Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission

Abstract

1. Introduction

2. Materials and Methods

3. Results

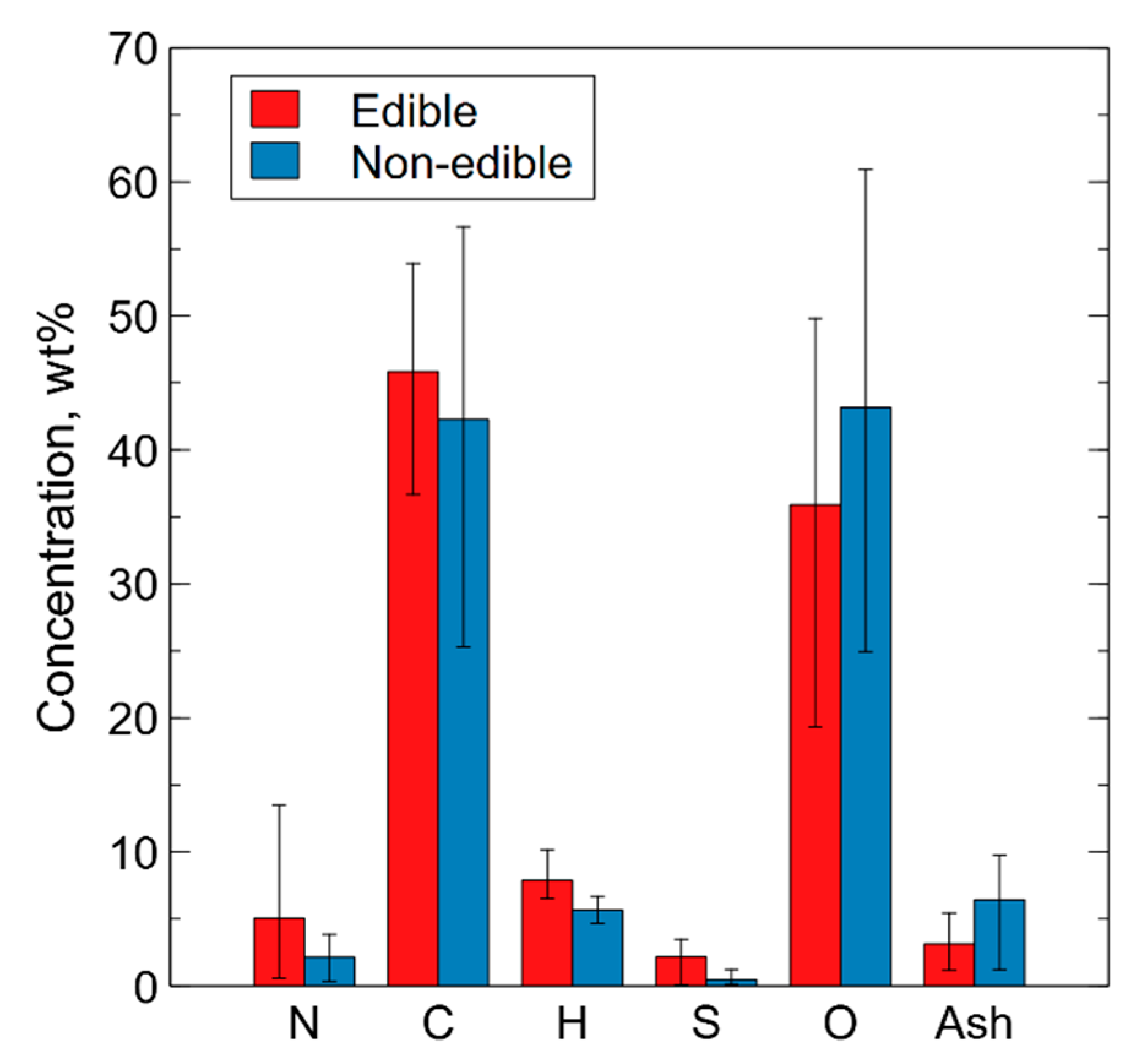

3.1. Pyrolysis Process

3.2. Negative Carbon Emission Scenario

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, S.; Lee, Y.; Lin, K.Y.A.; Hong, E.; Kwon, E.E.; Lee, J. The valorization of food waste via pyrolysis. J. Clean. Prod. 2020, 259, 120816. [Google Scholar] [CrossRef]

- Girotto, F.; Alibardi, L.; Cossu, R. Food waste generation and industrial uses: A review. Waste Manag. 2015, 45, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Pour, F.H.; Makkawi, Y.T. A review of post-consumption food waste management and its potentials for biofuel production. Energy Rep. 2021, 7, 7759–7784. [Google Scholar] [CrossRef]

- Food Waste Is Responsible for 6% of Global Greenhouse Gas Emissions—Our World in Data. Available online: https://ourworldindata.org/food-waste-emissions (accessed on 9 April 2023).

- UNEP Food Waste Index Report 2021|UNEP—UN Environment Programme. Available online: https://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 9 April 2023).

- Rakesh, B.; Mahendran, R. Upcycling of food waste and food loss—A sustainable approach in the food sector. Trends Food Sci. Technol. 2024, 143, 104274. [Google Scholar] [CrossRef]

- Trabold, T.A.; Nair, V. Conventional Food Waste Management Methods. In Sustainable Food Waste-to-Energy Systems; Academic Press: Cambridge, MA, USA, 2018; pp. 29–45. [Google Scholar] [CrossRef]

- Studies, Summary Tables, and Data Related to the Advancing Sustainable Materials Management Report|US EPA. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/studies-summary-tables-and-data-related (accessed on 25 December 2023).

- Luo, N.; Olsen, T.; Liu, Y.; Zhang, A. Reducing food loss and waste in supply chain operations. Transp. Res. E Logist. Transp. Rev. 2022, 162, 102730. [Google Scholar] [CrossRef]

- Fu, J.; Li, P.; Lin, Y.; Du, H.; Liu, H.; Zhu, W.; Ren, H. Fight for carbon neutrality with state-of-the-art negative carbon emission technologies. Eco-Environ. Health 2022, 1, 259–279. [Google Scholar] [CrossRef]

- Mazzotti, M. Status of Carbon Capture and Sequestration Projects Worldwide EuChemS—The Carbon Element. 2020. Available online: https://www.euchems.eu/wp-content/uploads/2021/04/Mazzotti_EuChemS_2021.pdf (accessed on 29 December 2024).

- Wang, S.; Wen, Y.; Shi, Z.; Zaini, I.N.; Jönsson, P.G.; Yang, W. Novel carbon-negative methane production via integrating anaerobic digestion and pyrolysis of organic fraction of municipal solid waste. Energy Convers. Manag. 2022, 252, 115042. [Google Scholar] [CrossRef]

- Elkhalifa, S.; Al-Ansari, T.; Mackey, H.R.; McKay, G. Food waste to biochars through pyrolysis: A review. Resour. Conserv. Recycl. 2019, 144, 310–320. [Google Scholar] [CrossRef]

- Grycová, B.; Koutník, I.; Pryszcz, A. Pyrolysis process for the treatment of food waste. Bioresour. Technol. 2016, 218, 1203–1207. [Google Scholar] [CrossRef]

- Opatokun, S.A.; Kan, T.; Al Shoaibi, A.; Srinivasakannan, C.; Strezov, V. Characterization of Food Waste and Its Digestate as Feedstock for Thermochemical Processing. Energy Fuels 2015, 30, 1589–1597. [Google Scholar] [CrossRef]

- Poudel, J.; Ohm, T.I.; Oh, S.C. A study on torrefaction of food waste. Fuel 2015, 140, 275–281. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619–620, 419–435. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Yuan, J.; Zhao, S.; Chang, H.; Li, R.; Lin, G.; Li, X. Is pyrolysis technology an advisable choice for municipal solid waste treatment from a low carbon perspective? Chem. Eng. J. 2022, 449, 137785. [Google Scholar] [CrossRef]

- Rasheed, T.; Anwar, M.T.; Ahmad, N.; Sher, F.; Khan, S.U.; Ahmad, A.; Khan, R.; Wazeer, I. Valorisation and emerging perspective of biomass based waste-to-energy technologies and their socio-environmental impact: A review. J. Environ. Manag. 2021, 287, 112257. [Google Scholar] [CrossRef] [PubMed]

- Jamaludin, H.; Elmaky, H.S.E.; Sulaiman, S. The future of food waste: Application of circular economy. Energy Nexus 2022, 7, 100098. [Google Scholar] [CrossRef]

- Goswami, M.; Pant, G.; Mansotra, D.K.; Sharma, S.; Joshi, P.C. Biochar: A Carbon Negative Technology for Combating Climate Change. In Energy, Environment, and Sustainability; Springer: Singapore, 2021; pp. 251–272. [Google Scholar] [CrossRef]

- Torres-Morales, E.; Khatiwada, D.; Xylia, M.; Johnson, F.X. Investigating biochar as a net-negative emissions strategy in Colombia: Potentials, costs, and barriers. Curr. Res. Environ. Sustain. 2023, 6, 100229. [Google Scholar] [CrossRef]

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable biochar to mitigate global climate change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef] [PubMed]

- Shrestha, R.K.; Jacinthe, P.A.; Lal, R.; Lorenz, K.; Singh, M.P.; Demyan, S.M.; Ren, W.; Lindsey, L.E. Biochar as a negative emission technology: A synthesis of field research on greenhouse gas emissions. J. Environ. Qual. 2023, 52, 769–798. [Google Scholar] [CrossRef]

- Li, S.; Tasnady, D. Biochar for Soil Carbon Sequestration: Current Knowledge, Mechanisms, and Future Perspectives. C 2023, 9, 67. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S.; Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef]

- Nagy, G.; Dobó, Z. Experimental investigation of fixed-bed pyrolysis and steam gasification of food waste blended with woody biomass. Biomass Bioenergy 2020, 139, 105580. [Google Scholar] [CrossRef]

- Yasmin, N.; Jamuda, M.; Panda, A.K.; Samal, K.; Nayak, J.K. Emission of greenhouse gases (GHGs) during composting and vermicomposting: Measurement, mitigation, and perspectives. Energy Nexus 2022, 7, 100092. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, T.; Sun, Y.; Huang, Y.; He, Y.; Huang, C.; Li, F.; Xue, C.; Sun, X. How does load-side re-electrification help carbon neutrality in energy systems: Cost competitiveness analysis and life-cycle deduction. Renew. Sustain. Energy Rev. 2023, 187, 113745. [Google Scholar] [CrossRef]

- Wu, X.; Mao, Y.; Fan, H.; Sultan, S.; Yu, Y.; Zhang, Z. Investigation on the performance of EDA-based blended solvents for electrochemically mediated CO2 capture. Appl. Energy 2023, 349, 121656. [Google Scholar] [CrossRef]

| Base Material | Sample ID | Concentration on Dry Basis, wt% | Moisture, wt% | |||||

|---|---|---|---|---|---|---|---|---|

| Carbon | Hydrogen | Nitrogen | Sulfur | Oxygen | Ash | |||

| Roast pork and breaded chicken | RPBC | 54.84 | 7.49 | 11.56 | 0.77 | 22.14 | 3.20 | 55.25 |

| Rice and french fries | RFF | 49.86 | 6.93 | 1.78 | 1.06 | 38.50 | 1.87 | 49.47 |

| Rice and roast pork | RRP | 53.84 | 7.51 | 9.87 | 1.37 | 24.89 | 2.52 | 61.76 |

| Sample | Temp, °C | ηs-s, % | ηs-g, % | Char Yield, g/kgsample | Composition of the Dry Samples, wt% | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Carbon | Hydrogen | Nitrogen | Sulfur | Oxygen | Ash | |||||

| RPBC | 650 | 38.7 | 61.3 | 149 | 63.77 | 2.91 | 3.52 | <100 ppm | 17.28 | 12.52 |

| RPBC | 725 | 28.5 | 71.5 | 101 | 69.22 | 1.95 | 2.42 | <100 ppm | 1.85 | 24.56 |

| RPBC | 900 | 25.3 | 74.7 | 85 | 73.11 | 1.17 | 2.18 | <100 ppm | 1.87 | 21.67 |

| RFF | 650 | 58.1 | 41.9 | 212 | 69.01 | 5.19 | 1.41 | <100 ppm | 18.33 | 6.06 |

| RFF | 725 | 37.1 | 62.9 | 115 | 81.31 | 1.75 | 0.68 | <100 ppm | 7.63 | 8.64 |

| RFF | 900 | 29.3 | 70.7 | 87 | 84.79 | 1.88 | 0.54 | 0.48 | 4.99 | 7.32 |

| RRP | 650 | 44.8 | 55.2 | 152 | 60.66 | 1.98 | 5.44 | <100 ppm | 21.33 | 10.59 |

| RRP | 725 | 34.6 | 65.4 | 89 | 80.04 | 1.20 | 0.62 | <100 ppm | 3.02 | 15.12 |

| RRP | 900 | 31.5 | 68.5 | 80 | 81.10 | 1.09 | 0.50 | 0.68 | 2.49 | 13.13 |

| Period | Sample | Temp, °C | H2 | CO | CH4 | C2Hx | CO2 | H2S |

|---|---|---|---|---|---|---|---|---|

| Heat up | RPBC | 650 | 16.57 | 12.83 | 10.2 | 6.31 | 20.73 | 0.52 |

| RPBC | 725 | 11.19 | 10.81 | 10.97 | 7.5 | 25.58 | 0.58 | |

| RPBC | 900 | 32.06 | 20.26 | 6.34 | 5.49 | 17.89 | <0.01 | |

| RFF | 650 | 27.4 | 27.78 | 5.07 | 8.8 | 23.26 | 0.13 | |

| RFF | 725 | 17.36 | 27.53 | 10.26 | 7.55 | 31.38 | <0.01 | |

| RFF | 900 | 27.13 | 32.44 | 6.23 | 9.87 | 16.21 | 0.76 | |

| RRP | 650 | 16.34 | 26.27 | 10.28 | 8.6 | 34.09 | 0.57 | |

| RRP | 725 | 19.61 | 24.41 | 7.87 | 6.02 | 12.99 | 0.11 | |

| RRP | 900 | 24.51 | 12.21 | 11.71 | 10.73 | 16.28 | <0.01 | |

| Constant temperature | RPBC | 650 | 36.1 | 29.9 | 5.84 | 1.46 | 8.9 | <0.01 |

| RPBC | 725 | 39.3 | 37.7 | 4.32 | 1.08 | 5.6 | <0.01 | |

| RPBC | 900 | 48.2 | 38.1 | 1.92 | 0.48 | 3.7 | <0.01 | |

| RFF | 650 | 38.3 | 28.1 | 3.36 | 0.84 | 23.2 | <0.01 | |

| RFF | 725 | 42.9 | 40.2 | 2.32 | 0.58 | 10.9 | <0.01 | |

| RFF | 900 | 50.2 | 40.1 | 1.44 | 0.36 | 2.8 | <0.01 | |

| RRP | 650 | 41.4 | 23.3 | 4.24 | 1.06 | 10.1 | <0.01 | |

| RRP | 725 | 45.8 | 37.2 | 2.56 | 0.64 | 6.4 | <0.01 | |

| RRP | 900 | 47.1 | 37.1 | 1.68 | 0.42 | 3.1 | <0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobó, Z.; Kovács, H.; Nagy, G. Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. Energies 2025, 18, 144. https://doi.org/10.3390/en18010144

Dobó Z, Kovács H, Nagy G. Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. Energies. 2025; 18(1):144. https://doi.org/10.3390/en18010144

Chicago/Turabian StyleDobó, Zsolt, Helga Kovács, and Gábor Nagy. 2025. "Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission" Energies 18, no. 1: 144. https://doi.org/10.3390/en18010144

APA StyleDobó, Z., Kovács, H., & Nagy, G. (2025). Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. Energies, 18(1), 144. https://doi.org/10.3390/en18010144