Study on the Effect of Coal Grain Size on the Morphology of Soot Generated During Combustion

Abstract

1. Introduction

2. Experimental Procedure and Methodology

2.1. Experimental Parameters

2.2. Experimental Sampling Methodology

2.3. Theoretical Analysis Method

3. Results and Discussion

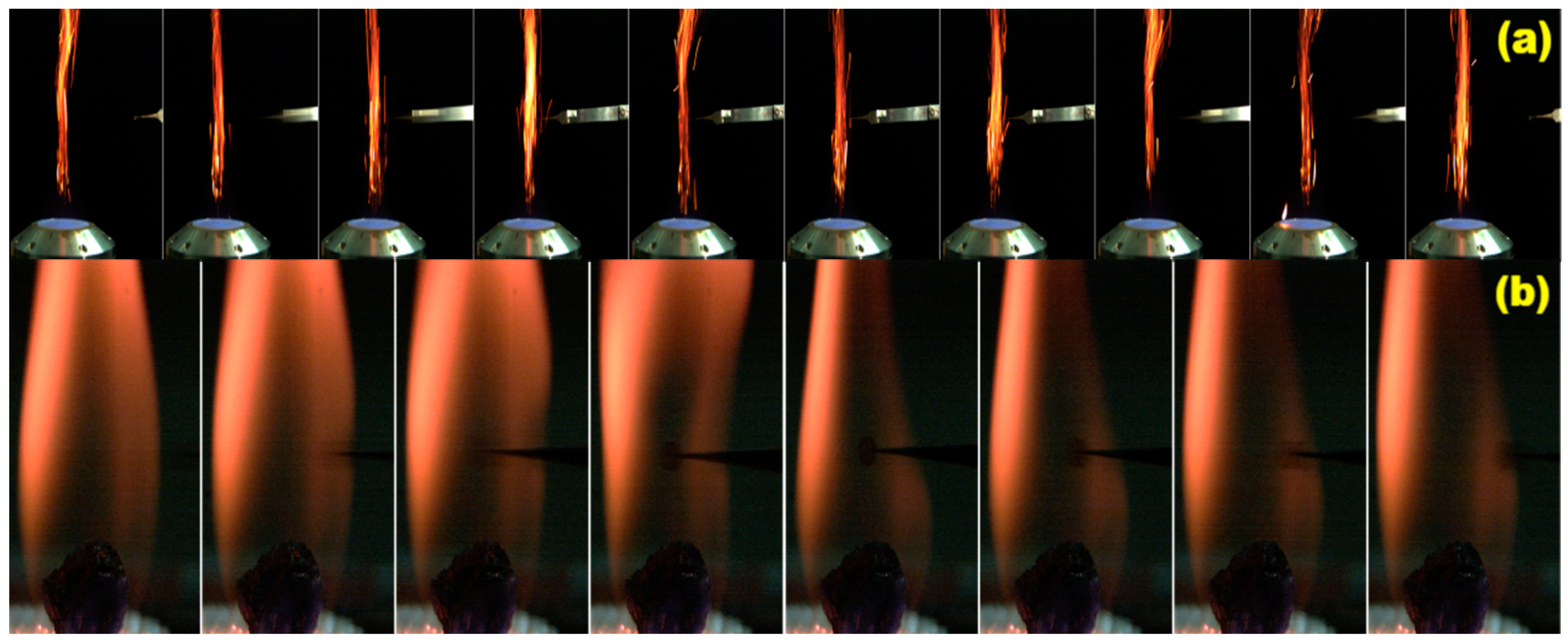

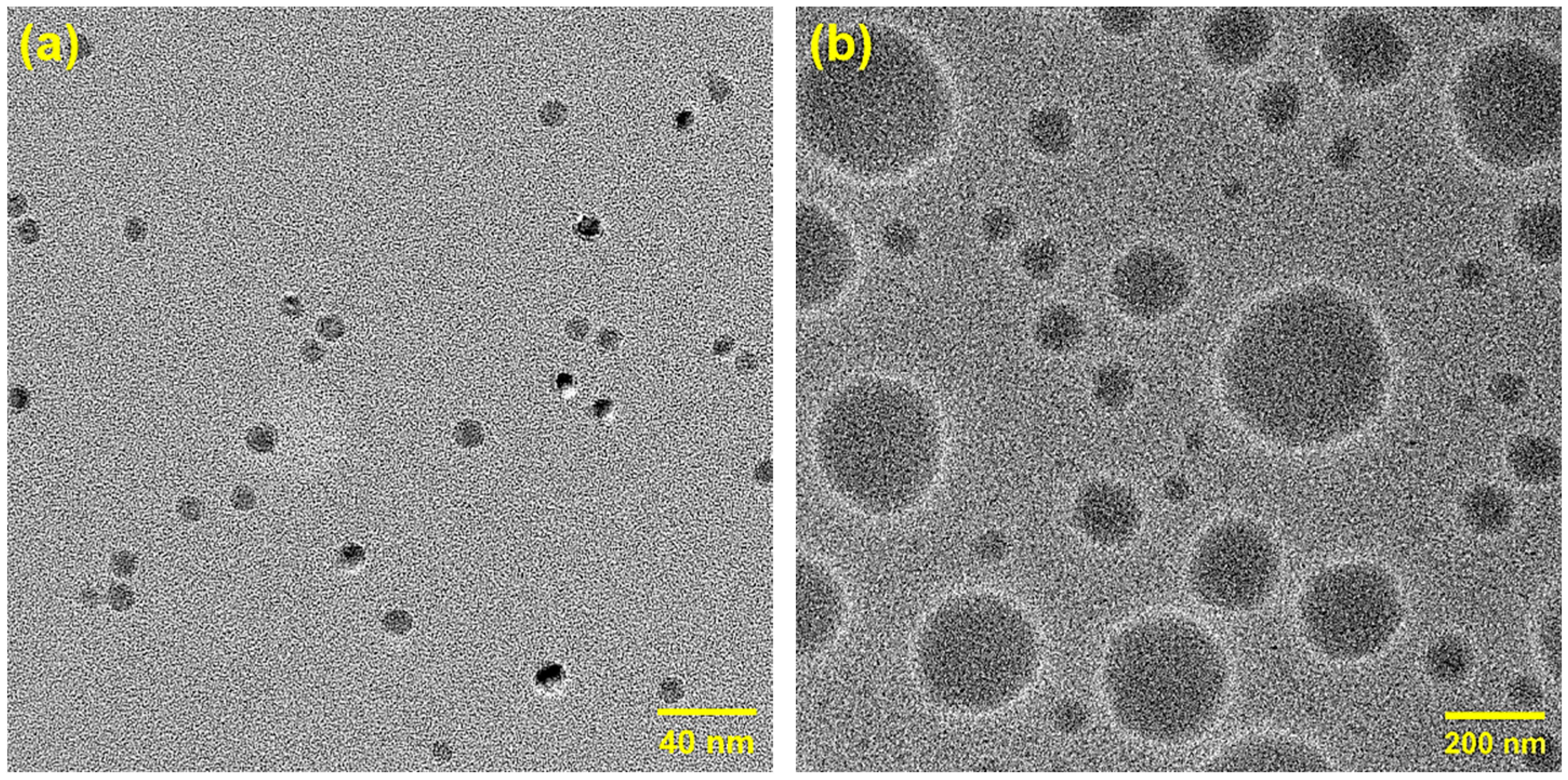

3.1. Influence of Grain Size on the Morphology of Nascent Soot

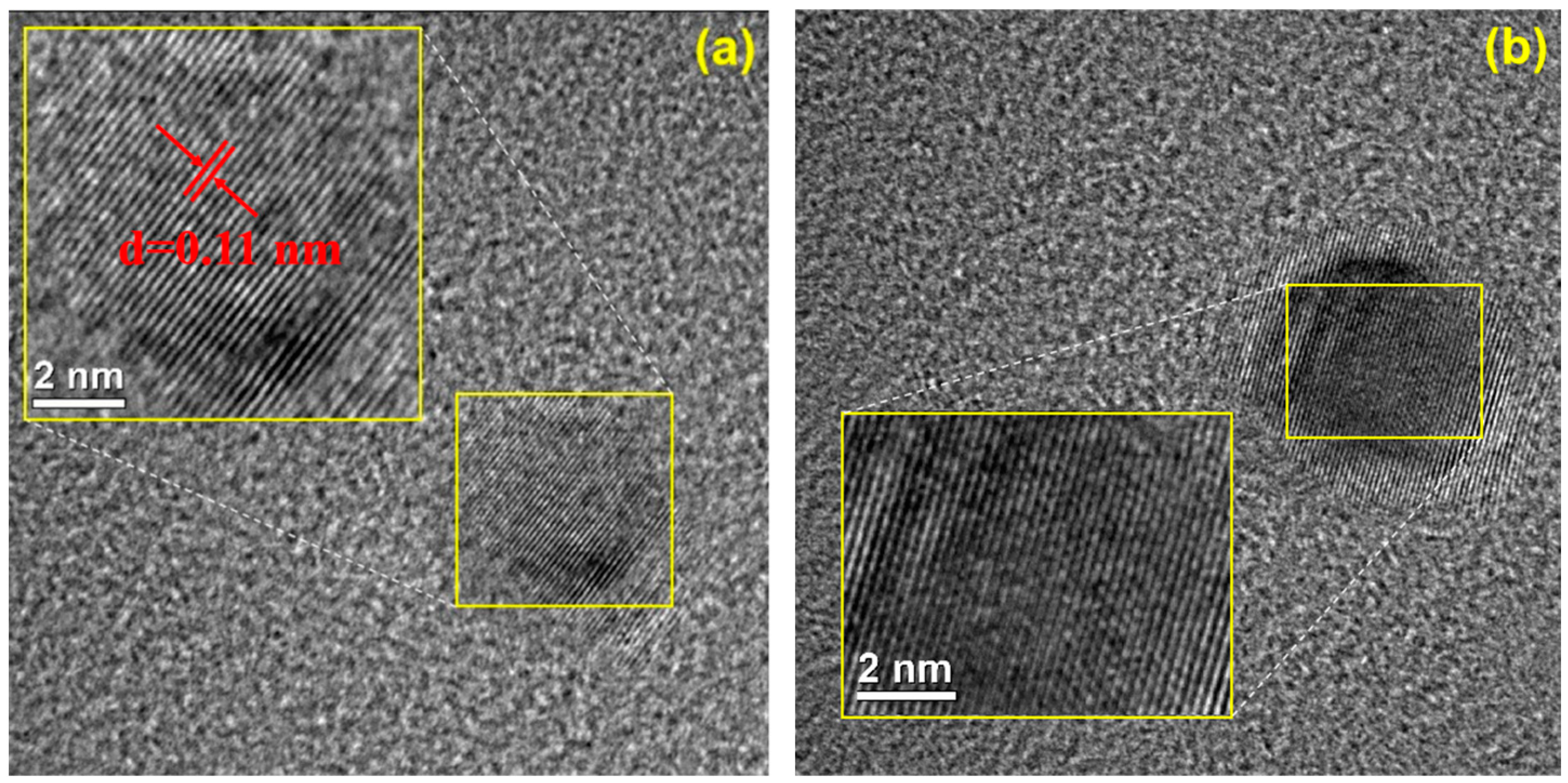

3.2. Influence of Particle Size on the Microstructural Characteristics of Nascent Soot Particles

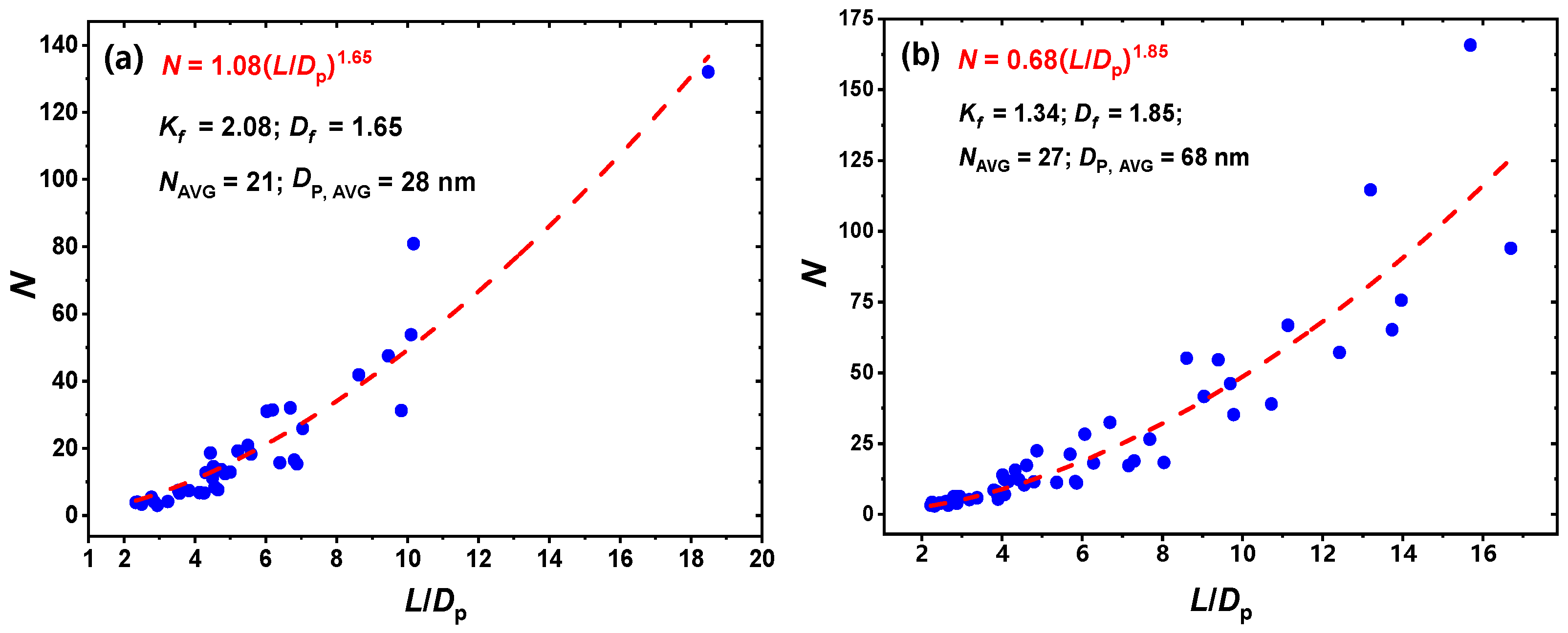

3.3. Influence of Grain Size on the Morphology of Mature Soot Particles

3.4. Industrial Application

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| HRTEM | High-resolution transmission electron microscopy; |

| SEM | Scanning electron microscope; |

| Kf | Pre-exponential factor; |

| Df | Fractal dimension. |

References

- Lin, B.; Ullah, S. Modeling the impacts of changes in nuclear energy, natural gas, and coal in the environment through the novel DARDL approach. Energy 2024, 287, 129572. [Google Scholar] [CrossRef]

- Fletcher, T.H.; Ma, J.; Rigby, J.R.; Brown, A.L.; Webb, B.W. Soot in coal combustion systems. Prog. Energy Combust. Sci. 1997, 23, 283–301. [Google Scholar] [CrossRef]

- Wang, Y.; Chung, S.H. Soot formation in laminar counterflow flames. Prog. Energy Combust. Sci. 2019, 74, 152–238. [Google Scholar] [CrossRef]

- Feng, D.; Shang, Q.; Dong, H.; Zhang, Y.; Wang, Z.; Li, D.; Xie, M.; Wei, Q.; Zhao, Y.; Sun, S. Catalytic mechanism of Na on coal pyrolysis-derived carbon black formation: Experiment and DFT simulation. Fuel Process. Technol. 2021, 224, 107011. [Google Scholar] [CrossRef]

- Linak, W.P.; Yoo, J.I.; Wasson, S.J.; Zhu, W.; Wendt, J.O.; Huggins, F.E.; Chen, Y.; Shah, N.; Huffman, G.P.; Gilmour, M.I. Ultrafine ash aerosols from coal combustion: Characterization and health effects. Proc. Combust. Inst. 2007, 31, 1929–1937. [Google Scholar] [CrossRef]

- Duan, S.; Zhang, M.; Sun, Y.; Fang, Z.; Wang, H.; Li, S.; Peng, Y.; Li, J.; Li, J.; Tian, J.; et al. Mechanism of PM2. 5-induced human bronchial epithelial cell toxicity in central China. J. Hazard. Mater. 2020, 396, 122747. [Google Scholar] [CrossRef]

- Liu, X.; Xu, Y.; Qi, J.; Wang, H.; Zhang, T.; Xu, M. Effects of kaolin-limestone blended additive on the formation and emission of particulate matter: Field study on a 1000 MW coal-firing power station. J. Hazard. Mater. 2020, 399, 123091. [Google Scholar] [CrossRef] [PubMed]

- Im, K.; Ahluwalia, R.K. Radiation properties of coal combustion products. Int. J. Heat Mass Transf. 1993, 36, 293–302. [Google Scholar] [CrossRef]

- Wen, W.-Y. Mechanisms of Alkali Metal Catalysis in the Gasification of Coal, Char, or Graphite. Catal. Rev. 1980, 22, 1–28. [Google Scholar] [CrossRef]

- Trubetskaya, A.; Jensen, P.A.; Jensen, A.D.; Garcia Llamas, A.D.; Umeki, K.; Gardini, D.; Kling, J.; Bates, R.B.; Glarborg, P. Effects of several types of biomass fuels on the yield, nanostructure and reactivity of soot from fast pyrolysis at high temperatures. Appl. Energy 2016, 171, 468–482. [Google Scholar] [CrossRef]

- Wang, X.; Bai, S.; Jin, Q.; Li, S.; Li, Y.; Li, Y.; Tan, H. Soot formation during biomass pyrolysis: Effects of temperature, water-leaching, and gas-phase residence time. J. Anal. Appl. Pyrolysis 2018, 134, 484–494. [Google Scholar] [CrossRef]

- Han, Y.; Chen, Y.; Feng, Y.; Song, W.; Cao, F.; Zhang, Y.; Li, Q.; Yang, X.; Chen, J. Different formation mechanisms of PAH during wood and coal combustion under different temperatures. Atmos. Environ. 2020, 222, 117084. [Google Scholar] [CrossRef]

- Jiang, X.; Zheng, C.; Yan, C.; Liu, D.; Qiu, J.; Li, J. Physical structure and combustion properties of super fine pulverized coal particle. Fuel 2002, 81, 793–797. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, L.; Ren, K.; Xu, R.; Teng, Z.; Zhu, J. Kinetic and experimental analysis of the effect of particle size on combustion performance of low-rank coals. Fuel 2023, 349, 128675. [Google Scholar] [CrossRef]

- Cong, K.; Zhang, Y.; Han, F.; Li, Q. Influence of particle sizes on combustion characteristics of coal particles in oxygen-deficient atmosphere. Energy 2019, 170, 840–848. [Google Scholar] [CrossRef]

- Yan, X.Z.; Chen, D.L.; Liu, L.; Wang, X.W. Experimental investigation of the influence of coal powder fineness on combustion characteristics. J. Power Eng. 2007, 27, 684–686. [Google Scholar]

- Liu, H.; Wu, S.H.; Zhao, G.B.; Qiu, P.H.; Qin, Y.K. Influence of coal particle size on the combustion characteristics of yuanbaoshan lignite. J. Harbin Inst. Technol. 2008, 112, 11357–11362. [Google Scholar]

- Yang, Y.; Liu, J.; Jin, S.; Li, T. Experimental study about influence of particle size and oxygen atmosphere on straw powder’s combustion characteristics. In Proceedings of the 2011 International Conference on Electrical and Control Engineering, Yichang, China, 16–18 September 2011. [Google Scholar]

- Yi, B.; Zhang, L.; Mao, Z.; Huang, F.; Zheng, C. Effect of the particle size on combustion characteristics of pulverized coal in an O2/CO2 atmosphere. Fuel Process. Technol. 2014, 128, 17–27. [Google Scholar] [CrossRef]

- Guo, Z.; Lou, C.; Liu, Z.; Zhou, H. The impact of combustion characteristics and flame structure on soot formation in oxy-enhanced and oxy-fuel diffusion flames. Sci. China Technol. Sci. 2013, 56, 1618–1628. [Google Scholar] [CrossRef]

- Du, J.; Axelbaum, R.L. The effect of flame structure on soot-particle inception in diffusion flames. Combust. Flame 1995, 100, 367–375. [Google Scholar] [CrossRef]

- Ma, J.; Fletcher, T.H.; Webb, B.W. Conversion of coal tar to soot during coal pyrolysis in a post-flame environment. Symp. (Int.) Combust. 1996, 26, 3161–3167. [Google Scholar] [CrossRef]

- Moghiman, M.; Gruenberger, T.M.J. Experimental and computational studies of soot emission in a gas fuelled swirl stabilized combustor. Iran. J. Sci. Technol. 2013, 26, 541–554. [Google Scholar]

- Lou, C.; Li, Z.; Zhang, Y.; Kumfer, B.M. Soot formation characteristics in laminar coflow flames with application to oxy-combustion. Combust. Flame 2021, 227, 371–383. [Google Scholar] [CrossRef]

- Sadeq, A.M. Combustion Advancements: From Molecules to Future Challenges; Independently published: Chicago, IL, USA, 2023. [Google Scholar]

- Si, M.; Cheng, Q.; Zhang, Q.; Wang, D.; Luo, Z.; Lou, C. Study of temperature, apparent spectral emissivity, and soot loading of a single burning coal particle using hyper-spectral imaging technique. Combust. Flame 2019, 209, 267–277. [Google Scholar] [CrossRef]

- Si, M.; Cheng, Q.; Yuan, L.; Luo, Z. High Temporal–spatial Distribution of Soot Temperature and Volume Fraction in Single Coal Combustion Flame. Combust. Sci. Technol. 2022, 194, 3246–3258. [Google Scholar] [CrossRef]

- Köylü, Ü.Ö.; McEnally, C.S.; Rosner, D.E.; Pfefferle, L.D. Simultaneous measurements of soot volume fraction and particle size/microstructure in flames using a thermophoretic sampling technique. Combust. Flame 1997, 110, 494–507. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, J.; Liu, X.; Qi, J.; Wang, H.; Cheng, X.; Xu, J. Insight into soot formed in coal combustion flame: Evolution of physiochemical structure, oxidation reactivity. Fuel 2022, 312, 122948. [Google Scholar] [CrossRef]

- Saha, M.; Dally, B.B.; Medwell, P.R.; Chinnici, A. Effect of particle size on the MILD combustion characteristics of pulverised brown coal. Fuel Process. Technol. 2017, 155, 74–87. [Google Scholar] [CrossRef]

- Koeylue, U.; Xing, Y.; Rosner, D.E. Fractal Morphology Analysis of Combustion-Generated Aggregates Using Angular Light Scattering and Electron Microscope Images. Langmuir 2002, 11, 4848–4854. [Google Scholar] [CrossRef]

- Wentzel, M.; Gorzawski, H.; Naumann, K.H.; Saathoff, H.; Weinbruch, S. Transmission electron microscopical and aerosol dynamical characterization of soot aerosols. J. Aerosol Sci. 2003, 34, 1347–1370. [Google Scholar] [CrossRef]

- Köylü, Ü.Ö.; Faeth, G.M.; Farias, T.L.; Carvalho, M.G. Fractal and projected structure properties of soot aggregates. Combust. Flame 1995, 100, 621–633. [Google Scholar] [CrossRef]

- Gwaze, P.; Schmid, O.; Annegarn, H.J.; Andreae, M.O.; Huth, J.; Helas, G. Comparison of three methods of fractal analysis applied to soot aggregates from wood combustion. J. Aerosol Sci. 2006, 37, 820–838. [Google Scholar] [CrossRef]

- Yu, J.; Chen, L.; Zhang, J.; Wu, J.; Wu, X.; Zeng, Q.; Cen, K. Influences of Coal Type and Particle Size on Soot Measurement by Laser-Induced Incandescence and Soot Formation Characteristics in Laminar Pulverized Coal Flames. Energy Fuels 2020, 34, 13740–13749. [Google Scholar] [CrossRef]

- Harris, S.J.; Weiner, A.M. Chemical Kinetics of Soot Particle Growth. Annu. Rev. Phys. Chem. 1985, 36, 31–52. [Google Scholar] [CrossRef]

- Hagen, F.P.; Vlavakis, P.; Bockhorn, H.; Suntz, R.; Trimis, D. From molecular to sub-μm scale: The interplay of precursor concentrations, primary particle size, and carbon nanostructure during soot formation in counter-flow diffusion flames. Combust. Flame 2023, 258, 112729. [Google Scholar] [CrossRef]

| Nascent Soot | Mature Soot | |||||

|---|---|---|---|---|---|---|

| Dp,AVG (nm) | d * (A) | Kf | Df | NAVG | Dp,AVG (nm) | |

| Sample #1 | 10.4 | 0.11 | 2.08 | 1.65 | 21 | 28 |

| Sample #1 | 123.9 | 0.15 | 1.34 | 1.85 | 27 | 68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Si, M.; Zhang, Y.; Liu, B.; Shi, C. Study on the Effect of Coal Grain Size on the Morphology of Soot Generated During Combustion. Energies 2024, 17, 5734. https://doi.org/10.3390/en17225734

Liu J, Si M, Zhang Y, Liu B, Shi C. Study on the Effect of Coal Grain Size on the Morphology of Soot Generated During Combustion. Energies. 2024; 17(22):5734. https://doi.org/10.3390/en17225734

Chicago/Turabian StyleLiu, Jiani, Mengting Si, Yindi Zhang, Bing Liu, and Changqian Shi. 2024. "Study on the Effect of Coal Grain Size on the Morphology of Soot Generated During Combustion" Energies 17, no. 22: 5734. https://doi.org/10.3390/en17225734

APA StyleLiu, J., Si, M., Zhang, Y., Liu, B., & Shi, C. (2024). Study on the Effect of Coal Grain Size on the Morphology of Soot Generated During Combustion. Energies, 17(22), 5734. https://doi.org/10.3390/en17225734