Cadmium-Free Buffer Layer Materials for Kesterite Thin-Film Solar Cells: An Overview

Abstract

1. Introduction

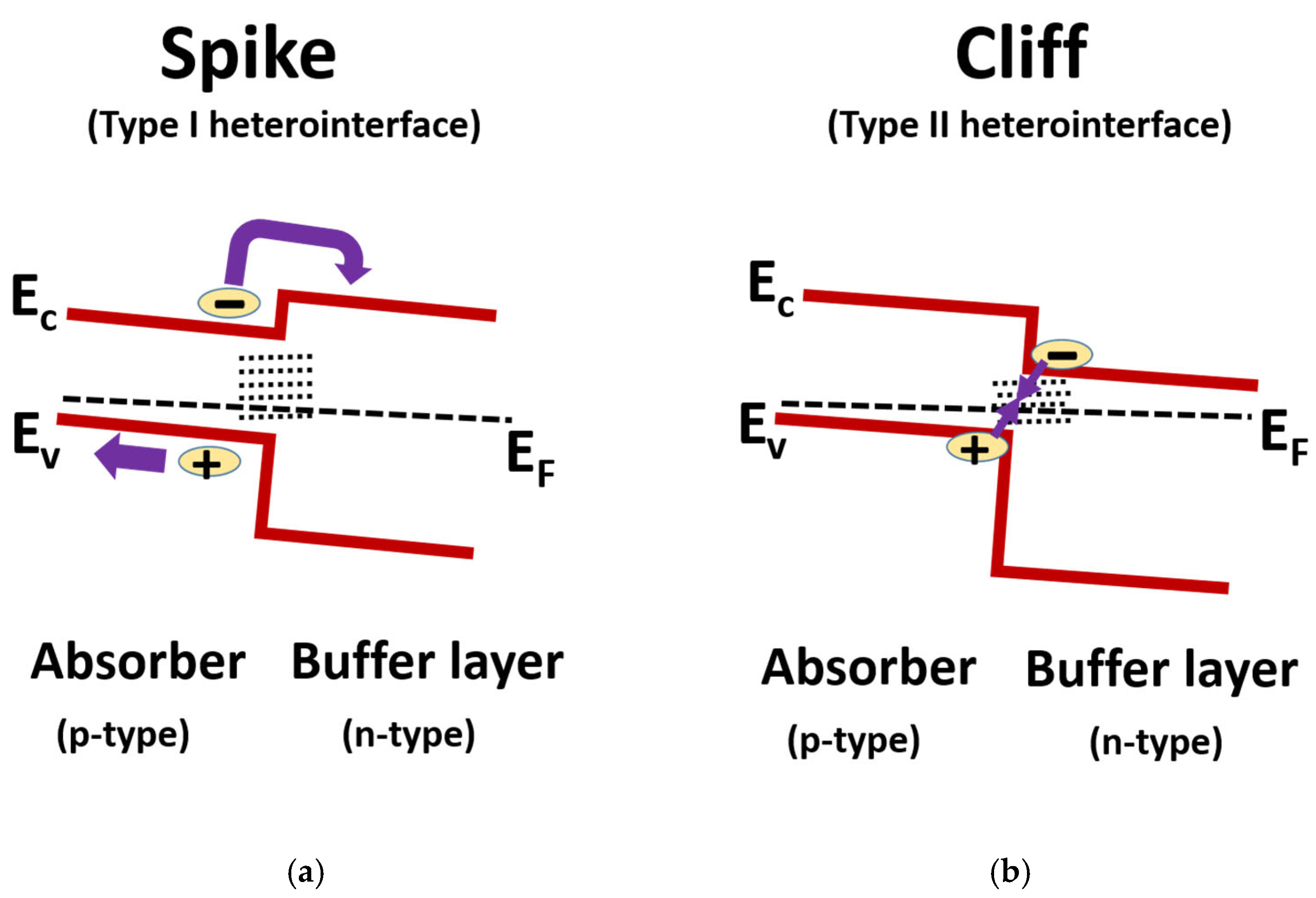

2. CdS/CZT (S, Se) Interface

3. Cadmium-Free Buffer Layer

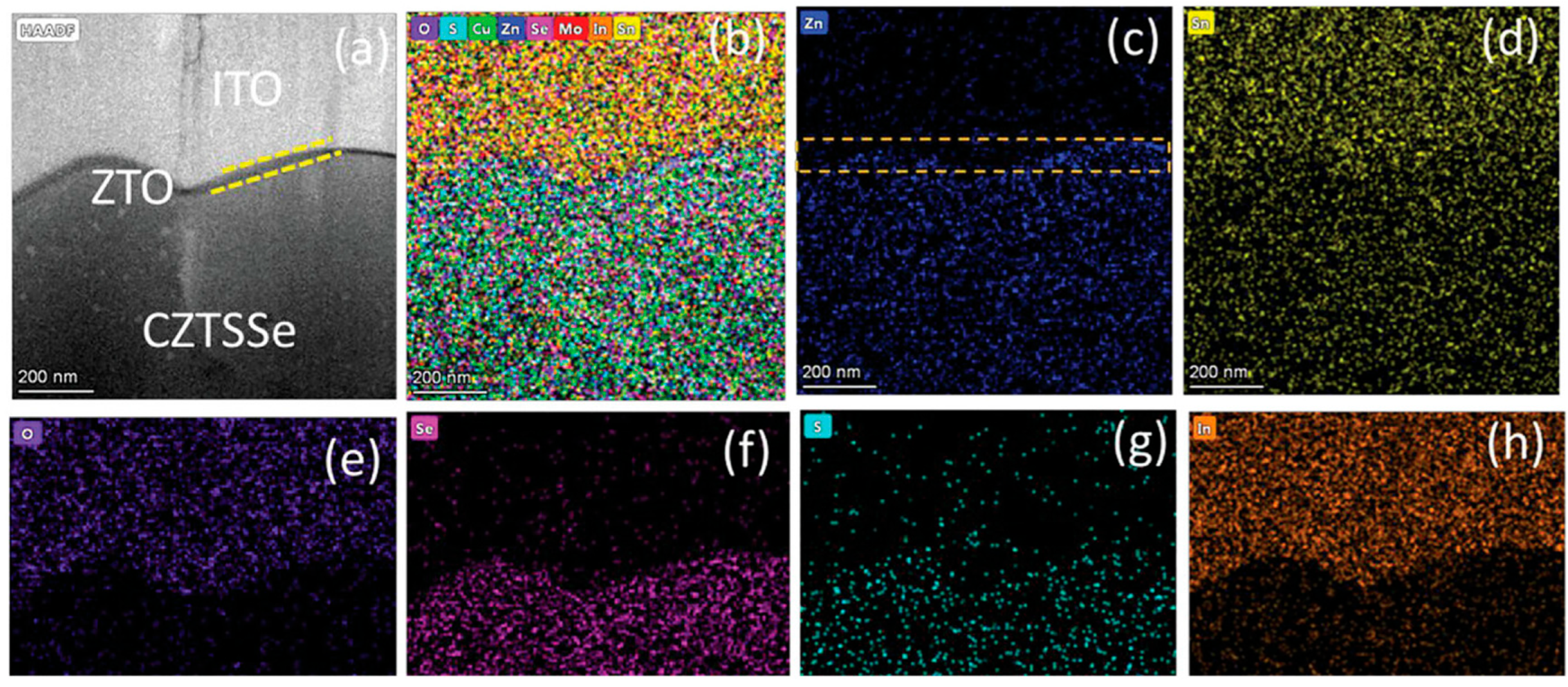

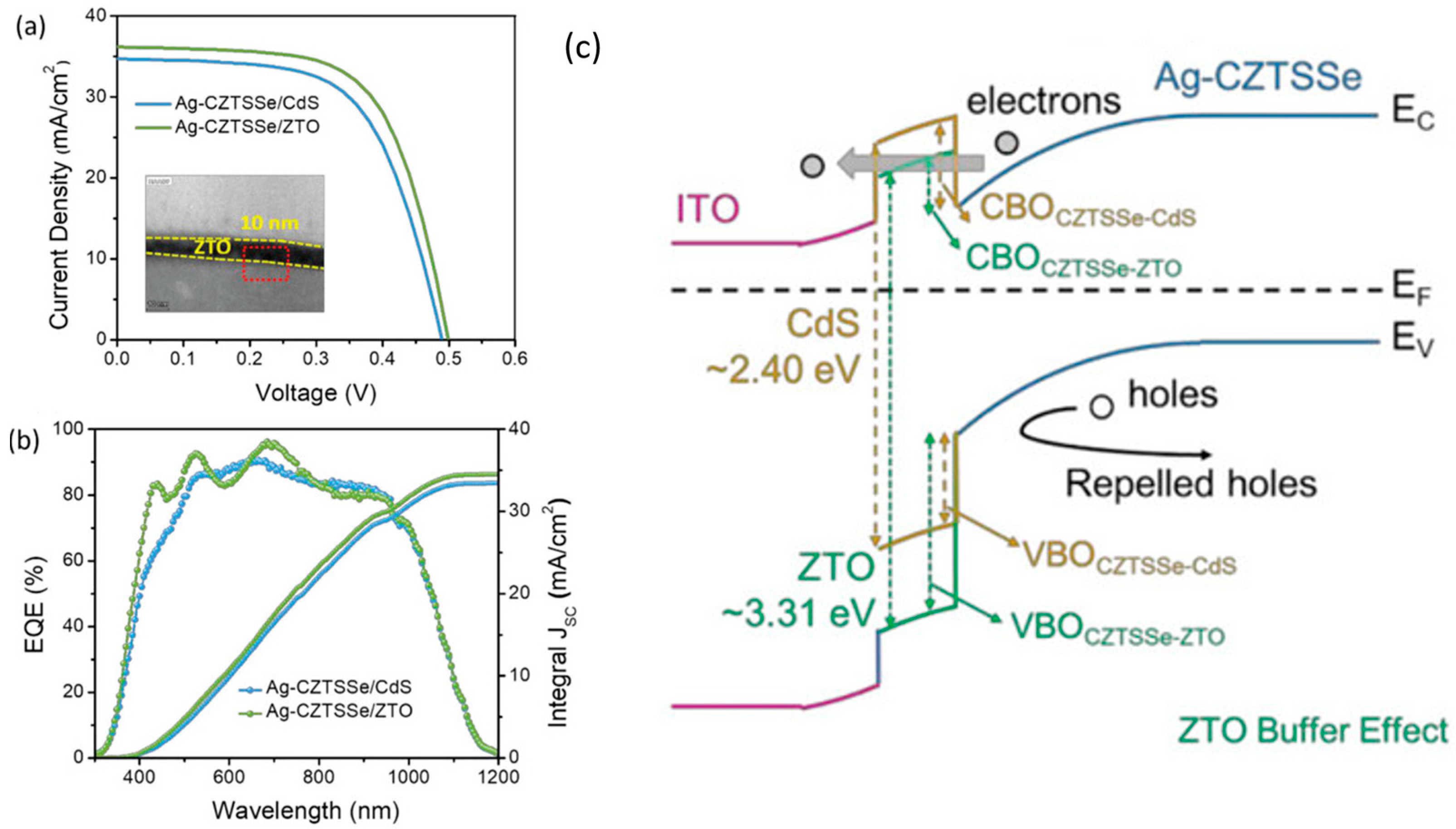

3.1. Zinc Tin Oxide (ZTO)-Based Buffer Layer

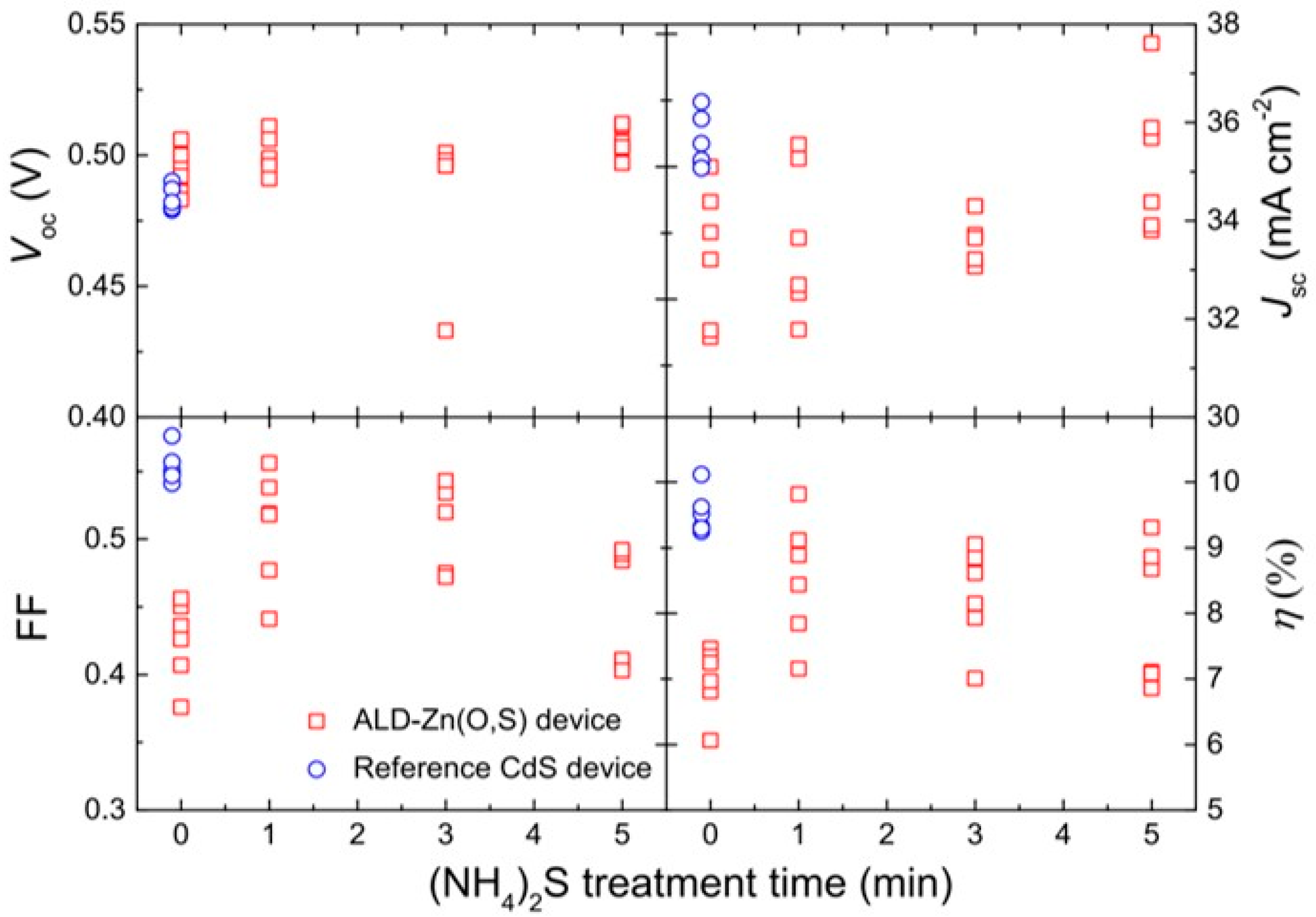

3.2. Zn (O, S)

3.3. Indium Sulfide (In2S3)

3.4. Titanium Dioxide (TiO2)

| Absorber | Buffer Layer | Deposition Technique | Voc (mV) | Jsc (mA/cm2) | FF (%) | PCE (%) | Ref. |

|---|---|---|---|---|---|---|---|

| CZTSSe | ZTO | ALD | 714.0 | 34.1 | 61.0 | 8.6 | [41] |

| CdS | CBD | 404.0 | 32.5 | 60.4 | 8.1 | ||

| CZTS | ZTO | ALD | 720.0 | 20.4 | 64.0 | 9.3 | [42] |

| CdS | CBD | 652 | 16.5 | 64.2 | 6.9 | ||

| CZTS | ZTO | ALD | 679.0 | 21.6 | 61.0 | 9.0 | [43] |

| CdS | CBD | 608.0 | 20.5 | 58.0 | 7.2 | ||

| CZTSSe | ZTO | ALD | 445.0 | 36.3 | 69.0 | 11.2 | [50] |

| CdS | CBD | - | - | - | 9.0 | ||

| CZTS | ZTO | Sputtering | 721.0 | 14.0 | 51.0 | 5.2 | [51] |

| CdS | CBD | 615.0 | 12.9 | 58.3 | 4.6 | ||

| CZTSSe | ZTO/CdS | - | 448 | 36.7 | 58.7 | 9.3 | [52] |

| CdS | CBD | 419 | 34.6 | 69.0 | 8.5 | ||

| CZTS | ZTO | ALD | 736.0 | 22.0 | 66.0 | 10.2 | [53] |

| CdS | CBD | 652.0 | 16.5 | 69.0 | 6.9 | ||

| CZTS | ZTO | ALD | 630.0 | 18.7 | 49.0 | 5.7 | [58] |

| CdS | CBD | 660.0 | 17.0 | 62.0 | 7.0 | ||

| CZTS | ZTO | ALD | 682.2 | 17.9 | 60.0 | 7.4 | [59] |

| CdS | CBD | 666.0 | 19.4 | 55.6 | 7.2 | ||

| CZTS | ZTO | ALD | 746.0 | 19.1 | 68.0 | 9.7 | [60] |

| CdS | CBD | 809.0 | 17.0 | 61.2 | 8.4 | ||

| Ag-CZTSSe | ZTO | ALD | 498.0 | 36.2 | 66.53 | 11.8 | [61] |

| CdS | CBD | 490.0 | 34.0 | 92.9 | 10.7 | ||

| CZTS | Zn (O, S) | ALD | 482.0 | 17.2 | 55.5 | 4.6 | [68] |

| CdS | CBD | 652.0 | 17.5 | 63.8 | 7.3 | ||

| CZTSSe | Zn (O, S) | CBD | 376.0 | 29.0 | 52.0 | 5.8 | [69] |

| CdS | CBD | 389.0 | 34.0 | 55.0 | 7.0 | ||

| CZTSSe | Zn (O, S) | CBD | 336.0 | 25.0 | 51.0 | 5.0 | [70] |

| CdS | CBD | - | - | - | 8.0 | ||

| CZTSSe | ZnS | CBD | 596.0 | 15.4 | 49.1 | 4.5 | [26] |

| CdS | CBD | 640.0 | 15.4 | 48.5 | 4.7 | ||

| CZTSSe | ZnS | CBD | 309.0 | 23.5 | 54.0 | 3.8 | [71] |

| CdS | Sputtering | 362.0 | 24.0 | 60.0 | 5.2 | ||

| CZTS | ZnS | CBD | 311.0 | 12.1 | 55.7 | 2.1 | [72] |

| CdS | ALD | 561.0 | 18.4 | 48.2 | 4.9 | ||

| CZTSSe | Zn (O, S) | CBD | 496 | 35.6 | 56.0 | 9.8 | [73] |

| CBD | CBD | 482 | 36.4 | 58.0 | 10.1 | ||

| CZTSSe | Zn (O, S) | CBD | 358 | 33.5 | 60 | 7.2 | [74] |

| Zn (O, S) | CBD | 388 | 35.9 | 58 | 8.0 | ||

| CZTSSe | ZnS(O,OH) | CBD | 332 | 32.6 | 51.8 | 5.6 | [75] |

| CdS | 401 | 30.5 | 56.3 | 6.9 | |||

| CZTS | Zn (O, S) | PCD | 516.0 | 16.8 | 35.3 | 3.0 | [77] |

| CdS | CBD | - | - | - | 4.3 | ||

| CZTS | ZnO, Zn (O, S) | Sulfurization | 610.1 | 21.1 | 40.0 | 5.1 | [78] |

| CdS | CBD | - | - | - | 5.0 | ||

| CZTS | Zn (O, S) | CBD | 708.0 | 19.2 | 54.0 | 7.2 | [79] |

| CdS | CBD | - | - | - | - | ||

| CZGSSe | Zn (O, S) | Sputtering | 730.0 | 13.0 | 48.0 | 4.6 | [80] |

| CdS | - | - | - | - | 6.0 | ||

| CZTSSe | Zn (O, S) | ALD | 496.0 | 35.6 | 56.0 | 9.8 | [73] |

| CdS | CBD | - | - | - | 10.1 | ||

| CZTS | In2Se3 | CBD | 621 | 20 | 54.5 | 6.9 | [83] |

| CdS | CBD | 705 | 18 | 63.2 | 8.1 | ||

| In2Se3 | CBD | 424 | 32.3 | 55.0 | 7.5 | [86] | |

| CdS | CBD | 465 | 27.1 | 62.1 | 7.7 | ||

| CZTSe | In2Se3 | CSP | 431.0 | 28.3 | 47.1 | 5.7 | [87] |

| CdS | CBD | - | - | - | - | ||

| CZTSSe | TiO2 | Sputtering | 490.0 | 31.4 | 63.0 | 9.7 | [96] |

| CdS | CBD | - | - | - | - | ||

| CZTS | TiO2 | ALD | 476 | 17.4 | 44.0 | 3.71 | [97] |

| CdS | CBD | 555 | 16.1 | 59.7 | 4.14 |

4. Summary and Outlook

- It is urgently required to focus on new, cost-effective, Cd-free buffer layer materials, such as multiple metal oxides and sulfides, which could be an efficient alternative to boost the performance of KTFSCs. Additionally, heterojunction designs such as hybrid organic–inorganic buffer materials could be employed.

- The integration of kesterite with tandem and emerging photovoltaic technologies can boost the PCE beyond 20%; for example, kesterite–perovskite tandem solar devices and optimized flexible buffer layers for wearable applications.

- Investigating a self-healing photoactive passivation layer that dynamically mitigates defects under light will be highly favorable.

- The machine learning model is an efficient route to select suitable candidates with an optimal energy level alignment, wider bandgap, and cost-effective and stable materials using large databases for screening purposes.

- An interlayer doping approach, such as doping Ag into the ZnSnO buffer layer, could be a promising strategy.

- It is most important to design a “toolbox” of integrated characterization tools that delivers key information about different characterization techniques from nano-level to micro-level, from different aspects, to build a clear picture of interface issues.

- In situ admittance spectroscopy revealed that interface defects are more detrimental to the solar cells’ performance than bulk defects. Real-time characterization should be performed during interface formation to understand the main factors affecting low performance, which could be helpful in device optimization on a large scale.

- It is necessary to focus on the impact of mechanical deformation on charge transport across the interface.

- For future aerospace missions, space environmental simulation to explore its compatibility is also needed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, J.; Yang, J.; Dong, W.; Ren, S.; Zhu, H.; Wang, Y.; Hao, J.; Wu, J.; Wang, R.; Zhao, D. A critical review of solution-process engineering for kesterite thin-film solar cells: Current strategies and prospects. J. Mater. Chem. A 2024, 12, 545–566. [Google Scholar] [CrossRef]

- Scaffidi, R.; Birant, G.; Brammertz, G.; de Wild, J.; Flandre, D.; Vermang, B. Ge-alloyed kesterite thin-film solar cells: Previous investigations and current status—A comprehensive review. J. Mater. Chem. A 2023, 11, 13174–13194. [Google Scholar] [CrossRef]

- Ahmad, N.; Yuan, J.; Zou, Y. One More Step Towards Better Stability of Non-Fullerene Organic Solar Cells: Advances, Challenges, Future Perspective, and Era of Artificial Intelligence. Energy Environ. Sci. 2025, 18, 5093–5158. [Google Scholar] [CrossRef]

- Park, S.W.; He, M.; Jang, J.S.; Kamble, G.U.; Suryawanshi, U.P.; Baek, M.C.; Suryawanshi, M.P.; Gang, M.G.; Park, Y.; Choi, H.J. Facile Approach for Metallic Precursor Engineering for Efficient Kesterite Thin-Film Solar Cells. ACS Appl. Mater. Interfaces 2024, 16, 16328–16339. [Google Scholar] [CrossRef]

- Miccoli, I.; Prete, P.; Marzo, F.; Cannoletta, D.; Lovergine, N. Synthesis of vertically-aligned GaAs nanowires on GaAs/(111) Si hetero-substrates by metalorganic vapour phase epitaxy. Cryst. Res. Technol. 2011, 46, 795–800. [Google Scholar] [CrossRef]

- Di Carlo, V.; Prete, P.; Dubrovskii, V.G.; Berdnikov, Y.; Lovergine, N. CdTe Nanowires by Au-catalyzed metalorganic vapor phase epitaxy. Nano Lett. 2017, 17, 4075–4082. [Google Scholar] [CrossRef]

- Cingolani, R.; Lomascolo, M.; Lovergine, N.; Dabbicco, M.; Ferrara, M.; Suemune, I. Excitonic properties of ZnSe/ZnSeS superlattices. Appl. Phys. Lett. 1994, 64, 2439–2441. [Google Scholar] [CrossRef]

- Cretì, A.; Prete, P.; Lovergine, N.; Lomascolo, M. Enhanced optical absorption of GaAs near-band-edge transitions in GaAs/AlGaAs core–shell nanowires: Implications for nanowire solar cells. ACS Appl. Nano Mater. 2022, 5, 18149–18158. [Google Scholar] [CrossRef]

- Wang, H.; Hou, Y.; He, Y.; Wen, C.; Giron-Palomares, B.; Duan, Y.; Gao, B.; Vavilov, V.P.; Wang, Y. A Physical-constrained decomposition method of infrared thermography: Pseudo restored heat flux approach based on Ensemble Bayesian Variance Tensor Fraction. IEEE Trans. Ind. Inform. 2023, 20, 3413–3424. [Google Scholar] [CrossRef]

- Hang, J.; Qiu, G.; Hao, M.; Ding, S. Improved fault diagnosis method for permanent magnet synchronous machine system based on lightweight multi-source information data layer fusion. IEEE Trans. Power Electron. 2024, 39, 13808–13817. [Google Scholar] [CrossRef]

- Chander, S.; Tripathi, S.; Kaur, I.; De, A.K. Nontoxic and earth-abundant Cu2ZnSnS4 (CZTS) thin film solar cells: A review on high throughput processed methods. Mater. Today Sustain. 2024, 25, 100662. [Google Scholar] [CrossRef]

- Miaofen, L.; Youmin, L.; Tianyang, W.; Fulei, C.; Zhike, P. Adaptive synchronous demodulation transform with application to analyzing multicomponent signals for machinery fault diagnostics. Mech. Syst. Signal Process. 2023, 191, 110208. [Google Scholar] [CrossRef]

- Jia, Y.; Chen, G.; Zhao, L. Defect detection of photovoltaic modules based on improved VarifocalNet. Sci. Rep. 2024, 14, 15170. [Google Scholar] [CrossRef]

- Paul, R.; Shukla, S.; Lenka, T.R.; Talukdar, F.A.; Goyal, V.; Boukortt, N.E.I.; Menon, P.S. Recent progress in CZTS (CuZnSn sulfide) thin-film solar cells: A review. J. Mater. Sci. Mater. Electron. 2024, 35, 226. [Google Scholar] [CrossRef]

- Shi, J.; Wang, J.; Meng, F.; Zhou, J.; Xu, X.; Yin, K.; Lou, L.; Jiao, M.; Zhang, B.; Wu, H. Multinary alloying for facilitated cation exchange and suppressed defect formation in kesterite solar cells with above 14% certified efficiency. Nat. Energy 2024, 9, 1095–1104. [Google Scholar] [CrossRef]

- Baek, M.C.; Jang, J.S.; Karade, V.C.; Suryawanshi, M.P.; Kim, J.; Hong, T.E.; Park, S.W.; Shin, S.W.; Kim, J.H. Achieving highly efficient kesterite solar cells using simultaneous surface Ge substitution and rear interface engineering strategies. Chem. Eng. J. 2024, 479, 147842. [Google Scholar] [CrossRef]

- Pan, X.; Li, X.; Yang, Y.; Xiang, C.; Xu, A.; Liu, H.; Yan, W.; Huang, W.; Xin, H. 12.3% Efficient Low Voc Loss Pure Sulfide Kesterite Solar Cells from DMSO Solution via Cadmium Alloying. Adv. Energy Mater. 2023, 13, 2301780. [Google Scholar] [CrossRef]

- Wang, A.; Huang, J.; Cong, J.; Yuan, X.; He, M.; Li, J.; Yan, C.; Cui, X.; Song, N.; Zhou, S. Cd-Free Pure Sulfide Kesterite Cu2ZnSnS4 Solar Cell with Over 800 mV Open-Circuit Voltage Enabled by Phase Evolution Intervention. Adv. Mater. 2024, 36, 2307733. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Yao, B.; Li, Y.; Ding, Z.; Ma, D.; Wang, T.; Zhang, J.; Zhang, D.; Liu, Y.; Liu, R. Mechanism of improvement of efficiency of Cu2ZnSn(S,Se)4 solar cells by optimization of deposition temperature of CdS buffer layer. Sol. Energy 2023, 262, 111847. [Google Scholar] [CrossRef]

- Järup, L.; Åkesson, A. Current status of cadmium as an environmental health problem. Toxicol. Appl. Pharmacol. 2009, 238, 201–208. [Google Scholar] [CrossRef]

- Tseberlidis, G.; Gobbo, C.; Trifiletti, V.; Di Palma, V.; Binetti, S. Cd-free kesterite solar cells: State-of-the-art and perspectives. Sustain. Mater. Technol. 2024, 41, e01003. [Google Scholar] [CrossRef]

- Ahmad, N.; Liang, G.; Fan, P.; Zhou, H. Anode interfacial modification for non-fullerene polymer solar cells: Recent advances and prospects. InfoMat 2022, 4, e12370. [Google Scholar] [CrossRef]

- Lin, B.; Sun, Q.; Zhang, C.; Deng, H.; Li, Y.; Xie, W.; Li, Y.; Zheng, Q.; Wu, J.; Cheng, S. Efficient Cd-Free Flexible CZTSSe Solar Cells with Quality Interfaces by Using the Zn1–xSnxO Buffer Layer. ACS Appl. Energy Mater. 2023, 6, 1037–1045. [Google Scholar] [CrossRef]

- Boubakeur, M.; Aissat, A.; Chenini, L.; Arbia, M.B.; Maaref, H.; Vilcot, J.-P. Optimization of CdZny S1−y Buffer Layer Properties for a ZnO/CZTSxSe1−x/Mo Solar Cell to Enhance Conversion Efficiency. J. Electron. Mater. 2023, 52, 284–292. [Google Scholar] [CrossRef]

- Yan, G.; Zeng, C.; Yuan, Y.; Wang, G.; Cen, G.; Zeng, L.; Zhang, L.; Fu, Y.; Zhao, C.; Hong, R. Significantly enhancing response speed of self-powered Cu2ZnSn(S,Se)4 thin film photodetectors by atomic layer deposition of simultaneous electron blocking and electrode protective Al2O3 layers. ACS Appl. Mater. Interfaces 2019, 11, 32097–32107. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, M.; Ernits, K.; Tai, K.F.; Ng, C.F.; Pramana, S.S.; Sasangka, W.A.; Batabyal, S.K.; Holopainen, T.; Meissner, D.; Neisser, A. ZnS buffer layer for Cu2ZnSn(SSe)4 monograin layer solar cell. Sol. Energy 2015, 111, 344–349. [Google Scholar] [CrossRef]

- Wei, H.; Li, Y.; Cui, C.; Wang, X.; Shao, Z.; Pang, S.; Cui, G. Defect suppression for high-efficiency kesterite CZTSSe solar cells: Advances and prospects. Chem. Eng. J. 2023, 462, 142121. [Google Scholar] [CrossRef]

- Wang, A.; He, M.; Green, M.A.; Sun, K.; Hao, X. A critical review on the progress of kesterite solar cells: Current strategies and insights. Adv. Energy Mater. 2023, 13, 2203046. [Google Scholar] [CrossRef]

- Karade, V.C.; Sutar, S.S.; Jang, J.S.; Gour, K.S.; Shin, S.W.; Suryawanshi, M.P.; Kamat, R.K.; Dongale, T.D.; Kim, J.H.; Yun, J.H. Unraveling the Effect of Compositional Ratios on the Kesterite Thin-Film Solar Cells Using Machine Learning Techniques. Crystals 2023, 13, 1581. [Google Scholar] [CrossRef]

- Charghandeh, R.; Abbasi, A. Effect of In (O, S) buffer layer on the band alignment and the performance of CZT (S, Se) thin film solar cells. Mater. Today Commun. 2023, 37, 107299. [Google Scholar] [CrossRef]

- Park, H.K.; Cho, Y.; Kim, J.; Kim, S.; Kim, S.; Kim, J.; Yang, K.-J.; Kim, D.-H.; Kang, J.-K.; Jo, W. Flexible kesterite thin-film solar cells under stress. npj Flex. Electron. 2022, 6, 91. [Google Scholar] [CrossRef]

- Jang, J.S.; Karade, V.C.; Suryawanshi, M.P.; Lee, D.M.; Kim, J.; Jang, S.; Baek, M.C.; He, M.; Kim, J.H.; Shin, S.W. Improving Long-Term Stability of Kesterite Thin-Film Solar Cells with Oxide/Metal/Oxide Multilayered Transparent Conducting Electrodes. Sol. RRL 2023, 7, 2300199. [Google Scholar] [CrossRef]

- Trifiletti, V.; Frioni, L.; Tseberlidis, G.; Vitiello, E.; Danilson, M.; Grossberg, M.; Acciarri, M.; Binetti, S.; Marchionna, S. Manganese-substituted kesterite thin-films for earth-abundant photovoltaic applications. Sol. Energy Mater. Sol. Cells 2023, 254, 112247. [Google Scholar] [CrossRef]

- Ahmad, N.; Moussa, I.M.; Mahmood, A.; Zou, Y. Designing of Polymers for Photovoltaics Applications and Prediction of Band Gap as a Polymers Screening Criterion. ACS Appl. Energy Mater. 2025, 8, 2543–2552. [Google Scholar] [CrossRef]

- Ahmad, F.; Mahmood, A.; El Azab, I.H.; Ahmad, N.; Mahmoud, M.; El-Bahy, Z.M. Machine learning assisted designing of Y-series small molecule acceptors: Library generation and property prediction. J. Photochem. Photobiol. A Chem. 2024, 453, 115670. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Wang, Y.; Zhao, X.; Zhang, X.; Zhang, X.; Liu, Y. High-Efficiency Cd-Free CZTSSe Solar Cells with Organic Semiconductor PCBM as a Buffer Layer. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2024, 18, 2300186. [Google Scholar] [CrossRef]

- Lai, F.-I.; Yang, J.-F.; Chen, W.-C.; Hsu, Y.-C.; Kuo, S.-Y. All-Vacuum-Deposited Bifacial Cu2ZnSnSe4 Photovoltaic Cells with Sputtered Cd-Free Buffer Layer. Int. J. Energy Res. 2023, 2023, 9215680. [Google Scholar] [CrossRef]

- Martin, N.M.; Saini, N.; Babucci, M.; Törndahl, T.; Platzer-Björkman, C. Properties of the Interface Between the Atomic Layer Grown Zinc–Tin–Oxide and Cu2ZnGeS4 Relevant for Kesterite Thin-Film Solar Cells. Phys. Status Solidi (a) 2024, 221, 2300695. [Google Scholar] [CrossRef]

- Koné, K.E.; Bouich, A.; Soucase, B.M.; Soro, D. Manufacture of different oxides with high uniformity for copper zinc tin sulfide (CZTS) based solar cells. J. Mol. Graph. Model. 2023, 121, 108448. [Google Scholar] [CrossRef]

- Chauhan, P.; Agarwal, S.; Srivastava, V.; Hossain, M.K.; Pandey, R.; Madan, J.; Lohia, P.; Dwivedi, D.; Amami, M. Kesterite CZTS based thin film solar cell: Generation, recombination, and performance analysis. J. Phys. Chem. Solids 2023, 183, 111631. [Google Scholar] [CrossRef]

- Li, X.; Su, Z.; Venkataraj, S.; Batabyal, S.K.; Wong, L.H. 8.6% Efficiency CZTSSe solar cell with atomic layer deposited Zn-Sn-O buffer layer. Sol. Energy Mater. Sol. Cells 2016, 157, 101–107. [Google Scholar] [CrossRef]

- Cui, X.; Sun, K.; Huang, J.; Lee, C.-Y.; Yan, C.; Sun, H.; Zhang, Y.; Liu, F.; Hossain, M.A.; Zakaria, Y. Enhanced heterojunction interface quality to achieve 9.3% efficient Cd-free Cu2ZnSnS4 solar cells using atomic layer deposition ZnSnO buffer layer. Chem. Mater. 2018, 30, 7860–7871. [Google Scholar] [CrossRef]

- Ericson, T.; Larsson, F.; Törndahl, T.; Frisk, C.; Larsen, J.; Kosyak, V.; Hägglund, C.; Li, S.; Platzer-Björkman, C. Zinc-tin-oxide buffer layer and low temperature post annealing resulting in a 9.0% efficient Cd-free Cu2ZnSnS4 solar cell. Sol. RRL 2017, 1, 1700001. [Google Scholar] [CrossRef]

- Gobbo, C.; Di Palma, V.; Trifiletti, V.; Malerba, C.; Valentini, M.; Matacena, I.; Daliento, S.; Binetti, S.; Acciarri, M.; Tseberlidis, G. Effect of the ZnSnO/AZO interface on the charge extraction in Cd-free kesterite solar cells. Energies 2023, 16, 4137. [Google Scholar] [CrossRef]

- He, W.; Hang, J.; Ding, S.; Sun, L.; Hua, W. Robust diagnosis of partial demagnetization fault in PMSMs using radial air-gap flux density under complex working conditions. IEEE Trans. Ind. Electron. 2024, 71, 12001–12010. [Google Scholar] [CrossRef]

- Li, K.; Zhao, Z.; Zhao, H.; Zhou, M.; Jin, L.; Danyun, W.; Zhiyu, W.; Zhang, L. Three-stage training strategy phase unwrapping method for high speckle noises. Opt. Express 2024, 32, 48895–48914. [Google Scholar] [CrossRef]

- Al-Selwi, M.; Ning, H.; Gao, Y.; Chao, Y.; Li, Q.; Li, J. Enhancing object pose estimation for RGB images in cluttered scenes. Sci. Rep. 2025, 15, 8745. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Z.; Zhu, C.; Goetz, S.M. Fault-tolerant multiparallel three-phase two-level converters with adaptive hardware reconfiguration. IEEE Trans. Power Electron. 2024, 39, 3925–3930. [Google Scholar] [CrossRef]

- Garg, R.; Gonuguntla, S.; Sk, S.; Iqbal, M.S.; Dada, A.O.; Pal, U.; Ahmadipour, M. Sputtering thin films: Materials, applications, challenges and future directions. Adv. Colloid Interface Sci. 2024, 330, 103203. [Google Scholar] [CrossRef]

- Lee, J.; Enkhbat, T.; Han, G.; Sharif, M.H.; Enkhbayar, E.; Yoo, H.; Kim, J.H.; Kim, S.; Kim, J. Over 11% efficient eco-friendly kesterite solar cell: Effects of S-enriched surface of Cu2ZnSn (S,Se)4 absorber and band gap controlled (Zn, Sn) O buffer. Nano Energy 2020, 78, 105206. [Google Scholar] [CrossRef]

- Grenet, L.; Emieux, F.; Andrade-Arvizu, J.; De Vito, E.; Lorin, G.r.; Sanchez, Y.; Saucedo, E.; Roux, F. Sputtered ZnSnO buffer layers for kesterite solar cells. ACS Appl. Energy Mater. 2020, 3, 1883–1891. [Google Scholar] [CrossRef]

- Lin, B.; Sun, Q.; Zhang, C.; Deng, H.; Xie, W.; Tang, J.; Zheng, Q.; Wu, J.; Zhou, H.; Cheng, S. 9.3% Efficient Flexible Cu2ZnSn(S,Se)4 Solar Cells with High-Quality Interfaces via Ultrathin CdS and Zn0.8Sn0.2O Buffer Layers. Energy Technol. 2022, 10, 2200571. [Google Scholar] [CrossRef]

- Lee, Y.S.; Gershon, T.; Todorov, T.K.; Wang, W.; Winkler, M.T.; Hopstaken, M.; Gunawan, O.; Kim, J. Atomic layer deposited aluminum oxide for interface passivation of Cu2ZnSn (S,Se)4 thin-film solar cells. Adv. Energy Mater. 2016, 6, 1600198. [Google Scholar] [CrossRef]

- Wu, T.; Yang, H.; Wang, P.; Zhang, C.; Zhang, M. Data-driven fatigue reliability evaluation of offshore wind turbines under floating ice loading. J. Struct. Eng. 2024, 150, 05024004. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhang, R.; Zhang, H.; Qiao, S.; Huang, F.; Tian, Q.; Peng, Y. GCCNet: A Novel Network Leveraging Gated Cross-Correlation for Multi-View Classification. IEEE Trans. Multimed. 2024, 27, 1086–1099. [Google Scholar] [CrossRef]

- Zhi, S.; Shen, H.; Wang, T. Gearbox localized fault detection based on meshing frequency modulation analysis. Appl. Acoust. 2024, 219, 109943. [Google Scholar] [CrossRef]

- Atosuo, E.; Mäntymäki, M.; Ritala, M. ALD of Metal Fluorides–Potential Applications and Current State. Adv. Mater. Interfaces 2025, 12, 2400372. [Google Scholar] [CrossRef]

- Tajima, S.; Umehara, M.; Mise, T. Photovoltaic properties of Cu2ZnSnS4 cells fabricated using ZnSnO and ZnSnO/CdS buffer layers. Jpn. J. Appl. Phys. 2016, 55, 112302. [Google Scholar] [CrossRef]

- Platzer-Björkman, C.; Frisk, C.; Larsen, J.; Ericson, T.; Li, S.-Y.; Scragg, J.; Keller, J.; Larsson, F.; Törndahl, T. Reduced interface recombination in Cu2ZnSnS4 solar cells with atomic layer deposition Zn1−xSnxOy buffer layers. Appl. Phys. Lett. 2015, 107, 243904. [Google Scholar] [CrossRef]

- Larsen, J.K.; Larsson, F.; Törndahl, T.; Saini, N.; Riekehr, L.; Ren, Y.; Biswal, A.; Hauschild, D.; Weinhardt, L.; Heske, C. Cadmium free Cu2ZnSnS4 solar cells with 9.7% efficiency. Adv. Energy Mater. 2019, 9, 1900439. [Google Scholar] [CrossRef]

- Ahmad, N.; Zhao, Y.; Ye, F.; Zhao, J.; Chen, S.; Zheng, Z.; Fan, P.; Yan, C.; Li, Y.; Su, Z. Cadmium-Free Kesterite Thin-Film Solar Cells with High Efficiency Approaching 12%. Adv. Sci. 2023, 10, 2302869. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Yanxun, L.; Zhang, X.; Wang, B.; Zhang, Y.; Zhou, H. A biopolymeric buffer layer improves device efficiency and stability in inverted organic solar cells. J. Mater. Chem. C 2020, 8, 15795–15803. [Google Scholar] [CrossRef]

- Ahmad, N.; Zhou, H.; Fan, P.; Liang, G. Recent progress in cathode interlayer materials for non-fullerene organic solar cells. EcoMat 2022, 4, e12156. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, L.; Xiao, G.; Wang, P.; Gu, Y.; Lu, J. Elevator fault diagnosis based on digital twin and PINNs-e-RGCN. Sci. Rep. 2024, 14, 30713. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Peng, M. Interpretability study of a typical fault diagnosis model for nuclear power plant primary circuit based on a graph neural network. Reliab. Eng. Syst. Saf. 2025, 261, 111151. [Google Scholar] [CrossRef]

- Ju, X.; Jiang, Y.; Jing, L.; Liu, P. Quantized predefined-time control for heavy-lift launch vehicles under actuator faults and rate gyro malfunctions. ISA Trans. 2023, 138, 133–150. [Google Scholar] [CrossRef] [PubMed]

- Gour, K.S.; Parmar, R.; Kumar, R.; Singh, V.N. Cd-free Zn (O, S) as alternative buffer layer for chalcogenide and kesterite based thin films solar cells: A review. J. Nanosci. Nanotechnol. 2020, 20, 3622–3635. [Google Scholar] [CrossRef]

- Ericson, T.; Scragg, J.J.; Hultqvist, A.; Wätjen, J.T.; Szaniawski, P.; Törndahl, T.; Platzer-Björkman, C. Zn (O, S) buffer layers and thickness variations of CdS buffer for Cu2 ZnSnS4 solar cells. IEEE J. Photovolt. 2013, 4, 465–469. [Google Scholar] [CrossRef]

- Grenet, L.; Grondin, P.; Coumert, K.; Karst, N.; Emieux, F.; Roux, F.; Fillon, R.; Altamura, G.; Fournier, H.; Faucherand, P. Experimental evidence of light soaking effect in Cd-free Cu2ZnSn(S,Se)4-based solar cells. Thin Solid Films 2014, 564, 375–378. [Google Scholar] [CrossRef]

- Steirer, K.X.; Garris, R.L.; Li, J.V.; Dzara, M.J.; Ndione, P.F.; Ramanathan, K.; Repins, I.; Teeter, G.; Perkins, C.L. Co-solvent enhanced zinc oxysulfide buffer layers in Kesterite copper zinc tin selenide solar cells. PCCP 2015, 17, 15355–15364. [Google Scholar] [CrossRef]

- Park, J.Y.; Chalapathy, R.; Lokhande, A.; Hong, C.W.; Kim, J.H. Fabrication of earth abundant Cu2ZnSnSSe4 (CZTSSe) thin film solar cells with cadmium free zinc sulfide (ZnS) buffer layers. J. Alloys Compd. 2017, 695, 2652–2660. [Google Scholar] [CrossRef]

- Kim, J.; Park, C.; Pawar, S.; Inamdar, A.I.; Jo, Y.; Han, J.; Hong, J.; Park, Y.S.; Kim, D.-Y.; Jung, W. Optimization of sputtered ZnS buffer for Cu2ZnSnS4 thin film solar cells. Thin Solid Films 2014, 566, 88–92. [Google Scholar] [CrossRef]

- Jeong, H.; Nandi, R.; Cho, J.Y.; Pawar, P.S.; Lee, H.S.; Neerugatti, K.E.; Kim, J.H.; Heo, J. CZTSSe/Zn (O, S) heterojunction solar cells with 9.82% efficiency enabled via (NH4) 2S treatment of absorber layer. Prog. Photovolt. Res. Appl. 2021, 29, 1057–1067. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Liu, W.; Wu, L.; Ge, B.; Lin, S.; Gao, S.; Zhou, Z.; Liu, F.; Sun, Y. Restraining the Band Fluctuation of CBD-Zn (O, S) Layer: Modifying the Hetero-Junction Interface for High Performance Cu2ZnSnSe4 Solar Cells with Cd-Free Buffer Layer. Sol. RRL 2017, 1, 1700075. [Google Scholar] [CrossRef]

- Neuschitzer, M.; Lienau, K.; Guc, M.; Barrio, L.C.; Haass, S.; Prieto, J.M.; Sanchez, Y.; Espindola-Rodriguez, M.; Romanyuk, Y.; Perez-Rodriguez, A. Towards high performance Cd-free CZTSe solar cells with a ZnS (O, OH) buffer layer: The influence of thiourea concentration on chemical bath deposition. J. Phys. D Appl. Phys. 2016, 49, 125602. [Google Scholar] [CrossRef]

- Delgado-Sanchez, J.-M.; Lillo-Bravo, I.; López-Álvarez, J.A.; Pérez-Aparicio, E. Zn (O, S) Buffer Layer Deposited by High Vapor Transport Deposition for Controlling Band Alignment of Cu2ZnSn (SxSe1−x)4 Thin-Film Solar Cell Heterojunction. Sol. RRL 2022, 6, 2200818. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, J.; Feng, Y.; Liao, J.; Xue, S.; Shao, L.; Liang, G. Fabrication of Zn (O, S) thin films by ozone assisted photochemical deposition and its potential applications as buffer layers in kesterite-based thin film solar cells. Thin Solid Films 2019, 670, 80–85. [Google Scholar] [CrossRef]

- Yang, S.; Wang, S.; Liao, H.; Xu, X.; Tang, Z.; Li, X.; Li, X.; Wang, T.; Liu, D. Sulfurizing Sputtered-ZnO as buffer layer for cadmium-free Cu2ZnSnS4 solar cells. Mater. Sci. Semicond. Process. 2019, 101, 87–94. [Google Scholar] [CrossRef]

- Huang, L.; Li, J.; Wang, S.; Zhong, L.; Xiao, X. Forming an ultrathin SnS Layer on Cu2ZnSnS4 surface to achieve highly efficient solar cells with Zn (O, S) Buffer. Sol. RRL 2020, 4, 2000010. [Google Scholar] [CrossRef]

- Schnabel, T.; Seboui, M.; Bauer, A.; Choubrac, L.; Arzel, L.; Harel, S.; Barreau, N.; Ahlswede, E. Evaluation of different buffer materials for solar cells with wide-gap Cu2ZnGeSxSe4−x absorbers. RSC Adv. 2017, 7, 40105–40110. [Google Scholar] [CrossRef]

- Hironiwa, D.; Matsuo, N.; Sakai, N.; Katou, T.; Sugimoto, H.; Chantana, J.; Tang, Z.; Minemoto, T. Sputtered (Zn, Mg) O buffer layer for band offset control in Cu2ZnSn (S,Se)4 solar cells. Jpn. J. Appl. Phys. 2014, 53, 106502. [Google Scholar] [CrossRef]

- Ahmad, N.; Eid, G.; El-Toony, M.M.; Mahmood, A. Harnessing machine learning for the rational design of high-performance fluorescent dyes. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2025, 334, 125918. [Google Scholar] [CrossRef]

- Jiang, F.; Ikeda, S.; Tang, Z.; Minemoto, T.; Septina, W.; Harada, T.; Matsumura, M. Impact of alloying duration of an electrodeposited Cu/Sn/Zn metallic stack on properties of Cu2ZnSnS4 absorbers for thin-film solar cells. Prog. Photovolt. Res. Appl. 2015, 23, 1884–1895. [Google Scholar] [CrossRef]

- Yan, C.; Liu, F.; Sun, K.; Song, N.; Stride, J.A.; Zhou, F.; Hao, X.; Green, M. Boosting the efficiency of pure sulfide CZTS solar cells using the In/Cd-based hybrid buffers. Sol. Energy Mater. Sol. Cells 2016, 144, 700–706. [Google Scholar] [CrossRef]

- Kim, J.; Hiroi, H.; Todorov, T.K.; Gunawan, O.; Kuwahara, M.; Gokmen, T.; Nair, D.; Hopstaken, M.; Shin, B.; Lee, Y.S. High efficiency Cu2ZnSn(S,Se)4 solar cells by applying a double In2S3/CdS emitter. Adv. Mater. 2014, 26, 7427–7431. [Google Scholar] [CrossRef]

- Barkhouse, D.A.R.; Haight, R.; Sakai, N.; Hiroi, H.; Sugimoto, H.; Mitzi, D.B. Cd-free buffer layer materials on Cu2ZnSn (SxSe1−x) 4: Band alignments with ZnO, ZnS, and In2S3. Appl. Phys. Lett. 2012, 100, 193904. [Google Scholar] [CrossRef]

- Wu, J.; Yin, J.; Zhang, Q. Institute of Electrical and Electronics Engineers. In Proceedings of the IEEE 13th International Conference on Electronic Measurement & Instruments, Yangzhou, China, 20–23 October 2017; pp. 20–22. [Google Scholar]

- Mathur, A.; Singh, P.P.; Upadhyay, S.; Yadav, N.; Singh, K.; Singh, D.; Singh, B. Role of absorber and buffer layer thickness on Cu2O/TiO2 heterojunction solar cells. Sol. Energy 2022, 233, 287–291. [Google Scholar] [CrossRef]

- Nunez, P.; Richter, M.H.; Piercy, B.D.; Roske, C.W.; Cabán-Acevedo, M.; Losego, M.D.; Konezny, S.J.; Fermin, D.J.; Hu, S.; Brunschwig, B.S. Characterization of electronic transport through amorphous TiO2 produced by atomic layer deposition. J. Phys. Chem. C 2019, 123, 20116–20129. [Google Scholar] [CrossRef]

- Su, T.; Yang, Y.; Na, Y.; Fan, R.; Li, L.; Wei, L.; Yang, B.; Cao, W. An insight into the role of oxygen vacancy in hydrogenated TiO2 nanocrystals in the performance of dye-sensitized solar cells. ACS Appl. Mater. Interfaces 2015, 7, 3754–3763. [Google Scholar] [CrossRef]

- Wu, G.; Yang, T.; Li, X.; Ahmad, N.; Zhang, X.; Yue, S.; Zhou, J.; Li, Y.; Wang, H.; Shi, X. Molecular engineering for two-dimensional perovskites with photovoltaic efficiency exceeding 18%. Matter 2021, 4, 582–599. [Google Scholar] [CrossRef]

- Wu, G.; Ahmad, N.; Zhang, Y. High-efficiency of 15.47% for two-dimensional perovskite solar cells processed by blade coating with non-thermal assistance. J. Mater. Chem. C 2021, 9, 9851–9858. [Google Scholar] [CrossRef]

- Dagdeviren, O.E.; Glass, D.; Sapienza, R.; Cortés, E.; Maier, S.A.; Parkin, I.P.; Grütter, P.; Quesada-Cabrera, R. The effect of photoinduced surface oxygen vacancies on the charge carrier dynamics in TiO2 films. Nano Lett. 2021, 21, 8348–8354. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Tian, H.; Wang, X.; Xue, G.; Tian, Z.; Zhang, J.; Yuan, S.; Yu, T.; Zou, Z. The role of oxygen vacancy-Ti3+ states on TiO2 nanotubes’ surface in dye-sensitized solar cells. Mater. Lett. 2013, 100, 51–53. [Google Scholar] [CrossRef]

- Hsu, W.; Sutter-Fella, C.M.; Hettick, M.; Cheng, L.; Chan, S.; Chen, Y.; Zeng, Y.; Zheng, M.; Wang, H.-P.; Chiang, C.-C. Electron-Selective TiO2 Contact for Cu(In,Ga)Se2 Solar Cells. Sci. Rep. 2015, 5, 16028. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Taghipour, N.; Peng, L.; Konstantatos, G. Ag-Refined Kesterite in Superstrate Solar Cell Configuration with 9.7% Power Conversion Efficiency. Adv. Funct. Mater. 2022, 32, 2205948. [Google Scholar] [CrossRef]

- Tseberlidis, G.; Di Palma, V.; Trifiletti, V.; Frioni, L.; Valentini, M.; Malerba, C.; Mittiga, A.; Acciarri, M.; Binetti, S.O. Titania as buffer layer for Cd-free kesterite solar cells. ACS Mater. Lett. 2022, 5, 219–224. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Tripathi, S.K.; Tiwari, D.; Chauhan, A.S.; Dwivedi, P.K.; Prasad, N.E. Low cost copper zinc tin sulphide (CZTS) solar cells fabricated by sulphurizing sol-gel deposited precursor using 1,2-ethanedithiol (EDT). Sol. Energy 2021, 224, 210–217. [Google Scholar] [CrossRef]

- Nisika, N.; Kaur, K.; Arora, K.; Chowdhury, A.H.; Bahrami, B.; Qiao, Q.; Kumar, M. Energy level alignment and nanoscale investigation of a-TiO2/Cu-Zn-Sn-S interface for alternative electron transport layer in earth abundant Cu-Zn-Sn-S solar cells. J. Appl. Phys. 2019, 126, 193104. [Google Scholar] [CrossRef]

- Li, K.; Zhu, Y.; Chang, X.; Zhou, M.; Yu, X.; Zhao, X.; Wang, T.; Cai, Z.; Zhu, X.; Wang, H. Self-induced bi-interfacial modification via fluoropyridinic acid for high-performance inverted perovskite solar cells. Adv. Energy Mater. 2025, 15, 2404335. [Google Scholar] [CrossRef]

- Li, X.; Wang, H.; He, Y.; Gao, Z.; Zhang, X.; Wang, Y. Active thermography non-destructive testing going beyond camera’s resolution limitation: A heterogenous Dual-band single-pixel approach. IEEE Trans. Instrum. Meas. 2025, 74, 4502608. [Google Scholar]

- Xiong, J.; Yang, B.; Zhou, C.; Yang, J.; Duan, H.; Huang, W.; Zhang, X.; Xia, X.; Zhang, L.; Huang, H. Enhanced efficiency and stability of polymer solar cells with TiO2 nanoparticles buffer layer. Org. Electron. 2014, 15, 835–843. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, L.; Zhang, J.; Wu, Q.; Jiang, L.; Shi, Y.; Lyu, L.; Cai, G. Fault diagnosis of energy storage batteries based on dual driving of data and models. J. Energy Storage 2025, 112, 115485. [Google Scholar] [CrossRef]

- Meng, Q.; He, Y.; Li, S.; Hussain, S.; Lu, J.; You, G.; Guerrero, J.M. Adaptive two-step power prediction and improved perturbation method for accelerated MPPT with reduced oscillations in photovoltaic systems. Energy Rep. 2025, 13, 5328–5338. [Google Scholar] [CrossRef]

- Lu, G.; Lin, Q.; Zheng, D.; Zhang, P. Online Degradation Fault Prognosis for DC-Link Capacitors in Multistring-connected Photovoltaic Boost Converters Subject to Cable Uncertainties. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 13, 1107–1117. [Google Scholar] [CrossRef]

- Larramona, G.; Choné, C.; Meissner, D.; Ernits, K.; Bras, P.; Ren, Y.; Martín-Salinas, R.; Rodríguez-Villatoro, J.; Vermang, B.; Brammertz, G. Stability, reliability, upscaling and possible technological applications of kesterite solar cells. J. Phys. Energy 2020, 2, 024009. [Google Scholar] [CrossRef]

- Shi, X.; Ren, Z.; Niu, S.; Wang, C.; Liu, X.; Wang, K.; Wang, Q. Highly Efficient ultra-thin solar selective absorber based on Self-assembled tangent Nano-Ball-Cap arrays. Chem. Eng. J. 2025, 505, 159459. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, N.; Wu, G. Cadmium-Free Buffer Layer Materials for Kesterite Thin-Film Solar Cells: An Overview. Energies 2025, 18, 3198. https://doi.org/10.3390/en18123198

Ahmad N, Wu G. Cadmium-Free Buffer Layer Materials for Kesterite Thin-Film Solar Cells: An Overview. Energies. 2025; 18(12):3198. https://doi.org/10.3390/en18123198

Chicago/Turabian StyleAhmad, Nafees, and Guangbao Wu. 2025. "Cadmium-Free Buffer Layer Materials for Kesterite Thin-Film Solar Cells: An Overview" Energies 18, no. 12: 3198. https://doi.org/10.3390/en18123198

APA StyleAhmad, N., & Wu, G. (2025). Cadmium-Free Buffer Layer Materials for Kesterite Thin-Film Solar Cells: An Overview. Energies, 18(12), 3198. https://doi.org/10.3390/en18123198