Optimizing Power Density in Partially Coated Cantilever Beam Energy Harvesters: A Cost-Effective Design Strategy

Abstract

1. Introduction

1.1. Effect of Host Beam Shape on Power Output

1.2. Effect of Host Beam Tapering/Thickness on Power Output

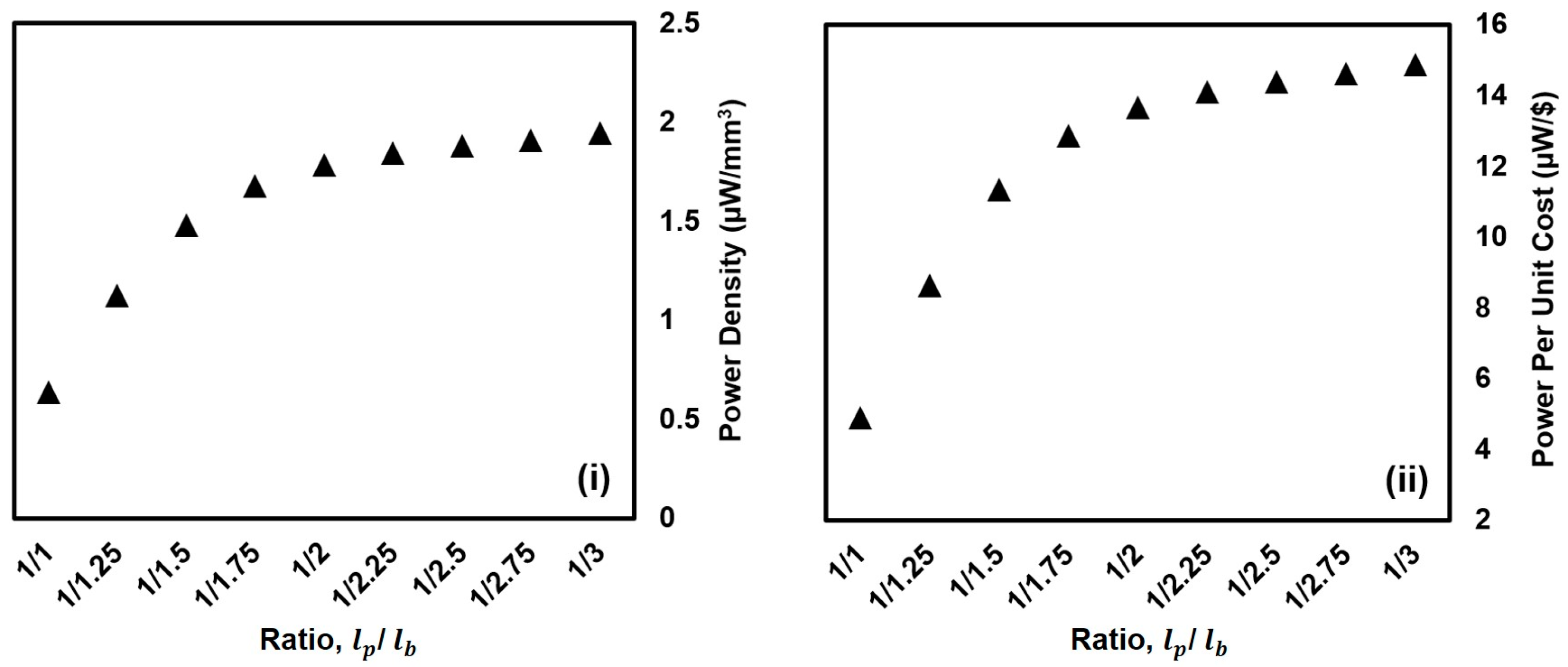

1.3. Effect of Geometry and Positioning of the Piezoelectric Material in Host Structure on Power Output

1.4. Advances in Piezoelectric Energy Harvesting Mechanisms

1.5. Model/PZT Dimension from an Economics Perspective

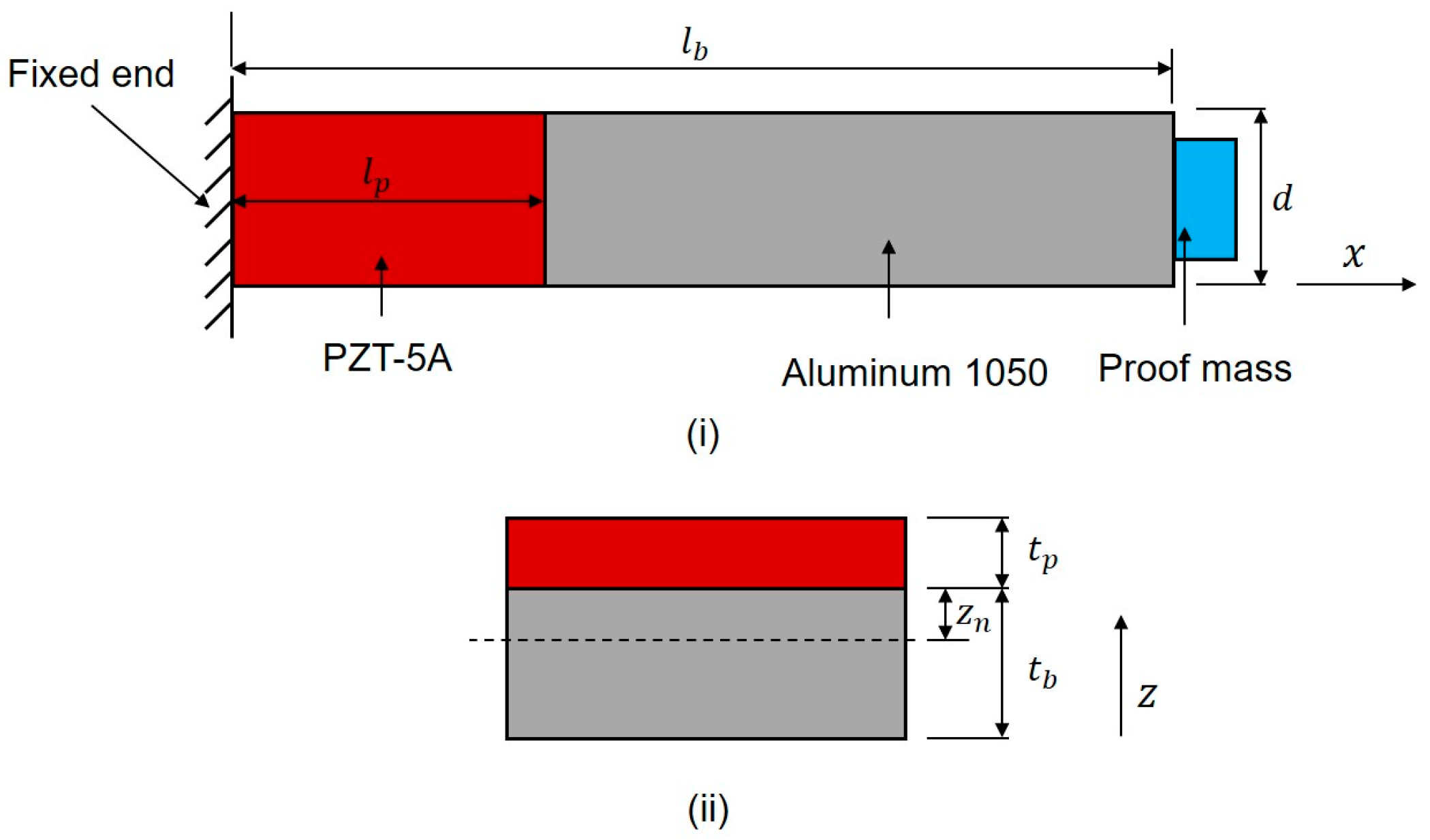

2. Theoretical Background

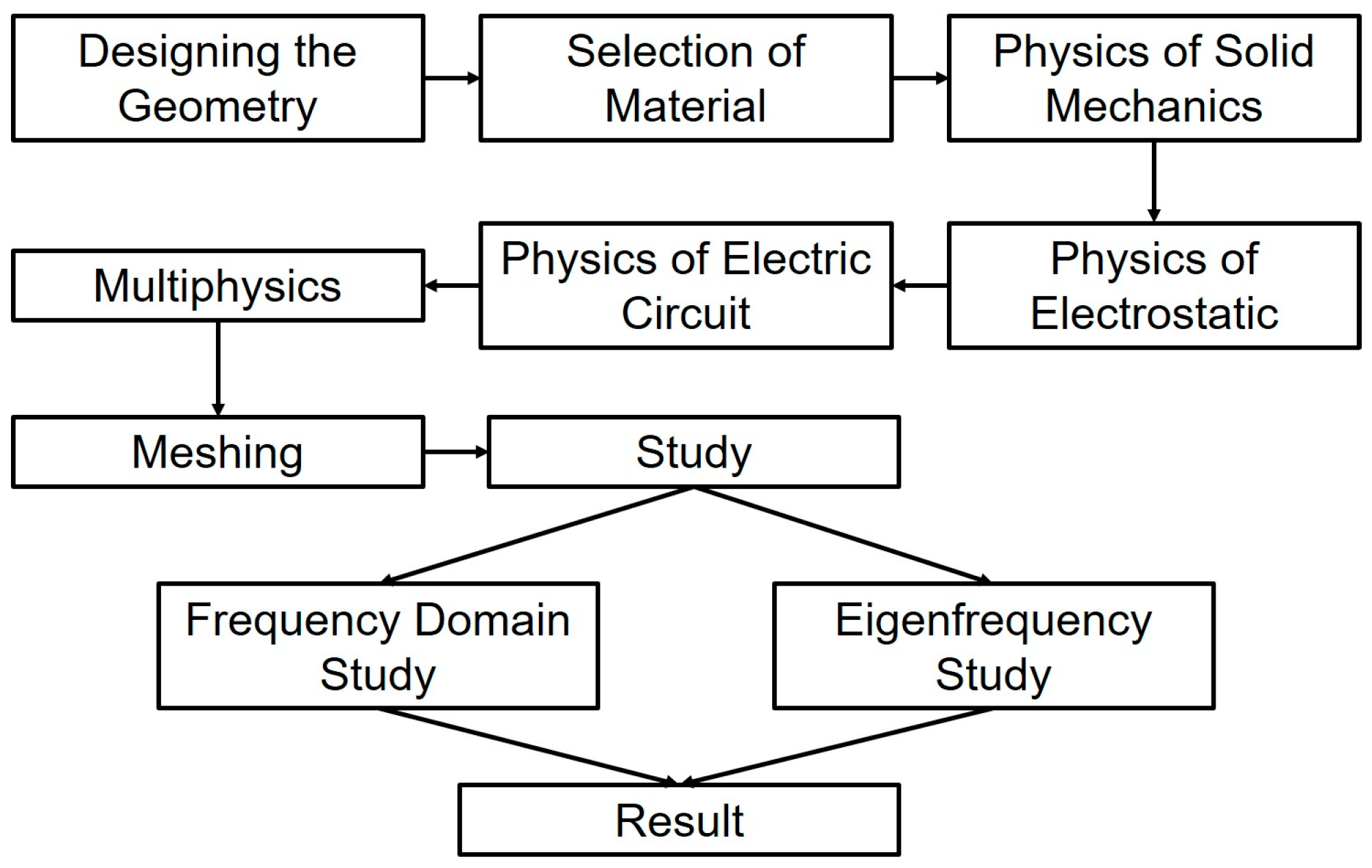

3. General Procedure of Numerical Analysis

4. Validation of Procedure Analysis

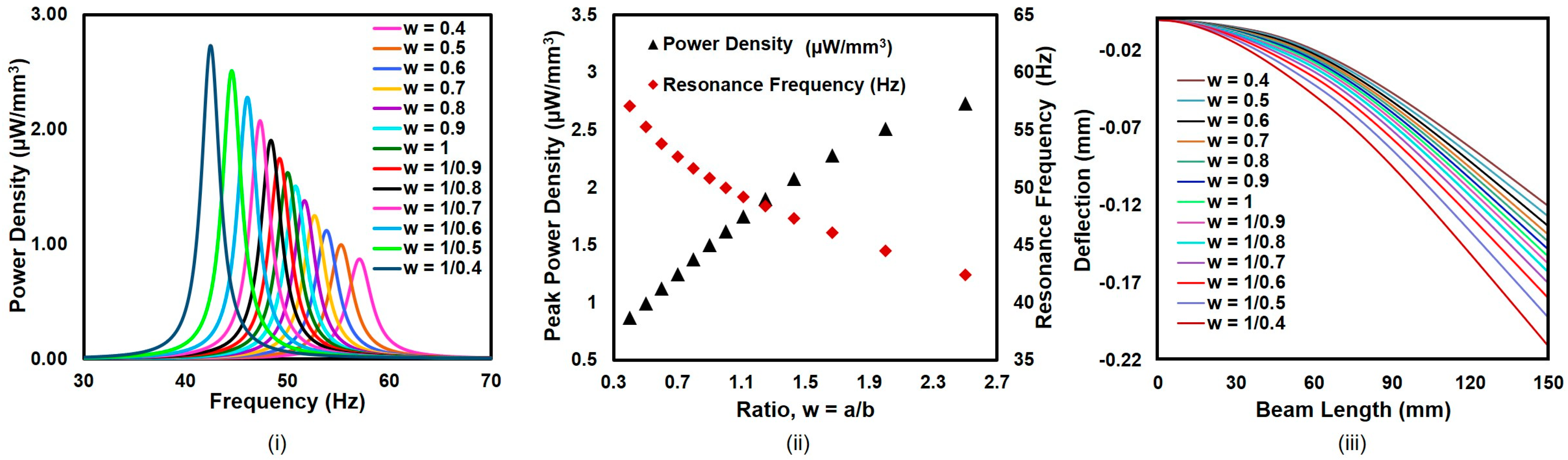

5. Finding an Effective PZT-to-Base Beam Ratio

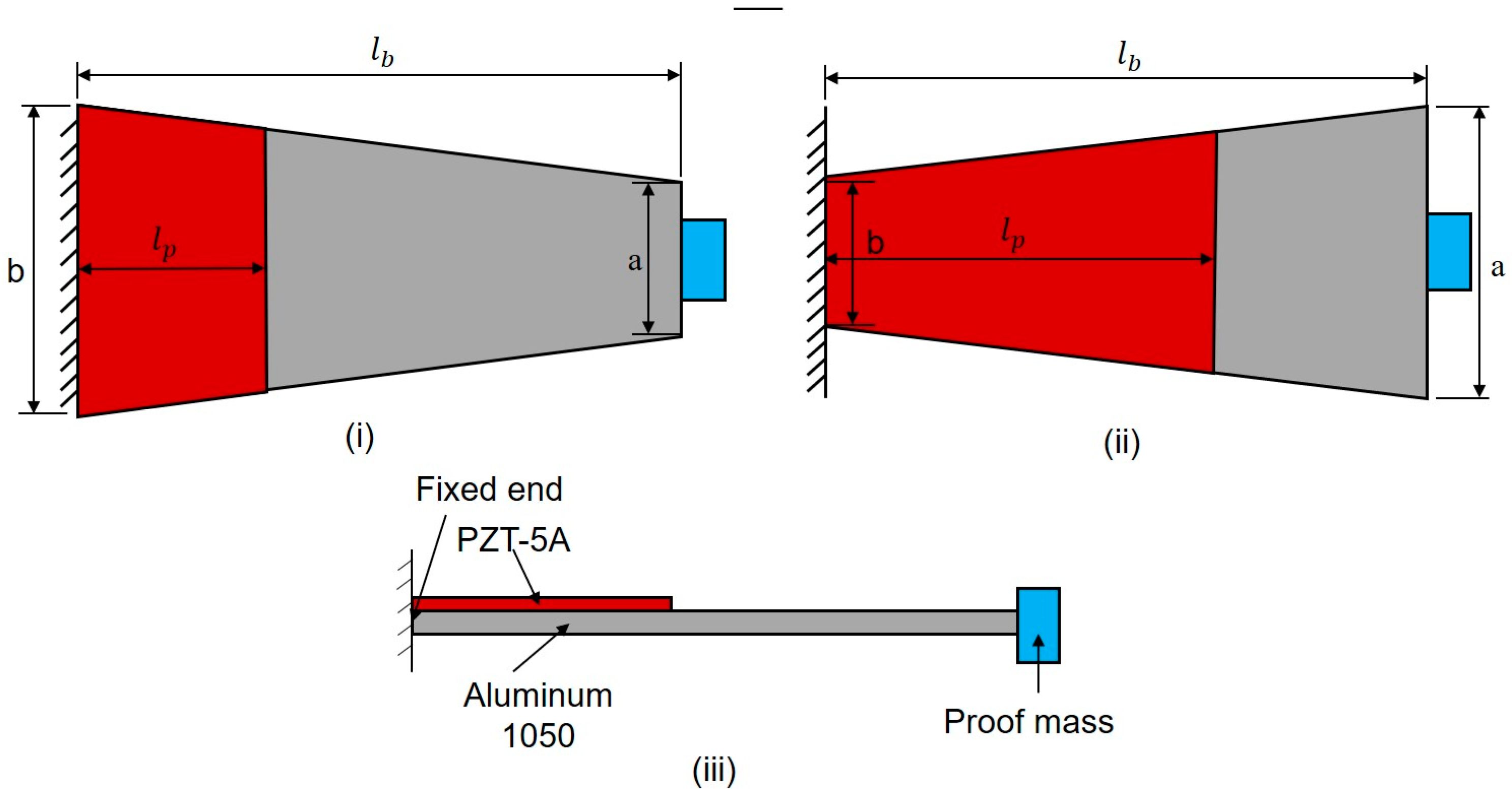

6. Analysis of Different Beam Shapes

6.1. Analysis of Trapezoidal Beam

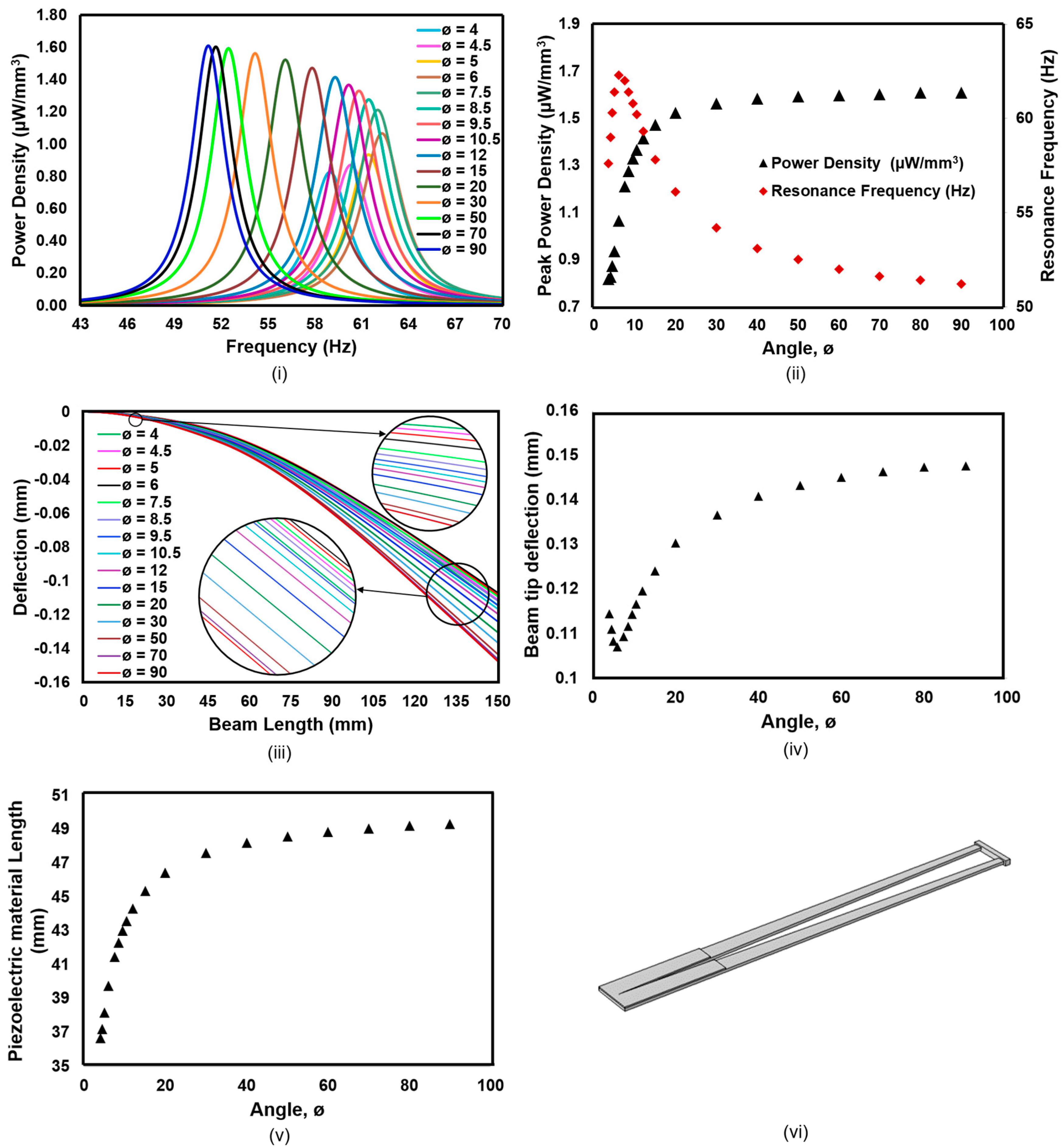

6.2. Analysis of Concave Beam

6.3. Analysis of Convex Beam

6.4. Analysis of V-Cut Beam

6.5. Analysis of Triangular Beam

7. Comparison Among Beam Types

8. Effect of Beam and Piezoelectric Material Thickness

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.W.; Lin, L. A Comprehensive Review on Piezoelectric Energy Harvesting Technology: Materials, Mechanisms, and Applications. Appl. Phys. Rev. 2018, 5, 041306. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.K.; Rabaey, J. A Study of Low Level Vibrations as a Power Source for Wireless Sensor Nodes. Comput. Commun. 2003, 26, 1131–1144. [Google Scholar] [CrossRef]

- Baker, J.; Roundy, S.; Wright, P. Alternative Geometries for Increasing Power Density in Vibration Energy Scavenging for Wireless Sensor Networks. In Collection of Technical Papers, Proceedings of the 3rd International Energy Conversion Engineering Conference, San Francisco, CA, USA, 15–18 August 2005; AIAA: Las Vegas, NV, USA, 2005; Volume 2, pp. 959–970. [Google Scholar] [CrossRef]

- Zhang, G.; Gao, S.; Liu, H.; Niu, S. A Low Frequency Piezoelectric Energy Harvester with Trapezoidal Cantilever Beam: Theory and Experiment. Microsyst. Technol. 2017, 23, 3457–3466. [Google Scholar] [CrossRef]

- Rosmi, A.S.; Isa, M.; Ismail, B.; Rohani, M.N.K.H.; Wahab, Y. An Optimization of Electrical Output Power for Piezoelectric Energy Harvester Using Different Micro-Cantilever Beam Geometries. J. Phys. Conf. Ser. 2018, 1019, 012033. [Google Scholar] [CrossRef]

- Hosseini, R.; Hamedi, M. Improvements in Energy Harvesting Capabilities by Using Different Shapes of Piezoelectric Bimorphs. J. Micromech. Microeng. 2015, 25, 125008. [Google Scholar] [CrossRef]

- Benasciutti, D.; Moro, L.; Zelenika, S.; Brusa, E. Vibration Energy Scavenging via Piezoelectric Bimorphs of Optimized Shapes. Microsyst. Technol. 2010, 16, 657–668. [Google Scholar] [CrossRef]

- Jin, L.; Gao, S.; Zhou, X.; Zhang, G. The Effect of Different Shapes of Cantilever Beam in Piezoelectric Energy Harvesters on Their Electrical Output. Microsyst. Technol. 2017, 23, 4805–4814. [Google Scholar] [CrossRef]

- Chen, Z.S.; Yang, Y.M.; Deng, G.Q. Analytical and Experimental Study on Vibration Energy Harvesting Behaviors of Piezoelectric Cantilevers with Different Geometries. In Proceedings of the 1st International Conference on Sustainable Power Generation and Supply, SUPERGEN ’09, Nanjing, China, 6–7 April 2009. [Google Scholar] [CrossRef]

- Alameh, A.H.; Gratuze, M.; Nabki, F. Impact of Geometry on the Performance of Cantilever-Based Piezoelectric Vibration Energy Harvesters. IEEE Sens. J. 2019, 19, 10316–10326. [Google Scholar] [CrossRef]

- Goldschmidtboeing, F.; Woias, P. Characterization of Different Beam Shapes for Piezoelectric Energy Harvesting. J. Micromech. Microeng. 2008, 18, 104013. [Google Scholar] [CrossRef]

- Muthalif, A.G.A.; Nordin, N.H.D. Optimal Piezoelectric Beam Shape for Single and Broadband Vibration Energy Harvesting: Modeling, Simulation and Experimental Results. Mech. Syst. Signal Process. 2015, 54–55, 417–426. [Google Scholar] [CrossRef]

- Karadag, C.V.; Ertarla, S.; Topaloglu, N.; Okyar, A.F. Optimization of Beam Profiles for Improved Piezoelectric Energy Harvesting Efficiency. Struct. Multidiscip. Optim. 2021, 63, 631–643. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Y.Q.; Zuo, L.; Zu, J. Introducing Arc-Shaped Piezoelectric Elements into Energy Harvesters. Energy Convers. Manag. 2017, 148, 260–266. [Google Scholar] [CrossRef]

- Ibrahim, D.S.; Beibei, S.; Fatai, S.; Oluseyi, O.A.; Sharif, U. Numerical and Experimental Study of a Gauge-Shaped Beam for Improved Performance of Piezoelectric Energy Harvester. Microsyst. Technol. 2021, 27, 4253–4268. [Google Scholar] [CrossRef]

- Raju, S.S.; Umapathy, M.; Uma, G. Design and Analysis of High Output Piezoelectric Energy Harvester Using Non Uniform Beam. Mech. Adv. Mater. Struct. 2020, 27, 218–227. [Google Scholar] [CrossRef]

- Mohamed, K.; Elgamal, H.; Kouritem, S.A. An Experimental Validation of a New Shape Optimization Technique for Piezoelectric Harvesting Cantilever Beams. Alex. Eng. J. 2021, 60, 1751–1766. [Google Scholar] [CrossRef]

- Pradeesh, E.L.; Udhayakumar, S. Effect of Placement of Piezoelectric Material and Proof Mass on the Performance of Piezoelectric Energy Harvester. Mech. Syst. Signal Process. 2019, 130, 664–676. [Google Scholar] [CrossRef]

- Pradeesh, E.L.; Udhayakumar, S. Investigation on the Geometry of Beams for Piezoelectric Energy Harvester. Microsyst. Technol. 2019, 25, 3463–3475. [Google Scholar] [CrossRef]

- Hajheidari, P.; Stiharu, I.; Bhat, R. Performance of Tapered Cantilever Piezoelectric Energy Harvester Based on Euler–Bernoulli and Timoshenko Beam Theories. J. Intell. Mater. Syst. Struct. 2019, 31, 487–502. [Google Scholar] [CrossRef]

- Mehraeen, S.; Jagannathan, S.; Corzine, K.A. Energy Harvesting from Vibration with Alternate Scavenging Circuitry and Tapered Cantilever Beam. IEEE Trans. Ind. Electron. 2010, 57, 820–830. [Google Scholar] [CrossRef]

- Ibrahim, D.S.; Beibei, S.; Oluseyi, O.A.; Sharif, U. Performance Analysis of Width and Thickness Tapered Geometries on Electrical Power Harvested from a Unimorph Piezoelectric Cantilever Beam. In Proceedings of the 2020 IEEE 3rd International Conference on Electronics Technology, ICET 2020, Chengdu, China, 8–12 May 2020; pp. 100–104. [Google Scholar] [CrossRef]

- Paquin, S.; St-Amant, Y. Improving the Performance of a Piezoelectric Energy Harvester Using a Variable Thickness. Smart Mater. Struct. 2010, 19, 105020. [Google Scholar] [CrossRef]

- Xie, X.D.; Carpinteri, A.; Wang, Q. A Theoretical Model for a Piezoelectric Energy Harvester with a Tapered Shape. Eng. Struct. 2017, 144, 19–25. [Google Scholar] [CrossRef]

- Matova, S.P.; Renaud, M.; Jambunathan, M.; Goedbloed, M.; Van Schaijk, R. Effect of Length/Width Ratio of Tapered Beams on the Performance of Piezoelectric Energy Harvesters. Smart Mater. Struct. 2013, 22, 075015. [Google Scholar] [CrossRef]

- Kim, G.Y.; Peddigari, M.; Lim, K.W.; Hwang, G.T.; Yoon, W.H.; Choi, H.S.; Lee, J.W.; Ryu, J. Effect of Thickness Ratio in Piezoelectric/Elastic Cantilever Structure on the Piezoelectric Energy Harvesting Performance. Electron. Mater. Lett. 2019, 15, 61–69. [Google Scholar] [CrossRef]

- Patel, R.; McWilliam, S.; Popov, A.A. A Geometric Parameter Study of Piezoelectric Coverage on a Rectangular Cantilever Energy. Smart Mater. Struct. 2011, 20, 085004. [Google Scholar] [CrossRef]

- Salem, M.S.; Ahmed, S.; Shaker, A.; Alshammari, M.T.; Al-Dhlan, K.A.; Alanazi, A.; Saeed, A.; Abouelatta, M. Bandwidth Broadening of Piezoelectric Energy Harvesters Using Arrays of a Proposed Piezoelectric Cantilever Structure. Micromachines 2021, 12, 973. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, R.; Hamedi, M.; Im, J.; Kim, J.; Dayou, J. Analytical and Experimental Investigation of Partially Covered Piezoelectric Cantilever Energy Harvester. Int. J. Precis. Eng. Manuf. 2017, 18, 415–424. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, S.; Jin, L.; Liu, H.; Li, P. Effects of Changing PZT Length on the Performance of Doubly-Clamped Piezoelectric Energy Harvester with Different Beam Shapes under Stochastic Excitation. Microsyst. Technol. 2018, 24, 3799–3813. [Google Scholar] [CrossRef]

- Fu, H.; Chen, G.; Bai, N. Electrode Coverage Optimization for Piezoelectric Energy Harvesting from Tip Excitation. Sensors 2018, 18, 804. [Google Scholar] [CrossRef]

- Hu, K.; Zhou, B.; Wang, F.; Yang, Z.; Wang, M. Influence of Effective Electrode Coverage on the Energy Harvesting Performance of Piezoelectric Cantilevers. Energy Convers. Manag. 2021, 248, 114758. [Google Scholar] [CrossRef]

- Du, S.; Jia, Y.; Seshia, A. Maximizing Output Power in a Cantilevered Piezoelectric Vibration Energy Harvester by Electrode Design. J. Phys. Conf. Ser. 2015, 660, 012114. [Google Scholar] [CrossRef]

- Wang, J.; Geng, L.; Zhou, S.; Zhang, Z.; Lai, Z.; Yurchenko, D. Design, Modeling and Experiments of Broadband Tristable Galloping Piezoelectric Energy Harvester. Acta Mech. Sin. Xuebao 2020, 36, 592–605. [Google Scholar] [CrossRef]

- Deng, H.; Ye, J.; Huang, D. Modeling and Theoretical Analysis of a Stochastic Novel Vibro-Impact Galloping Energy Harvester with a U-Shaped Base. Commun. Nonlinear Sci. Numer. Simul. 2025, 140, 108354. [Google Scholar] [CrossRef]

- Huang, D.; Wang, K.; Li, R.; Li, W. Complexity and Response of Bio-Inspired Energy Harvesters Based on Wing-Beat Pattern. Phys. Scr. 2024, 99, 115241. [Google Scholar] [CrossRef]

- Kwon, S.D. A T-Shaped Piezoelectric Cantilever for Fluid Energy Harvesting. Appl. Phys. Lett. 2010, 97, 164102. [Google Scholar] [CrossRef]

- Shi, G.; Xu, J.; Xia, Y.; Zeng, W.; Jia, S.; Li, Q.; Wang, X.; Xia, H.; Ye, Y. An Annular Tubular Wearable Piezoelectric-Electromagnetic Hybrid Vibration Energy Harvester Driven by Multi Magnetic Beads. Energy Convers. Manag. 2022, 269, 116119. [Google Scholar] [CrossRef]

- Zhou, N.; Ao, H.; Chen, X.; Jiang, H. A Wearable Piezoelectro-Triboelectric Sensor with Nanocomposite Electrodes for Human Physiological Detection. Nano Energy 2022, 96, 107127. [Google Scholar] [CrossRef]

- Mousavi Lajimi, S.A.; Friswell, M.I. Design, Analysis, and Feedback Control of a Nonlinear Micro-Piezoelectric–Electrostatic Energy Harvester. Nonlinear Dyn. 2020, 100, 3029–3042. [Google Scholar] [CrossRef]

- McMaster-Carr. Available online: https://www.mcmaster.com/products/aluminum/shape~sheet-and-bar/system-of-measurement~metric/thickness~2mm/width~10-mm/ (accessed on 8 August 2023).

- Mohiuddin, M.; Mostafijur Rahman, K.; Ahmed, U.Z.; Riaz, A. Impact of Base Beam Length on Piezoelectric Cantilever Energy Harvesters: A Numerical Investigation. In Proceedings of the 6th Industrial Engineering and Operations Management Bangladesh Conference, Dhaka, Bangladesh, 26–28 December 2023. [Google Scholar] [CrossRef]

- Piezoelectric Sheets & Plates|PIEZO.COM. Available online: https://piezo.com/collections/piezo-sheets-plates?_=pf&pf_t_quantity=Quantity__1&pf_t_piezo_material=Piezo Material__PZT 5A&pf_t_thickness=Thickness(in.)__0.0200 (accessed on 8 August 2023).

- Tao, J.; Cheng, H. Dynamic Stress Response and Fatigue Life of Cantilever Beam Under Non-Gaussian Base Excitation. J. Vibroeng. 2022, 16, 63–79. [Google Scholar] [CrossRef]

- Bai, X.; Wen, Y.; Li, P.; Yang, J.; Peng, X.; Yue, X. Multi-Modal Vibration Energy Harvesting Utilizing Spiral Cantilever with Magnetic Coupling. Sens. Actuators A Phys. 2014, 209, 78–86. [Google Scholar] [CrossRef]

- Izadgoshasb, I.; Lim, Y.Y.; Padilla, R.V.; Sedighi, M.; Novak, J.P. Performance Enhancement of a Multiresonant Piezoelectric Energy Harvester for Low Frequency Vibrations. Energies 2019, 12, 2770. [Google Scholar] [CrossRef]

| Properties | PZT-5A | Aluminum |

|---|---|---|

| Elastic modulus (GPa) | 61 | 70 |

| Density (KG/m3) | 7750 | 2700 |

| Piezoelectric constant, (C/m2) | 10.4 | - |

| Permittivity, (F/m) | 1700 | - |

| Shape | Resonance Frequency (Hz) | Maximum Output Power Density (µW/mm3) | Base Width (mm) |

|---|---|---|---|

| Inverted Trapezoid | 42.4 | 2.73 | 5.71 |

| Concave | 49.6 | 1.55 | 10.85 |

| Convex | 49.7 | 2.003 | 2.53 |

| V-Cut | 51.2 | 1.61 | 10.13 |

| Triangular | 30.1 | 1.08 | 11.29 |

| Presenter | Model Description | Output Power Density (µW/mm3) |

|---|---|---|

| Benasciutti et al. [7] | Trapezoid | 0.73 |

| Bai et al. [45] | Spiral | 2.0538 |

| Izadgoshasb et al. [46] | Two triangular branches | 2.003 |

| Yang et al. [14] | Arc-shaped | 8.58 |

| This study | Inverted trapezoid | 2.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohiuddin, M.; Rahman, K.M.; Ahmed, Z.; Ahmed, R. Optimizing Power Density in Partially Coated Cantilever Beam Energy Harvesters: A Cost-Effective Design Strategy. Energies 2024, 17, 5572. https://doi.org/10.3390/en17225572

Mohiuddin M, Rahman KM, Ahmed Z, Ahmed R. Optimizing Power Density in Partially Coated Cantilever Beam Energy Harvesters: A Cost-Effective Design Strategy. Energies. 2024; 17(22):5572. https://doi.org/10.3390/en17225572

Chicago/Turabian StyleMohiuddin, Md., Kazi Mostafijur Rahman, Zahir Ahmed, and Riaz Ahmed. 2024. "Optimizing Power Density in Partially Coated Cantilever Beam Energy Harvesters: A Cost-Effective Design Strategy" Energies 17, no. 22: 5572. https://doi.org/10.3390/en17225572

APA StyleMohiuddin, M., Rahman, K. M., Ahmed, Z., & Ahmed, R. (2024). Optimizing Power Density in Partially Coated Cantilever Beam Energy Harvesters: A Cost-Effective Design Strategy. Energies, 17(22), 5572. https://doi.org/10.3390/en17225572