Abstract

The utilization of gypsum mine goaf (GMG) for strategic oil reserves can realize the coordinated development of mining and oil storage. However, the variation in mechanical and permeability characteristics of gypsum rock under the action of crude oil erosion is not clear. At the same time, the deformation of gypsum rock caused by crude oil erosion will pose a threat to wellbore integrity. In this paper, a series of tests were carried out on gypsum rock before and after crude oil immersion to explore the effect of crude oil erosion on the mechanical and permeability characteristics of gypsum rock. The results show that crude oil soaking enhances the plastic deformation ability of gypsum rock. After soaking, the cohesion of gypsum rock increases by 14%, but the internal friction angle decreases by 7.2%. During the soaking process, crude oil invades the pores of gypsum rock, which can reduce the value of gypsum rock by 10−20 m2. Crude oil immersion enhances the deformation resistance of gypsum rock surrounding rock and significantly reduces the permeability, which is conducive to the stability and sealing of gypsum rock goaf during oil storage. The research results are helpful in deepening the understanding of using GMG technology to construct crude oil storage and provide inspiration for the study of the influence of gypsum rock deformation on wellbore integrity under crude oil erosion.

1. Introduction

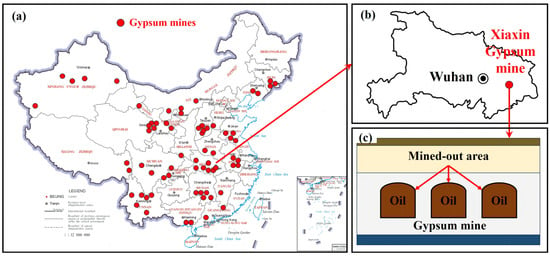

China is rich in gypsum mineral resources. By the end of 2017, 23 provinces or autonomous regions in China had gypsum mine output (Figure 1a). There are 169 mining areas with proven reserves, with total reserves of 98.5 billion tons [1]. The gypsum mine has a shallow buried depth and high backfilling cost. If gypsum mine goaf (GMG) is not effectively utilized and maintained, it may cause geological disasters such as land subsidence and surface subsidence. Making full use of the GMG and reducing the risk of geological disasters are key problems that need to be solved urgently in mining engineering.

Figure 1.

Xiaxin gypsum mine location and Oil storage diagram of GMG: (a) Xiaxin gypsum mine location in China; (b) Xiaxin gypsum mine location in Hubei Province; (c) the oil storage diagram of GMG.

It is an effective way to prevent large-scale geological disasters in GMG by using GMG for the oil strategic reserve (Figure 1c). Gypsum rock has the characteristics of low permeability and small porosity, which is a good sealing layer for many large oil and gas reservoirs [2]. For example, many super-large oil and gas fields in the world, such as the Gulf of Mexico, the Persian Gulf, and the Caspian Sea, are formed under gypsum layers [3,4,5,6]. At present, the deterioration mechanism of gypsum rock mechanics and permeability characteristics under crude oil immersion is not clear, and the stability and sealing of GMG under oil storage conditions are difficult to evaluate. Xiaxin gypsum mine has formed a number of gypsum mine goaves after mining, so it is necessary to find a way to reuse gypsum mine goaf. The Xiaxin gypsum mine is now studying the use of gypsum mine goaf for oil storage. Therefore, this paper takes the Xiaxin gypsum mine in Huangmei County, Hubei Province, as an example to study the variation law of mechanical properties and permeability characteristics of gypsum mine surrounding rock under the condition of crude oil immersion, which lays a theoretical foundation for the reconstruction of oil storage in GMG.

Obtaining the mechanical properties of gypsum rock under various conditions is the prerequisite for evaluating the stability of GMG. Through a series of laboratory tests, the uniaxial compressive strength, elastic modulus, Poisson’s ratio, and stress–strain curve characteristics of gypsum rock are analyzed [7,8,9,10]. The results show that the mechanical properties of gypsum rock are significantly different due to the gypsum rock’s heterogeneity. The strength of gypsum rock is also related to factors such as water content and impurity content. Liu et al. [11] carried out mechanical tests on gypsum mudstone with different gypsum volume fractions. They found that the higher the volume fraction of anhydrite, the greater its compressive strength. The higher the water content, the greater the instantaneous and long-term creep deformation rate of gypsum rock; additionally, the water content has a significant effect on the long-term deformation of gypsum rock [12,13]. Auvray et al. [14] found that relative humidity is the main factor affecting the volume shrinkage of the gypsum mines by analyzing the stability of the Grozon gypsum mine in France. In order to further explore the erosion effect of water and other fluids on gypsum rock, the mechanical test of gypsum rock under water immersion conditions has been widely carried out [15,16,17]. The results show that the soaking effect of water not only significantly reduces the compressive strength and elastic modulus of gypsum rock but also changes the failure mode of gypsum rock, which has a negative impact on the stability of GMG. Wang et al. believed that the oil storage in GMG has good stability and tightness [18,19,20,21,22]. However, in the process of oil storage in the GMG, the deterioration of the mechanical strength of gypsum rock under the condition of crude oil immersion may lead to the instability of the goaf. In order to explore the change law of mechanical properties of gypsum rock during oil storage, the mechanical properties test of oil-immersed gypsum rock under different confining pressures was carried out [23,24,25]. The change rate of uniaxial compressive strength of gypsum rock under different oil immersion days is −10%~+33%. Mao found that the triaxial compressive strength of gypsum rock decreased by 26.4% after oil immersion. The above research describes the deterioration law of mechanical properties of gypsum rock under the action of crude oil erosion, but it still has the following shortcomings: (1) The erosion rate of crude oil to gypsum rock may change under the influence of temperature and pressure, but at present, no detailed research has been conducted. (2) The operation time of oil storage is very long, and the influence of long-term erosion on gypsum rock has not been studied. (3) Under high pressure, the infiltration of crude oil may change the permeability characteristics of gypsum rock, and no scholars have conducted in-depth research on this.

Therefore, the main purpose of this paper is to study the mechanics and permeability characteristics of gypsum rock under oil storage conditions. Firstly, the core of the Xiaxin gypsum mine in Huangmei County, Hubei Province, China, was obtained, and the gypsum rock immersion test scheme was formulated. Secondly, a series of rock mechanics tests of gypsum rock before and after crude oil immersion were carried out, and the influence of crude oil immersion on the mechanical properties of gypsum rock was analyzed. Third, the permeability and pore distribution characteristics of gypsum rock before and after crude oil immersion were analyzed. The research results can provide a theoretical basis for the use of GMG for crude oil reserves.

2. Preparation of Samples and Tests

2.1. Sample Preparation

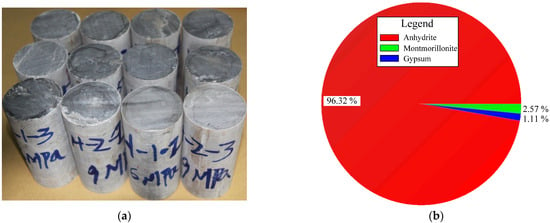

Gypsum samples were taken from the Xiaxin gypsum mine (Figure 1b) in Huangmei County, Hubei Province, with sampling depths of 395.21–399.72 m and 404.36–409.48 m. Using the water-based grinding method, multiple sets of samples with a diameter of 50 mm and height of 100/25 mm were prepared for testing; some samples are shown in Figure 2. The prepared samples are the same batch of samples taken from the same place at the same time, and it is found that there is a high similarity among the samples. Therefore, the gypsum rock samples were randomly divided into an oil-soaked group and a non-soaked group to ensure that the two groups of samples could represent the surrounding rock of the gypsum rock goaf. A total of 59 samples were prepared: 32 soaked samples, including 27 samples with a height of 100 mm and 5 samples with a height of 25 mm, and 27 samples without crude oil soaking, including 22 samples with a height of 100 mm and 5 samples with a height of 25 mm. With the exception of the Brazilian splitting test, which required samples with a height of 25 mm, the other tests used samples with a height of 100 mm. The uniaxial compression test uses 4 samples without crude oil soaking and 4 after soaking, the triaxial compression test uses 15 samples without crude oil soaking and 15 after soaking, the Brazilian splitting test uses 5 samples without crude oil soaking and 5 samples after soaking, and the penetration test uses 3 samples without crude oil soaking and 3 samples after soaking. The size of the prepared samples was measured, and it was found that the diameter of the prepared sample was between 49.83 mm and 50.34 mm, with an error between −0.34% and 0.68%, and the height of the sample required for the Brazilian splitting test was between 24.91 mm and 25.08 mm, with an error between −0.36% and 0.32%. The height of the samples required for other tests is between 99.76 mm and 100.12 mm, and the error is between −0.24% and 0.12%, and it is found that the size difference between the prepared samples is slight. All samples meet the requirements of the rock mechanics test [26]. The composition and content of gypsum rock samples were quantitatively analyzed by X-ray diffractometer. The X-ray diffractometer uses a closed X-ray tube, the maximum tube current is 80 mA, the minimum step angle is 0.0001, the angle reproducibility is 0.0001, and the test temperature range is room temperature ~1600 °C. The sample can be placed on the carbon fiber translation axis, and the three-dimensional full-diameter scanning can be realized by rotating the ray source and moving the translation axis. The results are shown in Figure 2b. Anhydrite is the main component of the sample, with an average content of 96.32%. Montmorillonite and gypsum are secondary components, with an average content of 2.57% and 1.11%

Figure 2.

Gypsum samples and X-ray diffraction results: (a) gypsum samples; (b) the result of X-ray diffraction.

2.2. Crude Oil Soaking

The standard gypsum rock samples were soaked by high-temperature and high-pressure crude oil erosion experimental devices (Figure 3a). The maximum working pressure of the device is 50 MPa, the control accuracy is ±1%, the working temperature is from room temperature to 110 °C, and the control accuracy is ±1 °C. During the test, the gypsum rock sample was placed in the device, and the pressure and temperature were set to soak the crude oil at high temperature and high pressure. The target layer depth of the Xiaxin gypsum mine is about 400 m, and the formation temperature is about 32 °C. The density of crude oil is about 900 kg/m3, and the pressure of the oil storage is about 3.6 MPa. Therefore, the temperature and pressure of the gypsum rock sample during immersion are set at 32 °C and 3.6 MPa. The crude oil used in the test was taken from Jianghan Oilfield, which has poor fluidity, high density, and a lot of solid precipitates at room temperature. In order to make the crude oil better intrude into the gypsum samples, the crude oil was diluted. The gypsum sample is placed in the autoclave of the high-temperature and high-pressure crude oil erosion experimental device. The cumulative immersion of crude oil erosion was about 2000 h.

Figure 3.

Main instruments and equipment of the experiment: (a) high-temperature and high-pressure crude oil erosion test equipment; (b) MTS rock mechanics test system; (c) RMT150C rock mechanics test; (d) rock permeability test platform under multi-field coupling conditions; (e) magnetic resonance imaging systems.

2.3. Rock Mechanics Testing

In order to systematically study the changes in mechanical properties of gypsum rock during oil storage, the uniaxial compression, triaxial compression, and Brazilian splitting tests were carried out. Uniaxial and triaxial compression tests were carried out on the MTS rock mechanics test system (Figure 3b). The system can apply a maximum axial load of 4600 kN and a confining pressure of 140 MPa, and its frame stiffness is 11 GN/m. During the test, the sample was wrapped in a heat-shrinkable sleeve, the strain monitor was installed and placed in the confining pressure chamber, the confining pressure was set, the loading mode was selected, the stress loading was carried out, and the stress–strain curve was drawn. The Brazilian splitting test was carried out in the RMT150C rock mechanics test system (Figure 3c). The maximum vertical output is 1000 kN, the maximum horizontal output is 500.0 kN, and the maximum confining pressure that could be applied is 50.0 MPa. During the test, the sample was wrapped in a heat-shrinkable sleeve, and the axial and radial strain monitors were installed and placed in the confining pressure chamber. The loading mode was set, the stress was loaded, and the stress–strain curve was drawn. The number of tests in each group is not less than 3. The original in situ stress value of the sampling layer is about 12 MPa. The confining pressure in triaxial compression is taken as 6 MPa, 9 MPa, and 12 MPa, respectively.

2.4. Permeability Test

The permeability tests of gypsum rock were carried out before and after crude oil soaking. The test device is the experimental platform for the rock permeability test under multi-field coupling conditions (Figure 3d). The sampling rate is 100 MHz, the resolution is 16-bit, the positioning accuracy is less than 1 mm, the wavelength range is 1510~1590 nm, and the speed interval is 40 ns. Considering the low permeability of gypsum rock, the unsteady-state method is used to test the permeability. The test permeability medium is nitrogen (N2), the confining pressure is 4 MPa, the temperature is 32 °C, and the gas pressure is 6 MPa.

The corresponding permeability can be calculated as:

where k is the permeability, m2; A is the cross-sectional area of the sample, m2; L is the length of the sample, m; μ is the dynamic viscosity of the test gas, Pa·s, where pp is the initial pulse pressure, Pa; ∆p is the pressure difference between upstream and downstream; Vup and Vdown are the volume of upstream and downstream pressure chambers, respectively, m3; δ is the gas compressive coefficient; t is the test time, s.

2.5. Pore Distribution Test

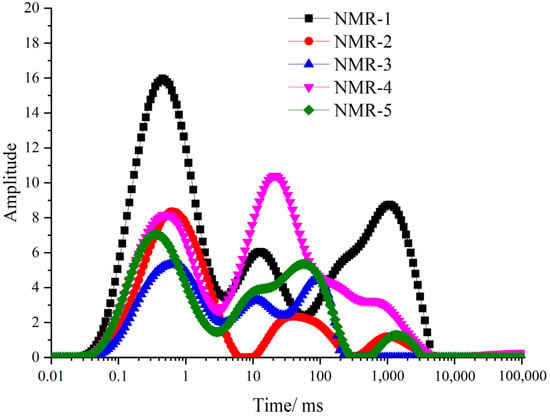

In order to evaluate the degree of crude oil erosion in gypsum samples, nuclear magnetic resonance (NMR) experiments were carried out on five gypsum samples soaked in crude oil. The instrument is the Macro MR12 NMR imaging system (Figure 3e). The magnetic field intensity is 0.3 ± 0.05 T, the main frequency is 12.8 MHz, and the probe coil diameter is 150 mm, which can effectively detect samples with a diameter of 150 mm. The sample is placed in the probe coil, the imaging parameters are set, and the imaging is run. The selected samples are randomly selected from the same batch of samples. Because the prepared samples are from the same area, after observation, it is considered that the similarity of each sample is high, and there is no significant difference. Therefore, the test results are considered to be repetitive and reliable. The principle of nuclear magnetic resonance is to use the hydrogen ions in crude oil under the action of the magnetic field to generate signals by collision on the pore wall surface. By capturing these signals, the porosity of the sample is measured. The sample is fully dried before the test, so there is no interference of free water. If the crude oil does not invade the micro cracks of the sample, the data cannot be measured. It can be seen from Figure 4 that the NMR T2 distribution of the samples is relatively clear and complete, and the regularity of the distribution is basically the same, indicating that the crude oil has intruded into the interior of the gypsum sample and filled tiny cracks in it. Meanwhile, the T2 zoning amplitude of the gypsum samples is small, generally about a dozen. According to the existing experimental results [27], the amplitude of granite with a porosity of about 2% is generally 300–400. This indicates that the porosity of the Xiaxin gypsum mine is very small, which is conducive to maintaining the airtight nature of crude oil storage. The results in Figure 4 also show that the proportions of the sum of the first and the second peak areas in the total area of different samples differ greatly. This indicates that the distribution uniformity of fractures in gypsum samples is poor, which may lead to great differences in rock mechanical parameters between different gypsum samples.

Figure 4.

Results of NMR T2 zoning experiment of the five gypsum samples.

3. Results and Discussion

3.1. Uniaxial Compression Test

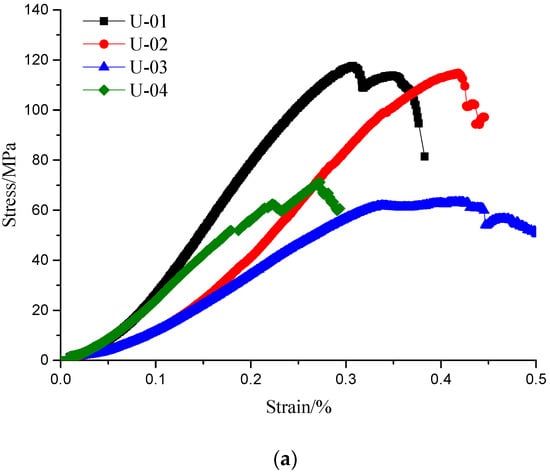

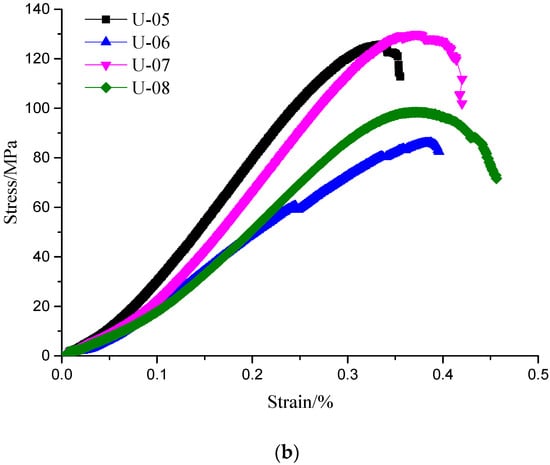

It can be seen from Figure 5 that the gypsum shows strong brittle failure characteristics during the uniaxial failure process. According to the experimental results, the stress–strain curve can be divided into the following four stages under uniaxial experimental conditions: (1) compaction stage, (2) elastic deformation stage, (3) unstable failure stage, and (4) post-peak stage.

Figure 5.

Axial stress–strain curve of gypsum samples: (a) original samples; (b) oil-soaked samples.

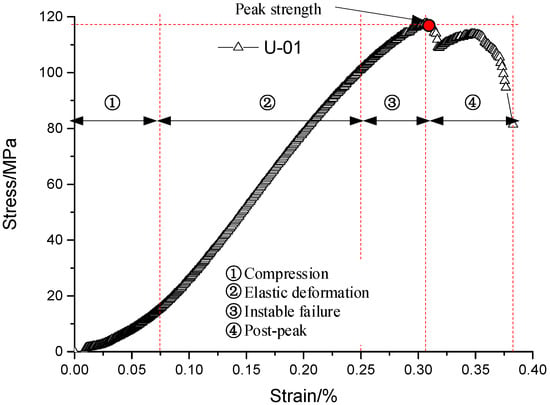

In order to explain these four stages and their characteristics more clearly, this section takes U-01 as an example to analyze the axial stress–strain curve of gypsum rock (Figure 6).

Figure 6.

Axial stress–strain curve of U-01 sample.

Compaction stage: The slope of the stress–strain curve is small in the initial loading stage. Through the observation of the calculation results of samples, it can be found that the compaction stage occurs before the strain reaches 0.1%. By comparing the experimental results of soaked and unsoaked samples, it can be seen that the strain in the compaction stage of the soaked sample tends to be greater than the strain in the compaction stage of the sample without soaking. This is mainly because the cracks and micro-cracks in the soaked samples are filled with crude oil, which has partial bearing capacity when the sample is subjected to the external load, which slows down the closing speed of the cracks and micro-cracks. This indicates that the gypsum samples have been soaked sufficiently, and the oil has filled cracks and micro-cracks inside the samples.

Linear elastic stage: After the compaction stage, the stress–strain curve enters the linear elastic stage. The linear elastic stage of the gypsum sample is relatively short. The linear elastic strain of gypsum failure is 0.25%, which means the brittleness of gypsum is very weak. However, in the linear elastic stage of common brittle rock, such as granite, the linear elastic stage of granite can reach about 0.4%, which is significantly longer than that of the gypsum sample [26].

Plastic deformation stage: When the load increases to a certain value, it enters the unstable stage of asymptotic failure. Comparing the experimental results in Figure 5, it can be found that the duration of the plastic deformation stage of the crude oil-soaked samples is longer than that of the original samples. This may be because the crude oil in the pores and micro-cracks of the gypsum sample after soaking makes the surrounding rock around the pores and cracks bear more uniform stress, which improves the ductile deformation ability of the sample.

Post-peak stage: When the stress reaches the peak strength, the cracks develop gradually and form a macroscopic fracture surface until the sample loses its bearing capacity. By comparing the experimental results in Figure 5, it can be seen that the post-peak strength and post-peak duration of gypsum samples soaked with crude oil are significantly higher than those without soaking, showing typical ductile failure characteristics. This shows that crude oil immersion has an obvious effect on improving the post-peak strength and ductile deformation capacity of gypsum, which is beneficial to improving the stability of a GMG used for oil storage.

According to the above experimental results, the peak stress and elastic modulus of the gypsum sample without oil immersion and after oil immersion can be calculated. The average peak stress and average uniaxial compressive strength of unsoaked gypsum samples were 91.73 MPa and 30.59 GPa, respectively. In comparison, those of crude oil-soaked gypsum samples were 110.09 MPa and 41.14 GPa. After crude oil immersion, the uniaxial compressive strength and elastic modulus of gypsum rock increase by 20% and 34.49%, respectively. From the above experimental results, it can be seen that the uniaxial compressive strength of gypsum can be improved after crude oil soaking, which is conducive to the stability of GMG where crude oil is stored.

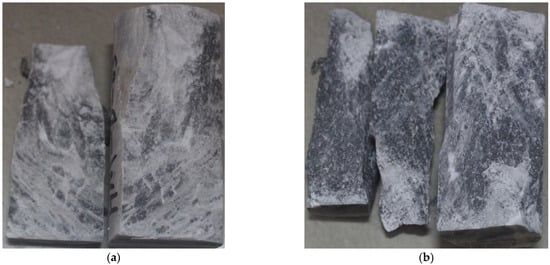

Figure 7 shows the photos of failure surfaces after uniaxial failure of crude oil-soaked and unsoaked gypsum samples. The sample numbers are U-01 and U-05, respectively. According to the comparison between Figure 7a,b, the main failure surface appears first in the gypsum samples without crude oil immersion and then slides along the main failure surface, finally resulting in the loss of bearing capacity of the whole sample. Therefore, there is a lot of gypsum powder generated by sliding friction on the failure surface. The bearing capacity of the samples after crude oil immersion is high, and the cracking occurs quickly after reaching the peak strength. Then, the slabs formed by cracking are unstable, so there is only a small amount of gypsum powder on the failure surface. This is consistent with the experimental results in Figure 6.

Figure 7.

Uniaxial failure surfaces of samples without and with oil soaking: (a) samples without crude oil soaking; (b) samples with crude oil soaking.

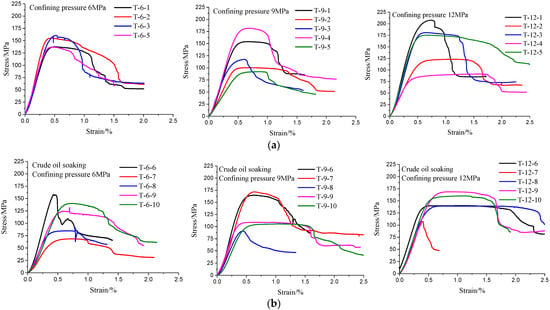

3.2. Triaxial Compression Tests

From Figure 8, with the increase in confining pressure, the brittleness characteristics of gypsum gradually weakened, the ductility gradually increased, and the strain softening phenomenon gradually weakened. The stress–strain curve can still be roughly divided into the following four stages.

Figure 8.

Axial stress–strain curves of gypsum samples under different confining pressures without and with crude oil soaking: (a) samples without crude oil soaking; (b) samples with crude oil soaking.

Compaction stage: The compressive strain of the gypsum sample during the triaxial compression test is 0~0.1%, and that during the uniaxial compression test is 0~0.075%. The stress in the triaxial compression test compaction stage can reach about 14.73 MPa, and that in the uniaxial compression test is about 14.38 MPa. It was found that the stress–strain curve of the triaxial compression test sample only increased by 0.025% and 0.35 MPa compared with that of the uniaxial compression test sample. The duration of the compaction stage of soaked gypsum samples is shorter and less significant. This may be because the immersion makes the cracks and micro-cracks in these gypsum samples filled with crude oil, which improves the bearing capacity of the cracks and micro-cracks.

Linear elastic stage: After the compaction stage (about 0~0.1% strain), entering the linear elastic stage, the strains of the samples without oil immersion and after oil immersion are both 0.1~0.5% at this stage. This indicates that oil immersion has no significant effect on the linear elastic deformation of the gypsum samples under triaxial loading. With the increase in confining pressure, the slopes of the stress–strain relationship curve of the samples without and after crude oil immersion do not increase significantly, and the duration of the linear elastic stage is basically unchanged under the two conditions.

Plastic deformation stage: At low confining pressure (6 MPa), the yield stress point of elastic–plastic transformation of unsoaked samples is difficult to distinguish, which indicates that the expansion, penetration, and failure of gypsum microcracks are completed in a short period, and its brittleness is relatively strong. When the confining pressure increases, the stress–strain curve gradually flattens, the slope decreases, the plastic deformation stage gradually lengthens, the yield stress point of elastic–plastic transformation gradually becomes obvious, and the toughness of gypsum increases. When the confining pressure of the gypsum samples after crude oil immersion is low (6 MPa), the gypsum samples have different degrees of stress drop (Figure 8b). With the increase in confining pressure, the stress drop phenomenon gradually decreases (9 MPa) and finally disappears (12 MPa). Compared with the experimental results of the unsoaked gypsum samples, the plastic deformation ability of the soaked samples is enhanced, indicating that the crude oil soaking is beneficial in improving the plastic deformation ability of the gypsum. The large deformation of the rock mass will occur before the failure of the goaf.

Post-peak stage: By comparing the post-peak data of the stress–strain curves of soaked samples and non-soaked samples, it was found that the post-peak residual strength and residual deformation capacity of the stress–strain curves of soaked samples are greater than those of unsoaked samples. This indicates that crude oil soaking has an important influence on the residual strength and deformation capacity of gypsum samples.

The experimental results in Figure 8 also show that the peak stress of the gypsum samples without soaking and after soaking is not significantly affected by the increase in confining pressure. When gypsum is damaged, its plastic deformation capacity increases with the increase in confining pressure.

From Table 1, it can be seen that under the same confining pressure, the peak strength of differential stress of different samples varies greatly, which can be caused by the great difference in the development degree of internal cracks and micro-cracks in different samples. Due to the randomness of the development degree of internal cracks and micro-cracks in the samples, the peak strength of differential stress of the samples without crude oil immersion at the confining pressure of 9 MPa is the smallest. Compared with the experimental results of the unsoaked gypsum sample, the samples after soaking have better uniformity, but the peak values of differential stress are lower than those of the unsoaked gypsum sample under the same conditions. According to the experimental results in Table 1, it can be observed that the cohesion C of unsoaked gypsum is 17.5 MPa, and its internal friction angle φ is 45.6°. After crude oil immersion, the average cohesion and internal friction angle of the gypsum sample are 19.95 MPa and 42.30°, respectively.

Table 1.

Experimental results of stress peak in triaxial compression tests of gypsum without immersion and after immersion.

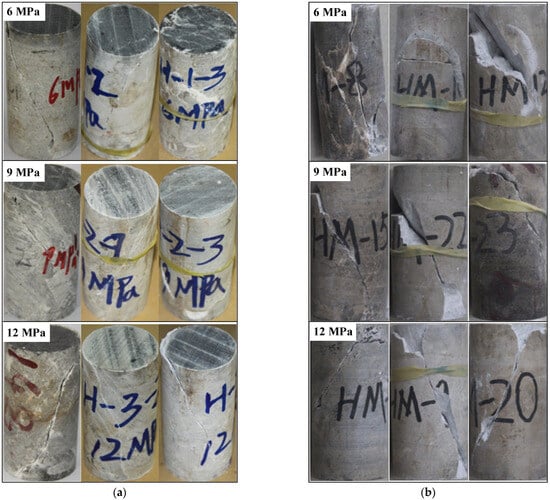

Figure 9 shows that the failure mode of gypsum samples is relatively single, mainly shear failure. There is basically a macroscopic fracture surface in the samples. This is mainly because, with the increase in confining pressure when the axial stress reaches the peak strength, the fracture energy required for gypsum failure gradually increases, the elastic energy released is gradually insufficient to make gypsum further damage, the dynamic failure phenomenon weakening, and the fracture mode is mainly shear failure. With the increase in confining pressure, the number of fracture surfaces decreases gradually, the brittle fracture features gradually weaken, and the ductile fracture features become obvious. Therefore, the fracture mode is mainly single-shear failure.

Figure 9.

Gypsum samples after triaxial compression under different confining pressures: (a) original samples; (b) oil-soaked samples.

Compared with the triaxial compression failure test results of gypsum samples without immersion, the samples after immersion with crude oil are more broken after failure dynamic damage degree of the gypsum samples after soaking is relatively strong, so many smaller fragments are formed after the sample failure.

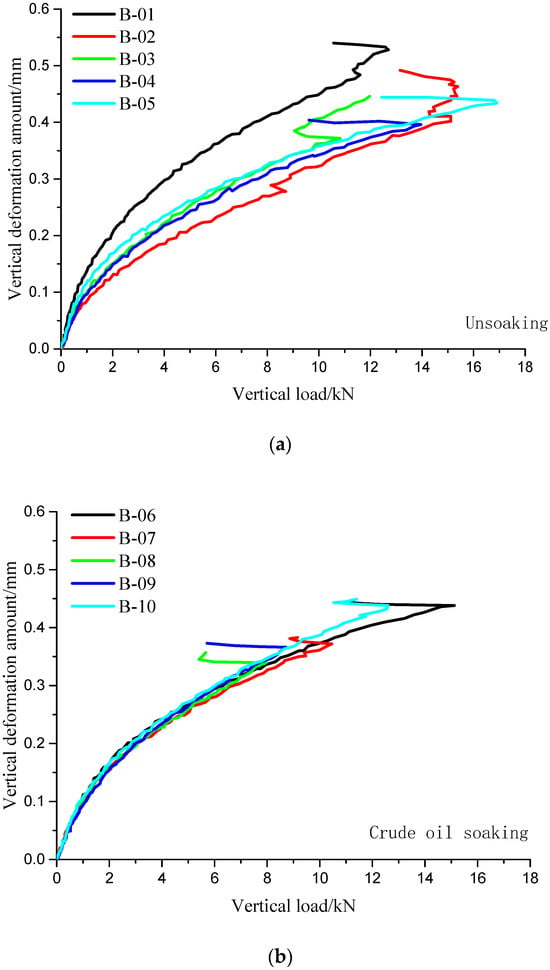

3.3. Brazilian Splitting Tests

It can be seen from Figure 10 that the vertical deformation gradually increases with the load increases, and the increasing rate presents a change rule of fast first and then slow. The load loses its bearing capacity immediately after the load reaches the peak during the loading process, and there is basically no residual strength. Compared with the gypsum samples without crude oil soaking, the load–deformation curve of the Brazilian splitting test of the gypsum samples soaked in crude oil is more uniform. This may be because the micro-cracks and cracks in the soaked samples are filled with crude oil. According to these results, the average tensile strength of the unsoaked gypsum sample is 7.00 MPa, and the average tensile strength of the soaked gypsum sample is 5.42 MPa.

Figure 10.

The load–deformation curves of gypsum samples during the Brazil splitting test under different conditions: (a) samples without soaking; (b) samples with soaking.

Figure 11 shows the experimental results of gypsum samples after Brazil splitting without soaking and after soaking. The gypsum samples have strong heterogeneity and uneven distribution of micro-cracks, so they cannot be spilt on the central axis during the Brazilian splitting test. Compared with the unsoaked samples, the symmetry of the two halves of the damaged gypsum sample after soaking is better, which indicates that the homogeneity of gypsum samples after soaking is better, indicating that the crude oil soaking is beneficial to improve the homogeneity of gypsum samples.

Figure 11.

Photographs of gypsum samples after Brazil splitting experiment.

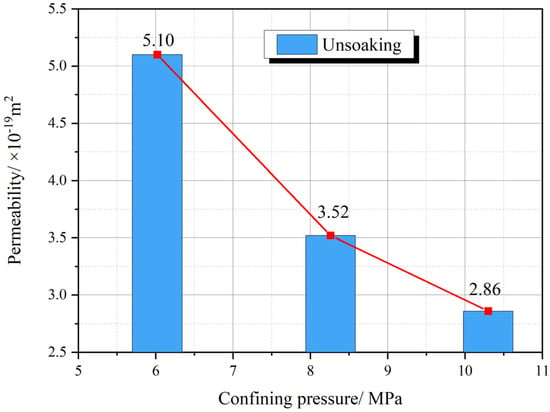

3.4. Permeability Tests

It can be seen from Figure 12 that the permeability of unsoaked gypsum samples decreases with the increase in confining pressure. This is mainly because the increase in confining pressure closes the micro-cracks in the sample. At the same time, the calculation results also show that the permeability of gypsum samples is extremely low and can reach the level of 10−19 m2, indicating that the Xiaxin gypsum mine is relatively dense, which can provide effective storage of crude oil. The permeability of gypsum samples soaked with crude oil is significantly lower than that of unsoaked gypsum samples. This indicates that the permeability of the gypsum samples after crude oil immersion is lower than the minimum measurement accuracy of the experimental system, which is beneficial to the sealing of the storage.

Figure 12.

The relationship between permeability and confining pressure of unsoaked and soaked gypsum samples under different confining pressures.

4. Conclusions

In this paper, a series of mechanical and permeability tests of gypsum rock before and after crude oil immersion is carried out, including uniaxial compression, triaxial compression, Brazil splitting, and permeability tests. The conclusions are as follows:

- (1)

- During the uniaxial compression experiment, the failure of the gypsum sample experienced a compaction stage, linear elastic stage, plastic deformation stage, and post-peak stage. Crude oil increases the post-peak strength and plastic deformation ability of the sample. The uniaxial compressive strength and elastic modulus of gypsum rock increased by 20% and 34.49%, respectively.

- (2)

- During the triaxial compression experiment, the gypsum sample after crude oil immersion had better plastic deformation ability, and the sample after the failure test had stronger fragmentation. The cohesion of crude oil-soaked samples increased by about 14% compared with that of unsoaked samples, the internal friction angle decreased by about 7.2%, and the peak strength of differential stress under the same confining pressure had little difference.

- (3)

- In the process of the Brazil splitting experiment, the load–deformation relationship curve of crude oil-soaked samples has better normalization. The average tensile strength of gypsum rock before and after crude oil immersion is 7.00 MPa and 5.42 MPa, respectively, which decreases by 22.6%. This is mainly because crude oil erosion intensifies the development of micro-cracks in the sample and significantly reduces the tensile strength of the sample.

- (4)

- The permeability of gypsum rock can reach the level of 10−19 m2, and the permeability of gypsum sample after immersion is even lower. This is mainly because the adhesion and blockage of pores by resins and asphaltenes in crude oil cause the permeability of gypsum samples to decrease.

- (5)

- The results show that crude oil erosion is beneficial to oil storage in the goaf of the Xiaxin gypsum mine, but the properties of gypsum rock vary greatly in different areas. Subsequent studies may require comparative analysis of gypsum rocks from different regions to obtain results that are generally applicable nationwide or even worldwide.

Author Contributions

Conceptualization, T.J.; methodology, X.S.; software, D.X.; validation, D.Y.; formal analysis, M.L.; investigation, C.Z.; resources, T.J.; data curation, T.J.; writing—original draft preparation, X.S.; writing—review and editing, X.S.; visualization, D.X.; supervision, D.Y.; project administration, C.Z.; funding acquisition, D.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (No. 51804236); National Natural Science Foundation of Hubei Province (Study on hydraulic fracturing experiment and network fracture control technology of shale reservoir in western Hubei Province).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclatures

| A | Sample cross-sectional area [m2] | t | Test time [s] |

| k | Permeability [m2] | Vup | Volume of upstream pressure chambers [m3] |

| L | Sample length [m] | Vdown | Volume of downstream pressure chambers [m3] |

| pp | initial pulse pressure [Pa] | δ | Gas compressive coefficient |

| ∆p | Pressure difference between upstream and downstream [Pa] | μ | Gas dynamic viscosity [Pa·s] |

References

- Ministry of Natural Resources. Report on reserves of China’s major mineral resources published by Ministry of Natural Resources. Geol. China 2018, 45, 1315–1316. [Google Scholar]

- Yin, S.; Zhou, W.; Shan, Y.; Ding, W.; Xie, R.; Guo, C. Assessment of the geostress field of deep-thick gypsum cap rocks: A case study of Paleogene Formation in the southwestern Tarim Basin, NW China. J. Pet. Sci. Eng. 2017, 154, 76–90. [Google Scholar] [CrossRef]

- Jin, Z.; Zhou, Y.; Yun, J. Distribution of gypsum-salt cap rocks and near-term hydrocarbon exploration targets in the marine sequences of China. Oil Gas Geol. 2010, 31, 715–724. [Google Scholar]

- Kamal, M.S.; Hussein, I.; Mahmoud, M.; Sultan, A.S.; Saad, M.A.S. Oilfield scale formation and chemical removal: A review. J. Pet. Sci. Eng. 2018, 171, 127–139. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, H.; Liu, Q.; Zhou, B.; Zhang, D.; Wang, J.; Lu, L.; Luo, H.; Meng, Q.; Wu, X. Significance of gypsum-salt rock series for marine hydrocarbon accumulation. Pet. Res. 2017, 2, 222–232. [Google Scholar] [CrossRef]

- Yılmaz, I.; Sendır, H. Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng. Geol. 2002, 66, 211–219. [Google Scholar] [CrossRef]

- Caselle, C.; Bonetto, S.; Colombero, C.; Comina, C. Mechanical properties of microcrystalline branching selenite gypsum samples and influence of constituting factors. J. Rock Mech. Geotech. Eng. 2019, 11, 228–241. [Google Scholar] [CrossRef]

- Kong, L.; Ostadhassan, M.; Li, C.; Tamimi, N. Can 3-D Printed Gypsum Samples Replicate Natural Rocks? An Experimental Study. Rock Mech. Rock Eng. 2018, 51, 3061–3074. [Google Scholar] [CrossRef]

- Meng, T.; Zhang, D.; Hu, Y.; Jianlin, X.; Sufang, S.; Xiaoming, L. Study of the deformation characteristics and fracture criterion of the mixed mode fracture toughness of gypsum interlayers from Yunying salt cavern under a confining pressure. J. Nat. Gas Sci. Eng. 2018, 58, 1–14. [Google Scholar] [CrossRef]

- Sadeghiamirshahidi, M.; Vitton, S.J. Analysis of drying and saturating natural gypsum samples for mechanical testing. J. Rock Mech. Geotech. Eng. 2019, 11, 219–227. [Google Scholar] [CrossRef]

- Liu, S.; Yang, S.; Shan, F.; Huang, T.; Yin, S.; Liu, X.X. Rock mechanics properties experiment and analysis of deep gypsum cap rocks. Fault-Block Oil Gas Field 2018, 25, 635–638. [Google Scholar]

- Hoxha, D.; Giraud, A.; Homand, F. Modelling long-term behaviour of a natural gypsum rock. Mech. Mater. 2005, 37, 1223–1241. [Google Scholar] [CrossRef]

- Hoxha, D.; Homand, F.; Auvray, C. Deformation of natural gypsum rock: Mechanisms and questions. Eng. Geol. 2006, 86, 1–17. [Google Scholar] [CrossRef]

- Auvray, C.; Homand, F.; Hoxha, D. The influence of relative humidity on the rate of convergence in an underground gypsum mine. Int. J. Rock Mech. Min. Sci. 2008, 45, 1454–1468. [Google Scholar] [CrossRef]

- Liang, W.; Yang, X.; Gao, H.; Zhang, C.; Zhao, Y.; Dusseault, M.B. Experimental study of mechanical properties of gypsum soaked in brine. Int. J. Rock Mech. Min. Sci. 2012, 53, 142–150. [Google Scholar] [CrossRef]

- Meng, T.; Hu, Y.; Fang, R.; Fu, Q.; Yu, W. Weakening mechanisms of gypsum interlayers from Yunying salt cavern subjected to a coupled thermo-hydro-chemical environment. J. Nat. Gas Sci. Eng. 2016, 30, 77–89. [Google Scholar] [CrossRef]

- Salih, N.; Mohammed, A. Characterization and modeling of long-term stressestrain behavior of water confined pre-saturated gypsum rock in Kurdistan Region, Iraq. J. Rock Mech. Geotech. Eng. 2017, 9, 741–748. [Google Scholar] [CrossRef]

- Du, A. Study on Stability and Sealing of Surrounding Rock of Deep Anhydrite Cavern. Master’s Thesis, China University of Geosciences, Beijing, China, 2022. [Google Scholar]

- Liu, S.; Wang, H.; Du, A.; Zhang, B. Tightness Analysis of Anhydrite Mine-Out Used for Underground Crude Oil Storage Considering Seepage–Stress Coupling: A Case Study. Energies 2022, 15, 2929. [Google Scholar] [CrossRef]

- Wang, H.-X.; Zhang, B.; Fu, D.; Ndeunjema, A. Stability and airtightness of a deep anhydrite cavern group used as an underground storage space: A case study. Comput. Geotech. 2018, 96, 12–24. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, H.; Wang, L.; Xu, N. Stability analysis of a group of underground anhydrite caverns used for crude oil storage considering rock tensile properties. Bull. Eng. Geol. Environ. 2019, 78, 6249–6265. [Google Scholar] [CrossRef]

- Zhang, G.; Li, H.; Wang, M.; Li, X. Crack initiation of granite under uniaxial compression tests: A comparison study. J. Rock Mech. Geotech. Eng. 2020, 12, 656–666. [Google Scholar] [CrossRef]

- Donggui, M. Study on Damage Evolution Law and Stability of Surrounding Rock in Underground Oil Storage Space of Abandoned Gypsum Mine. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2022. [Google Scholar]

- Han, P.; Zhang, C.; Wang, X.; Wang, L. Study of mechanical characteristics and damage mechanism of sandstone under long-term immersion. Eng. Geol. 2023, 315, 107020. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, B.; Wang, L.; Yu, X.; Shi, L.; Fu, D. Experimental investigation on the long-term interactions of anhydrite rock, crude oil, and water in a mine-out space for crude-oil storage. Eng. Geol. 2020, 265, 105414. [Google Scholar] [CrossRef]

- Professional Standard Compilation Group of People’s Republic of China. Specifications for Rock Tests in Water Conservancy and Hydroelectric Engineering; China Standards Press: Beijing, China, 2007. (In Chinese) [Google Scholar]

- Sun, Z.G.; Jiang, D.Y.; Xie, K.N.; Wang, K.; Li, L.; Jiang, X. Thermal damage study of Beishan granite based on low field magnetic resonance. J. China Coal Soc. 2020, 45, 1081–1088. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).