Abstract

The steam flooding–gravity drainage technology has become one of the effective alternative development methods in the middle and later stages of thin-layer ultra-viscous oil steam throughput, with predicted recovery rate of over 50%. Currently, there is a lack of relevant technical research on the composite swallowing and spitting preheating stage. This is in response to the slow preheating of the oilfield and the large differences in connectivity between injection and production wells. The dynamic analysis method was used to analyze the key factors that restrict the efficient connectivity of steam throughput preheating. Based on this, a series steam throughput preheating efficient connectivity technologies were proposed. Physical simulation, numerical simulation, and other methods were used to characterize and demonstrate the technical principles and operating of the efficient connectivity technology. The research results were successfully applied to the super-viscous oil reservoirs of the Fengcheng oilfield in Xinjiang. The results show that the main factors severely limiting the balanced and rapid connectivity between injection and production wells are the limited radius of steam coverage, low utilization degree oil layers, and frequent unilateral steam breakthroughs. The reservoir expansion transformation has improved the reservoir properties along the horizontal section, increasing the utilization rate of the horizontal section from 51% to 90%, achieving rapid connectivity injection and production wells, and shortening the conventional throughput preheating cycle by 3–4 cycles. The group combination steam injection method achieved a centralized increase in thermal energy, with the inter-well connectivity changing from unidirectional to a broader area The reasonable steam injection intensity was 15 t/m, the regional temperature field increased from 83 °C to 112 °C, and the steam area expanded by approximately 10 m. The multi-medium composite technology achieved a dual increase in steam coverage and profile utilization, with the steam coverage radius increasing by 15 m and the oil reservoir profile utilization increasing by more than 30%. The temporary plugging and fracturing of the reservoir achieved the sealing of inherited breakthrough channels, directing the steam to unused areas, increasing the utilization rate to 89.2%, and shortening the throughput preheating cycle by 3 cycles. This series of technologies has achieved remarkable results in actual application in super-heavy oilfield, which has certain reference significance for the efficient and low-carbon development of heavy oil steam throughput reservoir turning into drive and release.

1. Introduction

Currently, the mainstream approach of the global heavy oil recovery practice is thermal recovery by steam injection, including steam huff and puff (huff-n-puff), steam flooding and steam-assisted gravity drainage (SAGD) [1]. In terms of annual oil production, steam huff-n-puff still holds dominance (contributing 70% of the total production) among the various thermal recovery methods, followed by SAGD and steam flooding. Due to the low thermal efficiency and low recovery factor of steam huff-n-puff mode, the conversion of the development approach is always worthy of consideration in the mid-late development stage. DENG et al. [2] analyzed the development approaches and their applicable reservoir geological conditions, developed the applicability chart of heavy oil development techniques, and drew clear conclusions that heavy oil reservoirs with crude oil viscosity less than 2 × 104 mPa·s under formation conditions are suitable for steam flooding after steam huff-n-puff, and for those with the continuous reservoir thickness greater than 15 m, SAGD can be applied after steam huff-n-puff. Fang et al. [3] proposed the optional enhanced oil recovery (EOR) techniques after steam huff-n-puff, such as steam flooding, combined chemical flooding and reservoir combustion, to deliver the recovery factor growth of 49–70%, in view of the thermal efficiency improvement and economic benefits. Liu [4] performed numerical simulation of steam flooding for thin interbedded super-heavy oil reservoirs, and the oil production of well groups can be increased by 75%, representing a good development performance. Wang et al. [5] systematically reviewed a SAGD technique suite for medium and deep heavy oil reservoirs from the perspectives of the recovery mechanism, reservoir engineering and surface engineering process, and the resultant recovery factor can exceed 60%. For thin super-heavy oil reservoirs with crude oil viscosity greater than 20 × 104 mPa·s under formation conditions and continuous oil layer thickness less than 15 m, Sun et al. [6,7,8,9,10,11] presented a composite development approach of steam flooding and gravity drainage based on SAGD, whose principle is to exploit the vertical height difference of 2–5 m between the injection–production wells. Specifically, steam is continuously injected via the steam injector, and a steam chamber is formed in the connected zone preheated by steam huff-n-puff. Due to the steam onlap, the steam chamber is driven to propagate and merge along the upper part of the reservoir by the production drawdown of the horizontal producer. Meanwhile, the crude oil heated by the latent heat of vaporization seepages downward along the boundary of the unproduced zone above the horizontal wellbore, contributing to an estimated recovery factor of 50%. Sang et al. [12], with the help of numerical simulation, described the steam chamber evolution pattern and production characteristics of the integrated steam flooding and gravity drainage for a well group consisting of a vertical well and a horizontal well. Four stages were identified in the steam flooding–gravity drainage recovery, namely the steam huff-n-puff preheating and the formation, propagation, and move-down of the steam chamber. Zhao et al. [13] characterized the propagation front of the steam chamber front via two-dimensional and three-dimensional physical simulation experiments and revealed the displacement mechanisms of the early steam flooding and mid-late gravity drainage. By building heterogeneous numerical models, Tao et al. [14] researched the refined regulation and control of the vertical–horizontal well group converted to the integrated steam flooding–gravity drainage. The key reservoir engineering parameters of the well group were identified, and the control measures, such as the operation parameter adjustment to stimulate liquid production, steam huff-n-puff for efficiency improvement, and on-purpose well shutdown for steering, were developed to double the oil production and oil–steam ratio of the well group. For steam huff-n-puff of heavy oil, Lu et al. [15] realized the irreversible viscosity reduction of crude oil using the catalytic modifier technology. The viscosity of crude oil was reduced by more than 88.5%, and the content of the components heavier than C25 in produced oil was reduced by 54.4–37%. Lu et al. [16] investigated the mechanisms of electric heating to improve the oil recovery along the horizontal wellbore and the geological limits and optimal timing of electric heating applications via physical model simulation. It was demonstrated that after the helping steam huff-n-puff, the whole horizontal wellbore can be effectively recovered, with a recovery factor growth of 7.7%. To deal with the production contradictions of steam huff-n-puff, such as the uneven production profile, frequent steam channeling, and insufficient drainage capacity of oil wells, researchers have implemented a series of fluid-assisted measures for production stimulation and efficiency improvement, such as flue gas [17], multi-component thermal fluids [18], multi-medium [19], nitrogen foam [20], and non-condensable gas foam oil [21], which did deliver certain stimulation effects. Yang et al. [22] numerically simulated the huff-n-puff preheating program for superheated steam-assisted gravity drainage in mid-deep reservoirs. It was found that the temperature elevation of the inter-well temperature field is considerably higher than that in the case of wet steam and the huff-n-puff preheating duration is reduced. As shown in the above review, studies are still insufficient on how to efficiently perform huff-n-puff preheating, shorten the preheating duration, and improve the production connectivity between injection–production wells in the integrated steam flooding–gravity drainage recovery of shallow thin ultra-heavy oil reservoirs. Given this, this research, based on the main control factors restraining inter-well connectivity of steam huff-n-puff preheating wells in the study area, developed targeted control measures to quickly establish uniform and effective hydrodynamic connectivity between injection and production wells and well prepare for the conversion to integrated steam flooding–gravity drainage with high inter-well connectivity, outstanding performance and improved efficiency.

2. Basics of the Oil Reservoir

The Karamay Fengcheng oilfield is located in the northern part of the northwest margin of the Junggar Basin. Two sets of oil-bearing strata are developed, namely the Jurassic Badaowan Formation and Qigu Formation, both of the multi-stage continental braided fluvial deposition with proximal provenance. Structurally, the reservoir is a fault-controlled south-dipping monocline, with a formation dip angle of 5–10° and the dominant lithology of conglomerate, glutenite and medium–fine sandstone. From bottom to top, the Qigu Formation reservoir, the research target, develops three oil layer series for development, namely J3q3, J3q22−3 and J3q22−1 + J3q22−2, with an average burial depth of 190–235 m and a continuous thickness of 7.6–22.3 m (averaging 13.6 m). The porosity and permeability are 29.1–31.4% (averaging 30.5%) and 0.7–3.7 μm2 (averaging 2.4 μm2). The oil saturations are 68.0–71.4%, with an average of 69.3%. The crude oil viscosity under formation conditions is 58.8 × 104–65.2 × 104 mPa·s, averaging 73.6 × 104 mPa·s, and the original formation pressure is 1.9–2.3 MPa, with an average of 2.1 MPa. These represent a shallow thin-bedded structural–lithologic super heavy oil reservoir with high porosity and high permeability. The recovery of this oil reservoir was started in 2008 using steam huff-n-puff with an alternating well pattern of vertical wells (well spacing of 60 m × 60 m) and horizontal wells (row spacing of 60 m). Since 2013, the scale of the conversion to the integrated steam flooding–gravity drainage has been gradually expanded. The integrated steam flooding–gravity drainage uses the vertical depth difference of 2–5 m between the injection and production wells and continuously injects steam via the steam injection well to form a steam chamber in the connected zone preheated by steam huff-n-puff. Due to the steam onlap, the pressure decline attributed to the production of the horizontal well drives the steam chamber to merge and expand in the upper part of the oil layer along the horizontal wellbore. Moreover, due to gravity, the crude oil heated by the latent heat of vaporization flows downward across the boundary of the unproduced zone above the horizontal wellbore. As of November 2024, 72 well groups of the reservoir have been converted to the integrated steam flooding–gravity drainage, with an annual oil production capacity of more than 20 × 104 tons.

3. Problems in Preheating by Steam Huff-N-Puff

For super-heavy oil reservoirs, sufficient steam huff-n-puff preheating is needed before the integrated steam flooding–gravity drainage. The uniform hydrodynamic communication channel between injection and production wells established during multiple cycles of steam huff-n-puff preheating is the key and premise to realizing efficient recovery by integrated steam flooding–gravity drainage. In this research, the 72 well groups in the study area converted to the integrated steam flooding–gravity drainage were investigated, demonstrating three key aspects restraining the uniform producer–injector connectivity of steam huff-n-puff preheating.

- (1)

- High reservoir heterogeneity and low recovered degrees of oil layers: The oil reservoir in the study area is of the multi-stage proximal provenance continental braided fluvial deposition, with well-developed interbeds between oil layers, and the reservoir heterogeneity is high, with a coefficient of variation of 3.7. The numerical simulation and production performance monitoring of production wells showed that after eight to ten cycles of steam huff-n-puff preheating, the recovery of vertical wells is mainly concentrated in the middle and upper parts of the oil reservoir, with a recovered degree of only 63.8%, while that of horizontal wells is mainly concentrated at the heels or toes. The production profile along the horizontal wellbore is mostly unimodal (accounting for 76.5% of the total cases), with a recovered degree of only 54.4%. Consequently, the recovery of oil layers is uneven along the vertical direction, resulting in the failure to rapidly form uniform connectivity between injection and production wells.

- (2)

- Small swept radius of steam and limited radial recovery of oil layers: After multiple cycles of steam huff-n-puff preheating, the continuous expansion of the steam-swept zone ends up with an insufficient result, and steam cannot reach the remote zone far away from the wellbore; the preheating merely repeatedly heats the produced zone of oil layers, and the heat energy utilization rate is greatly reduced. Based on Dou Hongen’s model [23], the preheating radius of production wells in the study area is estimated to be 20–25 m, which is 5–10 m smaller than the spacing between the vertical and horizontal wells in the study area and results in low connectivity between injection and production wells.

- (3)

- Frequent inherited steam channeling and severe steam fingering: High reservoir heterogeneity leads to the uneven sweep of steam around the injection center (injection well) during steam huff-n-puff, and the zones along the braided fluvial channel and channel bar with high porosity and permeability are prone to inter-well steam channeling. After multiple cycles of steam sweep, the fine debris and filling materials of the reservoir are entrained and produced, and the connectivity of pores of the reservoir is greatly improved—the permeability of the inherited permeable channel of steam channeling is increased by nearly three times [24]. Therefore, the reservoir heterogeneity grows, and steam channeling along even more permeable channels becomes increasingly frequent and severe. The part of the reservoir between the injection and production wells cannot be effectively exploited.

4. High-Efficiency Steam Huff-N-Puff Preheating Technique and Its Performance

In view of the above challenge troubling the steam huff-n-puff preheating to establish effective hydrodynamic connectivity, this research, based on the reservoir conditions in the study area and numerical and physical simulations, investigated the high-efficiency rapid steam huff-n-puff preheating technique. The reservoir heterogeneity was reduced via reservoir dilatancy of reservoir stimulation to improve the utilization of oil layers. The swept radius of steam was expanded by the group combined steam injection and multi-medium composite injection. Temporary plugging and micro-fracturing were applied to plug inherited permeable channels of steam channeling and increase the absorption capacity of the unproduced zone for injected steam. The above efforts were made to ultimately reduce the preheating cycle and rapidly establish uniform hydrodynamic connectivity between injection and production wells.

4.1. Reservoir Dilatancy for Reservoir Stimulation

Loosely cemented (unconsolidated) oil sands are prone to shear or tensile dilatancy attributed to dislocating or separation of rock particles under pore pressure. Based on this feature, reservoir dilatancy for reservoir stimulation creates a field of pressure close to the formation breakdown pressure to promote the formation of micro-fractures. Water is continuously injected into the oil well with low porosity and permeability before bringing it into production. With the continuous increase in injected water, the injection pressure gradually grows, and the effective confining pressure of pores of the oil sands around the wellbore gradually declines—a shear dilatancy zone occurs in the water-affected zone. Water injection is not stopped until the treatment pressure approaches the formation breakdown pressure. At this time, the effective confining pressure of the oil sand pores around the wellbore falls to the lowest, and the tensile dilatancy is triggered in the oil sands, forming micro-fractures extending deeper into the oil layer. Consequently, the physical properties of the reservoir are improved, which lays the foundation for the wide sweep of steam and high utilization of the reservoir during steam huff-n-puff and is in favor of the rapid establishment of uniform high-connectivity dominant channels between injection and production wells.

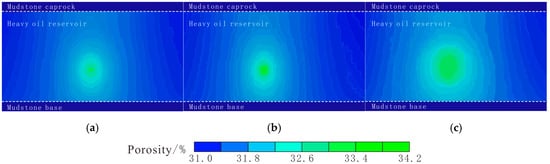

For production wells with reservoir permeability less than 2 μm2 in the study area, reservoir dilatancy for reservoir stimulation can be used to suppress reservoir heterogeneity and improve the recovered degree of reservoirs (produced uniformly). The process of reservoir dilatancy for reservoir stimulation is divided into two stages: low-pressure squeeze-injection and high-pressure reservoir stimulation. The former is to slowly squeeze-inject fluids to occupy the near-wellbore reservoir space and cultivate initial micro-fractures. The high-pressure reservoir stimulation is to extend micro-factures to the remote zone far away from the wellbore by increasing the near-wellbore pore pressure and thus improve the porosity and permeability of the reservoir. The finite element method (FEM) simulation software was used to build an FEM model of reservoir dilatancy that complies with the reservoir conditions in the study area. In the model, two 2.5 m thick mudstone layers at the top and bottom of the reservoir were set as the caprock and bottom layer, respectively. The horizontal wellbore was defined as the seepage boundary, while the other areas were all defined as the non-flow surfaces. The reservoir was 13 m thick, with porosity, permeability, and oil saturation of 31%, 1.6 μm2 and 72%, respectively. The original formation pressure was 2.2 MPa. The rock mechanical parameters were set according to the testing results of the reservoir in the study area [25]. The 3D displacement/stress–pore pressure coupling elements were applied. In the simulation, low-pressure squeeze-injection was assigned with a water injection volume of 10 m3 and an injection rate of 5–10 L/min. The low-pressure injection was stopped once the bottomhole pressure reached 2.8 MPa. The high-pressure reservoir stimulation was assigned with the water injection volume of 50 m3 and the injection rate of 50–100 L/min. It was stopped once the bottomhole pressure reached 4.7 MPa. The simulation results showed that as the pressure slowly rises to 2.8 MPa in the low-pressure squeeze-injection stage, the porosity of the near-wellbore formation gradually climbs up, with the maximum porosity of 32.3% (the original porosity of the model was 31.0%); as the pressure rises to 4.7 MPa in the high-pressure reservoir stimulation stage, the spatial range of reservoir porosity improvement expands, and the maximum porosity reaches 33.9%. It should also be noted that the lateral range of reservoir porosity improvement is larger than the vertical range (Figure 1).

Figure 1.

Distribution of reservoir porosity in different stages of dilatancy. (a) Original. (b) End of low-pressure squeeze-injection. (c) End of high-pressure reservoir stimulation.

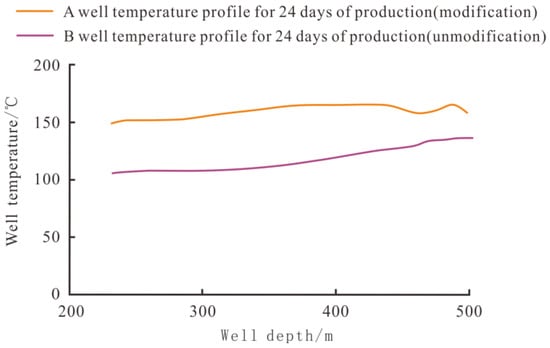

This technique was used in the oilfield to perform reservoir stimulation (dilatancy) for Well A under the integrated steam flooding–gravity drainage. Well A, an infill horizontal well, was completed using a long–short tubing structure. The well spacing between Well A and the existing horizontal well was 35 m, and the horizontal wellbore was 196 m. The permeability max–min ratio was 3.2. The oil layer was 16.3 m thick, associated with the porosity, permeability and oil saturation of 31.6%, 3245 mD and 50%, respectively. The reservoir dilatancy stimulation was performed via water injection before production. Afterward, the well was subjected to five cycles of steam huff-n-puff, with average production of 391 t per cycle and an oil–steam ratio of 0.18. Well B is an adjacent infill horizontal well of the same drilling batch, with similar physical properties of the oil reservoir and no reservoir dilatancy stimulation. Compared with the production indexes of the first five cycles of Well B, the average oil production per cycle of Well A is 168 t higher and the oil–steam ratio is larger by 0.08. The well temperature testing data showed that the downhole temperature along the horizontal wellbore presents no considerable fluctuation after reservoir stimulation and stays generally above 150 °C, representing the plateau type of recovery. In contrast, the downhole temperature along the horizontal wellbore free of reservoir stimulation grows from the heel to toe with a temperature difference of 32 °C, representing the unimodal type of recovery. Fluids flow from the toe to heel in the horizontal wellbore during the steam huff-n-puff, and the temperature drop between two adjacent temperature measuring points is constant (the temperature gradient in the study area is 0.22 °C/m) [26]. Therefore, it can be determined that the wellbore interval at the measuring point is unproduced once the temperature gradient is greater than 0.22 °C/m. According to this criterion, the recovered rate of the horizontal wellbore after reservoir restimulation is about 90%, while that in the case of no reservoir stimulation is only 51% (Figure 2). The field testing showed that the stimulated production well is connected with the wells on both sides after five cycles of huff-n-puff, which is four cycles earlier than that of the well with no reservoir stimulation.

Figure 2.

Downhole temperature profiles of the 2nd steam huff-n-puff round: treated well vs. untreated well.

4.2. Group Combined Steam Injection

Group combined steam injection is used to simultaneously implement combined steam injection in multiple wells of the area prone to frequent inter-well steam channeling, under the principles of maximizing the area and energy concentration. The advantage is that with steam gathering and energy concentration, the inter-well steam channeling is suppressed, the swept zone of steam is expanded, and the unproduced zone between wells can be produced.

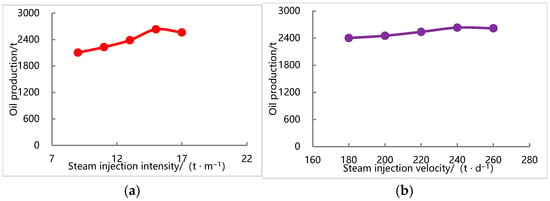

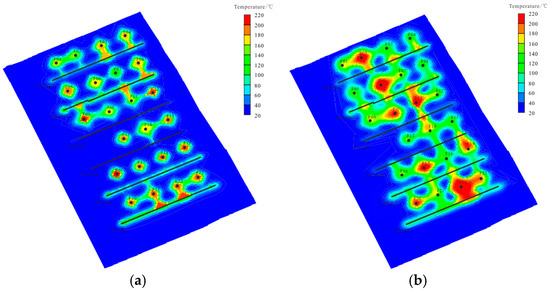

After multiple cycles of steam huff-n-puff preheating, some oil wells suffer from steam channeling in high-permeability areas, and highly permeable steam channels are formed. The distributed steam injection mode of oil wells gradually aggravates steam channeling, making it more difficult to produce the unproduced zone of oil layers, and the oil wells in the corresponding area cannot be effectively connected. In view of the production wells with frequent steam channeling in the study area, the 68 well groups of the integrated steam flooding–gravity drainage in the oilfield block were divided into 37 steam injection groups, each consisting of 10–24 wells, according to the maximum steam supply capacity. The production wells of one steam injection group are steam-injected or shut-in at the same time. The numerical simulation software CMG was used to optimize the steam injection intensity and rate of group injection. The oil production simulated scenarios of steam injection intensity included 9 t/m, 11 t/m, 13 t/m, 15 t/m, and 17 t/m, and the optimal steam injection intensity for one well was identified as 15 t/m (Figure 3a). When the amount of steam injection is excessive, it causes the crude oil move even further away from the wellbore during the injection stage, making it even more difficult to flow back during the production stage as the temperature decreases. Moreover, in order to expand the steam sweep range as much as possible, the steam injection rate of production wells shall not be too low. The oil production simulated scenarios of vertical well injection rates included 90 t/m, 110 t/m, 130 t/m, 150 t/m, and 170 t/m, and those of horizontal well injection rates included 180 t/m, 200 t/m, 220 t/m, 240 t/m, and 260 t/m. The injection rates of vertical and horizontal wells were optimized to be 130–150 t/d and 220–240 t/d, respectively (Figure 3b). After four cycles of group combined steam injection, the regional temperature field was increased from 83 °C to 112 °C, the inter-well communication changed from one-way communication to regional contiguous communication, and the steam sweep range expanded by about 10 m (Figure 4). These improvements lay a foundation of high connectivity for the conversion to the integrated steam flooding–gravity drainage.

Figure 3.

Optimization curves of steam injection parameters. (a) Optimization curve of steam injection intensity. (b) Optimization curve of steam injection rates of horizontal wells.

Figure 4.

Temperature fields before and after group steam injection. (a) Temperature field before group steam injection. (b) Temperature field after group steam injection.

4.3. Multi-Medium Composite Huff-N-Puff

Multi-medium composite huff-n-puff uses a multi-medium composite system of urea + foaming agents to implement steam huff-n-puff preheating, in view of the problems of liquid drainage difficulties and uneven recovery along wellbores faced by steam huff-n-puff preheating of production wells. In the multi-medium system, urea reacts with water to decompose into CO2 and NH3 at high temperatures of 150 °C and above. CO2 exists in two forms in formations: free and dissolved. CO2 dissolved in crude oil reduces the viscosity of crude oil. Meanwhile, free CO2 in the reservoir pores recharges the formation energy. It can also be mixed with foaming agents to form foam flow, which, to some extent, functions for profile control and channel plugging. In terms of NH3, it is easy to dissolve into water, and the alkaline mixture can result in alkaline flooding. The above jointly leads to the expanded steam sweep, improved production well drainage, and enhanced production profiles of oil layers, which provides good conditions for uneven production after conversion to the integrated steam flooding–gravity drainage.

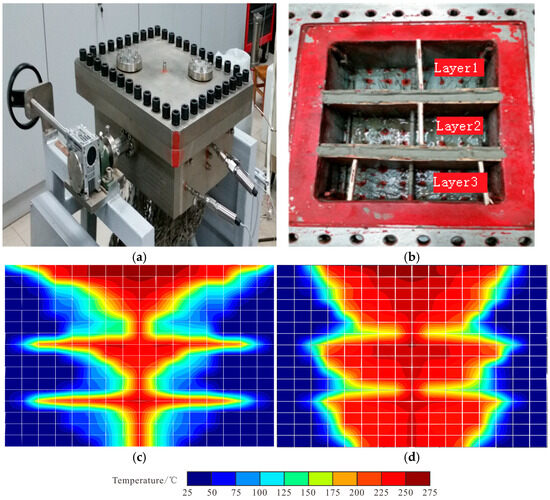

Based on the reservoir conditions in the study area, a three-dimensional physical model was built according to the similarity criteria of Pujol and Boberg [19]. The model dimensions were 30 cm × 15 cm × 40 cm, designed with three oil layers with equal thickness. Each oil layer is interbedded by two barriers with a thickness of 2.0 cm and permeability of 0.01 μm2. Each oil layer was quartz sand-packed in a way to deliver two different permeability values. In other words, the model had six values of permeability. The porosity of the sand pack model was measured layer-by-layer by saturating the model with distilled water, and the permeability of each layer was measured by injecting distilled water at a constant rate. The permeability measurements from top to bottom were 5.0 μm2, 1.0 μm2, 3.0 μm2, 0.6 μm2, 4.0 μm2, and 0.7 μm2. The model was used to carry out the physical simulation experiments of conventional steam huff-n-puff preheating (seven cycles) and multi-medium composite huff-n-puff preheating (four cycles). The steam temperature was 280 °C. The steam injection rate of each cycle of conventional steam huff-n-puff preheating was 150 cm3/min. The steam injection rate of multi-medium composite huff-n-puff preheating was 130 cm3/min, and that of multi-medium mixture was 20 cm3/min. The concentrations of multi-medium solutions were 300 g/L urea plus 5 g/L foaming agents. For each cycle, steam injection lasted for 8 min, well shut-in for 2 min, and production for 30 min. The temperature field monitoring of the reservoir cross-section (Figure 5) illustrates that the steam onlap is significant during the conventional huff-n-puff preheating, and the steam absorption of the high-permeability layer reaches 81.6%, leading to high difficulties in producing the low-permeability layer. After the multi-medium composite huff-n-puff preheating is started, the steam turns to the low-permeability layer, and the reservoir production profile is greatly improved—the steam absorption of the low-permeability layer is increased to 61.4%. In the field, multi-medium composite huff-n-puff preheating was performed for 19 well groups with no interference between wells and yet uneven recovery. Thirty tons of urea and 0.5 t of foaming agents were injected into one well (the mass concentration of liquid urea was 33.3% and that of foaming agents was 5.3%), and the steam injection rate was 135 t/d. The steam injection lasted for 8 days, after which the well was shut-in for 2 days. The production indexes after well shut-in were considerably improved. The oil production of wells per cycle was increased by 480 t, the oil–steam ratio by 0.12, the recovery rate by 1.2% (Table 1) and the swept radius of steam by 15 m. The input–output ratio is 1:2.11 (the basic operation cost of oil is 440¥ per ton, the total of multi-medium agent and construction is 100,000¥).

Figure 5.

Temperature fields before and after multi-medium composite huff-n-puff preheating. (a) Model ontology. (b) Staggered and well layout. (c) Conventional steam huff-n-puff preheating. (d) Multi-medium composite huff-n-puff preheating.

Table 1.

Production indexes before and after multi-medium composite huff-n-puff preheating.

4.4. Temporary Plugging Micro-Fracturing

Temporary plugging micro-fracturing of reservoirs is used to plug the high-permeability steam channels of the horizontal wellbore after multiple cycles of steam huff-n-puff preheating with slugs of multiple plugging agents, then reconstructing the low-permeability intervals by exploiting the pressure-driven dilatancy feature of reservoirs. This technique is used to improve the steam absorption capacity of the reservoir, improve the recovered rate of the horizontal wellbore, expand the sweep of steam, and promote the rapid uniform connection between wells.

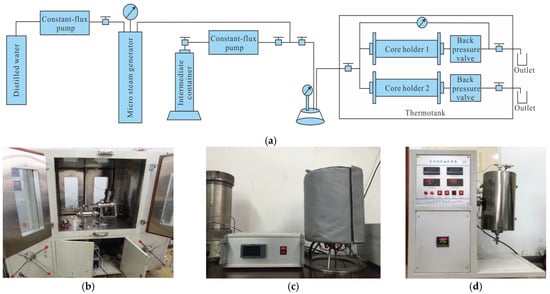

For the oil wells in the study area, suffering from inter-well interference and a low recovered degree of oil layers and having a permeability max–min ratio exceeding three, the temporary plugging micro-fracturing technique can be used to slow down the steam channeling between wells and improve the reservoir recovered degree. The process of reservoir temporary plugging micro-fracturing can be divided into four stages: water absorption testing, high-temperature low-pressure squeeze-injection for channel plugging, high-pressure reservoir dilatancy, and expanded reservoir stimulation. The water absorption testing is mainly used to identify the high-water-absorption interval by circulating well flushing, and the injected water occupies the pore space of the unproduced zone. In high-temperature low-pressure squeeze-injection for channel plugging, the temporary plugging liquid mixture is slowly injected at low pressure (the temporary plugging agents begin to fail and flow back after 3–5 cycles of steam huff-n-puff) to ensure that the temporary plugging liquid mixture enters the high-water-absorption interval. The high-pressure reservoir dilatancy and expanded stimulation is conducted by injecting clear water with the injection pressure slowly raised up to the formation breakdown pressure after consolidation of the temporary plugging liquid mixture to create micro-fractures of tensile dilatancy in the unproduced zone. The parallel core temporary plugging dilatancy tests based on the reservoir conditions were implemented (Figure 6). The specific experimental steps are as follows: ① Setting up four sets of cores and saturating the cores 1 to 8 in sequence to measure the porosity and permeability, then calculating the oil-containing saturation (Table 2). ② During the disposal experiment, each group of high-permeability cores is placed in core holder 1, the low-permeability core is placed in core holder 2, the back pressure is set at 2.1 MPa. ③ The experiment of the first core blank control group was performed, and pure steam was displaced, with steam temperature of 280 °C and steam injection speed of 50 mL/min. The experiment was stopped until pure steam was seen at the exit of core No. 1, and the oil output was recorded. ④ In the experiment of the second core temporary blocking and displacement group, steam injection is consistent with step ③. When pure steam is seen in core No. 3, steam injection is stopped and temporary blocking mixture (20 mL) is slowly infected into core No. 4 at a pressure of less than 2.5 MPa. After 1 h, steam injection will be resumed. Until the experiment is seen in core No. 3, the oil output is recorded. ⑤ In the third group of core micro-fracture transformation and displacement experiments, steam injection is consistent with step ③. When pure steam is seen in core No. 5, steam injection is stopped, and 80 °C water is injected into core No. 6 for pressure raising and transformation (after the pressure reaches 4.5 MPa, the pressure is stabilized for 10 min). Then steam injection is resumed until the experiment is stopped when pure steam is seen in core No. 5, and the oil output is recorded. ⑥ In the fourth group of core temporary blockage and micro-fracturing and discharging experiment, steam injection is consistent with step ③. When pure steam is seen in core No. 7, core No. 7 is blocked according to step ④, and core No. 8 is pressure-reinforced and transformed according to step ⑤. Then, steam injection is resumed until the experiment is stopped when pure steam is seen in core No. 7, and the oil output is recorded.

Figure 6.

Experimental procedure and experimental device for parallel core temporary plugging and capacity expansion. (a) Experimental flow chart. (b) Multi-functional core displacement device. (c) Steam generator. (d) Crude oil sampler.

Table 2.

Experimental core parameters.

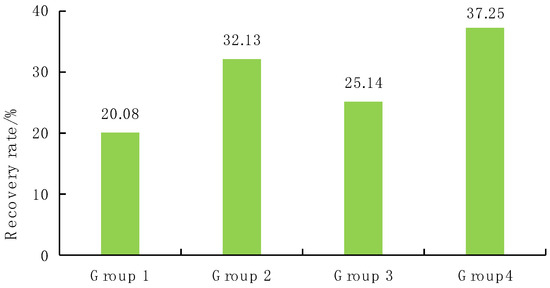

The parallel core experiment results show that the steam absorption of the pure steam replacement high-osmotic core reached 85.6%, the low-osmotic core was basically unused, and the recovery rate was only 20.08%. After only temporary blocking was performed on the basis of pure steam displacement, the steam turned to start the low-permeability section, and the recovery rate increased to 32.13%. On the basis of pure steam displacement, only fracturing transformation is carried out. The high-permeability section still exists. Only a small part of the steam turns to start the low-permeability section, and the recovery rate is only 25.14%. On the basis of pure steam displacement, the high-permeability section is temporarily blocked and the low-permeability section is fractured to curb the one-way blast of the high-permeability layer, forcing the steam to turn to start the low-permeability unused layer, causing the low-permeability core to absorb steam to reach 79.4%, and the low-permeability difficult-to-use section is well-used, with a recovery rate of 37.25% (Figure 7).

Figure 7.

Comparison of recovery ratio between different displacement methods.

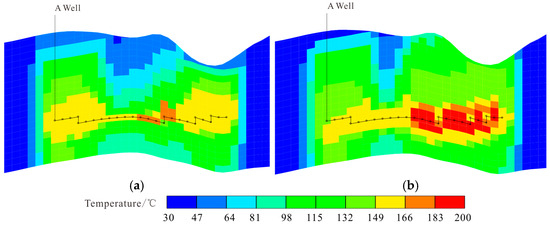

This technique was applied in four wells in the oilfield. Here, Well A is taken as an example, and the permeability max–min ratio of the horizontal wellbore is 3.4. After nine cycles of steam huff-n-puff preheating, the production profile of the horizontal wellbore is bimodal (two peaks), and the recovered degree is 63.7%. The well was treated via temporary plugging micro-fracturing. First, clear water was circulated until the injection rate was nearly equal to the discharge rate. Then, slugs of polymer solutions (15 m3), polymer gel (25 m3), phenolic high-temperature gel (55 m3) and polymer solutions (13 m3) were injected successively, and the treatment pressure was controlled within 2.5 MPa to effectively plug the high-permeability produced zone. Subsequently, with the pressure as the main control parameter, the surface treatment pressure was controlled at 0.8–2.5 MPa to slowly raise the bottomhole pressure to approach the formation breakdown pressure of 4.5 MPa, with the designed injection rate of clear water of 6–10 m3/h. Tensile dilatancy fracturing occurs in the low-permeability reservoir, with a radius of about 5–8 m. The well was shut-in for three days after the temporary plugging micro-fracturing and then restored to two cycles of steam huff-n-puff preheating. The flow conductivity of the middle low-permeability section of the horizontal wellbore was improved. The preheating was shortened from 15 cycles to 12 cycles, and the recovered rate of the horizontal wellbore was raised to 89.2% (Figure 8).

Figure 8.

Temperature fields of Well A before and after temporary plugging micro-fracturing. (a) Temperature field after 9 cycles of steam huff-n-puff preheating. (b). Temperature field after temporary plugging micro-fracturing and then 2 cycles of preheating.

5. Conclusions

In view of the multiple problems faced by the composite heating method of displacement and diversion, a series of technologies such as reservoir expansion reconstruction, block steam injection, and medium auxiliary and temporary plugging micro-fracturing are proposed and successfully applied to the ultra-heavy oil reservoir, which breaks the limitations of the previous single-technology research and targeted technology optimization can be carried out according to the main heating contradiction of different oil wells. The following understandings are obtained from the study:

- (1)

- The oil reservoir of the study area is of the multi-stage continental braided fluvial deposition with proximal provenance. The reservoir heterogeneity is high, and the recovered degree of the oil reservoir is low. The small steam sweep radius and the limited radial recovery are the key restraints on the efficient connection between wells during steam huff-n-puff preheating.

- (2)

- Reservoir dilatancy for reservoir stimulation can reduce reservoir heterogeneity before oil wells are put into production, and the recovered degree of reservoirs can be increased from 51% to 90%. The group combined steam injection and multi-medium combination technique can expand the steam sweep radius by 10–15 m and quickly build a regional thermal field with 3–4 fewer cycles during steam huff-n-puff preheating. Temporary plugging micro-fracturing of reservoirs can plug inherited steam channels after multiple cycles of steam huff-n-puff preheating and improve the effectiveness of the recovery of unproduced zones—the recovered degree grows from 63.7% to 89.2%.

- (3)

- The field applications of high-efficiency steam huff-n-puff preheating all deliver good production performance. The production profile of oil layers has been improved, the steam sweep radius has been expanded, and the temperature field between wells has been connected, which meets the goal of high-efficiency steam huff-n-puff preheating. The developed steam huff-n-puff technique has high potential for application promotion and can provide technical support for analogous heavy oil reservoirs converted to integrated steam flooding–gravity drainage.

- (4)

- It is suggested that promotion of nitrogen, flue gas, and other non-condensable gases can be carried out in steam pulse preheating. Such efforts can not only improve the heat utilization rate of steam and expand steam sweep but also reduce carbon emissions of enterprises and help to achieve the goals of carbon peak and carbon neutrality.

Author Contributions

Conceptualization, Y.L. and B.L.; methodology, Y.L.; software, Y.L. and B.L.; validation, W.C., C.C. and P.H.; formal analysis, G.Y., G.W. and P.H.; data curation, Y.L.; writing—original draft preparation, P.H. and B.L.; writing—review and editing, P.L. and G.Y.; funding acquisition, B.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by PetroChina Major Special Projects, grant number 2019B-1411, 2017E-0408 and 2021DJ1403.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Author Yingbo Lu, Bolin Lv, Guo Yang, Wenshun Chen, Pengcheng Hu, Chao Chen and Guiqing Wang were employed by the company PetroChina. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Jiang, Q.; You, H.; Pan, J.; Wang, Z.; Gai, P.Y.; Gates, I.; Liu, J. Preliminary Discussion on Current Status and Development Direction of Heavy Oil Recovery Technologies. Spec. Oil Gas Reserv. 2020, 27, 30–39. [Google Scholar]

- Rui, D.; Ming, L.; Song, L.H.; Yang, R.X. Sensitivity analysis of steam injection parameters of steam injection thermal recovery technology. Fresenius Environ. Bull. 2021, 30, 5385–5394. [Google Scholar]

- Fang, J.C.; Li, X.Q.; Ji, B.Y.; Wang, H.B.; Lu, X. Prospect of replacement technology for enhanced oil recovery after cyclic steam stimulation of heavy oil in China. Fault-Block Oil Gas Field 2022, 29, 378–382+389. [Google Scholar]

- Liu, Q. Study and Test on Steam Flooding Technology for Thin Interbedded Ultra-Heavy Oil Reservoirs. Spec. Oil Gas Reserv. 2022, 29, 97–103. [Google Scholar]

- Wang, H.Y.; Yang, L.Q. The Practice of Steam Assisted Gravity Drainage in Liaohe Oilfield. Spec. Oil Gas Reserv. 2020, 27, 20–29. [Google Scholar]

- Sun, X.G.; Zhao, C.H.; Xiong, W.; Li, L.D.; Liang, S. Enhanced Oil Recovery in the Late Stage of Shallow Super-Heavy Oil Reservoir with Steam Huff-Puff. Spec. Oil Gas Reserv. 2018, 25, 72–76+81. [Google Scholar]

- Suhag, A.; Ranjith, R.; Balaji, K.; Peksaglam, Z.; Malik, V.; Zhang, M.; Biopharm, F.; Putra, D.; Energy, R.; Wijaya, Z.; et al. Optimization of steam-flooding heavy oil reservoirs. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 23–27 April 2017; SPE 185653. pp. 1–35. [Google Scholar]

- Lu, Y.B.; Sun, X.G.; Zhao, C.H.; Hu, P.C. Study and application of high-efficiency development technology of shallow and thin layer ultra-heavy oil. China Sci. Pap. 2025, 20, 95–105. [Google Scholar]

- Shao, G.L. Mechanism of steam chamber expansion and economic and technical limits of injection and production in VHSD development for extra-heavy oil reservoirs. Pet. Geol. Recovery Eff. 2025, 32, 134–144. [Google Scholar]

- Sun, X.; Ma, H.; Zhao, C. Research on Ultra-Heavy Oil Development by Steam Stimulation Converting into Steam Drive Combination. Xinjiang Pet. Geol. 2015, 36, 61–64. [Google Scholar]

- Qian, G.; Sun, X.; Zhao, C.; Wang, T.; Yang, Z.; Li, L.; Xiong, W. Application of Vertical-Horizontal Steam Drive Process to Fengcheng Extra-Heavy Oil Reservoir, Junggar Basin. Xinjiang Pet. Geol. 2015, 36, 733–737. [Google Scholar]

- Sang, L.X.; Lv, B.L.; Lu, Y.B.; Xue, M.N.; Huang, C.; Zhaom, H.L.; Yang, R.J.; Wang, G.Q. Expansion Law of Steam Cavity in Ultra-heavy Oil Combined Development of Vertical Well and Horizontal Well. Sci. Technol. Eng. 2022, 22, 10519–10525. [Google Scholar]

- Zhao, C.; Sun, X.; Lu, Y.; Wang, L.; Hu, P.; Xin, X.; Wang, G. Physical simulation experiment of steam chamber evolution in compound development of thin-layer and ultra-heavy oil flooding and drainage. Lithol. Reserv. 2023, 35, 92–99. [Google Scholar]

- Tao, L.; Li, L.D.; Yuan, Y.X.; Yang, S.B.; Ren, K.Q. Fine Control of Vertical-Horizontal SAGDD in Super-Heavy Oil Heterogeneous Reservoir. Spec. Oil Gas Reserv. 2018, 25, 80–84. [Google Scholar]

- Lv, B.L.; Ma, P.; Lu, Y.B.; Hu, P.C.; Wang, R. In-situ catalytic modification and viscosity reduction technology in shallow ultra-heavy oil reservoirs in Fengcheng. Oil Drill. Prod. Technol. 2023, 45, 632–637. [Google Scholar]

- Lu, Y.B.; Hu, P.C.; Shen, T.T.; Hong, F.; Dong, S.M.; Ma, P.; Chen, C. Enhancing technique of the horizontal-interval developed degree by electrical-heating-assistant steam huff and puff for the horizontal well. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 167–174. [Google Scholar]

- Zhang, L. Numerical Simulation Study on Flue Gas-Assisted Steam Huff and Puff in Heavy Oil Reservoirs. ACS Omega 2024, 9, 39523–39532. [Google Scholar] [CrossRef]

- Tian, J.; Yan, W.; Qi, Z.; Huang, S.; Yuan, Y.; Dong, M. Cyclic Supercritical Multi-Thermal Fluid Stimulation Process: A Novel Improved-Oil-Recovery Technique for Offshore Heavy Oil Reservoir. Energies 2022, 15, 9189. [Google Scholar] [CrossRef]

- Huo, J.; Lv, B.L.; Yang, Z.C.; Lu, Y.B.; Hu, P.C. Displacement mechanism of multi-component compound steam stimulation in heavy-oil reservoir. Spec. Oil Gas Reserv. 2020, 27, 93–97. [Google Scholar]

- Gong, Y.; Xin, X.; Yu, G.; Ni, M.; Xu, P. Optimization Study of Injection and Production Parameters for Shallow- and Thin-Layer Heavy Oil Reservoirs with Nitrogen Foam-Assisted Steam Flooding. Processes 2023, 11, 3004. [Google Scholar] [CrossRef]

- Lu, Y.B. Formation mechanism and percolation characteristics of secondary foamy oil by gas injection in super heavy oil. Lithol. Reserv. 2022, 34, 152–159. [Google Scholar]

- Yang, J.P.; Wang, S.Z.; Lin, R.Y.; Han, F.; Wang, X.W.; Guo, B.; Wang, Z.Y.; Yang, Z.D. Simulation and scheme optimization of using superheated steam for huff and puff for preheating in SAGD. J. China Univ. Pet. (Ed. Nat. Sci.) 2020, 44, 105–113. [Google Scholar]

- Dou, H.E.; Chang, Y.W.; Yu, J.; Wang, X.L.; Ma, Y.W. A new theory of relationship between heating radius and well pattern during CSS process. Spec. Oil Gas Reserv. 2006, 13, 58–61+107. [Google Scholar]

- Wu, Y.Z.; Chen, K.G.; Mu, H.; Li, J.; Zhang, L. Law and mechanism of reservoir parameters change both before and after steam stimulation in heavy oil reservoir. Fault-Block Oil Gas Field 2012, 19, 5–8. [Google Scholar]

- Shen, T.T. Microfracturing-based Expansion Technology and Application in Shallow Ultra-heavy Oil Horizontal Wells. Spec. Oil Gas Reserv. 2022, 29, 111–118. [Google Scholar]

- Sang, L.X.; Zhang, J.H.; Ning, M.; Xu, Q.N.; Li, C.H.; Pan, H.F. Study on judgement method of producing degree and producing mode of SAGD horizontal section. Pet. Geol. Recovery Eff. 2020, 27, 136–142. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).