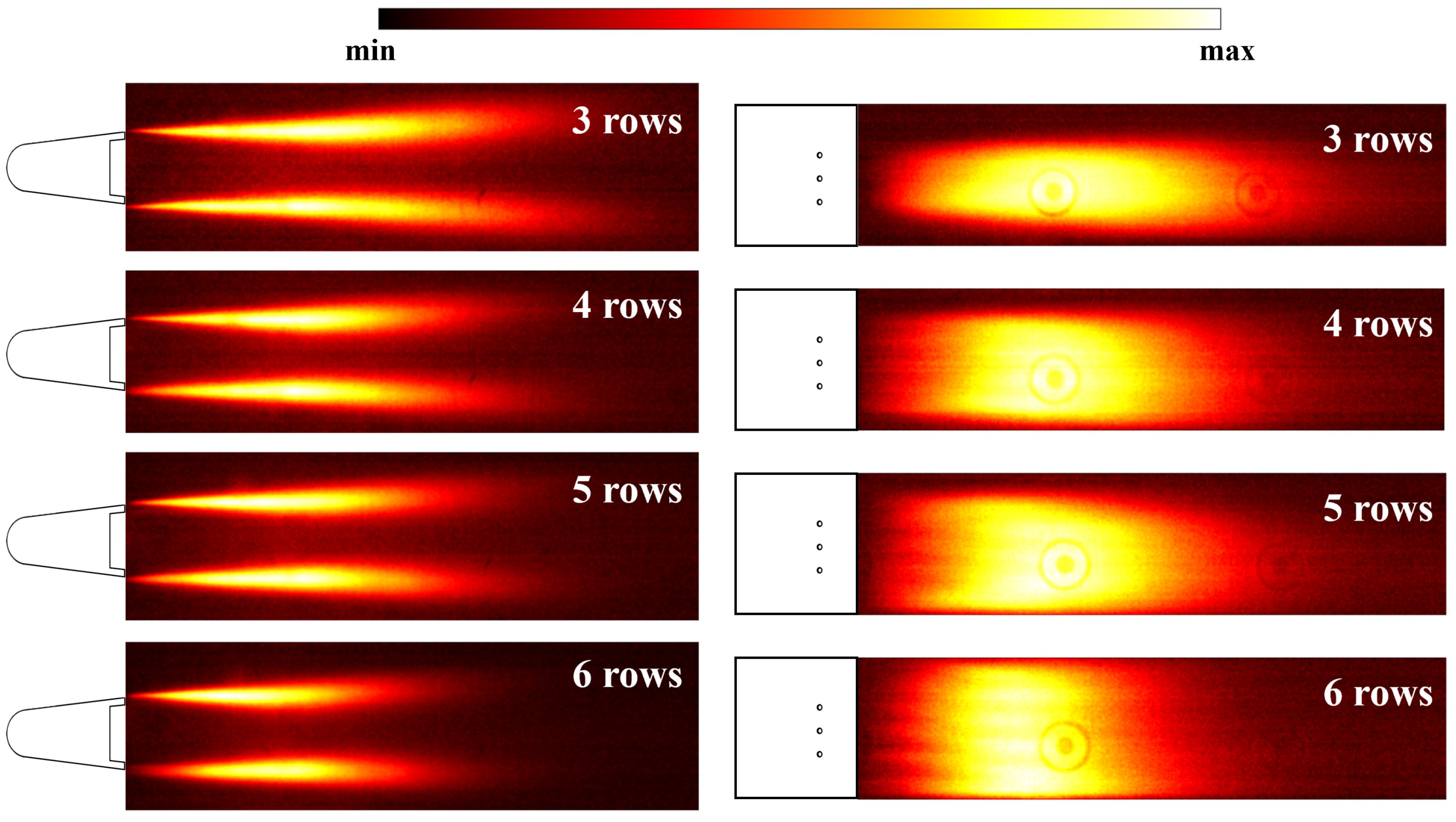

3.2. Analysis of Flame Morphology

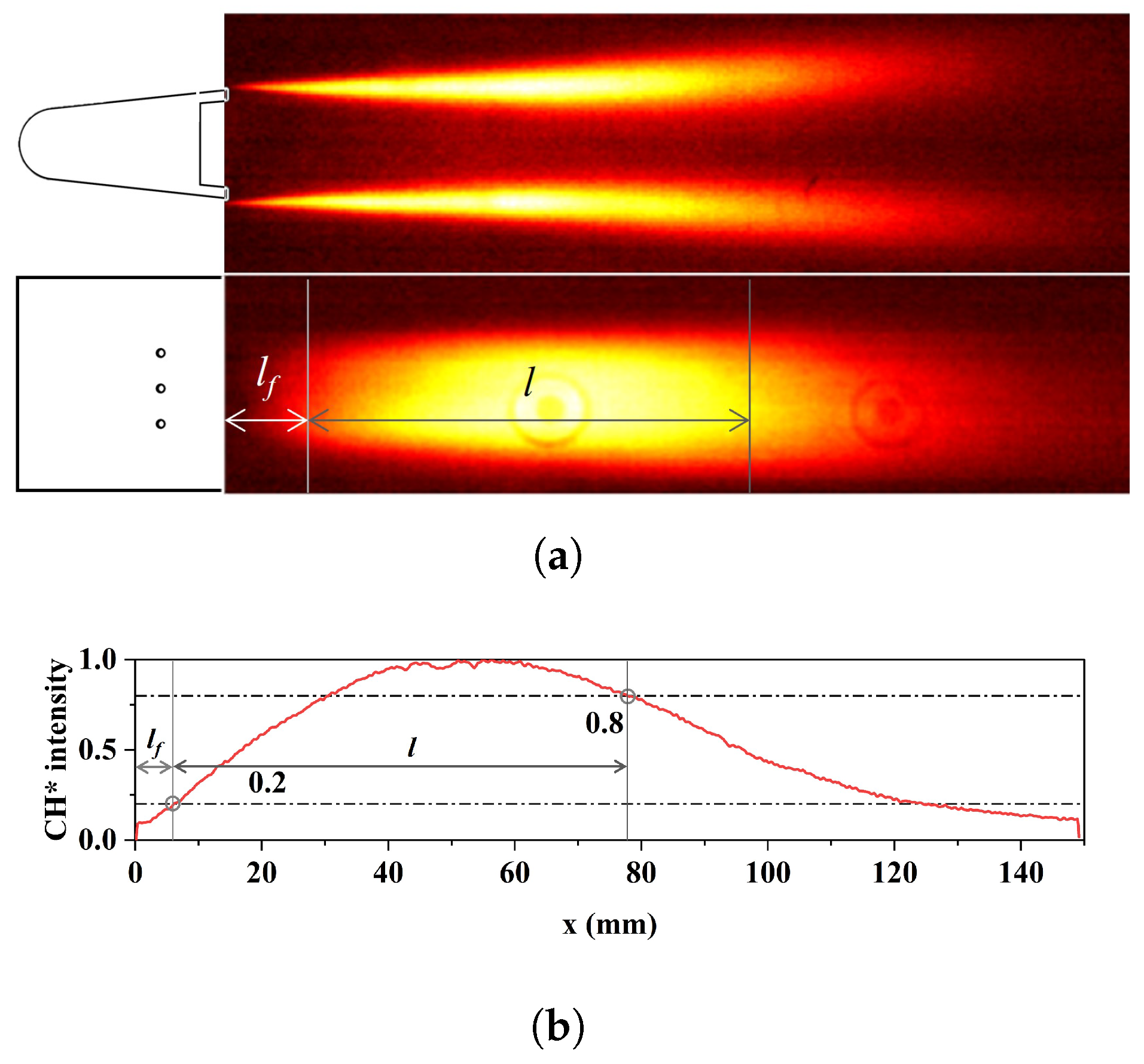

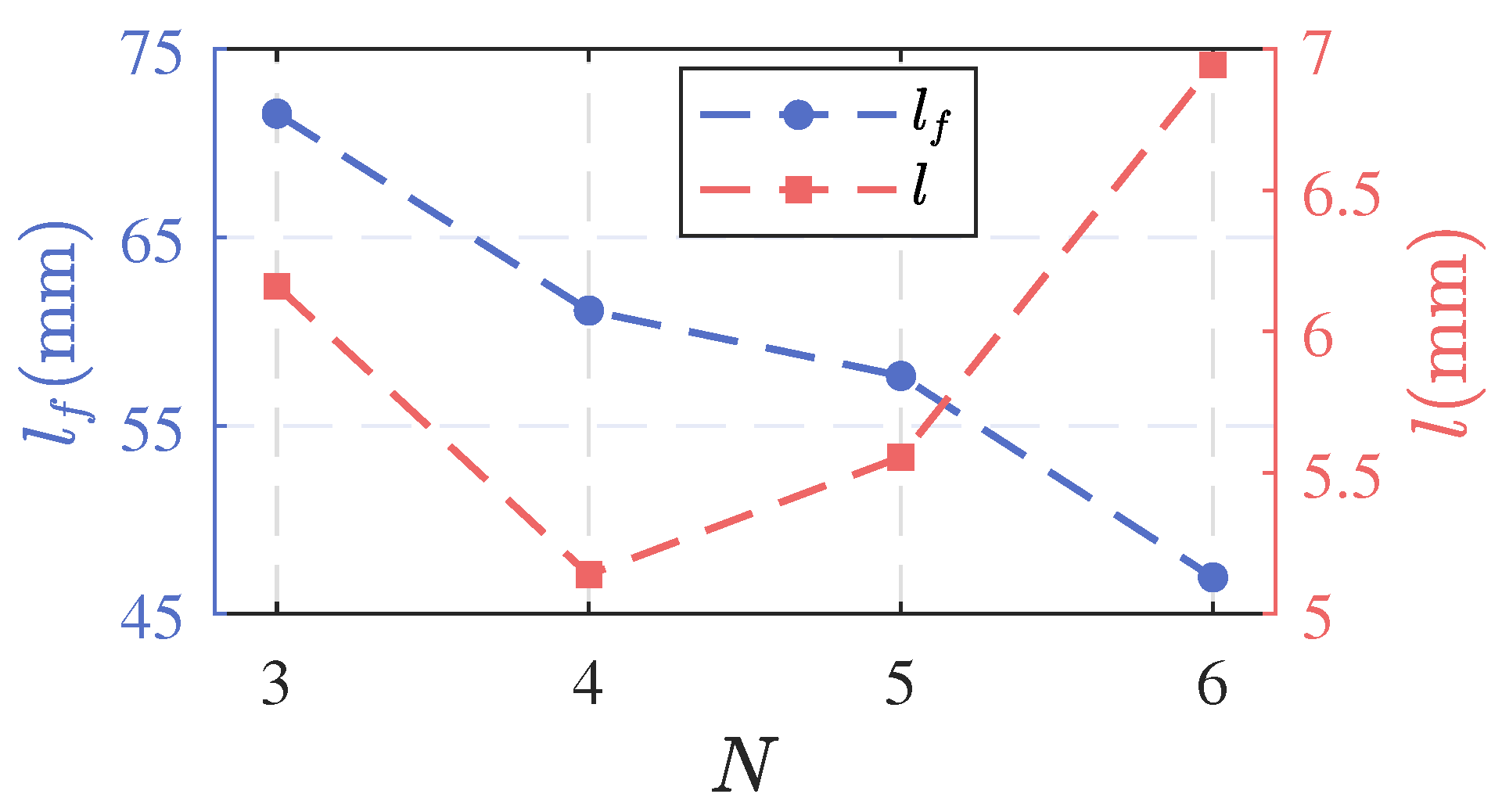

- Obtain line-of-sight integrated time-averaged CH* chemiluminescence images along the z-axis.

- Calculate the vertically integrated (y-direction) light intensity profile.

- Define as the x-coordinate corresponding to 20% of the maximum intensity.

- Define l as the axial distance () between the locations corresponding to 20% and 80% of the maximum intensity.

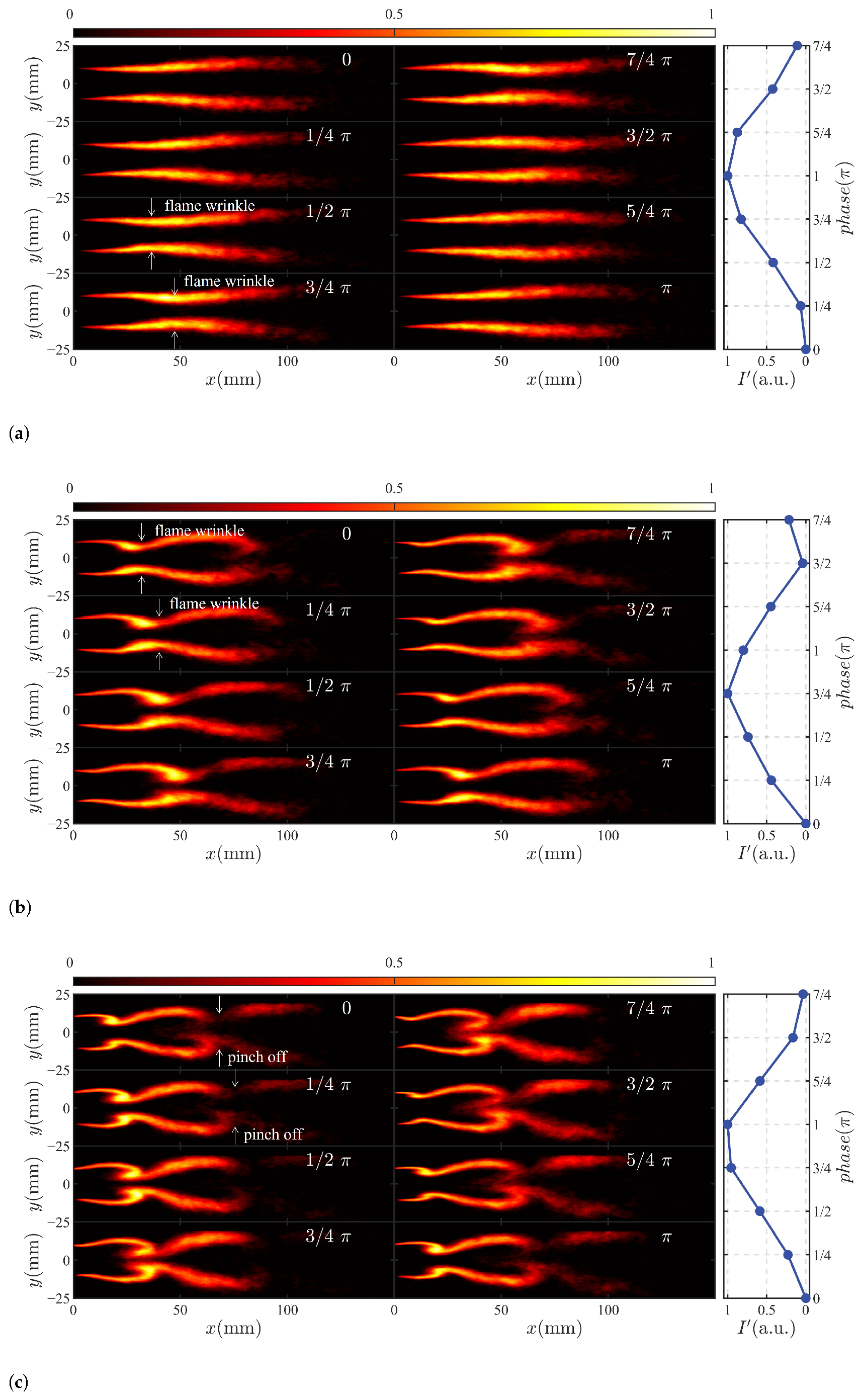

3.3. Analysis of Flame Dynamics

- Time-averaged HRR distribution: Calculate the line-of-sight integrated luminosity along the y direction for the time-averaged flame image to obtain the time-mean HRR distribution along the x direction, denoted as .

- Phase-resolved HRR quantification: Compute the CH* chemiluminescence intensity distribution along the x-direction () for each phase-averaged flame result.

- HRR fluctuation derivation: Derive the HRR fluctuation distribution along the x direction by calculating .

4. Conclusions

- The FTF gain exhibits a dual-peak structure across all tested configurations, with local maxima and minima at specific frequencies.For all N conditions, the maximum FTF gain occurred between 90 Hz and 120 Hz, while the minimum gain values were distributed between 160 Hz and 220 Hz. As N increases, the gain initially decreases, then increases, indicating a non-monotonic effect on combustion stability. The frequencies corresponding to the gain peaks in the FTF shift to higher values with increasing N, attributed to reduced flame length and enhanced flame responsiveness.

- The time delay between velocity fluctuations and heat release-rate fluctuations, derived from the FTF phase, decreases as N increases, signifying a quicker flame response to perturbations. Increasing N leads to shorter flame lengths and increased flame heights. Specifically, flame lengths for configurations of N = 3, 4, 5, and 6 are approximately 72 mm, 61 mm, 58 mm, and 47 mm, respectively. This trend arises from improved fuel distribution and mixing, which promote more compact and efficient combustion.

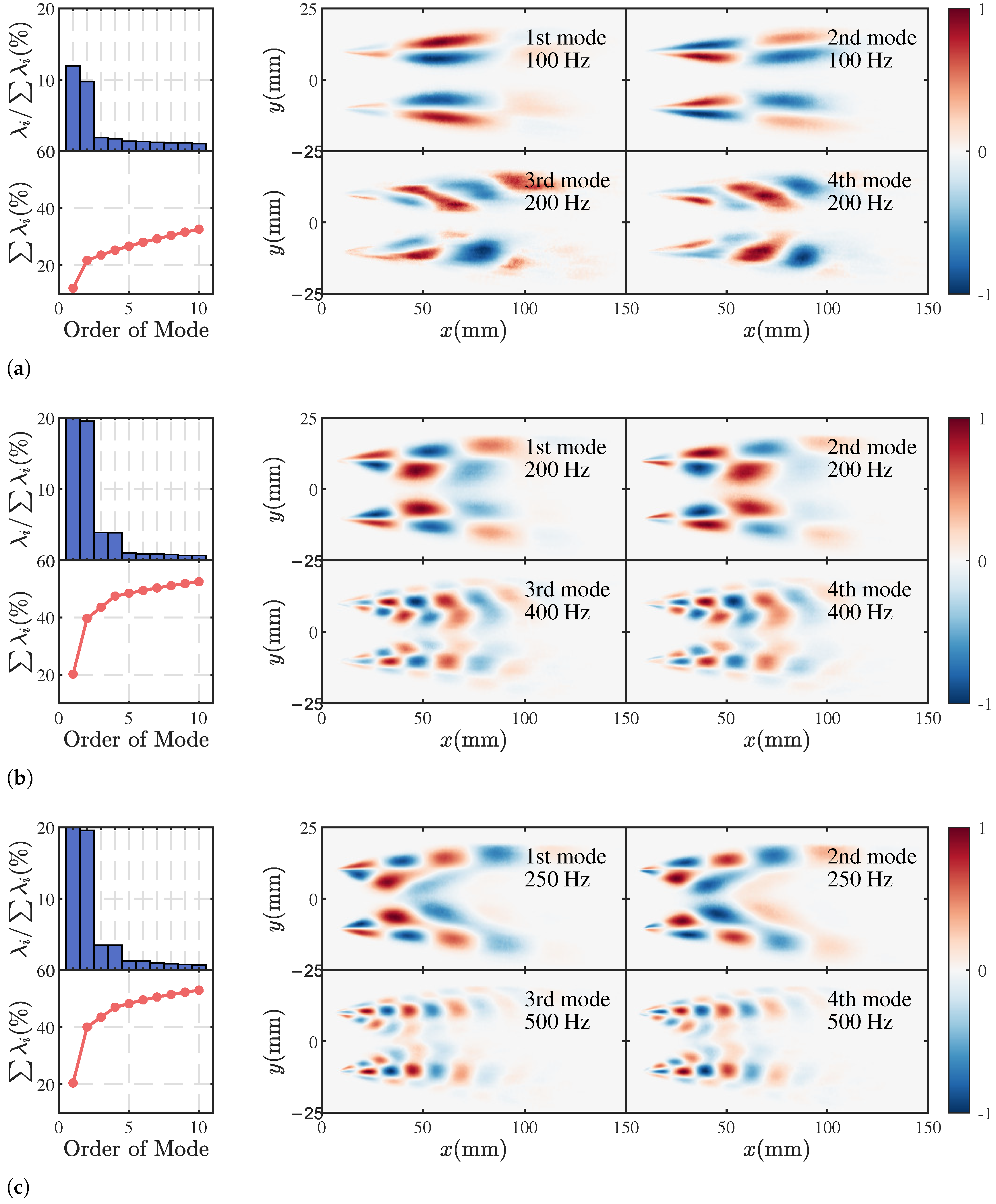

- Analysis of phase-averaged images and proper orthogonal decomposition (POD) reveals distinct pulsation modes at different excitation frequencies. At lower frequencies, large-scale structural pulsations dominate, while at higher frequencies, flame pinch-off dynamics and convective transport of corrugations drive heat release rate fluctuations. Flames with higher N exhibit greater sensitivity to high-frequency excitations, as evidenced by more pronounced reductions in flame length and enhanced heat release-rate fluctuations under such conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, Z.; Fan, Y.; Wang, Y.; Han, Q. Experimental and numerical investigation on oscillatory combustion characteristics of an integrated flameholder. Aerosp. Sci. Technol. 2024, 153, 109441. [Google Scholar] [CrossRef]

- Poinsot, T. Prediction and control of combustion instabilities in real engines. Proc. Combust. Inst. 2017, 36, 1–28. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, L.; Cheng, R.; Guo, P.; Yan, Y. Experimental study on phase transfer of longitudinal mode combustion oscillations in bluff body diffusion flames. Aerosp. Sci. Technol. 2025, 159, 110014. [Google Scholar] [CrossRef]

- Dharmaputra, B.; Nagpure, P.; Impagnatiello, M.; Noiray, N. Flame transfer function measurement of a sequential combustor fuelled with natural gas and hydrogen. Combust. Flame 2025, 274, 113972. [Google Scholar] [CrossRef]

- Yang, C.; Liu, Y.; Zhang, X.; Li, H.; Ge, X.; Jin, F.; Liu, C. Experimental Study on Flame Response Characteristics of a Non-Premixed Swirl Model Combustor. Energies 2023, 16, 6834. [Google Scholar] [CrossRef]

- Han, X.; Li, J.; Morgans, A.S. Prediction of combustion instability limit cycle oscillations by combining flame describing function simulations with a thermoacoustic network model. Combust. Flame 2015, 162, 3632–3647. [Google Scholar] [CrossRef]

- Preetham; Santosh, H.; Lieuwen, T. Dynamics of Laminar Premixed Flames Forced by Harmonic Velocity Disturbances. J. Propuls. Power 2008, 24, 1390–1402. [Google Scholar] [CrossRef]

- Ni, F.; Nicoud, F.; Mery, Y.; Staffelbach, G. Including Flow–Acoustic Interactions in the Helmholtz Computations of Industrial Combustors. AIAA J. 2018, 56, 1–15. [Google Scholar] [CrossRef]

- Ahn, B.; Indlekofer, T.; Dawson, J.R.; Worth, N.A. Heat release rate response of azimuthal thermoacoustic instabilities in a pressurized annular combustor with methane/hydrogen flames. Combust. Flame 2022, 244, 112274. [Google Scholar] [CrossRef]

- Morgans, A.S.; Yang, D. Thermoacoustic Instability in Combustors. Annu. Rev. Fluid Mech. 2025, 57, 9–33. [Google Scholar] [CrossRef]

- Lee, T.; Park, J.; Han, D.; Kim, K.T. The dynamics of multiple interacting swirl-stabilized flames in a lean-premixed gas turbine combustor. Proc. Combust. Inst. 2019, 37, 5137–5145. [Google Scholar] [CrossRef]

- Ahn, M.; Lim, D.; Kim, T.; Yoon, Y. Pinch-off process of Burke–Schumann flame under acoustic excitation. Combust. Flame 2021, 231, 111478. [Google Scholar] [CrossRef]

- Ahn, M.; Kim, T.; Yoon, Y. Comparison of flame response characteristics between Non-premixed and premixed flames under acoustic excitation. Exp. Therm. Fluid Sci. 2022, 139. [Google Scholar] [CrossRef]

- Kim, K.T.; Hochgreb, S. The nonlinear heat release response of stratified lean-premixed flames to acoustic velocity oscillations. Combust. Flame 2011, 158, 2482–2499. [Google Scholar] [CrossRef]

- Kim, K.T.; Hochgreb, S. Effects of Nonuniform Reactant Stoichiometry on Thermoacoustic Instability in a Lean-Premixed Gas Turbine Combustor. Combust. Sci. Technol. 2012, 184, 608–628. [Google Scholar] [CrossRef]

- Mejia, D.; Miguel-Brebion, M.; Ghani, A.; Kaiser, T.; Duchaine, F.; Selle, L.; Poinsot, T. Influence of flame-holder temperature on the acoustic flame transfer functions of a laminar flame. Combust. Flame 2018, 188, 5–12. [Google Scholar] [CrossRef]

- Chen, Y.; Fan, Y.; Bai, X.S.; Xu, L.; Shan, X.; Bi, Y.; Deng, Y.; Han, Q. Experimental study on combustion and flow resistance characteristics of an afterburner with air-cooled bluff-body flameholder. Aerosp. Sci. Technol. 2022, 123, 107488. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.; Zhong, S.; Deng, Y.; Wang, J.; Zhang, F. Influence of incoming flow parameters on the flow field in a trapped vortex cavity with radial bluff-body. Aerosp. Sci. Technol. 2023, 132, 108050. [Google Scholar] [CrossRef]

- Manikandan, S.; Sujith, R.I. Rate dependent transition to thermoacoustic instability via intermittency in a turbulent afterburner. Exp. Therm. Fluid Sci. 2020, 114, 110046. [Google Scholar] [CrossRef]

- Dicholkar, A.; Lønbæk, K.; Madsen, M.H.A.; Zahle, F.; Sørensen, N.N. From bluff bodies to optimal airfoils: Numerically stabilized RANS solvers for reliable shape optimization. Aerosp. Sci. Technol. 2025, 161, 110153. [Google Scholar] [CrossRef]

- Wei, L.; Yu, L.; Bo, H.; Yunpeng, L.; Yingwen, Y. Method for calculating the combustion performance of an afterburner through gas components analysis. Aerosp. Sci. Technol. 2025, 164, 110400. [Google Scholar] [CrossRef]

- Wei, L.; Longchao, X.; Chaodi, Y.; Dong, D.; Yibo, W.; Yingwen, Y. Experimental investigation of the characteristics of direct injection nozzle sprays in an afterburner environment. Aerosp. Sci. Technol. 2025, 157, 109763. [Google Scholar] [CrossRef]

- Xu, L.; Liu, Y.; Cheng, R.; Yan, Y. Experimental and theoretical investigating on measurement of dynamic response characteristics of the semi-infinite pressure tube with non-uniform temperature. Appl. Acoust. 2025, 233, 110589. [Google Scholar] [CrossRef]

- Kim, K.T.; Lee, J.G.; Quay, B.D.; Santavicca, D.A. Spatially distributed flame transfer functions for predicting combustion dynamics in lean premixed gas turbine combustors. Combust. Flame 2010, 157, 1718–1730. [Google Scholar] [CrossRef]

- Zhao, D.; Ji, C.; Wang, B. Geometric shapes effect of in-duct perforated orifices on aeroacoustics damping performances at low Helmholtz and Strouhal number. J. Acoust. Soc. Am. 2019, 145, 2126–2137. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Tan, J.; Wang, H.; Lv, L. Characterization of heat release rate by OH* and CH* chemiluminescence. Acta Astronaut. 2019, 154, 44–51. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, S.; Liu, Y. Heat release rate responses in self-excited thermoacoustic instabilities of tangential swirling non-premixed flames. Phys. Fluids 2025, 37, 035132. [Google Scholar] [CrossRef]

- Wang, X.; Han, X.; Sung, C.J. Transitions of thermoacoustic modes and flame dynamics in a centrally-staged swirl combustor. Energy 2023, 263, 125813. [Google Scholar] [CrossRef]

- Fu, P.; Wen, Q.; Hou, L.; Li, J.; Ma, H. Interaction among flame structures and thermoacoustic instabilities in a centrally staged combustor. Appl. Therm. Eng. 2024, 254, 123862. [Google Scholar] [CrossRef]

- Di, D.; Yan, Y.; Liu, Y. Study on the flow characteristics and oscillating mechanism of a swirl flame. Fuel 2021, 306, 121657. [Google Scholar] [CrossRef]

- Higham, J.E.; Brevis, W.; Keylock, C.J. Implications of the selection of a particular modal decomposition technique for the analysis of shallow flows. J. Hydraul. Res. 2018, 56, 796–805. [Google Scholar] [CrossRef]

| Case | N | u | Range of f | ||

|---|---|---|---|---|---|

| (-) | (m/s) | (-) | (Hz) | (-) | |

| N3 | 3 | ||||

| N4 | 4 | ||||

| (Ref. Configure) | 10.0 | 0.068 | 60–310 | 0.02 | |

| N5 | 5 | ||||

| N6 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Zhao, Y.; Zhang, X.; Wang, S.; Liu, Y. Influence of the Configurations of Fuel Injection on the Flame Transfer Function of Bluff Body-Stabilized, Non-Premixed Flames. Energies 2025, 18, 4349. https://doi.org/10.3390/en18164349

Sun H, Zhao Y, Zhang X, Wang S, Liu Y. Influence of the Configurations of Fuel Injection on the Flame Transfer Function of Bluff Body-Stabilized, Non-Premixed Flames. Energies. 2025; 18(16):4349. https://doi.org/10.3390/en18164349

Chicago/Turabian StyleSun, Haitao, Yan Zhao, Xiang Zhang, Suofang Wang, and Yong Liu. 2025. "Influence of the Configurations of Fuel Injection on the Flame Transfer Function of Bluff Body-Stabilized, Non-Premixed Flames" Energies 18, no. 16: 4349. https://doi.org/10.3390/en18164349

APA StyleSun, H., Zhao, Y., Zhang, X., Wang, S., & Liu, Y. (2025). Influence of the Configurations of Fuel Injection on the Flame Transfer Function of Bluff Body-Stabilized, Non-Premixed Flames. Energies, 18(16), 4349. https://doi.org/10.3390/en18164349