1. Introduction

To achieve the ambitious goal of attaining net-zero greenhouse gas emissions, numerous nations have diligently honored their legal obligations. This objective demands the widespread adoption of diverse renewable energy technologies. Solar energy, owing to its abundant and sustainable nature, stands out as a promising solution. Through solar-integrated energy systems, solar radiation is converted into thermal energy, which is then used in a series and logically structured to increase efficiency [

1]. The concentrating solar power (CSP) technique efficiently converts solar energy into thermal energy, employing four of the most advanced technologies: a parabolic trough collector (PTC), a linear Fresnel reflector (LFR), a solar power tower (SPT), and a parabolic dish collector (PDC). The PDC is recommended for smaller generating capacities between 0.01 and 0.4 MW, whereas the PTC, LFR, and SPT are well suited for power generation capacities ranging from 10 to 200 MW [

2].

The most widely employed technology is the PTC, which is approximately 75% of the installed capacity of the CSP technology [

3]. Elfeky et al. conducted a comparative analysis between a photovoltaic power plant and a solar thermal system based on a PTC. Their findings reveal that the PTC-based CSP plant achieved an impressive capacity utilization factor of 48.7%. In contrast, the photovoltaic plant lagged behind, utilizing only 29.2% of its capacity. This discrepancy underscored the superior efficiency of the PTC-based CSP technology in harnessing solar energy [

4]. Ghozouani et al. presented the optimization results derived from the integration of a PTC within an industrial process. The findings underscored the viability and cost-effectiveness of employing a PTC in industrial heat processes as a sustainable alternative to fossil fuels. Each optimized PTC system yielded approximately 12.84 MWh annually, with an average cost of less than 0.022 USD/kWh [

5].

In Europe, waste incineration stands out as a widely embraced method for managing municipal solid waste (MSW), gaining increasing popularity in numerous other countries, including China [

6]. The EU Directive 2018/851 establishes aggressive goals for recycling and reuse readiness, which must be met by 2025 (55%), 2030 (60%), and 2035 (65%) [

7]. The EU27 produced about 231 million tons of MSW in 2020 [

8]. In Europe in 2021, landfills constituted approximately 23% of MSW disposal. Around 30% of MSW underwent material recovery processes, while 19% underwent biological treatment specifically for organic waste. Moreover, 26% of MSW was incinerated for energy recovery purposes. The remaining 2% was allocated to other disposal methods [

9]. Pan et al. conducted a thorough investigation into a waste-to-energy power plant employing an organic Rankine cycle. The outcomes revealed a noteworthy enhancement in energy efficiency, surging to an impressive 41.22%. Additionally, the study demonstrated a substantial reduction in the payback period, plummeting from 6 years to a mere 1.1 years. These findings underscore the promising viability and economic feasibility of the proposed waste-to-energy system, signaling its potential as a sustainable and efficient energy solution [

10]. Amulen et al. presented a case study in Kampala city based on a municipal solid waste power plant. Considered a USD 157 million capital expenditure with a project duration of 25 years, the project’s net present value came to USD 30 million, with a payback period of 6 years [

11].

The organic Rankine cycle (ORC) is the most effective and adaptable power cycle below 400 °C and is extensively utilized in the industry for low-temperature waste heat recovery [

12]. Wang et al. introduced a pioneering hybrid system that combines a PTC with a waste incineration power plant. Under optimization conditions, the levelized cost of energy for this innovative system was reported to be 23.96 EUR /MWh [

13]. In a parallel effort, Alirahmi et al. presented the design of a hybrid green energy system seamlessly integrated with an ORC. The exergy efficiency achieved by this system stands at an impressive 50.6%, while the total cost rate is reported as 322.8 USD/h [

14]. An innovative solar–geothermal system based on the ORC was introduced by Li et al. In this study, four locations in China were carefully selected as case studies. In comparison to conventional single solar energy power plants, the hybrid ORC system exhibited a remarkable improvement in thermal efficiency. The annual electricity generation witnessed a substantial increase of 25.34%, underscoring the system’s enhanced performance and potential for sustainable energy production [

15].

The inherent benefits of self-adaptation, self-learning, nonlinear mapping, and fault tolerance have propelled the artificial neural network (ANN) method to the forefront of design and performance enhancement in the realm of thermal energy engineering in recent years [

16]. Feng et al. developed an ORC model leveraging data from 950 experimental sets. The model was simulated using an ANN and subsequently validated for a comprehensive bi-objective optimization [

17]. Alirahmi et al. integrated an ANN with multi-objective optimization to reveal the optimal solution for the proposed system. Through the optimization process, the cost rate and output power were determined as 28.5 USD/GJ and 1368 kW, respectively [

18]. Palagi et al. meticulously crafted a compact ORC system, augmented by the utilization of an ANN for performance prediction. Remarkably, the prediction accuracy achieved within a 10 s timeframe exhibited an impressively low error rate, remaining below 5% [

19].

To address multi-objective optimization problems effectively, the non-dominated sorting genetic algorithm II (NSGA-II) stands out as a powerful decision space exploration engine grounded in the principles of genetic algorithms [

20]. NSGA-II stands out for its structured methodology, which aims to enhance the convergence rate iteratively while preserving population diversity. It achieves this through the integration of fast-non-dominated sorting, an intelligent maintenance strategy, and efficient crowding distance measurement [

21]. NSGA-II efficiently constructs a diverse and optimal Pareto frontier through the strategic incorporation of elitism. By combining elitism with a selective function, the algorithm generates a new population by blending parent and child populations via mutation operators. It subsequently identifies the most favorable solution by assessing the fitness, extent, and distribution of the responses [

22]. Ozahi and Tozlu conducted a comprehensive simulation of a real MSW power plant, employing the NSGA-II method for system performance optimization. The resulting exergy efficiency reached an impressive 24.15%, accompanied by an output power of 954.6 kW. Post NSGA-II optimization, the power output experienced a noteworthy increase of 3.62%, concurrently leading to a commendable reduction in the total cost rate by 1.47% (USD/h) [

23]. Alirahmi et al. conducted a case study in Dezful City, Iran, utilizing NSGA-II for optimization solutions. The exergy efficiency was 31.66%, accompanied by a cost rate of 21.9 USD/GJ. Additionally, the optimization calculation time was compared under conditions with and without an ANN. When employing an ANN, the optimization time was reduced to 5 min, while in the absence of an ANN, it was extended to 10 h [

24]. This article’s distinctiveness and novelty are highlighted by the following elements, which are mostly attributed to this approach:

The co-optimization of district heat and power generation is achieved through the synergistic application of an ANN and NSGA-II, aimed at minimizing optimization time while identifying the optimal operational conditions of the system.

The integration of waste incineration with solar thermal energy effectively addresses the challenge of energy intermittency, concurrently contributing to a reduction in carbon dioxide emissions.

To discern the influence of decision factors on the objective functions, a parametric research phase is conducted before the optimization process.

The ORC system attains its optimal design and operational parameters through the utilization of NSGA-II. This integration is pivotal for enhancing the system’s economic viability and maximizing its exergy efficiency.

The technique for order preference by similarity to ideal situation (TOPSIS) method is employed as a decision-making tool to determine the optimal configuration for the cogeneration system.

4. Conclusions

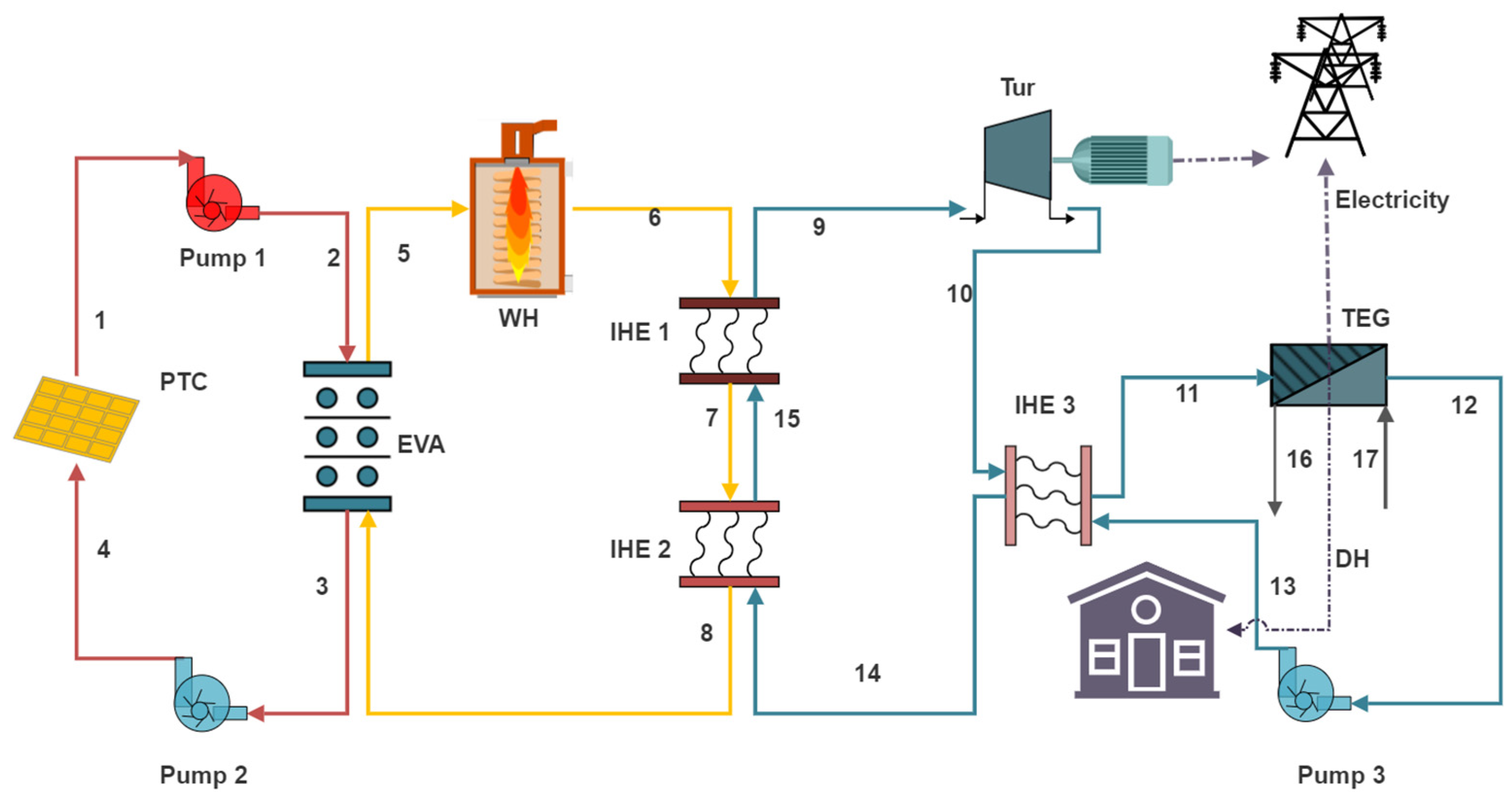

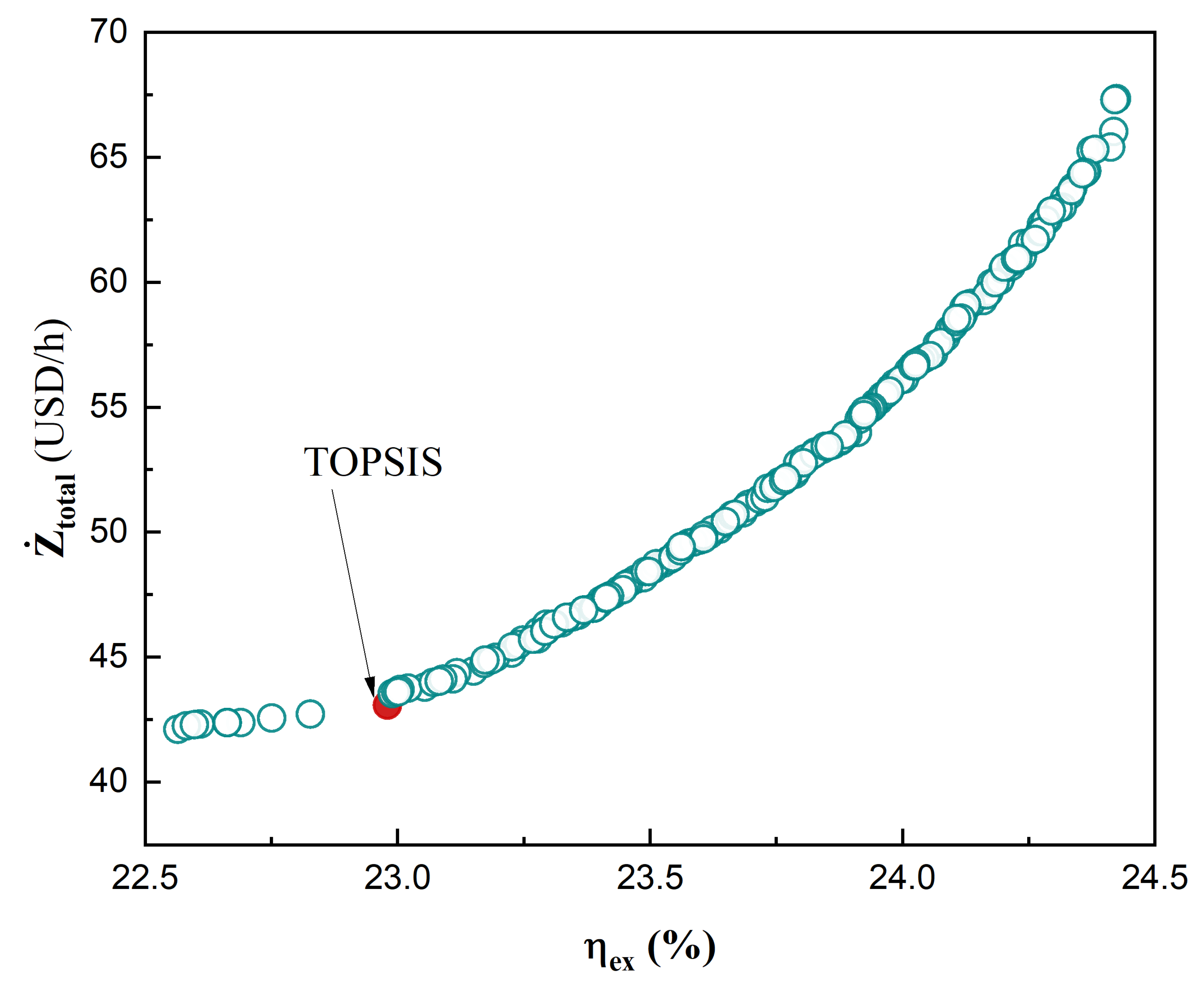

The primary focus of this investigation centered around designing a pioneering hybrid solar–waste power plant utilizing an ORC. The WI unit was integrated to solve the intermittent challenge of solar energy. The TEG was incorporated into the system, replacing the traditional condenser in the ORC, to enhance the cycle’s output power. The created models were optimized by combining NSGA II and ANN optimization techniques, and the Pareto optimal frontier was used to show the best results. In the set of optimization results, the TOPSIS decision-making method was employed to select the optimal solution for the system.

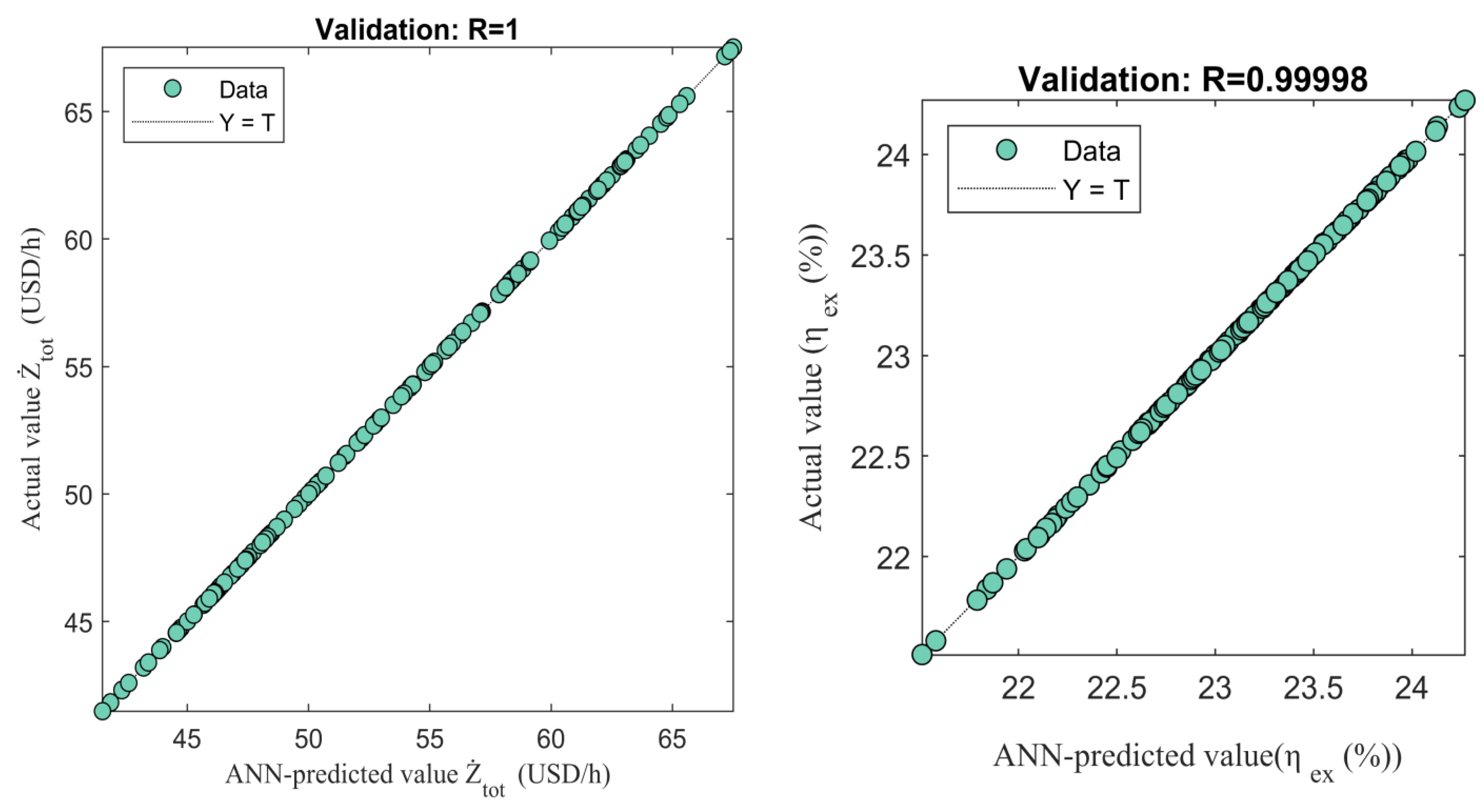

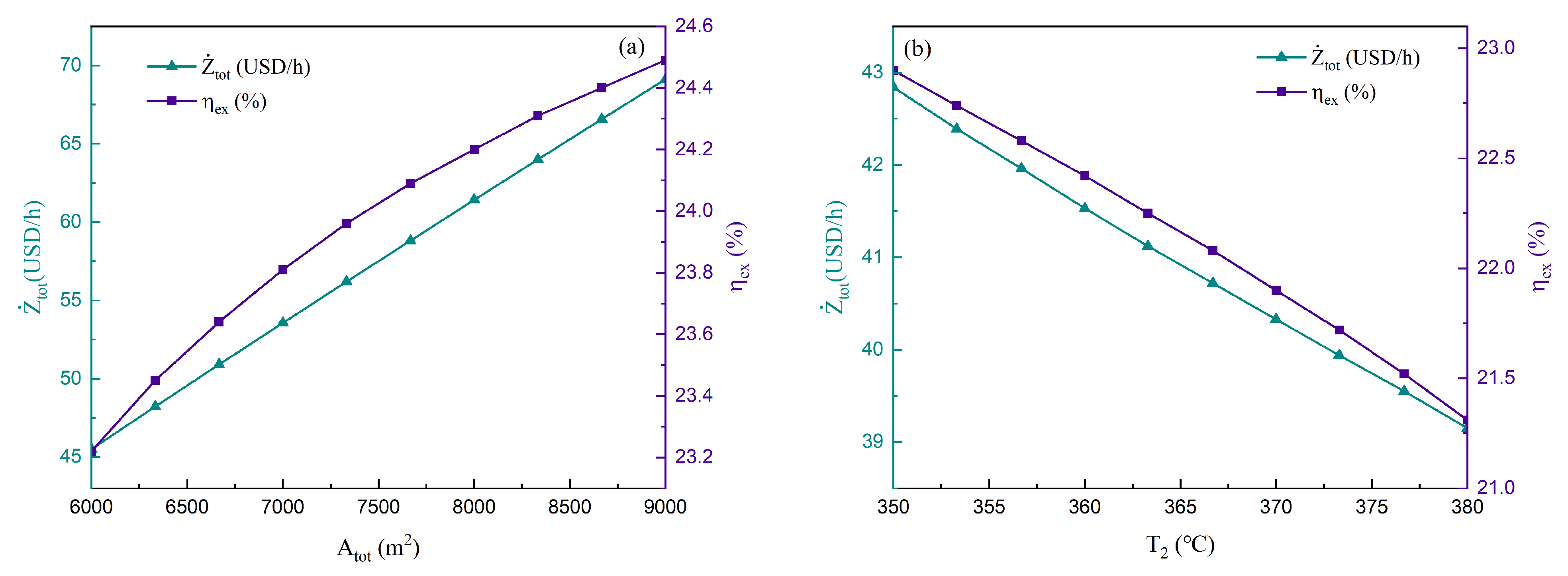

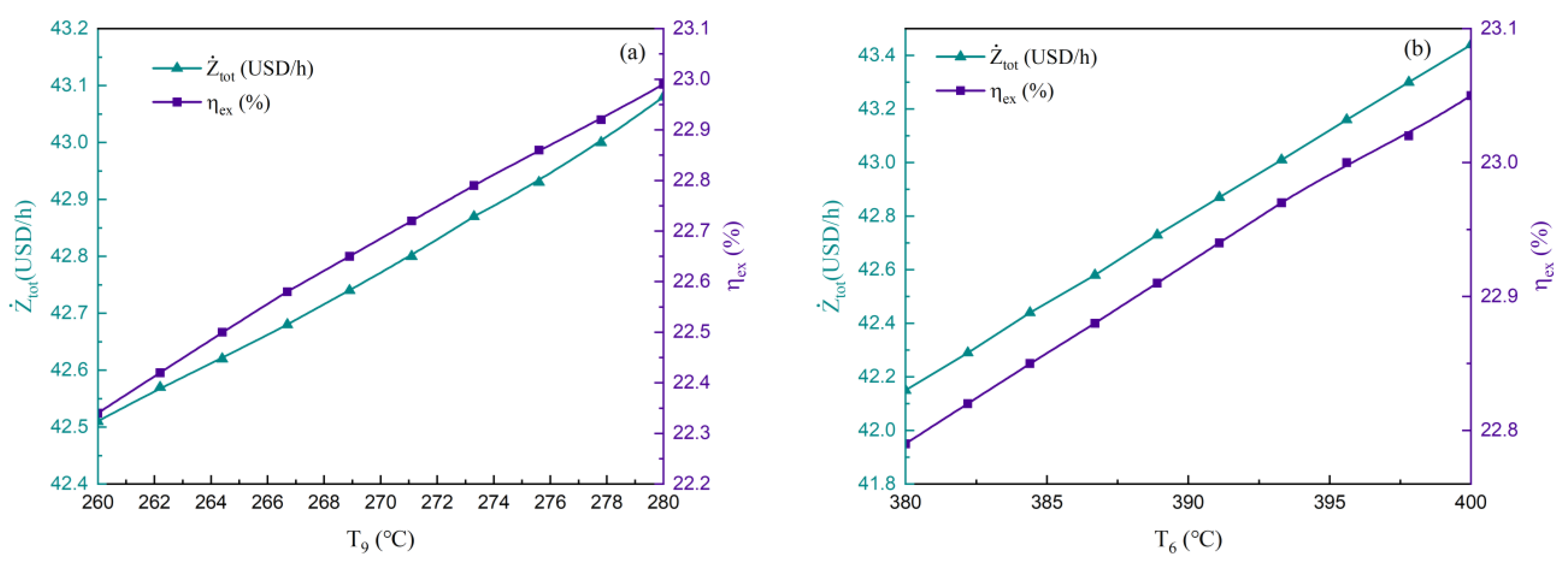

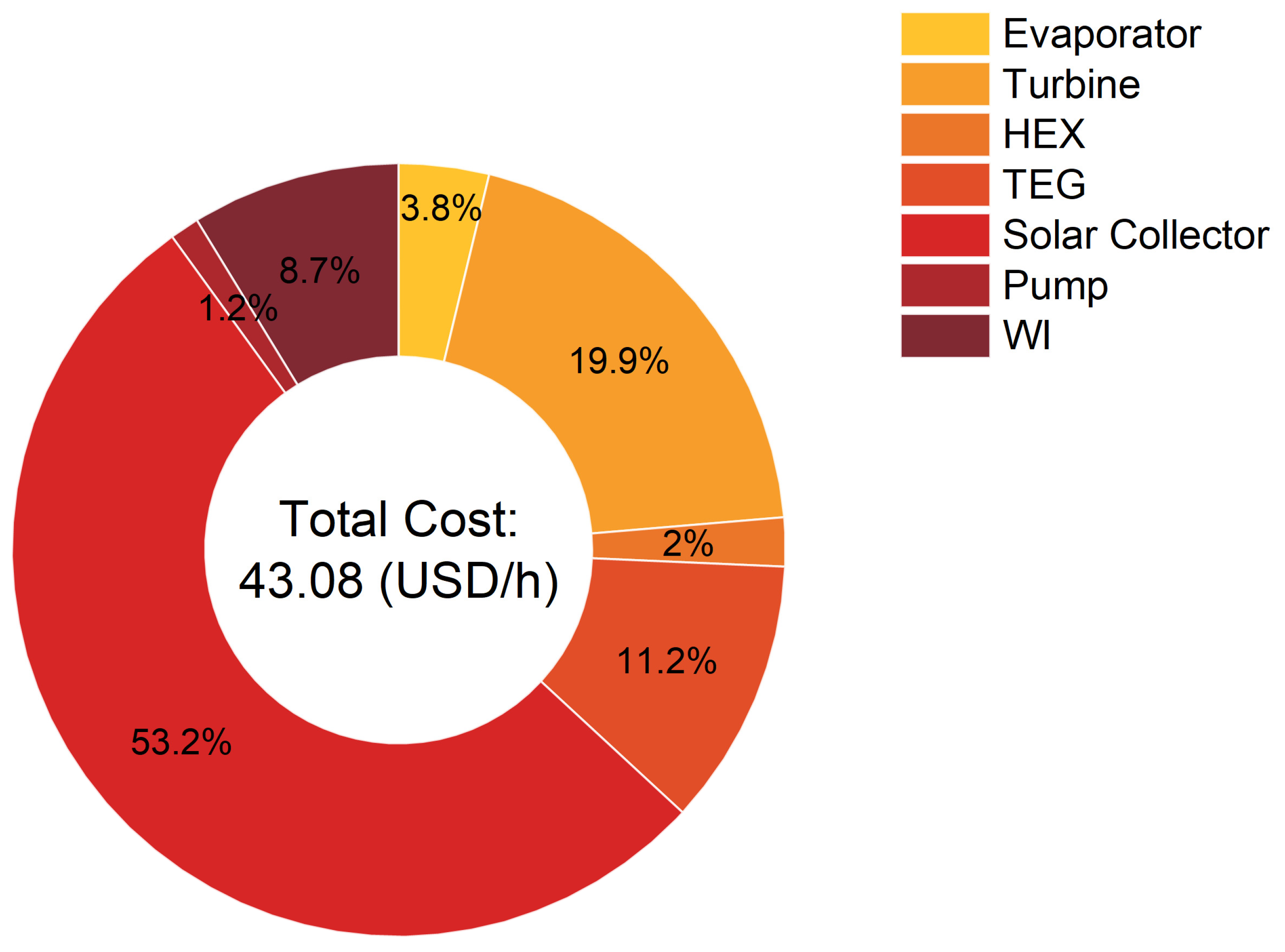

The parametric analysis reveals that four input parameters—the total area of the solar collector (), the output temperature of the PTC (), the inlet temperature of the turbine (), and the outlet temperature of the WI ()—significantly influence the performance of the system. The hourly cost of the initial investment () and the exergy efficiency () increase with the , , and , but decrease as the increases. The Pareto frontier also presents a set of optimal points that choose the and as optimization variables. TOPSIS identifies the best solution as the one with an hourly cost of the initial investment at USD 43.08/h and an exergy efficiency of 22.98%. Under this condition, the , , , and are 5705.82 m2, 348.27 °C, 279.83 °C, and 394.33 °C, respectively.

The economic analysis reveals that the solar collector constitutes the most significant portion of the total initial hourly cost, accounting for 53.2%, equivalent to USD 22.9/h. The ranking of the remaining components in terms of their contribution to the total initial hourly cost is as follows: turbine (19.9%), TEG (11.2%), WI (8.7%), evaporator (3.8%), HEX (2%), and pump (1.2%). Future work can focus on reducing the cost of the solar collector, for instance, by exploring alternative working fluids to enhance its efficiency.