Text Correction

There was an error in the original publication [1]. The total annual potential energy savings from the electric steam and thermal oil boiler applications were inaccurate.

A correction has been made to the Abstract:

“Process heating is typically more than half of the total final energy demand in the textile industry, most of which is usually provided by fossil fuels. There is significant potential to decarbonize the textile industry by the electrification of process heating where low-carbon electricity is used. This study aims to quantify the potential for the electrification of process heating in the textile sector in three of the top textile manufacturing and exporting countries in the world. The results show that the total annual potential energy savings due to the electric steam boiler applications are estimated to be around 84, 2.2, and 2.3 PJ in China, Japan, and Taiwan, respectively, by 2050. This is equal to approximately 19% of the total boiler energy demand in the three economies. Similarly, annual potential energy savings of 35, 0.9, and 0.9 PJ can be realized if the existing fossil-fuel-fired thermal oil boilers are electrified in the textile industry in China, Japan, and Taiwan, respectively, by 2050. Moreover, the potential CO2 abatement resulting from electrification is highly dependent on the carbon intensity of the electricity used. The economic analysis shows that switching from combustion boilers to electric boilers may result in higher energy costs, primarily because the average electricity prices in all three economies are substantially higher than fossil fuel prices. Finally, some key recommendations that different stakeholders can take to scale up electrification in the textile industry are provided.”

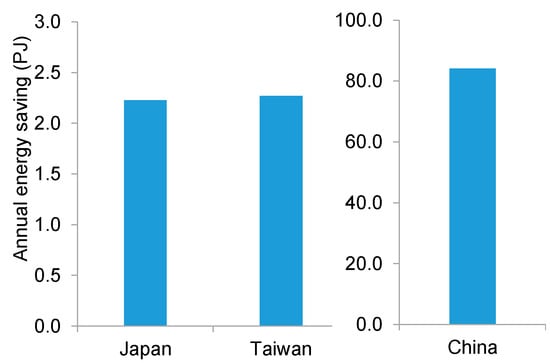

There was an error in the original publication. The annual energy savings from the electric steam boiler applications were inaccurate.

A correction has been made to 3. Results and Discussion, 3.1. Electrifying the Textile Industry through Electric Steam Boilers, Paragraph 1:

“Using the methods described in Section 2, potential applications of electric steam boilers in the textile industry in China, Japan, and Taiwan are investigated. The results show that the electrification of steam boilers could substantially reduce the annual final energy demand for steam generation in the textile industry in these three economies up to 2050 (Figure 4). Approximately 84, 2.2, and 2.3 PJ per year of annual boiler energy demand in the textile industry in China, Japan, and Taiwan, respectively, can be saved if the existing combustion boilers are electrified. This is equal to approximately 19% of the total boiler energy demand in the three economies. The annual energy saving potentials shown in Figure 4 are projected to remain at the same level in future years because this study assumes that the amount of textile production and, consequently, the energy and steam demand in the textile industry in each economy will remain more or less the same during 2021–2050.”

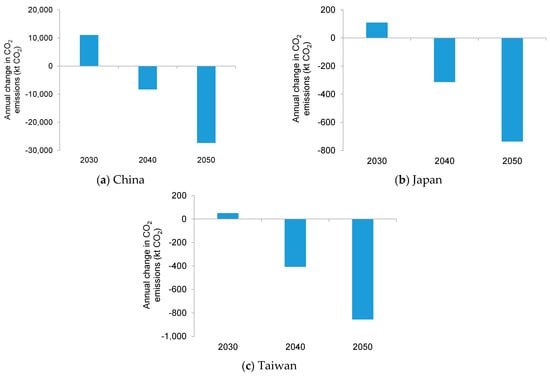

There was an error in the original publication. The potential changes in annual CO2 emissions due to electric steam boiler applications were stated slightly inaccurately.

A correction has been made to 3. Results and Discussion, 3.1. Electrifying the Textile Industry through Electric Steam Boilers, Paragraph 2:

“If the average national grid electricity is used, the electrification of combustion steam boilers in the textile industry in China, Japan, and Taiwan could initially lead to an increase in annual CO2 emissions by around 11,000, 110, and 51 kt CO2 in 2030, respectively (assuming a 100% adoption rate), refer to Figure 5a–c. This is because the estimated average electricity grid emission factors for these three economies in 2030 are still much higher than the weighted average emission factors of the fuel used in combustion steam boilers. However, boiler electrification is projected to result in 27,300, 736, and 856 kt CO2 of annual CO2 abatement in 2050, as also shown in the same figures. This substantial decrease in future annual CO2 emissions is projected as the consequence of electricity grid decarbonization up to 2050 (we assumed the electricity grid will be carbon neutral in 2050 in all three economies).”

There was an error in the original publication. The annual final energy savings from electric thermal oil boiler applications were inaccurately stated.

A correction has been made to 3. Results and Discussion, 3.2. Electrifying the Textile Industry through Electric Thermal Oil Boiler, Paragraph 1:

“Potential applications of electric thermal oil boilers in the textile industry in China, Japan, and Taiwan are further investigated in this study. The results show that electrification could substantially reduce the annual final energy demand for thermal oil boilers in the Chinese, Taiwanese, and Japanese textile industries by 2050 (refer to Figure 12). Approximately 13% of the annual thermal oil boiler energy demand in the textile industry can be saved if the existing fossil-fuel-fired thermal oil boilers are electrified. This results in annual final energy savings of 35, 0.91, and 0.91 PJ per year in China, Japan, and Taiwan, respectively. As stated earlier, the energy savings potential shown in the figure remains at the same level because this work assumes that the heat demand provided by thermal oil boilers in the textile industry in each economy will remain the same until 2050 (conservative assumption).”

There was an error in the original publication. The potential changes in annual CO2 emissions due to electric thermal oil boiler applications were inaccurately stated.

A correction has been made to 3. Results and Discussion, 3.2. Electrifying the Textile Industry through Electric Thermal Oil Boiler, Paragraph 2:

“With average national grid electricity, the electrification of thermal oil boilers in the textile industry in China, Taiwan, and Japan could initially lead to an increase in annual CO2 emissions by around 8470, 100, and 70 kt CO2, respectively (assuming a 100% adoption rate), refer to Figure 13a–c. This is because the electricity grid in the three economies is not projected to be decarbonized enough in 2030, based on our assumptions. However, thermal oil boiler electrification will result in 16,560, 440, and 500 kt of annual CO2 abatement by 2050. This substantial decrease in future annual CO2 emissions is projected as a consequence of electricity grid decarbonization between 2021 and 2050. Like the case for the electric steam boiler discussed earlier, if a given textile plant in any economy electrifies its thermal oil boilers today and purchases renewable electricity to supply the electricity demand of the electric thermal oil boiler, then the CO2 emissions reductions from electrification can be achieved immediately.”

There was an error in the original publication. The potential changes in annual energy and CO2 emissions after the electrification of both steam and thermal oil boilers were inaccurately stated.

A correction has been made to 3. Results and Discussion, 3.3. Overall Summary, Paragraph 1:

“The total annual energy savings and CO2 abatement due to the electrification of both steam and thermal oil boilers in the textile industry in all three economies are presented in this section. The electrification of boilers could lead to annual total final energy savings of approximately 119, 3.9, and 3.1 PJ per year in China, Taiwan, and Japan, respectively, in 2050. If the electricity from the 2030 grid is used, the electrification of steam and thermal oil boilers slightly increases the CO2 emissions from the textile industry. However, a substantial reduction in emissions can be anticipated in 2040 and 2050 due to large-scale grid decarbonization and energy efficiency improvements. The annual reduction in CO2 emissions in 2050 is estimated at approximately 44, 1.4, and 1.2 Mt CO2 per year in China, Taiwan, and Japan, respectively.”

There was an error in the original publication. The potential changes in annual electricity consumption after the electrification of both steam and thermal oil boilers were inaccurately stated.

A correction has been made to 3. Results and Discussion, 3.3. Overall Summary, Paragraph 2:

“It is important to note that while industrial electrification decreases net final energy consumption, it increases electricity consumption. Electrifying steam and thermal oil boilers will increase annual electricity consumption by 168, 4.5, and 4.4 TWh per year in China, Taiwan, and Japan, respectively, in 2050. This increase may directly translate into a rise in electricity load of over 35, 1.1, and 1.0 GW in China, Taiwan, and Japan, respectively, in 2050. For comparison, note that China had around 2380 GW, Taiwan had around 59 GW, and Japan had around 313 GW of power generation capacity in 2021 [27,28]. To calculate the aforementioned additional loads, this study assumes that all additional loads are based on renewable energy sources. More specifically, to estimate the capacity factors, this study assumes that two-thirds and one-third of the additional loads will be coming from solar and wind power, respectively.”

A correction has been made to 4. Discussion and Recommendations, Paragraph 3: The word “country” has been changed to “country/region”.

There was an error in the original publication. The potential changes in annual energy and CO2 emissions after the electrification of both steam and thermal oil boilers in country/region-specific textile industries were inaccurately stated.

A correction has been made to 5. Conclusions, Paragraph 2:

“The results show that the total annual potential energy savings due to the electric steam boiler applications in the textile industry are estimated to be around 84, 2.2, and 2.3 PJ per year in China, Japan, and Taiwan, respectively, in 2050. This is equal to approximately 19% of the total boiler energy demand in the three economies. Similarly, annual potential energy savings of 35, 0.91, and 0.91 PJ per year can be realized if the existing fossil-fuel-fired thermal oil boilers are electrified in the textile industry in China, Japan, and Taiwan, respectively, in 2050. Moreover, the potential CO2 abatement resulting from the electrification is highly dependent on the carbon intensity of the electricity used. More specifically, if the average national grid electricity is used, the electrification of combustion steam boilers in the textile industry in China, Japan, and Taiwan could initially lead to an increase in annual CO2 emissions by around 11, 0.11, and 0.05 Mt CO2 in 2030, respectively (assuming a 100% adoption rate). This is because the estimated average electricity grid emission factors for the three economies in 2030 are found to be much higher than the weighted average emission factors of fuel used in combustion steam boilers. However, steam boiler electrification is projected to result in 27.3, 0.7, and 0.9 Mt of annual CO2 abatement in 2050. Similarly, thermal oil boiler electrification could result in 16.5, 0.4, and 0.5 Mt of annual CO2 abatement in 2050. This substantial decrease in future annual CO2 emissions is projected as the consequence of electricity grid decarbonization up to 2050 (assuming the electricity grids will be carbon neutral in 2050 in all three economies).”

Error in Figure

In the original publication, there was a mistake in Figure 4 as published. The annual energy savings from the electric steam boiler applications were inaccurate. The corrected Figure 4 appears below.

Figure 4.

Total annual final energy savings after electrification of steam boilers in the textile industry in China, Japan, and Taiwan up to 2050.

In the original publication, there was a mistake in Figure 5 as published. The potential changes in annual CO2 emissions due to electric steam boiler application were inaccurate. The corrected Figure 5 appears below.

Figure 5.

Potential change in steam boilers’ annual CO2 emissions after electrification in the textile industry in China, Japan, and Taiwan.

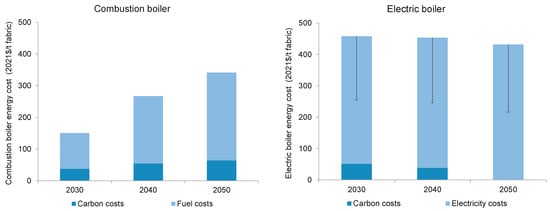

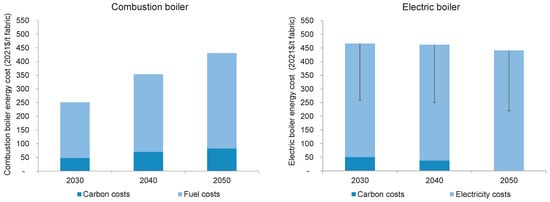

In the original publication, there was a mistake in Figure 9 as published. The presented energy costs per unit of production for combustion and electric steam boilers in the textile industry in China were slightly inaccurate. The corrected Figure 9 appears below.

Figure 9.

Energy costs per unit of production for combustion and electric steam boilers in the textile wet-processing industry in China.

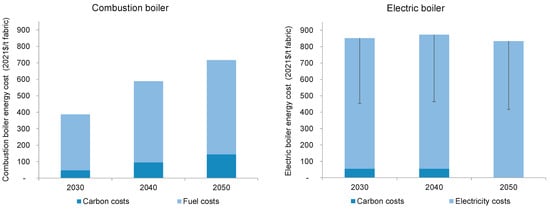

In the original publication, there was a mistake in Figure 10 as published. The presented energy costs per unit of production for combustion and electric steam boilers in the textile industry in Japan were slightly inaccurate. The corrected Figure 10 appears below.

Figure 10.

Energy costs per unit of production for combustion and electric steam boilers in the textile wet-processing industry in Japan.

In the original publication, there was a mistake in Figure 11 as published. The presented energy costs per unit of production for combustion and electric steam boilers in the textile industry in Taiwan were slightly inaccurate. The corrected Figure 11 appears below.

Figure 11.

Energy costs per unit of production for combustion and electric steam boilers in the textile wet-processing industry in Taiwan.

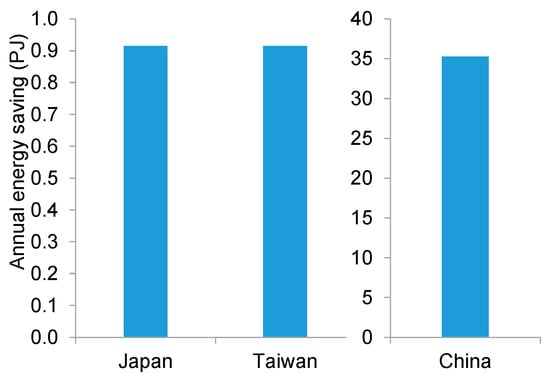

In the original publication, there was a mistake in Figure 12 as published. The annual final energy savings from the electric thermal oil boiler applications were inaccurate. The corrected Figure 12 appears below.

Figure 12.

Total annual energy saving after electrification of thermal oil boilers in the textile industry in China, Japan, and Taiwan up to 2050.

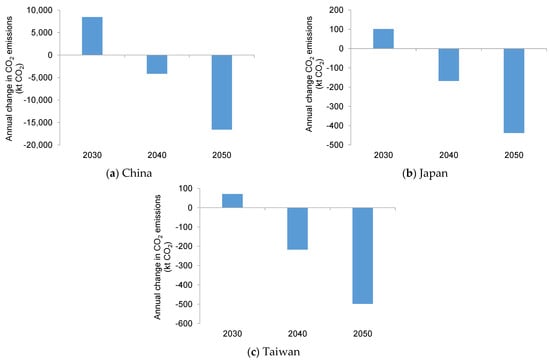

In the original publication, there was a mistake in Figure 13 as published. The potential changes in annual CO2 emissions due to electric thermal oil boiler applications were inaccurate. The corrected Figure 13 appears below.

Figure 13.

Potential change in thermal oil boilers’ annual CO2 emissions after electrification in the textile industry in China, Japan, and Taiwan.

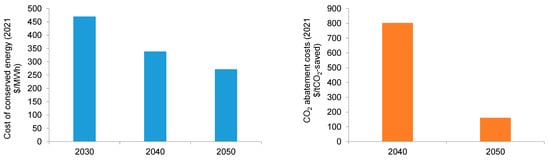

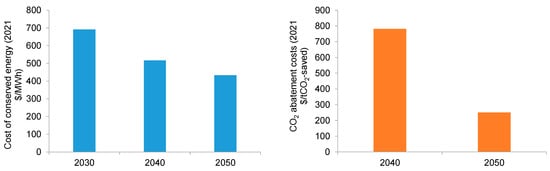

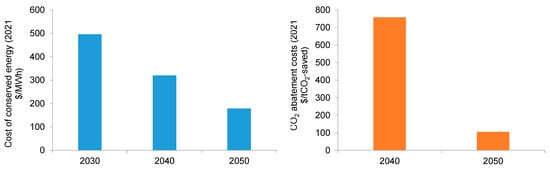

In the original publication, there was a mistake in Figure 14 as published. The presented costs for electric thermal oil boilers in the textile industry in China were slightly inaccurate. The corrected Figure 14 appears below.

Figure 14.

Cost of conserved energy and CO2 abatement for electric thermal oil boilers in the textile industry in China.

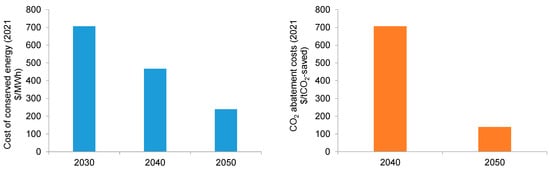

In the original publication, there was a mistake in Figure 15 as published. The presented costs for electric thermal oil boilers in the textile industry in Japan were slightly inaccurate. The corrected Figure 15 appears below.

Figure 15.

Cost of conserved energy and CO2 abatement for electric thermal oil boilers in the textile industry in Japan.

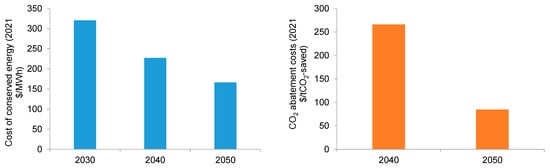

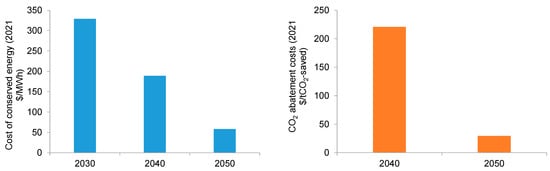

In the original publication, there was a mistake in Figure 16 as published. The presented costs for electric thermal oil boilers in the textile industry in Taiwan were slightly inaccurate. The corrected Figure 16 appears below.

Figure 16.

Cost of conserved energy and CO2 abatement for electric thermal oil boilers in the textile industry in Taiwan.

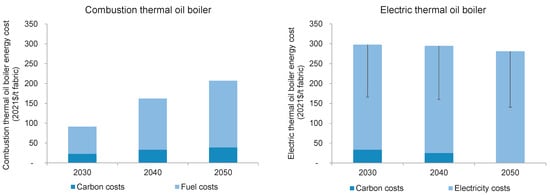

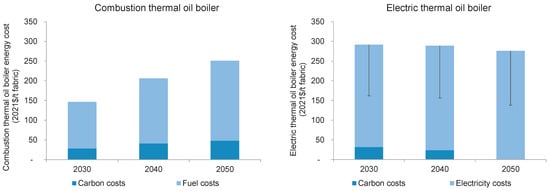

In the original publication, there was a mistake in Figure 17 as published. The presented energy costs per unit of production for combustion and electric thermal oil boilers in the textile industry in China were slightly inaccurate. The corrected Figure 17 appears below.

Figure 17.

Energy costs per unit of production for combustion and electric thermal oil boilers in the textile industry in China.

In the original publication, there was a mistake in Figure 18 as published. The presented energy costs per unit of production for combustion and electric thermal oil boilers in the textile industry in Japan were slightly inaccurate. The corrected Figure 18 appears below.

Figure 18.

Energy costs per unit of production for combustion and electric thermal oil boilers in the textile industry in Japan.

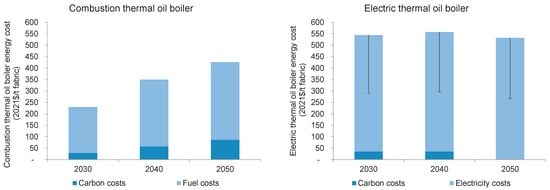

In the original publication, there was a mistake in Figure 19 as published. The presented energy costs per unit of production for combustion and electric thermal oil boilers in the textile industry in Taiwan were slightly inaccurate. The corrected Figure 19 appears below.

Figure 19.

Energy costs per unit of production for combustion and electric thermal oil boilers in the textile industry in Taiwan.

In the original publication, there was a mistake in Figure A4 as published. The presented costs for electric thermal oil boilers under the CO2 price scenario for the textile industry in China were inaccurate. The corrected Figure A4 appears below.

Figure A4.

Cost of conserved energy and CO2 abatement for electric thermal oil boilers under the CO2 price scenario in the textile industry in China.

In the original publication, there was a mistake in Figure A5 as published. The presented costs for electric thermal oil boilers under the CO2 price scenario for the textile industry in Japan were inaccurate. The corrected Figure A5 appears below.

Figure A5.

Cost of conserved energy and CO2 abatement for electric thermal oil boilers under the CO2 price scenario in the textile industry in Japan.

In the original publication, there was a mistake in Figure A6 as published. The presented costs for electric thermal oil boilers under the CO2 price scenario for the textile industry in Taiwan were inaccurate. The corrected Figure A6 appears below.

Figure A6.

Cost of conserved energy and CO2 abatement for electric thermal oil boilers under the CO2 price scenario in the textile industry in Taiwan.

The authors state that the scientific conclusions are unaffected. This correction was approved by the Academic Editor. The original publication has also been updated.

Reference

- Hasanbeigi, A.; Zuberi, M.J.S. Electrification of Steam and Thermal Oil Boilers in the Textile Industry: Techno-Economic Analysis for China, Japan, and Taiwan. Energies 2022, 15, 9179. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).