Study of Efficient and Clean Combustion of Diesel–Natural Gas Engine at Low Loads with Concentration and Temperature Stratified Combustion

Abstract

1. Introduction

2. Methodology

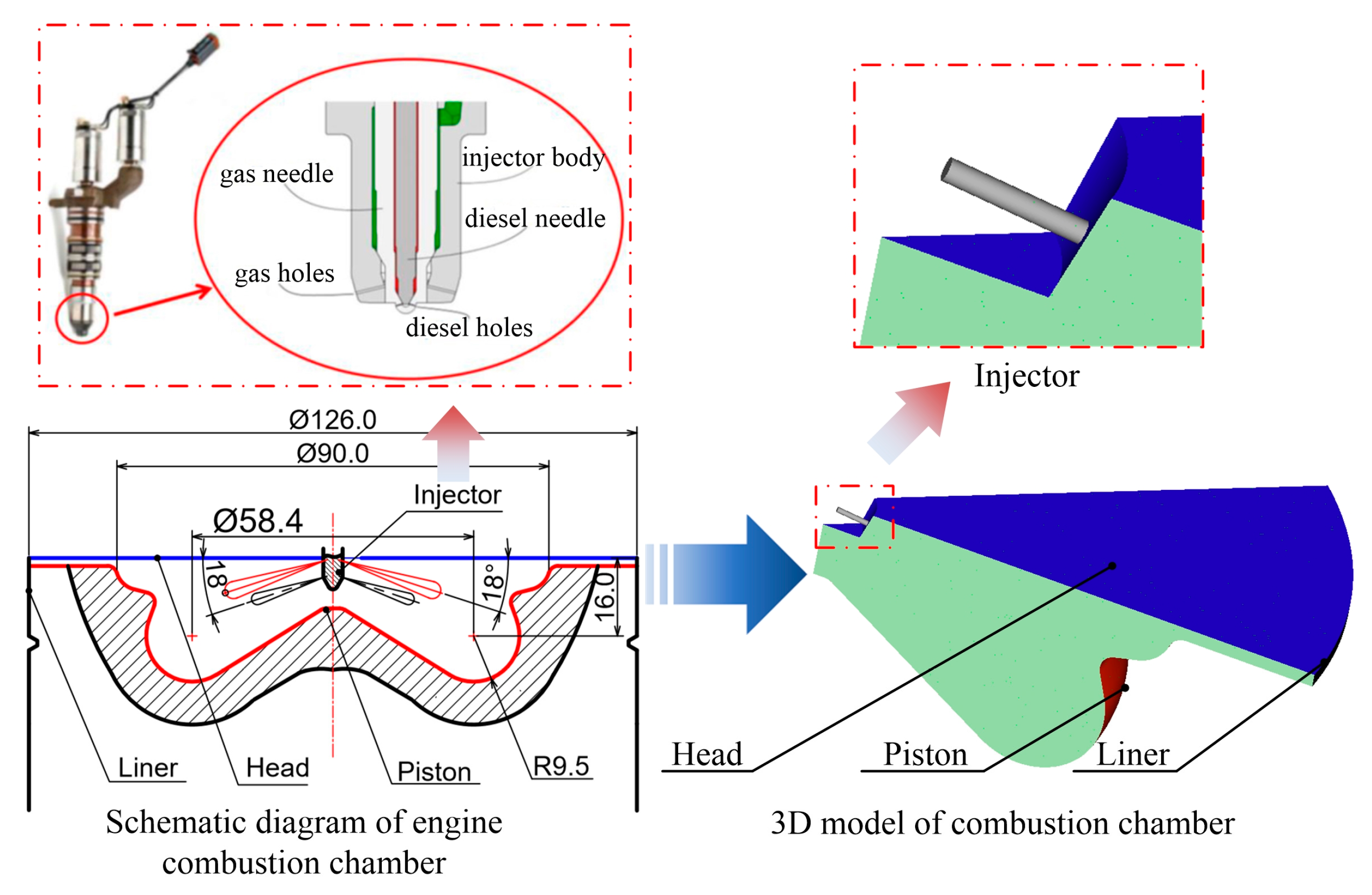

2.1. Experimental Setup

2.2. Model and Validation

2.2.1. Simulation Model

2.2.2. Model Validation

- (1)

- Diesel spray validation

- (2)

- NG spray model validation

- (3)

- Combustion and emissions validation

2.3. Definition

3. Results and Discussion

3.1. Organization of Different Stratified Mixture

3.2. Combustion in Moderate React Ratio Mixture (Case 1)

3.3. Combustion in Lean React Ratio Mixture (Case 2, 3)

3.4. Combustion in Rich React Ratio Mixture (Case 4)

4. Conclusions

- (1)

- At low engine loads, stratified combustion increased the reactivity of combustible mixture for concentration and temperature stratification. Different stratified combustion can be organized by controlling pressures, timings, and durations of diesel and NG injections. According to the react ratio distributions of the unburned mixture during the combustion process, typical stratified combustion can be classified into moderate, lean, and rich stratified combustion mode.

- (2)

- Combining with the concentration and temperature stratification of the mixture, high thermal efficiency and low emissions can be realized simultaneously in stratified combustion. The concept of CTSC was put forward to suggest that more mixtures should burn with the react ratio of 0.4 to 0.8 for low NOx emissions, low UHC emissions and rapid combustion. The proper temperature stratification should provide a high-temperature charge around the over-lean NG-stratified mixture to improve combustion efficiency and reduce UHC emissions.

- (3)

- Stratified combustion strategy was adopted at low NG engine load operation (IMEPg = 5 bar), of which the PDR was 11%, and ITEg was above 47.0%. The drawbacks of significant cycle-to-cycle variations of the NG engine at low load can be overcome. Furthermore, ISUHC values were below 1.6 g/kWh, and ISNOx values were below 0.6 g/kWh.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| NG | natural gas |

| UHC | unburned hydrocarbon |

| CO2 | carbon dioxide |

| EGR | exhaust gas recirculation |

| PDR | pilot diesel ratio |

| CO | carbon monoxide |

| TDC | top dead center |

| ATDC | after the top dead center |

| IVC | intake valve closing |

| EVO | exhaust valve opening |

| SOI | start of injection |

| AHRR | apparent heat release rate |

| HTL | heat transfer loss |

| EL | exhaust loss |

| CL | combustion loss |

| Pin | intake pressure |

| HPDI | high-pressure direct injection |

| NOx | nitrogen oxides |

| IMEPg | gross indicated mean effective pressure |

| BMEP | brake mean effective pressure |

| ITEg | indicated thermal efficiency |

| CTSC | concentration and temperature-stratified combustion |

| ISUHC | indicated specific emissions of UHC |

| ISNOx | indicated specific emissions of nitrogen oxide |

| HCCI | homogeneous charge compression ignition |

| DIDF | diesel-ignited dual fuel |

| RCCI | reactivity-controlled compression ignition |

| Png | injection pressure of NG |

| Pdiesel | injection pressure of diesel |

| FSOIdiesel | first start of diesel injection timing |

| SSOIdiesel | second start of diesel injection timing |

| FSOIng | first start of NG injection timing |

| SSOIng | second start of NG injection timing |

| Fng | proportion of the first NG injection |

| DI2 | co-direct injection of NG and diesel fuel |

| CH4 | methane |

References

- Fasching, P.; Sprenger, F.; Eichlseder, H. Experimental Optimization of a Small Bore Natural Gas-Diesel Dual Fuel Engine with Direct Fuel Injection. SAE Int. J. Engines 2016, 9, 1072–1086. [Google Scholar] [CrossRef]

- Yu, H.; Su, W. Numerical Study on a High Efficiency Gasoline Reformed Molecule HCCI Combustion Using Exergy Analysis; SAE Technical Paper 2017-01-0735; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Papagiannakis, R.; Kotsiopoulos, P.; Zannis, T.; Yfantis, E.; Hountalas, D.; Rakopoulos, C. Theoretical study of the effects of engine parameters on performance and emissions of a pilot ignited natural gas diesel engine. Energy 2010, 35, 1129–1138. [Google Scholar] [CrossRef]

- Lu, X.; Han, D.; Huang, Z. Fuel design and management for the control of advanced compression-ignition combustion modes. Prog. Energy Combust. Sci. 2011, 37, 741–783. [Google Scholar] [CrossRef]

- Christensen, M.; Johansson, B.; Amnéus, P.; Mauss, F. Supercharged Homogeneous Charge Compression Ignition; SAE Technical Paper 980787; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef]

- Kuzuyama, H.; Machida, M.; Akihama, K.; Inagaki, K.; Ueda, M. A Study on Natural Gas Fueled Homogeneous Charge Compression Ignition Engine—Expanding the Operating Range and Combustion Mode Switching; SAE Technical Paper 2007-01-0176; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Handford, D.I.; Checkel, M.D. Extending the Load Range of a Natural Gas HCCI Engine Using Direct Injected Pilot Charge and External EGR; SAE Technical Paper 2009-01-1884; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Shim, E.; Park, H.; Bae, C. Intake air strategy for low HC and CO emissions in dual-fuel (CNG-diesel) premixed charge compression ignition engine. Appl. Energy 2018, 225, 1068–1077. [Google Scholar] [CrossRef]

- Yousefi, A.; Birouk, M. Investigation of natural gas energy fraction and injection timing on the performance and emissions of a dual-fuel engine with pre-combustion chamber under low engine load. Appl. Energy 2017, 189, 492–505. [Google Scholar] [CrossRef]

- Vávra, J.; Bortel, I.; Takáts, M.; Diviš, M. Emissions and performance of diesel–natural gas dual-fuel engine operated with stoichiometric mixture. Fuel 2017, 208, 722–733. [Google Scholar] [CrossRef]

- Li, D.; Liu, Z.; Wu, Y. Experimental and theoretical analysis of the combustion process at low loads of a diesel natural gas dual-fuel engine. Energy 2016, 94, 728–741. [Google Scholar] [CrossRef]

- Mikulski, M.; Balakrishnan, P.R.; Hunicz, J. Natural gas-diesel reactivity controlled compression ignition with negative valve overlap and in-cylinder fuel reforming. Appl. Energy 2019, 254, 113638. [Google Scholar] [CrossRef]

- Ansari, E.; Shahbakhti, M.; Naber, J. Optimization of performance and operational cost for a dual mode diesel-natural gas RCCI and diesel combustion engine. Appl. Energy 2018, 231, 549–561. [Google Scholar] [CrossRef]

- Li, Y.; Jia, M.; Xu, L.; Bai, X.-S. Multiple-objective optimization of methanol/diesel dual-fuel engine at low loads: A comparison of reactivity controlled compression ignition (RCCI) and direct dual fuel stratification (DDFS) strategies. Fuel 2020, 262, 116673. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.; Zhou, D. Review on the management of RCCI engines. Renew. Sustain. Energy Rev. 2017, 69, 65–79. [Google Scholar] [CrossRef]

- Poorghasemi, K.; Saray, R.K.; Ansari, E.; Irdmousa, B.K.; Shahbakhti, M.; Naber, J.D. Effect of diesel injection strategies on natural gas/diesel RCCI combustion characteristics in a light duty diesel engine. Appl. Energy 2017, 199, 430–446. [Google Scholar] [CrossRef]

- Di Blasio, G.; Belgiorno, G.; Beatrice, C.; Fraioli, V.; Migliaccio, M. Experimental Evaluation of Compression Ratio Influence on the Performance of a Dual-Fuel Methane-Diesel Light-Duty Engine. SAE Int. J. Engines 2015, 8, 2253–2267. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Birouk, M.; Liko, B. On greenhouse gas emissions and thermal efficiency of natural gas/diesel dual-fuel engine at low load conditions: Coupled effect of injector rail pressure and split injection. Appl. Energy 2019, 242, 216–231. [Google Scholar] [CrossRef]

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, G.; et al. Changes in atmospheric constituents and in radiative forcing. In 4th Assessment Report of the IPCC WG1: The Physical Science Basis; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- McTaggart-Cowan, G. Pollutant Formation in a Gaseous-Fuelled, Direct Injection Engine. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2006. [Google Scholar]

- Faghani, E.; Patychuk, B.; McTaggart-Cowan, G.; Rogak, S. Soot Emission Reduction from Post Injection Strategies in a High Pressure Direct Injection Natural Gas Engine. In Proceedings of the 11th International Conference on Engines & Vehicles, Napoli, Italy, 15–19 September 2013; SAE Technical Paper 2013-24-0114. Available online: https://saemobilus.sae.org/content/2013-24-0114 (accessed on 8 August 2024).

- Mctaggart-Cowan, G.; Mann, K.; Huang, J.; Singh, A.; Patychuk, B.; Zheng, Z.X.; Munshi, S. Direct Injection of Natural Gas at up to 600 Bar in a Pilot-Ignited Heavy-Duty Engine. SAE Int. J. Engines 2015, 8, 981–996. [Google Scholar] [CrossRef]

- Faghani, E.; Kheirkhah, P.; Mabson, C.W.; McTaggart-Cowan, G.; Kirchen, P.; Rogak, S. Effect of Injection Strategies on Emissions from a Pilot-Ignited Direct-Injection Natural-Gas Engine—Part I: Late Post Injection; SAE Technical Paper 2017-01-0774; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Faghani, E.; Kheirkhah, P.; Mabson, C.W.; McTaggart-Cowan, G.; Kirchen, P.; Rogak, S. Effect of Injection Strategies on Emissions from a Pilot-Ignited Direct-Injection Natural-Gas Engine—Part II: Slightly Premixed Combustion; SAE Technical Paper 2017-01-0763; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Florea, R.; Neely, G.D.; Abidin, Z.; Miwa, J. Efficiency and Emissions Characteristics of Partially Premixed Dual-Fuel Combustion by Co-Direct Injection of NG and Diesel Fuel (DI2); SAE Technical Paper 2016-01-0779; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Neely, G.D.; Florea, R.; Miwa, J.; Abidin, Z. Efficiency and Emissions Characteristics of Partially Premixed Dual-Fuel Combustion by Co-Direct Injection of NG and Diesel Fuel (DI2)-Part 2; SAE Technical Paper 2017-01-0766; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Rochussen, J.; Yeo, J.; Kirchen, P. Effect of Fueling Control Parameters on Combustion and Emissions Characteristics of Diesel-Ignited Methane Dual-Fuel Combustion; SAE Technical Paper 2016-01-0792; SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Su, W.; Yu, W. Effects of mixing and chemical parameters on thermal efficiency in a partly premixed combustion diesel engine with near-zero emissions. Int. J. Engine Res. 2012, 13, 188–198. [Google Scholar] [CrossRef]

- Han, Z.; Reitz, R.D. Turbulence Modeling of Internal Combustion Engines Using RNG κ-ε Models. Combust. Sci. Technol. 1995, 106, 267–295. [Google Scholar] [CrossRef]

- Han, Z.; Reitz, R.D. A temperature wall function formulation for variable-density turbulent flows with application to engine convective heat transfer modeling. Int. J. Heat Mass Transf. 1997, 40, 613–625. [Google Scholar] [CrossRef]

- Li, Y.; Jia, M.; Chang, Y.; Kokjohn, S.L.; Reitz, R.D. Thermodynamic energy and exergy analysis of three different engine combustion regimes. Appl. Energy 2016, 180, 849–858. [Google Scholar] [CrossRef]

- Nie, X.; Su, W. Numerical Study of Ignition Core Formation and the Effects on Combustion in a Pilot Ignited NG Engine; SAE Technical Paper 2017-01-2273; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Ra, Y.; Reitz, R.D. A reduced chemical kinetic model for IC engine combustion simulations with primary reference fuels. Combust. Flame 2008, 155, 713–738. [Google Scholar] [CrossRef]

- Li, Y.; Guo, H.; Li, H. Evaluation of Kinetics Process in CFD Model and Its Application in Ignition Process Analysis of a Natural Gas-Diesel Dual Fuel Engine; SAE Technical Paper 2017-01-0554; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Baratta, M.; Catania, A.E.; Spessa, E.; Herrmann, L.; Roessler, K. Multi-Dimensional Modeling of Direct Natural-Gas Injection and Mixture Formation in a Stratified-Charge SI Engine with Centrally Mounted Injector. SAE Int. J. Engines 2009, 1, 607–626. [Google Scholar] [CrossRef]

- Li, Y.; Kirkpatrick, A.; Mitchell, C.; Willson, B. Characteristic and Computational Fluid Dynamics Modeling of High-Pressure Gas Jet Injection. Mod. Hosp. 2004, 126, 192–197. [Google Scholar] [CrossRef]

- Moon, S.; Matsumoto, Y.; Nishida, K. Entrainment, Evaporation and Mixing Characteristics of Diesel Sprays around End-of-Injection; SAE Technical Paper, 2009-01-0849; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Ouellette, P.; Hill, P.G. Turbulent Transient Gas Injections. J. Fluids Eng. 2000, 122, 743–752. [Google Scholar] [CrossRef]

- Yadollahi, B.; Boroomand, M. The effect of combustion chamber geometry on injection and mixture preparation in a CNG direct injection SI engine. Fuel 2013, 107, 52–62. [Google Scholar] [CrossRef]

- Yu, J.; Vuorinen, V.; Hillamo, H.; Sarjovaara, T.; Kaario, O.; Larmi, M. An experimental investigation on the flow structure and mixture formation of low pressure ratio wall-impinging jets by a natural gas injector. J. Nat. Gas Sci. Eng. 2012, 9, 1–10. [Google Scholar] [CrossRef]

- Ansari, E.; Menucci, T.; Shahbakhti, M.; Naber, J. Experimental investigation into effects of high reactive fuel on combustion and emission characteristics of the Diesel—Natural gas Reactivity Controlled Compression Ignition engine. Appl. Energy 2019, 239, 948–956. [Google Scholar] [CrossRef]

- Sitkei, G. Heat Transfer and Thermal Loading in Internal Combustion Engines; Akademiai Kaido: Budapest, Hungary, 1974. [Google Scholar]

- Zhou, L.; Hua, J.; Liu, F.; Liu, F.; Feng, D.; Wei, H. Effect of internal exhaust gas recirculation on the combustion characteristics of gasoline compression ignition engine under low to idle conditions. Energy 2018, 164, 306–315. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, T.; Zhang, J. Numerical analysis of flow, mixture formation and combustion in a direct injection natural gas engine. Fuel 2020, 259, 116268. [Google Scholar] [CrossRef]

- Baratta, M.; Misul, D. Development and assessment of a new methodology for end of combustion detection and its application to cycle resolved heat release analysis in IC engines. Appl. Energy 2012, 98, 174–189. [Google Scholar] [CrossRef]

- Akihama, K.; Takatori, Y.; Inagaki, K.; Sasaki, S.; Dean, A.M. Mechanism of the Smokeless Rich Diesel Combustion by Reducing Temperature; SAE Technical Paper 2001-01-0655; SAE International: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Kamimoto, T.; Bae, M.-H. High Combustion Temperature for the Reduction of Particulate in Diesel Engines; SAE Technical Paper 880423; SAE International: Warrendale, PA, USA, 1988. [Google Scholar] [CrossRef]

| Parameters | Values | |

|---|---|---|

| Base engine | WP12 | |

| Cylinder arrangement | I6 | |

| Bore/Stroke | 126/155 mm | |

| Connecting rod length | 253 mm | |

| Displacement | 11.596 L | |

| Compression ratio | 17:1 | |

| Inlet valve close timing | −146° CA ATDC | |

| Exhaust valve open timing | 131° CA ATDC | |

| Rated power (KW/rpm) | 353 KW/2100 rpm | |

| Max torque (Nm/rpm) | 1970 N·m/1200~1500 rpm | |

| Injection system [26,27] | Hole number/angle | Diesel: 9/18°; Gas: 9/18° |

| Diesel hole diameter | 0.17 mm | |

| NG hole diameter | 0.66 mm | |

| Diesel injection pressure (Pdiesel (bar)) | ≤200 bar | |

| NG injection pressure (Png (bar)) | Pdiesel − 10 bar | |

| Model | Sub-Model |

|---|---|

| Turbulence model | RANS RNG k- |

| Heat transfer model | Han and Reitz |

| Spray model | KH–RT |

| Turbulent dispersion | O’Rourke |

| Combustion model | SAGE |

| Chemical kinetic mechanism | Reitz PRF |

| NOx | Extended Zeldovich NOx |

| SOOT | Hiroyasu Soot |

| Moon | Simulation | |

|---|---|---|

| Injector diameter [mm] | 0.135 | 0.135 |

| Injection quantity [mg] | 6.70 | 6.70 |

| Injection duration [ms] | 1.44 | 1.44 |

| Injection pressure [MPa] | 120 | 120 |

| Ambition pressure [MPa] | 4 | 4 |

| Ambition temperature [K] | 830 | 830 |

| Fuel | 1,3-DMN | n-heptane |

| Parameters | Values |

|---|---|

| Gas Injection Pressure (bar) | 7 |

| Injected Gas | N2 |

| Ambient Pressure (bar) | 1 |

| Ambient Temperature (K) | 293.15 |

| Impinging Distance (mm) | 33 |

| Impinging Angle (°) | 83 |

| Case | Png /bar | Pdiesel /bar | Pin /bar | FSOIdiesel /°CA ATDC | SSOIdiesel /°CA ATDC | FSOIng /°CA ATDC | SSOIng /°CA ATDC | Fng /% | PRD /% |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 100 | 110 | 1.5 | −38 | — | −25 | — | 100 | 11 |

| 2 | 590 | 600 | 1.5 | −7 | — | −15 | — | 100 | 11 |

| 3 | 280 | 290 | 1.5 | −35 | −16 | −25 | −8 | 80 | 17.6 |

| 4 | 100 | 110 | 1.5 | −20 | — | −8 | — | 100 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Su, W.; Jia, Z. Study of Efficient and Clean Combustion of Diesel–Natural Gas Engine at Low Loads with Concentration and Temperature Stratified Combustion. Energies 2024, 17, 4351. https://doi.org/10.3390/en17174351

Zhang M, Su W, Jia Z. Study of Efficient and Clean Combustion of Diesel–Natural Gas Engine at Low Loads with Concentration and Temperature Stratified Combustion. Energies. 2024; 17(17):4351. https://doi.org/10.3390/en17174351

Chicago/Turabian StyleZhang, Min, Wanhua Su, and Zhi Jia. 2024. "Study of Efficient and Clean Combustion of Diesel–Natural Gas Engine at Low Loads with Concentration and Temperature Stratified Combustion" Energies 17, no. 17: 4351. https://doi.org/10.3390/en17174351

APA StyleZhang, M., Su, W., & Jia, Z. (2024). Study of Efficient and Clean Combustion of Diesel–Natural Gas Engine at Low Loads with Concentration and Temperature Stratified Combustion. Energies, 17(17), 4351. https://doi.org/10.3390/en17174351