Impacts and Countermeasures of Present-Day Stress State and Geological Conditions on Coal Reservoir Development in Shizhuang South Block, Qinshui Basin

Abstract

1. Introduction

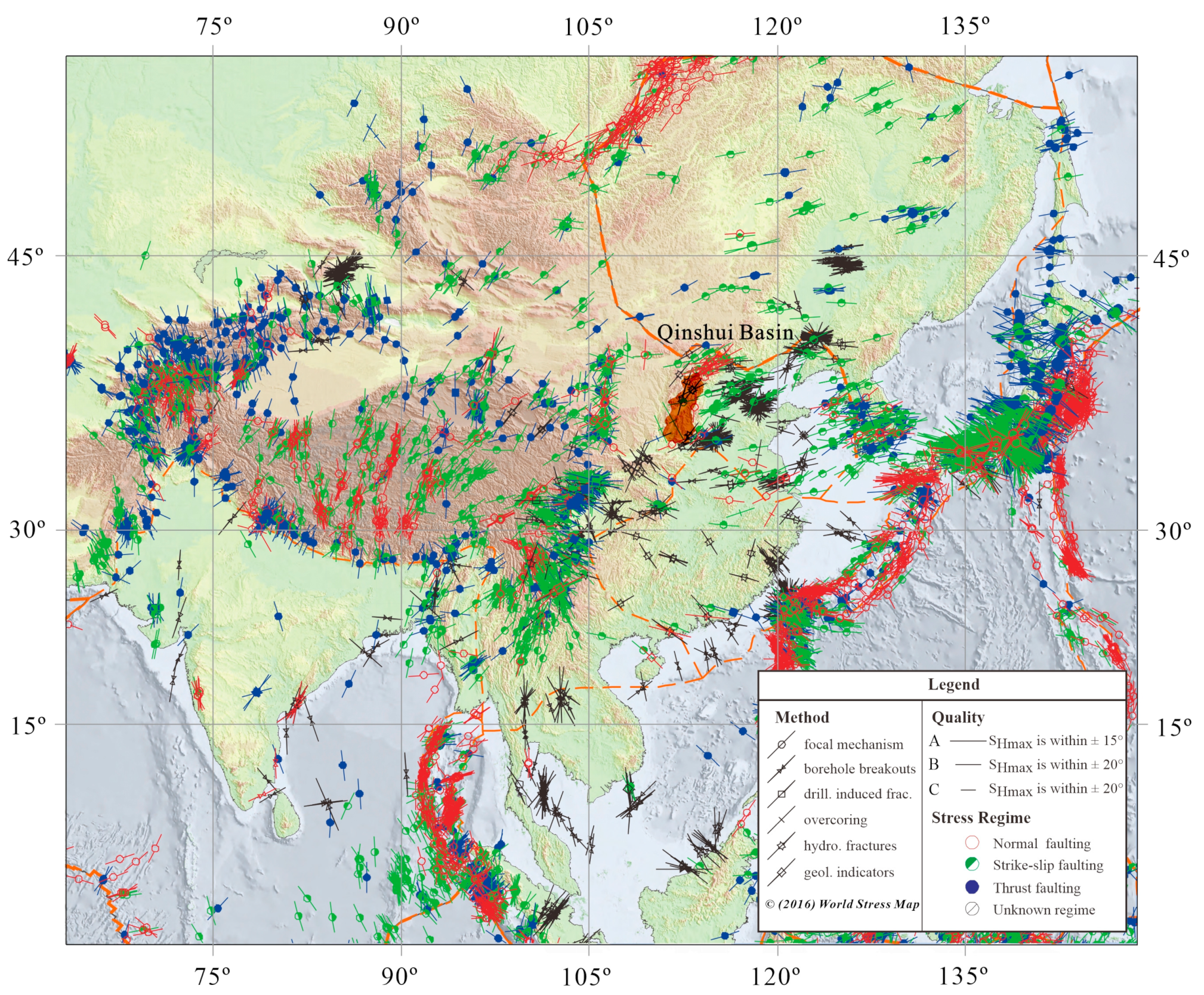

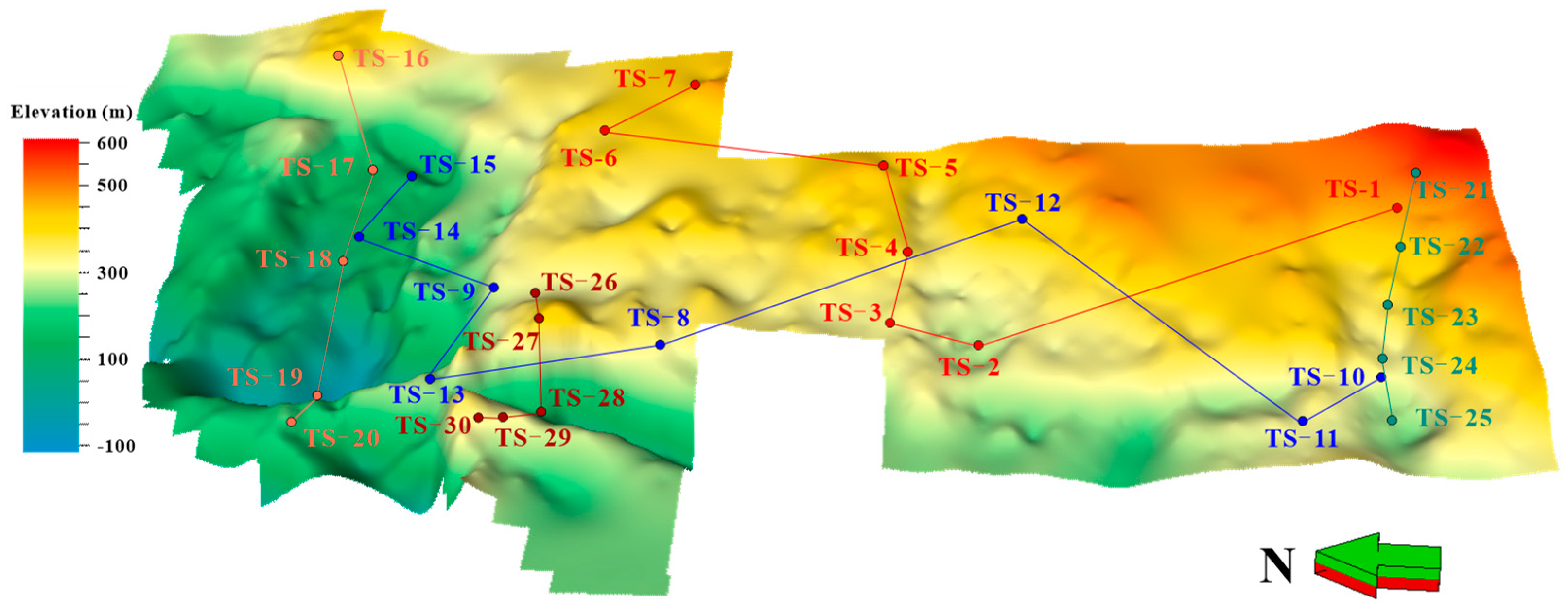

2. Geological Settings

3. Methodology

4. Results

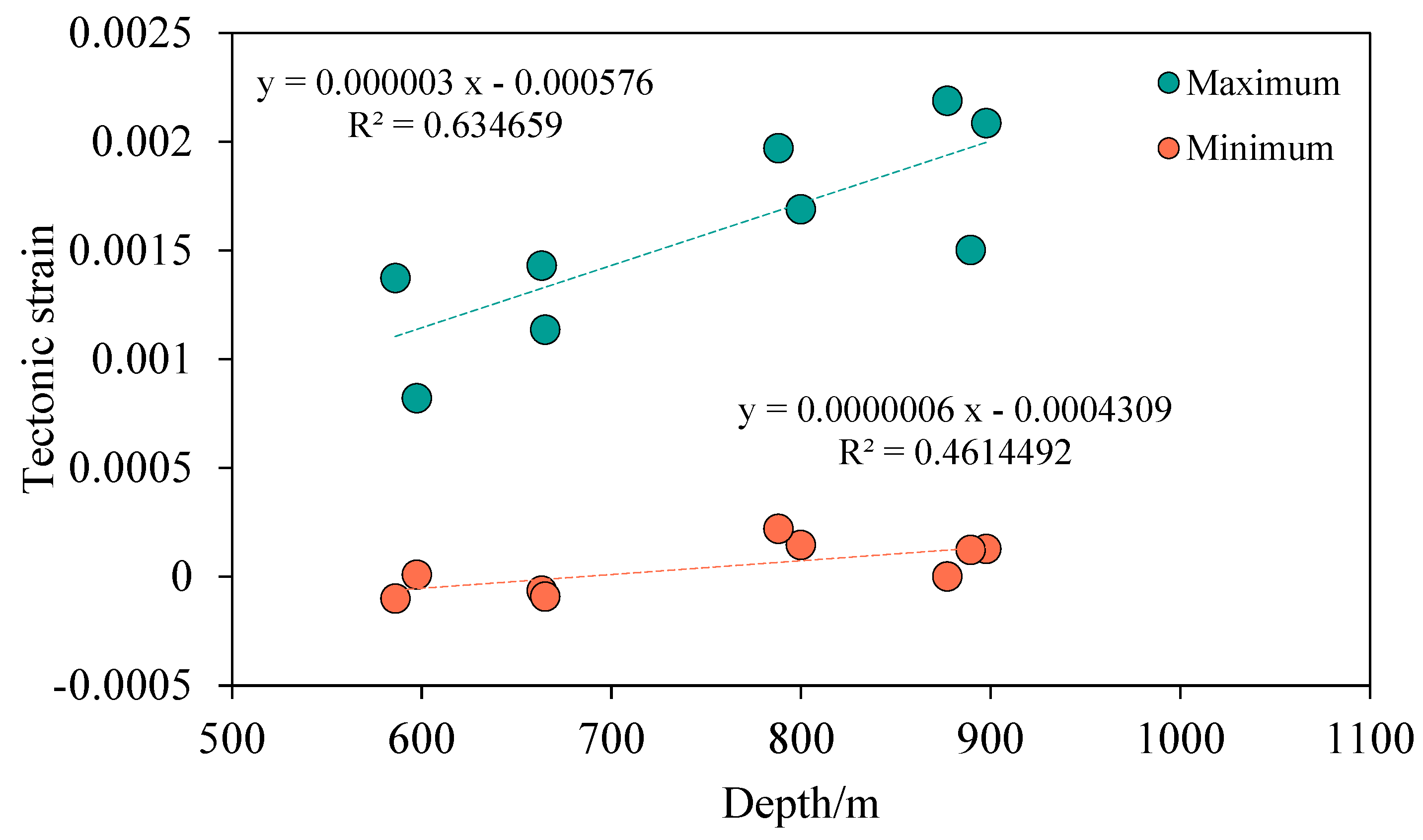

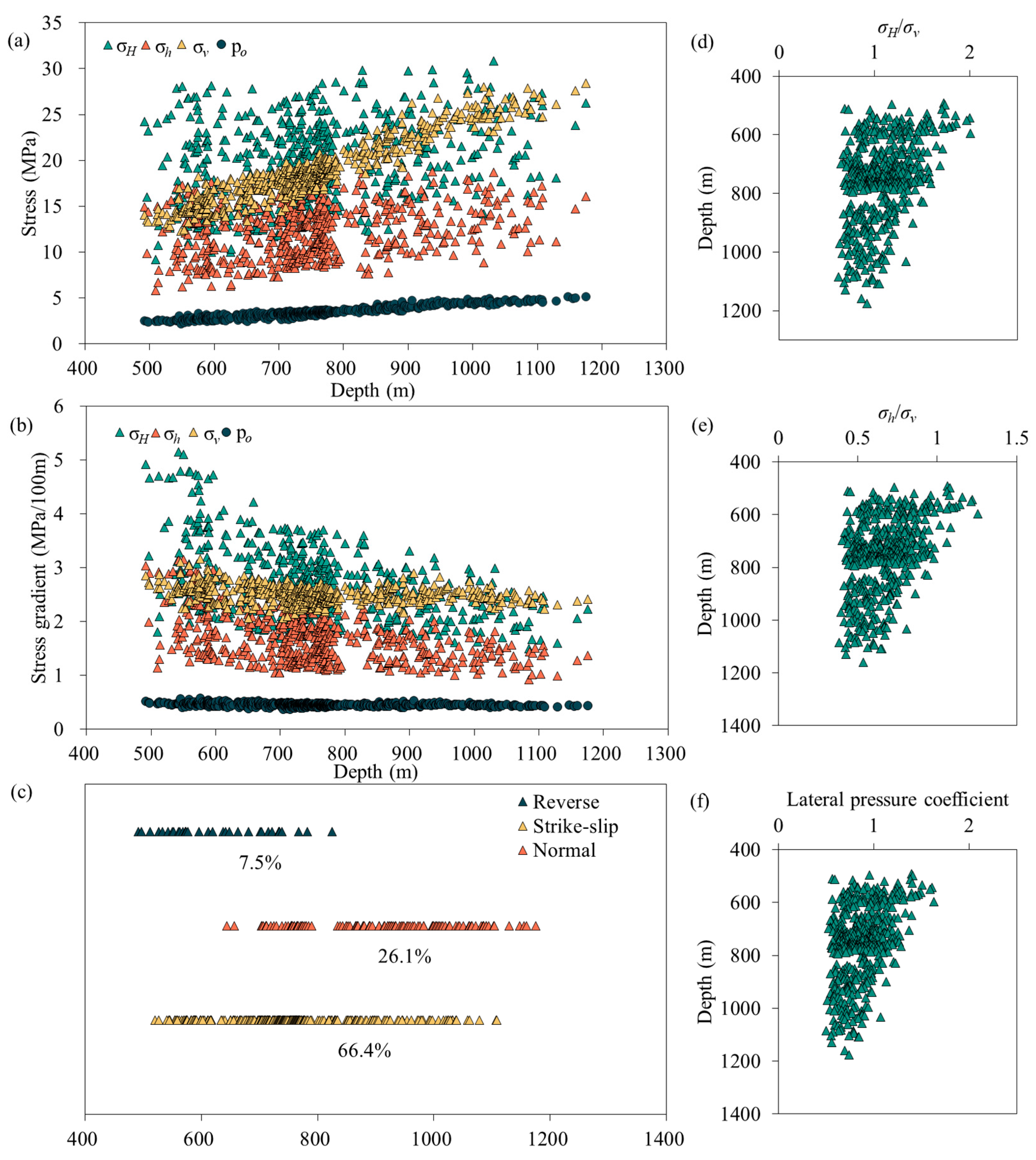

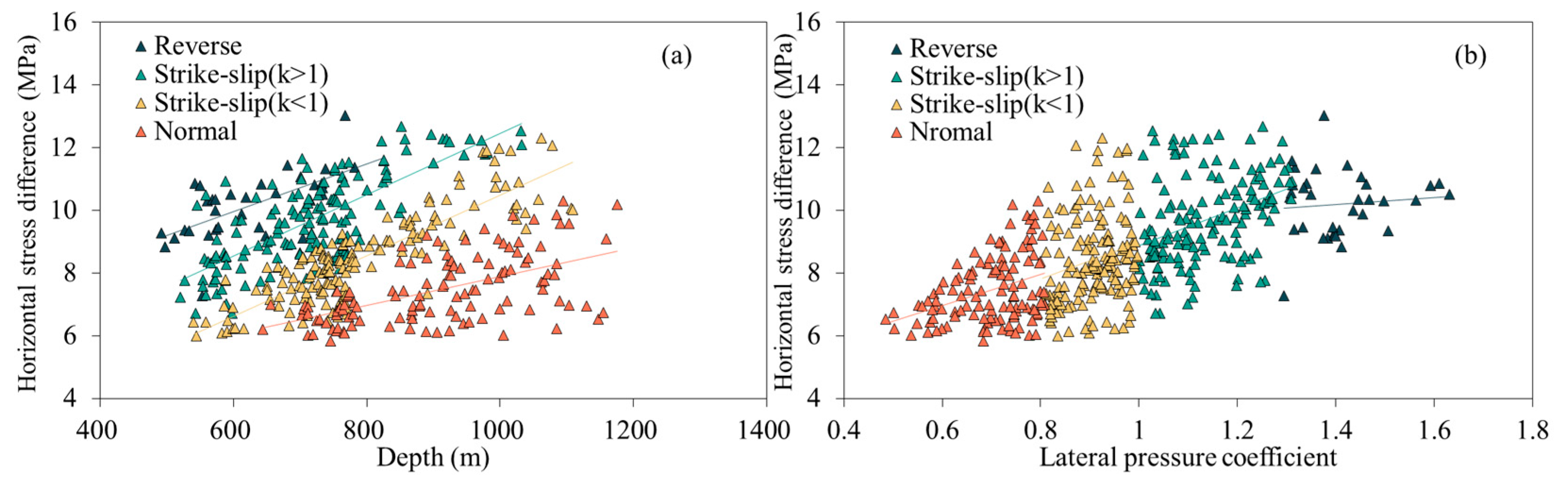

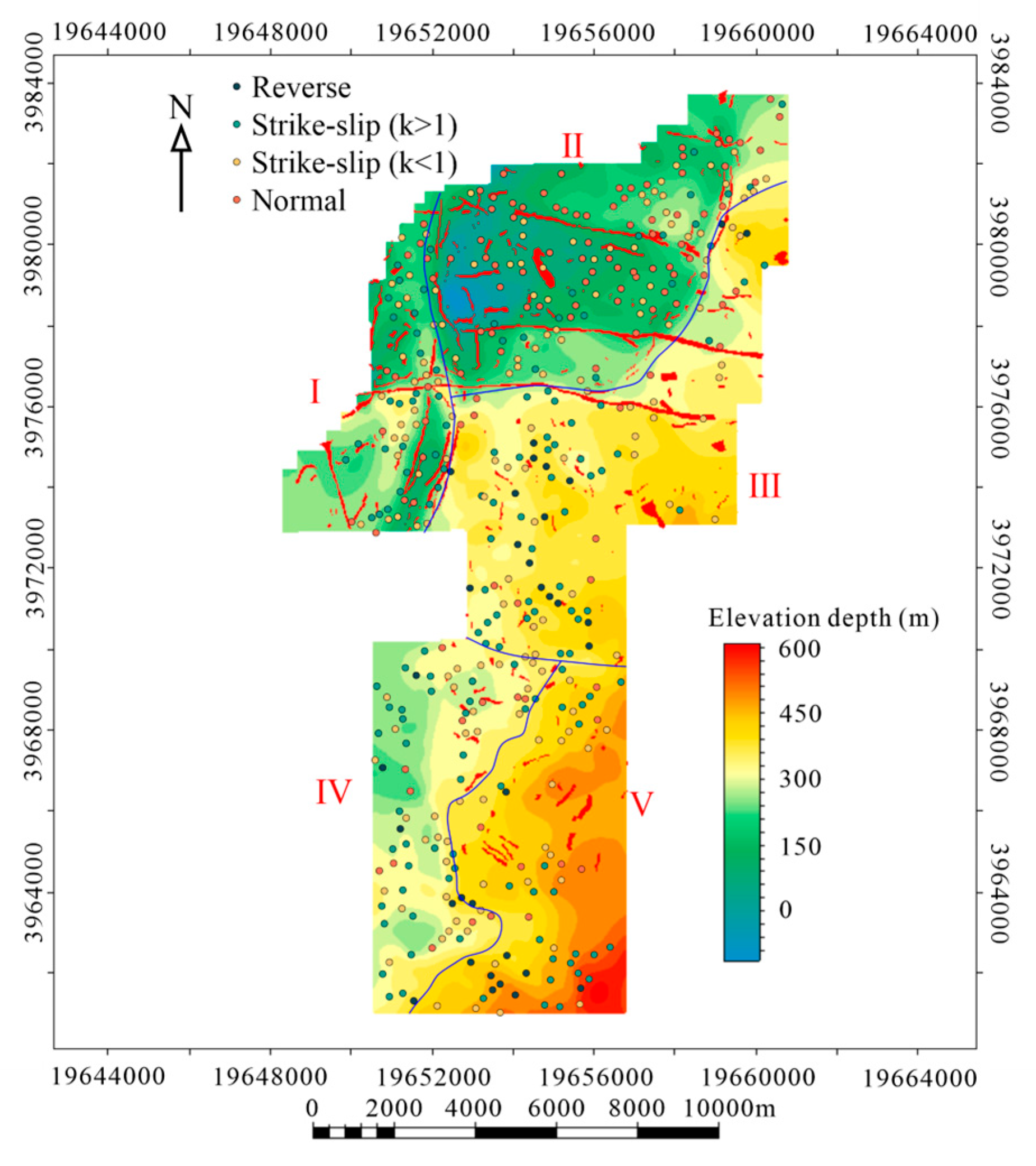

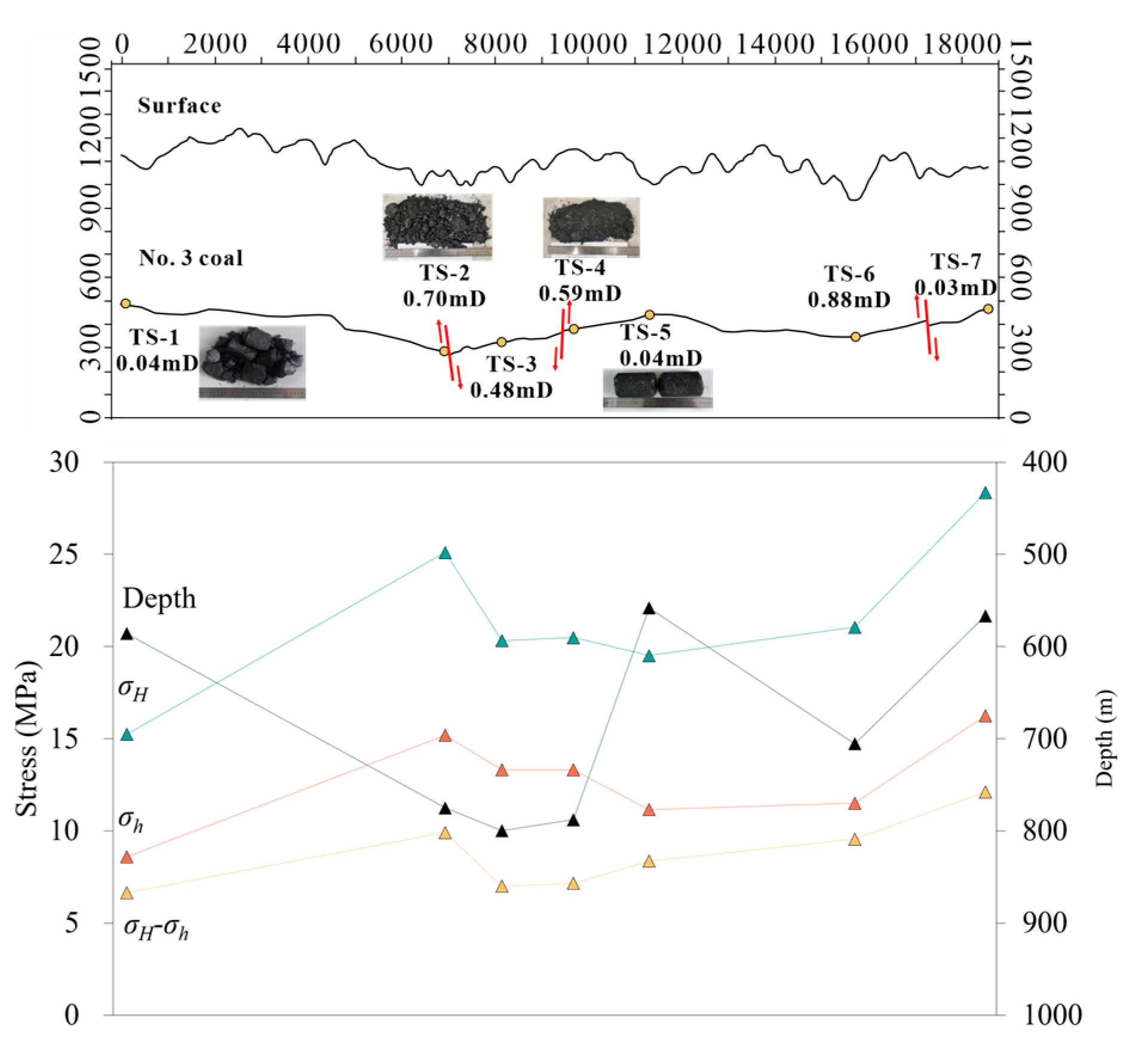

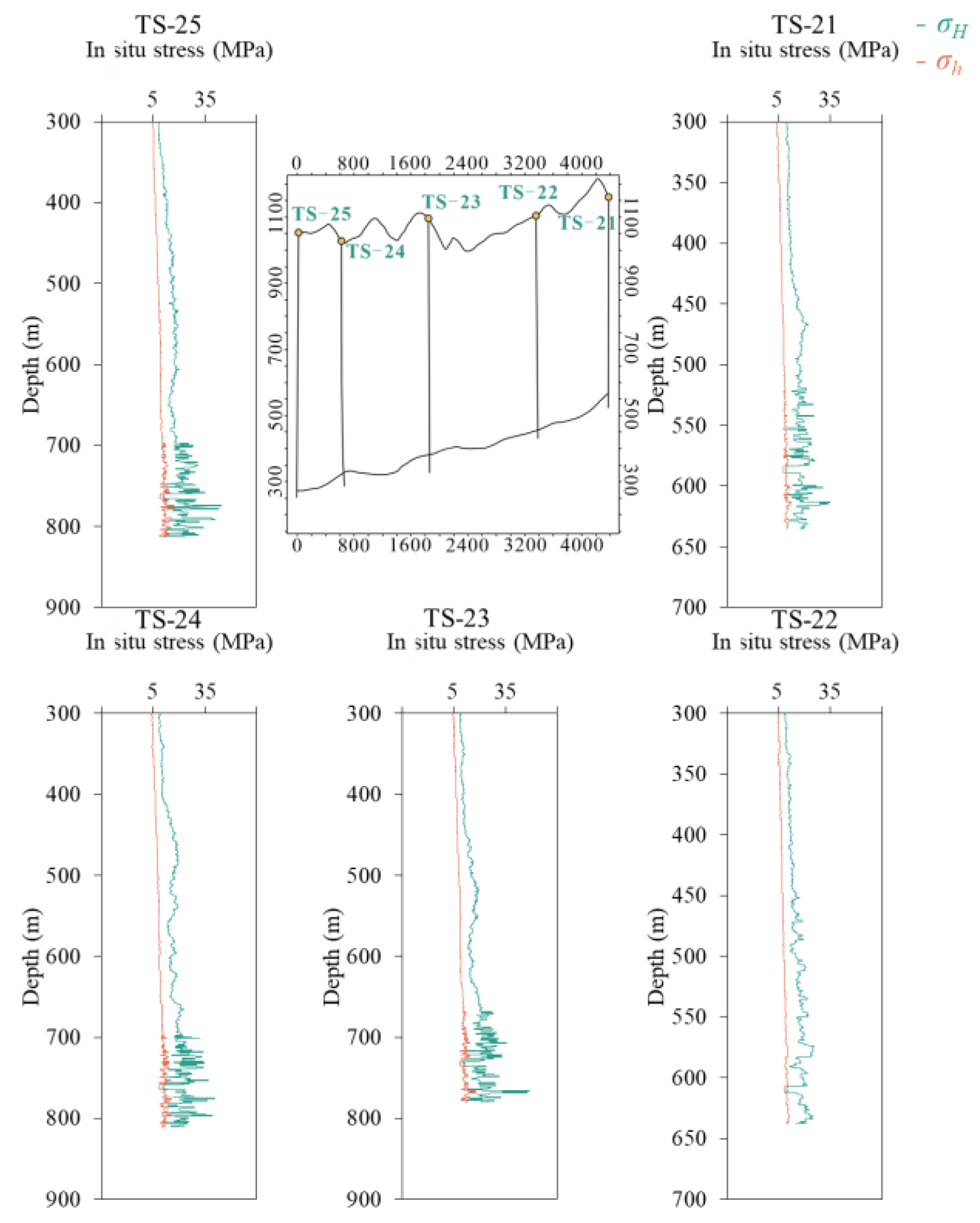

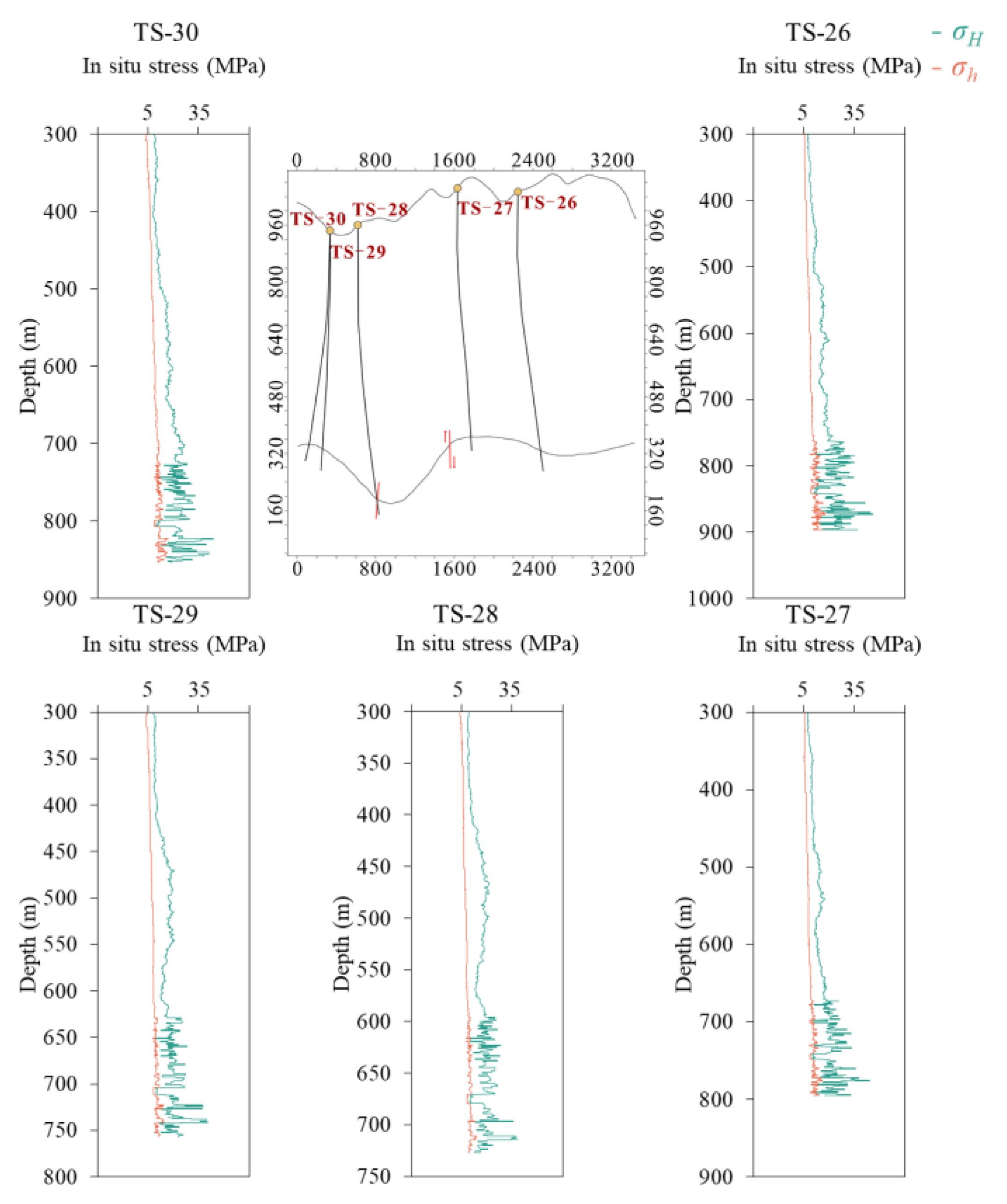

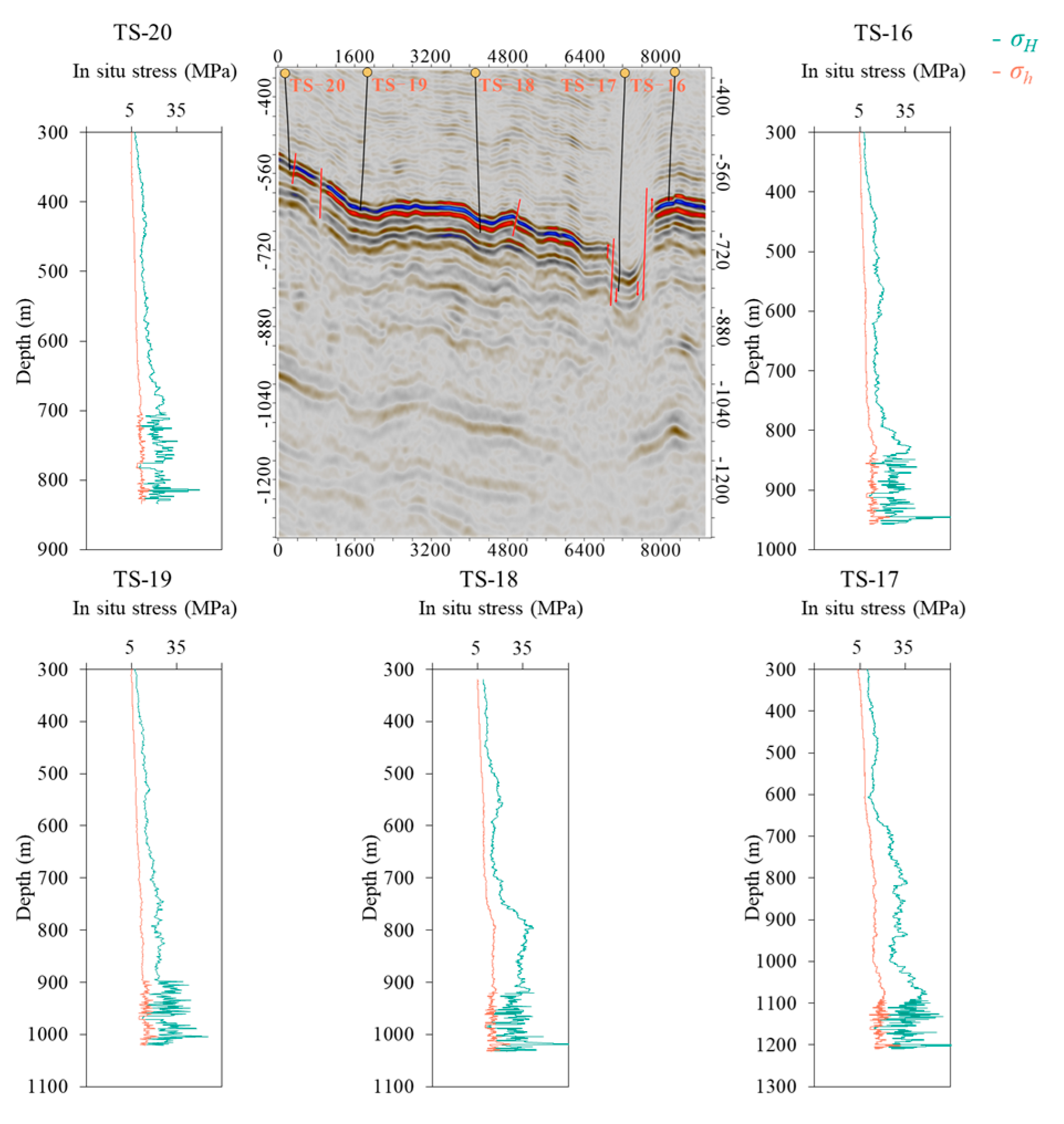

4.1. Stress Magnitudes

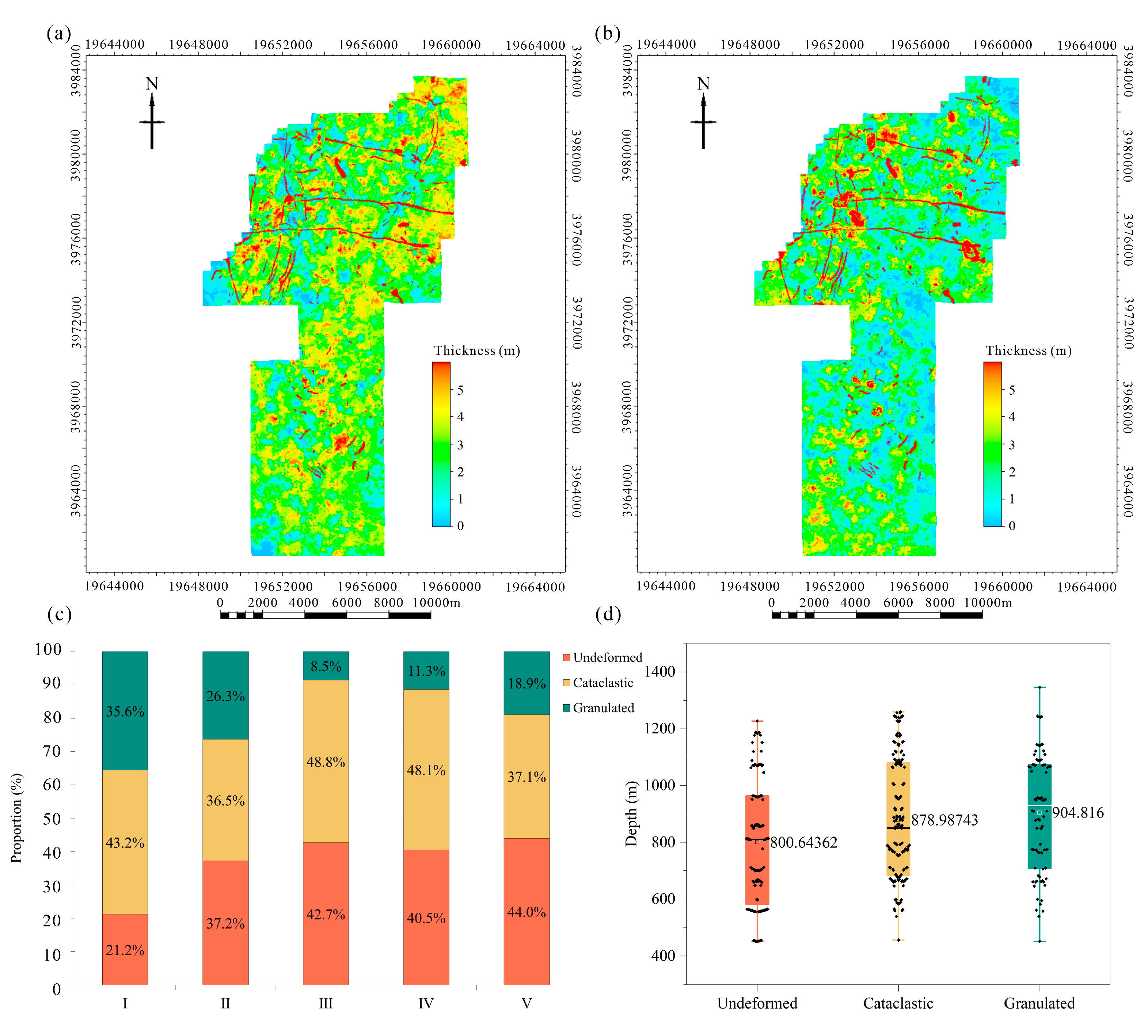

4.2. Geological Parameters

4.2.1. Coal Permeability and Porosity

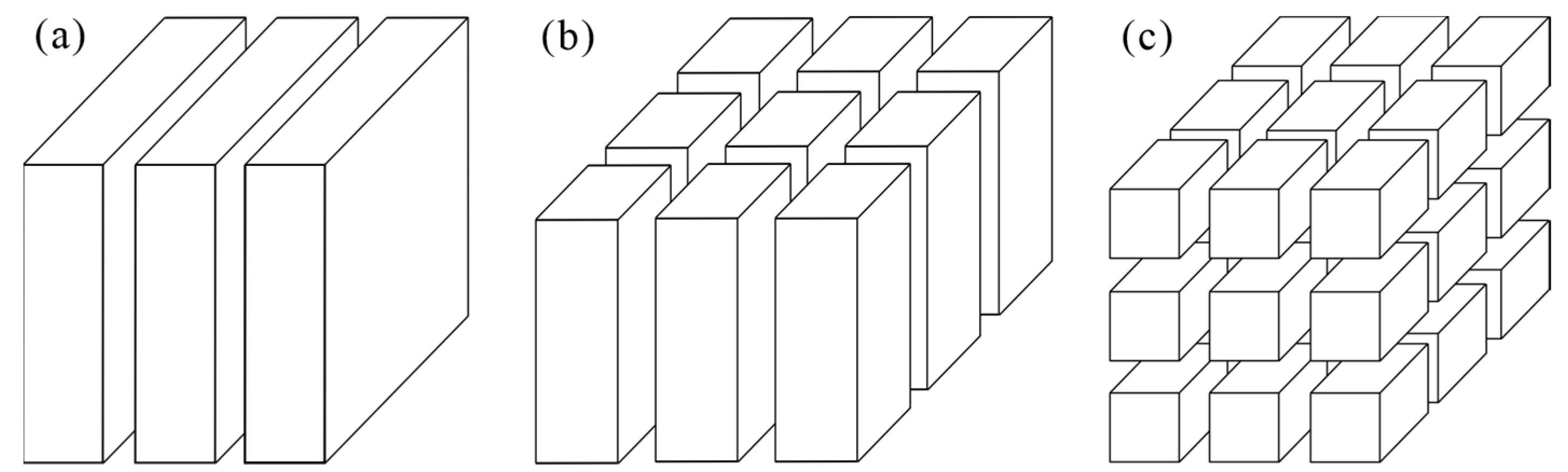

4.2.2. Coal Texture

5. Discussion

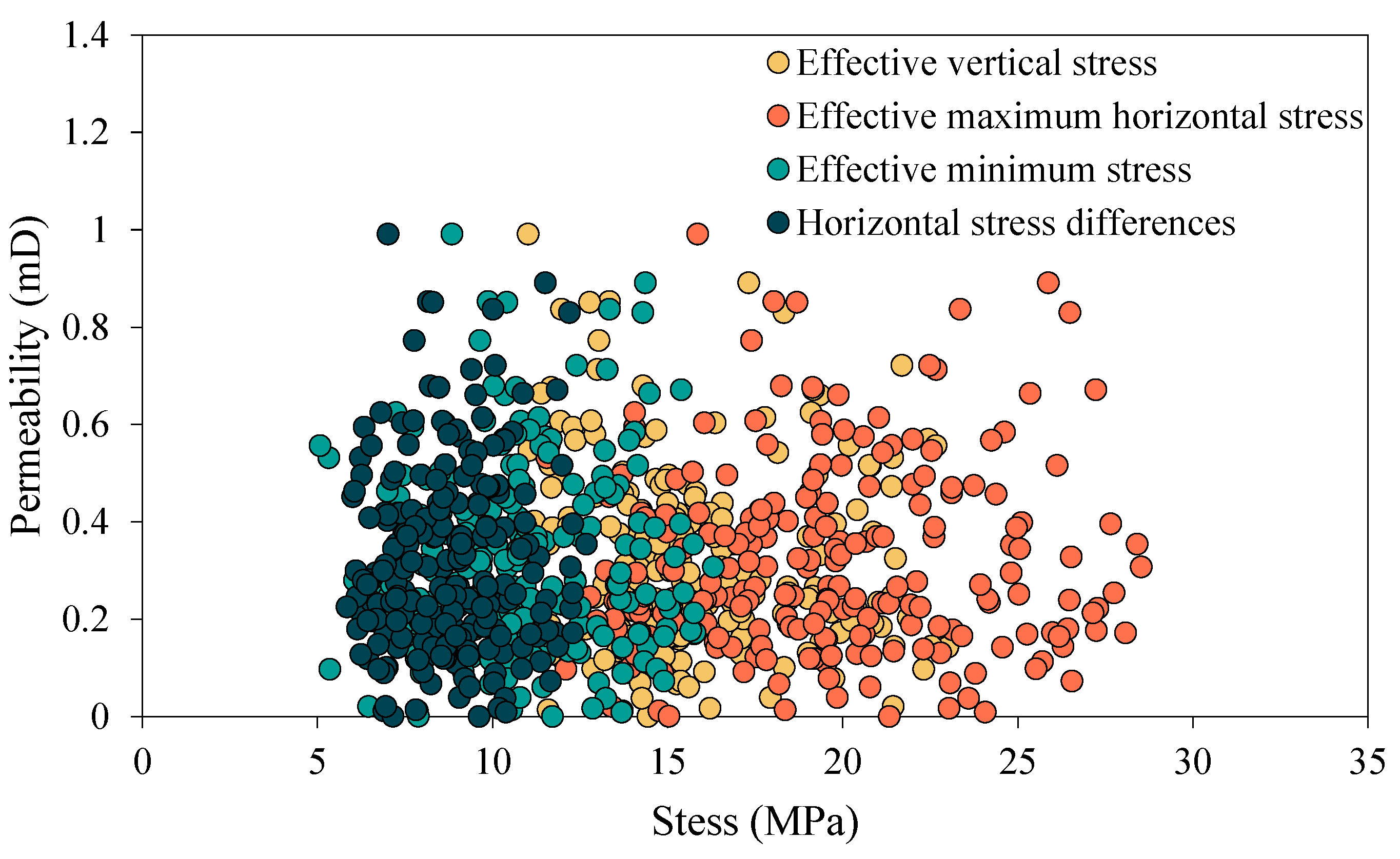

5.1. Effects of In situ Stress and Coal Texture on Porosity and Permeability of Coal Reservoirs

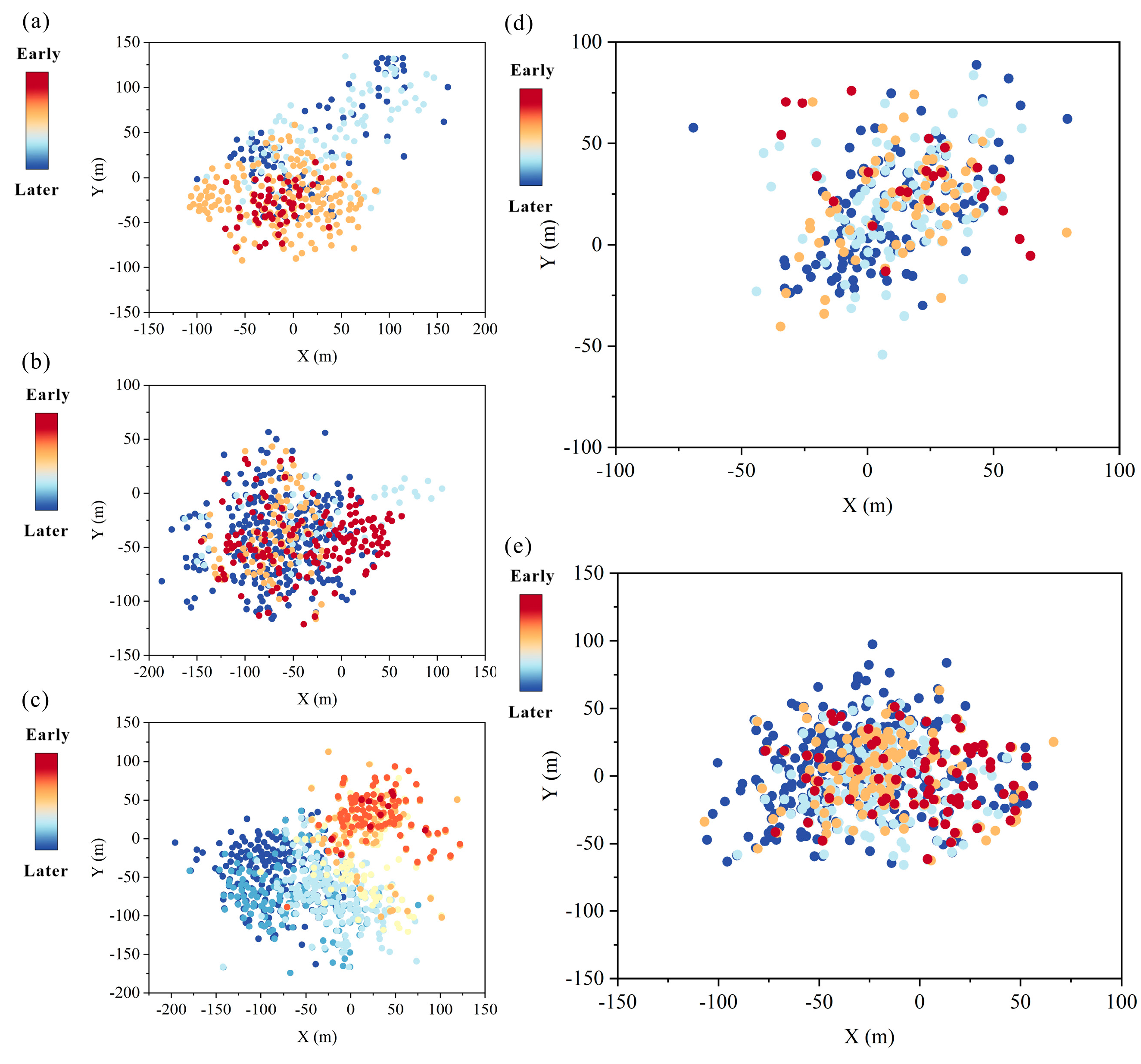

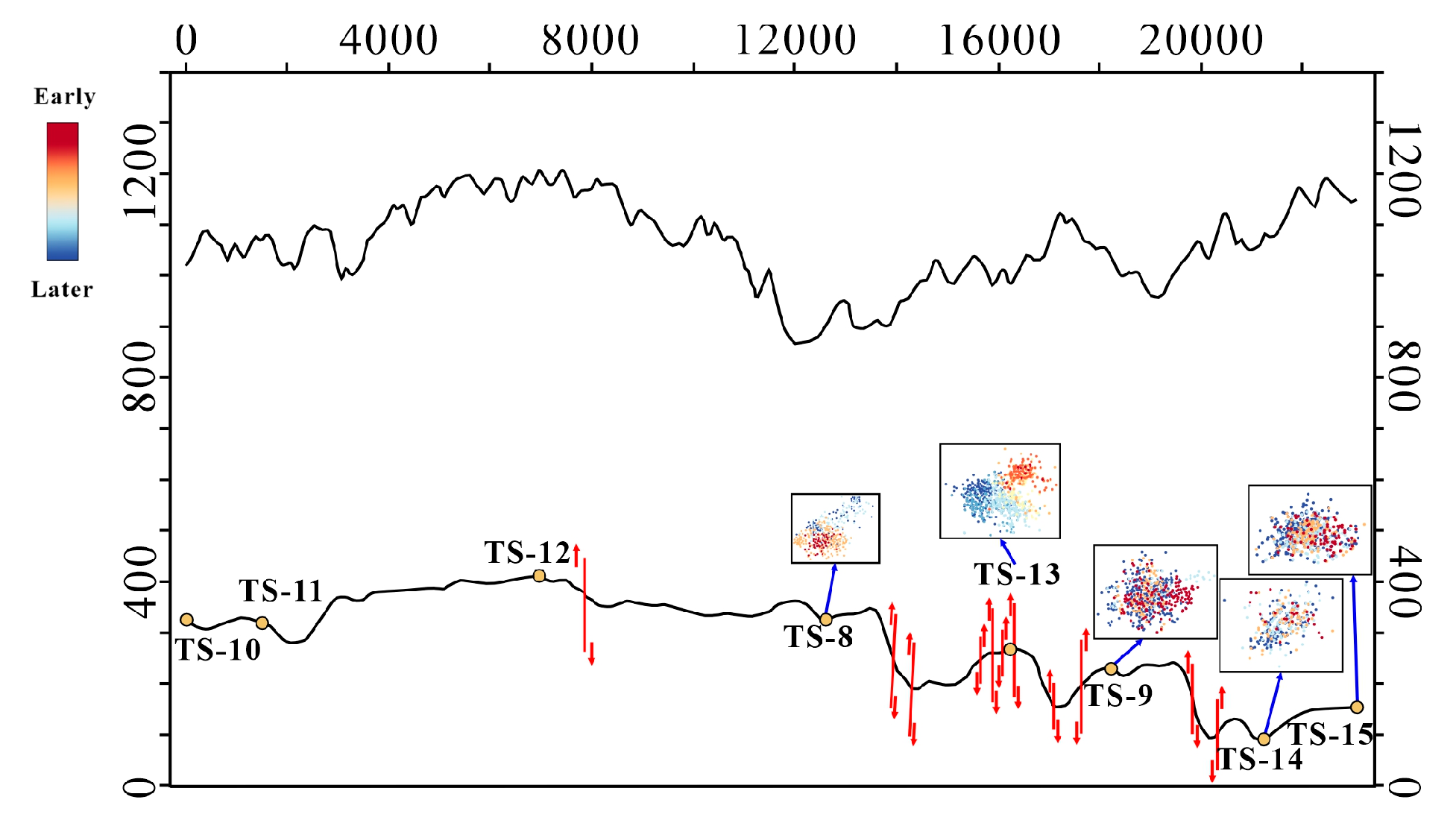

5.2. The Effect of In situ Stress on Hydraulic Fracturing of CBM

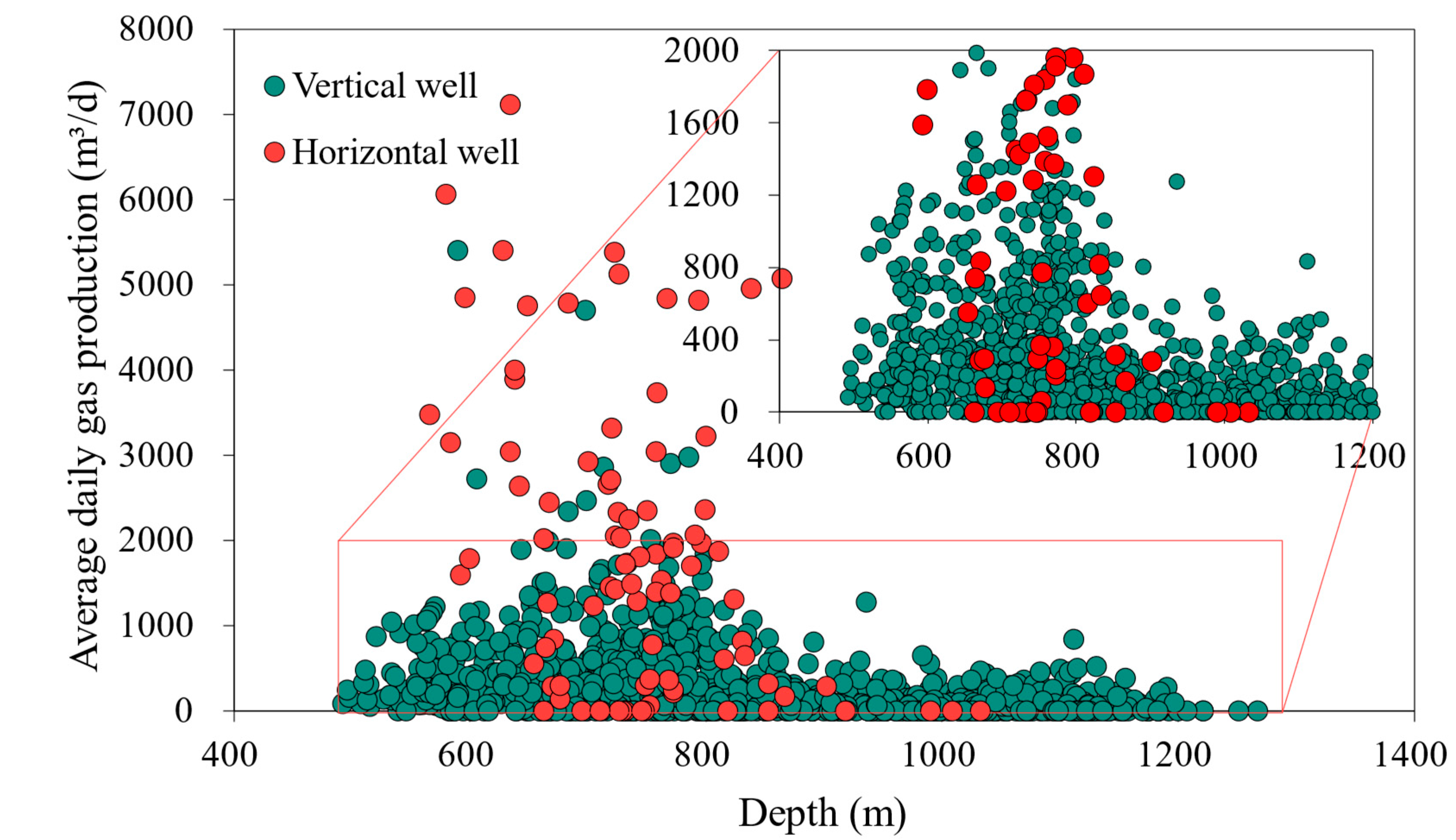

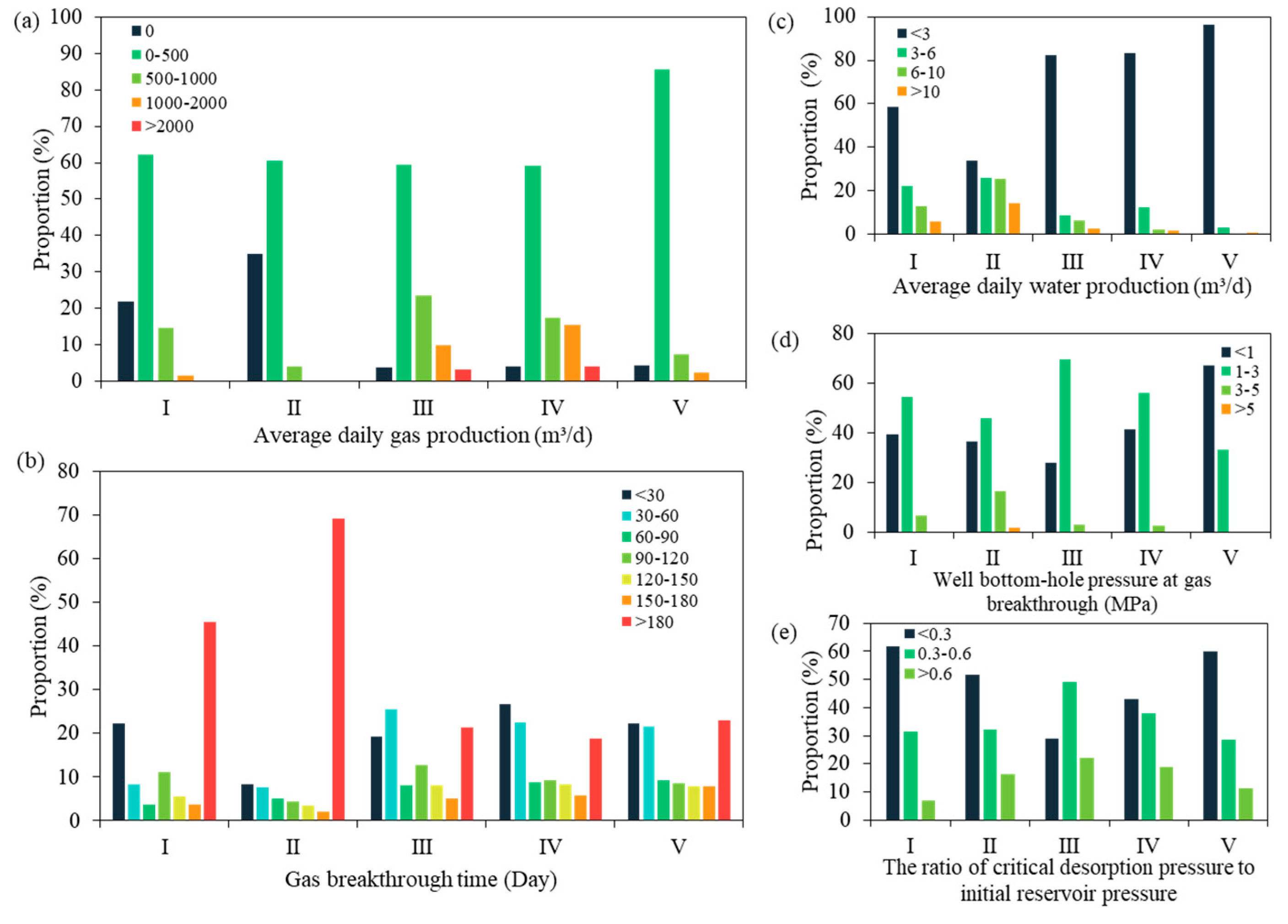

5.3. Statistics of Geo-Engineering Parameters in Different Stress Zones and Development Recommendations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, S.; Tao, S.; Tang, D. In situ coal permeability and favorable development methods for coalbed methane (CBM) extraction in China: From real data. Int. J. Coal Geol. 2024, 284, 104472. [Google Scholar] [CrossRef]

- Huang, Q.; Du, Z.; Liu, H.; Niu, Q.; Fang, H.; Yang, J.; Lou, M. Investigation of cleat and micro-fracture and its aperture distribution in the coals of different ranks in North China: Relative to reservoir permeability. Front. Earth Sci. 2023, 10, 1048042. [Google Scholar] [CrossRef]

- Li, R.; Jin, L.; Wang, S.; Liu, H.; Cui, Z.; Xiang, W. A new mode of visible fracture system in coal seams and its implications for coalbed methane seepage. Geofluids 2023, 2023, 2455954. [Google Scholar] [CrossRef]

- Ren, F.; Zhou, F.; Jeffries, M.; Beaney, S.; Sharma, V.; Lai, W. Affecting Factors on History Matching Field-Level Coal Seam Gas Production from the Surat Basin, Australia. Energy Fuels 2024, 38, 3131–3147. [Google Scholar] [CrossRef]

- Wang, W.; Liu, S.; Sang, S.; Du, R.; Liu, Y. A Study on the Production Simulation of Coal–Shale Interbedded Coal Measure Superimposed Gas Reservoirs under Different Drainage Methods. Processes 2023, 11, 3424. [Google Scholar] [CrossRef]

- Zhou, D.; Wang, J.; Wang, B.; Gao, D.; Zhao, J. Physical characteristics and controlling factors of coal gas reservoir in Pingdingshan No. 10 coal mine. Processes 2023, 11, 3130. [Google Scholar] [CrossRef]

- Ma, T.; Liu, J.; Fu, J.; Wu, B. Drilling and completion technologies of coalbed methane exploitation: An overview. Int. J. Coal Sci. Technol. 2022, 9, 68. [Google Scholar] [CrossRef]

- Tao, S.; Pan, Z.; Tang, S.; Chen, S. Current status and geological conditions for the applicability of CBM drilling technologies in China: A review. Int. J. Coal Geol. 2019, 202, 95–108. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, P.; Cheng, Y.; Shu, L.; Liu, Y.; Zhang, Z.; Zhou, H.; Wang, L. A new technology to enhance gas drainage in the composite coal seam with tectonic coal sublayer. J. Nat. Gas Sci. Eng. 2022, 106, 104760. [Google Scholar] [CrossRef]

- Danesh, N.N.; Zhao, Y.; Teng, T.; Masoudian, M.S. Prediction of interactive effects of CBM production, faulting stress regime, and fault in coal reservoir: Numerical simulation. J. Nat. Gas Sci. Eng. 2022, 99, 104419. [Google Scholar] [CrossRef]

- Pan, J.; Du, X.; Wang, X.; Hou, Q.; Wang, Z.; Yi, J.; Li, M. Pore and permeability changes in coal induced by true triaxial supercritical carbon dioxide fracturing based on low-field nuclear magnetic resonance. Energy 2024, 286, 129492. [Google Scholar] [CrossRef]

- Yang, R.; Chen, J.; Qin, X.; Huang, Z.; Li, G.; Liu, L. Stress evolution and permeability enhancement mechanism of multistage cavity completion in coalbed methane horizontal wells. SPE J. 2023, 28, 2767–2789. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Qiu, Y. Variable gas content, saturation, and accumulation characteristics of Weibei coalbed methane pilot-production field in the southeastern Ordos Basin, China. AAPG Bull. 2013, 97, 1371–1393. [Google Scholar] [CrossRef]

- Liu, D.; Jia, Q.; Cai, Y.; Gao, C.; Qiu, F.; Zhao, Z.; Chen, S. A new insight into coalbed methane occurrence and accumulation in the Qinshui Basin, China. Gondwana Res. 2022, 111, 280–297. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, Y.; Tang, D.; Tao, S.; Pu, Y.; Chen, Z. Present-day stress regime, permeability, and fracture stimulations of coal reservoirs in the Qinshui Basin, North China. AAPG Bulletin 2024, (20,240,401). Available online: https://archives.datapages.com/data/bulletns/aop/2024-04-01/aapgbltn22056aop.html (accessed on 15 May 2024).

- Xia, Y.; Yang, X.; Hu, C.; Lin, H.; Li, H. Sedimentary infill of Early-Middle Jurassic in the southeastern Tarim Basin and its constraints on the evolution of the Altyn Tagh Fault in the Northeast Tibet Plateau. Mar. Pet. Geol. 2024, 161, 106657. [Google Scholar] [CrossRef]

- Liu, G.; Li, J.; Qi, X.; Zhu, M. Geochemistry of High-Maturity Crude Oil and Gas from Deep–Ultradeep Reservoirs and Their Geological Importance in a Foreland Basin: A Case Study of the Southern Thrust Belt, Junggar Basin, Northwest China. J. Energy Eng. 2024, 150, 04023051. [Google Scholar] [CrossRef]

- Bott, M.H.P. The mechanics of oblique slip faulting. Geol. Mag. 1959, 96, 109–117. [Google Scholar] [CrossRef]

- Jones, O.T. The Dynamics of Faulting and Dyke Formation: With Applications to Britain. Nature 1942, 149, 651–652. [Google Scholar] [CrossRef]

- Salmachi, A.; Rajabi, M.; Wainman, C.; Mackie, S.; McCabe, P.; Camac, B.; Clarkson, C. History, geology, in situ stress pattern, gas content and permeability of coal seam gas basins in Australia: A review. Energies 2021, 14, 2651. [Google Scholar] [CrossRef]

- Han, J.; Zhang, H.; Liang, B.; Rong, H.; Lan, T.; Liu, Y.; Ren, T. Influence of large syncline on in situ stress field: A case study of the Kaiping Coalfield, China. Rock Mech. Rock Eng. 2016, 49, 4423–4440. [Google Scholar] [CrossRef]

- Pu, Y.; Li, S.; Tang, D.; Chen, S. Effect of magmatic intrusion on in situ stress distribution in deep coal measure strata: A case study in Linxing Block, eastern margin of Ordos Basin, China. Nat. Resour. Res. 2022, 31, 2919–2942. [Google Scholar] [CrossRef]

- Yu, G.; Liu, K.; Xi, K.; Yang, X.; Yuan, J.; Xu, Z.; Zhou, L.; Hou, S. Variations and causes of in-situ stress orientations in the Dibei-Tuziluoke Gas Field in the Kuqa Foreland Basin, western China. Mar. Pet. Geol. 2023, 158, 106528. [Google Scholar] [CrossRef]

- Zeng, L.; Song, Y.; Liu, G.; Tan, X.; Xu, X.; Yao, Y.; Mao, Z. Natural fractures in ultra-deep reservoirs of China: A review. J. Struct. Geol. 2023, 175, 104954. [Google Scholar] [CrossRef]

- Ganguli, S.S.; Sen, S. Investigation of present-day in-situ stresses and pore pressure in the south Cambay Basin, western India: Implications for drilling, reservoir development and fault reactivation. Mar. Pet. Geol. 2020, 118, 104422. [Google Scholar] [CrossRef]

- Rajabi, M.; Tingay, M.; Heidbach, O.; Hillis, R.; Reynolds, S. The present-day stress field of Australia. Earth-Sci. Rev. 2017, 168, 165–189. [Google Scholar] [CrossRef]

- Rajabi, M.; Esterle, J.; Heidbach, O.; Travassos, D.; Fumo, S. Characterising the contemporary stress orientations near an active continental rifting zone: A case study from the Moatize Basin, central Mozambique. Basin Res. 2022, 34, 1292–1313. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; You, Z.; Yang, Z. Distribution characteristics of in situ stress field and vertical development unit division of CBM in Western Guizhou, China. Nat. Resour. Res. 2021, 30, 3659–3671. [Google Scholar] [CrossRef]

- Burra, A.; Esterle, J.S.; Golding, S.D. Horizontal stress anisotropy and effective stress as regulator of coal seam gas zonation in the Sydney Basin, Australia. Int. J. Coal Geol. 2014, 132, 103–116. [Google Scholar] [CrossRef]

- Ren, P.; Wang, Q.; Tang, D.; Xu, H.; Chen, S. In situ Stress–Coal Structure Relationship and Its Influence on Hydraulic Fracturing: A Case Study in Zhengzhuang Area in Qinshui Basin, China. Nat. Resour. Res. 2022, 31, 1621–1646. [Google Scholar] [CrossRef]

- Zou, G.; Zhang, Q.; Peng, S.; She, J.; Teng, D.; Jin, C.; Che, Y. Influence of geological factors on coal permeability in the Sihe coal mine. Int. J. Coal Sci. Technol. 2022, 9, 6. [Google Scholar] [CrossRef]

- Mou, P.; Pan, J.; Wang, K.; Wei, J.; Yang, Y.; Wang, X. Influences of hydraulic fracturing on microfractures of high-rank coal under different in-situ stress conditions. Fuel 2021, 287, 119566. [Google Scholar] [CrossRef]

- Huang, J.; Morris, J.P.; Fu, P.; Settgast, R.R.; Sherman, C.S.; Ryerson, F.J. Hydraulic-Fracture-Height Growth Under the Combined Influence of Stress Barriers and Natural Fractures. SPE J. 2018, 24, 302–318. [Google Scholar] [CrossRef]

- Fu, H.; Wang, X.; Zhang, L.; Gao, R.; Li, Z.; Zhu, X.; Xu, W.; Li, Q.; Xu, T. Geological controls on artificial fracture networks in continental shale and its fracability evaluation: A case study in the Yanchang Formation, Ordos Basin, China. J. Nat. Gas Sci. Eng. 2015, 26, 1285–1293. [Google Scholar] [CrossRef]

- Rajabi, M.; Tingay, M.; Heidbach, O. The present-day stress field of New South Wales, Australia. Aust. J. Earth Sci. 2016, 63, 1–21. [Google Scholar] [CrossRef]

- Rajabi, M.; Tingay, M.; King, R.; Heidbach, O. Present-day stress orientation in the Clarence-Moreton Basin of New South Wales, Australia: A new high density dataset reveals local stress rotations. Basin Res. 2017, 29, 622–640. [Google Scholar] [CrossRef]

- Li, S.; Qin, Y.; Tang, D.; Shen, J.; Wang, J.; Chen, S. A comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Qin, Y. Research progress of symbiotic accumulation of coal measure gas in China. Nat. Gas Ind. B 2018, 5, 466–474. [Google Scholar] [CrossRef]

- Tao, S.; Chen, S.; Pan, Z. Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci. Eng. 2019, 7, 1059–1074. [Google Scholar] [CrossRef]

- Ni, X.; Zhao, Z.; Wang, Y.; Wang, L. Optimisation and application of well types for ground development of coalbed methane from no. 3 coal seam in shizhuang south block in Qinshui basin, Shanxi province, China. J. Pet. Sci. Eng. 2020, 193, 107453. [Google Scholar] [CrossRef]

- Su, X.; Lin, X.; Zhao, M.; Song, Y.; Liu, S. The upper Paleozoic coalbed methane system in the Qinshui basin, China. AAPG Bull. 2005, 89, 81–100. [Google Scholar] [CrossRef]

- Ni, X.; Jia, Q.; Wang, Y. The Relationship between Current Ground Stress and Permeability of Coal in Superimposed Zones of Multistage Tectonic Movement. Geofluids 2019, 2019, 9021586. [Google Scholar] [CrossRef]

- Cao, L.; Yao, Y.; Cui, C.; Sun, Q. Characteristics of in-situ stress and its controls on coalbed methane development in the southeastern Qinshui Basin, North China. Energy Geosci. 2020, 1, 69–80. [Google Scholar] [CrossRef]

- Yang, S.; Yao, R.; Cui, X.; Chen, Q.; Huang, L. Analysis of the characteristics of measured stresses in Chinese mainland. Chin. J. Geophys. 2012, 55, 708–718. [Google Scholar] [CrossRef]

- Heidbach, O.; Rajabi, M.; Cui, X.; Fuchs, K.; Müller, B.; Reinecker, J.; Reiter, K.; Tingay, M.; Wenzel, F.; Xie, F.; et al. The World Stress Map database release 2016: Crustal stress pattern across scales. Tectonophysics 2018, 744, 484–498. [Google Scholar] [CrossRef]

- GB/T 24504-2009; The Method of Injection/Falloff Well Test for Coalbed Methane Well. National Coal Standardization Technical Committee: Beijing, China, 2009.

- DB/T 14-2018; Specification of Hydraulic Fracturing and Overcoring Method for In-Situ Stress Measurement. National Seismological Standardization Technical Committee: Beijing, China, 2018.

- GB/T 29172-2012; Practices for Core Analysis. National Oil & Gas Standardization Technical Committee: Beijing, China, 2012.

- GB/T 19559-2021; Method of Determining Coalbed Methane Content. National Coal Standardization Technical Committee: Beijing, China, 2021.

- GB/T 30050-2013; Classification of Coal-Body Structure. National Coal Standardization Technical Committee: Beijing, China, 2013.

- Haimson, B.; Cornet, F. ISRM Suggested Methods for rock stress estimation—Part 3: Hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF). Int. J. Rock Mech. Min. Sci. 2003, 40, 1011–1020. [Google Scholar] [CrossRef]

- Haimson, B. The hydrofracturing stress measuring method and recent field results. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 167–178. [Google Scholar] [CrossRef]

- Kang, H.; Zhang, X.; Si, L.; Wu, Y.; Gao, F. In-situ stress measurements and stress distribution characteristics in underground coal mines in China. Eng. Geol. 2010, 116, 333–345. [Google Scholar] [CrossRef]

- Li, C.; Nordlund, E. Experimental verification of the Kaiser effect in rocks. Rock Mech. Rock Eng. 1993, 26, 333–351. [Google Scholar] [CrossRef]

- Cerfontaine, B.; Collin, F. Cyclic and Fatigue Behaviour of Rock Materials: Review, interpretation and Research Perspectives. Rock Mech. Rock Eng. 2017, 51, 391–414. [Google Scholar] [CrossRef]

- Kang, H.; Gao, F.; Xu, G.; Ren, H. Mechanical behaviors of coal measures and ground control technologies for China’s deep coal mines—A review. J. Rock Mech. Geotech. Eng. 2023, 15, 37–65. [Google Scholar] [CrossRef]

- Reiss, L.H.; Creusot, M.; Du Pétrole Et Des Moteurs, E.N.S. The Reservoir Engineering Aspects of Fractured Formations; Editions Technip: Paris, France, 1980; Available online: https://ci.nii.ac.jp/ncid/BA90642290 (accessed on 15 May 2024).

- Harpalani, S.; Chen, G. Influence of gas production induced volumetric strain on permeability of coal. Geotech. Geol. Eng. 1997, 15, 303–325. [Google Scholar] [CrossRef]

- Hou, J.S. Logging Evaluation Technologies and Its Applications For Coalbed Methane Reservoirs; Metallurgical Industry Press: Beijing, China, 2000. [Google Scholar]

- Li, J.; Liu, D.; Yao, Y.; Cai, Y.; Qiu, Y. Evaluation of the reservoir permeability of anthracite coals by geophysical logging data. Int. J. Coal Geol. 2011, 87, 121–127. [Google Scholar] [CrossRef]

- Chatterjee, R.; Pal, P. Estimation of stress magnitude and physical properties for coal seam of Rangamati area, Raniganj coalfield, India. Int. J. Coal Geol. 2010, 81, 25–36. [Google Scholar] [CrossRef]

- Asquith, G.; Krygowski, D.; Henderson, S.; Hurley, N. Basic Well Log Analysis; American Association of Petroleum Geologists eBooks: Tulsa, OK, USA, 2004. [Google Scholar] [CrossRef]

- Teng, J.; Yao, Y.; Liu, D.; Cai, Y. Evaluation of coal texture distributions in the southern Qinshui basin, North China: Investigation by a multiple geophysical logging method. Int. J. Coal Geol. 2015, 140, 9–22. [Google Scholar] [CrossRef]

- Ghosh, S.; Chatterjee, R.; Paul, S.; Shanker, P. Designing of plug-in for estimation of coal proximate parameters using statistical analysis and coal seam correlation. Fuel 2014, 134, 63–73. [Google Scholar] [CrossRef]

- Chen, S.; Liu, P.; Tang, D.; Tao, S.; Zhang, T. Identification of thin-layer coal texture using geophysical logging data: Investigation by Wavelet Transform and Linear Discrimination Analysis. Int. J. Coal Geol. 2021, 239, 103727. [Google Scholar] [CrossRef]

- Fu, X.; Qin, Y.; Wang, G.G.; Rudolph, V. Evaluation of coal structure and permeability with the aid of geophysical logging technology. Fuel 2009, 88, 2278–2285. [Google Scholar] [CrossRef]

- Zhao, Z.; Tao, S.; Tang, D.; Chen, S.; Ren, P. A mathematical method to identify and forecast coal texture of multiple and thin coal seams by using logging data in the Panguan syncline, western Guizhou, China. J. Pet. Sci. Eng. 2020, 185, 106616. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, S.; Yan, Z.; Zhang, S.; Xi, Z.; Zhang, K.; Wang, K.; Zhang, Q.; Yang, X. Three-Dimensional geological modeling of coal reservoirs and analysis of sensitivity factors for combined mining capacity. Processes 2023, 11, 3448. [Google Scholar] [CrossRef]

- Bashmagh, N.M.; Lin, W.; Radwan, A.E.; Manshad, A.K. Comprehensive analysis of stress magnitude and orientations and natural fractures in complex structural regimes oil reservoir: Implications for tectonic and oil field development in the Zagros suture zone. Mar. Pet. Geol. 2024, 160, 106615. [Google Scholar] [CrossRef]

- Somerton, W.H.; Söylemezoḡlu, I.M.; Dudley, R.C. Effect of stress on permeability of coal. Int. J. Rock Mech. Min. Sci. Geomech. Abstracts. 1975, 12, 129–145. [Google Scholar] [CrossRef]

- Palmer, I.; Mavor, M.; Gunter, B. Permeability changes in coal seams during production and injection: 2007 International Coalbed Methane Symposium: Tuscaloosa. Ala. Univ. Ala. Pap. 2007, 713, 20. [Google Scholar]

- Gao, Q.; Liu, J.; Huang, Y.; Li, W.; Shi, R.; Leong, Y.; Elsworth, D. A critical review of coal permeability models. Fuel 2022, 326, 125124. [Google Scholar] [CrossRef]

- Lin, Y.; Qin, Y.; Ma, D.; Wang, S.; Qiao, J. In situ stress variation and coal reservoir permeability response of the Jurassic Yan’an formation in the southwestern Ordos basin, China: Its impact on coalbed methane development. Geoenergy Sci. Eng. 2023, 222, 211444. [Google Scholar] [CrossRef]

- Pan, J.; Zhao, Y.; Hou, Q.; Jin, Y. Nanoscale pores in coal related to coal rank and deformation structures. Transp. Porous Media 2015, 107, 543–554. [Google Scholar] [CrossRef]

- Yang, G.; Hu, W.; Tang, S.; Zhou, Z.; Song, Z. Impacts of vertical variation of coal seam structure on hydraulic fracturing and resultant gas and water production: A case study on the Shizhuangnan Block, Southern Qinshui Basin, China. Energy Explor. Exploit. 2023, 42, 52–64. [Google Scholar] [CrossRef]

- Temizel, C.; Canbaz, C.H.; Palabiyik, Y.; Hosgor, F.B.; Atayev, H.; Ozyurtkan, M.H.; Aydin, H.; Yurukcu, M.; Narendra, B. A review of hydraulic fracturing and latest developments in unconventional reservoirs. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2 May 2022. [Google Scholar] [CrossRef]

- Gong, X.; Ma, X.; Liu, Y. Analysis of geological factors affecting propagation behavior of fracture during hydraulic fracturing shale formation. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 102. [Google Scholar] [CrossRef]

- Song, J.; Qiao, Q.; Chen, C.; Zheng, J.; Wang, Y. Numerical Analysis of the Stress Shadow Effects in Multistage Hydrofracturing Considering Natural Fracture and Leak-Off Effect. Water 2024, 16, 1308. [Google Scholar] [CrossRef]

- Mukherjee, S.; Rajabi, M.; Esterle, J.; Copley, J. Subsurface fractures, in-situ stress and permeability variations in the Walloon Coal Measures, eastern Surat Basin, Queensland, Australia. Int. J. Coal Geol. 2020, 222, 103449. [Google Scholar] [CrossRef]

- Qiu, G.; Chang, X.; Li, J.; Guo, Y.; Zhou, Z.; Wang, L.; Wan, Y.; Wang, X. Study on the interaction between hydraulic fracture and natural fracture under high stress. Theor. Appl. Fract. Mech. 2024, 130, 104259. [Google Scholar] [CrossRef]

- Huang, L.; Li, B.; Wu, B.; Li, C.; Wang, J.; Cai, H. Study on the extension mechanism of hydraulic fractures in bedding coal. Theor. Appl. Fract. Mech. 2024, 131, 104431. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, T.; Elsworth, D.; He, Y.; Zhou, W.; Zhuang, L.; Zeng, J.; Wang, S. Controls of natural fractures on the texture of hydraulic fractures in rock. J. Pet. Sci. Eng. 2018, 165, 616–626. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, D.; Cai, Y.; Yao, Y.; Pan, Z. Constraining coalbed methane reservoir petrophysical and mechanical properties through a new coal structure index in the southern Qinshui Basin, northern China: Implications for hydraulic fracturing. AAPG Bull. 2020, 104, 1817–1842. [Google Scholar] [CrossRef]

- Wu, Y.; Men, X.; Lou, Y. New progress and prospect of coalbed methane exploration and development in China during the 14th Five-Year Plan period. China Pet. Explor. 2024, 29, 1–13. [Google Scholar]

- Xu, F.; Nie, Z.; Sun, W.; Xiong, X.; Xu, B.; Zhang, L.; Shi, X.; Liu, Y.; Liu, S.; Zhao, Z.; et al. Theoretical and technological system for Highly efficient development of deep coalbed methane in the Eastern edge of Erdos Basin. J. China Coal Soc. 2023, 49, 528–544. [Google Scholar]

- Zhang, C.; Li, M.; Hu, Q.; Jia, H.; Li, K.; Wang, Q.; Yang, R. Moderately deep coalbed methane reservoirs in the southern Qinshui Basin: Characteristics and technical strategies for exploitation. Coal Geol. Explor. 2024, 52, 122–133. [Google Scholar]

| Well Name | Fracture Length (m) | Fracture Width (m) | Fracture Height (m) | Azimuth | Depth (m) |

|---|---|---|---|---|---|

| TS-8 | 290 | 160 | 56 | N51° E | 672.38 |

| TS-9 | 310 | 180 | 42 | N70° E | 774.76 |

| TS-10 | 250 | 180 | 50 | N55° W | 758.81 |

| TS-11 | 300 | 110 | 66 | N55° W | 737.14 |

| TS-12 | 400 | 65 | 35 | N57° E | 764.92 |

| TS-13 | 280 | 240 | 42 | N48° E | 691.73 |

| TS-14 | 155 | 125 | 46 | N40° E | 978.23 |

| TS-15 | 180 | 140 | 32 | N42° E | 982.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Men, X.; Tao, S.; Chen, S.; Wu, H.; Zhang, B. Impacts and Countermeasures of Present-Day Stress State and Geological Conditions on Coal Reservoir Development in Shizhuang South Block, Qinshui Basin. Energies 2024, 17, 4221. https://doi.org/10.3390/en17174221

Men X, Tao S, Chen S, Wu H, Zhang B. Impacts and Countermeasures of Present-Day Stress State and Geological Conditions on Coal Reservoir Development in Shizhuang South Block, Qinshui Basin. Energies. 2024; 17(17):4221. https://doi.org/10.3390/en17174221

Chicago/Turabian StyleMen, Xinyang, Shu Tao, Shida Chen, Heng Wu, and Bin Zhang. 2024. "Impacts and Countermeasures of Present-Day Stress State and Geological Conditions on Coal Reservoir Development in Shizhuang South Block, Qinshui Basin" Energies 17, no. 17: 4221. https://doi.org/10.3390/en17174221

APA StyleMen, X., Tao, S., Chen, S., Wu, H., & Zhang, B. (2024). Impacts and Countermeasures of Present-Day Stress State and Geological Conditions on Coal Reservoir Development in Shizhuang South Block, Qinshui Basin. Energies, 17(17), 4221. https://doi.org/10.3390/en17174221