Power Dispatching Strategy Considering the Health Status of Multi-Energy Conversion Equipment in Highway Power Supply Systems

Abstract

1. Introduction

2. Health Status Analysis of Multi-Energy Conversion Equipment

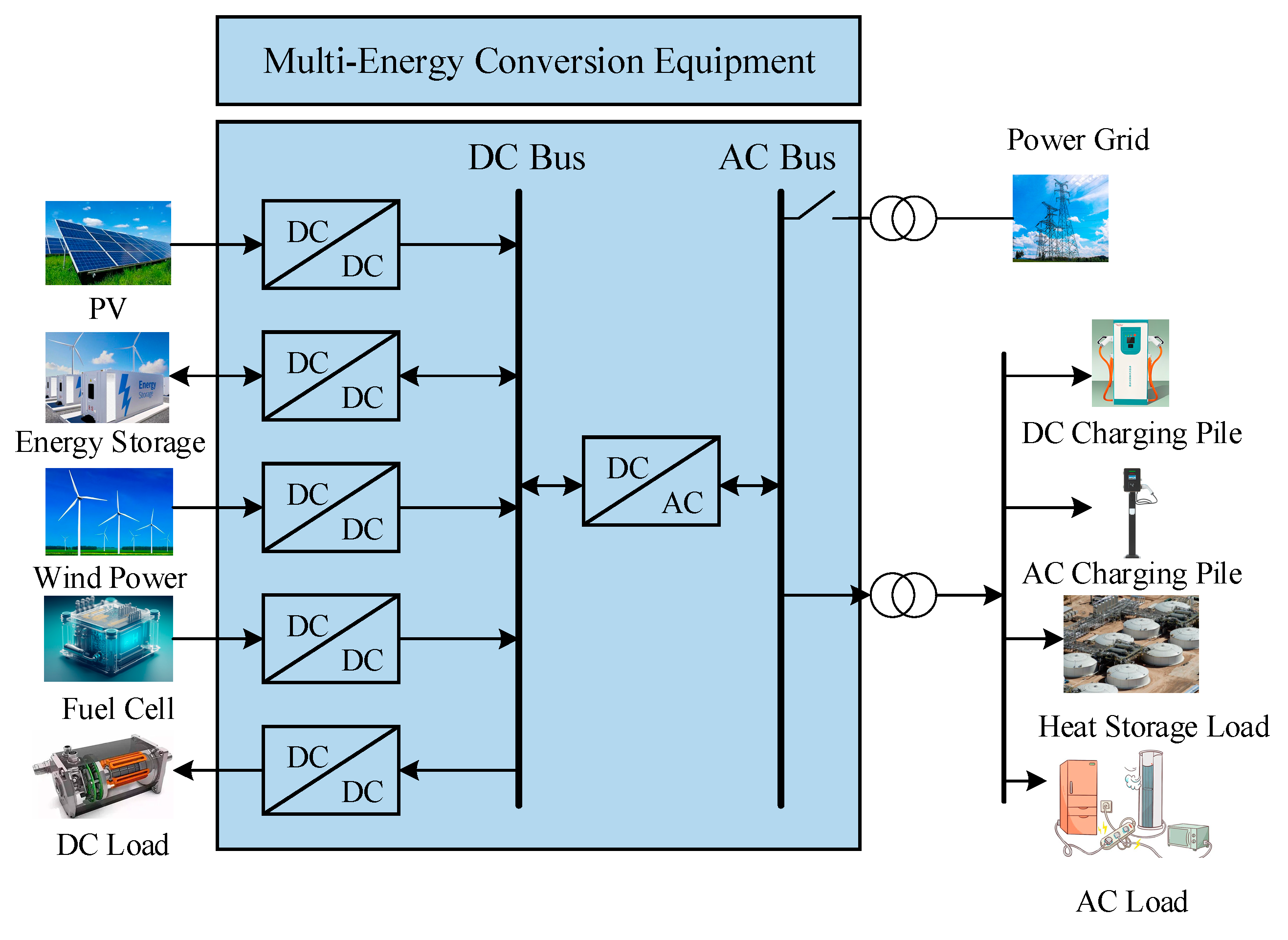

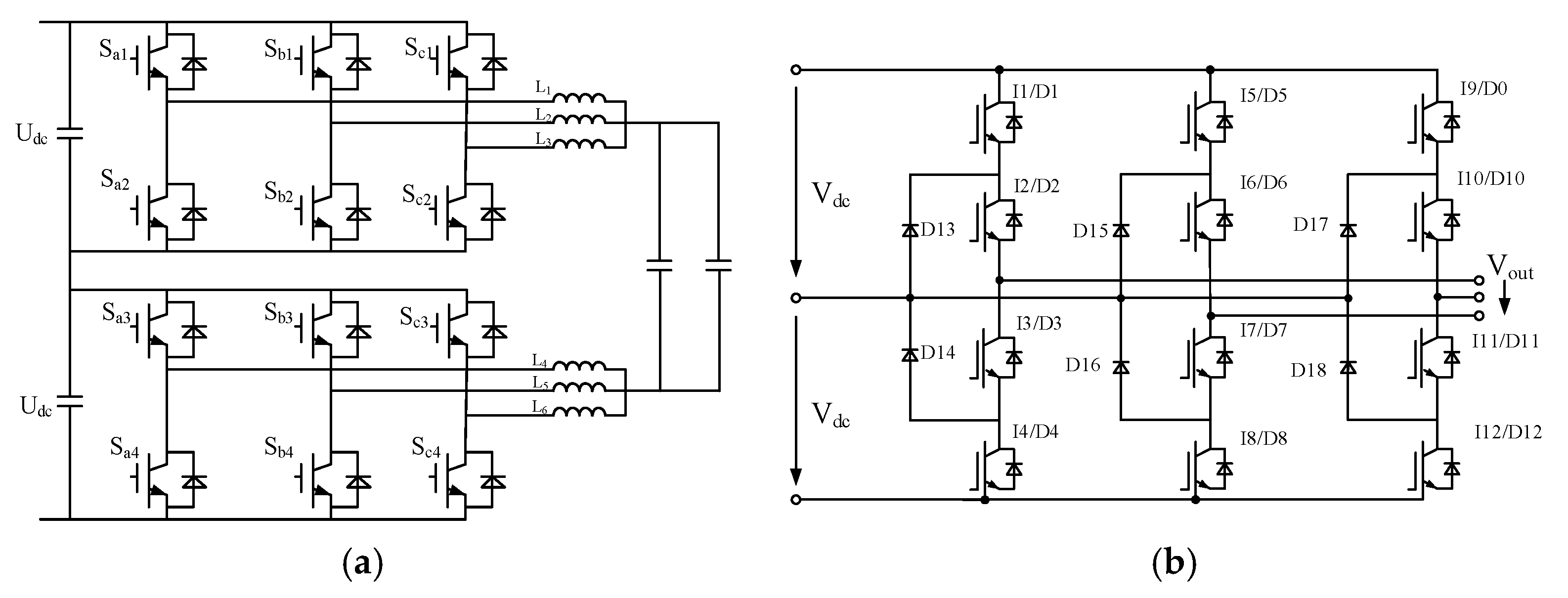

2.1. Multi-Energy Conversion Equipment of Highway Power Supply Systems

2.2. Health Index of Multi-Energy Conversion Equipment Based on Operating Status

3. Multi-Objective Optimization Model for Power Dispatching Strategy of Highway Power Supply System Considering Equipment Health and New Energy Consumption

3.1. Objective Function

3.2. Constraints

- 1.

- The power constraints of each new energy unit are as follows:where, is the lower limit of the output power of the new energy unit in the jth control period, which is generally determined by the minimum operating power of the new energy unit; and is the upper limit of the output power of the new energy unit in the jth control period, which can be equivalent to its predicted power.

- 2.

- In order to cope with the power demand of the highway power supply system when the external grid power supply is lost, the SOC constraint of the energy storage system at any time is as follows:

- 3.

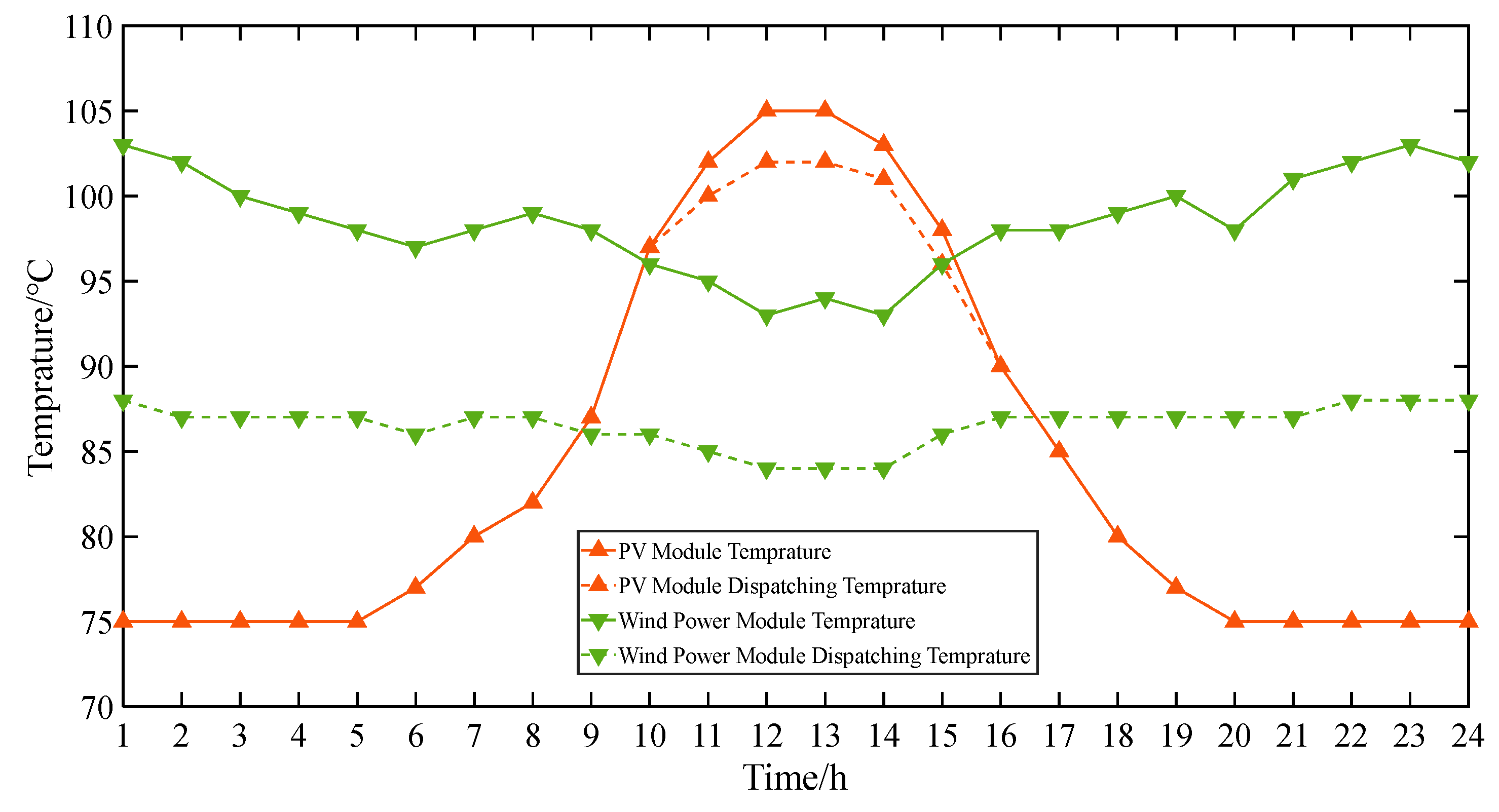

- The module temperature is mainly affected by the module power. Simulation analysis shows that the module temperature is linearly related to the power. Therefore, the relationship between the module temperature and power can be approximately expressed as follows:where, k is the proportional coefficient, which can be obtained through experiments; T0 is the initial temperature of the module; and P0 is the initial power.

- 4.

- The module output voltage is also related to the power of the module. When the power increases, the module output voltage decreases. When the power decreases, the module output voltage increases. The relationship between voltage and power is approximately expressed as follows:where V0 is the voltage corresponding to the module power P0.

- 5.

- The power constraints of the DC–DC module and the DC–AC module. Considering the loss of the DC–DC module, the power of the DC–AC module is as follows:where PAC is the DC–AC module power from DC side to AC side; PDG is the total generation power of new energy; PDL is the total load power of DC side; and PDl is the total power loss of DC–DC modules.

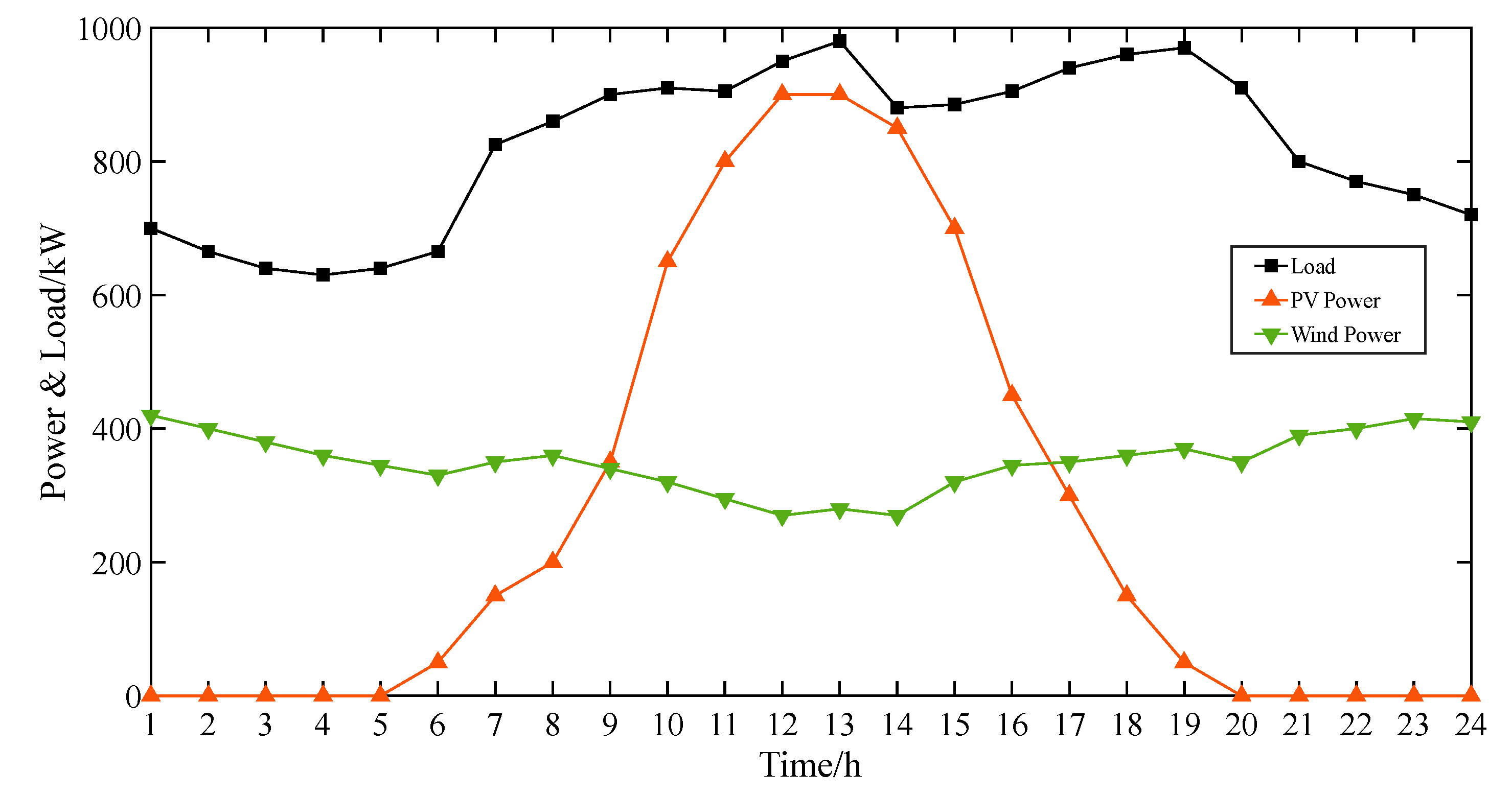

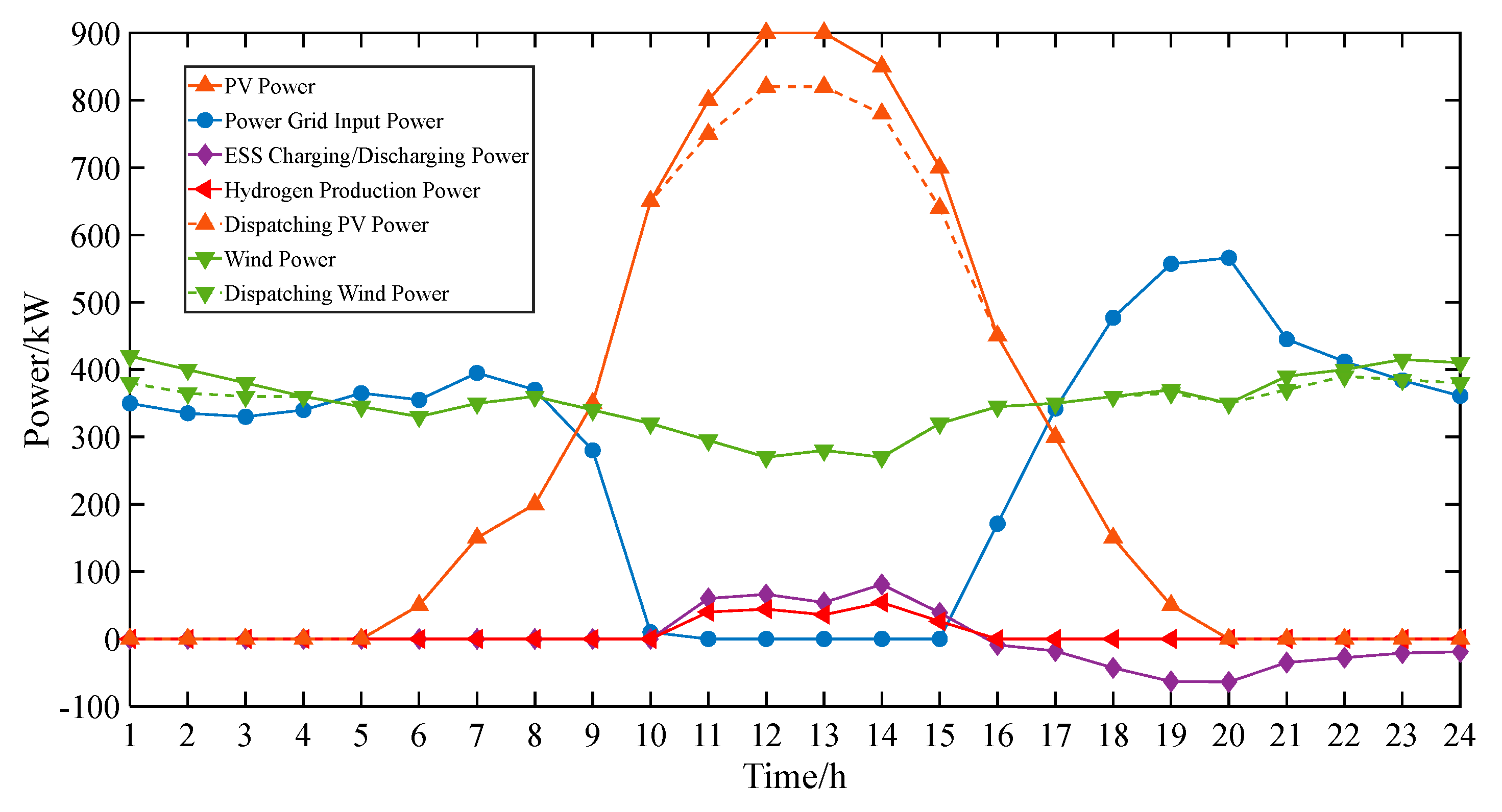

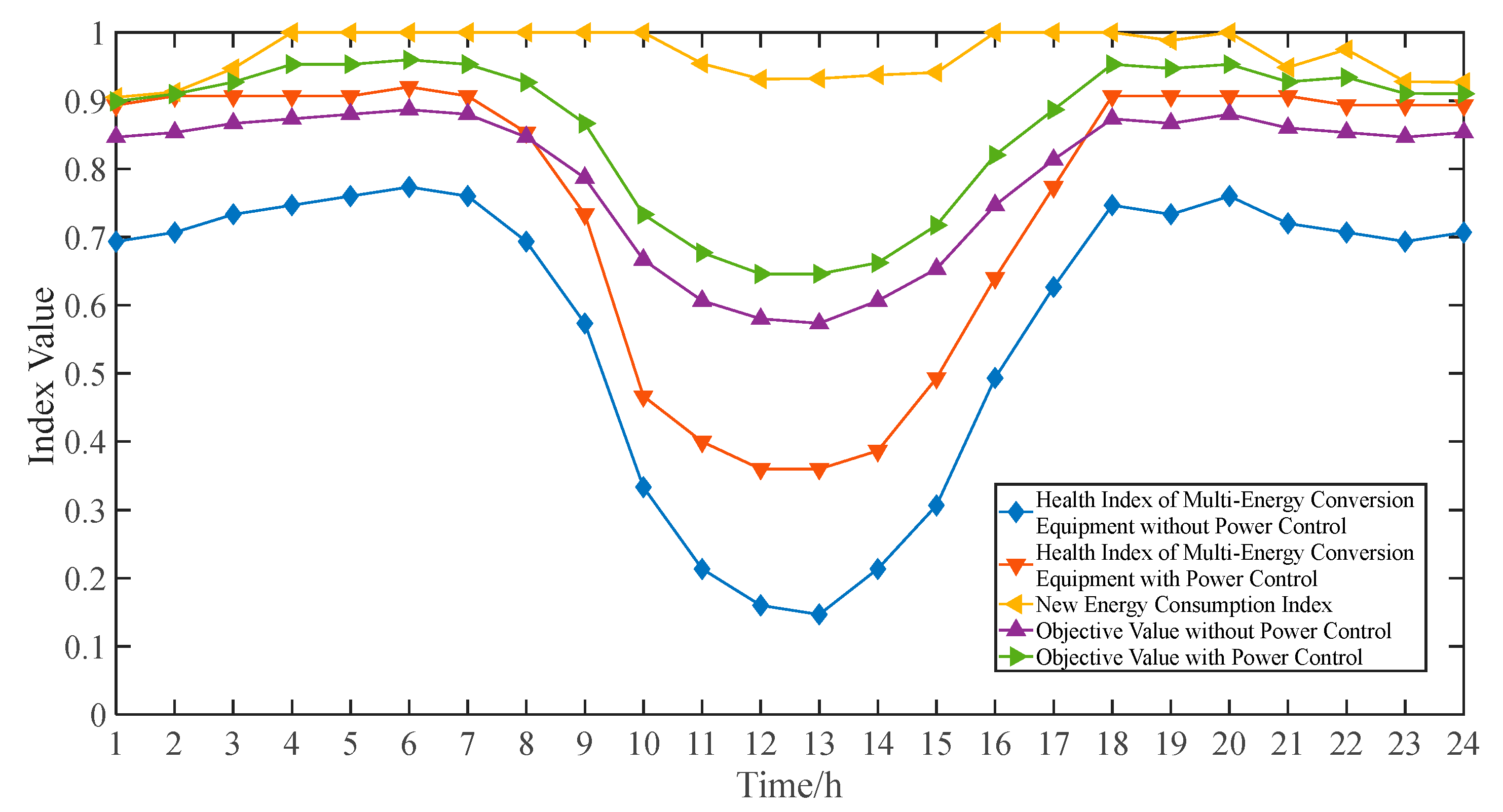

4. Case Analysis

5. Conclusions

- (1)

- In multi-energy conversion equipment, the module temperature and power have a certain relationship, and temperature is an important parameter affecting the multi-energy conversion equipment health status;

- (2)

- The health index based on temperature and output voltage can describe the operating status of multi-energy conversion equipment to a certain extent;

- (3)

- The power dispatching strategy based on equipment health index and new energy consumption index in this paper can reduce the module temperature during the peak period of new energy power while taking into account the consumption of new energy and can delay the aging process of multi-energy conversion equipment and improve the reliability of the power supply system. In addition, since wind power lasts for a long time and has a large heat accumulation, wind power dispatching should be given priority.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Du, X.; Wang, L.; Zhao, J.; He, Y.; Sun, K. Power Dispatching of Multi-Microgrid Based on Improved CS Aiming at Economic Optimization on Source-Network-Load-Storage. Electronics 2022, 11, 2742. [Google Scholar] [CrossRef]

- Peng, C.Y.; Kuo, C.C.; Tsai, C.T. Optimal Configuration with Capacity Analysis of PV-Plus-BESS for Behind-the-Meter Application. Appl. Sci. 2021, 11, 7851. [Google Scholar] [CrossRef]

- Zhang, Q.W.; Wang, X.L.; Li, Y. Optimal Scheduling of Hybrid Wind-Photovoltaic-Hydro-Pumped Storage Power System. Power Energy 2017, 38, 581–586. [Google Scholar]

- Shi, L.; Yao, L.; Wang, R. Modeling and Solutions of Coordinated Economic Dispatch with Wind-Hydro-Thermal Complex Power Source Structure. IET Renew. Power Gener. 2016, 11, 262–270. [Google Scholar] [CrossRef]

- Ge, X.L.; Jin, Y.; Xia, S.; Fu, Y. A Coordinated Optimization Scheduling of Wind-hydro-thermal Power System Based on Requirement of Peak Load and Frequency Regulation. Power Syst. Technol. 2019, 43, 3918–3925. [Google Scholar]

- Chen, Q.; Yang, X.; He, G.Q. Optimal scheduling system for wind farm and hydro power plant coordinating operation. Appl. Energy Symp. Forum 2018, 145, 277–282. [Google Scholar] [CrossRef]

- Zhao, S.Q.; Liu, D.Z.; Xie, Y.Q.; Liu, J.; Hu, Y.Q. Scheduling Strategy of Energy Storage in Wind-Solar-Battery Hybrid Power System Based on Dependent-Chance Goal Programming. Autom. Electr. Power Syst. 2015, 39, 30–36. [Google Scholar]

- An, L.; Wang, M.B.; Qi, X.; Li, F.H.; Qu, J.H. Optimal Dispatching of Multi-Power Sources Containing Wind/Photovoltaic/Thermal/Hydro-Pumped and Battery Storage. Renew. Energy Resour. 2018, 36, 1492–1498. [Google Scholar]

- Zhang, G.B.; Chen, Y.; Zhang, J.H.; Tang, N.N. Research on Optimization of Day-Ahead Dispatching of Wind Power-Photovoltaic-Hydropower-Thermal Power-Pumped Storage Combined Power Generation System. Acta Energiae Solaris Sin. 2020, 41, 80–85. [Google Scholar]

- Ye, Z.; Li, X.Q.; Jang, F.; Chen, L.; Wang, Y.L.; Dai, S.F. Hierarchical Optimization Economic Dispatching of Combined Wind-PV-thermal-energy Storage System Considering the Optimal Energy Abandonment Rate. Powre Syst. Technol. 2021, 45, 2270–2279. [Google Scholar]

- Wang, K.Y.; Luo, X.J.; Jia, R.; Zhou, C.W. Short-term Coordinated Scheduling of Wind-pumped-hydro-thermal Power System With Multi-energy Complementarities. Powre Syst. Technol. 2020, 44, 3631–3640. [Google Scholar]

- Wang, Y.M.; Zhao, M.Z.; Chang, J.X.; Wang, X.B.; Tian, Y.Y. Study on the Combined Operation of A Hydro Thermal-Wind Hybrid Power System Based on Hydro-Wind Power Compensating Principles. Energy Convers. Manag. 2019, 194, 94–111. [Google Scholar] [CrossRef]

- Li, T.; Li, Z.W.; Yang, J.Y.; Cui, D.; Wang, Z.H.; Ma, K.; Hu, W. Coordination and Optimal Scheduling of Multi-energy Complementary System Considering Peak Regulation Initiative. Powre Syst. Technol. 2020, 44, 3623–3630. [Google Scholar]

- Li, M.J.; Chen, G.P.; Dong, C.; Liang, Z.F.; Wang, W.S.; Fan, G.F. Research on Power Balance of High Proportion Renewable Energy System. Powre Syst. Technol. 2019, 43, 3979–3986. [Google Scholar]

- Shu, Y.B.; Zhang, Z.G.; Guo, J.B.; Zhang, Z.L. Study on Key Factors and Solution of Renewable Energy Accommodation. Proc. CSEE 2017, 37, 1–8. [Google Scholar]

- Veillard, J.; Champagne, F.; Klazinga, N.; Kazandjian, V.; Arah, O.A.; Guisset, A.L. A performance assessment framework for hospitals: The WHO regional office for Europe PATH project. Int. J. Qual. Health Care J. Int. Soc. Qual. Health Care 2005, 17, 487–496. [Google Scholar] [CrossRef]

- Yang, F.; Habibullah, M.S.; Zhang, T.; Xu, Z.; Lim, P.; Nadarajan, S. Health index-based prognostics for remaining useful life predictions in electrical machines. IEEE Trans. Ind. Electron. 2016, 63, 2633–2644. [Google Scholar] [CrossRef]

- Liu, K.; Gebraeel, N.; Shi, J. A Data-Level Fusion Model for Developing Composite Health Indices for Degradation Modeling and Prognostic Analysis. Autom. Sci. Eng. IEEE Trans. 2013, 10, 652–664. [Google Scholar] [CrossRef]

- Xu, L.; Xu, J.P. Integrated system health management-based progressive diagnosis for space avionics. IEEE Trans. Aerosp. Electron. Syst. 2014, 50, 1390–1402. [Google Scholar] [CrossRef]

- Li, M.K.; Song, D.N. Fault diagnosis method of converter circuit base on wavelet analyze and RF algorithm. Electr. Eng. 2016, 17, 36–40. [Google Scholar]

- Bian, L.; Bian, C.Y. Review on intelligence fault diagnosis in power networks. Power Syst. Prot. Control 2014, 42, 146–153. [Google Scholar]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Capolino, G.-A. Advances in electrical machine, power electronic, and drive condition monitoring and fault detection: State of the art. IEEE Trans. Ind. Electron. 2014, 62, 1746–1759. [Google Scholar] [CrossRef]

- Shen, G.; Zhou, L.W.; Du, X.; Yang, X.; Xu, M.W. Characteristics analysis of IGBT module with bond wire lift-off based on wavelet singular entropy theory. Trans. China Electrotech. Soc. 2013, 28, 165–171. [Google Scholar]

- Amaral, A.M.; Cardoso, A.M.J. Simple experimental techniques to characterize capacitors in a wide range of frequencies and temperatures. IEEE Trans. Instrum. Meas. 2010, 59, 1258–1267. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, X.; Wang, J.; Guo, S.; Liu, K. Power Dispatching Strategy Considering the Health Status of Multi-Energy Conversion Equipment in Highway Power Supply Systems. Energies 2024, 17, 4499. https://doi.org/10.3390/en17174499

Hou X, Wang J, Guo S, Liu K. Power Dispatching Strategy Considering the Health Status of Multi-Energy Conversion Equipment in Highway Power Supply Systems. Energies. 2024; 17(17):4499. https://doi.org/10.3390/en17174499

Chicago/Turabian StyleHou, Xianhong, Jiao Wang, Shaoyong Guo, and Ketian Liu. 2024. "Power Dispatching Strategy Considering the Health Status of Multi-Energy Conversion Equipment in Highway Power Supply Systems" Energies 17, no. 17: 4499. https://doi.org/10.3390/en17174499

APA StyleHou, X., Wang, J., Guo, S., & Liu, K. (2024). Power Dispatching Strategy Considering the Health Status of Multi-Energy Conversion Equipment in Highway Power Supply Systems. Energies, 17(17), 4499. https://doi.org/10.3390/en17174499