1. Introduction

Modern child car seats are advanced constructions designed with the utmost protection of young passengers in mind. Over the years, systems enhancing safety during collisions, such as ISOFIX (International Standards Organisation FIX) side impact protection and harnesses, have been continuously developed. However, with the growing number of sensors and consumer electronics, there is an increasing need to power the car seat even during everyday driving. At the same time, vibrations and shaking experienced by the child, so far mainly considered as a source of discomfort, may turn out to be a new source of energy. This work attempts to combine two often overlooked aspects: travel comfort and the use of vibrations to power intelligent monitoring systems that can operate independently of the vehicle’s power supply.

Child car seats are primarily designed with safety during collisions in mind—their main function is to protect the child and minimize injuries in the event of an accident [

1,

2,

3]. Therefore, most scientific studies focus on collision-related issues and the effectiveness of car seats under crash conditions. Since the 1960s, the development of child car seats has focused on improving protection during collisions (e.g., the introduction of rear-facing seats, ISOFIX systems, additional harnesses, and side impact protection) [

1]. Unfortunately, child comfort during travel, especially vibration-related comfort, is a topic much less frequently addressed in the literature. A review of the literature indicates that child seats are mainly studied in terms of safety, while issues of vibrational comfort are largely neglected.

Although manufacturers of car seats claim to care about the comfort of small passengers (e.g., upholstery, recline adjustment, addition of temperature sensors, or monitoring the child’s position), comfort related to vibrations transmitted to the child remains an overlooked area in research and design. Moreover, the market lacks car seats equipped with solutions that actively ensure vibrational comfort; for example, acceleration sensors are not used to measure and dampen vibrations affecting the seat. In other words, current seats offer a high level of passive safety but do not integrate this with active systems aimed at increasing the child’s travel comfort, particularly in terms of vibration reduction [

4,

5,

6].

The ISOFIX system, introduced to reduce child seat installation errors, provides a standardized and rigid connection between the child seat and the car body. It uses fixed anchor points built into the vehicle and locking connectors on the seat base, allowing for fast, tool-free attachment. Many ISOFIX bases also include a support leg or top tether, which further stabilizes the seat by limiting forward rotation in a crash. Compared to seatbelt mounting, ISOFIX improves crash performance and repeatability while simplifying proper installation.

Previous research on child car seats has primarily focused on three key areas: crash safety, correct installation and usage, and the role of ergonomics and comfort in the overall effectiveness of child protection systems. By far, the most extensive body of research deals with how well these seats perform in traffic accidents, particularly in frontal, side, and rollover crashes. These studies typically use anthropomorphic test dummies (ATDs) and computer simulations to analyze the forces acting on a child’s body and to assess the risk of injury across various installation setups.

Among the findings, it has been shown that correctly installed seats—especially those using rigid ISOFIX systems—significantly reduce the forces experienced by a child’s head and chest compared to traditional seatbelt-only installations. The ISOFIX system helps prevent independent seat movement during rollovers, resulting in lower acceleration and force loads on the child. In addition, protection systems for the head and neck are being developed, with dynamic tests indicating that these solutions can reduce neck strain by as much as 40–75%, marking an important direction in design innovation. Modern seats also feature additional harnesses, energy-absorbing side panels, and headrests with optimized geometry, all of which help improve passive safety performance [

7,

8,

9].

Another critical research area addresses user error during installation and day-to-day use. Numerous studies have shown that up to 70% of child seats are installed incorrectly by caregivers [

8]. Common mistakes include improper seatbelt routing, loose seat attachment, incorrect recline angle, or misplacement of the harness straps. In some cases, the upper seatbelt strap was routed behind the child’s back, drastically increasing injury risk in a crash—even higher than not using a seat at all. These findings underscore the need for better user education and the development of systems that can verify correct installation. In response, newer car seats now include sensors that alert users to ISOFIX engagement, harness tension, or seat orientation, aiming to reduce errors caused by a lack of knowledge or rushed installation.

Although comfort and ergonomics have long been considered secondary concerns, more and more studies suggest they can indirectly affect a child’s safety. Discomfort can lead to poor posture, fiddling with straps, or caregivers switching to larger—but less safe—seats too early. Clinical observations show that poorly adjusted harnesses or pressure from rigid seat parts can trigger compensatory movements in children, which reduce the protective function of the seat. Notably, parents often make decisions based on subjective perceptions of comfort, which can lead to unintended misuse.

To address these issues, efforts have begun to create objective methods for evaluating comfort, such as seat pressure mapping, behavioral analysis during travel, and age-appropriate questionnaires [

9,

10,

11]. Still, there is a lack of validated tools to quantitatively assess the comfort of the youngest passengers. It is also worth noting that ISO vibration standards apply only to adult passengers; there are currently no equivalents for children. Only recently have pioneering studies begun to examine the actual levels of vibration transmitted from the road to the child seat. Some of these have found that vibration levels on child seat surfaces can exceed those measured on the driver’s seat. Interestingly, while rigid ISOFIX attachments offer clear safety benefits, they may reduce vibrational comfort compared to more flexible seatbelt-based setups.

In parallel, ergonomic studies on how pressure is distributed across a child’s body in the seat have helped develop models for optimizing seat materials and design. These findings pave the way for improvements that balance both safety and comfort in future child seat innovations.

The aim of this study is to determine whether the mechanical vibrations transmitted to a child car seat during vehicle travel can be effectively harnessed as a power source for intelligent safety systems. The hypothesis assumes that vertical vibrations, particularly at the ISOFIX mounting point, carry enough energy to sustain the operation of microsensors without relying on traditional batteries.

There is a growing awareness that the development of modern child car seats should take into account not only passive safety requirements, but also aspects of ergonomics and user comfort. Increasing interest in vibrations, sensory experiences, and the child–seat interaction is opening up new research directions, especially in the context of integrating smart monitoring systems powered autonomously through vibration energy harvesting [

12,

13,

14].

Electric vehicles (EVs) are designed with maximum energy efficiency in mind, and energy recovery systems have become a standard feature. The most widely known example is regenerative braking, which converts the vehicle’s kinetic energy into electrical energy during deceleration. In practice, the electric motor temporarily acts as a generator, reversing the energy flow during braking and converting motion into electricity stored in the battery [

15,

16]. This technology significantly increases driving range and reduces energy losses. Estimates suggest that regenerative braking can recover anywhere from 10% to 40% of braking energy, depending on the system design and driving style. As a result, regenerative braking not only extends the range on a single charge but also reduces brake wear and heat emissions.

Beyond the drivetrain, engineers are exploring other opportunities for energy recovery in EVs. One such area involves vibrations and mechanical oscillations generated while driving. Every vehicle traveling over uneven surfaces produces vibrations—energy that is usually dissipated through the suspension system and vehicle body, and partly experienced as discomfort by passengers. The concept of energy harvesting proposes that even small and dispersed energy sources, such as structural vibrations, can be captured and converted into usable electricity for powering low-energy devices [

17,

18,

19].

In the context of electric mobility, ongoing research includes energy recovery from suspension vibrations, body oscillations, and even seat vibrations. For example, the vibrations of a heavy truck or bus suspension system can be harnessed using specialized shock absorbers with built-in generators. Studies show that regenerative dampers or supplemental inerters can reclaim a meaningful portion of that energy, improving overall vehicle efficiency while also helping to reduce vibrations for enhanced ride comfort.

Furthermore, prototype systems have been described in the literature where active seat suspension mechanisms convert seat vibrations into electricity while simultaneously damping them to improve passenger comfort. In one such example, applied to the driver’s seat of an electric delivery vehicle, a system achieved approximately 42% energy recovery efficiency alongside a 36% reduction in perceived seat acceleration. This demonstrates that with the right design, it is possible to combine vibration reduction (comfort) with energy harvesting, aligning with the principles of sustainable mobility [

20].

There are several technical solutions that enable the conversion of mechanical vibration energy into electrical energy. The three main classes of vibration transducers are electromagnetic, piezoelectric, and electrostatic. They differ in their operating principles, performance characteristics, and typical areas of application. Below is a brief overview of each:

Electromagnetic transducers: These utilize the phenomenon of electromagnetic induction; the movement of a magnet relative to a coil generates an electric current (according to Faraday’s law). This type of vibration generator generally has a relatively simple design (magnet + coil) and is particularly effective at low vibration frequencies, common in many practical applications. They are especially useful in contexts where slow, high-amplitude vibrations occur, such as in vehicle suspension systems, civil structures, or wearable devices. Electromagnetic transducers can offer high energy conversion efficiency due to strong electromechanical coupling; literature suggests they often outperform other types in terms of power yield [

21]. For example, in one experiment, a small electromagnetic generator achieved around 51% efficiency in converting vibration energy (0.6 m/s

2 at 52 Hz) into electricity, which is a very good result. Nonetheless, this solution tends to have drawbacks, such as larger size and mass (due to the need for magnets and coils) and low output voltages. In practice, the voltage induced by small vibrations may be so low that additional circuitry is needed to boost it before rectification and use. Moreover, increasing output power requires larger magnets or coils, which may reduce power density and scalability, especially in MEMS devices. For this reason, electromagnetic transducers are typically used where there is sufficient space available and low-frequency operation is required—e.g., in vehicle kinetic energy recovery (suspension vibration harvesters, energy harvesting tires), or in large wearables (e.g., shoe devices generating energy from footsteps).

Piezoelectric transducers: These operate based on the piezoelectric effect—deformation of a piezoelectric material (e.g., crystal or ceramic) results in the appearance of electric charge and voltage across its surfaces [

22,

23,

24]. Piezoelectric vibrating elements thus act as miniature generators: even small mechanical deformations (compression, bending, vibration) can generate measurable voltage. These transducers have attracted great interest in various fields (construction, biomechanics, wearable electronics) thanks to several advantages: self-sufficiency (they do not require external power to operate), relatively high output voltages, small size, and strong electromechanical coupling [

25,

26]. This allows for decent power density in small-scale devices. The literature reports that piezo generators can offer significantly higher power densities than other types at a similar scale [

27]. However, piezo technology has limitations: it is highly dependent on vibration frequency and force levels. Piezo materials operate best at relatively high vibration frequencies (often above 1 kHz) [

28,

29] and moderate acceleration levels. With very slow, gentle vibrations, efficiency drops significantly; there must be a certain deformation rate to generate usable voltage. On the other hand, extremely high deformations or accelerations can introduce nonlinearities, reduce durability, or even damage the material (e.g., piezoelectric crystal cracking) [

30]. Furthermore, long-term performance may degrade due to material fatigue, with the characteristics changing over time [

31,

32]. Comparative studies show that under low vibration conditions, piezo transducers underperform relative to electrostatic ones (they have higher losses at low energies), whereas under moderate to high vibrations, they outperform other technologies in terms of output power [

33]. At very high acceleration levels (e.g., impacts), efficiency again drops, partly due to the electrical breakdown limits (dielectric failure), which is why electrostatic techniques are sometimes preferred in such extremes. Piezoelectric transducers have wide applications: from vibration energy harvesting in bridges and machinery and powering sensors in deforming structures (e.g., overload monitoring), to medical implants using body vibrations (pulse, breathing) to power internal devices. In automotive, their potential uses include vibration energy harvesting from tires or suspension elements, and even piezo arrays in seats that convert small vibrations into power for sensors.

Electrostatic transducers: These are based on variable capacitor technology and the phenomenon of electrostatic induction. A typical electrostatic harvester consists of two electrodes (e.g., plates or opposing surfaces) whose relative position changes under vibration. This motion causes periodic changes in the capacitance, either through distance variation or surface overlap, which in turn leads to charge movement and the generation of electrical current, if the system is connected to a voltage source or uses a pre-charged material (electret) [

22,

24,

34]. A major advantage of electrostatic transducers is that they can be easily miniaturized; the technology is compatible with MEMS manufacturing, making it possible to create micro-generators that integrate directly with electronic circuits. Electrets (permanently charged materials) are often used to provide the initial electric field without the need for continuous external voltage. However, there are challenges: effective operation requires either pre-charging or the presence of a high-voltage bias, which introduces system complexity, i.e., the device needs a high-voltage source or durable electret, which may affect longevity and design. In addition, the mechanical displacements in typical electrostatic harvesters are small (often millimeters or less), so they work best in environments with low amplitude but relatively high-frequency vibrations. For large, slow movements (e.g., vehicle rocking), the required capacitor size becomes impractical unless mechanical amplification is used, which adds complexity [

22,

30]. In terms of energy efficiency, electrostatic generators often underperform piezoelectric ones in mid-level vibration conditions, producing lower power. However, at very low vibration levels, they can outperform piezos due to lower internal losses. Their niche is micro-powering, such as in wireless sensors, smart building systems, or wearable electronics, where environmental vibrations are weak but constant. In automotive, they could be used in tire pressure sensors powered by wheel vibrations—some prototype TPMS units based on electrostatic or piezoelectric micro-generators have already been tested. Overall, the biggest strengths of electrostatic transducers are their compatibility with standard silicon technology, lack of exotic materials, and potential for mass integration in IoT and sensing systems. However, further development is needed to improve long-term charge stability and reliability.

The energy harvesting technologies discussed above offer an interesting opportunity for application in the context of child car seats, particularly in modern electric vehicles. As previously mentioned, vibrations acting on the car seat (caused by road irregularities, suspension operation, etc.) are a major factor reducing travel comfort for the child. Instead of treating them solely as an unavoidable drawback, they could be utilized for electricity generation, bringing a dual benefit: partial vibration damping (as not all the energy would be transmitted to the child’s body, some would be absorbed by the generator) and power supply for onboard devices in the seat.

In practice, one could imagine a child seat equipped with piezoelectric or electromagnetic elements, placed, for example, in the seat base or in a damping layer between the seat shell and the ISOFIX base. Vibrations during driving would cause deformation or movement of these elements, thus generating an electric current. While the amount of recovered energy would be small, typically in the microwatt to milliwatt range, it would be sufficient to power basic comfort and safety sensors.

This energy could be used to power temperature, humidity, or heart rate sensors, or a seatbelt tension monitor, all without the need for external batteries or connection to the car’s electrical system. Moreover, the energy could be stored in a capacitor or a small rechargeable battery, maintaining power for monitoring systems even after the engine is turned off.

Although no complete implementations of such systems have yet appeared in the literature, some analogies can be found in existing research. The previously mentioned regenerative seat suspension mechanism demonstrates that vibration energy recovery from a seat is technically feasible, with energy conversion efficiencies reaching dozens of percent. Of course, a child seat is much smaller and lighter than a truck driver’s seat, but the working principle could be similar, for example, using a built-in inerter or an elastomeric damping module with a generator. Alternatively, a layer of piezoelectric material in the seat padding could harvest the vibrations felt by the child. An especially promising concept is the use of flexible piezo transducers (e.g., PVDF films) integrated into the backrest and seat base. When the child moves or when the seat vibrates, the film would generate current. Similar solutions are already used in other areas, such as “smart floors”, that power LEDs from footstep-induced deformations.

Integrating energy harvesting into child seats could significantly improve their autonomy and functionality. The harvested energy could power comfort-enhancing devices, such as micro-fans to cool the child on hot days, or vibration modules synchronized with lullabies. Some car seat concepts already include vibrating cradle functions for infants—energy harvesting could power such soothing vibrations without draining the car battery [

19,

20].

In addition, decoupling the sensors from the vehicle’s electrical system would increase system reliability and safety; for instance, a belt-unfastened warning or an alert about a child left in the car could remain active even with the ignition turned off, using energy harvested during the last drive.

In summary, combining the concepts of child comfort and safety with energy harvesting opens new directions for research and development in child car seat design. As shown, vibrational comfort remains an underexplored area, and the market currently lacks solutions that integrate active vibration damping with top-tier safety seats. At the same time, vibration harvesting technologies, already mature in other industries, could be adapted to seat-scale applications, providing onboard power and additional vibration damping.

The scientific challenge lies in developing a truly “smart” child car seat, which can autonomously monitor and improve the child’s travel experience using harvested energy, all without compromising safety. The initial steps are promising: available technologies (electromagnetic, piezoelectric, and electrostatic) can be miniaturized and adapted to the design of child seats, and successful demonstrations of vibration energy harvesting from seats confirm the feasibility of this approach.

Therefore, we can expect that future child car seats will no longer be just passive safety devices, but active systems that enhance comfort, monitor health and positioning, and reclaim energy that would otherwise be wasted as vibration.

This work presents an experimental concept study aimed at assessing the feasibility of recovering energy from vertical vibrations in child car seats, rather than a fully developed and implemented energy harvesting system. The goal is to evaluate the vibration environment, estimate available energy levels, and determine whether such conditions could realistically support low-power onboard sensors. The physical integration of actual transducers, power management circuits, and storage components will be part of subsequent research. A functional schematic of the proposed energy harvesting concept has already been submitted for protection to the Polish Patent Office (UPRP) under application number P.451685 on 4 April 2025.

The remainder of this article is structured as follows.

Section 2 describes the materials, experimental setup, and test procedures used in the study.

Section 3 presents the results of vibration measurements collected at different points of the child seat system under various conditions.

Section 4 analyzes the energy harvesting potential based on the recorded data, including performance estimations and a proposed technical solution. Finally,

Section 5 provides a discussion of comfort-related implications and integration challenges, followed by conclusions and future research directions.

2. Materials and Methods

The study was conducted under real-world conditions using a passenger car and two types of child car seats. Mechanical vibrations occurring within the structure of the seats and ISOFIX bases were evaluated while driving over various road surfaces and under different simulated child weights. The recorded acceleration signals served as the basis for further analysis of the potential to recover electrical energy from mechanical vibrations. This chapter presents the objectives of the study, the measurement setup configuration, test conditions, and specifications of the equipment used. The experiments were carried out at the Department of Motor Vehicles and Transport, Kielce University of Technology, Kielce, Poland.

2.1. Aim of the Research

The objective of this study was to determine the level of mechanical vibrations occurring within the structure of a child car seat and its mounting system, particularly at the ISOFIX base frame and the support leg, during real-world passenger car driving under varied road conditions. Acceleration measurements were used to quantitatively assess the intensity of vibrations transmitted from the road surface to the components of the seat–vehicle system, providing the basis for evaluating the feasibility of converting these vibrations into electrical energy using appropriate transducers.

The research has an application-oriented character and aims to identify vibration parameters that can be utilized as a power source for microelectronic systems, such as child presence sensors, temperature or heart rate monitors, or vibrational comfort assessment modules. Such solutions align with the modern approach to designing smart child seats, integrating safety, comfort, and autonomous power supply capabilities, in accordance with the principles of sustainable development.

Measurements were conducted during driving over three types of road surfaces:

Well-maintained asphalt—smooth, uniform surface,

Damaged asphalt—cracked, deformed, patched surface,

Speed bumps—regular, artificially introduced irregularities with known geometry.

The seats were loaded with masses corresponding to typical values for children at different stages of development, based on population percentile data:

Accelerations were measured at three key structural points:

On the seat surface—at the contact point with the simulated child body mass,

Beneath the seat—on the ISOFIX base frame connecting the seat to the vehicle structure,

On the ISOFIX support leg—acting as a stabilizing and load-bearing point for the entire system.

Based on the research objectives and measurement setup, the following research questions were formulated:

Q1: What are the vibration acceleration levels at the child seat and ISOFIX base depending on the type of road surface?

Q2: Does the simulated child mass significantly affect the dynamic characteristics of vibrations transmitted to the seat structure?

Q3: Do the vibrations observed at the selected structural points exhibit parameters suitable for effective energy conversion using piezoelectric, electromagnetic, or electrostatic transducers?

Q4: Which mounting point (seat surface, ISOFIX frame, or ISOFIX leg) demonstrates the most stable and energetically useful vibration characteristics?

Obtaining answers to these questions will enable an assessment of the feasibility and future directions for vibration energy recovery technologies in the context of developing modern, intelligent child seat mounting systems, and their integration with low-power monitoring electronics.

2.2. Experiment Conditions

The experiment was conducted under real-world road conditions using a premium mid-size passenger vehicle (segment E), an Audi A6, adapted for the installation of child car seats using both seat belts and the ISOFIX system.

Figure 1 shows the Audi A6 vehicle during a test run over speed bumps.

Before the tests began, the vehicle underwent a detailed technical inspection, with particular attention paid to the condition of the suspension system, shock absorber performance, and wheel balancing (with an accuracy of 2 g). Tire pressure was set according to the manufacturer’s recommendations: 0.25 MPa on the front axle and 0.20 MPa on the rear axle. Acceleration measurements were carried out while driving over three types of road surfaces:

Well-maintained asphalt—smooth and uniform surface,

Damaged asphalt—with visible cracks, potholes, and patches,

Speed bumps—representing point-source, regular dynamic disturbances.

For the asphalt surfaces, tests were conducted at a constant driving speed of 50 km/h, while for the speed bump scenarios, the speed was limited to 20 km/h to reduce the impact of sudden loads on the suspension components and the child seat mounting system. Each road condition scenario included 10 measurement repetitions, which enabled result averaging and improved data reliability.

Throughout the entire experiment, the vehicle was driven by the same driver, maintaining a constant speed and avoiding sudden acceleration or braking. This approach ensured a high level of methodological consistency and comparability of the obtained measurement results.

2.3. Configuration of Seats and Loads

The study involved two different models of child car seats from the same height–weight group, intended for children approximately 67–105 cm tall and weighing up to 18 kg. Both seats, the Avionaut model (Seat 1) (

Figure 2) and the Britax Römer model (Seat 2) (

Figure 3), were installed on a shared ISOFIX base equipped with a support leg, which ensured a rigid connection to the vehicle structure and helped limit the transmission of vibrations and movement of the seat structure relative to the car body.

The vehicle used in the study was a 2019 Audi A6 sedan equipped with a multilink rear suspension, adaptive shock absorbers, and a wheelbase of 2924 mm. The test vehicle featured factory-installed ISOFIX anchoring points and a flat rear floor surface, which ensured consistent mounting conditions for the support leg. Tire pressure was set to 0.25 MPa (front) and 0.20 MPa (rear), in accordance with the manufacturer’s recommendations. The Avionaut seat (Seat 1) features a more compact frame design and uses softer padding materials with additional side impact protection inserts. It weighs approximately 4.8 kg and includes passive ventilation channels. In contrast, the Britax Römer seat (Seat 2) has a higher headrest profile, a more rigid shell structure, and slightly stiffer internal padding. It weighs around 5.5 kg and includes a built-in harness tension indicator. These differences in mass distribution and structural stiffness may influence the way vibrations are transmitted and dampened through the seat base.

Both the Avionaut and Britax Römer child seats were tested under identical dynamic conditions. In each configuration, the seat was installed in a rear-facing position, consistent with recommended practice for children in this age and weight group.

To simulate the load corresponding to a child’s body weight, the seats were weighted using test masses of 9 kg and 15 kg. The loads were placed centrally on the seat surface, at the location corresponding to the child’s torso, allowing for a realistic distribution of forces and ensuring repeatability of the test conditions. Each configuration, defined by the seat model and the applied test mass, was tested separately under controlled road conditions and at a specified speed, which enabled a comparative analysis of the influence of seat design on the level of recorded vibrations. The resulting data provided the basis for further evaluation of the potential to harness vibration energy as a power source for electronic systems integrated into the child seat.

2.4. Measuring

To record mechanical vibrations transmitted to the child seat and its mounting elements, a measurement track based on three-axis acceleration sensors, a data logger, and an independent power source was used. The aim of the system was to obtain reliable data on vertical accelerations that could be used to analyze vibration comfort and assess the potential for obtaining electrical energy from vibrations.

2.4.1. Acceleration Sensors

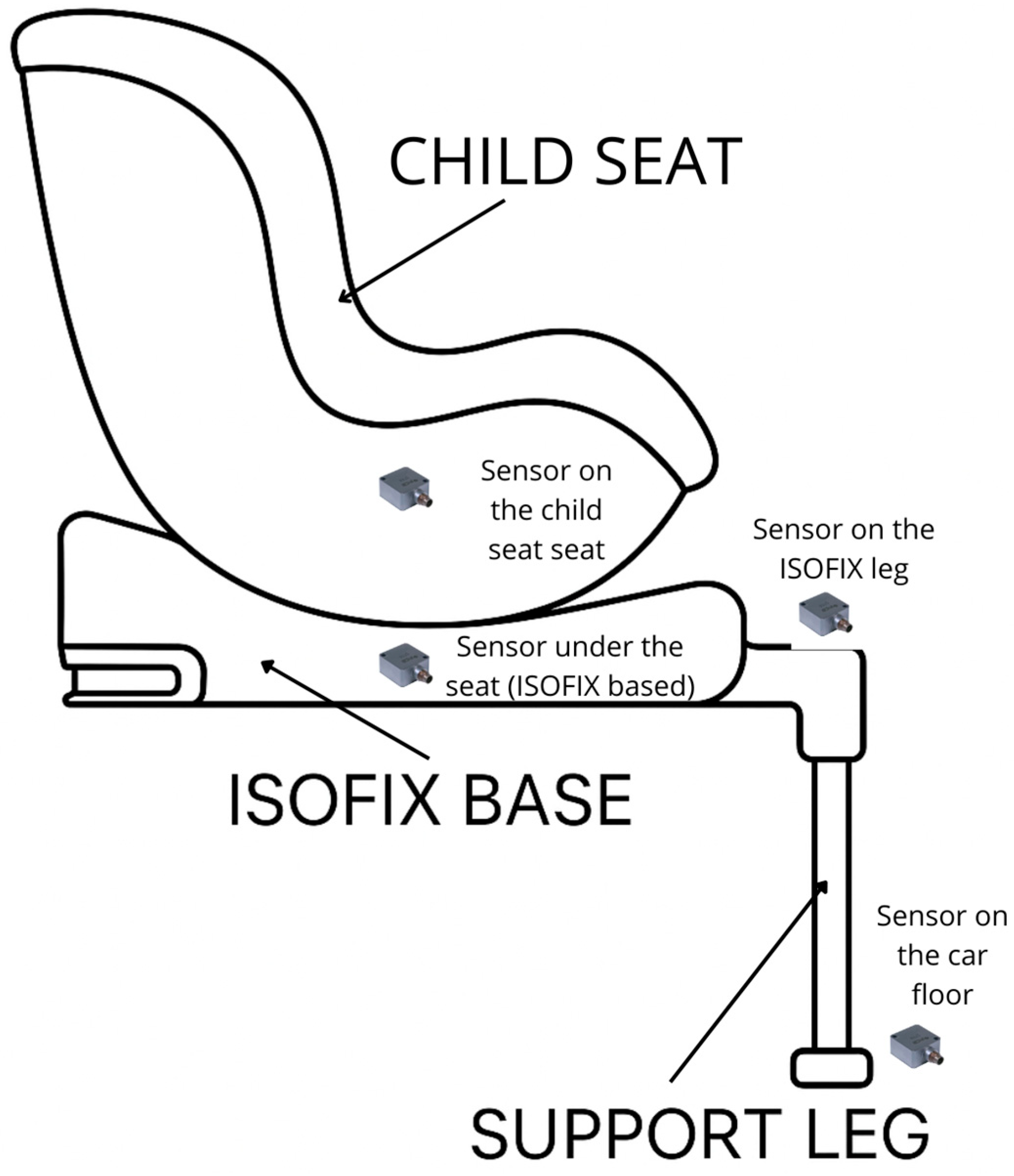

Four triaxial accelerometers were used in the study, enabling the recording of vibration signals in three spatial directions: longitudinal (X), lateral (Y), and vertical (Z). The sensors were installed at the following locations:

On the child seat surface, at the point of contact with the child’s body.

Beneath the seat, on the ISOFIX base frame.

On the ISOFIX support leg, which acts as the third support point in the mounting system.

On the floor of a passenger vehicle, next to the ISOFIX support leg.

Each sensor was securely mounted using cable ties and spacer elements to ensure rigid attachment and eliminate unwanted micro-vibrations. The mounting positions were selected to enable accurate assessment of vibration transmission to critical components of the seating system. For the purpose of this analysis, only the vertical (Z-axis) acceleration component was considered, as it is the most relevant in terms of passenger comfort and energy harvesting potential. Vibrations in the horizontal directions (X and Y) were recorded but excluded from further analysis.

Figure 4 presents an example of a sensor mounted on the seating surface of the child car seat, showing its position relative to the overall seat structure.

Figure 5 illustrates the full schematic of all accelerometer placements used in the experiment, including sensors located on the seat shell, ISOFIX base, and the support leg.

2.4.2. Data Logging

Signal acquisition was carried out using the LMS SCADAS Recorder SCR02 digital data acquisition system (ECTS Systems, Kraków, Poland), which is the property of Kielce University of Technology, and allows for simultaneous high-precision sampling from multiple channels.. Data were collected at a sampling rate of 1024 Hz, which made it possible to capture detailed signal characteristics, including higher-frequency components typical of vibrations generated by road surfaces and the dynamic response of the suspension system and child seat structure. The measurement system was connected to a recording computer and powered by an independent 12 V battery with a voltage converter, ensuring stable operation and full independence from the vehicle’s electrical system.

2.4.3. Conditions for Conducting Tests

During the experiment, no automatic system for measuring the speed of the vehicle was used. All journeys were made by the same driver, who controlled the speed based on the speedometer. The movement of the vehicle was uniform, with no sudden changes in acceleration or braking, in accordance with scenarios with specific test speeds.

2.5. Procedura Oceny i Analizy Próbek Pomiarowych

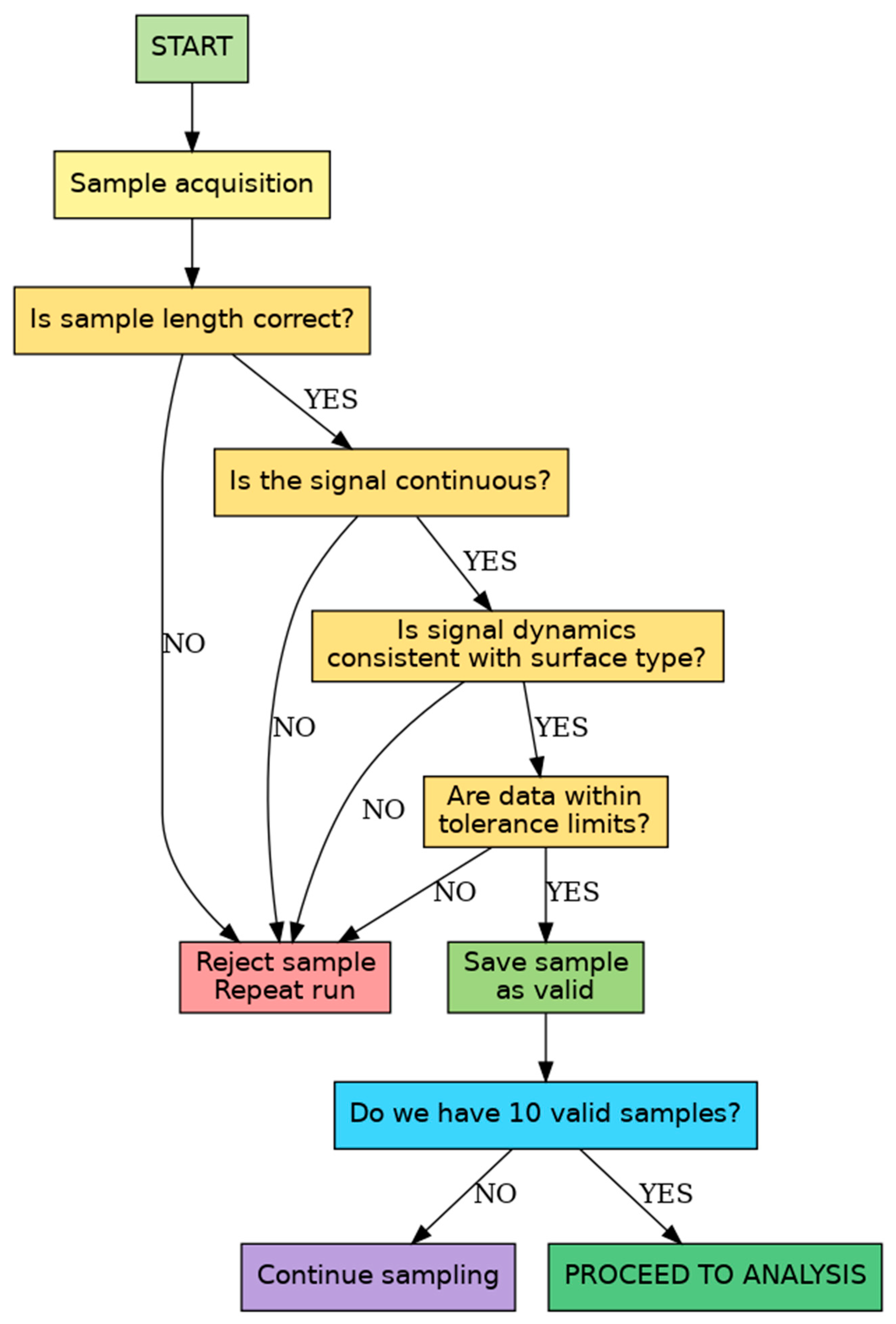

In order to ensure high data quality and reliability of the results, each recorded sample of the vertical acceleration signal was subjected to methodological verification, in accordance with the PRIXIMA methodology. Only those signals that met strict acceptance criteria were analyzed, and all samples that did not comply with the assumptions were rejected and re-recorded. A single sample corresponded to one test run for a given seat configuration, installation method, weight of the simulated child, road surface, and driving speed. Prior to analysis, each sample was evaluated for:

signal length (whether it corresponds to the assumed route section),

continuity and lack of interruptions in recording,

dynamic correctness (compliance of the course with the type of surface),

stability before and after the disturbance (e.g., at a speed bump).

If any of the above criteria did not comply with any of the above criteria, the sample was rejected and the drive was repeated until full-value data was obtained. For each test configuration, 10 accepted attempts were made. Only vertical vibrations (in the Z-axis) were analyzed, as they are the most important from the point of view of passenger comfort and the possibility of energy recovery from vibration movement. Longitudinal and transverse components (X, Y) were recorded but omitted in further analysis. Once the sample was approved, the data was numerically processed. For each pass, basic dynamic parameters were calculated, including RMS acceleration, peak, mean, standard deviation, and Fourier transform (FFT) frequency analysis of the signal. Data that did not comply with the dynamic tolerance range for a given configuration was also discarded and replaced by another measurement.

Figure 6 below shows a diagram of how to handle measurement samples in the form of a logic diagram in accordance with the PRIXIMA methodology.

After the sample was valid, the data was analyzed using two tools: Microsoft Excel and Statistica 13.3 (StatSoft). Excel was used to calculate basic statistical parameters such as RMS, peak, mean, and standard deviation, as well as to visualize time-domain signals. The Statistica suite was used to perform statistical analyses, including tests for the significance of differences (e.g., ANOVA), analysis of variance, and correlation between variables such as mass, pavement, and installation method.

Despite maintaining high research standards, the experiment had some limitations. The most important of them was the limited number of tested configurations; two types of seats and a limited range of simulation masses do not reflect the full spectrum of use. In addition, the analysis included only vertical vibrations, ignoring the potential influence of vibrations in horizontal directions. In addition, the speed of the vehicle was controlled manually by the driver, which, despite his experience and uniformity of passages, may introduce slight deviations from the assumed values. The measurement was also carried out using one vehicle with a specific technical condition and one model of the ISOFIX base, which limits the possibility of generalizing the results to all types of car seats and cars available on the market.

3. Results

This chapter presents selected results of vertical acceleration measurements recorded on the child seat surface and the support leg of the ISOFIX base. The displayed plots refer to the first of the analyzed child seats and serve an illustrative purpose.

Due to the large number of test repetitions, each configuration was recorded ten times to ensure repeatability and result reliability; only a selection of representative examples is shown. This approach allows for a clear illustration of the vibration characteristics under different road conditions and load scenarios, without overloading this section with excessive graphical data.

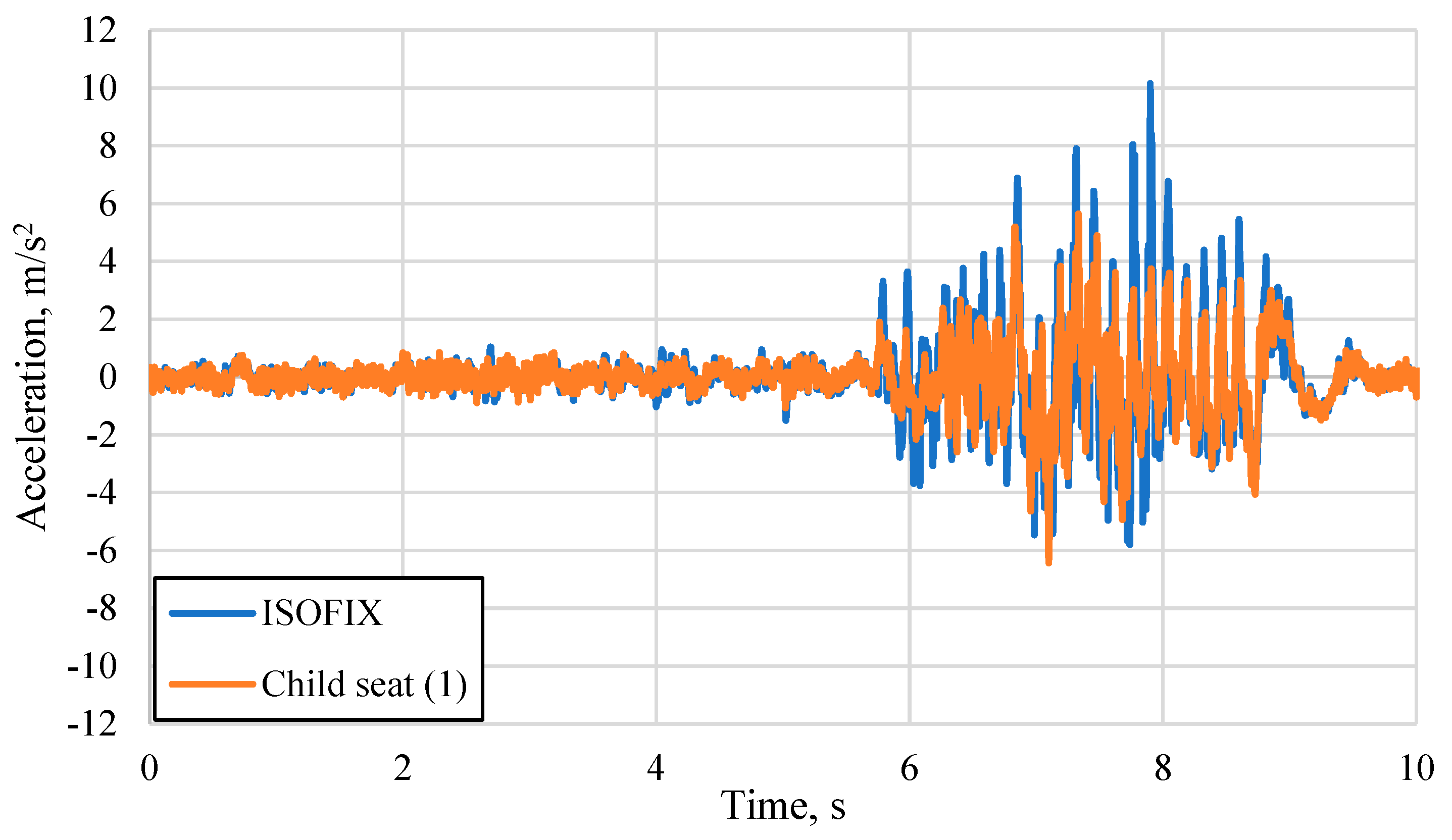

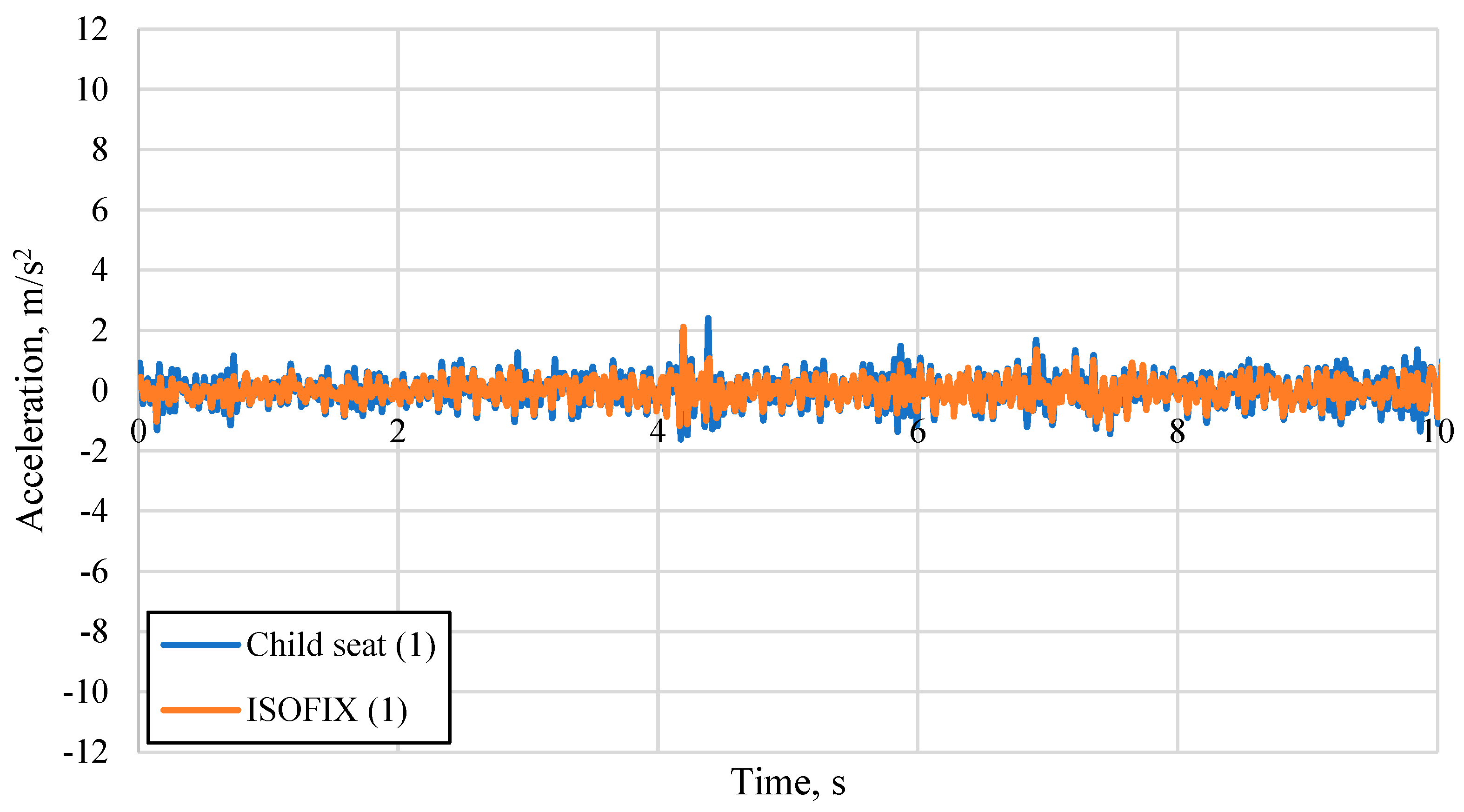

Figure 7 shows the vertical acceleration waveforms recorded on the child seat surface and the ISOFIX base support leg during a speed bump crossing, with a load of 9 kg.

In the time interval between approximately 3 and 6 s, a significant increase in acceleration values can be observed, corresponding to the moment of passing over the obstacle. The peak instantaneous acceleration values on the ISOFIX support leg reach approximately ±10 m/s2, while those on the child seat surface do not exceed ±8 m/s2. Outside of the speed bump crossing period (i.e., from 0 to 2.5 s and 7–10 s), the signals at both measurement points remain relatively stable, oscillating within ±1 m/s2, indicating an absence of major dynamic disturbances during these segments of the run.

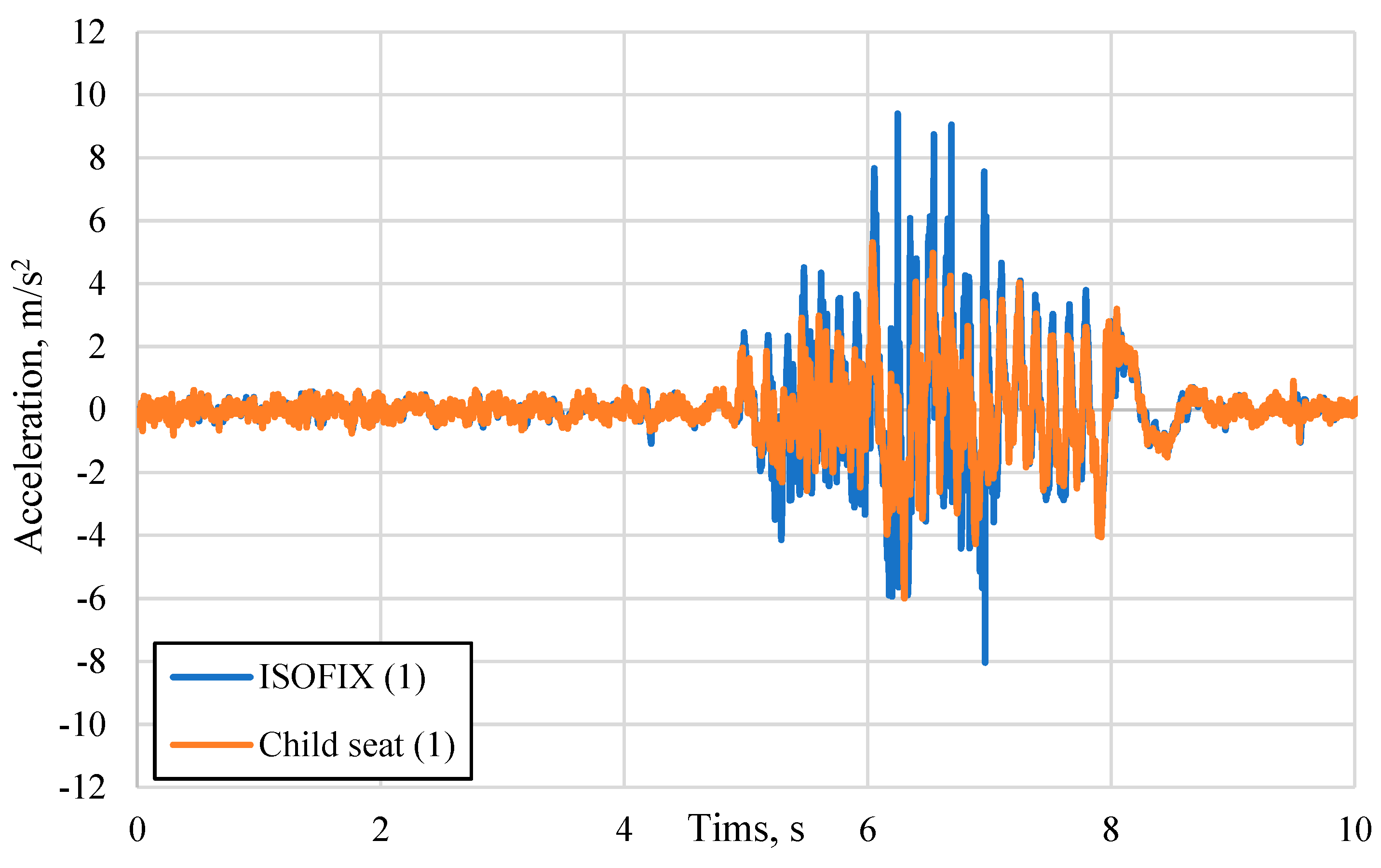

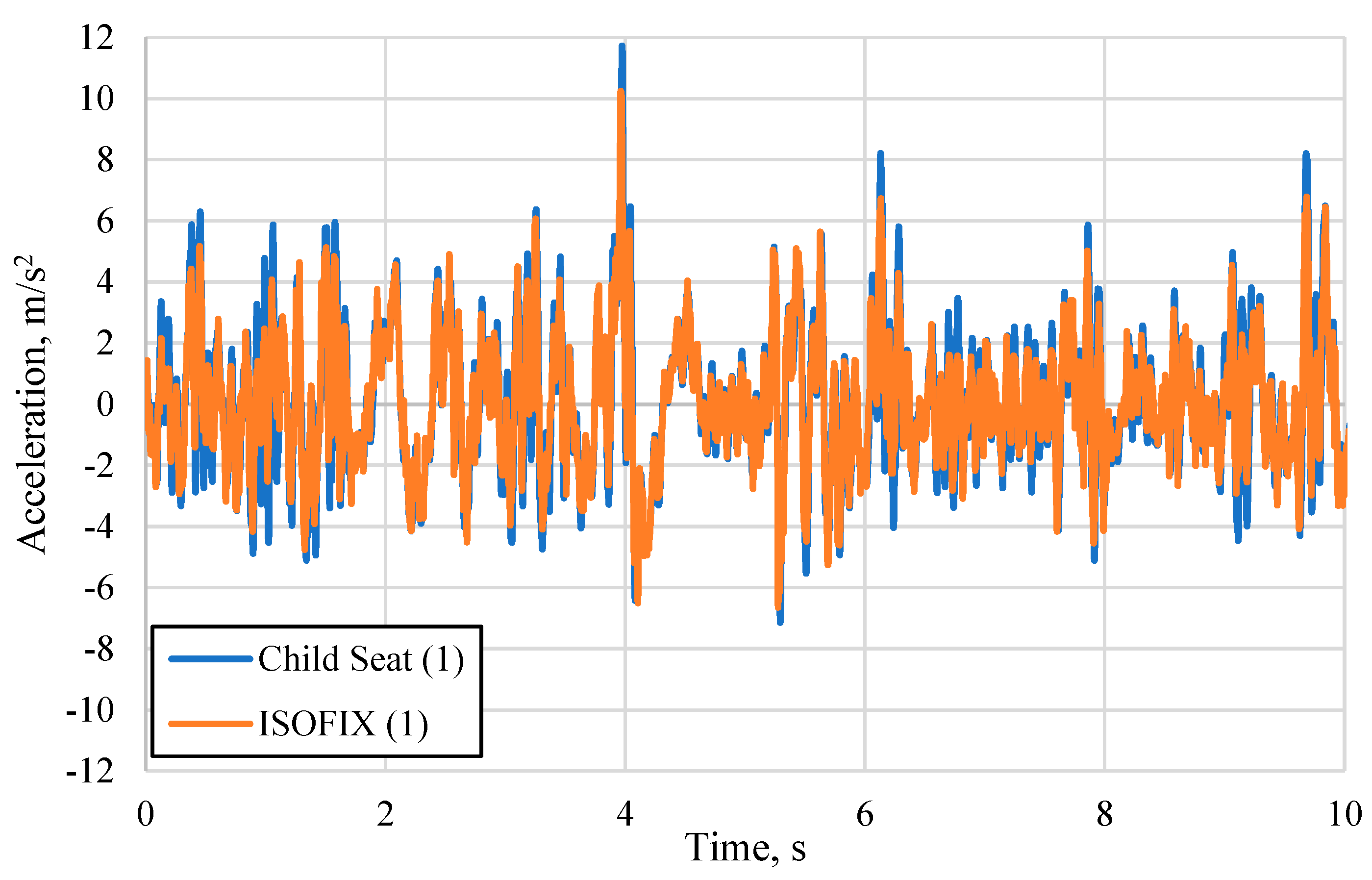

Figure 8 shows the vertical acceleration waveforms recorded on the child seat surface and the ISOFIX base support leg during the speed bump crossing, with a load of 15 kg. In the time range between approximately 3 and 6 s, a clear increase in signal dynamics is observed, again corresponding to the moment the vehicle crosses the bump. The maximum instantaneous acceleration values at the ISOFIX support leg reach approximately ±11 m/s

2, while at the measurement point on the child seat surface, they do not exceed ±9 m/s

2. In the remaining time intervals—i.e., before (0–2.5 s) and after (7–10 s) the bump crossing—the accelerations remain low and stable, within a range of ±1 m/s

2, consistent with driving over a smooth road surface.

Figure 9 presents the vertical acceleration waveforms recorded on the child seat surface and the ISOFIX base support leg during driving on a well-maintained asphalt road, with a load of 9 kg. Throughout the entire analyzed time interval (0–10 s), the acceleration values at both measurement points remain low and stable, with no noticeable spikes or dynamic disturbances. The maximum instantaneous values do not exceed ±2 m/s

2, and the signal is characterized by low-energy content. The recorded waveforms suggest minimal dynamic interaction from the road surface, which is typical for smooth, uniform asphalt sections without structural damage.

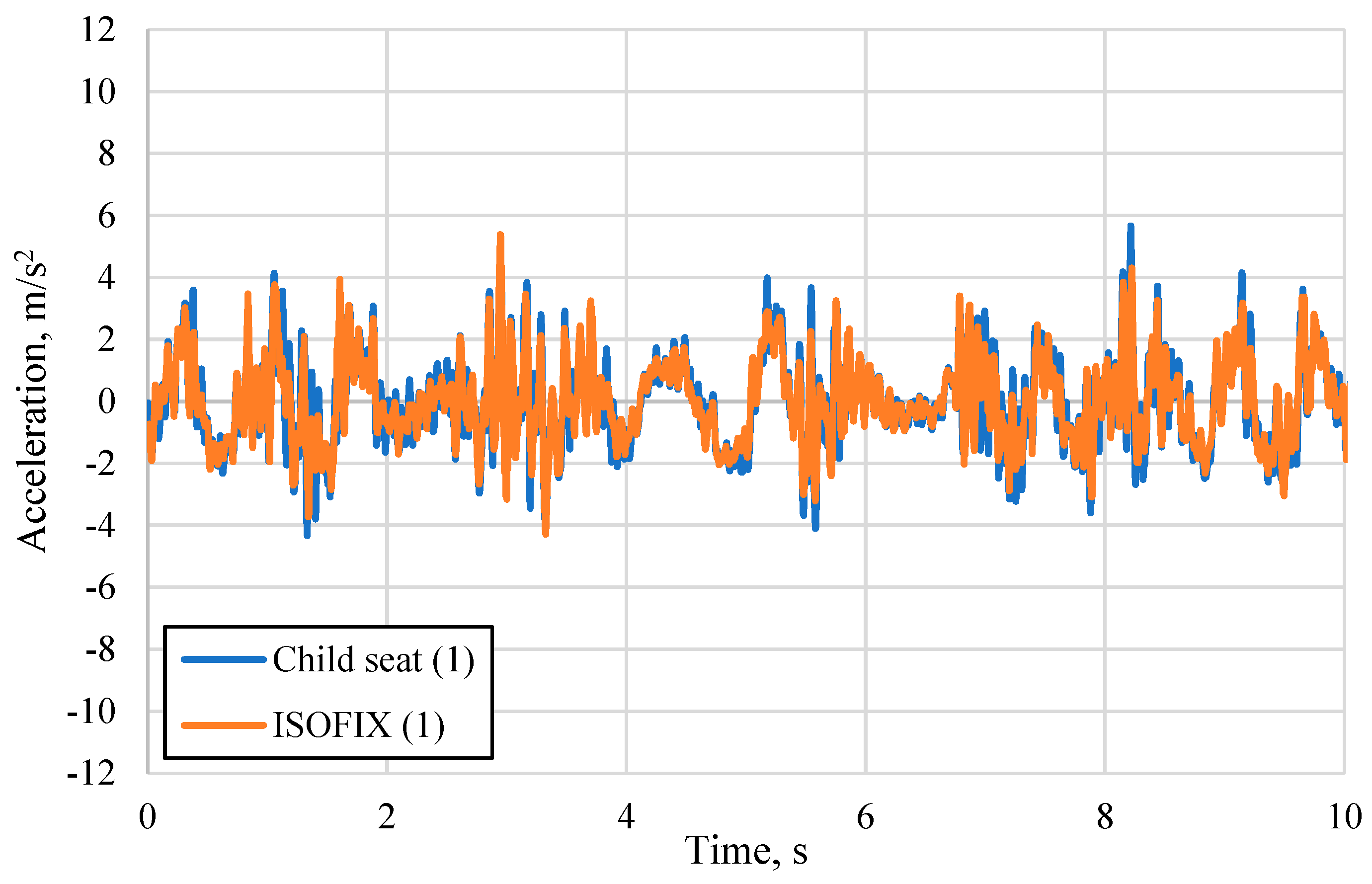

Figure 10 shows the vertical acceleration waveforms recorded on the child seat surface and the ISOFIX base support leg during driving on a damaged asphalt road, with a load of 9 kg. Throughout the entire time interval (0–10 s), irregular and intense variations in acceleration values can be observed, which are typical for driving on uneven surfaces. The peak instantaneous values reach approximately ±6 m/s

2 on both measurement channels, and the signal variability is clearly greater than in the case of a smooth surface. A higher frequency of high-amplitude vibration impulses is also evident, indicating frequent dynamic interactions caused by potholes and surface deformations in the road.

Figure 11 presents the vertical acceleration waveforms recorded on the child seat surface and the ISOFIX base support leg during driving on a well-maintained asphalt road, with a load of 15 kg. The waveforms throughout the entire time interval (0–10 s) are characterized by low amplitude and stable signal behavior. Maximum instantaneous acceleration values do not exceed ±2 m/s

2 at any of the analyzed measurement points. The recorded fluctuations are minor and evenly distributed over time, indicating the absence of significant dynamic disturbances resulting from the high-quality road surface.

Figure 12 shows the vertical acceleration waveforms recorded on the child seat surface and the ISOFIX base support leg during driving on a damaged asphalt road, with a load of 15 kg. In the analyzed time interval (0–10 s), significant signal variability with high amplitude is observed, reflecting intense dynamic interactions caused by surface irregularities. Peak instantaneous acceleration values exceed ±8 m/s

2, and the frequency of high-amplitude vibration impulses is greater than in the lower load scenario. The signals exhibit high irregularity and dynamic behavior, characteristic of driving on a degraded road surface with numerous structural defects.

Analysis of the vertical acceleration time waveforms recorded on the child seat surface and the ISOFIX base support leg revealed clear differences in dynamic characteristics depending on the type of road surface and the applied load. During driving on well-maintained asphalt (for both 9 kg and 15 kg loads), low vibration levels were recorded, peak instantaneous accelerations did not exceed ±2 m/s2, and the signals remained stable and uniform, regardless of the measurement point. In contrast, driving on damaged asphalt led to increased vibration intensity; peak values reached up to ±6 m/s2 (for 9 kg) and over ±8 m/s2 (for 15 kg), with more irregular signal patterns and a higher frequency of vibration impulses.

The highest acceleration levels were observed during speed bump crossings, where impulses reached ±10–11 m/s2 for both load values, especially in the signals recorded at the ISOFIX support leg. These values confirm significant dynamic loads under such conditions, indicating a potentially valuable source of mechanical energy for harvesting applications. Throughout all test scenarios, acceleration amplitudes recorded at the ISOFIX support leg were generally higher than those recorded at the seat surface, indicating differences in local dynamic behavior. This suggests that the support leg is a promising location for vibration energy harvesting. The combination of qualitative and quantitative data from the waveforms forms the basis for further evaluation of the energy harvesting potential and the impact of road conditions on the dynamic response of the seat–vehicle system.

To assess the level of dynamic impact on a child seated in the car seat, the root mean square (RMS) values of vertical acceleration were analyzed in accordance with ISO 2631-1:1997 (Mechanical vibration and shock—Evaluation of human exposure to whole-body vibration—Part 1: General requirements. International Organization for Standardization: Geneva, Switzerland, 1997.), which provides classification guidelines for human exposure to mechanical vibrations, with particular attention to comfort perception and potential physiological effects.

Calculations were carried out for two child seat models, Avionaut and Britax Römer, under two load conditions (9 kg and 15 kg) and across three road surface types: well-maintained asphalt, damaged asphalt, and speed bump crossings. Measurements were taken at two points: the ISOFIX support leg and the seat surface.

For well-maintained asphalt, RMS values ranged from 0.37 to 0.39 m/s2 for the Avionaut seat and from 0.44 to 0.48 m/s2 for the Britax Römer model. According to ISO classification, these values correspond to moderate to clearly perceptible vibrations, which do not represent a significant source of discomfort for the child. Under such conditions, the ride can be considered comfortable, both in terms of vibration intensity and its impact on the young passenger’s well-being.

Significantly higher values were recorded on damaged asphalt, with RMS levels reaching 1.55 m/s2 for the Avionaut seat and up to 1.93 m/s2 for the Britax Römer under the 9 kg load. According to the standard, these levels qualify as very uncomfortable vibrations, which may cause considerable physical discomfort for the child and negatively affect their perception of the ride and overall well-being. Elevated values were observed regardless of the load, and the highest vibration levels consistently appeared at the ISOFIX support leg, indicating that this component is particularly susceptible to vibration transmission from road surface irregularities.

The highest RMS acceleration values were recorded during speed bump crossings, with results reaching 2.25 m/s2 for the Avionaut seat and up to 2.89 m/s2 for the Britax Römer seat, for both load values (9 kg and 15 kg). According to ISO 2631-1, these levels are classified as extremely uncomfortable, meaning they may not only cause serious discomfort for the child but, if prolonged, could also have adverse physiological effects and negatively impact postural stability. It is particularly concerning that these values were also recorded at the seat surface, indicating that mechanical vibrations were partially transmitted through the seat structure despite the presence of an ISOFIX base.

Comparison of the two seats revealed that the Britax Römer model consistently produced higher RMS values than the Avionaut seat in every test configuration, which may indicate lower effectiveness in damping mechanical vibrations. The differences between the 9 kg and 15 kg loads were minor, suggesting that child mass did not have a significant effect on vibration levels within the tested range. The road surface quality and the structural path of vibration transmission from the vehicle body to the seat frame proved to be the most influential factors.

The collected data clearly indicate that vibration levels can significantly affect a child’s ride comfort, and under intense vibration conditions, such as driving over damaged roads or speed bumps, they can exceed thresholds classified as very or even extremely uncomfortable according to ISO 2631-1. This justifies the need for further research and development of damping systems integrated into modern child car seats. The RMS values of vertical accelerations [m/s

2] recorded at the child seat and ISOFIX base, depending on child mass, road surface type, and seat model, are summarized in

Table 1.

Based on the vertical acceleration measurements taken at selected structural points of the child seat–ISOFIX system, detailed information was obtained regarding the dynamic characteristics of vibrations generated under typical vehicle operating conditions. The recorded root mean square (RMS) values clearly indicate that vibration intensity strongly depends on the type of road surface and the measurement point location, with the highest acceleration values consistently occurring at the ISOFIX base support leg. This finding, combined with the cyclical nature of the vibrations and their repetitive occurrence during driving, opens up the prospect of practically utilizing these phenomena for harvesting mechanical energy and converting it into electrical energy.

To evaluate the impact of seat design and load mass on the level of transmitted vibrations, a Pearson correlation coefficient (r) analysis was conducted between the RMS values of vertical acceleration and two variables: (1) the type of child seat (encoded as a binary variable: 0—Avionaut, 1—Britax Römer), and (2) the mass of the simulated child (9 kg or 15 kg).

The analysis revealed a significant positive correlation between seat type and RMS value (r = 0.68), indicating that the Britax Römer model exhibited higher vibration levels than the Avionaut model under the tested conditions, regardless of road surface type. These differences may be attributed to variations in design and damping materials.

Regarding the effect of load mass, a weaker but still positive correlation was found (r = 0.42), suggesting that increased child mass contributed to higher vibration intensity, although the effect was less pronounced than the impact of seat construction.

Both results confirm that seat design and child weight influence vibrational comfort during travel, which is important in the context of designing child seats with integrated energy harvesting systems and comfort sensors.

Due to the limited number of measurement repetitions (10 samples per configuration), a full statistical significance analysis of the differences between seats was not performed. However, it is worth noting that within-group variability was very low; RMS differences between individual samples for a given configuration did not exceed 0.0005 m/s2. This indicates high measurement repeatability and allows for qualitative comparisons between the seats.

In future studies with larger sample sizes, it would be advisable to apply formal statistical tests (e.g., ANOVA) to confirm the observed differences related to seat design. The next section of the study presents an approach aimed at estimating the potential for converting vibration energy, measured at the ISOFIX support point, into electrical energy using appropriately selected transducers (piezoelectric, electromagnetic, or electrostatic).

The goal of this analysis was to determine whether and to what extent energy harvesting technologies could be applied to power low-power measurement systems integrated into a child car seat, such as presence, temperature, humidity, or seatbelt tension sensors. This approach aligns with the growing interest in intelligent transportation systems and autonomous passenger safety solutions, particularly in the context of electric vehicles and energy-efficient technologies.

4. Evaluation of the Vibration Energy Potential of a Child Seat

In the era of energy-efficient systems, mobile electronics, and the Internet of Things (IoT), solutions enabling autonomous power supply for microsystems without the need for an external energy source play a key role. One of the most promising directions is energy harvesting, which involves capturing small amounts of mechanical, thermal, light, or electromagnetic energy from the environment and converting it into usable electrical energy.

A particularly interesting source of mechanical energy is the vibrations generated during vehicle travel, which, although often of low amplitude, are continuous and cyclical. In vehicles equipped with child seats mounted using the ISOFIX system, repetitive vibrations of the ISOFIX support leg can serve as a local energy source to power small sensors. While most of the child’s and seat’s weight is supported by the car seat and safety belts, the ISOFIX support leg maintains contact with the vehicle floor and registers vertical vibrations caused by road surface irregularities.

The aim of this study is to conduct a detailed analysis of the potential for harvesting electrical energy from vertical vibrations of a single ISOFIX support leg, and to determine whether it can serve as a power source for a low-power safety sensor, such as one that detects if a child has unbuckled the seatbelt. The harvested energy is stored in a power bank acting as an energy buffer, and then used to power the sensor through a high-efficiency converter.

To illustrate the impact of road conditions on the effectiveness of the energy harvesting system, two real-world driving scenarios were considered:

Driving for 1 h on a damaged asphalt road, characterized by frequent and intense vibrations with higher amplitudes and frequencies,

Driving for 1 h on a well-maintained asphalt road, characterized by smoother ride quality and lower dynamic loads.

Based on vertical-axis (Z-axis) sensor data collected from the ISOFIX seat base, the kinetic power of vibrations was estimated for both scenarios. Then, taking into account conversion efficiency, the actual amount of electrical energy that could be stored in the power bank was calculated. Losses due to power transmission, voltage conversion, and sensor operation were also considered.

This approach helps answer the question of whether and to what extent vibration energy can power practical child safety systems in a vehicle, and how strongly road quality affects the system’s effectiveness. The results demonstrate the performance limits of the energy harvesting system and highlight scenarios where its use may be justified—for example, during frequent use on rough roads or as a backup system.

4.1. Assumptions and Formulas

In order to analyze the amount of electrical energy that can be extracted from the vibrations of one leg stabilizing the ISOFIX car seat in the car, a set of realistic and simplified assumptions was made, resulting from the measurements and the physical design of the system. The analysis was carried out for two road scenarios: driving for one hour on an asphalt surface in poor technical condition and driving for one hour on an asphalt surface in good technical condition. Both cases are based on vertical acceleration measurements (in the Z-axis) recorded by an acceleration sensor attached to the ISOFIX base of the child seat.

It was assumed that the total weight of the seat and the dummy is 9.5 kg, but due to the design of the mounting, only a small part of this weight is dynamically transferred to the ISOFIX leg. For the purposes of this simplified model, a value of 10% was adopted, resulting in an effective mass of 0.95 kg. This approximation reflects the behavior of semi-rigid support systems and is consistent with the mechanical distribution observed in statically loaded cantilevered configurations. It is also in line with the general principles described in ISO 13216:1999 (Road vehicles—Anchorages in vehicles and attachments to anchorages for child restraint systems—Part 1: Seat bight anchorages and attachments. International Organization for Standardization: Geneva, Switzerland, 1999) regarding load paths in ISOFIX-mounted child restraint systems. Although no standard precisely defines dynamic mass distribution to the support leg, the 10% value provides a conservative and technically reasonable basis for evaluating the energy harvesting potential. This estimate is based on observations of the system’s behavior in tests and analogies to point suspension models, where an auxiliary component (such as the ISOFIX leg) carries some of the dynamic load. Due to the lack of literature data on the exact dynamic share, this value can be considered an approximation, constituting a reference point for further comparative analyses. It was therefore determined that the effective oscillating weight on the ISOFIX leg is about 10% of the total weight, which is 0.95 kg. This mass takes part in the vertical vibrations generated by the unevenness of the road surface and the movement of the vehicle.

The kinetic energy of vibrations is determined on the basis of the classical formula (1):

where: E

k is the kinetic energy at a given moment in time, m is the effective mass, and v is the instantaneous vertical velocity due to the accelerations recorded by the sensor. This velocity is calculated numerically as the approximate integral of acceleration over time, according to formula (2):

where: υ

i is the successive acceleration samples, and Δt is the time interval between the samples, resulting from the sensor’s sampling frequency, equal to 256 Hz, which gives Δt = 1256\s. The velocity is calculated for each sample and then substituted into the kinetic energy formula. The total kinetic energy (E

kin) of vibration during one hour of driving is determined as the sum of instantaneous kinetic energies or, alternatively, on the basis of the average kinetic power of P

kin for a given mass (3):

where:

t = 3600 s is the duration of the ride.

Based on previous calculations for the measurement data, the average kinetic vibration power for a mass of 50 g (0.05 kg) was assumed to be 3.7 mW for a road surface in poor condition and 0.15 mW for a road surface in good condition. Assuming a linear dependence of power on weight, these values were scaled to an effective mass of 0.95 kg. Assuming a linear dependence of kinetic power on weight, these values were scaled to an effective mass of 0.95 kg. This relationship is based on Newton’s second law (F = ma), where an increased mass under the same vibrational input leads to proportionally higher inertial forces, and thus higher energy. Additionally, kinetic energy scales with the square of velocity and linearly with mass. While nonlinear damping effects may occur in real-world systems, the approximation of linearity has been validated in similar engineering studies and is supported by ISO 2631-1, which relates acceleration levels and exposure duration to vibration-induced discomfort in human passengers. In this context, linear scaling provides a justified and practical approach to estimating energy variation due to changing child mass. The average kinetic power acting on the ISOFIX leg was calculated using formula (4) for poor road conditions and formula (5) for road surface in good condition.

The kinetic energy obtained is then converted into electrical energy using a piezoelectric element. For the entire energy conversion and storage path, the acquisition efficiency η

p = 20% was taken into account, which corresponds to typical values for piezoelectric systems with suboptimal resonance frequency matching, and the transmission and storage efficiency in the power bank η

m = 80%. The total efficiency of energy acquisition is thus expressed as (6):

Therefore, the electrical energy that can be stored in a power bank during one hour of driving is expressed by the formula (7):

where:

Eelec—electrical energy obtained,

Ekin—available kinetic energy,

ηtotal—total efficiency of the energy conversion system.

The energy storage is a power bank with a typical capacity of 10,000 mAh and a voltage of 3.7 V, which gives a total capacity of 37 Wh. This resource is used to power a safety sensor with a constant power consumption of 10 μW. The operating time of the sensor is determined from the formula (8):

where: η

z is the efficiency of the power converter (assumed as 90%) and Psensor = 0.00001 W (10 μW). All calculations will be carried out separately for surfaces in poor and good condition, which will allow us to determine the impact of road conditions on the amount of energy that can be recovered and the operating time of the sensor powered only by the energy harvesting system.

4.2. Analyze the Results

In the calculations carried out, the basis for determining the amount of energy that can be obtained was the kinetic power resulting from the vibrations recorded on the ISOFIX leg of the child seat. This parameter describes how much mechanical energy is generated in the system as a result of vibrations per unit of time and is the starting point for further conversion into electrical energy that can be stored and used.

For the scenario of driving on a road surface in poor technical condition, the value of kinetic power was determined on the basis of measurement data obtained from an acceleration sensor installed in the base of the ISOFIX seat. The sensor recorded acceleration in the vertical axis (Z) during the actual driving of the vehicle on uneven asphalt surfaces. After processing the signal using numerical calculations, the variable vibration velocities were calculated for the 0.05 kg mass sample and on their basis—the average kinetic power. The duration of the recorded sample was about 0.48 s, and the total kinetic energy reached a value of about 1.8 mJ. All mathematical symbols and abbreviations referenced in this formula are defined in the Abbreviations section of the manuscript. The calculated kinetic power was (9):

At the same time, a second registration was carried out in conditions of driving on an asphalt surface in good technical condition. The measurement was made with the same sensor and under similar test conditions, but this time the vehicle was moving on a level road. The collected data showed significantly lower accelerations, and thus lower vibration velocities and kinetic energy. For the same mass of 0.05 kg, the average kinetic power of (10) was calculated:

These values form the basis for further calculations and analysis of the efficiency of the energy harvesting system in two realistic road scenarios. Both values were obtained in an experimental manner, without using theoretical assumptions, which ensures the reliability and consistency of the final results.

In this section, calculations of the amount of energy that can be obtained from the vibrations of one ISOFIX leg in two cases have been carried out: driving on asphalt in poor and good technical conditions. In both scenarios, an effective vibration mass of 0.95 kg was assumed, which corresponds to about 10% of the combined weight of the seat and the dummy. The analysis takes one hour of driving (3600 s), and all the energy is to be stored in a power bank, which then powers the sensor with a power consumption of 10 μW.

For the mass of 0.05 kg, the average kinetic power was obtained from the measurements:

Surface in poor condition (11):

Surface in good condition (12):

After scaling to a weight of 0.95 kg (we assume a linear dependence of power on weight) for a surface in poor condition (13) and a surface in good condition (14):

We calculate the kinetic energy generated during one hour of driving for a surface in poor condition (15) and a surface in good condition (16):

Taking into account the efficiency of energy acquisition and storage (16%) for pavements in poor condition (17) and pavements in good condition (18):

With the efficiency of the converter supplying the sensor (90%), for pavement in poor condition (19) and pavement in good condition (20):

Operating time of a sensor with a consumption of 10 μW (i.e., 0.00001 W), for pavement in poor condition (21) and pavement in good condition (22):

Based on the performed calculations, it can be clearly stated that the efficiency of the energy harvesting system using vibrations from the ISOFIX support leg of a child car seat strongly depends on both road conditions and the mass of the seat’s user, that is, the child. In this analysis, a representative child mass of 7 kg was assumed. Combined with the seat mass (2.5 kg), this allowed for the estimation of an effective vibrating mass of 0.95 kg. However, it should be noted that the seat is designed for children weighing up to 15 kg, which means that under real-world conditions, the amount of recoverable energy could be up to twice as high as estimated here.

In the case of driving on a poorly maintained road surface, where stronger and more abrupt vertical vibrations occur, the measured kinetic power for the assumed mass was 70.3 mW. Over one hour of driving, this enabled the accumulation of approximately 40 J of electrical energy, of which 36.44 J was effectively delivered to the sensor after accounting for conversion and storage losses. At a constant power consumption of 10 µW, this would allow the sensor to operate for over 42 days of continuous use.

For comparison, on a well-maintained road surface, with much gentler vibrations, the harvested kinetic power was 2.85 mW, translating into 1.64 J of electrical energy over one hour of driving, of which 1.48 J remained usable. This amount of energy supports over 41 h of uninterrupted sensor operation.

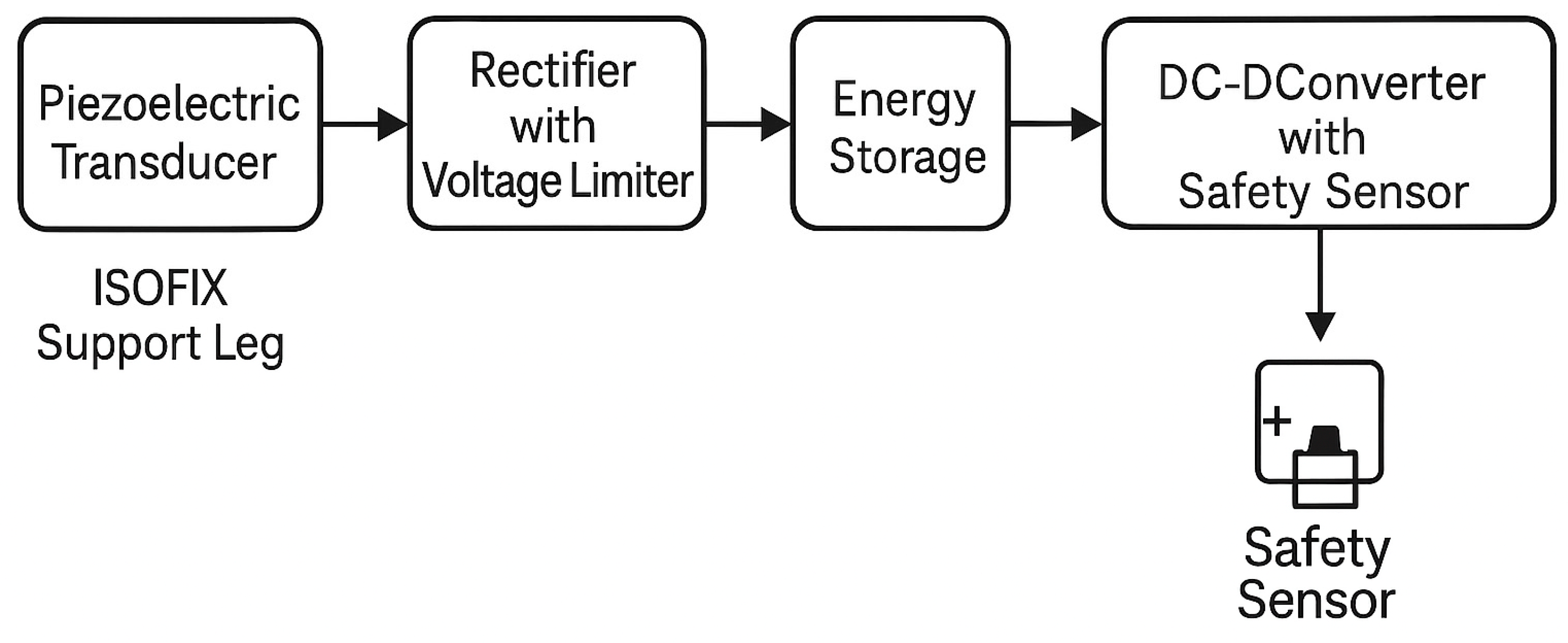

The energy harvesting and conversion process can be divided into six main stages, each responsible for a specific function within the system:

Vertical vibrations (ISOFIX)—The primary source of mechanical energy, generated by the vehicle’s suspension operation, road conditions, irregularities, and the child’s mass acting on the seat structure. The mechanical energy in these vibrations is time-varying, impulse-like, and dependent on driving conditions.

Piezoelectric transducer (~30% efficiency)—This component converts mechanical energy (vibrations) into alternating electrical voltage. In practice, its efficiency ranges from 20 to 40%, depending on transducer quality, resonant tuning, and the nature of the vibration.

Rectifier + signal conditioning circuit (~60% efficiency)—The resulting AC voltage must be converted to DC with appropriate parameters. This is achieved using a rectifier circuit (e.g., Graetz bridge) and smoothing capacitors. The energy efficiency of this stage is typically around 60%, depending on component selection.

Power bank (energy storage)—The electrical energy is stored in a battery or capacitor. In this case, a power bank acts as a buffer from which the sensor is powered. Losses related to charging, self-discharge, and storage are considered in the previous stage.

DC/DC converter (~90% efficiency)—The power bank outputs a charging voltage (e.g., 3.7–5 V), while low-power sensors usually require a regulated voltage (e.g., 3.3 V). The converter ensures voltage adaptation to the final load, with typical efficiency between 85 and 95%.

Sensor (e.g., child presence, seatbelt status)—The end consumer is a very low-power sensor (~10 µW), capable of detecting child presence, seatbelt status, temperature threshold exceedance, etc. Thanks to its low-energy demand, it can be powered for days or weeks from a single harvesting cycle.

Figure 13 shows a block diagram of the energy flow in the ISOFIX system, with the efficiency values of each energy stage indicated:

Piezoelectric transducer: ~30% efficiency—converts vibrations into voltage,

Rectifier and conditioning circuit: ~60% efficiency—converts AC to DC,

DC/DC converter: ~90% efficiency—matches voltage to sensor requirements.

The total system efficiency is approximately 16%, which was used in all energy availability calculations.

From the above data, it appears that the energy harvesting system, based solely on the vibrations of one ISOFIX leg, can successfully power a low-power safety sensor, especially in conditions of more intensive use, e.g., city driving on uneven roads or on longer routes with a child of a heavier weight. Importantly, the increase in the child’s weight causes a proportional increase in the effective vibrating mass, and thus, in the amount of energy obtained. In practice, this means that for a child with a weight close to the maximum permissible weight (e.g., 13–15 kg), powering the sensor for a much longer period of time becomes completely feasible even in moderate conditions of the surface.

These findings show that a system based on vibration energy recovery can not only complement conventional power sources, but can also provide power to low-power sensors on its own under the right conditions. This opens up the possibility of creating independent and long-lasting systems that monitor the safety of children in car seats, without the need to replace the battery or connect to the vehicle’s power supply.

4.3. Proposal for the Structure of the Energy Harvesting System for a Child Seat

Based on the measurements and analysis of the vertical vibration parameters recorded on the ISOFIX base support leg, a conceptual technical model of the energy harvesting system was developed, which can be used in a child seat. The main objective of the project is to enable autonomous power supply of low-power safety and comfort sensors, without the need for batteries or the vehicle’s electrical system.

The layout consists of five basic functional blocks:

Piezoelectric transducer—A piezoelectric PVDF transducer (e.g., model LDT0-028K (Measurement Specialties, Inc., Hampton, VA, USA)) is used as the main component of mechanical energy conversion, positioned between the ISOFIX footfoot and the vehicle floor surface. As a result of cyclic deformations caused by vibrations, the foil generates a variable voltage.

Voltage limiter rectifier—The voltage generated by the converter is transmitted to the rectifier circuit—a full-wave Graetz bridge with low voltage drop Schottky diodes (e.g., BAT54 (STMicroelectronics, Geneva, Switzerland)). For surge protection, a 5.1 V zener diode is used as voltage protection.

Energy storage (buffer)—The energy obtained is stored in a supercapacitor with a capacitance of 0.1–0.47 F and a nominal voltage of 5.5 V. This buffer allows energy to be supplied in pulses, e.g., to a sensor or transceiver.

Step-up DC/DC converter—To stabilize and raise the output voltage to a level useful for a microsystem, a boost converter with a low starting voltage (e.g., a TPS61200 (Texas Instruments, Dallas, TX, USA) system, which can operate from 0.3 V) is used.

Microcontroller and safety sensor module—A converter-powered microcontroller (e.g., ATTiny85 (Microchip Technology Inc., Chandler, AZ, USA) or ESP32-C3 (Espressif Systems, Shanghai, China)) works with a sensor such as a belt release, ambient temperature, or humidity sensor. The system can also send an alarm signal to the mobile app if an abnormality is detected (e.g., a child left in the vehicle).

The proposed concept of the energy harvesting system is illustrated by the block diagram shown in

Figure 14.

When the vehicle is moving, the vibrations transmitted by the ISOFIX leg deform the piezoelectric layer, generating an alternating voltage. This voltage is rectified and then stored in a supercapacitor. When the set voltage threshold is exceeded (e.g., 2.5 V), the converter switches on the power supply to the microcontroller. The system can operate periodically, during activation and sleep cycles, to conserve stored energy. The system is not dependent on the vehicle’s engine or ignition, ensuring its independence and continuity of operation even after the journey.

Potential applications for energy harvesting in a child seat include powering a range of low-power electronics that enhance the safety and comfort of the little passenger. First of all, the energy obtained can power the child’s presence sensors, which inform about leaving the child in the vehicle, which is particularly dangerous in the summer. Another functionality is the temperature and humidity sensors, which allow you to monitor the microclimate around the child and activate the alarm or ventilation when the permissible values are exceeded. The system can also support the operation of seat belt unfastening sensors, warning of incorrect harness fastening. In more advanced applications, the energy from vibrations can be used to power a microcontroller with a communication module (e.g., Bluetooth Low Energy), which periodically transmits data to the parent’s mobile application. In the future, it will also be possible to power modules that calm the baby, such as gentle vibrations or relaxation sounds. Importantly, all these functions can operate independently of the vehicle’s installation, even after it has been parked, which increases the reliability and safety of the entire system.

It is important to note that despite the positive results of the analysis and the promising potential of using vibrations as an energy source, the technology has significant limitations. First of all, the generated power is very low (in the order of microwatts), which requires the use of extremely energy-efficient components and well-thought-out energy management. In addition, the efficiency of transducers, especially piezoelectric transducers, depends strongly on the vibration characteristics and can significantly decrease at low frequency or low amplitude. There is also the problem of degradation of piezoelectric materials over a long period of use, sensitivity to mechanical overload, and difficulties in integrating transducers with soft or upholstered parts of the seat. It is also worth noting that despite intensive research, vibration energy recovery systems have not yet been commercially implemented in the child seat segment, suggesting that the technology is still in the experimental stage.

4.4. Implementation Potential and Cost-Effectiveness of Use

The results of the conducted study demonstrate that the vibrations recorded in the structure of a child car seat, particularly at the ISOFIX mounting point, reach vertical acceleration RMS values as high as 2.89 m/s2. According to ISO 2631-1:1997, this qualifies as extremely uncomfortable. From an engineering perspective, this intensity also indicates sufficient potential for converting mechanical energy into electrical energy using energy harvesting systems. Such systems could operate entirely based on vibrations generated during normal vehicle operation, without requiring any modifications to the car’s electrical system.

Calculations show that, with the use of simple piezoelectric transducers, it is possible to generate and store several dozen joules of energy during one hour of driving on poor-quality roads, an amount sufficient to power multiple low-power sensors integrated into the seat.

Such a solution could power autonomous monitoring systems, including child presence sensors, seatbelt tension indicators, humidity and temperature monitors, or motion detectors. Moreover, the storage of electrical energy in the child seat should be viewed as a milestone toward developing a “smart” seat capable not only of passive protection, but also active supervision of the child’s condition and behavior during travel. From a technological standpoint, this aligns with the growing demand for Internet of Things (IoT) solutions and autonomous passenger safety systems.

The same concept could also be applied to infant carriers, where the harvested energy might power sensors for monitoring vital signs such as heart rate, respiration, skin temperature, or body position, eliminating the need for external power sources. From an economic perspective, implementing a vibration energy harvesting system offers a favorable cost-to-functionality ratio. The average price of a high-end child car seat on the European market is approximately 2000 PLN (around 450 EUR). Adding an energy harvesting module, including a piezoelectric transducer, a basic electronic circuit, a buffer capacitor, and a power converter, would cost approximately 20–30 PLN (4–6 EUR) in mass production.

This represents only a 1–1.5% increase in product price, which can be easily offset by the added value for the end user: independent power supply, enhanced safety, user convenience, and automation of child monitoring functions within the vehicle. From a technical standpoint, a major advantage of this solution is its ability to be integrated with existing seat components, particularly the ISOFIX support leg or seat cushion layer, without interfering with passive safety systems. The availability of flexible piezoelectric materials, such as PVDF films, allows the transducer to be discreetly embedded into the seat structure, supporting both aesthetic quality and system reliability. As a result, it is possible to develop a seat that requires neither regular battery replacement nor connection to the vehicle’s electrical system, while still independently powering its onboard sensors in a fully autonomous manner.

In summary, the implementation of vibration-based energy harvesting in child car seats offers a low-cost, high-value, and forward-compatible solution. It represents a realistic pathway to transforming conventional child seats into next-generation devices that are energy-efficient, intelligent, and self-sufficient, which may soon become the new standard in child safety systems within transportation.

Although the amount of energy harvested in this study is relatively low, it remains within the functional range for powering essential low-energy safety sensors such as presence, temperature, and posture detectors. These devices typically require less than 20 µW, meaning that even modest energy recovery can enable completely autonomous sensor operation. This removes the need for periodic battery replacement and wiring, thereby increasing safety, reducing user error, and simplifying product design. From an implementation perspective, the integration of energy harvesting components into the ISOFIX base or support leg does not require substantial modification of seat geometry or weight distribution. While the present work does not provide a detailed cost analysis, future studies should evaluate the economic feasibility by considering the bill of materials, durability, installation costs, and potential savings over time. When combined with benefits such as sustainability and ease of maintenance, the proposed system may be justified in terms of both engineering and cost-effectiveness.

Among the commonly used vibration energy harvesting methods, piezoelectric transducers offer the most favorable trade-off between power density, system simplicity, and ease of integration. Compared to electromagnetic and electrostatic devices, piezoelectric systems are generally lighter and more compact and can operate efficiently in mid- to high-frequency ranges. Their low implementation complexity and moderate cost make them particularly suitable for integration into child seat structures, where minimal weight and mechanical interference are essential. For these reasons, piezoelectric energy harvesting appears to be the most practical approach for the type of application discussed in this study.

5. Discussion

The effective vibration acceleration values (RMS) obtained in the study, ranging from 0.37 to 2.89 m/s