1. Introduction

Permanent magnet synchronous motors (PMSMs) have become a cornerstone in modern electrical drive systems, owing to their high power density, compact structure, and excellent adaptability across diverse operating environments. They are widely employed in electric vehicles [

1], robotics [

2], and industrial automation systems [

3]. To ensure stable operation of PMSM-based systems under complex and dynamic conditions—while simultaneously achieving high efficiency and precise control—various advanced control strategies have been developed. These include field-oriented control (FOC) [

4], direct torque control (DTC) [

5], and model predictive control (MPC) [

6]. In recent years, MPC has garnered significant attention due to its fast dynamic response, ease of implementation, and robust multi-objective control capabilities.

According to the dynamic response requirements defined by the cost function, model predictive control (MPC) is conventionally categorized into two principal classes: continuous control set MPC (CCS MPC) and finite control set MPC (FCS MPC). CCS MPC exploits the continuous nature of the control input domain to compute the optimal voltage vector via online optimization, thereby refining the control policy in accordance with the cost function [

7]. In contrast, FCS MPC identifies the optimal switching state of the voltage vector at each switching interval by evaluating the cost function and subsequently applies these switching commands directly to the inverter output to regulate motor operation [

8]. Compared with CCS MPC, FCS MPC provides simpler implementation, more direct computation and execution of control actions [

7], and superior computational efficiency, resulting in its widespread adoption in motor control applications. Model predictive current control (MPCC), a fundamental technique within the FCS MPC paradigm, predicts future current trajectories based on the motor model and real-time current measurements, thereby enabling the optimal design of control inputs [

9]. However, control performance of the system depends critically on the accuracy of the model parameters [

10,

11]. Parameter mismatches lead to systematic deviations in the current response [

12,

13] and significantly amplify fluctuations. Among these parameters, inductance and flux linkage exert the most pronounced impact [

14,

15].

Model-free control strategies have been extensively adopted to surmount the limitations of model-dependent methods in terms of modeling accuracy and real-time responsiveness [

16,

17,

18]. Reference [

19] introduces a prediction current control (PCC) approach based on current difference detection, in which control is effected by measuring the discrepancy between actual and estimated currents and leveraging stator current differentials associated with various inverter switching states, thereby obviating reliance on motor parameters; Finite control set model-free predictive current control (FCS MFPCC) [

20] utilizes ULM combined with a current compensation strategy to enhance prediction accuracy. Model-free predictive current control with a balancing factor (MPF MPCC) [

16] examines the effects of current and voltage differentials on current variation and incorporates a balancing factor to weight these components within the predictive model. Another variant, MPF MPCC [

15], removes resistance and flux linkage parameters from the model and implements a streamlined real-time algorithm for current prediction. Reference [

21] presents an ETAV-MFPC control approach utilizing active-vector execution timing and an ultra-local model to attenuate current ripple. Moreover, MFPCC [

22] integrates an online gradient-update strategy to overcome stagnation issues inherent to conventional current gradient update methods.

Meanwhile, numerous studies have adopted parameter identification techniques for online estimation of system parameters, thereby mitigating the impact of dynamic parameter variations on model predictions [

23]. Reference [

24] exploits dynamic discrepancies in motor parameters by employing an affine projection algorithm to independently estimate inductance, flux linkage, and load torque. A model-reference adaptive framework with fuzzy-logic methods to infer controller parameters is integrated in [

25]. In [

26], a sliding-mode exponential-reaching-law approach is proposed for a stator-current and disturbance observer, thereby optimizing parameter mismatch issues.

Furthermore, to reduce computational complexity, several studies have proposed simplified voltage vector selection methods [

27]. The STV MPCC approach integrates reference voltage computation with differential free control, thereby reducing the number of voltage vector selections to five [

28]. Another enhanced MPCC method [

29] employs the reference voltage vector at the end of the next cycle—which counteracts current errors—to directly select the candidate voltage vector that most closely aligns with it, while the PFPCC approach [

30] reduces the candidate voltage vector combinations in three-vector MPCC from six to two, thereby alleviating the screening burden. However, existing approaches suffer from insufficient accuracy in current disturbance estimation and still entail substantial computational complexity in voltage vector selection.

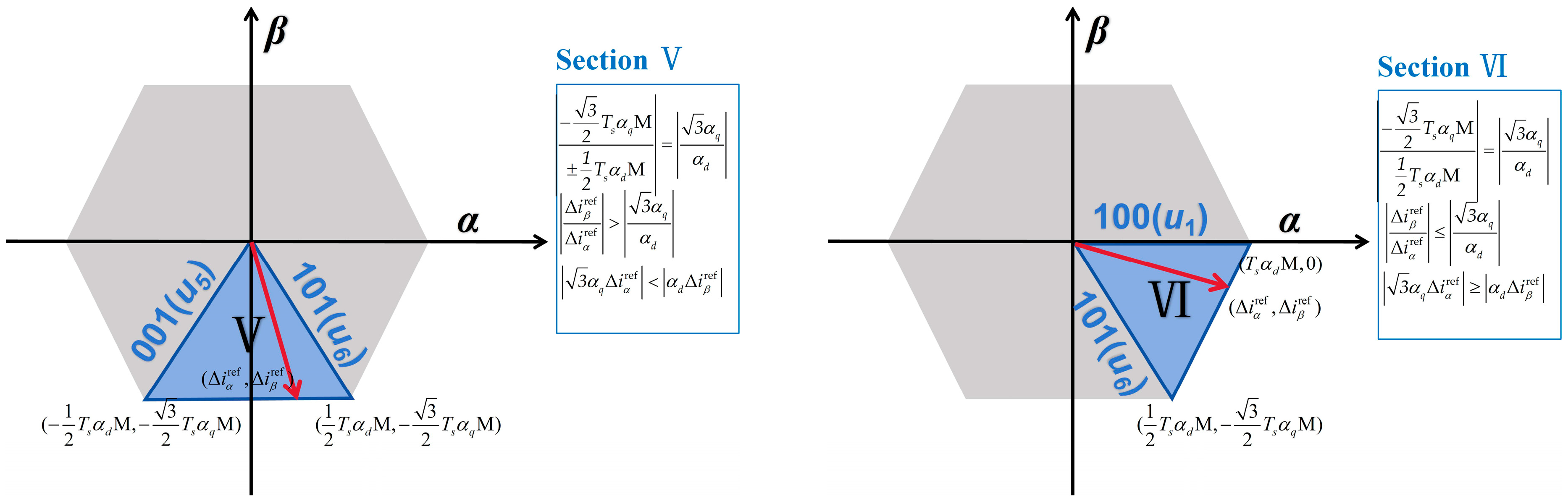

In this article, in order to enhance the accuracy of current estimation in model-free predictive control and streamline the voltage vector selection process. a current ULM based on a KF and an adaptive SMO is proposed. Moreover, by transforming the cost function, a vector selection method based on sector distribution is introduced. The main contributions of this study include:

A ULM for PMSM current control is developed to reduce dependence on precise motor parameters, thereby enabling highly adaptive control.

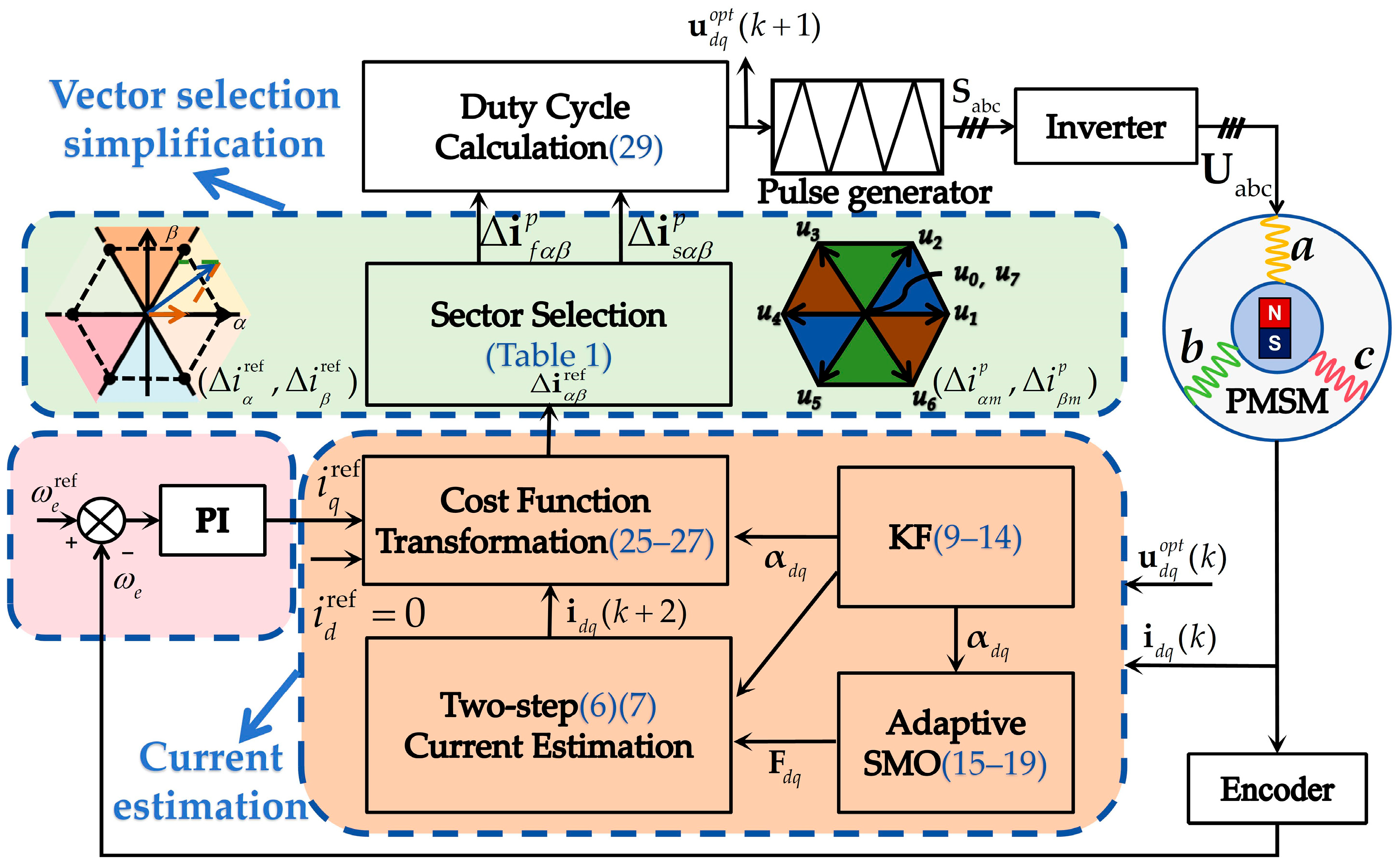

By designing a KF to monitor current gain and utilizing an adaptive SMO to detect current disturbances, the robustness of the system is enhanced and precise current prediction is realized.

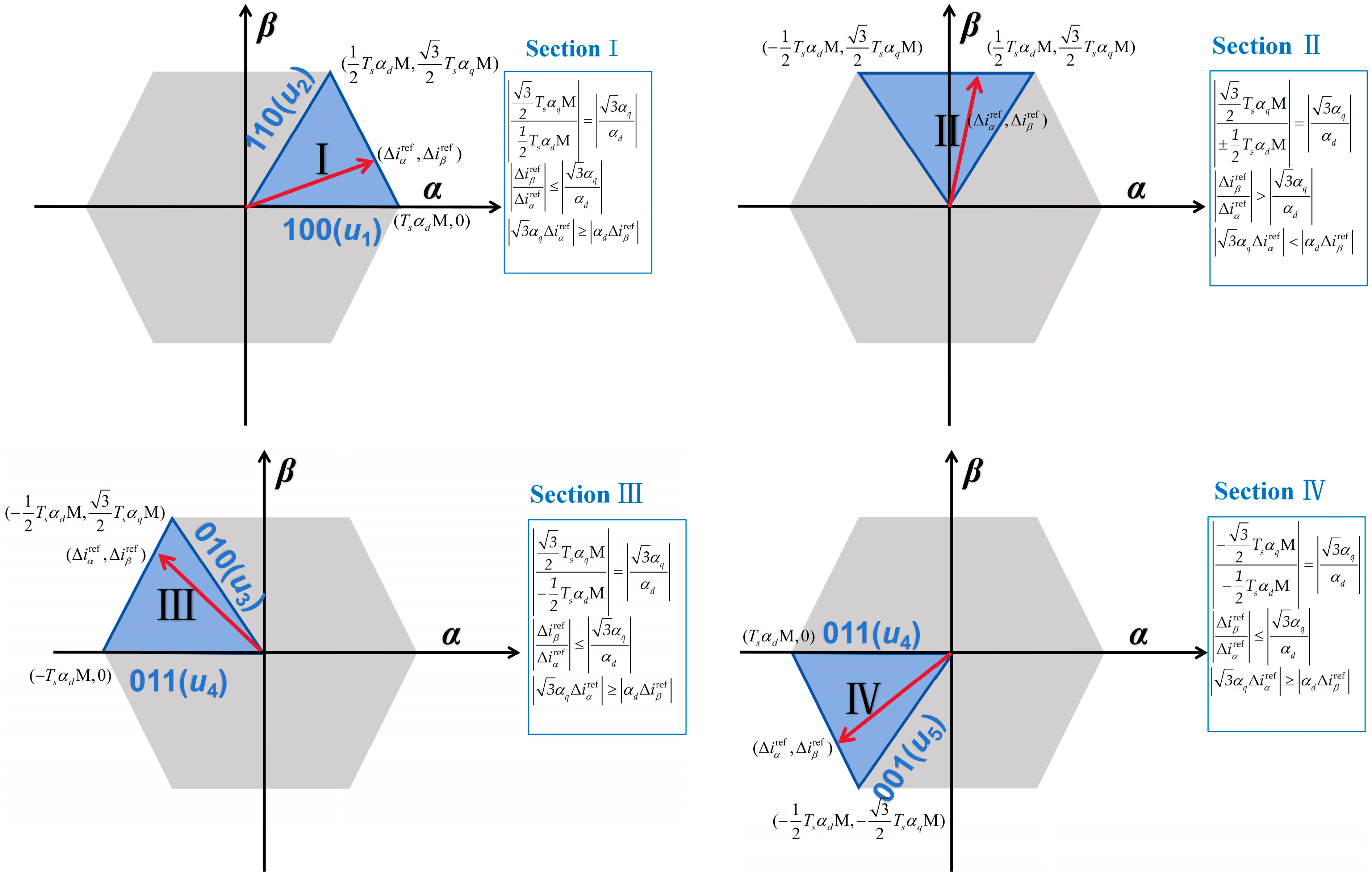

Based on the developed ULM, an equivalent transformation of the cost function in the αβ reference domain is executed, and a vector selection method based on sector distribution is introduced. The proposed method reduces the six possible voltage vector combinations to a single, unified voltage vector combination, thereby significantly reducing the computational complexity.

This paper is organized as follows.

Section 2 presents the mathematical model of the PMSM, followed by the introduction of the MFPCC control strategy, with detailed descriptions of its current estimation and voltage vector simplification processes. In

Section 3 and

Section 4, simulations and experiments are performed to validate the effectiveness of the proposed control strategy. Finally, a conclusion of this study is given in

Section 5.

4. Experiment Results and Analysis

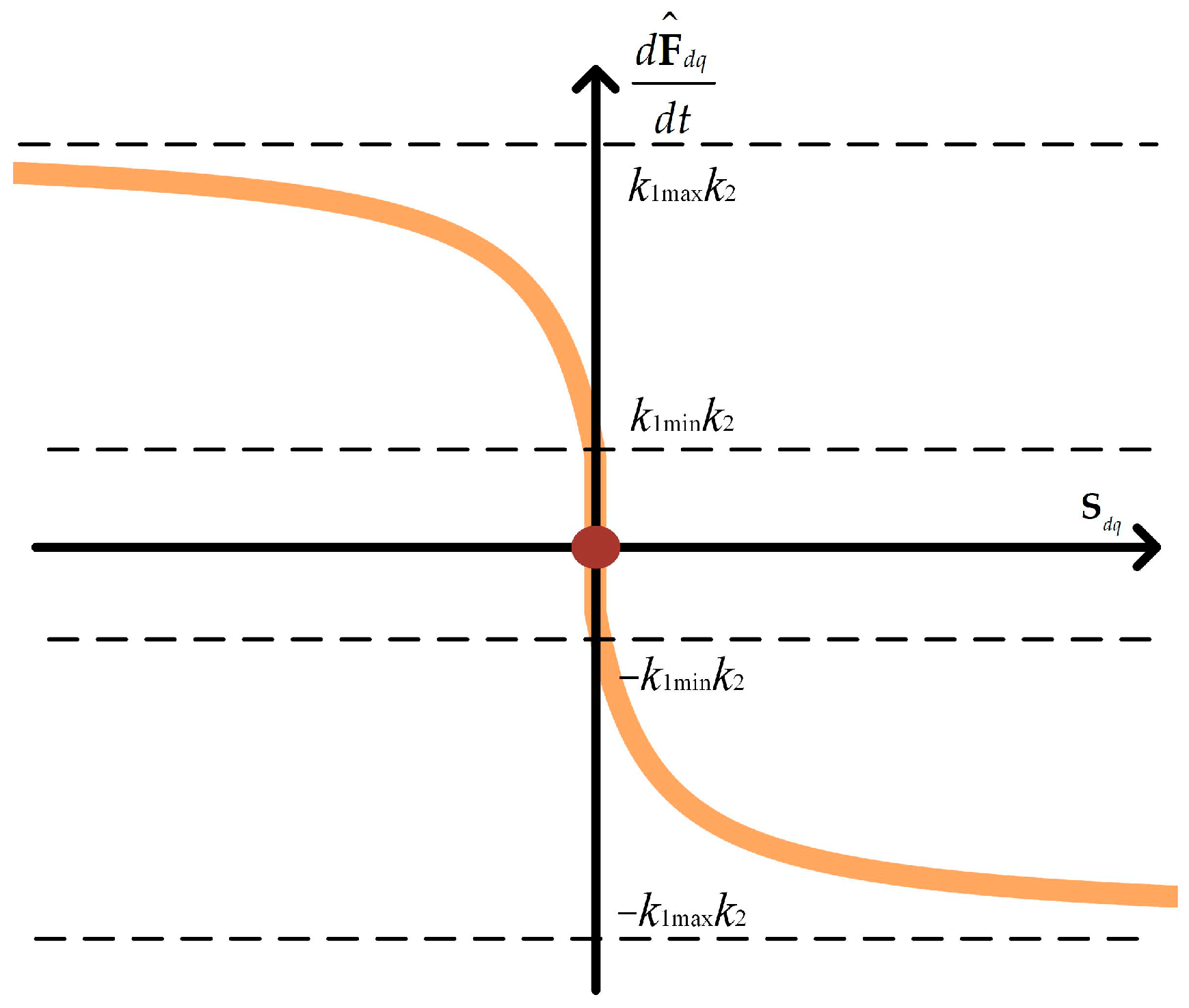

The experimental setup used a 2 kW permanent magnet synchronous motor, with parameters consistent with the simulation values presented in

Table 3. Photographs of the assembled hardware platform are shown in

Figure 14. In this configuration, the controlled motor is mechanically linked to a load motor via a coupling, with a torque-speed sensor installed at the interface to enable real-time monitoring of both torque and speed. These measurements are transmitted to the host computer via a communication cable. The load motor is connected to a general purpose inverter that controls the application and removal of load. Additionally, the experimental motor is equipped with a 2500-line incremental rotary encoder, with its rotational direction, position, and speed measured and computed using the enhanced quadrature encoder pulse (eQEP) module embedded in the controller’s primary chip, the TMS320F28377D. This dual-core chip from Texas Instruments concurrently executes the control algorithms and processes the communication signals. Additionally, peripheral devices—such as the analog-to-digital conversion (ADC) module, enhanced pulse-width modulation (ePWM) module, and serial communication interface (SCI) module—are used for voltage and current A/D data sampling, motor control algorithm calculations, power transistor switching signal output, and transmitting experimental data to the host computer for monitoring. The drive circuitry features an Infineon intelligent IPM module that responds to fault signals (including overvoltage, overcurrent, and overtemperature conditions) by interrupting the power transistor drive signals, thereby protecting the system.

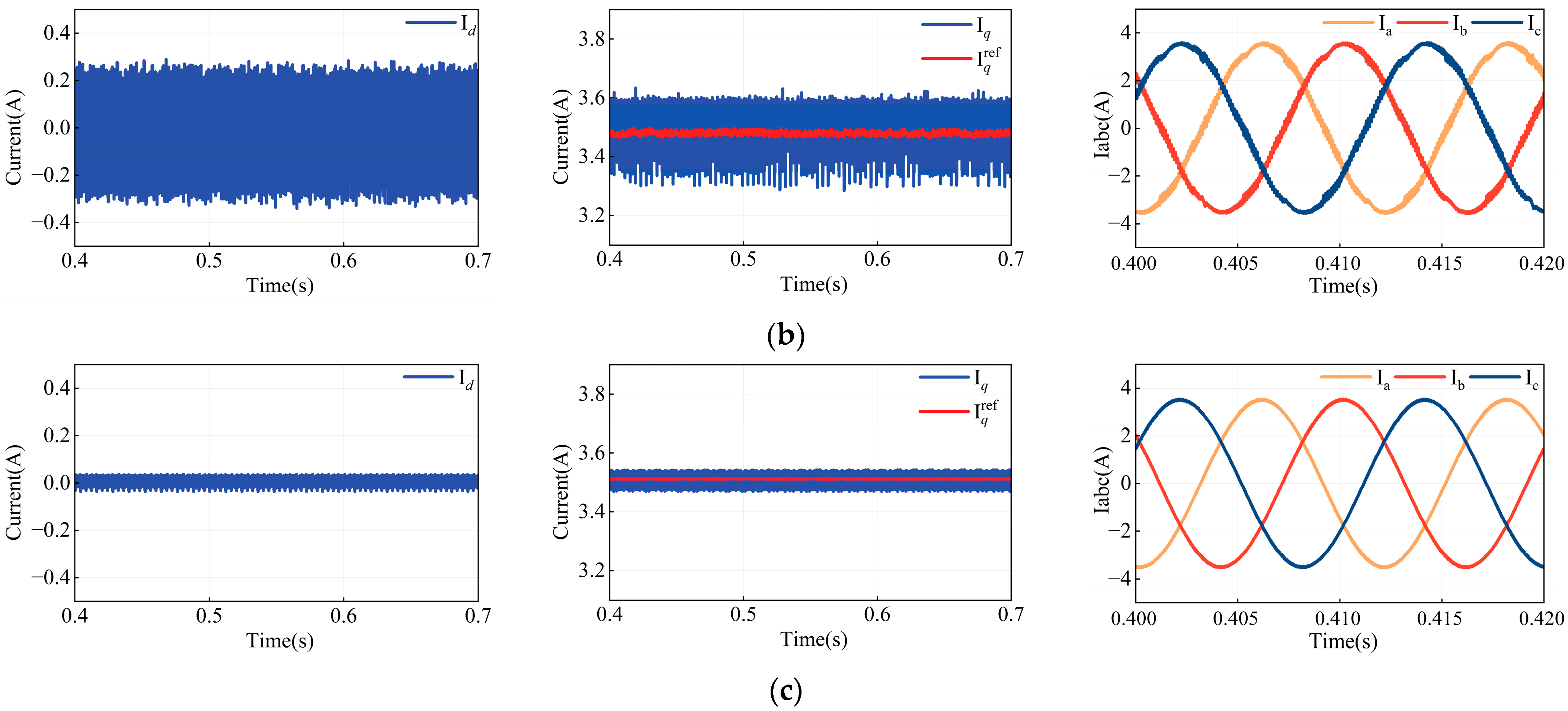

4.1. Stability Analysis of ULM Under Experimental Condition

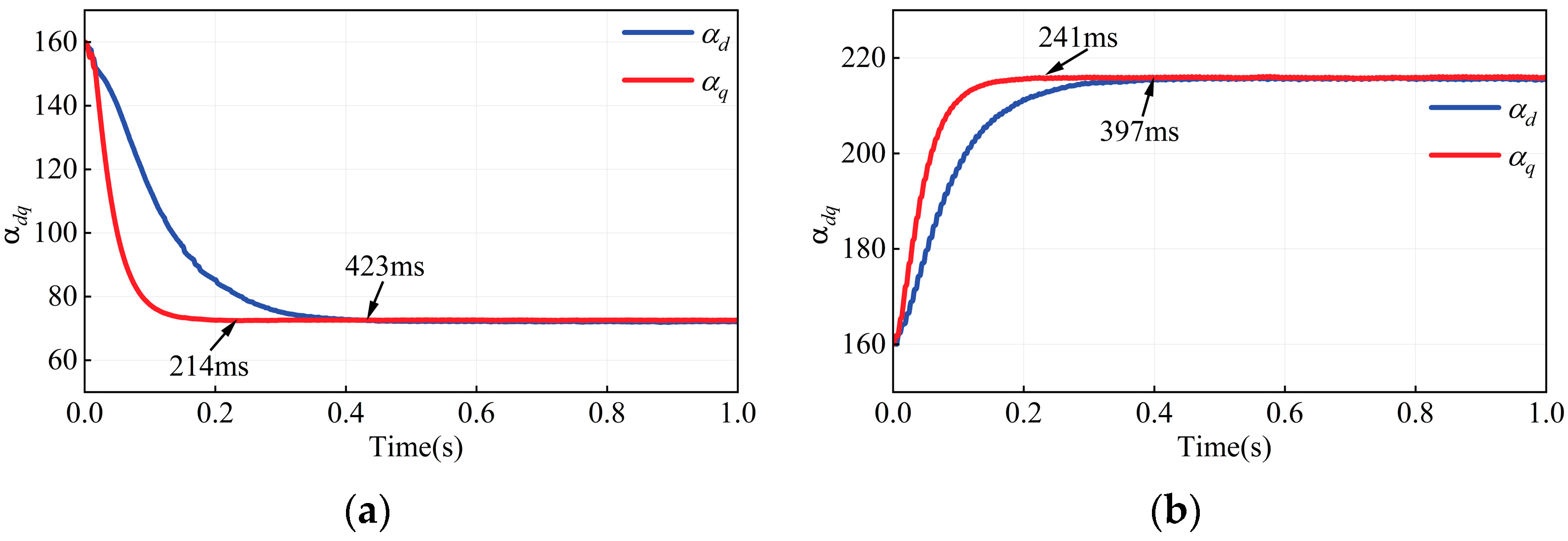

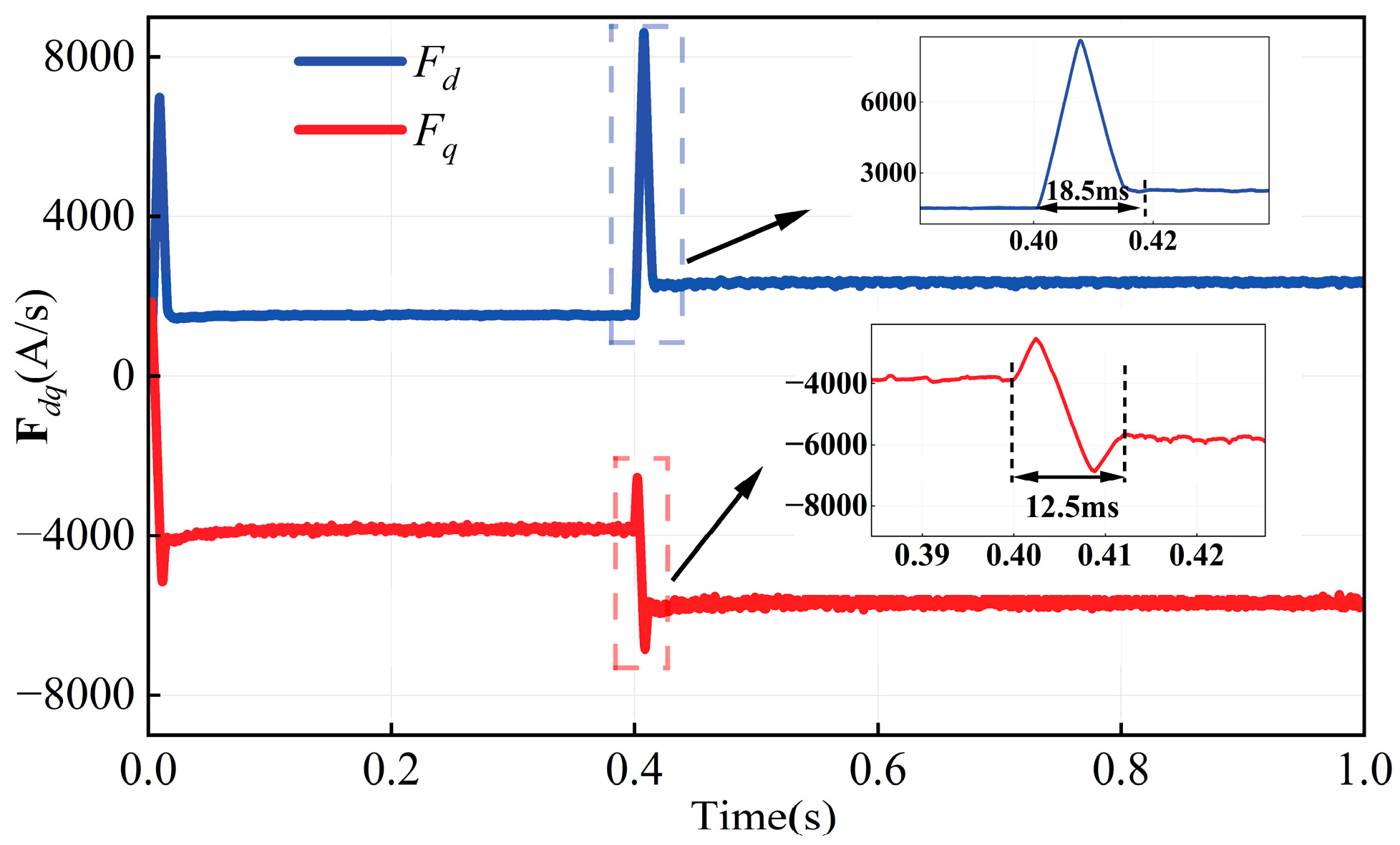

To validate the stability of the proposed ULM, experiments were conducted under a load torque of 2 N·m and a reference speed of 1000 r/min.

Figure 15 illustrates the evolution of

αdq and

Fdq during the transition from startup to steady-state operation. The results indicate that

αd and α

q stabilize at 368 ms and 226 ms, respectively, with their steady-state values closely approximating

. Similarly,

Fd and

Fq stabilize at 69 ms and 251 ms. These findings clearly demonstrate the superior performance of the proposed ULM.

4.2. Vector Distribution Analysis

To visually demonstrate the proposed vector selection method,

Figure 16a,b depict the steady-state fluctuation characteristics of Δ

and Δ

, respectively, under steady-state conditions and scatter distribution in the

αβ coordinate system with a load torque of 2 N·m and a reference speed of 1000 r/min. As illustrated in

Figure 16a, during system stability,

and Δ

exhibit periodic sinusoidal waveforms with a distinct phase difference between them. Meanwhile,

Figure 16b shows that the distribution of these two variables in the

αβ coordinate domain is relatively compact, forming an overall circular trajectory. Based on the sector position of each data point, appropriate candidate vectors are subsequently selected.

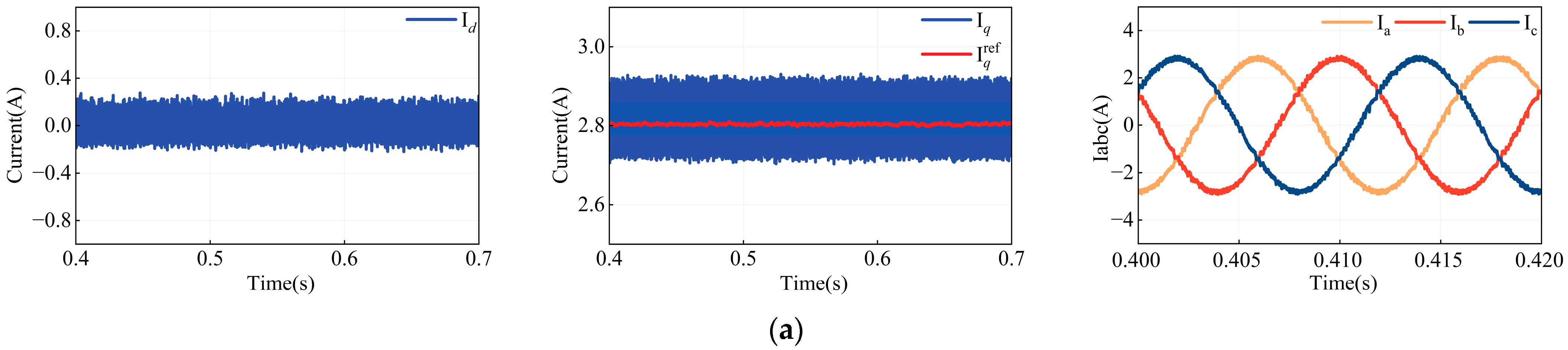

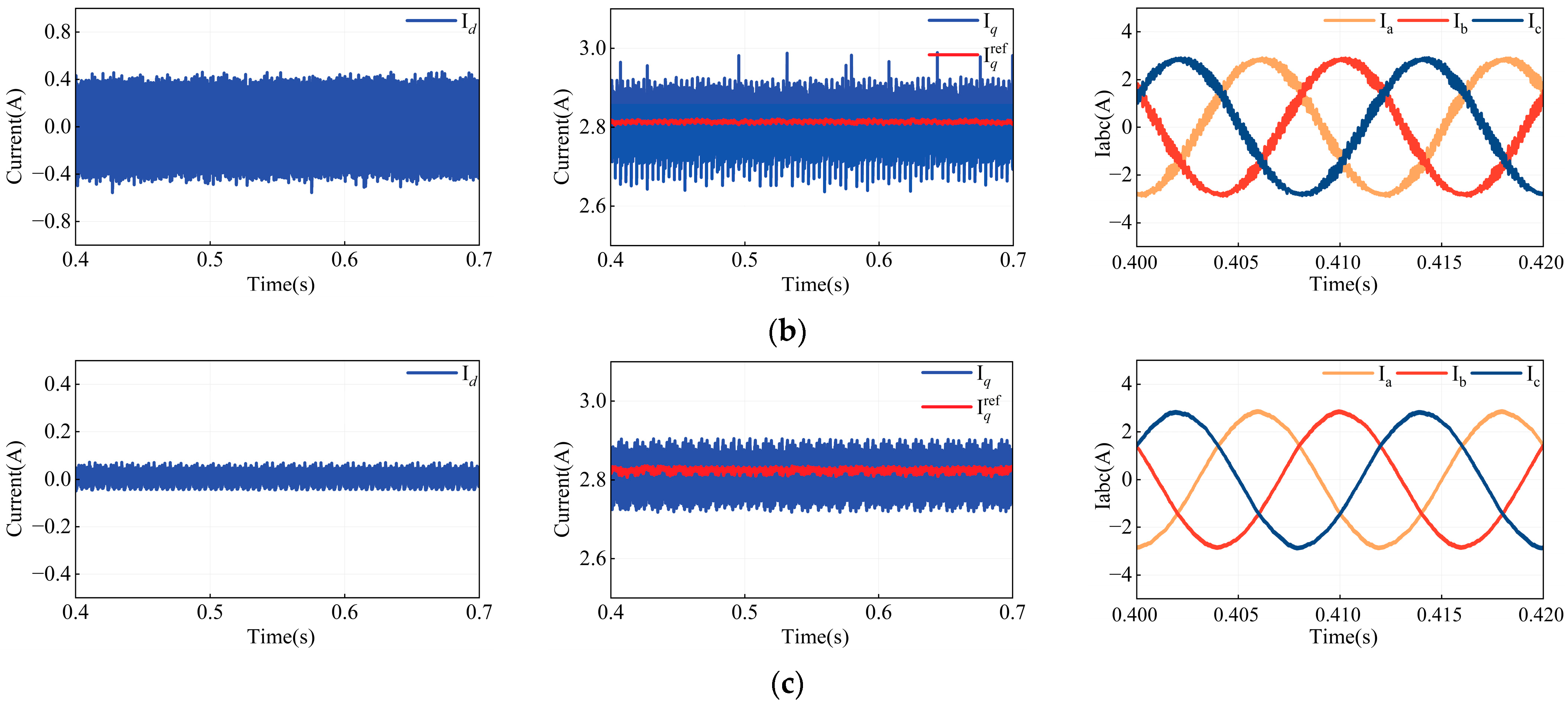

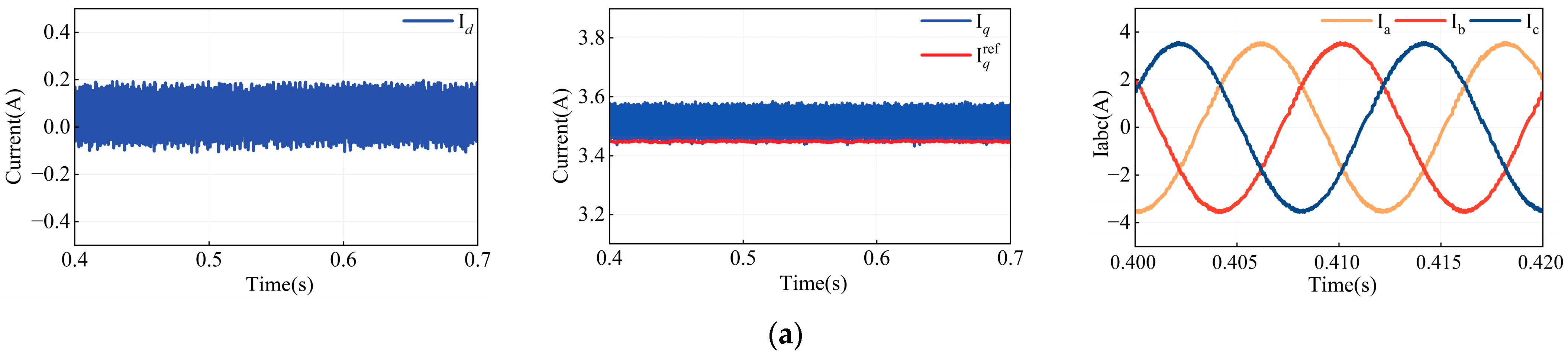

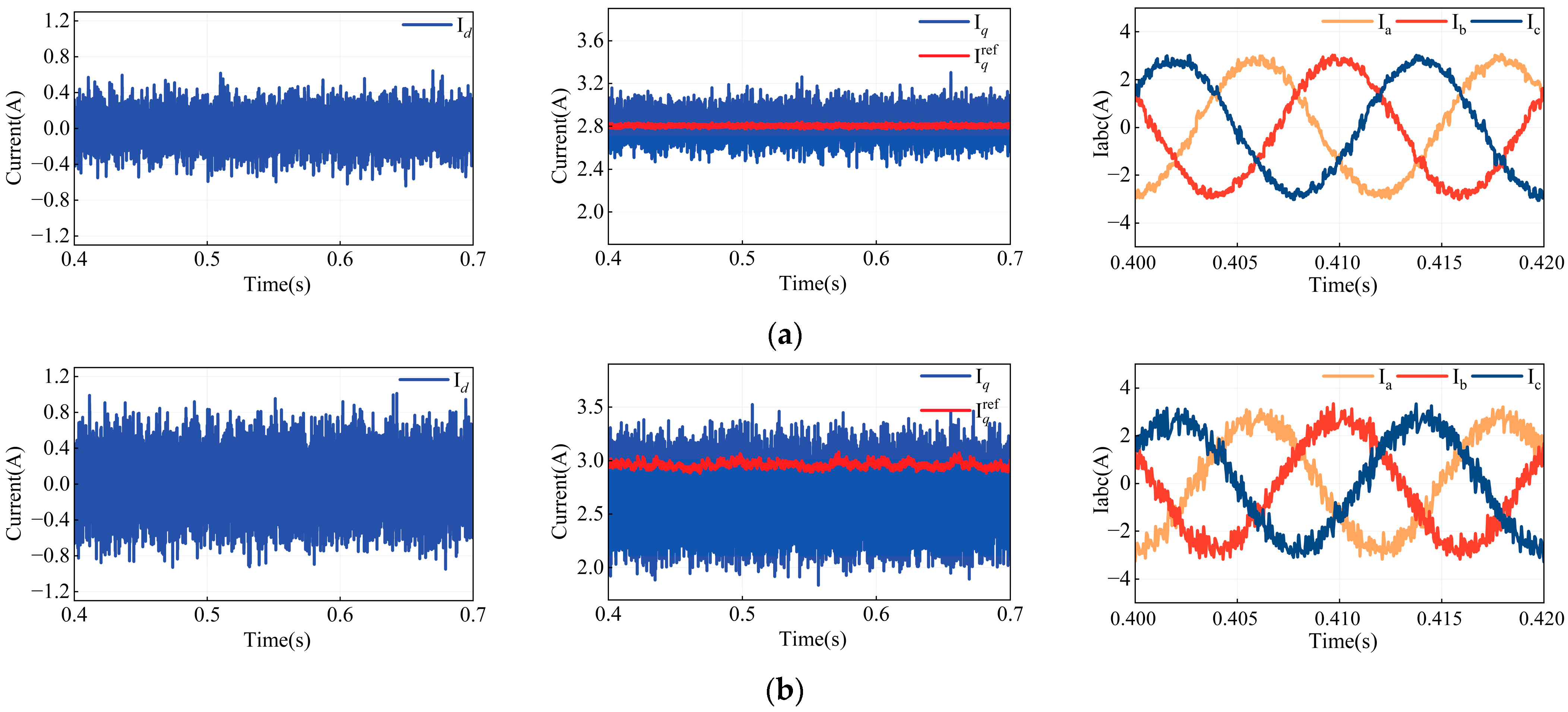

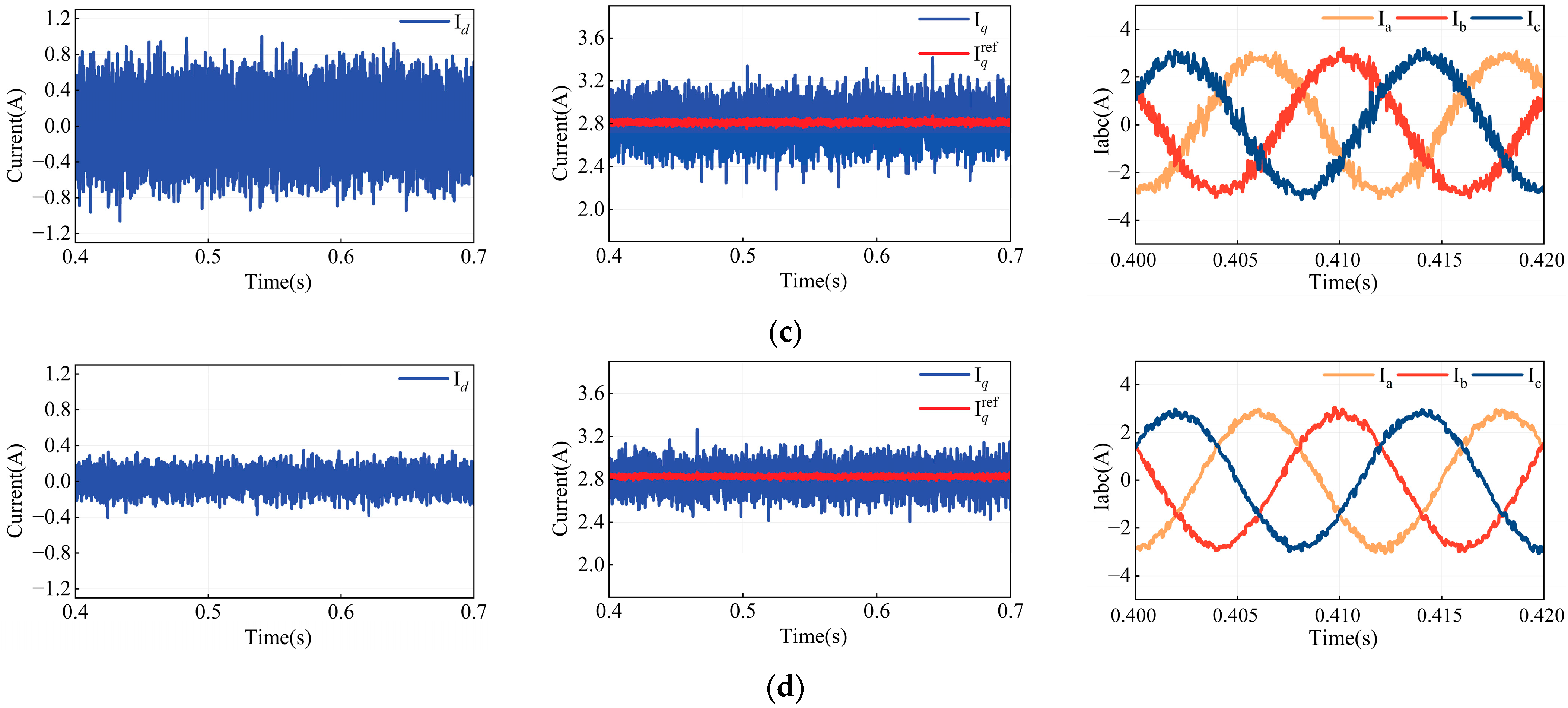

4.3. Analysis of Current Fluctuations Under Experimental Condition

Figure 17 presents the steady-state current fluctuations for MPCC (with accurately known motor parameters), MPCC (with model parameter

Ldq set to 50% of its original value), FCS-MFPCC, and the proposed MFPCC under a load torque of 2 N·m and a reference speed of 1000 r/min.

Table 7 summarizes the corresponding values of

Esd,

Esq, and THD. The results indicate that with accurate MPCC parameter settings, the

Idq are minimal, with

Esd = 0.1615 A,

Esq = 0.1087 A, and a low THD of 6.68%. However, when the model parameters are inaccurate,

Esd and

Esq increase by 67.8% and 132.4%, respectively, and THD rises by 6.09%, along with a significant deviation of the I

q from its reference.

Since both FCS-MFPCC and the proposed MFPCC are parameter-independent, they effectively prevent current deviation from the reference value. Nevertheless, the FCS-MFPCC method exhibits notable Id fluctuations, with Esd = 0.2717 A, Esq = 0.1370 A, and THD at 10.37%. In contrast, the proposed MFPCC demonstrates superior performance, achieving Esd = 0.0977 A, Esq = 0.1031 A, and a THD of only 5.08%. These results confirm that the proposed MFPCC accurately predicts system behavior without relying on model parameters, thereby ensuring robust system stability.

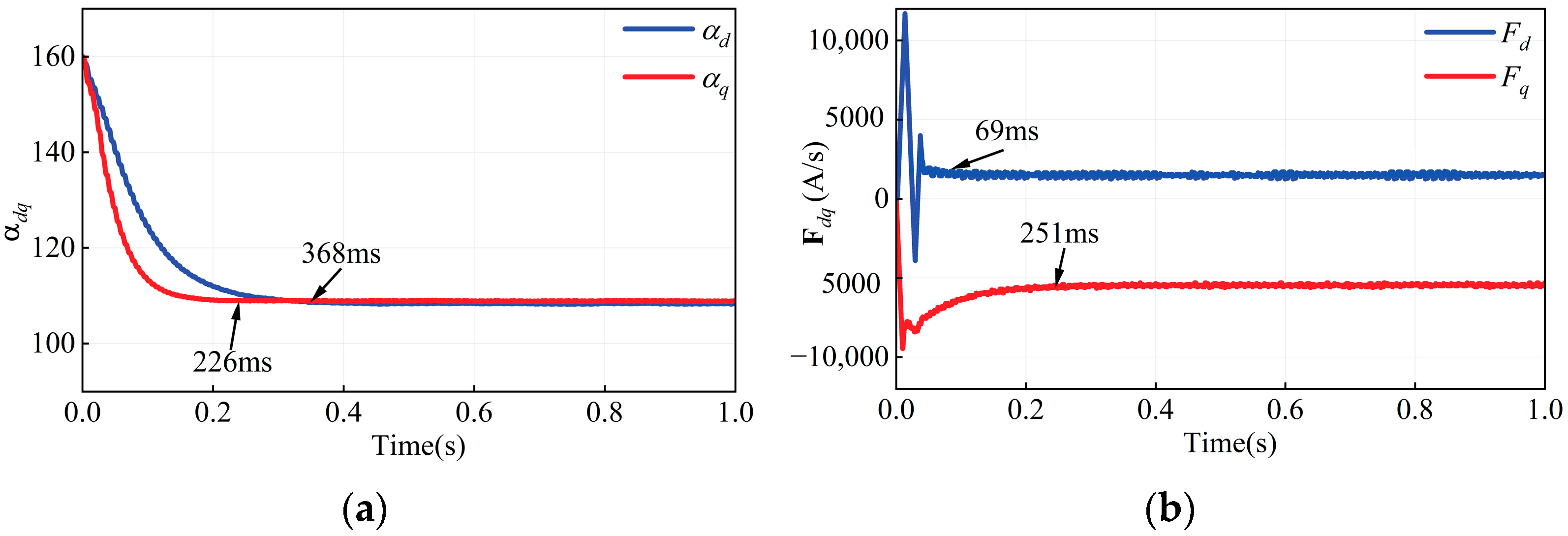

4.4. Robustness Assessment

Multiple experimental series were conducted under conditions of inductance parameter mismatch to further evaluate the robustness of the model under a load torque of 2 N·m and a reference speed of 1000 r/min. The integral of time and absolute error (ITAE) (30) [

31] are measured as shown in

Figure 18 to evaluate the response time and current tracking performance in the

dq-axis.

where

e(t) denotes the

d-axis (

q-axis) current tracking error. Experiments were conducted under a load torque of 2 N·m and a reference speed of 1000 r/min within 2s. Under inductance parameter mismatch, MPCC exhibits significant degradation in both current response and tracking performance along the

dq-axis. FCS-MFPCC, by contrast, shows pronounced sensitivity in the

d-axis current response and tracking, while the

q-axis current remains largely unaffected. The proposed MFPCC is inherently robust to such parameter mismatches, as it leverages KF to perform online estimation of the inductance and operates independently of fixed model parameters. This characteristic highlights the superior robustness of the proposed MFPCC in terms of current response and tracking under inductance uncertainty.