Extending the Lifetime of Offshore Wind Turbines: Challenges and Opportunities

Abstract

1. Introduction

- -

- Economic benefits: Lifetime extension saves capital expenditures (CapEx) needed for constructing new wind farms, mitigates financial risks compared to investing in greenfield projects, enhances return on investment (ROI), improves energy output, and ultimately lowers the levelized cost of electricity (LCoE).

- -

- Technical benefits: Lifetime extension improves the operational condition of aging OWTs by conducting repairs on damaged parts, implementing software upgrades and adjustments, and updating safety systems and protocols to an acceptable level.

- -

- Social benefits: Lifetime extension secures existing jobs while also potentially creating new job opportunities in the second-hand OWT sector (i.e., repair, refurbishment, and remanufacturing).

- -

- Environmental benefits: Lifetime extension helps protect the marine ecosystem and preserve the natural environment by reducing pollutant emissions associated with constructing new wind farms. It also supports biodiversity and maintains ecological balance in marine environments by minimizing disturbances to marine habitats.

- -

- Legal benefits: Lifetime extension provides legal certainty for investors and stakeholders by maintaining a stable operating framework and avoiding disruptions that could arise from the decommissioning and replacement of wind farm infrastructure.

2. PESTLE Analysis for Lifetime Extension of OWTs

2.1. PESTLE Background

2.2. PESTLE Analysis for OWT Lifetime Extension

2.2.1. Political Challenges

2.2.2. Economic Challenges

2.2.3. Sociological Challenges

2.2.4. Technological/Technical Challenges

Degradation of OWT Structures and Components

Lack of Good Quality Data

Lack of Appropriate Tools to Optimize Maintenance Activities

Technology Obsolescence

Selection of the Most Suitable Lifetime Extension Technology

2.2.5. Legal Challenges

2.2.6. Environmental/Ecological Challenges

3. Experiences and Lessons Learned from Conventional Energy Industries

3.1. Nuclear Power Industry

3.2. Offshore Oil and Gas Industry

4. Lifetime Extension Process for OWTs

4.1. Lifetime Estimation Process and Aging Failure Mode Analysis

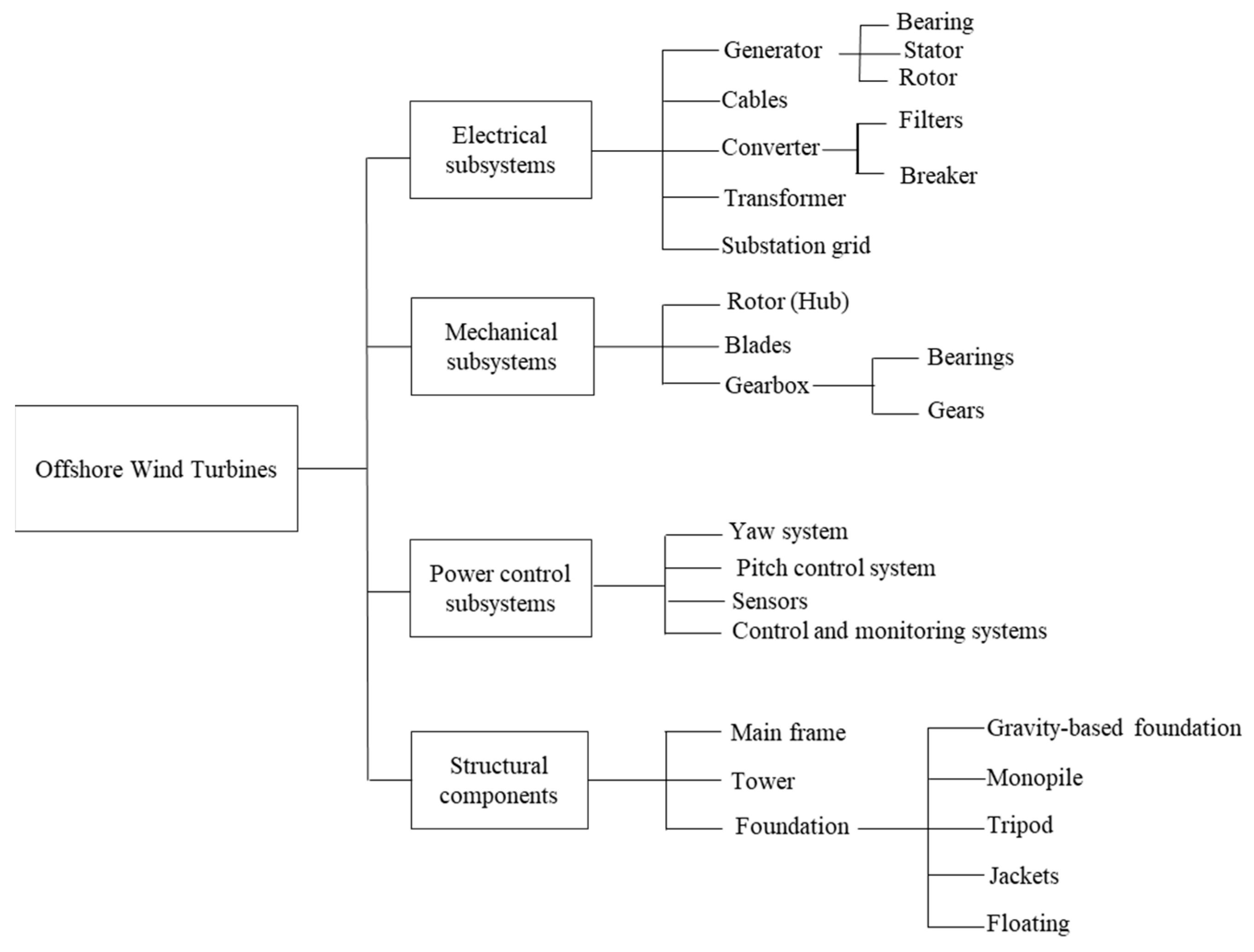

4.1.1. Electrical Subsystems

Generator

Cables

- -

- Low-voltage time domain reflectometry test: This test measures the true length of the cable, identifies splice locations, and assesses the condition of the concentric neutral.

- -

- Leakage current measurements at direct voltages or below the peak operating voltage: This test aims to detect cables that may be affected by water treeing.

- -

- Partial discharge measurements: This test is used to detect potential difference (PD) sites using time domain reflectometry.

- -

- Breakdown voltage test: This test uses a cos-rectangular or sine wave test supply to locate breakdown sites in buried cables for recovery and examination.

Converter, Filters and Circuit Breakers

Transformer

Substations

4.1.2. Mechanical Subsystems

Rotor (hub)

Blades

Gearbox

4.1.3. Power Control Systems

Pitch Control System

Yaw System

Sensors

Control and Monitoring Systems

4.1.4. Structural Components

Main Frame

Tower and Foundation

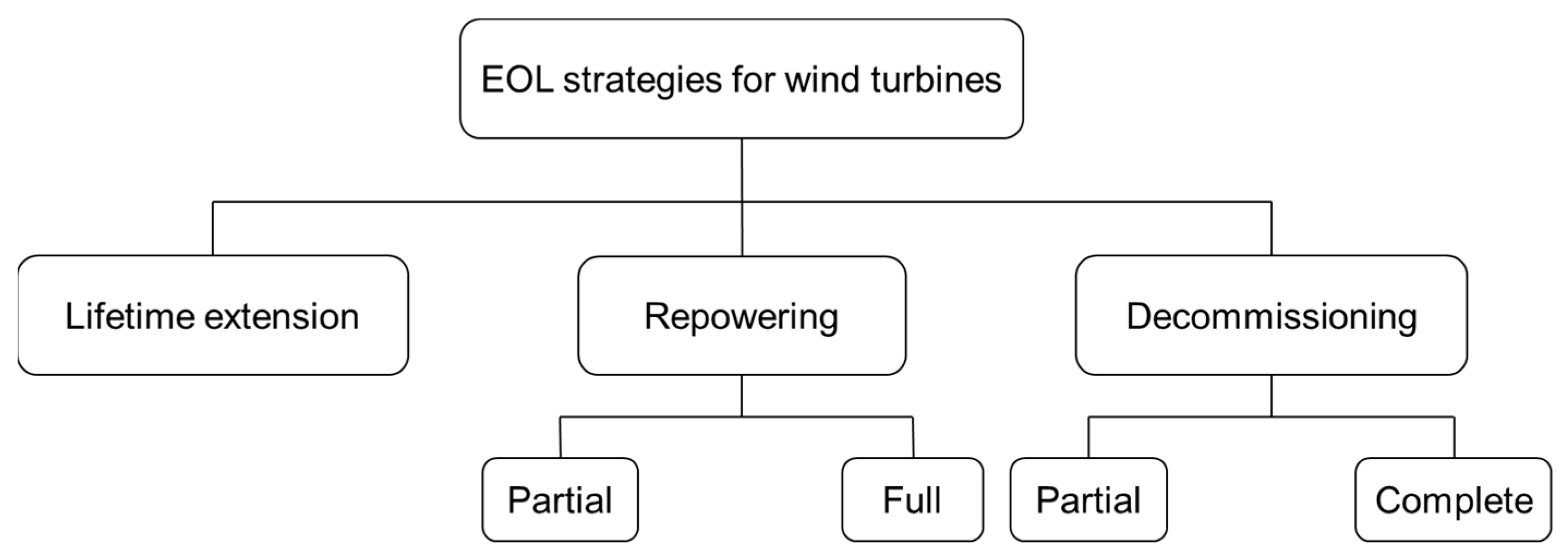

4.2. Lifetime Extension Strategies for OWTs

4.2.1. Retrofitting

4.2.2. Reconditioning

4.2.3. Remanufacturing

4.2.4. Reusing

4.2.5. Reclaiming

5. Lifetime Extension Decision-Making for OWTs

5.1. Planning, Evaluation and Information Update

5.2. Subsystems/Components Screening and Prioritisation

5.3. Safety and Structural Integrity Assessments

5.4. Economic, Environmental and Regulatory Assessments

5.5. Life Extension Decision Making

6. Opportunities

6.1. Business Opportunities

6.2. Research Opportunities

7. Conclusions

Funding

Conflicts of Interest

References

- Ang, T.-Z.; Salem, M.; Kamarol, M.; Das, H.S.; Nazari, M.A.; Prabaharan, N. A comprehensive study of renewable energy sources: Classifications, challenges and suggestions. Energy Strategy Rev. 2022, 43, 100939. [Google Scholar] [CrossRef]

- Long, Y.; Chen, Y.; Xu, C.; Li, Z.; Liu, Y.; Wang, H. The role of global installed wind energy in mitigating CO2 emission and temperature rising. J. Clean. Prod. 2023, 423, 138778. [Google Scholar] [CrossRef]

- Global Wind Energy Council (GWEC). Global Wind Report 2024. 16 April 2024. Available online: https://gwec.net/wp-content/uploads/2024/05/GWR-2024_digital-version_final-2.pdf (accessed on 4 July 2024).

- Dinmohammadi, A.; Shafiee, M. Determination of the most suitable technology transfer strategy for wind turbines using an integrated AHP-TOPSIS decision model. Energies 2017, 10, 642. [Google Scholar] [CrossRef]

- Simon, W.; Moro, A.; Reis, V.; Baniotopoulos, C.; Barth, S.; Bartoli, G.; Bauer, F.; Boelman, E.; Bosse, D.; Cherubini, A.; et al. Future emerging technologies in the wind power sector: A European perspective. Renew. Sustain. Energy Rev. 2019, 113, 109270. [Google Scholar] [CrossRef]

- Shafiee, M. A fuzzy analytic network process model to mitigate the risks associated with offshore wind farms. Expert Syst. Appl. 2015, 42, 2143–2152. [Google Scholar] [CrossRef]

- Hughes, G. The Performance of Wind Farms in the United Kingdom and Denmark; Renewable Energy Foundation: London, UK, 2012; Available online: https://www.ref.org.uk/attachments/article/280/ref.hughes.19.12.12.pdf (accessed on 4 July 2024).

- Staffell, I.; Green, R. How does wind farm performance decline with age? Renew. Energy 2014, 66, 775–786. [Google Scholar] [CrossRef]

- Ortegon, K.; Nies, L.F.; Sutherland, J.W. Preparing for end of service life of wind turbines. J. Clean. Prod. 2013, 39, 191–199. [Google Scholar] [CrossRef]

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime extension of onshore wind turbines: A review covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2018, 82, 1261–1271. [Google Scholar] [CrossRef]

- Piel, J.H.; Stetter, C.; Heumann, M.; Westbomke, M.; Breitner, M.H. Lifetime extension, repowering or decommissioning? decision support for operators of ageing wind turbines. IOP Conf. Ser. J. Phys. Conf. Ser. 2019, 1222, 012033. [Google Scholar] [CrossRef]

- Topham, E.; McMillan, D. Sustainable decommissioning of an offshore wind farm. Renew. Energy 2017, 102, 470–480. [Google Scholar] [CrossRef]

- Kerkvliet, H.; Polatidis, H. Offshore wind farms’ decommissioning: A semi quantitative multi-criteria decision aid framework. Sustain. Energy Technol. Assess. 2016, 18, 69–79. [Google Scholar] [CrossRef]

- Adedipe, T.; Shafiee, M. An economic assessment framework for decommissioning of offshore wind farms using a cost breakdown structure. Int. J. Life Cycle Assess. 2021, 26, 344–370. [Google Scholar] [CrossRef]

- Woo, S.M.; Whale, J. A mini-review of end-of-life management of wind turbines: Current practices and closing the circular economy gap. Waste Manag. Res. J. A Sustain. Circ. Econ. 2022, 40, 1730–1744. [Google Scholar] [CrossRef]

- Spyroudi, A. End-of-Life Planning In Offshore Wind. Offshore Renewable Energy Catapult, April 2021. Available online: https://ore.catapult.org.uk/wp-content/uploads/2021/04/End-of-Life-decision-planning-in-offshore-wind_FINAL_AS-1.pdf (accessed on 4 July 2024).

- Shafiee, M.; Animah, I. Life extension decision making of safety critical systems: An overview. J. Loss Prev. Process Ind. 2017, 47, 174–188. [Google Scholar] [CrossRef]

- Aguilar, F.J. Scanning the Business Environment; MacMillan Co.: New York, NY, USA, 1967. [Google Scholar]

- Thumiger, B. The Valuation of TESLA and BMW in a Disruptive Industry: A Comparative Analysis. Master’s Thesis, Zurich University of Applied Sciences, Zurich, Switzerland, 2021. [Google Scholar] [CrossRef]

- Sandoval, A.H. Wind Energy Development in Mexico—A Case Study of the Potential for Local Socio-Economic Benefits in Mareña. Master’s Thesis, Lund University, Lund, Sweden, 2015. Available online: https://www.lunduniversity.lu.se/lup/publication/5049119 (accessed on 6 July 2024).

- Valencia, G.E.; Cardenas, Y.D.; Acevedo, C.H. PEST analysis of wind energy in the world: From the worldwide boom to the emergent in Colombia. J. Phys. Conf. Ser. 2018, 1126, 012019. [Google Scholar] [CrossRef]

- Kansongue, N.; Njuguna, J.; Vertigans, S. A PESTEL and SWOT impact analysis on renewable energy development in Togo. Front. Sustain. 2023, 3, 990173. [Google Scholar] [CrossRef]

- Momentum Energy Group. Big Economic Challenges Ahead for Wind Turbine Owners. 11 May 2016. Available online: https://stateofgreen.com/en/news/big-economic-challenges-ahead-for-wind-turbine-owners/ (accessed on 6 July 2024).

- Abadie, L.M.; Goicoechea, N. Old wind farm life extension vs. full repowering: A review of economic issues and a stochastic application for Spain. Energies 2021, 14, 3678. [Google Scholar] [CrossRef]

- Natarajan, A.; Dimitrov, N.K.; Remigius, D.; Bergami, L.; Madsen, J.; Olesen, N.; Krogh, T.; Nielsen, J.; Sørensen, J.D.; Pedersen, M.; et al. Demonstration of Requirements for Life Extension of Wind Turbines Beyond Their Design Life. DTU Wind Energy, Project no 64017-05114. 2020. Available online: https://orbit.dtu.dk/en/publications/demonstration-of-requirements-for-life-extension-of-wind-turbines (accessed on 6 July 2024).

- Nielsen, J.S.; Miller-Branovacki, L.; Carriveau, R. Probabilistic and risk-informed life extension assessment of wind turbine structural components. Energies 2021, 14, 821. [Google Scholar] [CrossRef]

- International Electromechanical Commission (IEC). IEC 61400-1: Wind Energy Generation Systems–Part 1: Design Requirements. Edition 4.0. 2019. Available online: https://moodle.insa-toulouse.fr/pluginfile.php/85391/mod_resource/content/1/01_IEC_61400-1_Wind_Turbines_Part1%20Design_requirements_2019.pdf (accessed on 6 July 2024).

- Nielsen, J.S.; Sørensen, J.D. Risk-based derivation of target reliability levels for life extension of wind turbine structural components. Wind Energy 2021, 24, 939–956. [Google Scholar] [CrossRef]

- Guo, H.; Watson, S.; Tavner, P.; Xiang, J. Reliability analysis for wind turbines with incomplete failure data collected from after the date of initial installation. Reliab. Eng. Syst. Saf. 2009, 94, 1057–1063. [Google Scholar] [CrossRef]

- Hameed, Z.; Vatn, J.; Heggset, J. Challenges in the reliability and maintainability data collection for offshore wind turbines. Renew. Energy. 2011, 36, 2154–2165. [Google Scholar] [CrossRef]

- Igba, J.; Alemzadeh, K.; Durugbo, C.; Henningsen, K. Performance assessment of wind turbine gearboxes using in-service data: Current approaches and future trends. Renew. Sustain. Energy Rev. 2015, 50, 144–159. [Google Scholar] [CrossRef]

- Igba, J.; Alemzadeh, K.; Gibbons, P.M.; Friis, J. A framework for optimising product performance through feedback and reuse of in-service experience. Robot. Comput.-Integr. Manuf. 2015, 36, 2–12. [Google Scholar] [CrossRef]

- Igba, J.; Alemzadeh, K.; Durugbo, C.; Henningsen, K. Through-life engineering services: A wind turbine perspective. Procedia CIRP 2014, 22, 213–218. [Google Scholar] [CrossRef]

- Martinez-Luengo, M.; Shafiee, M.; Kolios, A. Data management for structural integrity assessment of offshore wind turbine support structures: Data cleansing and missing data imputation. Ocean. Eng. 2019, 173, 867–883. [Google Scholar] [CrossRef]

- Offshore Renewable Energy Catapult. System Performance, Availability and Reliability Trend Analysis (SPARTA)–Portfolio Review 2020/21. 2021. Available online: https://sparta-offshore-user-downloads.s3.eu-west-1.amazonaws.com/SPARTA-Review-2021.pdf (accessed on 6 July 2024).

- Shafiee, M.; Sørensen, J.D. Maintenance optimization and inspection planning of wind energy assets: Models, methods and strategies. Reliab. Eng. Syst. Saf. 2019, 192, 105993. [Google Scholar] [CrossRef]

- Wind Energy Ireland. Wind Energy Ireland Guide to Wind Turbine Lifetime Extension. 2021. Available online: https://windenergyireland.com/images/files/wind-energy-ireland-guide-to-lifetime-extension.pdf (accessed on 6 July 2024).

- Ortegon, K.; Nies, L.F.; Sutherland, J.W. The impact of maintenance and technology change on remanufacturing as a recovery alternative for used wind turbines. Procedia CIRP 2014, 15, 182–188. [Google Scholar] [CrossRef]

- Animah, I.; Shafiee, M.; Simms, N.; Tiwari, A. A multi-stage remanufacturing approach for life extension of safety critical systems. Procedia CIRP 2017, 59, 133–138. [Google Scholar] [CrossRef]

- NORSOK U-009; Life Extension for Subsea Systems. Standard Norge: Lysaker, Norway, 2023. Available online: https://online.standard.no/nb/norsok-u-009-2023 (accessed on 6 July 2024).

- NORSOK Y-002; Life Extension for Transportation Systems. Standard Norge: Lysaker, Norway, 2021. Available online: https://online.standard.no/nb/norsok-y-002-2021 (accessed on 6 July 2024).

- ISO/TS 12747; Technical Specification for Petroleum and Natural Gas Industries—Pipeline Transportation Systems—Recommended Practice for Pipeline Life Extension. ISO: Geneva, Switzerland, 2011. Available online: https://www.iso.org/standard/51657.html (accessed on 6 July 2024).

- DNVGL-ST-0262; Lifetime Extension of Wind Turbines. DNV: Oslo City, Norway, 2021. Available online: https://www.dnv.com/energy/standards-guidelines/dnv-st-0262-lifetime-extension-of-wind-turbines/ (accessed on 6 July 2024).

- DNVGL-SE-0263; Certification of Lifetime Extension of Wind Turbines. DNV: Oslo City, Norway, 2021. Available online: https://www.dnv.com/energy/standards-guidelines/dnv-se-0263-certification-of-lifetime-extension-of-wind-turbines/ (accessed on 6 July 2024).

- IEC TS 61400-28; Wind Energy Generation Systems—Part 28: Through Life Management and Life Extension of Wind Power Assets. International Atomic Energy Agency (IAEA): Geneva, Switzerland, 2022. Available online: https://www.iec.ch/dyn/www/f?p=103:7:314214208920786::::FSP_ORG_ID:1282 (accessed on 6 July 2024).

- IEA Wind TCP Task 42. Wind Turbine Lifetime Extension. 2021. Available online: https://iea-wind.org/task42/ (accessed on 6 July 2024).

- De Laurentis, C.; Windemer, R. When the turbines stop: Unveiling the factors shaping end-of-life decisions of ageing wind infrastructure in Italy. Energy Res. Soc. Sci. 2024, 113, 103536. [Google Scholar] [CrossRef]

- Galparsoro, I.; Menchaca, I.; Garmendia, J.M.; Borja, Á.; Maldonado, A.D.; Iglesias, G.; Bald, J. Reviewing the ecological impacts of offshore wind farms. Npj Ocean Sustain. 2022, 1, 1. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Yang, Y. Wind energy development and its environmental impact: A review. Renew. Sustain. Energy Rev. 2012, 16, 1031–1039. [Google Scholar] [CrossRef]

- IAEA-TECDOC-1402; Management of Life Cycle and Ageing at Nuclear Power Plants: Improved I&C Maintenance. International Atomic Energy Agency (IAEA): Vienna, Austria, 2004. Available online: https://www.iaea.org/publications/7065/management-of-life-cycle-and-ageing-at-nuclear-power-plants-improved-ic-maintenance (accessed on 6 July 2024).

- Bharteey, B.M.; Hart, T.J. Life extension of low and medium voltage equipment. In Proceedings of the IEEE Nuclear Science Symposium, Arlington, TX, USA, 22–27 October 1990; pp. 1001–1004. [Google Scholar]

- Stevens, G.L.; Ranganath, S. Use of on-line fatigue monitoring of nuclear reactor components as a tool for plant life extension. J. Press. Vessel Technol. 1991, 113, 349–357. [Google Scholar] [CrossRef]

- Shah, V.N.; MacDonald, P. Aging and life extension of major light water reactor components. Nucl. Technol. 1995, 109, 163–164. [Google Scholar] [CrossRef]

- Saldanha, P.L.C.; Frutuoso e Melo, P.F. Analysis of the qualified life extension of nuclear safety systems through modulated Poisson point processes. Prog. Nucl. Energy 2012, 60, 117–128. [Google Scholar] [CrossRef]

- Asmolov, V.G.; Povarov, V.P.; Vitkovskii, S.L.; Berkovich, V.Y.; Chetverikov, A.E.; Semchenkov, Y.M.; Suslov, A.I. The concept of extending the service life of the VVER-440-based power units at the Novovoronezh nuclear power plant. Therm. Eng. 2014, 61, 86–94. [Google Scholar] [CrossRef]

- Trampus, P. Role and importance of NDE in nuclear power plant life extension. Procedia Struct. Integr. 2019, 16, 161–168. [Google Scholar] [CrossRef]

- Kim, S.H.; Taiwo, T.A.; Dixon, B.W. The carbon value of nuclear power plant lifetime extensions in the United States. Nucl. Technol. 2022, 208, 775–793. [Google Scholar] [CrossRef]

- Woo, T.H. Dynamic assessment for life extension of nuclear power plants (NPPs) using system dynamics (SD) method. Kerntechnik 2023, 77, 431–437. [Google Scholar] [CrossRef]

- Dimova, G.T. Methodology for lifetime characteristics assessment of mechanical equipment in nuclear power plants. Ageing management of NPP mechanical equipment. IOP Conf. Ser. Earth Environ. Sci. 2023, 1128, 012020. [Google Scholar] [CrossRef]

- Stacey, A.; Birkinshaw, M.; Sharp, J.V. Life extension issues for ageing offshore installations. In Proceedings of the ASME 2008 27th International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008; American Society of Mechanical Engineers: New York, NY, USA, 2008; pp. 199–215. [Google Scholar] [CrossRef]

- Stacey, A. KP4: Ageing & life extension inspection programme—The first year. In Proceedings of the SPE Offshore Europe Oil and Gas Conference and Exhibition, Aberdeen, UK, 6–8 September 2011; pp. 1–12. [Google Scholar] [CrossRef]

- Ersdal, G.; Selnes, P.O. Life extension of aging petroleum production facilities offshore. In Proceedings of the SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, Rio de Janeiro, Brazil, 12–14 April 2010; pp. 1–14. [Google Scholar] [CrossRef]

- Jansen, M.; Van, G. Life extension of degraded main oil line pipeline sections through improved risk based integrity management. In Proceedings of the NACE—International Corrosion Conference, Paper Number: NACE-05143. Houston, TX, USA, 3–7 April 2005; pp. 1–15. [Google Scholar]

- Rincón, P.; González, F.; Vinccler, H. Case studies of successful pipeline life extension using integrity management practices. In Proceedings of the NACE—International Corrosion Conference, Paper Number: NACE-07141. Nashville, TN, USA, 11–15 March 2007; pp. 1–24. [Google Scholar]

- Hudson, B.G. Platform life extension. In Proceedings of the SPE Offshore Europe Oil and Gas Conference and Exhibition, Aberdeen, UK, 8–11 September 2009; pp. 1–11. [Google Scholar] [CrossRef]

- Saunders, C.; O’Sullivan, T. Integrity management and life extension of flexible pipe. In Proceedings of the SPE Offshore Europe Oil and Gas Conference and Exhibition, Aberdeen, Scotland, 4–7 September 2007; pp. 1–7. [Google Scholar] [CrossRef]

- Vaidya, P.; Rausand, M. Remaining useful life, technical health, and life extension. J. Risk Reliab. 2011, 225, 219–231. [Google Scholar] [CrossRef]

- Brandt, H.; Mohd Sarif, S. Life extension of offshore assets—Balancing safety & project economics. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 22–24 October 2013; pp. 1–9. [Google Scholar] [CrossRef]

- Tveit, E.; Sivertsen, H.; Hernaes, S. Experience from field life extension. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014; pp. 1–8. [Google Scholar] [CrossRef]

- Ramírez, P.A.P.; Utne, I.B. Use of dynamic Bayesian networks for life extension assessment of ageing systems. Reliab. Eng. Syst. Saf. 2015, 133, 119–136. [Google Scholar] [CrossRef]

- Shafiee, M.; Animah, I.; Simms, N. Development of a techno-economic framework for life extension decision making of safety critical installations. J. Loss Prev. Process Ind. 2016, 44, 299–310. [Google Scholar] [CrossRef]

- Animah, I.; Shafiee, M. Condition assessment, remaining useful life prediction and life extension decision making for offshore oil and gas assets. J. Loss Prev. Process Ind. 2018, 53, 17–28. [Google Scholar] [CrossRef]

- Ferreira, N.N.; Martins, M.R.; Gaya de Figueiredo, M.A.; Gagno, V.H. Guidelines for life extension process management in oil and gas facilities. J. Loss Prev. Process Ind. 2020, 68, 104290. [Google Scholar] [CrossRef]

- Shafiee, M.; Animah, I. An integrated FMEA and MCDA based risk management approach to support life extension of subsea facilities in high-pressure–high-temperature (HPHT) conditions. J. Mar. Eng. Technol. 2022, 21, 189–204. [Google Scholar] [CrossRef]

- Oubella, K. Platform life extension–Assessment methodology for pressure vessel and piping. In Proceedings of the ASME Pressure Vessels & Piping Conference, Las Vegas, NV, USA, 17–22 June 2022. [Google Scholar] [CrossRef]

- Ferreira, N.N.; Ramos Martins, M.R.; Dziedzic, R.; de Figueiredo, M.A.G. Obsolescence management for offshore oil and gas production facility life extension. Ocean. Eng. 2023, 285, 115388. [Google Scholar] [CrossRef]

- Shafiee, M.; Dinmohammadi, F. An FMEA-based risk assessment approach for wind turbine systems: A comparative study of onshore and offshore. Energies 2014, 7, 619–642. [Google Scholar] [CrossRef]

- MEGAVIND. Strategy for Extending the Useful Lifetime of A Wind Turbine. 2016. Available online: https://megavind.greenpowerdenmark.dk/publications/strategy-extending-the-useful-lifetime-of-a-wind-turbine (accessed on 6 July 2024).

- Popa, L.M.; Jensen, B.-B.; Ritchie, E.; Boldea, I. Condition monitoring of wind generators. In Proceedings of the 38th IAS Annual Meeting on Conference Record of the Industry Applications Conference, Salt Lake City, UT, USA, 12–16 October 2003; pp. 1839–1846. [Google Scholar] [CrossRef]

- Luengo, M.M.; Kolios, A. Failure mode identification and end of life scenarios of offshore wind turbines: A review. Energies 2015, 8, 8339–8354. [Google Scholar] [CrossRef]

- Dinmohammadi, F.; Flynn, D.; Bailey, C.; Pecht, M.; Yin, C.; Rajaguru, P.; Robu, V. Predicting damage and life expectancy of subsea power cables in offshore renewable energy applications. IEEE Access 2019, 7, 54658–54669. [Google Scholar] [CrossRef]

- Fischer, K.; Pelka, K.; Puls, S.; Poech, M.-H.; Mertens, A.; Bartschat, A.; Tegtmeier, B.; Broer, C.; Wenske, J. Exploring the causes of power-converter failure in wind turbines based on comprehensive field-data and damage analysis. Energies 2019, 12, 593. [Google Scholar] [CrossRef]

- Delaney, E.L.; Leahy, P.G.; McKinley, J.M.; Gentry, T.R.; Nagle, A.J.; Elberling, J.; Bank, L.C. Sustainability implications of current approaches to end-of-life of wind turbine blades—A review. Sustainability 2023, 15, 12557. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Tian, D.; Chen, G. Optimal power dispatch in wind farm with life extension of wind turbine blades as target. J. Renew. Sustain. Energy 2013, 5, 033115. [Google Scholar] [CrossRef]

- Bech, J.I.; Hasager, C.B.; Bak, C. Extending the life of wind turbine blade leading edges by reducing the tip speed during extreme precipitation events. Wind Energ. Sci. 2018, 3, 729–748. [Google Scholar] [CrossRef]

- Saathoff, M.; Rosemeier, M. Stress-based assessment of the lifetime extension for wind turbines. J. Phys. Conf. Ser. 2020, 1618, 052057. [Google Scholar] [CrossRef]

- Su, H.M.; Kam, T.Y. Reliability analysis of composite wind turbine blades considering material degradation of blades. Compos. Struct. 2020, 234, 111663. [Google Scholar] [CrossRef]

- Qiu, Y.; Chen, L.; Feng, Y.; Xu, Y. An approach of quantifying gear fatigue life for wind turbine gearboxes using supervisory control and data acquisition data. Energies 2017, 10, 1084. [Google Scholar] [CrossRef]

- Junior, V.L.J.; Basoalto, H.; Papaelias, M. A damage mechanics approach for lifetime estimation of wind turbine gearbox materials. Int. J. Fatigue 2020, 137, 105671. [Google Scholar] [CrossRef]

- Olave, M.; Urresti, I.; Hidalgo, R.; Zabala, H.; Neve, M. Deliverable 1.1: Technical, Environmental and Social Requirements of the Future Wind Turbines and Lifetime Extension. 2020. Available online: https://www.innterestingproject.eu/downloads/d1-1-technical-environmental-and-social-requirements-of-the-future-wind-turbines-and-lifetime-extension.pdf (accessed on 19 July 2024).

- Bill, S.; Bill, V. Lifetime extension of gears and main bearings in wind turbines, scientific calculations and practical implementation. IOP Conf. Ser. Earth Environ. Sci. 2022, 1073, 012001. [Google Scholar] [CrossRef]

- Loraux, C.; Brühwiler, E. The use of long term monitoring data for the extension of the service duration of existing wind turbine support structures. J. Phys. Conf. Ser. 2016, 753, 072023. [Google Scholar] [CrossRef]

- Ziegler, L.; Smolka, U.; Cosack, N.; Muskulus, M. Brief communication: Structural monitoring for lifetime extension of offshore wind monopiles: Can strain measurements at one level tell us everything? Wind Energ. Sci. 2017, 2, 469–476. [Google Scholar] [CrossRef]

- Vali, M.; Petrović, V.; Pao, L.Y.; Kühn, M. Lifetime extension of waked wind farms using active power control. J. Phys. Conf. Ser. 2019, 1256, 012029. [Google Scholar] [CrossRef]

- Njiri, J.G.; Beganovic, N.; Do, M.H.; Söffker, D. Consideration of lifetime and fatigue load in wind turbine control. Renewable Energy 2019, 131, 818–828. [Google Scholar] [CrossRef]

- Ziegler, L.; Muskulus, M. Fatigue reassessment for lifetime extension of offshore wind monopile substructures. J. Phys. Conf. Ser. 2016, 753, 092010. [Google Scholar] [CrossRef]

- Rubert, T. Life Extension for Wind Turbine Structures and Foundations. Ph.D. Thesis, University of Strathclyde, Glasgow, UK, 2018. Available online: https://stax.strath.ac.uk/concern/theses/v692t6278 (accessed on 22 July 2024).

- Kazemi Amiri, A.; Kazacoks, R.; McMillan, D.; Feuchtwang, J.; Leithead, W. Farm-wide assessment of wind turbine lifetime extension using detailed tower model and actual operational history. IOP Conf. Ser. J. Phys. 2019, 1222, 012034. [Google Scholar] [CrossRef]

- Grieve, N.; Kazemi Amiri, A.; Leithead, W.E. A straightforward approach to site-wide assessment of wind turbine tower lifetime extension potential. Energies 2022, 15, 3380. [Google Scholar] [CrossRef]

- Mitchell, H.; Pready, N.; García Cava, D.; Mehmanparast, A.; Thies, P. Informing asset life extension: Probabilistic fatigue life reassessment of offshore wind turbine structural components using a Bayesian network. In Proceedings of the ASME 5th International Offshore Wind Technical Conference, Exeter, UK, 18–19 December 2023. [Google Scholar] [CrossRef]

- Dingle, H.; Price, R.; Kurson, A.V.; Walker, G. Geotechnical considerations for assessing the life extension of offshore wind foundations. Ocean. Eng. 2023, 284, 115074. [Google Scholar] [CrossRef]

- Ortegon, K.; Nies, L.F.; Sutherland, J.W. Remanufacturing: An alternative for end of use of wind turbines. In Leveraging Technology for a Sustainable World; Dornfeld, D., Linke, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 155–160. [Google Scholar] [CrossRef]

- Dahane, M.; Sahnoun, M.; Bettayeb, B.; Baudry, D.; Boudhar, H. Impact of spare parts remanufacturing on the operation and maintenance performance of offshore wind turbines: A multi-agent approach. J. Intell. Manuf. 2017, 28, 1531–1549. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; Gallego-Schmid, A.; Velenturf, A.P.M.; Jensen, P.D.; Ibarra, D. Circular economy business models and technology management strategies in the wind industry: Sustainability potential, industrial challenges and opportunities. Renew. Sustain. Energy Rev. 2022, 163, 112523. [Google Scholar] [CrossRef]

- Shafiee, M. Circular economy and autonomous remanufacturing for end-of-life offshore wind turbines. In Advances in Remanufacturing, Proceedings of the VII International Workshop on Autonomous Remanufacturing; Springer: Berlin/Heidelberg, Germany, 2024; pp. 355–363. [Google Scholar] [CrossRef]

- Liu, P.; Meng, F.; Barlow, C.Y. Wind turbine blade end-of-life options: An economic comparison. Resour. Conserv. Recycl. 2022, 180, 106202. [Google Scholar] [CrossRef]

- Ochella, S.; Shafiee, M.; Dinmohammadi, F. Artificial intelligence in prognostics and health management of engineering systems. Eng. Appl. Artif. Intell. 2022, 108, 104552. [Google Scholar] [CrossRef]

- Yeter, B.; Garbatov, Y.; Soares, C.G. Review on artificial intelligence-aided life extension assessment of offshore wind support structures. J. Marine. Sci. Appl. 2022, 21, 26–54. [Google Scholar] [CrossRef]

- Yeter, B.; Garbatov, Y.; Soares, C.G. Life-extension classification of offshore wind assets using unsupervised machine learning. Reliab. Eng. Syst. Saf. 2022, 219, 108229. [Google Scholar] [CrossRef]

- Tartt, K.; Nejad, A.R.; Kazemi-Amiri, A.; McDonald, A. On lifetime extension of wind turbine drivetrains. In Proceedings of the 40th International Conference on Ocean, Offshore and Arctic Engineering (OMAE), Virtual, 21–30 June 2021. [Google Scholar] [CrossRef]

- Adedipe, T.; Shafiee, M.; Zio, E. Bayesian network modelling for the wind energy industry: An overview. Reliab. Eng. Syst. Saf. 2020, 202, 107053. [Google Scholar] [CrossRef]

- Schumacher, C.; Weber, F. Extending the Lifetime of Wind Turbines. TÜV SÜD. 2019. Available online: https://www.windsystemsmag.com/wp-content/uploads/2019/10/1019-IF-1.pdf (accessed on 22 July 2024).

- Guo, R.Y.; Li, W.; Xia, H.; Feng, J.Z.; Ren, H.H. Site-specific assessment of wind turbine residual life and health status. E3S Web Conf. 2021, 261, 03057. [Google Scholar] [CrossRef]

- He, R.; Yang, H.; Lu, L. Optimal yaw strategy and fatigue analysis of wind turbines under the combined effects of wake and yaw control. Appl. Energy 2024, 337, 120878. [Google Scholar] [CrossRef]

- Rubert, T.; McMillan, D.; Niewczas, P. A decision support tool to assist with lifetime extension of wind turbines. Renew. Energy 2018, 120, 423–433. [Google Scholar] [CrossRef]

- Yeter, B.; Garbatov, Y. Optimal life extension management of offshore wind farms based on the modern portfolio theory. Oceans 2021, 2, 566–582. [Google Scholar] [CrossRef]

- Yeter, B.; Garbatov, Y.; Soares, C.G. Analysis of life extension performance metrics for optimal management of offshore wind assets. J. Offshore Mech. Arct. Eng. 2022, 144, 052001. [Google Scholar] [CrossRef]

- Boyd, D.; Karimirad, M.; Sivakumar, V.; Jalilvand, S.; Desmond, C. A review of end-of-life decision making for offshore wind turbines. In Proceedings of the ASME 41st International Conference on Ocean, Offshore and Arctic Engineering (OMAE), Hamburg, Germany, 5–10 June 2022. [Google Scholar] [CrossRef]

- North Sea Region. DecomTools. Available online: https://northsearegion.eu/decomtools/ (accessed on 22 July 2024).

| Nuclear Power Industry | Offshore Oil & Gas Industry | Current Practices in Wind Energy | Recommendations for Wind Energy | |

|---|---|---|---|---|

| Lifetime extension standards | There is no universally accepted standard for lifetime extension; however, the periodic safety review (PSR) remains the primary regulatory process for authorizing such projects. | There are several standards for authorizing lifetime extension of subsea structures and pipeline systems: NORSOK U-009 [40], NORSOK Y-002 [41], ISO/TS 12747 [42]. | Several recent standards provide general principles, technical requirements, and guidance for certifying the lifetime extension of wind turbines: DNVGL-ST-0262 [43], DNVGL-SE-0263 [44], IEC/TS 61400-28 [45], IEA Wind TCP Task 42 [46]. | There is a pressing need to develop a ‘unified’ standard for the lifetime extension of OWTs. This standard should include guidelines that address structural integrity, operational efficiency, environmental impact, and economic viability throughout the wind farm lifecycle. |

| Lifetime extension methodologies | They often use comprehensive and structured technical assessment frameworks. | They usually apply methodological techno-economic feasibility assessment frameworks. | There is no comprehensive and structured approach for lifetime extension feasibility assessments. | There is a need for a ‘holistic’ approach that integrates technical, economic, environmental, social, and political aspects in the certification of lifetime extension for OWTs. |

| Lifetime extension monitoring | PSA tools are widely used to screen, prioritize, and monitor critical safety elements within a nuclear power plant. | Generic industrial tools are used for screening and prioritizing critical components for lifetime extension in subsea systems. Additionally, PSA tools are gradually being used. | There is currently no established approach in the wind energy sector for prioritizing and monitoring critical wind turbine components for lifetime extension. | There is a need to develop a ‘systematic’ decision-making approach that incorporates PSA tools to screen, prioritize, and monitor critical components within an offshore wind farm. |

| Lifetime extension risk assessment | Probabilistic risk assessment tools are widely used to estimate the consequences of system failure during lifetime extension. | Probabilistic risk assessment tools are often used to estimate the consequences of system failure during lifetime extension. | Probabilistic risk assessment tools are gradually being used to extend the lifetime of wind turbine components. | A more ‘thorough’ risk assessment methodology incorporating all aspects is needed for OWTs during the lifetime extension phase of operation. |

| Lifetime extension strategy selection | There are well-established approaches, such as MCDM, LCA, and BCA, for selecting a suitable lifetime extension strategy. | There are well-established approaches, such as MCDM, LCA, and BCA, for selecting a suitable lifetime extension strategy. | Currently, the selection of a lifetime extension strategy in the wind energy sector is predominantly based on expert opinion. | There is a need for a ‘structured’ framework to evaluate various factors, ensuring a more balanced assessment of lifetime extension strategies. |

| Subsystem/Component | Life Estimation Process | Dominant Failure Modes | Potential Mitigation Actions | Lifetime Extension Strategy |

|---|---|---|---|---|

| Generator | Lifetime estimation often relies on statistical analysis of historical inspection and maintenance data. | Crack in rotor bar and breakage of rotor bar. | Regular inspection and maintenance. | Reconditioning, remanufacturing, and reuse. |

| Cables | Lifetime estimation often relies on low voltage time domain reflectometry tests, leakage current measurements, partial discharge measurements, and breakdown voltage tests. | Water treeing and aging insulation material. | Through diligent design and proper material selection. | Reuse, reclaiming. |

| Converter, filters and circuit breakers | Lifetime estimation often relies on statistical analysis of historical inspection and maintenance data. | Electrical faults, capacitor fire, wear and tear. | Inspecting capacitors for potential damage and breakers for signs of wear and tear. | Retrofitting, reuse. |

| Transformer | Lifetime estimation often relies on partial discharge tests, insulation resistance tests and visual inspections. | Degrading insulating material properties, contaminated oil. | Inspecting for partial discharge, dust accumulation in cooling channels, and checking for bent connection rods between taps and other connections, along with regular oil testing for contaminants. | Retrofitting, reuse. |

| Substation grid | Lifetime estimation often relies on statistical analysis of visual inspection data and laboratory testing. | Corrosion, wear, tear and obsolescence. | Regular inspection, maintenance and testing of various systems for possible defects. | Retrofitting, reconditioning. |

| Rotor (Hub) | Lifetime estimation often relies on revisiting design phase load models and analyses, incorporating updated information. | Broken and/or loosely mounted bolts, corrosion fatigue of hub structure and material degradation. | Visual inspection for cracks and corrosion on the hub, supplemented by non-destructive testing (NDT) if necessary. | Reconditioning, remanufacturing. |

| Blades | The remaining fatigue life of the blades can be estimated using design phase load models updated with current information. | Cracks and delamination of the composite blades as a result of fatigue, leading-edge erosion. | Visual inspection and repair, supplemented by sensor monitoring, as an alternative solution. | Retrofitting, reuse, and reclaiming. |

| Gearbox | Lifetime estimation often relies on analyzing condition monitoring data obtained from sensors and inspections. | Damage to gear tooth and bearing through cracks. | Regular inspection for damaged parts for replacement. | Reconditioning, remanufacturing and reuse |

| Pitch control system | Lifetime estimation often relies on statistical analysis of historical inspection and maintenance data. | Cracked motor shaft, fractured gear teeth and cracked bearings. | Regular inspection and maintenance. | Reconditioning, remanufacturing, and reuse |

| Yaw system | Lifetime estimation of the yaw system is based on its functionality and the wear and tear of its parts. Assessment for functionality. | Crack in yaw drive shaft, damaged gear teeth, pitting of yaw bearing and worn out brake disc. | Regular inspection and maintenance. | Reconditioning, remanufacturing, and reuse |

| Sensors | Lifetime assessment of sensors is based on benchmarking their data against data from similar sensors | Sensors may fail or provide incorrect readings due to poor calibration. | Regular inspection for dust, dirt and moisture. | Retrofitting |

| Control and monitoring systems | Lifetime estimation of the control and monitoring software is based on expert judgment. | Aging-related faults, obsolescence | Regular update | Retrofitting |

| Main frame | The remaining fatigue life of the main frame can be estimated using crack growth models. | Fatigue crack. | Regular inspection and maintenance. | Reuse, reclaiming |

| Tower | The remaining fatigue life of the tower can be estimated using either S-N curves or crack growth models. | Fatigue crack. | Regular inspection and maintenance. | Reuse, reclaiming |

| Foundation | The remaining fatigue life of the foundation structures can be estimated using either S-N curves or crack growth models. | Fatigue crack, corrosion, and scour. | Regular inspection and maintenance. | Reuse, reclaiming |

| Type of Data | Required Information | Source of Data |

|---|---|---|

| Metocean data (post design and installation) | Wind speed | Sensors such as anemometers, Light Detection and Ranging (LIDAR) systems |

| Wind direction | ||

| Wave conditions | ||

| Current | ||

| Sea conditions | ||

| Atmospheric conditions | ||

| Design and modification records | OWT design criteria | Designers, OEMs, design codes, bill of materials, standard documents |

| Design specifications for various OWT components | ||

| CAD drawings | ||

| Design life models | ||

| Material specifications | ||

| Engineering modifications | ||

| Design regulations, standards and guidelines | ||

| Environmental loading data | Vibration | Sensors such as accelerometers, strain gauges, motion sensors |

| Sea loading | ||

| Seismic effects | ||

| Field inspection and maintenance data | Reliability levels | SCADA, maintenance records, condition monitoring systems |

| Maintenance data | ||

| Conditioning monitoring data | ||

| Operational data | Turbine’s availability | SCADA, operational data |

| Electricity production | ||

| Turbine’s capacity factor | ||

| Economic data | Cost of modification | Suppliers, maintenance providers, electricity market, Trade tariffs |

| Cost of installation | ||

| Cost of operations and maintenance | ||

| Taxes | ||

| Revenue accruing from sale of electricity | ||

| Delayed decommission cost |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shafiee, M. Extending the Lifetime of Offshore Wind Turbines: Challenges and Opportunities. Energies 2024, 17, 4191. https://doi.org/10.3390/en17164191

Shafiee M. Extending the Lifetime of Offshore Wind Turbines: Challenges and Opportunities. Energies. 2024; 17(16):4191. https://doi.org/10.3390/en17164191

Chicago/Turabian StyleShafiee, Mahmood. 2024. "Extending the Lifetime of Offshore Wind Turbines: Challenges and Opportunities" Energies 17, no. 16: 4191. https://doi.org/10.3390/en17164191

APA StyleShafiee, M. (2024). Extending the Lifetime of Offshore Wind Turbines: Challenges and Opportunities. Energies, 17(16), 4191. https://doi.org/10.3390/en17164191